Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Proficient in Inspection Equipment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Proficient in Inspection Equipment Interview

Q 1. Explain the principles of dimensional metrology.

Dimensional metrology is the science of measuring the physical geometry of objects. It’s about accurately determining dimensions like length, width, height, angles, and surface texture. Think of it as taking incredibly precise measurements to ensure parts meet design specifications. This involves using various instruments, from simple rulers to sophisticated Coordinate Measuring Machines (CMMs), to obtain highly accurate data. The principles underpinning dimensional metrology revolve around:

- Accuracy: How close a measurement is to the true value.

- Precision: How consistent or repeatable a measurement is.

- Traceability: Ensuring measurements can be linked back to national or international standards to verify their validity.

- Uncertainty: Acknowledging that every measurement has some degree of inherent error; quantifying this uncertainty is crucial.

For instance, in manufacturing a car engine, dimensional metrology ensures that all the parts fit together precisely. Even tiny discrepancies can lead to significant performance issues or catastrophic failure. The process involves comparing measured dimensions to CAD models and tolerances to ensure conformance.

Q 2. Describe your experience with CMM (Coordinate Measuring Machine) operation.

I have extensive experience operating CMMs, both in manual and automated modes. My expertise spans various CMM types, including bridge-type and horizontal-arm CMMs. I’m proficient in using different probing systems, including touch probes and laser scanners. I’m comfortable with various software packages used for programming CMM routines, data acquisition, and analysis.

In my previous role, I was responsible for inspecting complex aerospace components, ensuring they met the stringent dimensional requirements outlined in the specifications. This involved creating CMM inspection programs, performing measurements, analyzing the data, and generating comprehensive reports. I was also involved in the calibration and maintenance of the CMMs to ensure their accuracy and reliability. For example, I successfully used a CMM with a Renishaw probe to identify minute variations in the curvature of a turbine blade, preventing potential engine failure.

Q 3. What are the different types of non-destructive testing (NDT) methods you are proficient in?

My NDT proficiency encompasses several methods, including:

- Visual Inspection (VT): A basic yet crucial method involving visual examination of a part’s surface for defects.

- Liquid Penetrant Testing (LPT): This identifies surface-breaking defects by applying a dye that penetrates cracks, then reveals them after cleaning.

- Magnetic Particle Testing (MT): Used to detect surface and near-surface defects in ferromagnetic materials by magnetizing the part and applying magnetic particles which are attracted to discontinuities.

- Ultrasonic Testing (UT): Utilizes high-frequency sound waves to detect internal flaws; the reflection of these waves reveals defects.

- Radiographic Testing (RT): This involves using X-rays or gamma rays to penetrate the material and reveal internal defects.

The choice of NDT method depends on the material, the type of defect being sought, and the accessibility of the component. For instance, UT is ideal for detecting internal flaws in thick welds, while LPT is better suited for finding surface cracks in small parts. My expertise allows me to select the most appropriate method for each scenario, ensuring thorough and accurate inspection.

Q 4. How do you calibrate inspection equipment to ensure accuracy?

Calibrating inspection equipment is critical for ensuring accuracy. This is typically done using traceable standards, which are themselves calibrated against national or international standards. The process involves:

- Selecting appropriate standards: These should match the range and precision of the equipment being calibrated.

- Following a documented procedure: This ensures consistency and traceability.

- Performing measurements: Multiple measurements are taken to assess repeatability and accuracy.

- Analyzing results: Data is compared to the known values of the standards to determine any deviations.

- Adjusting the equipment (if needed): Corrective actions might involve adjustments to the instrument or replacement of worn parts.

- Generating a calibration certificate: This document records the calibration results and the equipment’s status.

Regular calibration is essential, the frequency depending on the equipment, its use, and the criticality of the inspections. For example, a CMM might be calibrated monthly, while a simpler instrument like a micrometer might require calibration annually.

Q 5. What are the common sources of error in inspection equipment and how do you mitigate them?

Common sources of error in inspection equipment include:

- Environmental factors: Temperature, humidity, and vibrations can affect measurement accuracy.

- Equipment wear and tear: Wear on measuring probes or other components can lead to inaccuracies.

- Operator error: Incorrect setup, improper handling, or misinterpretation of results.

- Calibration drift: Equipment can drift out of calibration over time, leading to increasingly inaccurate measurements.

Mitigation strategies include:

- Environmental control: Maintaining a stable environment for inspections.

- Regular calibration and maintenance: To address wear and tear and calibration drift.

- Operator training: To minimize operator error.

- Using multiple measurement techniques: To verify results and reduce reliance on a single instrument.

- Statistical process control (SPC): To monitor the variability in measurements and identify potential issues.

For example, if temperature fluctuations are suspected to influence CMM measurements, we might implement a climate-controlled inspection room and incorporate temperature compensation in the software.

Q 6. Explain your experience with image analysis software used in inspection.

I have considerable experience using image analysis software in inspection. My expertise includes software packages like ImageJ and specialized metrology software integrated with CMMs. These tools allow for automated analysis of images captured from microscopes, cameras, or scanners. I’m skilled in tasks such as:

- Image enhancement and processing: Improving image quality to enhance defect detection.

- Feature extraction: Automatically identifying and measuring key features of a component.

- Defect detection and classification: Identifying and categorizing flaws based on predefined criteria.

- Report generation: Creating detailed reports with quantitative data and images.

For instance, in a recent project involving the inspection of printed circuit boards, I utilized image analysis software to automatically identify and classify solder joints based on their shape and size, flagging any defects that fell outside acceptable tolerances. This significantly improved efficiency and consistency compared to manual inspection.

Q 7. Describe a time you identified a faulty inspection process and implemented a solution.

In a previous role, we were using a manual process to inspect the surface finish of a critical component. This involved visual inspection by multiple operators, leading to inconsistent results and delays. The subjective nature of visual inspection resulted in significant variations in the acceptance/rejection criteria.

To solve this, I proposed and implemented a new process based on a surface roughness measurement device. This device provided objective, repeatable measurements that could be easily compared to specified tolerances. We developed a standard operating procedure for using the device and implemented a statistical process control chart to monitor the process capability. The new process reduced inspection time by 50%, increased the consistency of results, and minimized the risk of human error. This improved efficiency, reduced waste, and significantly enhanced the overall quality of the manufactured component.

Q 8. How do you interpret and document inspection results?

Interpreting and documenting inspection results is crucial for ensuring quality and traceability. It involves a systematic approach that begins with understanding the inspection criteria, using the right equipment, and accurately recording the findings. I typically follow a structured process:

- Data Acquisition: I meticulously collect data using the appropriate inspection equipment, ensuring accurate readings and noting any unusual observations. For example, when using a micrometer to measure a part’s diameter, I’ll take multiple readings at different points to account for potential variations and record them in my log.

- Data Analysis: I then analyze the collected data, comparing it against the pre-defined specifications. This might involve calculating averages, standard deviations, or identifying trends. If a part deviates from specifications, I determine the extent of the deviation and note its potential impact.

- Documentation: Finally, I prepare a comprehensive report detailing all findings. This includes detailed descriptions of the inspected items, the inspection methods used, the obtained measurements, any deviations from specifications, and any recommendations for corrective action. I use clear, concise language and include visual aids like photos or diagrams whenever necessary to ensure the report is easily understood by others.

A well-documented inspection report provides a clear audit trail, facilitating continuous improvement and helping identify potential process issues early on. For instance, consistently high defect rates in a specific area might signal a need for equipment recalibration or process optimization.

Q 9. What safety precautions do you follow when operating inspection equipment?

Safety is paramount when operating inspection equipment. I always adhere to a strict set of safety precautions, including:

- Proper Training: Before using any equipment, I ensure I’ve received comprehensive training on its safe operation and maintenance.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, such as safety glasses, gloves, and hearing protection, as needed for the specific equipment and task. Working with lasers, for example, requires specialized eye protection.

- Equipment Inspection: I inspect all equipment before use to ensure it’s in good working order and free of damage. Any malfunctioning equipment is immediately reported and taken out of service.

- Safe Work Practices: I strictly follow established safety procedures and guidelines. This includes maintaining a clean and organized workspace, using appropriate lifting techniques for heavy equipment, and being mindful of potential hazards such as moving machinery or electrical outlets.

- Emergency Procedures: I’m familiar with emergency procedures and know how to react in case of an accident or equipment malfunction.

A thorough understanding of safety protocols minimizes the risk of accidents and ensures a safe work environment for myself and my colleagues. In one instance, routine inspection of equipment revealed a loose wire, which, if left unattended, could have caused a short circuit and potential fire hazard.

Q 10. How familiar are you with different types of gauges (e.g., dial indicators, micrometers)?

I am highly proficient in using various types of gauges, including dial indicators, micrometers, calipers, and height gauges. My experience extends to both analog and digital versions of these instruments. Here’s a breakdown of my familiarity with some common types:

- Dial Indicators: These are useful for measuring surface irregularities, runout, and small dimensional changes. I understand how to interpret the dial’s readings, including the units (e.g., thousandths of an inch or micrometers) and the meaning of plus and minus values. I’m also familiar with different types of dial indicators, including lever-type and contact-type.

- Micrometers: I’m skilled at using micrometers to precisely measure external and internal diameters with high accuracy. I know how to adjust the thimble and read the measurements accurately, accounting for the least count of the instrument.

- Calipers: I use calipers (both vernier and digital) for measuring external and internal dimensions, as well as depth. I’m adept at zeroing the instrument and interpreting the readings accurately.

My experience with these gauges extends across various applications, from measuring the dimensions of machined parts to assessing the wear of components in machinery. Accuracy is critical, and I consistently strive to obtain reliable and repeatable measurements. I know how to handle and store these instruments with care to maintain their accuracy over time.

Q 11. Explain your experience with statistical process control (SPC).

Statistical Process Control (SPC) is integral to maintaining consistent product quality. My experience includes applying SPC principles to monitor and control manufacturing processes. I am familiar with various control charts, including:

- X-bar and R charts: Used to monitor the average and range of measurements within a sample.

- X-bar and s charts: Used to monitor the average and standard deviation of measurements within a sample.

- p-charts: Used to monitor the proportion of nonconforming units in a sample.

- c-charts: Used to monitor the number of nonconformities per unit.

I can use these charts to identify trends, patterns, and unusual variations in the process. I understand how to interpret control limits, determine whether a process is in control, and identify assignable causes for variation. For instance, a sudden shift in the average of a control chart might indicate a problem with a machine or tool. By analyzing SPC data, I can help improve processes, reduce defects, and enhance overall product quality.

I have used Minitab and other statistical software packages to perform SPC analysis and generate reports. My proficiency extends beyond generating charts to interpreting the results, identifying the root cause of variation, and implementing corrective actions.

Q 12. How do you handle discrepancies between inspection results and specifications?

Discrepancies between inspection results and specifications require careful investigation and resolution. My approach involves a systematic process:

- Verification: First, I verify the inspection results by repeating the measurements using the same or different equipment. This step helps rule out potential errors in the initial measurements.

- Root Cause Analysis: If the discrepancy persists, I conduct a thorough investigation to identify the root cause. This could involve checking the calibration of the equipment, reviewing the manufacturing process, or inspecting the raw materials.

- Documentation: I meticulously document all findings, including the initial inspection results, the verification results, and the root cause analysis. This documentation is crucial for determining appropriate corrective actions and preventing similar discrepancies in the future.

- Corrective Actions: Based on the root cause analysis, I recommend appropriate corrective actions. This may involve recalibrating equipment, adjusting the manufacturing process, or replacing defective materials.

- Verification of Corrective Actions: Once the corrective actions are implemented, I verify their effectiveness by performing additional inspections to ensure the problem has been resolved.

In one instance, a discrepancy was traced back to a worn tool in the manufacturing process. Replacing the tool immediately resolved the issue and prevented the production of further non-conforming parts.

Q 13. What is your experience with different types of material testing (e.g., tensile testing, hardness testing)?

My experience encompasses a range of material testing methods, including tensile testing, hardness testing, and impact testing. Here’s a summary:

- Tensile Testing: I’m proficient in conducting tensile tests to determine the strength, ductility, and elasticity of materials. I understand how to prepare specimens, operate the testing machine, and interpret the resulting stress-strain curve. This is crucial for ensuring the material meets the required specifications for structural integrity. For example, I’ve used this testing method extensively for metals and plastics.

- Hardness Testing: I am experienced with various hardness testing methods, such as Rockwell, Brinell, and Vickers. I understand how to select the appropriate method based on the material type and its expected hardness. This helps verify material properties and helps prevent unexpected failures during service.

- Impact Testing: I have experience conducting Charpy and Izod impact tests to determine a material’s resistance to fracture under impact loading. This is crucial for applications involving dynamic loads, such as those in automotive components or aerospace structures.

My experience includes using both universal testing machines and portable hardness testers. I understand the importance of proper specimen preparation, calibration procedures, and data analysis to ensure the validity and accuracy of the test results.

Q 14. Describe your experience with robotic inspection systems.

My experience with robotic inspection systems is growing, focusing primarily on their integration into automated manufacturing processes. I’ve worked with systems that utilize vision systems (computer vision), laser scanning, and other sensors to perform automated inspections. My role involved:

- Programming and Setup: I have experience configuring and programming robotic inspection systems, defining inspection routines, and setting tolerance limits for acceptable variations.

- Data Analysis and Reporting: I am familiar with analyzing data generated by robotic inspection systems. This often involves identifying and classifying defects, and generating reports that track quality metrics over time.

- Troubleshooting and Maintenance: I have experience troubleshooting robotic inspection systems, identifying issues in sensor calibration or robotic movements, and carrying out routine maintenance to keep the systems operational.

- Integration with Existing Systems: I have worked on integrating robotic inspection systems with other automation systems in the manufacturing process, enabling seamless data flow and improved overall process efficiency.

Robotic inspection offers significant advantages in terms of speed, accuracy, and consistency. However, successful implementation requires careful planning and understanding of the system’s capabilities and limitations. For example, the type of lighting and the surface texture of the object being inspected need to be considered for optimal system performance.

Q 15. How do you troubleshoot malfunctioning inspection equipment?

Troubleshooting malfunctioning inspection equipment is a systematic process. It begins with a careful observation of the problem: What exactly is failing? Is it a complete shutdown, inaccurate readings, or something else? Once the symptom is identified, I follow a structured approach:

- Safety First: Always ensure the equipment is safely powered down before attempting any repairs or troubleshooting.

- Check the Obvious: Look for simple issues like loose connections, power supply problems, or incorrect settings. For example, I once spent hours troubleshooting a faulty weld inspection system only to discover a tripped circuit breaker!

- Consult the Manual: The equipment’s manual usually contains troubleshooting guides and diagnostic codes that pinpoint the source of the problem. This is invaluable in navigating complex systems.

- Systematic Testing: Isolate components one by one to determine the faulty part. If it’s a system with multiple sensors, I’ll test each sensor individually to identify the source of the error. This often involves using calibration standards or test samples to verify performance.

- Calibration Verification: Ensure that the equipment has been recently calibrated and is within acceptable tolerances. Out-of-calibration equipment will yield inaccurate results.

- Seek Expert Assistance: If the problem remains unresolved after these steps, I’ll consult the manufacturer or a qualified service technician. They have access to specialized tools and expertise.

This methodical approach minimizes downtime and ensures the equipment’s continued accuracy and reliability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with report writing and data analysis related to inspection?

I have extensive experience in generating comprehensive reports and performing detailed data analysis related to inspection results. My reports typically include a summary of the inspection process, detailed findings, supporting visual evidence (images, videos), statistical analysis of defects (e.g., frequency, severity), and recommendations for corrective actions. For instance, in a recent project involving the inspection of aircraft components, my data analysis highlighted a previously unnoticed trend in crack propagation, which led to the implementation of preventative maintenance protocols, preventing potential catastrophic failures.

My data analysis often involves using statistical software to identify trends, patterns, and outliers. This helps ensure the inspection results are statistically sound and represent the actual condition of the inspected asset. I always maintain clear and concise documentation, ensuring full traceability and transparency.

Q 17. What software packages are you proficient in for data acquisition and analysis?

I am proficient in several software packages for data acquisition and analysis, including:

- LabVIEW: For building custom data acquisition systems and automating testing procedures.

- MATLAB: For advanced data analysis, signal processing, and statistical modeling.

- Python (with libraries like NumPy, SciPy, and Pandas): For data manipulation, analysis, visualization, and report generation. For example, I’ve used Python to develop automated scripts for analyzing large datasets from non-destructive testing (NDT) scans.

- Specialized NDT Software: I’m also familiar with various commercial software packages specific to different NDT techniques (e.g., ultrasonic testing, radiographic testing software).

My expertise in these tools allows me to efficiently process and interpret vast amounts of inspection data, providing actionable insights to improve quality and reduce risks.

Q 18. How do you ensure the traceability of calibration standards?

Traceability of calibration standards is crucial for ensuring the accuracy and reliability of inspection equipment. This is achieved through a robust calibration chain that links the equipment to national or international standards. I follow these key steps:

- Documented Calibration History: Maintain detailed records of all calibrations, including the date, equipment identification, calibration procedures, results, and the identity of the calibrator. This creates an unbroken chain of traceability.

- Certified Calibration Labs: Ensure that calibration is performed by accredited laboratories that utilize traceable standards. This verifies the accuracy of the calibration process itself.

- Calibration Certificates: Obtain and maintain calibration certificates for all standards used. These certificates document the traceability to higher-level standards.

- Regular Calibration Intervals: Adhere to a schedule of regular calibrations based on the equipment’s specifications and the criticality of the inspection. Frequency varies depending on equipment type and use.

- Calibration Software: Utilize calibration software where applicable to manage and document the calibration process, reducing errors and enhancing traceability.

By meticulously following these procedures, I ensure that the calibration standards are fully traceable, maintaining the integrity and reliability of our inspection process.

Q 19. Describe your experience with different types of sensors used in inspection equipment.

My experience encompasses a wide array of sensors used in inspection equipment. This includes:

- Ultrasonic Sensors: Used for flaw detection in materials using high-frequency sound waves. I have experience using both contact and immersion techniques.

- Optical Sensors (e.g., laser scanners, cameras): For dimensional measurements, surface inspection, and image-based analysis. I’ve used these in applications like 3D scanning and automated visual inspection.

- Eddy Current Sensors: For detecting surface and subsurface flaws in conductive materials using electromagnetic fields. This is a critical technique in aerospace and pipeline inspection.

- Magnetic Particle Sensors: For detecting surface cracks in ferromagnetic materials. I’m experienced in interpreting the resulting patterns to identify defects.

- Radiographic Sensors (X-ray, Gamma-ray): Used to inspect internal features of materials and components. I understand the safety procedures and interpretation of radiographic images.

Understanding the strengths and limitations of each sensor type is critical to selecting the appropriate technology for a given inspection task. For example, ultrasonic testing might be ideal for internal flaws in metals, while optical sensors might be better suited for surface finish inspections.

Q 20. How do you maintain inspection equipment to prolong its lifespan and accuracy?

Maintaining inspection equipment is crucial for extending its lifespan and ensuring accurate measurements. My approach incorporates a multi-faceted strategy:

- Regular Cleaning and Maintenance: Regular cleaning of the equipment prevents the buildup of dust, debris, and contaminants that can affect sensor performance and accuracy. I follow manufacturer’s recommendations for cleaning procedures.

- Preventative Maintenance Schedules: I establish and adhere to preventative maintenance schedules that include regular checks of components, lubrication of moving parts, and replacement of worn-out parts. This helps prevent unexpected failures.

- Environmental Control: Storing the equipment in a clean, dry, and temperature-controlled environment protects it from damage and prolongs its life. Extreme temperatures or humidity can affect sensor accuracy.

- Proper Handling and Transportation: Careful handling and appropriate transportation techniques (using protective cases, etc.) prevent damage during transport and use.

- Training and Documentation: Proper operator training on safe use and maintenance procedures is vital. I ensure that maintenance logs are properly maintained for tracking and reporting.

Through proactive maintenance, we significantly reduce equipment downtime and ensure that inspection data remains reliable and accurate, saving considerable time and resources in the long run.

Q 21. What are the limitations of various inspection techniques?

Different inspection techniques have inherent limitations. Understanding these limitations is crucial for interpreting results accurately and avoiding misinterpretations:

- Ultrasonic Testing: Limited by material attenuation (the absorption of sound waves), surface finish, and the geometry of the inspected part. It may miss flaws that are oriented parallel to the sound beam.

- Radiographic Testing: Requires careful interpretation of the images and can be limited by material density and thickness. It may also pose safety concerns associated with radiation.

- Eddy Current Testing: Only applicable to conductive materials. The depth of penetration is limited, and surface conditions can affect the results.

- Visual Inspection: Subjective and prone to human error. Limited to surface defects and visibility. Requires proper lighting and magnification.

- Magnetic Particle Testing: Limited to ferromagnetic materials, and surface defects might be missed if not properly oriented to the magnetic field.

The choice of inspection technique must consider the material properties, defect type, and desired level of sensitivity. Often, a combination of techniques is employed to obtain a comprehensive and reliable assessment.

Q 22. How do you prioritize tasks when dealing with multiple inspection requests?

Prioritizing inspection requests involves a multi-faceted approach. I typically employ a system that considers urgency, criticality, and resource availability. Urgency refers to immediate needs, like addressing a safety concern or preventing production downtime. Criticality considers the potential impact of a defect—a critical component failure is far more important than a minor cosmetic flaw. Resource availability includes factors like equipment availability, personnel expertise, and time constraints.

For example, if I receive requests to inspect a potentially faulty pressure vessel, a batch of critical engine parts, and some minor cosmetic defects on a casing, I would prioritize the pressure vessel first (high urgency and criticality). The engine parts would follow (high criticality), and finally, the casing (low urgency and criticality). I use a Kanban-style board to visually track the progress and prioritize effectively. This ensures efficient workflow and timely resolution of critical issues.

Q 23. Explain your understanding of ISO 9001 standards related to inspection.

ISO 9001 is crucial for quality management systems, providing a framework for consistent processes and customer satisfaction. Within the context of inspection, ISO 9001 dictates that inspections must be planned, documented, and controlled. This includes defining inspection criteria, methods, and acceptance criteria. The standard also emphasizes the need for qualified personnel, calibrated equipment, and traceable results. Non-conformances must be properly identified, reported, and resolved, with effective corrective actions in place.

For example, before conducting an inspection, we’d reference our documented procedures, ensuring the correct equipment is used and calibrated to the required standards. Every step, from sample selection to report generation, is meticulously documented and audited, ensuring traceability and compliance with ISO 9001.

Q 24. Describe your experience with different types of surface finish inspection techniques.

My experience encompasses various surface finish inspection techniques. These range from simple visual checks using magnification tools like microscopes and borescopes to more sophisticated methods like profilometry and surface roughness measurements using instruments such as a surface roughness tester. Visual inspection helps identify obvious defects such as scratches, pitting, and discoloration. Profilometry, using a stylus or optical techniques, provides precise measurements of surface texture and roughness parameters like Ra (average roughness).

For instance, inspecting a polished metal component might involve visual checks for scratches under a microscope followed by a profilometry measurement to quantify the surface roughness to ensure it meets specifications. For a painted surface, visual inspection for orange peel or other imperfections would be coupled with gloss measurements to assess the quality of the coating.

Q 25. How do you ensure the integrity of inspection data?

Maintaining inspection data integrity is paramount. This is achieved through a combination of rigorous processes and technological safeguards. Firstly, we use calibrated equipment, ensuring accurate and repeatable measurements. Calibration certificates are meticulously maintained, providing traceability. Secondly, all inspection data is recorded digitally in a secure database, preventing alterations and losses. Data is timestamped and digitally signed whenever possible to maintain an auditable trail.

Moreover, we employ statistical process control (SPC) techniques to identify potential issues and deviations from expected values. Regular audits and cross-checking of results further enhance data integrity. For example, in a critical application, a second inspector might independently verify measurements to reduce the risk of human error or misinterpretation.

Q 26. What are your experience with different types of visual inspection equipment (e.g. borescopes, microscopes)?

I’m proficient with various visual inspection equipment. Borescopes are invaluable for inspecting internal components, such as the interior of pipes or engine cylinders. Their flexible design allows access to otherwise unreachable areas. Microscopes, both optical and digital, provide high magnification for detailed analysis of surface features, identifying very small defects invisible to the naked eye. I’ve used various models, from simple stereo microscopes to sophisticated confocal microscopes offering 3D surface imaging.

For example, I’ve used a borescope to inspect the internal diameter of a pipe for corrosion or blockage, and a digital microscope to analyze the microscopic flaws on a microchip surface, documenting the findings with high-resolution images and reports.

Q 27. Describe your experience with automated optical inspection (AOI) systems.

My experience with Automated Optical Inspection (AOI) systems includes programming, operating, and maintaining various systems. AOI systems automate the inspection process, significantly increasing speed and consistency compared to manual methods. They use cameras and sophisticated image processing algorithms to identify defects such as surface flaws, misalignments, and missing components on printed circuit boards (PCBs) or other manufactured parts. I’m familiar with both 2D and 3D AOI systems. The 2D systems analyze images from different angles, while 3D systems use structured light or other methods to create a 3D model of the part, allowing for more comprehensive defect detection.

In practice, I’ve used AOI to inspect PCBs for solder bridges, open circuits, and component placement errors. The speed and precision of AOI considerably improved the efficiency and reliability of the inspection process, enabling early detection of defects and minimizing production delays.

Q 28. How do you stay updated with the latest advancements in inspection technology?

Staying current with inspection technology advancements is a continuous process. I regularly attend industry conferences and webinars, participate in professional organizations, and read technical journals and publications specializing in inspection and quality control. I also maintain an active network of colleagues and experts in the field. Furthermore, I actively seek opportunities for training on new equipment and software.

For example, recently I attended a workshop on advanced image processing techniques used in AOI, enhancing my skills in identifying subtle defects and improving the accuracy of the inspection process. Continuous learning is key to maintaining expertise in this rapidly evolving field.

Key Topics to Learn for Proficient in Inspection Equipment Interview

- Types of Inspection Equipment: Understanding the various types of inspection equipment (e.g., visual inspection tools, non-destructive testing equipment, automated inspection systems) and their applications in different industries.

- Inspection Techniques and Methods: Mastering various inspection techniques, including visual inspection, dimensional inspection, surface finish inspection, and non-destructive testing methods (NDT) like ultrasonic testing, radiographic testing, and magnetic particle inspection.

- Data Analysis and Interpretation: Developing skills in analyzing inspection data, interpreting results, identifying defects, and generating reports. This includes understanding statistical process control (SPC) and its relevance to inspection.

- Calibration and Maintenance: Knowledge of proper calibration procedures for inspection equipment and routine maintenance practices to ensure accuracy and reliability.

- Quality Control and Assurance: Understanding the role of inspection equipment in ensuring quality control and adherence to industry standards and regulations (e.g., ISO 9001).

- Troubleshooting and Problem-Solving: Developing the ability to identify and troubleshoot issues with inspection equipment, interpret error messages, and perform basic repairs or identify the need for professional service.

- Safety Procedures and Regulations: Familiarity with safety protocols and regulations related to the operation and maintenance of specific inspection equipment.

- Specific Software and Systems: If applicable to the job description, demonstrate familiarity with any specific software or systems used to operate or manage inspection equipment (e.g., data acquisition software, image analysis software).

Next Steps

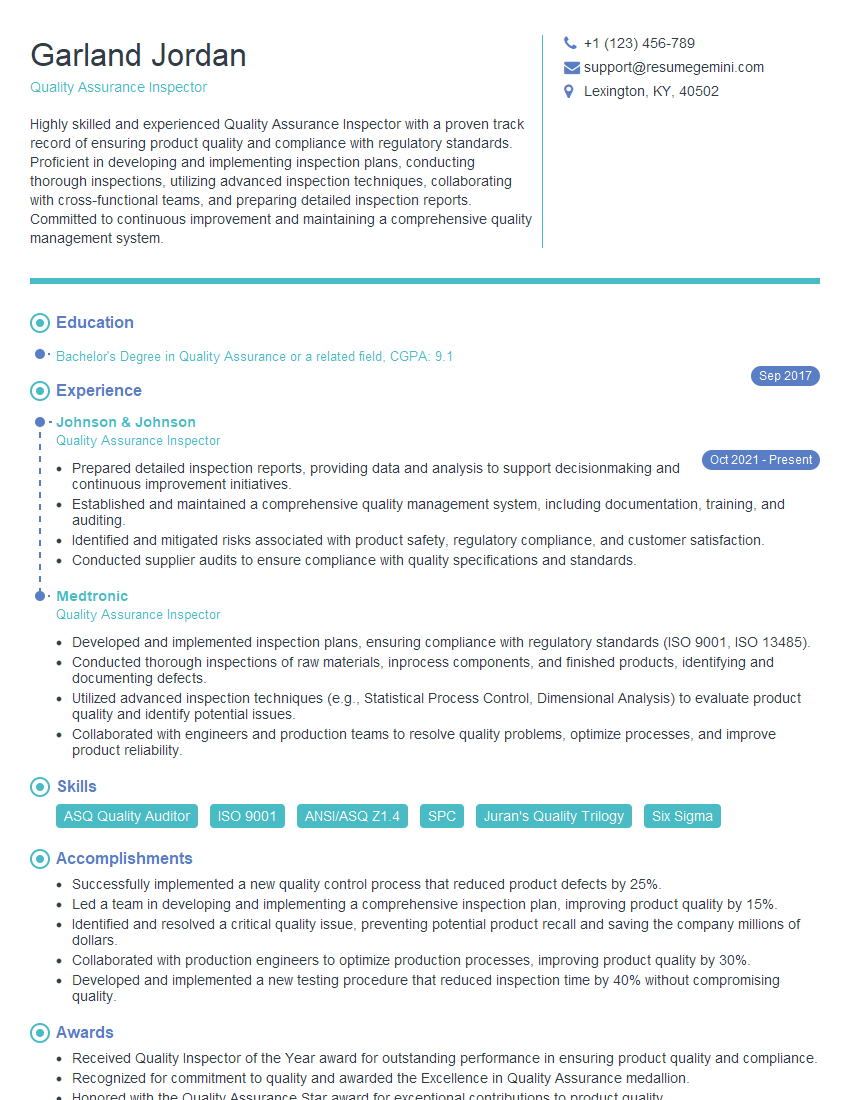

Mastering proficiency in inspection equipment opens doors to exciting career advancements, offering higher earning potential and increased responsibility within the quality control and assurance field. To maximize your job prospects, it’s crucial to present your skills effectively. Create an ATS-friendly resume that highlights your expertise and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. We provide examples of resumes tailored to professionals proficient in inspection equipment to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO