Preparation is the key to success in any interview. In this post, we’ll explore crucial Ability to lift and carry heavy objects interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Ability to lift and carry heavy objects Interview

Q 1. Describe your experience lifting and carrying heavy objects.

My experience with lifting and carrying heavy objects spans over 15 years, encompassing various roles in warehouse management, construction, and furniture relocation. I’ve handled everything from small packages to large industrial machinery, consistently prioritizing safety and efficiency. This experience has provided me with a deep understanding of different lifting techniques, the importance of proper equipment usage, and the recognition of potential hazards. For example, in my previous role at Acme Warehouse, I was responsible for loading and unloading trucks, often handling pallets weighing up to 1500 lbs. This involved strategically planning the lift, using appropriate equipment such as pallet jacks and hand trucks, and working with a team to ensure safety.

I’ve also managed teams involved in lifting heavy equipment, providing guidance and hands-on support to prevent injuries. This leadership role required in-depth knowledge of ergonomics, risk assessment, and emergency procedures.

Q 2. What is your maximum safe lifting capacity?

My maximum safe lifting capacity, as determined by regular strength testing and following OSHA guidelines, is 50 lbs without assistance and 100 lbs with proper equipment and assistance. It’s crucial to understand that this is a guideline, and the actual safe weight I can lift depends significantly on factors such as the object’s shape, distance of the lift, overhead clearance and my physical condition on any given day. I always prioritize safety and will never attempt a lift if I’m unsure I can do it safely. For instance, a 50-pound box lifted from the ground is different from a 50-pound box lifted from a high shelf. The latter would be considered far more dangerous.

Q 3. Explain the proper techniques for lifting heavy objects to prevent injury.

Proper lifting techniques are paramount to prevent injuries. The key principles revolve around minimizing strain on the back and using leg muscles for power. Think of it like this: your legs are the engine, your back is the chassis. You want to protect the chassis by not overloading it. The following steps outline the proper technique:

- Assess the weight and size: Determine if you can safely lift the object alone. If not, seek assistance.

- Get a good grip: Use both hands, keeping the object close to your body.

- Bend your knees: Squat down, keeping your back straight and your core engaged. Avoid twisting your back.

- Lift with your legs: Straighten your legs to lift the object. Keep the object close to your body throughout the lift.

- Control the movement: Move smoothly and deliberately, avoiding jerky movements.

- Maintain a stable posture: Keep your back straight and avoid twisting.

- Set the object down: Bend your knees to lower the object, using your leg muscles to control the descent.

For instance, when lifting a heavy box from the ground, I would always squat down, keeping my back straight, and lift using the powerful muscles in my legs, while keeping the box close to my body. This minimizes stress on the lower back and spine.

Q 4. How do you assess the weight of an object before lifting it?

Assessing the weight of an object before lifting is crucial. While I can estimate weight based on experience and size, if unsure, I always seek clarification or use tools to determine the exact weight. I might:

- Visually inspect the object: Size, material and packaging can help give clues to the object’s weight.

- Check for weight labels or markings: Many objects are labeled with their weight.

- Gently try to lift one corner: This provides a sense of weight distribution and stability.

- If still unsure, request assistance or use a scale: Better to be safe than sorry.

For example, if faced with an unusually shaped or oddly packaged item, I’d carefully examine it, look for weight labels, or gently try to lift a corner before committing to the full lift.

Q 5. Describe your experience using lifting equipment (e.g., hand trucks, dollies).

I’m proficient in using various lifting equipment, including hand trucks, dollies, pallet jacks, and forklifts (with proper certification). Understanding the limitations and capabilities of each piece of equipment is critical for safe and efficient lifting.

Using a hand truck for instance requires understanding its weight capacity, how to properly balance the load and the correct technique for maneuvering it. My experience with forklifts, for example, involves regular safety checks, following all procedures, and knowing when to enlist help.

In my previous role, I frequently used pallet jacks to move heavy pallets around the warehouse, significantly reducing the strain on my back and improving efficiency. Using the right tool for the right job is essential for safety and efficiency.

Q 6. What safety precautions do you take when lifting heavy objects?

Safety is my top priority. Before attempting any lift, I always:

- Assess the environment: Check for obstacles, slippery surfaces, and adequate lighting.

- Wear appropriate safety gear: This may include gloves, safety shoes, and back support.

- Ensure proper posture and technique: Follow the steps outlined previously.

- Communicate with others: Alert co-workers if I need assistance.

- Use proper equipment: Select the appropriate lifting aid for the task at hand.

For example, before lifting a heavy object from a high shelf, I would first ensure the shelf is stable, make sure my path is clear and if necessary, use a ladder to reach the item safely. If lifting with a team, we’d establish clear communication and a synchronized approach to prevent accidents.

Q 7. How do you handle situations where an object is too heavy to lift alone?

If an object is too heavy to lift alone, I never attempt it. My safety and the safety of others is paramount. Instead, I immediately:

- Seek assistance: I would find a coworker or supervisor and together we will determine the best approach to lifting the object safely.

- Utilize proper equipment: We would employ appropriate lifting equipment, such as a forklift, crane, or other mechanical assistance. This allows for a safe lift.

- Plan the lift: We coordinate the lift, establishing clear roles and responsibilities for everyone involved. This includes using a spotter when needed.

- Follow all safety procedures: We ensure adherence to all company safety protocols and OSHA guidelines.

For example, if we needed to move a large piece of machinery, we would use a forklift, ensure its weight is within the forklift’s capacity, and have at least two people involved, one operating the forklift and one acting as a spotter to guide and provide support.

Q 8. What are the signs of a potential lifting injury?

Recognizing the signs of a potential lifting injury is crucial for preventing serious harm. These signs can range from subtle discomfort to immediate, sharp pain. Early detection allows for prompt intervention and reduces the risk of long-term complications.

- Pain: Any pain, especially in the back, neck, shoulders, or legs, during or after lifting is a significant warning sign. This pain can be sharp, dull, aching, or even a burning sensation.

- Muscle spasms: Involuntary muscle contractions, often accompanied by pain, indicate that muscles are strained or injured.

- Stiffness and limited range of motion: Difficulty bending, twisting, or turning can signal muscle damage or inflammation.

- Numbness or tingling: These sensations, particularly in the arms or legs, suggest nerve compression or irritation.

- Weakness: Feeling unusually weak or unstable after lifting may indicate muscle damage or fatigue.

- Swelling: Noticeable swelling around a joint or muscle is a clear sign of inflammation and potential injury.

- Bruising: Discoloration of the skin indicates trauma to the underlying tissues.

For example, I once witnessed a colleague experience sudden lower back pain after lifting a heavy box improperly. He ignored the initial twinge, resulting in prolonged pain and a week off work. Early recognition is key!

Q 9. What steps do you take if you experience a lifting-related injury?

Experiencing a lifting-related injury requires immediate and appropriate action to minimize further damage and facilitate recovery. My protocol involves the following steps:

- Stop immediately: Cease all lifting activities and rest the affected area.

- RICE method: Apply the RICE method – Rest, Ice, Compression, and Elevation – to reduce inflammation and pain. Ice the affected area for 15-20 minutes at a time, several times a day.

- Seek medical attention: Consult a doctor or other healthcare professional for a proper diagnosis and treatment plan. This is especially crucial for severe injuries or persistent pain.

- Follow medical advice: Adhere strictly to the recommendations provided by your healthcare provider, including medication, physical therapy, and restrictions on activity.

- Report the incident: If the injury occurred at work, report it to your supervisor immediately according to company protocol.

- Focus on rehabilitation: Once the acute phase has passed, engage in a comprehensive rehabilitation program to restore strength, flexibility, and function. This often involves physical therapy exercises.

In a past incident involving a minor back strain, I promptly applied ice, rested, and sought physiotherapy. Early intervention helped prevent the injury from becoming chronic.

Q 10. Explain the importance of maintaining proper posture during lifting.

Maintaining proper posture during lifting is absolutely critical for preventing injuries. A poor posture increases the strain on the spine, muscles, and joints, significantly increasing the risk of back pain, herniated discs, and other musculoskeletal disorders.

Proper posture involves:

- Keeping your back straight: Avoid bending at the waist. Instead, bend your knees and hips to lower your body closer to the object.

- Engaging your core muscles: Strengthening and activating your core muscles (abdominals and lower back) provides stability and support during the lift.

- Lifting with your legs: Use your leg muscles to generate the power for the lift, reducing the strain on your back.

- Keeping the object close to your body: The closer the object is to your center of gravity, the less strain it places on your spine.

Imagine trying to lift a heavy suitcase by bending at your waist – you’re likely to strain your back. However, if you bend your knees, keep your back straight, and use your leg muscles, the lift becomes significantly easier and safer.

Q 11. How do you adapt your lifting techniques based on the shape and size of the object?

Adapting lifting techniques to the object’s shape and size is paramount for safety and efficiency. Different shapes and sizes require different approaches to ensure a secure and controlled lift.

- Awkwardly shaped objects: For objects with irregular shapes, I would use additional support or secure the object to prevent it from shifting or tipping during the lift.

- Large objects: Larger objects often require team lifting, with clear communication and coordinated movements to ensure safety.

- Bulky objects: For bulky objects that are difficult to grasp, I use appropriate lifting aids such as straps or pallet jacks.

- Fragile objects: Fragile items demand extra care; I use cushioning material and appropriate lifting techniques to prevent breakage.

For example, when lifting a long, narrow pipe, I would use two hands, keeping the pipe close to my body and ensuring a stable base before lifting. This prevents twisting and potential injury.

Q 12. Describe your experience working with different types of lifting aids.

My experience encompasses a wide range of lifting aids, each designed for specific situations. These tools are invaluable in reducing strain and risk of injury.

- Hand trucks: Useful for moving large, heavy, and relatively compact objects.

- Pallet jacks: Essential for efficiently moving heavy pallets of material.

- Overhead cranes: For extremely heavy loads that exceed manual handling capabilities.

- Lifting slings and straps: These offer secure support for awkward shapes and provide a better grip. They help distribute weight and prevent slips.

- Vacuum lifters: These are ideal for flat, smooth surfaces and offer efficient handling with minimal physical effort.

In a warehousing setting, I regularly utilized pallet jacks for moving large quantities of goods and overhead cranes for extremely heavy machinery components.

Q 13. How do you ensure a stable base of support when lifting heavy objects?

A stable base of support is crucial for preventing falls and injuries during heavy lifting. This is achieved by maintaining a wide, balanced stance.

- Feet shoulder-width apart: This distributes weight evenly and improves stability.

- Weight balanced: Ensure your weight is evenly distributed on both feet.

- Stable footing: Always lift on a firm, level surface, free of obstacles. Avoid lifting on uneven or slippery ground.

- Solid foundation: Consider using a sturdy platform or anti-fatigue mat if the surface is hard or uneven.

Before lifting anything heavy, I always take a moment to assess my footing and adjust my stance for optimal stability. It’s a crucial step I never skip, even for relatively lighter objects.

Q 14. How do you maintain a safe working environment when handling heavy loads?

Maintaining a safe working environment when handling heavy loads is a shared responsibility. A multi-faceted approach is required to minimize risk:

- Proper training: All personnel involved in lifting should receive adequate training on safe lifting techniques, use of lifting aids, and hazard identification.

- Clear communication: When team lifting, establish clear communication signals and coordination to prevent accidents.

- Adequate lighting: Sufficient lighting prevents obstacles from being overlooked and increases visibility, promoting safer movement.

- Organized workspace: A clutter-free workspace prevents trip hazards and improves maneuvering space, reducing the likelihood of accidents.

- Appropriate equipment: Use well-maintained, suitable equipment for the task, including lifting aids, gloves, and safety footwear.

- Regular inspections: Conduct regular safety inspections to identify and address potential hazards proactively.

For example, in a previous role, I initiated a program to improve warehouse safety by implementing standardized lifting procedures and regular safety training sessions, resulting in a significant reduction in lifting-related injuries.

Q 15. Explain your understanding of ergonomics and its role in heavy lifting.

Ergonomics is the science of designing the workplace to fit the worker, minimizing risk of injury. In heavy lifting, this means optimizing posture, movements, and the work environment to reduce strain on the musculoskeletal system. It’s about preventing injuries like back pain, sprains, and strains.

For example, proper ergonomics when lifting a heavy box involves bending your knees, keeping your back straight, and lifting with your legs, not your back. This minimizes the stress on your spine. Another example is using proper lifting aids, like dollies or hand trucks, to reduce the weight and strain on the body.

- Posture: Maintaining a neutral spine is crucial. Avoid twisting or reaching.

- Lifting Technique: Get close to the load, lift with your legs, and keep the load close to your body.

- Work Environment: Ensure the work area is clear, well-lit, and has adequate space for movement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience using personal protective equipment (PPE) when lifting heavy objects.

Personal Protective Equipment (PPE) plays a vital role in heavy lifting safety. My experience includes consistently using safety footwear with good ankle support to prevent slips, trips, and falls. In some situations, I’ve also utilized back supports to help maintain proper posture and reduce strain during repetitive lifting. Gloves with reinforced palms help improve grip and protect hands from abrasions. When dealing with potentially hazardous materials, I’ve used appropriate chemical-resistant gloves and protective eyewear.

For instance, when lifting heavy sacks of cement, I would always wear work boots with steel toes for protection, and heavy-duty gloves to prevent abrasions and maintain a strong grip.

Q 17. How do you communicate lifting tasks and safety procedures to coworkers?

Communicating lifting tasks and safety procedures effectively is paramount. I always start by clearly explaining the task, including the weight, size, and any potential hazards. I then demonstrate the proper lifting technique, emphasizing the importance of maintaining good posture and using the correct equipment. I encourage questions and ensure everyone understands the plan before starting. I use clear and concise language, avoiding jargon. If there’s a team involved, I assign roles and responsibilities to ensure efficiency and safety.

For example, before lifting a large piece of machinery, I would conduct a brief team meeting, outline the steps, assign roles (e.g., guiding, lifting, securing), and confirm everyone’s understanding of safety procedures.

Q 18. What are the potential hazards associated with improper lifting techniques?

Improper lifting techniques can lead to a variety of serious hazards, including:

- Musculoskeletal Injuries: Back pain, sprains, strains, herniated discs, and rotator cuff injuries are common consequences of improper lifting.

- Soft Tissue Injuries: Muscle tears and contusions can result from sudden or excessive strain.

- Falls: Improper lifting can cause loss of balance, leading to falls and further injuries.

- Crushing Injuries: Dropped objects can cause significant injuries to the feet, legs, or other body parts.

- Chronic Pain: Repeated improper lifting can lead to long-term pain and disability.

Think of it like this: Your body is a machine with specific limits. Ignoring those limits through improper lifting is like overloading the machine – it will eventually break down.

Q 19. How do you prioritize safety when working under time pressure?

When working under time pressure, safety remains my top priority. I never compromise safety for speed. Instead, I focus on efficiency. This means using the correct lifting techniques, utilizing available equipment (like hand trucks or hoists), and, if necessary, requesting additional help. It’s better to take an extra few minutes to lift an object safely than to risk injury and cause further delays.

In a high-pressure warehouse environment, for instance, I would prioritize using a pallet jack or forklift for heavier loads even if it might take a bit more time, rather than risk a back injury trying to manually lift a pallet.

Q 20. Describe a time you had to lift a particularly heavy or awkward object. What was your approach?

Once, I had to lift a large, awkwardly shaped piece of equipment – a heavy industrial motor – that weighed approximately 300 lbs. It was difficult to grip and had an uneven weight distribution. My approach involved:

- Assessment: I carefully assessed the weight, shape, and center of gravity of the object to determine the best lifting strategy.

- Equipment: I secured an appropriate lifting harness and a team of two other workers to help.

- Technique: We followed proper lifting techniques, maintaining straight backs, keeping the motor close to our bodies, and lifting with our legs. We communicated clearly throughout the lift.

- Placement: The motor was placed securely in its designated location, preventing any accidental drops.

Teamwork and careful planning were crucial in this situation. We made sure we had enough people and used the right equipment to avoid accidents.

Q 21. How familiar are you with OSHA regulations regarding heavy lifting?

I am very familiar with OSHA regulations concerning heavy lifting, particularly those related to material handling, hazard communication, and personal protective equipment. I understand the requirements for safe lifting practices, including the use of mechanical aids when appropriate, proper training for workers, and the importance of regular inspections of lifting equipment. I know the importance of reporting injuries and near-misses to ensure a safe working environment.

Knowing OSHA standards helps me proactively identify and mitigate risks, ensuring that I comply with all regulations and maintain a safe workplace.

Q 22. What training have you received on safe lifting practices?

My training in safe lifting practices is extensive. I’ve completed a comprehensive Occupational Safety and Health Administration (OSHA) 10-hour course covering hazard recognition, risk assessment, and safe lifting techniques. This included hands-on training using proper lifting methods, such as maintaining a straight back, bending at the knees, and keeping the load close to the body. Beyond OSHA, I’ve participated in company-specific training programs focusing on the safe handling of specific materials and equipment we use, such as pallet jacks and forklifts. These programs emphasized the importance of pre-lift planning, communication with co-workers, and understanding personal limitations.

For example, one training exercise involved lifting progressively heavier weights while instructors monitored our form. This allowed us to experience the strain on the body and reinforce the importance of correct posture. Regular refresher courses keep my skills sharp and up-to-date with the latest safety guidelines.

Q 23. How do you ensure the proper handling and storage of heavy objects?

Proper handling and storage of heavy objects is crucial for preventing injury and damage. It begins with choosing appropriate storage locations; areas must be well-lit, free of obstacles, and have adequate floor space. Objects should be stored at a height and location easily accessible without excessive reaching or straining. Heavier items should be placed lower to maintain stability and prevent toppling. We use a first-in, first-out (FIFO) system for inventory, ensuring that older items are used first to prevent unnecessary stacking.

Objects are secured using appropriate methods such as strapping, bracing, or stacking techniques to prevent shifting or falling. For instance, when stacking pallets, we use interleaving materials like cardboard to prevent slipping and ensure even weight distribution. Clear and visible labeling is implemented, indicating the weight, contents, and any handling instructions, reducing the risk of incorrect lifting or accidental damage.

Q 24. Describe your experience in using different lifting devices, including hoists and cranes.

My experience with lifting devices is significant. I’m proficient in operating various types of hoists, including chain hoists, lever hoists, and electric hoists. I understand the importance of regular inspection and maintenance of these devices, ensuring they are in safe working order before use. My training encompasses understanding load limits, proper rigging techniques (using appropriate slings and chains), and safety procedures for attaching and detaching loads. I’ve also received training on operating different types of cranes, including overhead cranes and mobile cranes, including pre-operational checklists, proper communication with crane operators, and ensuring the load is correctly balanced and secured.

For example, I’ve used a chain hoist to lift heavy engine components during engine overhaul, and I’ve worked with overhead cranes to move large pieces of machinery within a factory. This experience has highlighted the need for meticulous planning, clear communication, and adherence to safety protocols to prevent accidents.

Q 25. How do you manage the risk of back injury during heavy lifting?

Managing the risk of back injury during heavy lifting is paramount. The core principle is always to lift smart, not hard. This starts with assessing the weight and size of the object. If it’s too heavy, I’ll seek assistance or utilize appropriate lifting equipment. I always maintain a stable base, positioning my feet shoulder-width apart to keep my balance. The weight should be kept as close to my body as possible, reducing strain on my back. Bending at the knees and keeping a straight back is critical, avoiding twisting motions during the lift. This is often referred to as the ‘power lift’ technique. I would never lift anything unexpectedly; I would always know what I’m going to pick up before I commit to the lift. Post-lift, it is equally important to ease the weight down.

In addition to proper lifting techniques, regular stretching and exercise help strengthen my back muscles. I always report any back pain or discomfort immediately, ensuring early intervention to prevent serious injury.

Q 26. Explain your understanding of load balance and center of gravity in lifting.

Understanding load balance and center of gravity is vital for safe lifting. The center of gravity is the point where the weight of an object is evenly distributed. If the center of gravity is not properly aligned, the object becomes unstable, making it prone to tipping or falling. Maintaining a balanced load prevents strain and injury by keeping the weight evenly distributed. Imagine carrying a heavy box. If the weight is unevenly distributed, it’ll tilt and increase the risk of dropping it.

When lifting, it’s crucial to ensure the load’s center of gravity is close to my body and directly above my feet. This allows for greater control and stability, minimizing the risk of injury. If the load is unbalanced, I’d utilize mechanical assistance to move the load or to improve the balance of the load.

Q 27. What are the different types of lifting injuries and how can they be prevented?

Lifting injuries range from minor muscle strains and sprains to severe injuries like herniated discs, fractures, and even fatalities. Muscle strains and sprains are common due to improper lifting techniques or lifting excessive weight. More serious injuries can result from falls while lifting or from the object striking the body. Cumulative trauma disorders like carpal tunnel syndrome can develop over time due to repetitive lifting motions.

Prevention involves thorough training on safe lifting techniques, using appropriate lifting aids, maintaining good physical condition, and always assessing the risks before lifting. Following established protocols, working within personal lifting limits, and having a strong safety culture within a workplace are paramount to prevent injuries.

Q 28. How would you assess a workplace for potential hazards related to heavy lifting?

Assessing a workplace for potential hazards involves a systematic approach. This starts with a walkthrough of the area, observing lifting tasks being performed. I’d look for things like awkward lifting positions, inadequate lighting, slippery or uneven surfaces, obstructed walkways, and the lack of appropriate lifting equipment. I’d evaluate the weight of the objects being lifted, the frequency of lifting, and the distance the objects need to be carried. I’d then analyze the ergonomics of the workstation and assess whether adjustments can be made to improve the working posture of the employees.

Following the walkthrough, I’d create a detailed report, including photographs and recommendations for hazard mitigation. This might include installing better lighting, providing ramps to reduce inclines, implementing load-handling equipment, or providing training on safe lifting practices. Continuous monitoring and periodic reassessments are essential to ensure a safe and injury-free work environment.

Key Topics to Learn for Ability to Lift and Carry Heavy Objects Interview

- Proper Lifting Techniques: Understanding and applying safe lifting mechanics, including posture, foot placement, and the use of legs over back. This includes knowing the limitations of your own body and when to seek assistance.

- Weight Estimation and Assessment: Accurately judging the weight of objects before lifting to avoid injury. This involves understanding the difference between perceived and actual weight and using available tools (scales, etc.) when appropriate.

- Equipment and Tool Usage: Familiarity with and safe operation of lifting aids such as dollies, hand trucks, pallet jacks, and hoists. Knowing when and how to use these tools effectively to minimize strain.

- Safety Regulations and Procedures: Understanding and adhering to workplace safety regulations and procedures related to lifting and carrying heavy objects. This might include understanding load limits, wearing appropriate safety gear, and reporting any unsafe conditions.

- Teamwork and Communication: Effective communication with colleagues when lifting heavy objects as a team to ensure coordinated effort and safety. This involves clear verbal communication and non-verbal cues.

- Ergonomics and Injury Prevention: Applying ergonomic principles to minimize the risk of musculoskeletal injuries. This includes understanding repetitive strain injuries and how to prevent them through proper techniques and work organization.

- Situational Awareness and Problem Solving: Adapting lifting techniques to different environments and situations, such as uneven surfaces, obstacles, or limited space. Thinking ahead to prevent problems before they occur.

Next Steps

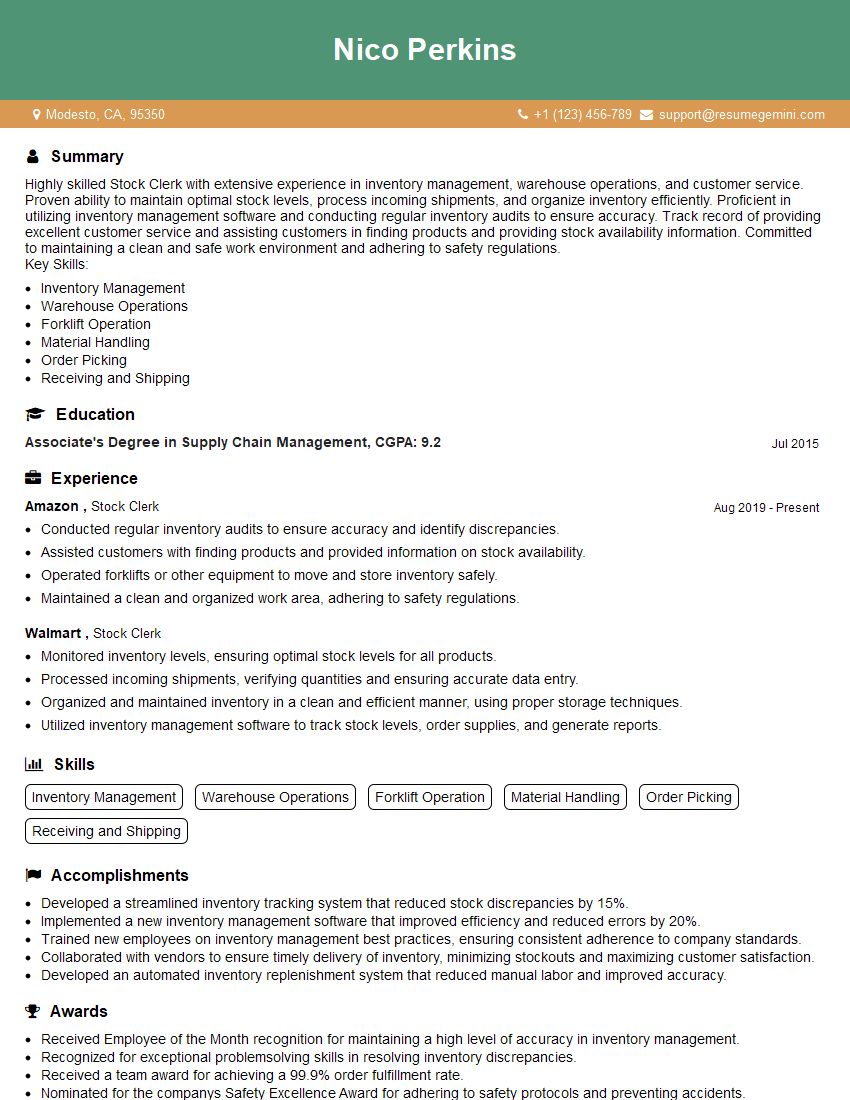

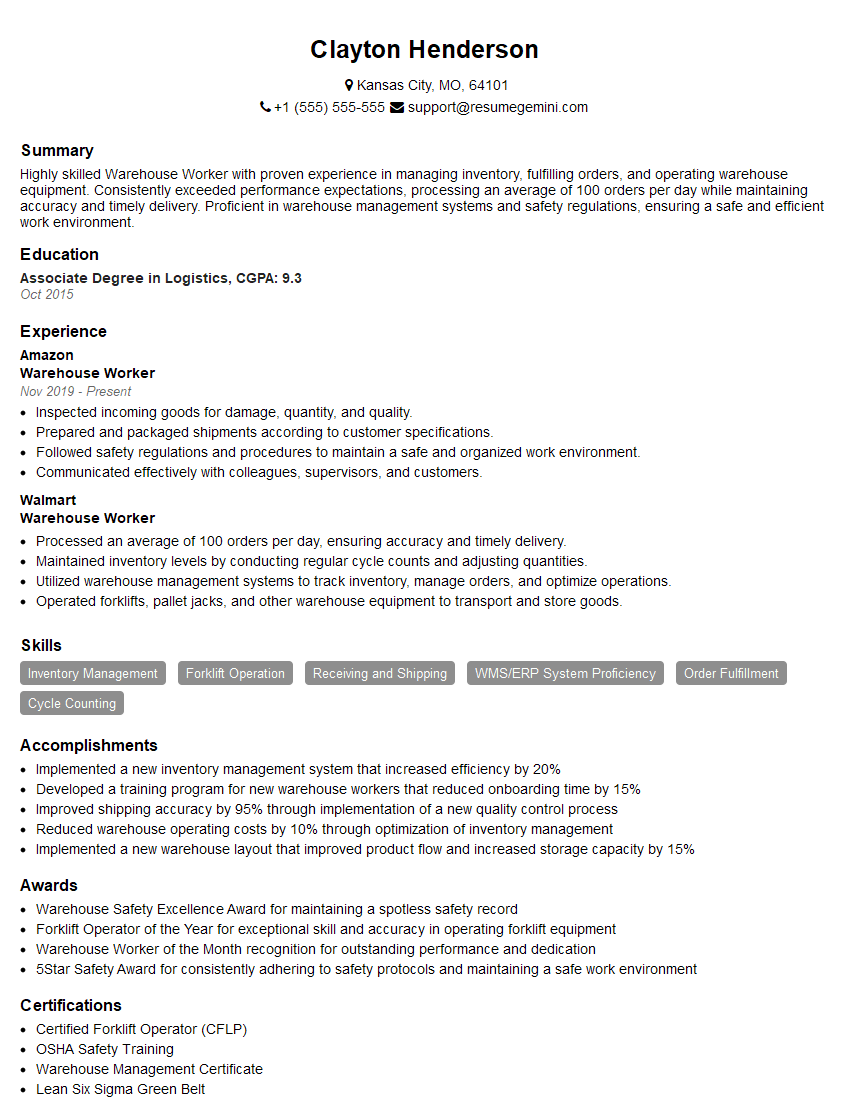

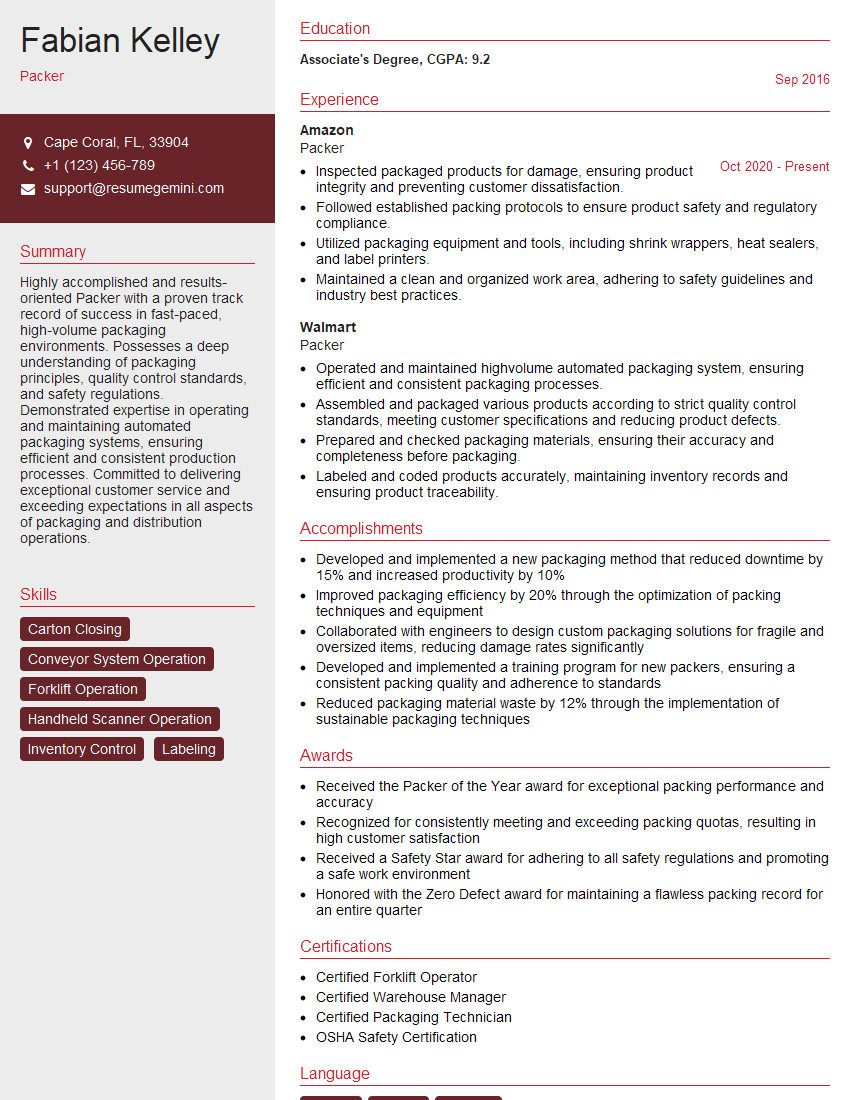

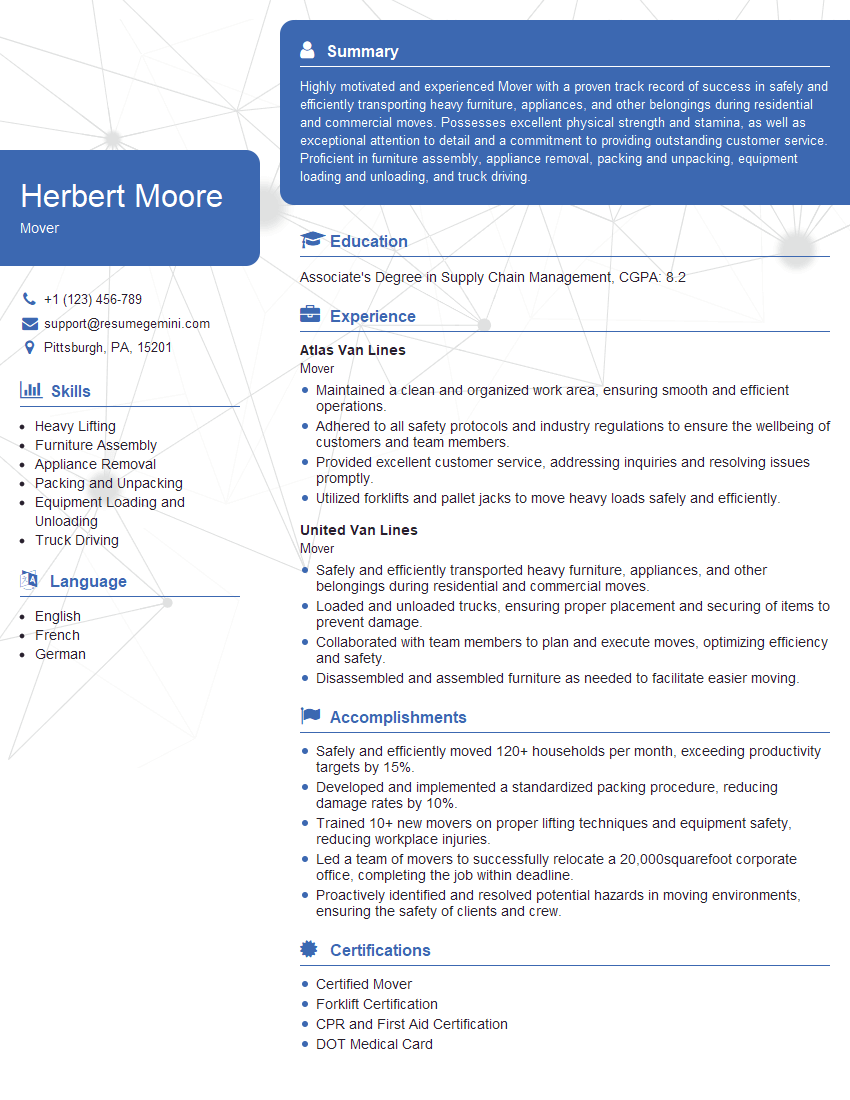

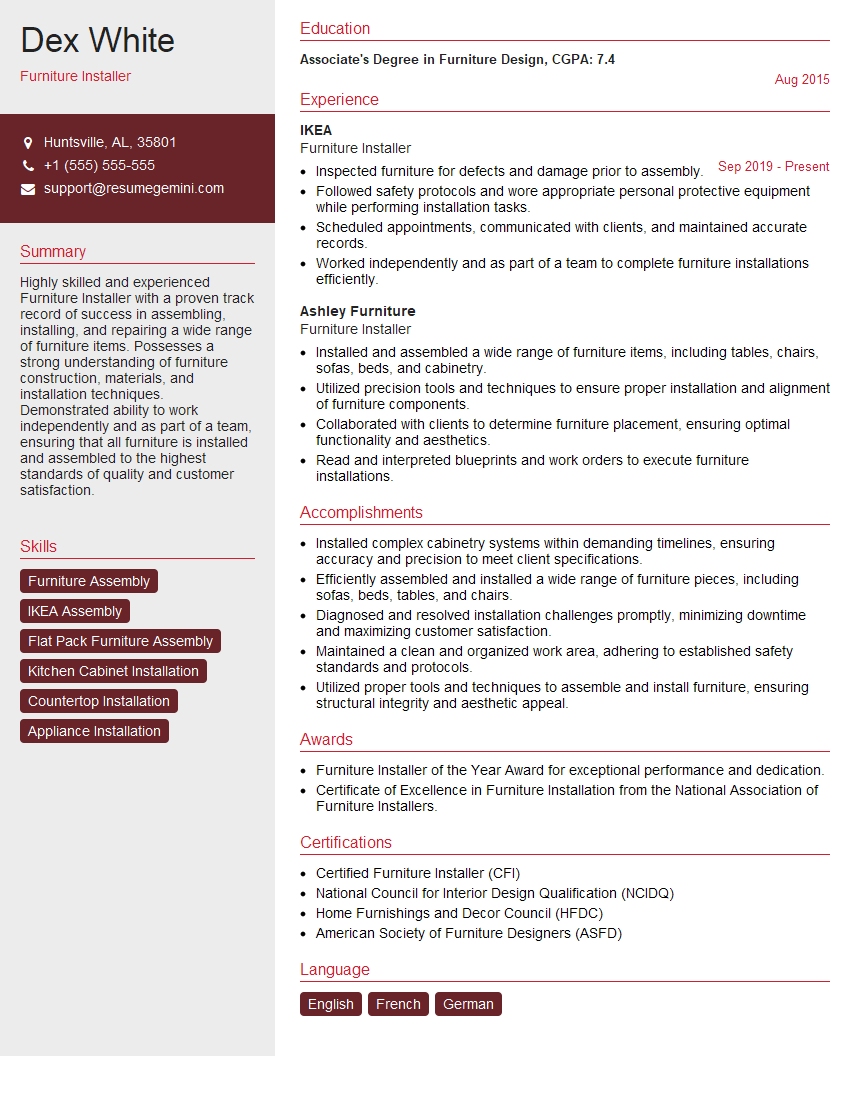

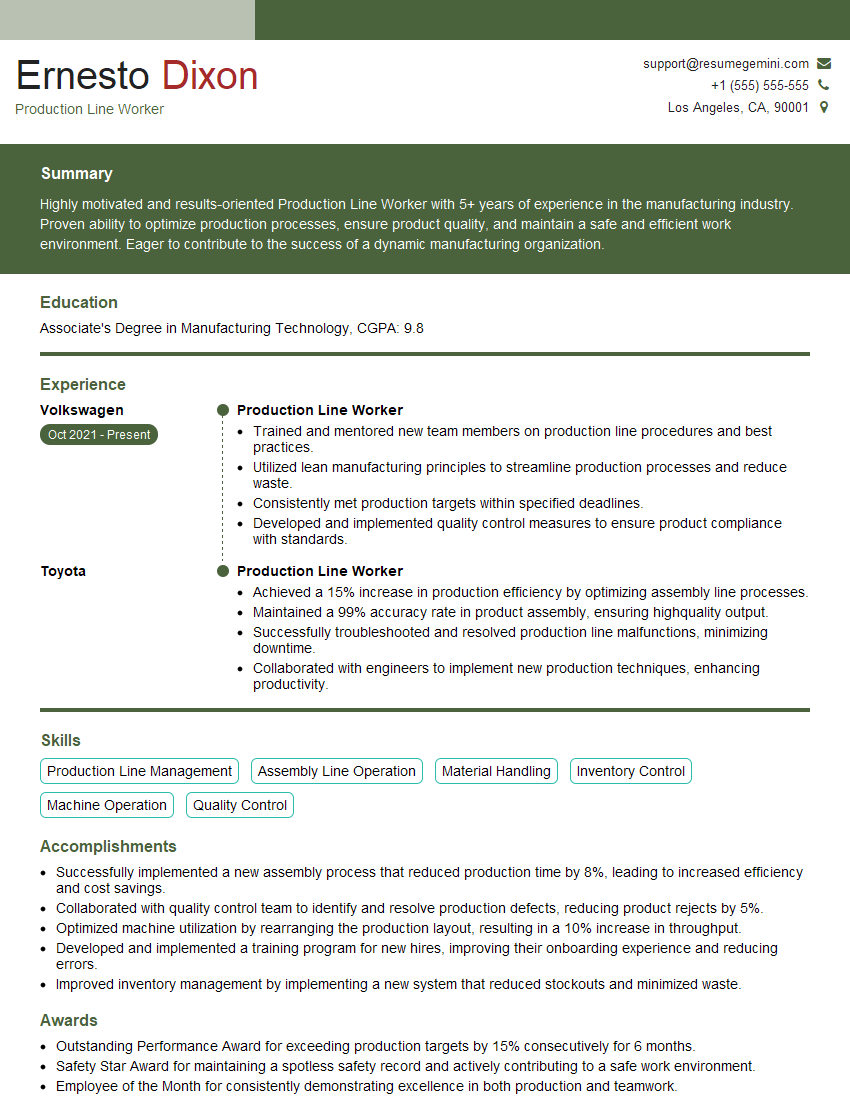

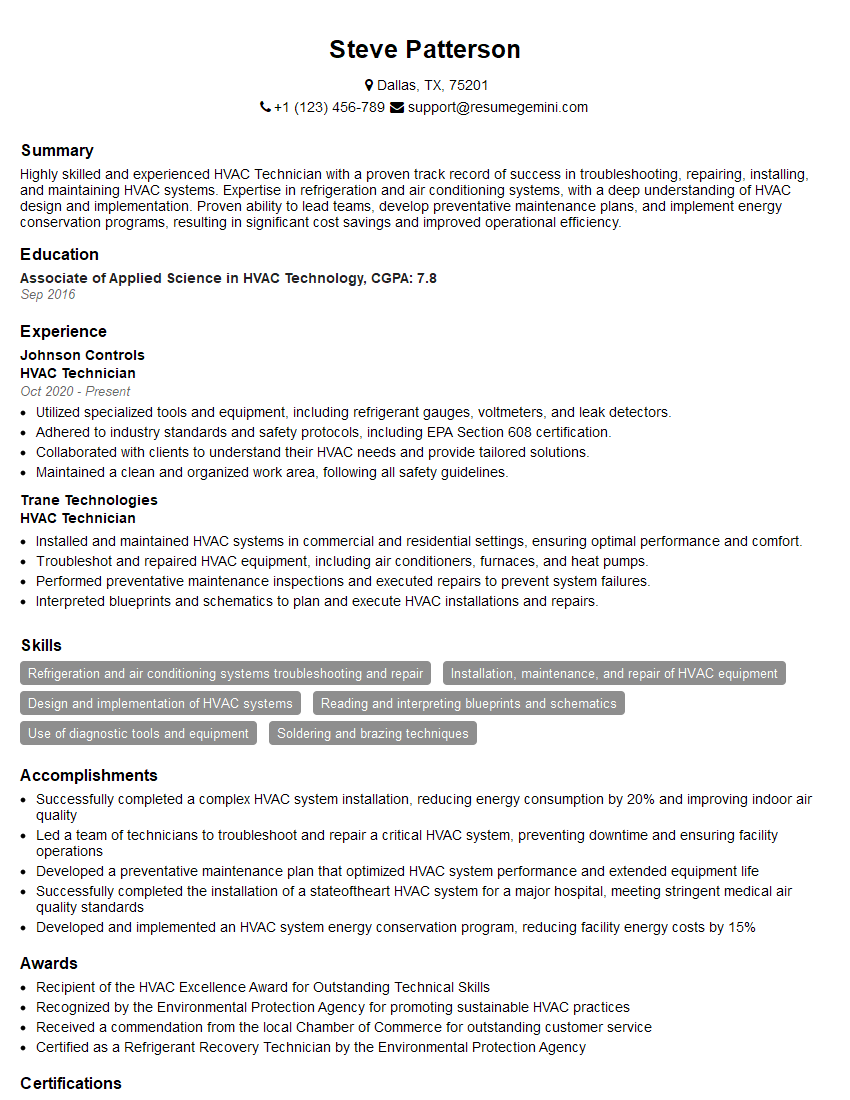

Mastering the ability to safely lift and carry heavy objects is crucial for many roles, significantly impacting your career growth and showcasing your commitment to workplace safety and efficiency. A strong resume highlighting your skills in this area is essential for attracting potential employers. To make sure your qualifications shine, create an ATS-friendly resume that emphasizes your capabilities. ResumeGemini is a trusted resource to help you build a professional and impactful resume that grabs the attention of recruiters. Examples of resumes tailored to highlight skills in lifting and carrying heavy objects are available through ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO