The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Air Entrainment Testing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Air Entrainment Testing Interview

Q 1. Explain the purpose of air entrainment in concrete.

Air entrainment in concrete involves intentionally incorporating microscopic air bubbles into the concrete mix. This seemingly simple addition significantly improves the concrete’s durability, particularly its resistance to freeze-thaw cycles and scaling.

Imagine a concrete sidewalk in a cold climate. When water freezes, it expands, putting immense pressure on the concrete’s structure. Without air entrainment, this pressure can cause cracks and deterioration. The air bubbles act as tiny cushions, absorbing this expansion pressure and preventing damage. They provide space for the expanding ice, reducing the stress on the cement matrix.

Q 2. Describe the different methods for measuring air entrainment in concrete.

Several methods exist for measuring air entrainment in concrete, each with its own strengths and weaknesses:

- The Pressure Method (ASTM C231): This is the most common and widely accepted method. It involves measuring the volume of air in a sample of concrete using a pressure-measuring device. The pressure is applied to the sample, forcing air out, and the volume of the released air is then measured. This method is precise and reliable.

- The Volumetric Method: This method involves determining the volume of concrete and the volume of solids in a known mass of concrete. The difference between these two volumes represents the air volume. It’s simpler than the pressure method but can be less accurate.

- The Chace Air Meter: This is a simpler, often field-used device that gives a quick estimation of air content. However, it’s less precise than the pressure method and is not suitable for formal testing.

The choice of method depends on the required accuracy, available equipment, and testing environment. For instance, a quick check on a construction site might utilize a Chace Air Meter, while laboratory quality control would necessitate the pressure method (ASTM C231).

Q 3. What is the significance of ASTM C231 in air entrainment testing?

ASTM C231 is the standard test method for determining the air content of freshly mixed concrete by the pressure method. It’s the gold standard in air entrainment testing, providing a detailed procedure and guidelines for ensuring accurate and reliable results. This standard is crucial for quality control in concrete production, ensuring consistency and meeting project specifications. Following ASTM C231 guarantees that the air content is correctly measured, leading to concrete with the desired durability characteristics. Any deviation from this standard can significantly impact the integrity and lifespan of the concrete structure. Think of it as the recipe book for consistently making durable concrete; without it, the results are unpredictable.

Q 4. How does air entrainment affect the durability of concrete?

Air entrainment dramatically enhances the durability of concrete, primarily by mitigating damage from freeze-thaw cycles. The air voids act as reservoirs for the expansion of water upon freezing, preventing the build-up of internal pressure that can lead to cracking. This protection is especially crucial in climates with frequent freeze-thaw cycles, extending the lifespan of structures like pavements, bridges, and parking lots significantly. Furthermore, air entrainment improves the concrete’s resistance to scaling (surface deterioration) and improves its resistance to the ingress of chlorides (which can cause corrosion of reinforcing steel).

Consider a bridge deck exposed to de-icing salts and repeated freeze-thaw cycles. Concrete without air entrainment would likely suffer extensive cracking and scaling within a few years, requiring costly repairs or even replacement. However, properly air-entrained concrete can withstand these harsh conditions for decades, reducing maintenance costs and ensuring structural integrity.

Q 5. Explain the relationship between air content and concrete strength.

The relationship between air content and concrete strength is generally inverse; as air content increases, concrete strength decreases. This is because air voids replace cement paste, reducing the overall volume of the binding material responsible for strength. However, this relationship is not strictly linear and depends on several factors including mix proportions, cement type, and aggregate characteristics. An optimal air content must be balanced to achieve the desired strength and durability. Too little air compromises durability, while too much significantly reduces strength. Think of it as a Goldilocks scenario – finding the “just right” amount of air to achieve the optimal balance of strength and durability is paramount.

Q 6. What are the common causes of low or high air content in concrete?

Low air content can result from insufficient air-entraining admixture, improper mixing, or the use of incompatible materials. High air content, conversely, may stem from excessive admixture, over-mixing, or the presence of contaminants in the mix. Another factor impacting air content is the type and amount of cement, as well as aggregate properties, like shape and surface texture. Incorrect dosage of water also plays a critical role in attaining the specified air content.

For example, a low air content might be observed if the air-entraining admixture wasn’t properly dispersed during mixing, leaving parts of the concrete mix lacking sufficient air voids. Conversely, over-mixing can introduce excessive air, exceeding the optimal range. Regular calibration of equipment and adherence to mix design specifications can help prevent these issues.

Q 7. Describe the procedures for preparing concrete samples for air entrainment testing.

Preparing concrete samples for air entrainment testing involves ensuring representative sampling and proper handling to prevent alteration of the air content. Samples should be taken from the concrete mix immediately after it’s been mixed, before it starts to set. A standard-sized mold should be completely filled, and any entrapped large air bubbles should be carefully removed. The sample should be handled gently to avoid entrapping additional air or releasing existing air. The testing should be performed promptly after sample preparation. The sample size is crucial; using an incorrect volume will result in inaccurate measurements. Proper procedure also includes maintaining consistent temperature and avoiding vibrations during preparation, which can affect the air content.

Q 8. How do you interpret the results of an air entrainment test?

Interpreting air entrainment test results involves understanding the relationship between the amount of air entrained in the concrete and its desired properties. The primary result is usually expressed as a percentage of air by volume (% air). This percentage is compared to the specified target range for the particular concrete mix design.

For example, if a mix design calls for 5-7% air entrainment, and the test yields a result of 6%, the concrete meets the specification. However, results outside this range indicate potential problems. A lower percentage suggests insufficient air entrainment, potentially leading to reduced freeze-thaw resistance. Conversely, a higher percentage than specified might indicate over-entrainment, potentially weakening the concrete’s strength.

Beyond the air content, the test also provides information about the air void size distribution. Ideally, the air voids should be small and well-distributed, maximizing their effectiveness in mitigating freeze-thaw damage. Analysis of the void size distribution (often presented visually in a graph) helps assess the quality of the air entrainment and ensures that the voids are not excessively large or clustered. An image analysis system can be used to quantify the characteristics of the air void system to ensure its appropriateness for the specific application.

Q 9. What are the limitations of different air entrainment testing methods?

Several methods exist for air entrainment testing, each with its own set of limitations. The most common methods include the pressure method (e.g., using a pressure-type air meter) and the volumetric method.

- Pressure Method: This method is relatively quick and simple but can be sensitive to operator technique and the specific equipment used. Variations in equipment calibration and operator skill can lead to inconsistencies in results. For example, a slight variation in the pressure applied during measurement can significantly affect the final result.

- Volumetric Method: This method involves measuring the volume of air in a known volume of concrete. While considered more precise, it’s more time-consuming and requires careful attention to detail in sample preparation and measurement. Incomplete mixing of the concrete sample, for instance, can lead to inaccurate results.

Both methods are subject to inherent uncertainties associated with the concrete’s properties (e.g., bleeding, slump), and the accuracy depends on proper sample preparation and calibration of instruments. Also, testing different concrete mixes (with varying water content, cement type, etc.) can also introduce variability. It’s crucial to adhere to standardized procedures for testing to minimize these limitations.

Q 10. Explain the importance of proper sample handling and storage in air entrainment testing.

Proper sample handling and storage are critical for obtaining accurate and reliable air entrainment test results. Any alteration of the concrete sample after it’s cast can affect the air content and void size distribution.

Samples should be protected from excessive moisture loss or gain by covering them with a moist burlap, and stored at a controlled temperature as per the standards. Rapid drying can cause shrinkage and affect the air void system. This is especially important for longer testing times. Additionally, samples should be tested within a specified timeframe to avoid significant changes in the air void structure due to hydration and setting.

Properly labeling samples with the date, time, mix design, and any relevant details helps ensure traceability and accurate record-keeping, which is essential for any quality control program or investigation into unexpected results. Any deviation from the standard practices can lead to misleading results, therefore, meticulously following established protocols is non-negotiable.

Q 11. How does temperature affect air entrainment test results?

Temperature significantly influences air entrainment test results. As temperature increases, the air bubbles in the concrete tend to expand, potentially leading to an overestimation of air content. Conversely, lower temperatures can cause contraction of the air bubbles, underestimating the air content.

To minimize temperature effects, it’s crucial to conduct tests under controlled temperature conditions, preferably at a standard temperature specified in relevant standards (often around 20-23°C). It’s also important to ensure that the temperature of the sample and the testing equipment are consistent to eliminate variability. Differences in temperature between the sample and the testing apparatus can cause errors in the measurements.

Temperature fluctuations during sample handling and storage can also influence the results, so maintaining consistent temperature throughout the entire testing process is paramount. The effect of temperature needs to be carefully considered during data interpretation.

Q 12. What are the effects of using different admixtures on air entrainment?

Different admixtures significantly impact air entrainment. Air-entraining admixtures (AEAs) are specifically designed to introduce and stabilize air bubbles in concrete. The type and dosage of AEA directly affect the amount and distribution of air voids.

For example, different AEAs might produce different air contents at the same dosage, and the same AEA can produce a varying amount of air entrainment based on the dosage. Some AEAs are more efficient than others. Similarly, other admixtures like water reducers or superplasticizers can also indirectly affect air entrainment. They might interact with the AEA, influencing the air content or void size distribution.

It’s essential to understand the interactions between various admixtures to achieve the desired air entrainment. This requires careful mix design and testing to find the optimal combination of admixtures to achieve the specified air content and desired concrete properties. For instance, using a high dosage of a superplasticizer might require adjusting the dosage of the AEA to compensate for the influence of the superplasticizer on air entrainment.

Q 13. Describe the role of air entrainment in freeze-thaw resistance.

Air entrainment plays a vital role in enhancing the freeze-thaw resistance of concrete. Water expands when it freezes, and this expansion can create internal pressure within the concrete, leading to cracking and deterioration. Air voids act as reservoirs to accommodate this expansion, preventing the build-up of damaging pressure.

The size and distribution of the air voids are crucial. Smaller, well-distributed air voids are more effective in mitigating freeze-thaw damage than larger, clustered voids. Proper air entrainment ensures that these voids are appropriately sized and uniformly dispersed throughout the concrete matrix, thereby significantly improving the concrete’s durability in freeze-thaw cycles.

Without sufficient air entrainment, the concrete is more susceptible to cracking and deterioration due to repeated freeze-thaw cycles. This is particularly important for concrete structures exposed to harsh climates with frequent freeze-thaw events.

Q 14. How can you troubleshoot issues encountered during air entrainment testing?

Troubleshooting issues during air entrainment testing involves systematically investigating potential sources of error. This often requires a methodical approach involving review of the testing procedure, equipment calibration, and sample preparation.

- Inconsistent Results: Repeated tests showing significant variations in air content might point to issues with the testing equipment (calibration, faulty sensors), inconsistent sample preparation (mixing, handling), or environmental factors (temperature fluctuations). Recalibrating the equipment, carefully reviewing the sample preparation process and maintaining a controlled temperature are crucial steps.

- Air Content Outside the Specified Range: If the measured air content is significantly lower or higher than expected, the mix design should be reviewed. This might involve adjusting the dosage of the AEA or investigating potential interactions with other admixtures.

- Air Void Size Distribution Issues: If the air void size distribution is undesirable (e.g., large, clustered voids), the AEA type or dosage might need adjustment. The use of other admixtures could also influence the size and distribution of air voids and needs review.

Accurate record keeping and a detailed analysis of the testing procedure are essential to pinpointing the source of error. If problems persist, consulting with an experienced concrete technologist or materials engineer is recommended.

Q 15. What are the acceptable ranges of air content in concrete for various applications?

The acceptable range of air content in concrete varies significantly depending on the application and the desired properties. It’s not a one-size-fits-all situation. Think of air entrainment like adding tiny bubbles to a sponge; too few, and it’s brittle; too many, and it’s weak. We need just the right amount.

- Pavements: Typically, 3-6% air content is targeted for pavements to improve durability and resistance to freeze-thaw cycles. Higher air contents can reduce strength, which is crucial for bearing traffic loads.

- Structures (e.g., Buildings, Bridges): For structural applications, lower air content is often preferred, typically in the range of 3-5%, to maximize strength and minimize potential risks of decreased durability due to excessive air voids. The specific requirement is influenced by the project’s specifications and the concrete mix design.

- Mass Concrete: Mass concrete structures, like dams, may have lower air content requirements, or may even not require air entrainment at all, depending on design considerations. Here, other methods of handling heat generation and potential cracking are employed.

- Special Applications: Specific applications, such as roller-compacted concrete, may require different air content ranges based on the construction method.

Always refer to the project specifications and relevant codes for the exact air content requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the difference between air entrainment and air voids.

While both air entrainment and air voids refer to air present in concrete, there’s a crucial distinction: Air entrainment is the intentional introduction of microscopic air bubbles (typically less than 0.1 mm in diameter) into the concrete mix using special air-entraining admixtures. These tiny bubbles are uniformly distributed and provide significant benefits. Air voids, on the other hand, are larger, randomly distributed pockets of air that can negatively impact concrete strength and durability. They may be due to improper mixing, improper consolidation, or the inherent presence of larger air bubbles that weren’t introduced using an air-entraining admixture. Air voids are generally undesirable, whereas air entrainment is usually beneficial.

Think of it like this: air entrainment is like adding finely dispersed pepper to a sauce, while air voids are like adding clumps of unmixed flour.

Q 17. How do you ensure accuracy and precision in air entrainment testing?

Ensuring accuracy and precision in air entrainment testing is paramount. It requires a meticulous approach encompassing several key aspects.

- Calibration of Equipment: Regular calibration of the air entrainment meter is essential, using traceable standards. This ensures the instrument is measuring accurately. We typically use certified calibration weights and check the meter’s functionality against ASTM standards.

- Proper Sample Preparation: A representative concrete sample must be obtained and prepared according to the relevant test standards (e.g., ASTM C231, AASHTO T 151). This includes proper mixing and consolidation to avoid introducing extra air.

- Strict Adherence to Test Procedures: Following the prescribed procedure meticulously is critical. Any deviation could lead to inaccurate results. This includes the correct measurement of the sample volume and accurate reading of the meter’s display.

- Operator Skill and Training: The person performing the test must be adequately trained and experienced. Proper training minimizes human errors in measurement and sample handling.

- Multiple Measurements: Taking multiple measurements and calculating the average increases accuracy and helps in identifying potential outliers.

By systematically implementing these measures, we minimize both random and systematic errors, leading to highly reliable and repeatable test results.

Q 18. What quality control measures are important in air entrainment testing?

Quality control in air entrainment testing is crucial for reliable results. Here are some critical measures:

- Regular Calibration Checks: Performing frequent calibration checks of the equipment using traceable standards ensures that the device is functioning within acceptable limits and providing accurate readings.

- Blank Tests: Performing blank tests without any air-entraining admixture helps check for any systematic errors or contamination in the equipment or procedure.

- Duplicate Testing: Performing duplicate tests on each sample allows for assessment of reproducibility and helps to identify any potential anomalies in the testing process.

- Control Charts: Maintaining control charts helps in tracking the results over time, identifying any trends or shifts, and maintaining consistency of testing.

- Proper Documentation: Maintaining thorough documentation of the testing procedures, calibration records, and results ensures traceability and compliance with quality standards. This documentation allows for auditing of the process and identification of potential issues.

- Operator Qualification: Having well-trained and qualified personnel conduct the testing is crucial in ensuring the quality of the results.

These quality control measures minimize errors and ensure that the air entrainment data collected is representative of the concrete’s actual air content.

Q 19. Describe your experience with different types of air entrainment meters.

My experience encompasses several different types of air entrainment meters, each with its own strengths and weaknesses. I’ve worked extensively with:

- Pressure Meters: These are commonly used and relatively straightforward. They measure the pressure change in a closed chamber after the introduction of a concrete sample. The pressure change is then used to calculate the air content. I’ve found them to be reliable for routine testing, provided proper calibration and sample preparation are followed.

- Volume Meters: Volume meters directly measure the volume of air in a known volume of concrete. These can be more precise, particularly when dealing with larger samples, but they are often more complex to operate and maintain. I’ve found that they are suitable for more demanding or high-precision projects.

- Chace Air Meter: A well-established and widely used method. The Chace Air Meter is a pressure meter that is known for its simplicity and reliability.

The choice of meter often depends on the project’s requirements, budget constraints, and laboratory resources. In my work, I’ve always prioritized selecting the meter best suited for the task at hand, considering the necessary precision and ease of use.

Q 20. What is the importance of calibration and maintenance in air entrainment testing equipment?

Calibration and maintenance are absolutely critical for reliable air entrainment testing. Neglecting these aspects can lead to inaccurate and unreliable results, potentially compromising the quality and durability of the concrete structures.

- Calibration: Air entrainment meters must be regularly calibrated against traceable standards, typically using certified weights and pressure gauges. The frequency of calibration depends on usage and manufacturer recommendations, but it’s generally advisable to calibrate before each testing campaign or at least annually. Calibration ensures that the meter’s readings accurately reflect the actual air content in the concrete.

- Maintenance: Regular maintenance is crucial to extend the lifespan and maintain the accuracy of the equipment. This includes cleaning the meter components, checking for leaks or damage, and replacing worn parts as necessary. Following manufacturer guidelines for cleaning and maintenance is key to avoiding damage and maintaining consistent performance.

Consider this analogy: imagine a kitchen scale used for weighing ingredients. If it is not properly calibrated, you won’t be able to weigh the ingredients accurately. Similarly, an uncalibrated or poorly maintained air entrainment meter will provide inaccurate data, potentially compromising the quality and performance of the concrete.

Q 21. How do you ensure the validity of air entrainment test results?

Ensuring the validity of air entrainment test results relies on several interconnected factors:

- Proper Sample Representation: The concrete sample used for testing must accurately represent the concrete in the structure. This requires careful sampling and preparation to avoid segregation or other biases that could affect the air content measurements.

- Adherence to Standards: Strict adherence to relevant test standards (e.g., ASTM C231, AASHTO T 151) is essential for the validity of the results. Following the specified procedures, including sample preparation, testing methods, and calculations, is paramount.

- Calibration and Maintenance Records: Keeping meticulous records of calibrations and maintenance procedures ensures traceability and verifies that the equipment was functioning correctly during the testing. These records demonstrate compliance with quality standards.

- Quality Control Measures: Implementing robust quality control measures, such as duplicate testing, blank tests, and control charts, provides checks on the reliability and accuracy of the test results.

- Operator Proficiency: The testing personnel must be properly trained and competent to perform the tests according to the established procedures.

- Data Analysis and Interpretation: A thorough analysis of the results is essential. This includes identifying outliers, calculating averages, and interpreting the results in the context of the project’s requirements and specifications.

By addressing these aspects meticulously, we can confidently confirm the validity and reliability of the air entrainment test results.

Q 22. Explain the relationship between air entrainment and concrete workability.

Air entrainment, the incorporation of tiny air bubbles into concrete, significantly impacts its workability. Workability refers to how easily concrete can be mixed, placed, and finished. The presence of air voids acts as tiny ball bearings, reducing internal friction between cement particles and aggregates. This leads to a more fluid concrete mix, easier to handle and requiring less effort to consolidate, improving its overall workability. Think of it like adding marbles to a bucket of sand – the marbles make the sand flow more freely. The optimal air content is crucial; too little air results in stiff, difficult-to-place concrete, while excessive air weakens the final product. The relationship is complex and depends on factors like cement type, aggregate characteristics, and the admixture used for air entrainment.

Q 23. Describe a situation where you had to troubleshoot a problem related to air entrainment.

During a large-scale highway project, we encountered unusually low air content in a batch of concrete. This resulted in high slump loss and significant difficulty in placing and finishing the concrete. The initial suspicion was a malfunctioning air-entraining admixture dispenser. My troubleshooting involved:

- Visual Inspection: We carefully examined the admixture dispenser for any blockages or leaks.

- Dosage Verification: We checked the admixture dosage against the specifications, comparing the amount dispensed with the intended quantity.

- Admixture Testing: We performed independent tests on the admixture itself to confirm its effectiveness and concentration.

- Concrete Sample Analysis: We took multiple samples from the problematic batch and performed air content tests using the pressure method. This verified the low air content and helped quantify the deficit.

It turned out that a clogged nozzle in the dispenser was the culprit. After cleaning and recalibrating the system, the subsequent batches showed the correct air content, resolving the workability issues.

Q 24. How do you handle discrepancies between test results and expected values?

Discrepancies between test results and expected values necessitate a systematic investigation. First, I would review the entire testing process, scrutinizing each step for potential errors. This includes checking the calibration of equipment, ensuring proper sample preparation and the correct testing procedure adherence. Then, I’d consider factors like variations in materials – different batches of cement or aggregates can influence air content. Environmental conditions, such as temperature and humidity, can also play a role. If no procedural errors or material inconsistencies are identified, I would perform additional tests to verify the initial results and potentially consult with materials experts to analyze any anomalies. A comprehensive report documenting all steps and findings is critical for addressing the discrepancy and preventing future issues.

Q 25. What are some common errors in air entrainment testing and how do you avoid them?

Common errors in air entrainment testing include:

- Improper Sample Preparation: Insufficient mixing or improper handling of the concrete sample can lead to inaccurate results.

- Equipment Calibration Issues: An uncalibrated air meter or pressure chamber will yield erroneous data.

- Operator Error: Incorrect reading of the pressure gauge or improper use of the equipment can also lead to errors.

- Incorrect Testing Method: Using the wrong method (e.g., using the pressure method for a sample unsuitable for that method).

To avoid these errors, a rigorous quality control program is crucial. This includes regular equipment calibration, standardized procedures, operator training, and the use of quality control charts to monitor test results over time. Employing a check-and-balance system – having multiple technicians perform the tests and compare results – provides an added layer of accuracy.

Q 26. How do you maintain a clean and organized workspace during air entrainment testing?

Maintaining a clean and organized workspace is paramount for accurate and efficient air entrainment testing. A cluttered space increases the risk of errors and accidents. My approach involves:

- Designated Workspace: Having a dedicated area for testing with ample space for equipment and materials.

- Clean Equipment: Cleaning and properly storing equipment after each test prevents contamination and ensures accuracy.

- Organized Materials: Materials such as sample containers, tools, and testing supplies should be neatly organized and easily accessible.

- Waste Management: Proper disposal of waste materials like concrete samples according to safety regulations.

- Regular Cleaning: Regular cleaning of the workspace to prevent the accumulation of debris and potential hazards.

A well-organized environment fosters a safer and more productive testing process, minimizing chances of mistakes and delays.

Q 27. Describe your experience with reporting and documenting air entrainment test results.

My experience with reporting and documenting air entrainment test results is extensive. I utilize standardized reporting formats that include all pertinent details: project information, date and time of testing, sample identification, equipment used, detailed test procedures followed, raw data obtained, calculations performed, final air content results, and any observations or deviations from normal procedures. The reports are meticulously reviewed for accuracy and completeness before being submitted. I maintain digital and hard copies of all records in a secure and organized filing system for easy retrieval. Data is often integrated into project databases for trend analysis and quality control purposes.

Q 28. How do you stay up-to-date with the latest advancements in air entrainment testing?

Staying current with advancements in air entrainment testing involves a multifaceted approach. I actively participate in professional organizations such as ACI (American Concrete Institute) and attend conferences and workshops to learn about new testing techniques, equipment, and standards. I regularly review relevant technical journals and publications, including online resources and industry newsletters. Furthermore, collaboration with peers in the field through professional networks and attending industry events provides valuable insights into best practices and emerging trends. Continuous professional development ensures my knowledge remains aligned with the latest advancements in this field.

Key Topics to Learn for Air Entrainment Testing Interview

- Fundamentals of Air Entrainment: Understanding the principles behind air entrainment in various applications, including concrete, wastewater treatment, and industrial processes. This includes the physics of bubble formation and stability.

- Testing Methods and Equipment: Familiarize yourself with different air entrainment testing methods, such as the pressure method and the volumetric method. Understand the operation and limitations of common testing equipment.

- Data Analysis and Interpretation: Learn how to analyze test results, interpret data, and draw meaningful conclusions. This includes understanding statistical analysis relevant to air entrainment data.

- Influence of Material Properties: Explore how factors like mix design, aggregate type, and admixtures impact air entrainment. Understand the relationship between air entrainment and concrete properties like workability and durability.

- Quality Control and Assurance: Become familiar with quality control procedures related to air entrainment testing, ensuring consistency and accuracy in results. Understand the role of air entrainment in meeting project specifications.

- Troubleshooting and Problem Solving: Develop your ability to identify and troubleshoot issues that may arise during air entrainment testing, including anomalies in test results and equipment malfunctions.

- Regulatory Compliance: Understand relevant industry standards and regulations related to air entrainment testing and reporting.

Next Steps

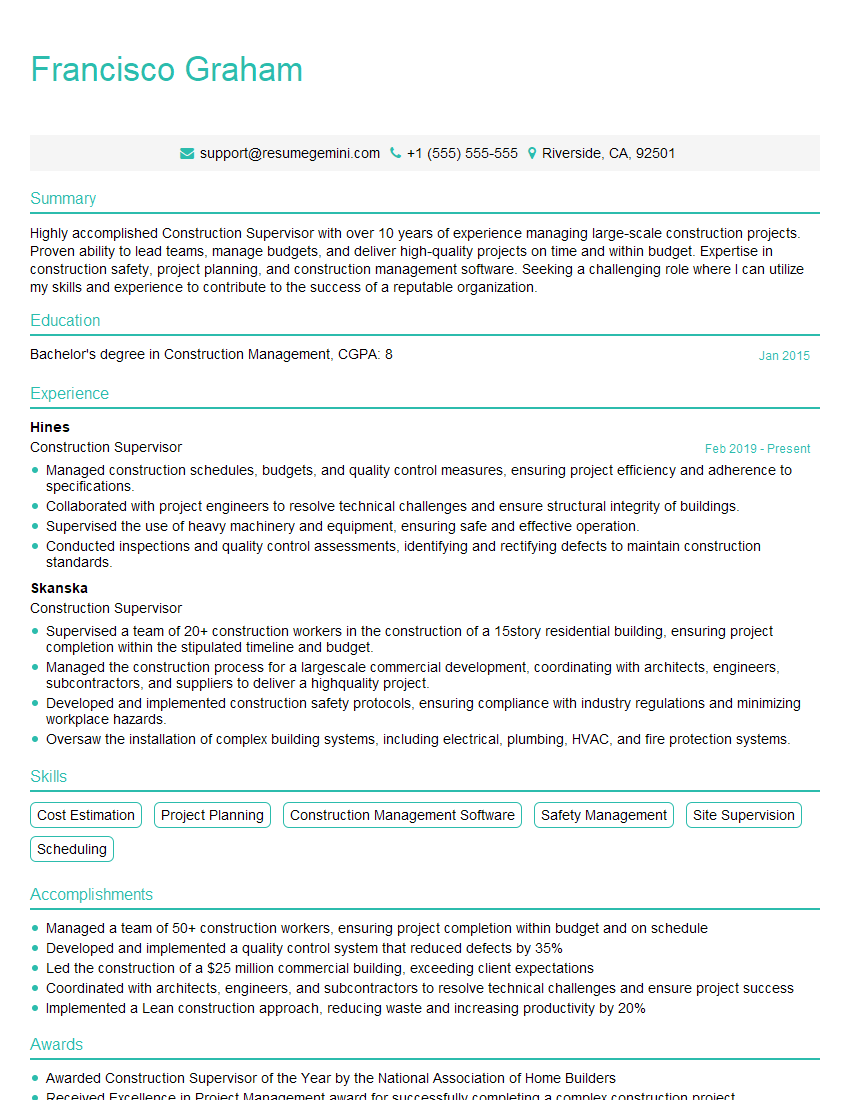

Mastering air entrainment testing opens doors to exciting career opportunities in construction materials, environmental engineering, and various industrial sectors. A strong understanding of this field demonstrates valuable technical skills and problem-solving capabilities highly sought after by employers. To maximize your job prospects, it’s crucial to present your expertise effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience. Examples of resumes tailored to Air Entrainment Testing are available, providing valuable templates to guide your resume creation process. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO