Preparation is the key to success in any interview. In this post, we’ll explore crucial Structural Fitting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Structural Fitting Interview

Q 1. Describe your experience with different welding techniques (e.g., MIG, TIG, stick).

My experience encompasses a wide range of welding techniques, with proficiency in MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. MIG welding, known for its speed and ease of use, is my go-to for larger projects requiring high deposition rates, like joining thick steel plates in a beam assembly. I often use it for fillet welds and continuous bead welds. TIG welding, while slower, provides exceptional precision and a clean, high-quality weld, ideal for intricate work and critical joints where appearance and strength are paramount. I utilize TIG extensively for stainless steel components and situations demanding superior corrosion resistance. Stick welding, or SMAW (Shielded Metal Arc Welding), is invaluable in field applications or where access to electricity is limited. Its robustness and portability make it suitable for on-site repairs or welding in challenging environments.

For instance, on a recent project constructing a large steel frame building, I employed MIG welding for most of the structural connections, leveraging its speed to meet the tight deadlines. However, for the intricate bracing elements that required a visually appealing and structurally perfect weld, I carefully switched to TIG.

Q 2. Explain the importance of blueprint reading in structural fitting.

Blueprint reading is the cornerstone of accurate structural fitting. It’s our roadmap, providing detailed information about the structure’s dimensions, material specifications, and the precise location and type of each component. Without a thorough understanding of the blueprints, it’s impossible to fabricate and assemble the structure correctly. We need to be able to interpret symbols, understand scaling, identify different views (plan, elevation, section), and comprehend tolerances. Missing even a minor detail can lead to significant errors and costly rework.

For example, a misinterpretation of a dimension could result in a member being too short or too long, causing structural instability. Similarly, overlooking a detail like the specified weld type could compromise the overall strength of the joint. Proficiency in blueprint reading ensures that every piece is correctly fabricated and assembled, minimizing errors and delays.

Q 3. How do you ensure the accuracy of measurements and alignments during fitting?

Ensuring accurate measurements and alignments is critical. We use a combination of tools and techniques. Precise measurements are made using measuring tapes, steel rules, and calipers, always double-checking readings. For alignment, we employ levels, squares, plumb bobs, and laser levels to guarantee perfect verticality, horizontality, and squareness. Jigging and clamping are crucial in holding components in place during welding. We frequently use shims to compensate for minor discrepancies, ensuring a tight and accurate fit. Throughout the process, we perform regular checks against the blueprint to verify that everything aligns with the design specifications.

Imagine constructing a multi-story building. Even a slight misalignment in the initial stages could result in cascading errors, impacting the structural integrity of the entire building. Meticulous measurement and alignment practices are essential to prevent such scenarios.

Q 4. What safety measures do you implement when working with structural steel?

Safety is paramount in structural steel work. We always wear appropriate Personal Protective Equipment (PPE), including safety glasses, hard hats, welding helmets with appropriate shade lenses, gloves, and flame-retardant clothing. The work area is kept clean and organized to minimize trip hazards. Proper ventilation is essential to avoid inhaling welding fumes. Before starting any welding operation, we ensure that the area is clear of flammable materials and that fire extinguishers are readily available. We adhere strictly to lockout/tagout procedures when working near energized equipment. We also consistently receive safety training and stay updated on the latest safety regulations.

A simple example is using a fire blanket to protect nearby materials from sparks and hot metal during welding. Another crucial step is regularly inspecting our equipment to ensure that it is in good working order and functioning safely.

Q 5. Describe your experience with different types of steel and their applications.

I’ve worked extensively with various steel types, each possessing unique properties and applications. A36 steel is a common structural steel, known for its strength and weldability, widely used in beams, columns, and other structural members. High-strength low-alloy (HSLA) steels offer superior strength-to-weight ratios, making them ideal for applications where weight reduction is critical, such as in bridge construction. Stainless steel is used where corrosion resistance is paramount, like in coastal structures or chemical plants. Different grades of stainless steel exhibit varying levels of strength and corrosion resistance.

For example, in a recent bridge project, we used HSLA steel for the main girders to maximize strength while minimizing the overall weight of the structure. Conversely, for handrails and other elements exposed to the elements, we opted for marine-grade stainless steel to ensure longevity and prevent corrosion.

Q 6. How do you handle discrepancies or errors found in blueprints or shop drawings?

Discrepancies or errors in blueprints or shop drawings are handled with care and precision. The first step involves a thorough review and verification of the drawing against any available revisions or addenda. If the discrepancy is minor and its impact on the structure’s integrity is negligible, I’d discuss the situation with the project engineer, seeking clarification and guidance on how to proceed. For significant discrepancies, I would halt the work immediately and bring it to the attention of the project manager and engineer. If a decision cannot be reached immediately, we may need to prepare a detailed report outlining the discrepancy, its potential implications, and suggested solutions. Accurate documentation is paramount, as are photos of the discrepancy and discussions with the relevant stakeholders.

Think of a situation where a dimension on the blueprint is incorrect. We would document the error, discuss it with the engineer, and get a confirmed correction. We would never proceed without proper authorization and clarification.

Q 7. Explain your understanding of tolerance levels in structural fitting.

Tolerance levels in structural fitting define the acceptable range of variation from the specified dimensions. They are crucial because it’s practically impossible to achieve perfect precision in all fabrications. Tolerances are specified in the blueprints and must be adhered to meticulously to ensure the structure’s overall integrity. Exceeding tolerances can lead to misalignment, weakening of connections, and even structural failure. The permitted tolerance varies depending on the size and type of the component and the overall design of the structure. Stricter tolerances are generally employed for critical components and highly precise assemblies.

For instance, a small tolerance might be acceptable for a simple beam, but much tighter tolerances would be necessary for a complex connection in a high-rise building. Understanding and adhering to these tolerances is a critical skill for any structural fitter.

Q 8. Describe your process for identifying and resolving fitting issues during assembly.

Identifying and resolving fitting issues starts with meticulous pre-assembly planning. I carefully review blueprints, specifications, and material lists to anticipate potential problems. During assembly, I employ a systematic approach: visual inspection for any discrepancies, precise measurements using various tools (calipers, levels, squares), and checking for proper alignment. If an issue arises, I first attempt minor adjustments, like shimming or using different fasteners. If the problem persists, I meticulously document the issue, including photos, and consult with the project engineer or supervisor to determine the best course of action, which may involve redesigning a component, sourcing a replacement part, or even adjusting the overall structure slightly.

For example, I once encountered a misalignment in a steel beam during a high-rise construction. Instead of forcing the fit, which could have compromised the structural integrity, I meticulously documented the issue, consulted the engineer, and we collaboratively determined a solution involving slight adjustments to adjacent supports, ensuring the overall structure remained stable and safe.

Q 9. How do you ensure the structural integrity of your work?

Ensuring structural integrity is paramount. It’s a multi-faceted process that begins long before assembly. I rely on understanding the material properties of each component – its strength, flexibility, and tolerance to stress. This allows me to choose appropriate fasteners and connection methods. Accurate measurements are crucial; I double-check every dimension, ensuring everything is precisely aligned and within tolerance. I also adhere strictly to building codes and safety regulations. Throughout the process, visual inspection plays a vital role, helping me identify any signs of stress, cracks, or other defects.

Think of it like building with LEGOs: each brick needs to fit perfectly; otherwise, the entire structure becomes unstable. Similarly, in structural fitting, any slight misalignment or improper connection can have significant consequences.

Q 10. What are some common challenges you face in structural fitting?

Common challenges include working with materials that have dimensional inaccuracies, which requires creative solutions, like shimming or machining. Another challenge is dealing with unforeseen site conditions – maybe the foundation isn’t perfectly level, necessitating on-site adjustments. Time constraints are always a factor in construction, often leading to pressure to compromise quality if one isn’t careful. Lastly, coordinating with other tradespeople to ensure smooth workflow and avoid conflicts is critical.

For example, I once had to work with slightly warped steel plates. Instead of rejecting them, I used precision grinding techniques to ensure a proper fit. That saved time and resources and demonstrated my problem-solving skills.

Q 11. How do you manage your time and prioritize tasks in a fast-paced construction environment?

In a fast-paced environment, effective time management is crucial. I prioritize tasks based on urgency and dependencies. I utilize checklists, detailed schedules, and daily planning sessions to stay organized and on track. Communication is key – keeping the team informed about potential delays or resource needs ensures everyone works collaboratively and efficiently. Breaking down large tasks into smaller, manageable steps makes them less daunting and improves focus.

I use project management tools such as Kanban boards to visualize progress and identify potential bottlenecks. Proactive communication regarding potential delays helps avoid major disruptions.

Q 12. Describe your experience working with various hand tools and power tools.

My experience with hand tools encompasses a wide range: from basic measuring tools like tapes, levels, and squares, to specialized tools like calipers, punches, and chisels. With power tools, I’m proficient in operating various drills, grinders, saws, and welders (following all safety regulations, of course). I understand the nuances of each tool and choose the most appropriate one for the task at hand. Safety is always the top priority.

For instance, knowing when to use a specific drill bit for different materials is crucial to prevent damage or injury. Choosing the correct welding technique for specific metals is essential for structural integrity.

Q 13. How do you maintain your tools and equipment?

Tool maintenance is non-negotiable. After each use, I clean and lubricate my tools, ensuring they’re stored properly to prevent damage or rust. I regularly inspect them for wear and tear, replacing or sharpening them as needed. Power tools require more specific maintenance; I adhere to manufacturer recommendations for lubrication and component replacements. I also document all maintenance activities and report any tool failures.

Proper tool maintenance equates to safety and efficiency. A well-maintained tool works more effectively and reduces the risk of workplace accidents.

Q 14. What is your experience with quality control procedures?

Quality control is integral to my work. It starts with verifying material quality upon delivery and continues throughout the assembly process. I perform regular inspections, checking for proper alignment, adherence to specifications, and signs of damage. I meticulously document my work, including measurements and photos, for future reference and auditing. I am familiar with various quality control procedures and standards, including ISO 9001. I actively participate in quality control meetings and provide feedback to improve processes.

For example, regular visual inspections for cracks or other defects in welded joints are vital for structural safety. Documenting every step of the process facilitates efficient troubleshooting and continuous improvement.

Q 15. Explain your understanding of different types of structural connections.

Structural connections are the critical elements that join different structural members together, ensuring the overall stability and load-bearing capacity of a structure. Understanding the various types is crucial for designing and constructing safe and efficient buildings and infrastructure.

- Bolted Connections: These are extremely common, utilizing bolts to fasten members together. The design considers factors like bolt diameter, material, grade, and the number of bolts to ensure sufficient shear and tensile strength. Think of the connections holding together a steel frame building – thousands of bolts ensuring structural integrity.

- Welded Connections: Welding fuses metal members together, creating a strong and continuous connection. Different welding techniques (like fillet welds, groove welds) are employed depending on the strength requirements and joint geometry. Consider the welds joining I-beams in a bridge structure – they must withstand immense forces.

- Riveted Connections: Though less prevalent now due to the ease of bolting and welding, riveted connections still appear in older structures. Rivets are mechanically fastened, creating a permanent connection. Think of the many rivets in historic bridges or older industrial buildings.

- Pinned Connections: These are often found in truss structures. A pin allows for rotation between members, transferring loads primarily through shear. Imagine the pins joining the individual members of a roof truss – they allow for efficient load distribution.

- Moment Connections: These connections transfer both shear and moment (bending forces), commonly found in continuous beams and frames. This is crucial to resist bending and torsion in the structure. Modern high-rise buildings often rely heavily on moment connections.

Choosing the right type of connection depends on several factors: material properties, load requirements, fabrication methods, cost, and design aesthetics. Often, a combination of connection types is used in a single structure to optimize performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret and follow detailed engineering specifications?

Interpreting engineering specifications is paramount. It requires meticulous attention to detail and a thorough understanding of engineering drawings, calculations, and material specifications. My approach involves a systematic review:

- Thorough Review of Drawings: I meticulously examine all drawings, paying close attention to dimensions, tolerances, material specifications, and connection details. I look for any discrepancies or ambiguities.

- Understanding Specifications: I carefully study the written specifications, cross-referencing them with the drawings to ensure consistency and clarity. I understand that these details usually define the required materials, quality standards, and acceptance criteria.

- Material Identification: Correct identification of materials is crucial. I verify the specified grades and properties of steel, aluminum, or other materials with their respective certificates of compliance. I know that the strength and properties of the material will directly impact the design and assembly.

- Tolerance Checks: I ensure that all components are within the specified tolerance ranges. Small deviations can compromise structural integrity. Understanding tolerances is key to ensuring the structure functions as designed.

- Collaboration and Clarification: If I encounter any ambiguities or inconsistencies, I consult the structural engineer or project manager for clarification before proceeding. Open communication is vital.

By following this procedure, I ensure that the structural fitting is executed precisely according to the engineering specifications, contributing to a safe and reliable structure. This systematic approach minimizes errors and ensures the final product meets the design criteria.

Q 17. Describe your experience with working at heights.

I have extensive experience working at heights, primarily during the installation of structural components on high-rise buildings and bridges. Safety is always my top priority.

- Fall Protection: I am proficient in using various fall protection equipment, including harnesses, lifelines, and anchors. I always ensure that the equipment is properly inspected and certified before use. This includes checking the expiry date and conducting a visual inspection.

- Scaffolding and Access Equipment: I’m experienced in the safe erection, use, and dismantling of scaffolding and other access equipment. This includes understanding the safe working load limits and ensuring appropriate stability and securing mechanisms are in place.

- Safety Training and Compliance: I have completed extensive safety training, including fall protection, working at heights, and hazard awareness training. I strictly adhere to all company safety regulations and site-specific safety procedures.

- Risk Assessment: Before commencing any work at height, I participate in and contribute to the site-specific risk assessments, identifying and mitigating potential hazards.

My experience has equipped me with the necessary skills and knowledge to work safely and efficiently at heights, always prioritizing safety over speed.

Q 18. What are your experience with using lifting equipment?

My experience with lifting equipment encompasses various types, ensuring safe and efficient handling of heavy structural components.

- Cranes: I am familiar with various crane types (tower cranes, mobile cranes, etc.) and their operation. I understand the importance of load charts, appropriate rigging techniques, and safe lifting procedures. This also includes pre-lift inspections and ensuring the operator’s qualifications.

- Forklifts: I have experience operating forklifts to move materials and components around the jobsite safely and efficiently. This includes understanding the load limits and maneuvering in tight spaces.

- Hoists and Chain Blocks: I am proficient in using hoists and chain blocks to lift and position components accurately, applying safe practices to prevent accidents. I am familiar with hand signals and appropriate checks before use.

- Rigging and Slinging: I possess a thorough understanding of proper rigging techniques, including selecting the appropriate slings, shackles, and other hardware, ensuring correct load distribution and securing to prevent slippage. Proper rigging is critical to the safe operation of any lifting equipment.

My experience ensures that lifting operations are conducted safely and efficiently, minimizing risk and ensuring the integrity of the components being lifted.

Q 19. Describe your experience working with different types of materials (e.g., steel, aluminum, stainless steel).

My experience working with various materials – steel, aluminum, and stainless steel – is extensive. Each material demands specific handling and installation techniques.

- Steel: I have worked extensively with structural steel, understanding its high strength but susceptibility to corrosion. I’m familiar with different steel grades (e.g., A36, A992) and their respective properties, ensuring proper selection based on design requirements. The proper selection of steel is important for load bearing and fatigue.

- Aluminum: Aluminum’s lightweight nature and corrosion resistance make it ideal for specific applications. However, it’s softer than steel, requiring careful handling during installation to prevent damage. This includes using appropriate tools to avoid scratches or dents.

- Stainless Steel: Stainless steel’s corrosion resistance is crucial in many applications. I understand its characteristics and the need to avoid surface damage to maintain its protective properties. Care must be taken to avoid contamination during the installation.

My expertise extends to understanding material properties, selecting appropriate fasteners, and employing proper installation techniques to ensure the longevity and performance of the structure.

Q 20. How do you ensure the proper installation of components to meet specified requirements?

Ensuring proper installation requires a multi-faceted approach, emphasizing precision, safety, and adherence to specifications.

- Pre-Installation Checks: Before installation, I carefully inspect all components for damage, ensuring that they meet the required specifications and tolerances. Dimensions are double-checked and any concerns are communicated immediately.

- Accurate Measurements and Layout: Precise measurements and layouts are vital. I use appropriate measuring tools and techniques to ensure accurate placement of components, adhering to the specified tolerances. Layout is critical, especially for complex structures.

- Proper Fastener Selection and Installation: I select the appropriate fasteners based on material properties, load requirements, and design specifications. I ensure that fasteners are installed correctly, achieving the required torque or clamping force, again, as specified by the engineer.

- Sequence of Installation: Following the correct sequence of installation is crucial, especially for complex structures. I carefully adhere to the specified sequence to ensure proper alignment and stability of the components.

- Quality Control Checks: Throughout the installation process, I conduct regular quality control checks, verifying that the work conforms to the specifications and that all components are correctly installed. This includes documenting the installation to ensure traceability and ease of problem solving.

This systematic approach ensures that the installation meets the specified requirements, resulting in a robust and reliable structure.

Q 21. What is your experience with troubleshooting and repairing structural issues?

Troubleshooting and repairing structural issues require a systematic approach, combining problem-solving skills with a deep understanding of structural mechanics.

- Problem Identification: The first step is to accurately identify the nature and extent of the structural issue. This might involve visual inspections, load testing, or reviewing design documents. Understanding the root cause is critical.

- Root Cause Analysis: Once the problem is identified, I conduct a thorough root cause analysis to determine the underlying cause, whether it’s faulty design, improper installation, material defects, or environmental factors.

- Repair Strategy: Based on the root cause analysis, I develop a suitable repair strategy. This might involve reinforcement, component replacement, or adjustments to existing connections. The strategy always considers the strength and stability of the existing structure and minimizes further damage.

- Repair Implementation: I implement the repair strategy carefully, ensuring that the repair work is executed correctly and that any necessary safety precautions are in place. The repair should restore structural integrity and ensure long-term stability.

- Post-Repair Inspection: After the repair is complete, I conduct a thorough inspection to verify its effectiveness and ensure that the structural integrity has been restored. This might involve further testing and documentation.

My experience in this area allows me to effectively diagnose, repair, and prevent future structural issues, ensuring the safety and longevity of the structure.

Q 22. Describe your experience using CAD software for structural fitting.

My experience with CAD software for structural fitting is extensive. I’m proficient in AutoCAD, SolidWorks, and Inventor, leveraging them throughout the entire process, from initial design and detailing to fabrication and assembly. For example, in a recent project involving a large steel framework for a warehouse, I used AutoCAD to create detailed 2D drawings specifying the dimensions, cuts, and weld preparations for each component. Then, in SolidWorks, I created a 3D model to verify clearances, interference, and overall structural integrity before fabrication. This allowed for early detection and correction of any design flaws, saving significant time and resources during the construction phase. I also utilize the software’s simulation capabilities to analyze stress and strain on critical joints under various load conditions, ensuring the final structure meets all safety and performance standards.

Q 23. What is your understanding of different welding codes and standards?

Understanding welding codes and standards is paramount in ensuring structural integrity and safety. I’m familiar with AWS D1.1 (Structural Welding Code – Steel), ASME Section IX (Welding and Brazing Qualifications), and relevant ISO standards. These codes dictate the acceptable welding procedures, welder qualifications, material specifications, and inspection requirements. For example, AWS D1.1 specifies the minimum weld sizes, types, and procedures depending on the load-bearing capacity required. Understanding these codes allows me to select appropriate welding processes (like GMAW, SMAW, or FCAW), ensure welders are properly certified, and specify the necessary non-destructive testing (NDT) methods such as visual inspection, radiography, or ultrasonic testing to verify the quality of the welds. Compliance with these standards is crucial for obtaining project approvals and ensuring the long-term safety and reliability of the structures.

Q 24. Explain your experience with working as part of a team on a large-scale project.

Teamwork is essential in large-scale projects. On a recent bridge refurbishment project, I worked collaboratively with engineers, welders, inspectors, and project managers. My role involved coordinating the fabrication and installation of new steel support beams. Effective communication was key; I used regular meetings and detailed progress reports to keep the team informed and address any arising issues. For instance, we faced a delay due to unforeseen corrosion on existing steel members. By quickly communicating this to the team, we collaboratively developed a revised plan, incorporating additional inspection and remediation steps, preventing significant project delays. Active listening and conflict resolution skills proved crucial in navigating diverse perspectives and maintaining a productive work environment.

Q 25. How do you maintain compliance with safety regulations and standards?

Maintaining compliance with safety regulations and standards is a top priority. I rigorously follow OSHA guidelines, relevant local regulations, and company safety protocols. This includes utilizing appropriate personal protective equipment (PPE) like safety glasses, gloves, and hearing protection, as well as ensuring the worksite is properly secured and organized. Before starting any task, I conduct thorough risk assessments, identifying potential hazards and implementing control measures. For example, before welding in confined spaces, I would ensure adequate ventilation and implement fire safety precautions. I also regularly participate in safety training and actively promote a safety-conscious work environment by encouraging colleagues to report hazards and follow safe working practices.

Q 26. What is your experience with different types of fasteners?

My experience encompasses a wide range of fasteners, including bolts (high-strength, hex-head, etc.), rivets (solid, blind), screws, and welds (considered a permanent fastener). The choice of fastener depends on various factors like the materials being joined, the load requirements, the accessibility of the joint, and aesthetic considerations. For example, high-strength bolts are often preferred for structural steel connections due to their ease of installation and predictable strength characteristics, while rivets might be used in situations where welding is impractical. I’m skilled in selecting appropriate fasteners based on design specifications and ensuring proper torque values during installation to guarantee secure connections that meet the design criteria. Improper fastener selection or installation can lead to significant structural weaknesses and potential failures.

Q 27. How do you ensure the proper fit and alignment of components before welding?

Ensuring proper fit and alignment before welding is crucial for producing strong, durable welds and preventing distortion. This involves meticulous planning and careful execution. I utilize various tools and techniques, including jigs and fixtures, to accurately position components and maintain their alignment during the welding process. For example, precision shims and clamping devices are used to eliminate gaps and ensure proper alignment before tack welding. After tack welding, the alignment is rechecked using precision measuring instruments to verify that it remains accurate. Any misalignment is corrected before proceeding with the final weld. Failure to achieve proper alignment can lead to weak welds, stress concentrations, and potential structural failure.

Q 28. Describe a time you had to solve a complex structural fitting problem.

During the construction of a large industrial building, we encountered a challenging situation involving the connection of a heavy crane girder to the supporting columns. The design called for a complex bolted connection, but initial attempts resulted in significant stress concentrations at the joint, indicated by finite element analysis (FEA). The problem stemmed from an unforeseen interference between the girder and some bracing members. To solve this, I worked closely with the design team and proposed a redesigned connection using a different arrangement of high-strength bolts and adding reinforcing plates to distribute the load more evenly. This solution, verified through FEA, ensured that the connection could withstand the anticipated loads while eliminating the stress concentrations. This experience highlighted the importance of thorough design review, accurate modeling, and collaborative problem-solving in complex structural fitting projects.

Key Topics to Learn for Structural Fitting Interview

- Blueprint Reading and Interpretation: Understanding architectural drawings, structural details, and specifications to accurately interpret fitting requirements.

- Material Selection and Properties: Knowledge of various materials used in structural fitting (steel, aluminum, wood), their properties (strength, weight, corrosion resistance), and appropriate selection based on project needs.

- Fabrication Techniques: Familiarity with different joining methods (welding, bolting, riveting), cutting techniques, and the use of relevant tools and equipment.

- Precision Measurement and Tolerances: Understanding the importance of accurate measurements and adherence to specified tolerances to ensure structural integrity and safety.

- Installation Procedures and Safety Protocols: Knowledge of safe installation practices, adherence to building codes and regulations, and the use of appropriate safety equipment.

- Troubleshooting and Problem-Solving: Ability to identify and resolve issues during the fitting process, such as misalignment, material defects, or unforeseen challenges.

- Quality Control and Inspection: Understanding quality control measures, inspection techniques, and documentation procedures to ensure compliance with standards.

- Structural Analysis Fundamentals: Basic understanding of load bearing, stress distribution, and structural stability principles to anticipate potential issues.

Next Steps

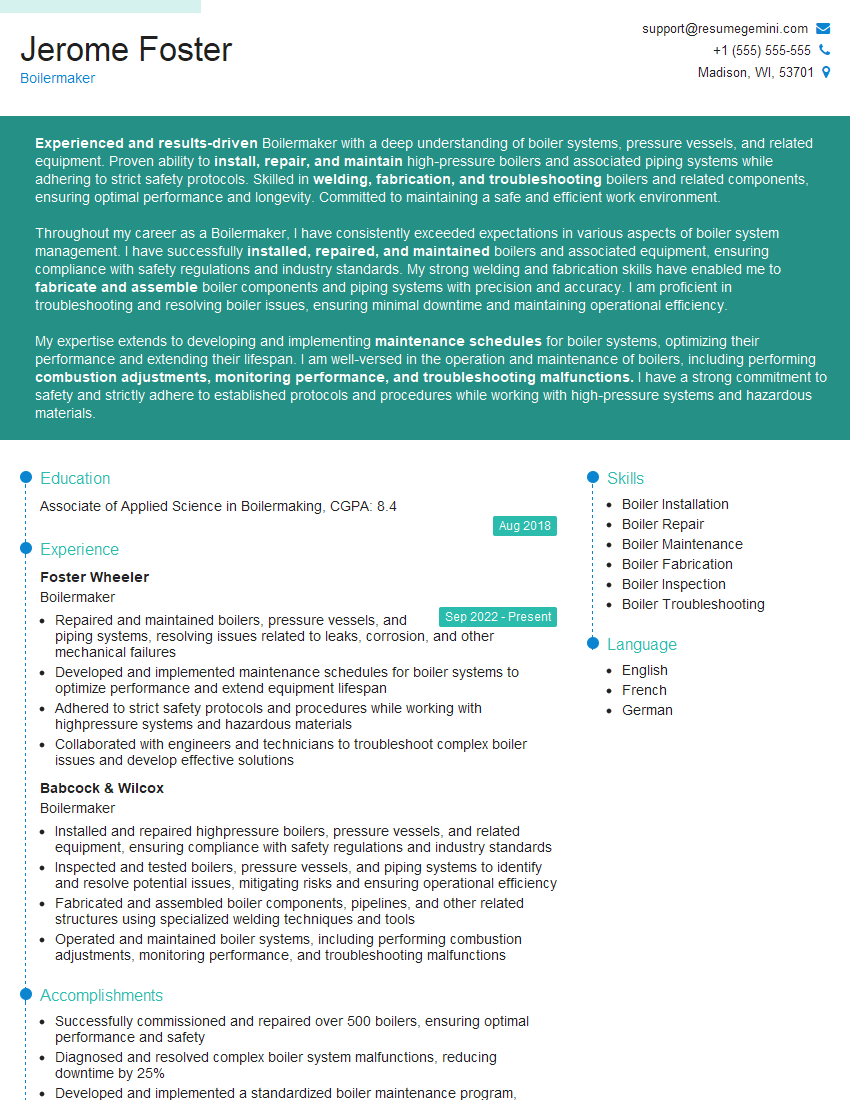

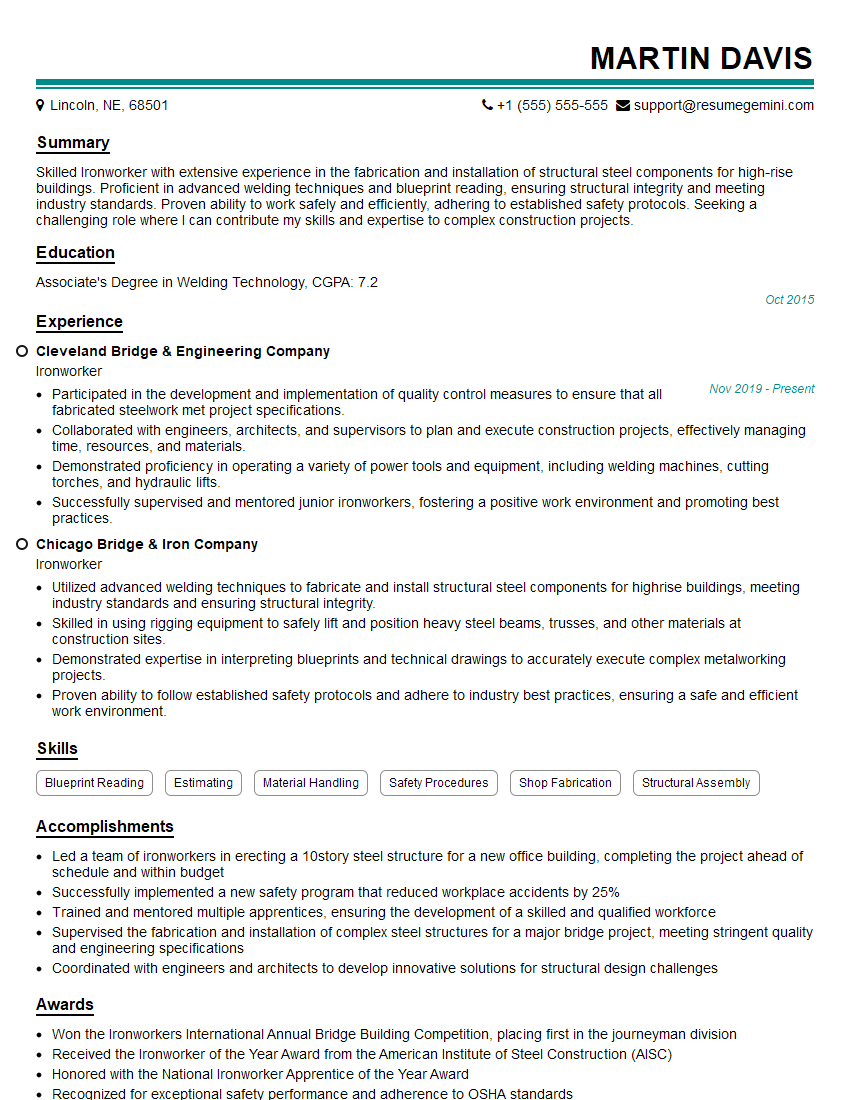

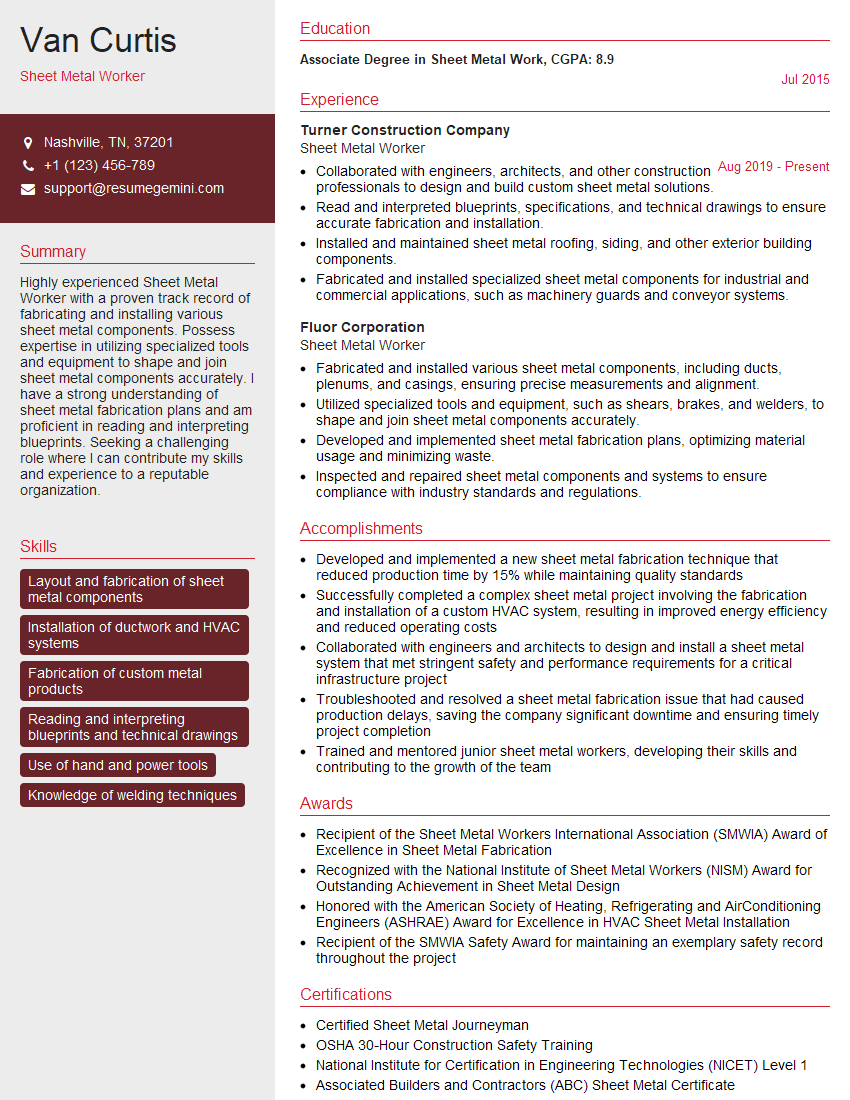

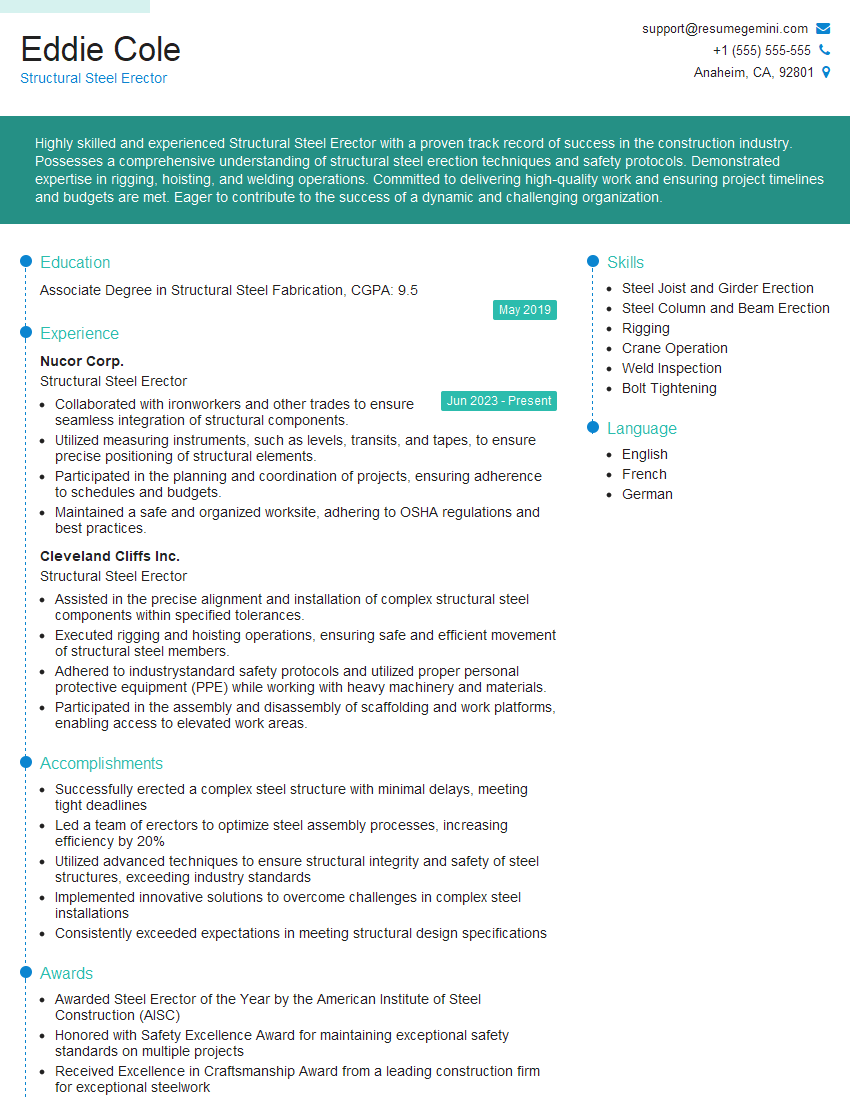

Mastering structural fitting opens doors to rewarding careers in construction, manufacturing, and engineering. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, it’s crucial to present your skills effectively. Create an ATS-friendly resume that highlights your expertise and experience. ResumeGemini can help you build a professional and impactful resume tailored to the structural fitting industry. Examples of resumes specifically designed for structural fitting professionals are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO