Are you ready to stand out in your next interview? Understanding and preparing for Aerospace Welding interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Aerospace Welding Interview

Q 1. Explain the different types of aerospace welding processes.

Aerospace welding demands precision and strength, utilizing various processes tailored to specific materials and applications. The choice of process depends heavily on factors like the base metal thickness, the joint design, and the required mechanical properties.

- Gas Tungsten Arc Welding (GTAW), or TIG welding: This method uses a non-consumable tungsten electrode to create an arc, melting the base metal and filler material. It’s known for its high quality and precision, ideal for thin sections and critical components. Think of it as a meticulous artist using a fine brush to create a perfect weld. I’ve extensively used GTAW on titanium alloys in the construction of spacecraft fuel tanks.

- Gas Metal Arc Welding (GMAW), or MIG welding: A consumable wire electrode feeds continuously into the weld pool, providing both the arc and filler metal. This process is faster than GTAW, suitable for thicker sections and higher production rates. However, it requires more skill to control the weld bead appearance and quality compared to TIG. I often utilize GMAW for welding aluminum alloys in aircraft structural components.

- Electron Beam Welding (EBW): This advanced technique uses a high-velocity electron beam to melt the base metal. It’s characterized by its deep penetration and narrow weld bead, excellent for joining thick sections with minimal heat-affected zones. However, it requires specialized equipment and a high-vacuum environment, often employed in the creation of high-performance engine parts.

- Laser Beam Welding (LBW): Similar to EBW, LBW uses a highly focused laser beam to generate the weld. It also provides excellent depth-to-width ratios and precise control. This process is used to weld intricate designs with minimal distortion, common for delicate aerospace instruments and sensor components.

Each process has unique advantages and disadvantages, and the selection is a critical aspect of ensuring the structural integrity of the aircraft or spacecraft.

Q 2. What are the common welding defects in aerospace applications?

Weld defects in aerospace applications can lead to catastrophic failures, so their prevention and detection are paramount. Common defects include:

- Porosity: The presence of small gas pockets within the weld, weakening its structure. This can stem from improper shielding gas coverage or contaminated base materials.

- Cracks: Breaks within the weld metal, often caused by rapid cooling, residual stresses, or improper welding parameters. These are particularly dangerous as they can act as stress concentrators.

- Incomplete Fusion: The weld metal fails to fully penetrate or fuse with the base metal, resulting in a weakened joint. This is often a result of insufficient current or improper technique.

- Undercutting: A groove or indentation at the edge of the weld, indicating excessive heat input or improper travel speed.

- Lack of Penetration: The weld does not extend fully to the required depth into the base metal. This can reduce the joint’s overall strength.

- Slag Inclusions: Trapped impurities within the weld, reducing strength and creating potential failure points. Proper cleaning of the base materials is vital to avoid this.

Identifying these defects through visual inspection, radiographic testing, ultrasonic testing, and dye penetrant testing is crucial before an aerospace component is ever put into service.

Q 3. How do you ensure weld quality and adherence to aerospace standards?

Ensuring weld quality and compliance with stringent aerospace standards necessitates a multi-faceted approach. It starts long before the welding torch is even turned on.

- Qualification of Welders and Procedures: Welders must undergo rigorous training and certification to demonstrate proficiency in specific welding processes and materials. Welding procedures are developed, documented, and rigorously qualified to ensure consistent results. This includes detailed specifications for parameters like current, voltage, travel speed, and shielding gas.

- Material Selection and Preparation: Choosing appropriate base materials and filler metals is crucial. Thorough surface cleaning, removal of oxides and contaminants, and proper joint preparation are essential for achieving sound welds. I often use specialized cleaning agents and techniques to ensure surface purity for titanium and aluminum alloys.

- Process Monitoring and Control: During welding, close monitoring of parameters like amperage, voltage, and welding speed is done. Data loggers frequently record this information, which is reviewed to ensure consistency. Sophisticated equipment like automated welding systems are also employed to improve accuracy and repeatability.

- Non-Destructive Testing (NDT): Various NDT techniques such as radiographic testing (RT), ultrasonic testing (UT), liquid penetrant testing (PT), and magnetic particle testing (MT) are used to inspect welds for internal and surface defects.

- Documentation and Traceability: Meticulous record-keeping is vital. All aspects of the welding process, from material identification to NDT results, are documented thoroughly. This ensures traceability and aids in identifying the root cause of any issues. We use specialized software to manage this documentation and ensure compliance with aerospace quality management systems (AS9100 etc.).

Adherence to standards such as AWS D17.1 (for structural steel welding) and specific aerospace standards like those established by Boeing or Airbus is mandatory. These standards dictate the acceptable ranges for weld defects and the required testing procedures.

Q 4. Describe your experience with different filler metals used in aerospace welding.

Filler metals are carefully chosen to match the base material’s properties and the desired weld characteristics. My experience encompasses a wide range of filler metals:

- Aluminum alloys: I’ve worked extensively with various aluminum filler alloys like 4043, 5356, and 5556, each offering specific characteristics regarding strength, ductility, and corrosion resistance. The choice depends on the application and the specific aluminum alloy being welded.

- Titanium alloys: Welding titanium requires specialized filler metals tailored to specific titanium grades, often involving gas-tungsten arc welding in a controlled atmosphere. I’ve used various titanium filler alloys in creating weldments that resist high temperatures and corrosion in rocket engine components.

- Stainless steels: Various stainless steel filler metals, such as 308 and 316, are chosen based on the grade of stainless steel being joined and the desired weld properties. For example, 308L provides low-carbon content to reduce the risk of weld cracking.

- Nickel-based superalloys: High-performance aerospace applications frequently involve nickel-based superalloys, requiring specialized filler metals that can withstand extreme temperatures and maintain strength. The selection of filler metals in this context often requires detailed material compatibility analysis. I’ve worked on alloys such as Inconel 625 and IN718, selecting appropriate filler metals to achieve the required mechanical properties under various operating conditions.

Selecting the wrong filler metal can lead to detrimental effects on the weld’s properties, like reduced strength, increased susceptibility to cracking, and poor corrosion resistance. The selection is not a trivial decision and involves detailed consideration of material compatibility and weld requirements.

Q 5. What are the safety precautions you take while performing aerospace welding?

Aerospace welding necessitates strict adherence to safety protocols. My routine includes:

- Personal Protective Equipment (PPE): This is non-negotiable and includes welding helmets with appropriate shade lenses, welding gloves, protective clothing (leather aprons, long sleeves), and safety footwear. I always ensure my PPE is in good condition before commencing any welding task.

- Ventilation and Shielding: Proper ventilation is vital to mitigate exposure to welding fumes and gases. In confined spaces or when working with specific materials, I ensure adequate ventilation, sometimes deploying specialized extraction systems. For processes that generate harmful ultraviolet radiation, appropriate shielding is essential.

- Fire Prevention: Flammable materials must be kept away from the welding area. Fire extinguishers are always readily available, and I know how to use them proficiently. I also check for fire hazards regularly and follow all fire safety procedures before and during the welding process.

- Electrical Safety: All equipment is regularly inspected for faulty wiring and proper grounding. I’m always careful to avoid contact with live electrical components and use appropriate lockout/tagout procedures when necessary.

- Material Safety Data Sheets (MSDS): Before working with any new material or filler metal, I always thoroughly review the MSDS to understand its potential hazards and necessary precautions. This ensures informed decisions regarding PPE and safety procedures.

Safety isn’t just a checklist; it’s a constant mindset. It’s about understanding and mitigating potential risks to protect myself and those around me.

Q 6. Explain the importance of pre- and post-weld inspections.

Pre- and post-weld inspections are crucial steps in ensuring the integrity of aerospace welds. They act as quality checkpoints that prevent defects from becoming catastrophic failures.

- Pre-weld Inspection: This focuses on preparing the weld joint for optimal results. It involves verifying the proper fit-up of the joint, ensuring clean and prepared surfaces free from contamination or defects, and verifying that the correct filler materials are used. The procedure parameters are also checked, ensuring they are compliant with approved specifications. This is like preparing the canvas for a painting – you need a clean and prepared surface to get a quality result.

- Post-weld Inspection: This is more comprehensive. It begins with visual inspection to identify any obvious surface flaws like cracks, porosity, or incomplete fusion. Then, more sophisticated methods are employed, including non-destructive testing methods such as radiographic inspection (RT), ultrasonic testing (UT), dye penetrant testing (PT), and magnetic particle inspection (MT). These tests uncover hidden flaws and verify that the weld meets the required standards. RT, for instance, uses X-rays to detect internal defects. UT uses high-frequency sound waves to detect internal flaws and measure weld thickness. I’ve often utilized these methods in quality control during manufacturing of aerospace parts.

These inspections are essential in identifying defects early, preventing costly repairs later on, and, most importantly, ensuring flight safety.

Q 7. How do you interpret welding symbols and blueprints?

Understanding welding symbols and blueprints is fundamental to the aerospace welding profession. They act as a common language between engineers, designers, and welders. They convey critical information regarding the joint type, weld type, dimensions, and location.

Welding symbols are standardized according to AWS standards (American Welding Society). They typically consist of a reference line, a basic symbol indicating the weld type, supplementary symbols for additional specifications, and dimensions for weld size and length. For example, a symbol might specify a fillet weld with a specific size and leg length. Example: A symbol showing a 6mm fillet weld with a specific welding process indicated by a supplementary symbol.

Blueprints provide a broader context, including the overall design of the component, the location of welds within the assembly, and material specifications. I carefully review blueprints to understand the intended function of the component and the specific requirements for each weld. This includes understanding the tolerances and permissible deviations. Detailed engineering drawings are meticulously studied to understand the component’s overall context within a larger assembly.

My experience involves reading and interpreting various types of welding symbols and blueprints using both standard drawing interpretation and specialized aerospace engineering documentation. Accurate interpretation is crucial to ensure the weld conforms precisely to the engineering intent.

Q 8. What are the common NDT methods used to inspect aerospace welds?

Non-Destructive Testing (NDT) is crucial in aerospace welding to ensure structural integrity without damaging the weld. Several methods are commonly employed, each offering unique advantages:

- Visual Inspection (VI): This is the simplest method, involving a thorough visual examination of the weld for surface defects like cracks, porosity, or lack of fusion. It’s often the first step in any NDT process. Think of it like a meticulous quality check with your eyes.

- Dye Penetrant Inspection (DPI): This technique uses a dye that penetrates surface-breaking defects. A developer is then applied, drawing the dye to the surface, making cracks visible. Imagine it like revealing hidden fingerprints with special powder.

- Magnetic Particle Inspection (MPI): Used for ferromagnetic materials (like many steels), MPI involves magnetizing the weld and applying magnetic particles. These particles accumulate at discontinuities, indicating flaws. This is similar to using a metal detector, but for surface and near-surface flaws.

- Radiographic Inspection (RT): This utilizes X-rays or gamma rays to penetrate the weld and reveal internal flaws like porosity, inclusions, or cracks. Think of it like taking an X-ray of the weld to see inside.

- Ultrasonic Inspection (UT): This employs high-frequency sound waves to detect both surface and internal flaws. The waves reflect off discontinuities, providing information about their size, location, and orientation. It’s like using sonar to map the internal structure of the weld.

The choice of NDT method depends on the specific application, material, and type of potential defect. Often, a combination of methods is used for comprehensive inspection.

Q 9. What is your experience with different types of joint designs used in aerospace welding?

My experience encompasses a wide range of joint designs commonly used in aerospace welding. The selection of a joint design depends on factors like the required strength, accessibility, and the materials involved. Here are some examples:

- Butt Joints: These are simple joints where two pieces are butted together, often requiring backing and filler material. They are widely used for joining sheets and plates, but need careful preparation for strong welds.

- Lap Joints: One component overlaps the other. This design is easier to weld than butt joints but may be less strong depending on the overlap and welding technique.

- Tee Joints: These involve joining two components at a 90-degree angle. They are commonly used in structural assemblies, and proper fixturing is crucial for successful welds.

- Corner Joints: Two components join at a corner. These can be challenging to weld due to accessibility issues and the potential for lack of fusion in corners. Often, specialized techniques and filler materials are required.

- Edge Joints: The edges of two parts are joined. These are used for thinner materials and often require edge preparation for a consistent weld.

In my experience, I’ve had to carefully select and prepare each joint type according to the design specifications and the material involved to ensure optimal strength and durability.

Q 10. Describe your experience with different welding positions.

Aerospace welding frequently necessitates proficiency in various welding positions due to the complex geometries of aircraft structures. My experience includes:

- Flat Position (1G): The simplest position, both the weld and the workpiece are horizontal. It’s ideal for training and many applications.

- Horizontal Position (2G): The weld is horizontal, but the workpiece is vertical. This requires more skill to control the weld pool and prevent sagging.

- Vertical Position (3G): The weld is vertical. Maintaining a consistent weld pool and preventing weld defects is challenging, needing a steady hand and good control of the welding parameters.

- Overhead Position (4G): The weld is made above the welder. This is the most difficult position, requiring significant skill and experience to control the weld pool and avoid sagging or spatter.

I have successfully executed welds in all four positions using various processes like Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW), adapting my technique to the specific challenges of each position.

Q 11. How do you handle welding defects during production?

Defect handling in aerospace welding is critical for safety and regulatory compliance. My approach follows a structured process:

- Identification: Thorough NDT is used to identify the type, size, and location of the defect.

- Assessment: The severity of the defect is assessed based on applicable codes and standards (like AWS D17.1). This determines if repair is necessary or if the weld needs to be scrapped.

- Repair or Replacement: If repair is feasible, appropriate techniques are employed. This may involve grinding out the defect, re-welding, and re-inspecting the area. If the defect is too severe, the weld is replaced. Often, a more experienced welder or a different welding process is used for repair.

- Documentation: All defect identification, assessment, repair procedures, and final inspection results are meticulously documented.

The overarching goal is to ensure that all welds meet stringent quality standards. Each repair is subject to another round of rigorous NDT to verify the integrity of the weld.

Q 12. What is your understanding of aerospace materials and their weldability?

Understanding aerospace materials and their weldability is fundamental to my work. Aerospace applications often employ high-strength, lightweight alloys like Aluminum, Titanium, and Nickel-based superalloys. Each presents unique challenges:

- Aluminum Alloys: Susceptible to porosity and cracking if not welded with proper parameters and shielding gas. They also require careful cleaning to avoid contamination.

- Titanium Alloys: Highly reactive with atmospheric gases, requiring welding in a controlled environment (e.g., vacuum or inert gas chamber). They also have specific heat input requirements to avoid cracking.

- Nickel-based Superalloys: High-temperature strength is crucial, but welding can be challenging due to their sensitivity to heat input and cracking. Special filler metals and welding processes are usually needed.

My experience involves selecting the appropriate welding process (GTAW is often preferred for these materials), filler metal, and parameters to ensure weld quality and achieve the desired mechanical properties. Pre- and post-weld heat treatments are sometimes necessary to optimize microstructure and mechanical properties.

Q 13. Describe your experience with different welding power sources.

My experience encompasses various welding power sources, each with its own strengths and weaknesses:

- Gas Tungsten Arc Welding (GTAW) Power Sources: These sources provide precise control over the arc, making them ideal for high-quality welds on aerospace materials. They allow for easy adjustment of current and voltage, vital for controlling penetration and heat input.

- Gas Metal Arc Welding (GMAW) Power Sources: These sources are often used for higher deposition rates, particularly on thicker sections. They offer options like pulsed current for improved control over heat input and weld bead shape.

- Resistance Welding Power Sources: These sources are employed for spot, seam, and projection welding, particularly for joining sheet metal. Precise control of the current and weld time is essential to create consistent welds.

The choice of power source depends on the material, joint design, required weld quality, and production rate. I have the skills to effectively utilize and maintain these power sources, ensuring they deliver reliable performance and consistent results. My experience also includes troubleshooting power source issues for optimal welding performance.

Q 14. What is your experience with automated welding systems?

I have extensive experience with automated welding systems, primarily robotic systems. These systems offer significant advantages in aerospace welding:

- Increased Productivity: Robotic systems can perform welds at much faster rates than manual welding, reducing production time and costs.

- Improved Consistency: Robots produce highly repeatable welds with consistent quality, minimizing variations. This is extremely important in aerospace manufacturing.

- Enhanced Safety: They can handle dangerous or ergonomically challenging welding tasks, protecting welders from hazardous environments and repetitive strain injuries.

- Complex Geometry Welding: Robotic systems can effectively weld complex geometries and access difficult-to-reach areas.

My experience involves programming and operating various robotic welding systems, including those employing GTAW, GMAW, and laser welding processes. I am proficient in troubleshooting system malfunctions, optimizing welding parameters for specific applications, and integrating robotic systems into production workflows. This often involves coordinating with engineers and technicians to ensure smooth and efficient operation.

Q 15. How do you maintain and calibrate welding equipment?

Maintaining and calibrating welding equipment is crucial for consistent, high-quality welds. Think of it like maintaining a precision instrument – regular care ensures accuracy and longevity. My process involves several key steps:

- Regular Cleaning: After each use, I meticulously clean the equipment, removing spatter and debris. This prevents build-up that can affect performance and accuracy. For example, neglecting to clean a MIG gun can lead to nozzle clogging and inconsistent weld bead formation.

- Gas Flow Rate Check: I verify the shielding gas flow rate using a flow meter, ensuring it’s within the manufacturer’s specified range. Incorrect flow can result in porosity (holes) in the weld, compromising its structural integrity.

- Voltage and Current Calibration: I use a calibrated multimeter to check the voltage and current output of the welding machine. Variations here can significantly impact penetration depth and weld bead geometry. I always refer to the manufacturer’s recommendations for acceptable tolerances.

- Torch and Electrode Inspection: Regularly inspecting the welding torch for cracks, leaks, or damage is essential. For example, worn-out tungsten electrodes (in TIG welding) lead to inconsistent arcing and weld quality. I replace them as needed.

- Scheduled Maintenance: I adhere to a strict maintenance schedule outlined by the manufacturer, performing tasks such as replacing consumables (e.g., contact tips, liners), lubricating moving parts, and inspecting internal components.

These steps ensure the welding equipment operates optimally, minimizing defects and maximizing efficiency. Failing to maintain equipment can lead to significant rework, increased costs, and potential safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of shielding gases?

Shielding gases are essential in preventing atmospheric contamination during welding, protecting the molten weld pool from oxidation and other reactions. My experience encompasses various gases, each suitable for different applications and materials:

- Argon (Ar): A very common inert gas used extensively in TIG welding, especially for aluminum and other reactive metals. Its high purity is vital for clean welds.

- Helium (He): Often mixed with argon to increase penetration in TIG welding, especially on thicker materials. It provides a hotter arc.

- Carbon Dioxide (CO2): Used primarily in MIG welding of steel, it’s less expensive than inert gases but can produce more spatter and slightly lower-quality welds compared to argon-based shielding.

- Argon/Helium Mixtures: Offer a balance between the properties of argon and helium, tailoring penetration and arc characteristics for specific applications.

- Argon/CO2 Mixtures: Sometimes employed in MIG welding of stainless steel to achieve a balance between cost and weld quality.

Selecting the appropriate shielding gas is crucial. The wrong gas can lead to porosity, poor weld penetration, or even embrittlement of the weld metal. I always carefully consider the base material and welding process to choose the optimal gas mixture and flow rate.

Q 17. Describe your experience with heat treatment of welds.

Heat treatment of welds is a critical post-weld process to relieve residual stresses and improve the mechanical properties of the weldment. It’s like annealing a piece of metal after it’s been significantly worked, allowing it to relax and become more stable. My experience includes:

- Stress Relieving: This is commonly performed to reduce residual stresses introduced during welding. High stresses can lead to cracking or distortion. I’m familiar with various stress-relieving methods, including furnace annealing and localized heating techniques.

- Solution Annealing: Used for materials like aluminum alloys to dissolve precipitates and improve ductility and corrosion resistance. Precise temperature control is crucial for optimal results.

- Age Hardening (Precipitation Hardening): Used for specific aluminum and titanium alloys to increase strength and hardness through controlled precipitation of secondary phases. I closely monitor time and temperature parameters.

Heat treatment procedures are strictly governed by aerospace specifications. Incorrect heat treatment can compromise the strength and fatigue life of the weldment, potentially leading to catastrophic failure. I always follow detailed procedures and verify results through non-destructive testing (NDT) methods such as radiography.

Q 18. Explain the importance of maintaining weld integrity.

Maintaining weld integrity is paramount in aerospace applications because it directly relates to safety and reliability. A compromised weld can lead to catastrophic failure with potentially devastating consequences. Think of it as the foundation of an entire structure – if that foundation is weak, the whole structure is at risk.

Weld integrity encompasses several aspects:

- Proper Welding Procedures: Following established welding procedures (WPS) meticulously ensures consistent weld quality. WPS documents provide detailed instructions on parameters like current, voltage, travel speed, and shielding gas.

- Non-Destructive Testing (NDT): Employing NDT techniques such as radiography, ultrasonic testing, and dye penetrant inspection is crucial to detect internal and surface flaws. NDT helps ensure welds meet stringent quality requirements.

- Material Selection: Choosing the right base materials and filler metals is crucial for compatibility and desired mechanical properties. Incorrect material selection can lead to cracking or embrittlement.

- Proper Joint Design: A well-designed weld joint minimizes stress concentrations and ensures adequate weld penetration.

Maintaining weld integrity requires a meticulous approach at every stage, from material preparation to final inspection. It’s a collaborative effort involving welders, inspectors, and engineers to ensure the safety and reliability of aerospace structures.

Q 19. How do you troubleshoot common welding problems?

Troubleshooting welding problems requires a systematic approach, much like diagnosing a medical condition. I start by observing the weld visually, then analyze the process parameters and the surrounding environment.

Common problems and solutions include:

- Porosity (holes in the weld): This often indicates insufficient shielding gas coverage, moisture contamination, or improper welding parameters. I’d check gas flow, clean the equipment thoroughly, and adjust parameters as needed.

- Lack of Fusion (incomplete weld penetration): This can result from low current, incorrect travel speed, or improper joint preparation. Adjusting parameters and verifying joint fit-up are key.

- Excessive Spatter: This frequently points to incorrect gas shielding, high current, or improper welding technique. Checking gas type and flow rate and refining technique can resolve this.

- Undercut (grooves at the weld edges): This can be caused by excessive current, incorrect travel speed, or improper electrode angle. Adjusting parameters and practicing consistent welding technique help.

- Cracking: Cracking can be due to improper heat input, material incompatibility, or residual stresses. Addressing these factors through parameter adjustments and heat treatments is needed.

My approach involves meticulously documenting observations, modifying parameters systematically, and utilizing appropriate NDT methods to verify the effectiveness of the solutions. Thorough documentation ensures traceability and allows for continual improvement.

Q 20. What are the differences between TIG, MIG, and laser welding?

TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), and laser welding are all fusion welding processes, but they differ significantly in their techniques and applications:

- TIG Welding: Uses a non-consumable tungsten electrode to create an arc, and a filler metal is added separately. It’s known for its precise control, excellent weld quality, and suitability for various metals, especially those requiring high purity like aluminum and titanium. However, it’s relatively slow.

- MIG Welding: Uses a consumable electrode (wire) that acts as both the electrode and filler metal. It’s faster than TIG welding and well-suited for mass production but may offer slightly less precise control and weld quality compared to TIG, particularly on thinner materials.

- Laser Welding: Uses a high-powered laser beam to melt the base materials, joining them without the need for a filler metal in many cases. It’s characterized by high speed, deep penetration, and narrow heat-affected zones, suitable for precision applications. However, it typically requires specialized and expensive equipment.

The choice of welding process depends heavily on the material, thickness, joint design, required weld quality, and production volume. In aerospace, all three processes are used, each with its own niche applications.

Q 21. Describe your experience working with different types of aerospace metals (e.g., aluminum, titanium, stainless steel).

My experience encompasses a wide range of aerospace metals, each presenting unique challenges and requiring specialized welding techniques:

- Aluminum: Requires careful control of heat input to prevent porosity and cracking. TIG welding is commonly used, employing pure argon shielding and specialized filler metals. The low melting point requires experience in controlling the heat input precisely.

- Titanium: Highly reactive, requiring a clean welding environment and inert shielding gases (argon). TIG welding is predominantly used, requiring skilled welders due to titanium’s susceptibility to contamination and cracking.

- Stainless Steel: Various grades exist, each requiring specific welding parameters and filler materials. MIG welding is frequently used for some grades, while TIG is preferred for critical applications. Proper shielding gas is important to prevent oxidation and maintain corrosion resistance.

- Nickel-Based Superalloys: These high-strength, high-temperature alloys often require specialized filler metals and welding procedures. TIG welding is the most common technique, but sometimes electron beam welding is used for high-quality, complex parts.

Welding each material requires in-depth knowledge of its properties and behavior during welding. I have extensive experience in selecting appropriate filler materials, welding parameters, and post-weld heat treatments to ensure optimal results. Thorough inspections and non-destructive testing are essential for ensuring the integrity of these welds in critical aerospace applications.

Q 22. What is your experience with specific aerospace welding codes and standards (e.g., AWS, ASME)?

My experience encompasses a wide range of aerospace welding codes and standards, primarily AWS (American Welding Society) and ASME (American Society of Mechanical Engineers) standards. I’m proficient in interpreting and applying codes such as AWS D17.1 (Specification for Welding Pipelines and Related Facilities) and ASME Section IX (Welding and Brazing Qualifications). These codes dictate the specific welding procedures, materials, and qualification requirements for different aerospace applications. For instance, I have extensive experience working with AWS D1.1, which details the structural welding of steel, a critical aspect of many aerospace structures. Understanding these codes ensures the structural integrity and safety of the welded components.

Beyond specific codes, I also understand the underlying principles of material selection, weld design, and non-destructive testing (NDT) methods as detailed within these standards. This allows me to adapt to evolving industry practices and emerging technologies while maintaining compliance.

Q 23. How do you manage time and resources effectively during a welding project?

Effective time and resource management in a welding project is crucial. My approach involves a multi-step process: Firstly, a thorough review of the project specifications, including drawings, material lists, and welding procedures, is essential to accurately estimate the time required for each task. This initial planning stage also allows for identification of potential bottlenecks or resource constraints.

Secondly, I meticulously plan the workflow, sequencing tasks logically to optimize efficiency. This may involve leveraging techniques like lean manufacturing principles to eliminate waste and streamline processes. For instance, pre-positioning welding materials and ensuring proper tooling availability reduces downtime. Thirdly, I monitor progress regularly, comparing actual progress against the planned schedule and adjusting the workflow as needed. This often involves utilizing project management software to track progress and identify any potential delays.

Finally, effective communication with the project team is paramount to ensure everyone is aligned and working towards the shared objectives. This proactive approach allows for timely identification and resolution of any issues, thus minimizing delays and ensuring the project remains on track and within budget.

Q 24. How do you document and track your welding work?

Comprehensive documentation and tracking are critical in aerospace welding, primarily for traceability and quality assurance. My documentation process starts with creating a detailed welding procedure specification (WPS) that outlines every aspect of the welding process, including the materials, welding parameters (current, voltage, travel speed), pre- and post-weld heat treatments, and NDT methods to be employed.

Each weld is meticulously documented using weld tracking forms or specialized software. These records include the WPS number, welder identification, date and time of welding, specific weld location on the component, and any observations made during the welding process. I also document all NDT results, including radiographic images, ultrasonic scans, and visual inspections, alongside the associated acceptance criteria. This meticulous record-keeping ensures full traceability of every weld made, facilitating quality control and problem solving in case of any issues.

The completed documentation is kept in a secure, organized system. This ensures easy access for audits and future reference, maintaining compliance with regulatory requirements.

Q 25. Describe a situation where you had to solve a challenging welding problem.

During the construction of a critical component for a satellite launch vehicle, we encountered a challenging problem involving the welding of a titanium alloy. The specific joint design required a high degree of precision and penetration, but repeated attempts resulted in inconsistent weld quality and porosity. The initial WPS wasn’t yielding satisfactory results despite adherence to parameters.

To solve this, I systematically investigated potential root causes, starting with a thorough material analysis to rule out any defects. Following this, I collaborated with metallurgists to fine-tune the pre-weld cleaning procedures and optimize the shielding gas composition. We also experimented with different welding techniques, eventually settling on a pulsed GTAW (Gas Tungsten Arc Welding) method which provided better control over the heat input and weld bead formation.

This systematic approach, combining analytical problem-solving and collaborative expertise, allowed us to achieve the required weld quality, delivering a component that met all specified criteria. This experience highlighted the importance of methodical troubleshooting and the value of cross-functional collaboration in resolving complex welding challenges.

Q 26. Explain your understanding of weld penetration and its importance.

Weld penetration refers to the depth of the weld fusion into the base materials being joined. It’s a critical parameter because insufficient penetration (under-penetration) compromises the joint strength and integrity, while excessive penetration (burn-through) weakens the base material and creates defects. Imagine trying to join two pieces of wood with glue; proper penetration ensures the glue fully bonds both pieces. Similarly, in welding, adequate penetration ensures a sound and strong metallurgical bond.

The importance of proper weld penetration cannot be overstated in aerospace applications, where component failure can have catastrophic consequences. Several factors influence penetration, including the welding process (e.g., GMAW, GTAW), the welding parameters (current, voltage, travel speed), the type of base materials, and the joint design. Therefore, precise control over these parameters is crucial to achieving the required level of penetration, typically verified through visual inspection and NDT techniques like radiography.

Q 27. How do you ensure compliance with safety regulations and environmental standards during welding?

Ensuring compliance with safety and environmental regulations is an absolute priority in my welding practice. This involves adherence to OSHA (Occupational Safety and Health Administration) guidelines for welding safety, including proper use of personal protective equipment (PPE) such as welding helmets, gloves, and protective clothing. I always ensure the work area is properly ventilated to mitigate exposure to harmful fumes and gases produced during welding. This often requires specialized ventilation systems or the use of fume extraction equipment.

Furthermore, I am knowledgeable about the handling and disposal of hazardous materials, such as welding rods and shielding gases, strictly following all environmental regulations and ensuring proper waste management practices are followed. This includes regular monitoring of air quality and proper disposal of waste materials according to local environmental laws. A commitment to safe and environmentally responsible practices is essential in aerospace welding, and I meticulously follow all necessary protocols to ensure compliance and protect the environment and those working in the vicinity.

Q 28. Describe your experience with different types of weld joints (e.g., butt, fillet, lap).

My experience includes a wide variety of weld joints commonly used in aerospace applications. Butt joints, where two components are joined edge-to-edge, are frequently used for structural elements, requiring precise alignment and sufficient penetration for maximum strength. Fillet welds, used to connect two intersecting components at an angle, are versatile and commonly employed in aerospace structures where strength isn’t the primary concern. Lap joints, where one component overlaps another, are useful in situations where access for welding is limited.

Beyond these common types, I also have experience with other joint configurations, such as T-joints and corner joints, each requiring specific welding techniques and considerations to ensure strength and integrity. The selection of the appropriate joint type depends critically on the application requirements, including the forces acting on the component and the accessibility for welding. Each joint type demands a detailed understanding of the appropriate welding procedure to ensure optimal strength and quality. My experience allows me to select and execute the most suitable joint and welding technique for any given task.

Key Topics to Learn for Aerospace Welding Interview

- Welding Processes: Understanding various aerospace welding techniques like Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and resistance welding. Consider the nuances of each process and their suitability for different aerospace materials.

- Material Science: A strong grasp of aerospace-grade materials (e.g., aluminum alloys, titanium, stainless steel) and their weldability characteristics is crucial. This includes understanding material properties, potential defects, and heat treatment implications.

- Weld Joint Design: Familiarity with different joint designs (butt, lap, tee, etc.) and their strengths, weaknesses, and applications in aerospace structures. Be prepared to discuss design considerations for optimizing weld strength and minimizing stress concentrations.

- Quality Control and Inspection: Knowledge of non-destructive testing (NDT) methods used in aerospace welding, such as radiographic inspection (RT), ultrasonic testing (UT), and liquid penetrant testing (PT), is vital. Understanding industry standards and quality assurance procedures is also essential.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols and regulatory compliance in aerospace welding environments. This includes personal protective equipment (PPE), handling of hazardous materials, and adherence to industry standards (e.g., AWS, ASME).

- Troubleshooting and Problem-Solving: Be ready to discuss common welding defects (porosity, cracks, incomplete fusion) and the techniques employed to identify and rectify them. Practical experience and analytical skills in troubleshooting will be highly valued.

- Industry Standards and Codes: Familiarity with relevant aerospace industry standards and codes (e.g., those related to welding procedures, quality control, and material specifications) will showcase your commitment to best practices.

Next Steps

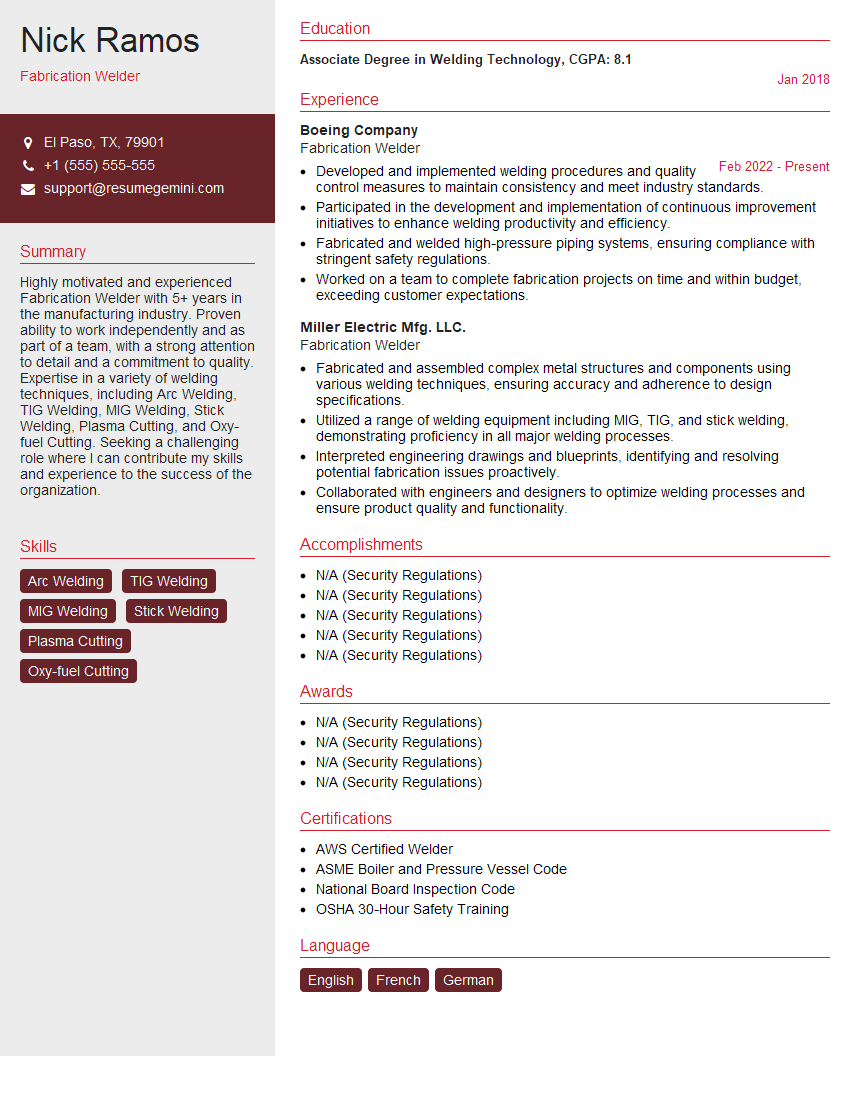

Mastering Aerospace Welding opens doors to a rewarding career with excellent growth potential in a highly specialized and innovative industry. To maximize your job prospects, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Aerospace Welding to help you get started. Invest the time to craft a compelling resume that showcases your expertise and passion for this challenging and rewarding field.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO