Cracking a skill-specific interview, like one for Air Conditioning and Heating Repair, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Air Conditioning and Heating Repair Interview

Q 1. Explain the difference between a heat pump and a furnace.

Heat pumps and furnaces both heat your home, but they do it in fundamentally different ways. A furnace burns fuel (natural gas, propane, or oil) to generate heat, which is then distributed through ductwork. Think of it like a big, efficient fireplace. A heat pump, on the other hand, moves heat rather than generating it. In the winter, it extracts heat from the outside air (even if it’s freezing!) and transfers it inside. In summer, it reverses the process, removing heat from inside and releasing it outside. This makes heat pumps much more energy-efficient than furnaces, especially in moderate climates.

Imagine a bucket brigade: a furnace is like someone creating fire to heat the water, while a heat pump is like a team passing the already-hot water from one bucket to the next, moving it from outside to inside.

Q 2. Describe the refrigeration cycle in detail.

The refrigeration cycle is the heart of both air conditioners and heat pumps. It’s a continuous loop involving four key components: the compressor, the condenser, the expansion valve, and the evaporator.

- Compressor: This is the ‘pump’ that compresses the refrigerant, raising its temperature and pressure. Think of it as squeezing a balloon – the air inside gets hotter and more pressurized.

- Condenser: The hot, high-pressure refrigerant releases heat to the outside air (in an AC unit) or to a different location (in a heat pump). This is why the outside unit of your AC feels hot to the touch.

- Expansion Valve: This valve reduces the refrigerant’s pressure, causing it to rapidly cool and change from a liquid to a low-pressure, low-temperature gas.

- Evaporator: The cool refrigerant absorbs heat from the indoor air, lowering the temperature. This cool air is then circulated through your home via ductwork.

The refrigerant then circulates back to the compressor, repeating the cycle. Different refrigerants exist with varying properties, but all share the fundamental goal of efficient heat transfer.

Q 3. What are the common causes of a malfunctioning condenser fan motor?

A malfunctioning condenser fan motor can stem from several issues. The most common include:

- Worn-out bearings: Over time, the bearings inside the motor wear down, leading to noisy operation and eventual failure. This is like the wheels of a car wearing down after many miles.

- Capacitor failure: The capacitor helps the motor start and run smoothly. A faulty capacitor will prevent the motor from starting or cause it to run erratically.

- Electrical issues: Problems with the wiring, power supply, or the motor itself (burnout) can cause the motor to fail to operate. Think of this as a power outage stopping your electrical devices from working.

- Blocked fan blades: Debris such as leaves, twigs, or other items can obstruct the fan, overloading the motor and causing it to malfunction. Regular cleaning is crucial.

Troubleshooting involves checking for power, testing the capacitor, inspecting the motor windings for damage, and thoroughly cleaning the unit.

Q 4. How do you diagnose a refrigerant leak?

Diagnosing a refrigerant leak requires a systematic approach. I’d start by visually inspecting the system for signs of leaks, such as oil stains, frost, or bubbling refrigerant. Electronic leak detectors utilizing specialized sensors can pinpoint the location of the leak with high accuracy. Another effective method is using a pressure gauge to check for pressure drops in the system over time, indicating a leak. If a significant leak is suspected, nitrogen pressurization might be used to identify the leak’s location more precisely.

Finding the leak is half the battle; repairing it involves carefully isolating and replacing the damaged component, then recharging the system with the proper amount of refrigerant.

Q 5. What are the safety precautions when working with refrigerants?

Safety is paramount when working with refrigerants. Many refrigerants are harmful if inhaled or exposed to open flames. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator. Work in a well-ventilated area. Never use open flames or sparks near refrigerant lines or components. Dispose of used refrigerant according to EPA regulations—never release it into the atmosphere. Understand the specific safety data sheets (SDS) for the type of refrigerant you are working with, to fully understand potential hazards and safety precautions.

Improper handling can lead to serious health consequences or environmental damage. Adherence to safety regulations is not merely recommended—it’s mandatory for responsible technicians.

Q 6. Explain the principles of air conditioning.

Air conditioning relies on the principle of heat transfer. By utilizing the refrigeration cycle (explained earlier), an AC system removes heat from the indoor air and transfers it to the outside air. This is achieved through the evaporation of a refrigerant inside the evaporator coil, which absorbs heat. The heated refrigerant is then compressed, condensed, and then returned to a liquid state, ready to repeat the cycle. The system’s design ensures that this heat transfer is efficient and effective, leading to a comfortable indoor temperature. A key aspect is the proper sizing of the system to the space it is cooling; an undersized system will struggle to maintain the set temperature, while an oversized unit may lead to uncomfortable drafts and uneven cooling.

Q 7. How do you troubleshoot a system with low airflow?

Low airflow can be caused by several factors. First, I’d check the air filter – a clogged filter is the most common culprit, restricting airflow significantly. Next, I’d inspect the ductwork for any blockages, leaks, or restrictions, paying attention to the blower motor and its connections. Problems with the blower motor itself (worn-out bearings, electrical issues) can also severely reduce airflow. In some cases, ice buildup in the evaporator coil might be restricting airflow. Finally, a problem with the refrigerant charge (low refrigerant level) might limit the cooling capacity, which can lead to the system running but with insufficient airflow. Troubleshooting requires a systematic approach, checking each component and eliminating possibilities one by one.

Think of the HVAC system as a network of pipes and fans; a single blockage anywhere can disrupt the entire flow. A thorough inspection is key to pinpoint the exact cause of the problem.

Q 8. What are the different types of HVAC systems?

HVAC systems come in a variety of types, each suited to different needs and building sizes. The most common types include:

- Split Systems: These are the most common type found in residential settings. They consist of an outdoor unit (condenser) and an indoor unit (evaporator), connected by refrigerant lines. These can be further categorized into single-zone, multi-zone, and ductless mini-split systems.

- Packaged Units: These systems house both the evaporator and condenser in a single unit, typically located on a roof or outside wall. They are often seen in smaller commercial buildings or larger homes.

- Heat Pumps: These systems function as both heaters and air conditioners. In cooling mode, they operate similarly to air conditioners, and in heating mode, they extract heat from the outside air and transfer it inside, making them energy-efficient in moderate climates.

- Central Air Systems: These systems distribute conditioned air through a network of ducts throughout the building. They are often used in conjunction with a furnace for heating and can be combined with other technologies such as geothermal heating and cooling.

- Geothermal Systems: These systems utilize the earth’s consistent temperature to heat and cool a building. They are highly energy-efficient but require significant upfront investment.

The best system for a particular application depends on factors like building size, climate, budget, and energy efficiency goals.

Q 9. How do you determine the appropriate size of an HVAC system for a building?

Determining the correct HVAC system size is crucial for optimal comfort and efficiency. An oversized system will cycle on and off frequently, leading to poor humidity control and increased energy bills. An undersized system will struggle to keep up with the cooling or heating demand, resulting in discomfort.

We use a process called ‘load calculation’ which considers several factors:

- Building size and insulation: Larger, poorly insulated buildings require larger systems.

- Climate: Hotter and more humid climates demand greater cooling capacity.

- Number of windows and their orientation: South-facing windows, for instance, can significantly increase heat gain.

- Number of occupants: More people generate more heat.

- Appliance heat output: Ovens, stoves, and other appliances add to the building’s heat load.

Specialized software and manual J calculations are used to determine the exact heating and cooling load. This calculation ensures we select the right sized system to provide comfortable and energy-efficient operation.

Q 10. Explain the function of a thermostat.

The thermostat acts as the ‘brain’ of your HVAC system. It monitors the temperature of the space and signals the system to turn on or off based on your programmed settings. Modern thermostats often incorporate advanced features such as:

- Programmable scheduling: Allows you to set different temperatures for different times of the day or week, saving energy when you’re away from home.

- Remote control: Mobile apps allow you to control your HVAC system from anywhere.

- Learning algorithms: Some thermostats learn your preferences and adjust settings automatically.

- Energy usage monitoring: These provide insights into your energy consumption to identify potential savings.

Essentially, the thermostat acts as a feedback loop, maintaining the desired temperature by communicating with the HVAC system’s components.

Q 11. Describe the process of installing a new air conditioning unit.

Installing a new air conditioning unit is a multi-step process requiring specialized knowledge and equipment. Here’s an overview:

- Site preparation: This involves checking electrical service capacity, refrigerant line routing, and condensate drain placement.

- Unit installation: The outdoor condenser unit is positioned on a level, stable base. The indoor evaporator coil is properly connected to the ductwork.

- Refrigerant lines: These are carefully connected, leak-tested, and vacuumed to remove air and moisture.

- Electrical connections: Electrical wiring is meticulously connected, adhering to strict safety standards.

- Ductwork modifications (if necessary): Any required adjustments to the ductwork are made to ensure optimal airflow.

- Testing and commissioning: The entire system is rigorously tested to verify its correct functionality and efficiency.

- Final inspection: A final check is conducted to confirm the unit’s proper operation and adherence to building codes.

Safety is paramount during installation, and proper handling of refrigerants is crucial. We always follow manufacturer guidelines and local codes.

Q 12. How do you maintain an HVAC system to prevent breakdowns?

Regular maintenance is essential for extending the lifespan and efficiency of your HVAC system and preventing costly breakdowns. Here’s a maintenance plan:

- Change air filters regularly: Dirty filters restrict airflow, reducing efficiency and increasing strain on the system. We recommend changing filters every 1-3 months or as needed.

- Inspect condensate drain lines: Clogged drain lines can lead to water damage and system malfunctions. Regularly check and clean these lines.

- Check refrigerant levels: Low refrigerant levels can drastically reduce cooling efficiency. Professional inspection and recharging are necessary.

- Clean evaporator and condenser coils: Dirt and debris buildup on coils impede heat transfer, reducing efficiency. Professional cleaning is recommended annually.

- Lubricate moving parts: Regular lubrication of motor bearings extends the lifespan of the system.

- Schedule professional maintenance: Annual inspections by a qualified technician ensure that everything is working correctly and identify potential issues before they become major problems.

A proactive maintenance approach avoids emergency repairs, maximizing system longevity and reducing energy consumption.

Q 13. What are the different types of heating systems?

Heating systems vary greatly depending on the fuel source and distribution method. Common types include:

- Furnaces: These use natural gas, propane, or electricity to heat air, which is then distributed throughout the house through ductwork.

- Heat Pumps: As mentioned earlier, these can provide both heating and cooling. They’re efficient in milder climates.

- Boilers: These heat water, which is then circulated through radiators or radiant floor systems.

- Electric Baseboard Heaters: These are electric resistance heaters that directly heat the air in a room. They are simple and relatively inexpensive, but less efficient.

- Radiant Floor Heating: This system uses tubing embedded in the floor to circulate hot water or electricity, radiating heat evenly throughout a space. It provides comfortable, even heating.

- Geothermal Systems: These utilize the stable temperature of the earth to heat and cool a home, offering exceptional energy efficiency.

The choice of heating system depends on factors such as climate, building design, budget, and energy efficiency goals.

Q 14. Explain the difference between a single-stage and a two-stage furnace.

The key difference between single-stage and two-stage furnaces lies in their operation and efficiency. A single-stage furnace operates at one speed – either on or off. When the thermostat calls for heat, it runs at full capacity until the desired temperature is reached, then shuts off completely.

A two-stage furnace offers more refined control. It can operate at two different capacity levels: a low-stage setting for maintaining temperature and a high-stage setting for rapid heating. This allows for more consistent temperature control and reduces the number of on/off cycles, leading to increased comfort and energy efficiency. The low-stage operation is particularly beneficial in maintaining a comfortable temperature with minimal energy usage on milder days. Think of it like a dimmer switch for your heating; a single-stage is like a light switch – it’s either completely on or off.

Q 15. How do you troubleshoot a furnace that won’t ignite?

Troubleshooting a furnace that won’t ignite involves a systematic approach, ruling out possibilities one by one. Think of it like a detective investigation – we need to find the culprit that’s preventing the ignition sequence.

Step 1: Safety First! Always turn off the power to the furnace at the breaker box before beginning any troubleshooting.

Step 2: Check the Obvious:

- Power Supply: Is the power switch on at the furnace and the breaker not tripped? A simple tripped breaker is often the cause.

- Gas Supply (if applicable): Is the gas valve open and is there gas flowing to the furnace? You might hear a distinct clicking sound if the gas valve is attempting to open but is blocked or faulty.

- Pilot Light (if applicable): For furnaces with pilot lights, is the pilot lit and burning steadily? If not, re-light it carefully following the manufacturer’s instructions. A constantly extinguishing pilot light indicates a draft problem or a gas flow issue.

Step 3: Deeper Dive:

- Igniter: Inspect the igniter (the glowing component that ignites the gas). If it’s not glowing, the igniter could be faulty and require replacement. A weak glow could also indicate a problem.

- Flame Sensor: The flame sensor (a small rod) detects the presence of the flame. If it’s dirty or damaged, it won’t detect the flame, and the furnace will shut down. Clean the sensor carefully with fine sandpaper or replace it if necessary.

- Gas Pressure: Low gas pressure can prevent ignition. This requires a professional gas technician to check gas line pressure.

- Thermostat: Ensure the thermostat is properly set and working correctly. Try setting the thermostat to a temperature significantly higher than the current room temperature to see if the furnace attempts to ignite.

Step 4: Call a Professional: If you’ve checked all of these and the furnace still won’t ignite, it’s time to call a qualified HVAC technician. Trying to fix complex issues yourself can be dangerous and may further damage the furnace.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of a frozen evaporator coil?

A frozen evaporator coil is a common problem in air conditioning systems, often caused by insufficient airflow or low refrigerant. Think of it like a refrigerator – if the airflow is blocked, the cooling coils will freeze up.

- Restricted Airflow: The most frequent culprit is a dirty air filter. A clogged filter restricts airflow, preventing the evaporator coil from absorbing enough heat and causing ice to form. Other blockages in the ductwork, like debris or closed vents, also reduce airflow.

- Low Refrigerant: A refrigerant leak reduces the amount of coolant circulating in the system. With less refrigerant, the evaporator coil can’t absorb heat efficiently, leading to freezing. Leaks can be a serious issue and require professional attention.

- Faulty Blower Motor: If the blower motor is weak or malfunctioning, insufficient airflow over the evaporator coil can result in freezing.

- Improperly sized system: An improperly sized AC system might struggle to efficiently cool the space, resulting in freezing on the evaporator coil.

- Refrigerant Charge Issues: Sometimes the refrigerant charge isn’t just low, but it’s also improperly distributed within the system. This can affect cooling capacity and lead to freezing.

Troubleshooting Steps: First, check and replace the air filter. Then, examine the system for airflow restrictions. If freezing persists, call a qualified HVAC technician to diagnose and repair any refrigerant leaks or other mechanical issues. Attempting to thaw a frozen evaporator coil yourself without addressing the root cause could damage the system further.

Q 17. How do you clean and maintain an air filter?

Cleaning and maintaining an air filter is crucial for optimal HVAC performance and indoor air quality. Think of it as the system’s first line of defense against dust and debris.

How to Clean:

- Disposable Filters: These are the most common type. Simply remove the old filter and replace it with a new one of the same size and type (check the MERV rating for desired filtration level).

- Washable Filters: Some filters can be washed. Carefully remove the filter, gently vacuum both sides to remove loose dust and debris, and then wash with lukewarm water and mild soap. Allow the filter to fully air dry before reinstalling.

Maintenance Schedule: Check and clean or replace disposable filters monthly, especially during peak seasons (summer and winter). Washable filters should be cleaned every 2-3 months.

Tips: Always handle filters carefully to avoid tearing. When replacing, make sure the arrows on the filter match the airflow direction indicated in your unit.

Q 18. Explain the importance of regular HVAC maintenance.

Regular HVAC maintenance is essential for ensuring efficient operation, extending the lifespan of your system, and maintaining a healthy indoor environment. Think of it as preventative car maintenance – it’s far better and cheaper to maintain than to repair.

- Improved Efficiency: A well-maintained system operates at peak efficiency, reducing energy consumption and saving money on utility bills.

- Extended Lifespan: Regular inspections and cleaning help identify and address minor issues before they escalate into major, costly repairs.

- Enhanced Indoor Air Quality: Cleaning and filter replacements remove allergens, dust, and other pollutants, leading to a healthier indoor environment for you and your family.

- Preventative Measures: Maintenance helps identify potential problems such as refrigerant leaks before they significantly impact the system’s performance or lead to costly repairs.

- Warranty Compliance: Many HVAC systems require annual maintenance to maintain their warranties.

Frequency: Most HVAC professionals recommend at least one annual maintenance inspection and cleaning.

Q 19. What are the common types of refrigerant used in HVAC systems?

Several types of refrigerants are used in HVAC systems, each with its own properties and environmental impact. The choice of refrigerant depends on several factors including system type and environmental regulations.

- R-22 (HCFC-22): Older systems often use R-22, but its production is being phased out due to its ozone-depleting potential.

- R-410A (HFC-410A): This is a common replacement for R-22 and is widely used in newer systems. However, it is also a potent greenhouse gas.

- R-32 (HFC-32): This is a low Global Warming Potential (GWP) refrigerant becoming increasingly popular as a more environmentally friendly option.

- Natural Refrigerants: These include ammonia (NH3), carbon dioxide (CO2), propane (R-290), and isobutane (R-600a). They have very low or zero ODP and GWP but require specific safety considerations due to their flammability or toxicity in some cases.

It’s crucial to note that handling refrigerants requires specialized knowledge and equipment. Always consult a qualified HVAC professional for any refrigerant-related work.

Q 20. What are the environmental concerns related to refrigerants?

Many refrigerants have significant environmental concerns related to their impact on ozone depletion and global warming. The main concerns include:

- Ozone Depletion Potential (ODP): Some refrigerants, such as older chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), contain chlorine atoms that deplete the ozone layer, which protects us from harmful UV radiation. The ODP for these refrigerants is being addressed by phasing out their production and use.

- Global Warming Potential (GWP): Many hydrofluorocarbons (HFCs), while not damaging the ozone layer, are potent greenhouse gases, contributing to global warming. Their high GWP is a significant concern and is driving the development and adoption of low-GWP alternatives.

Regulations and industry trends are pushing towards the use of refrigerants with low or zero ODP and GWP to mitigate these environmental impacts. The transition towards natural refrigerants and new HFC blends with lower GWP is ongoing.

Q 21. Describe your experience with different types of HVAC controls.

My experience encompasses a wide range of HVAC controls, from simple mechanical thermostats to sophisticated digital and smart systems. Understanding these controls is crucial for proper system operation and troubleshooting.

- Mechanical Thermostats: These are the simplest, using a bimetallic strip to sense temperature changes. They are reliable but offer limited features.

- Digital Thermostats: These provide more precise temperature control and often include features like programmable schedules and multiple temperature settings.

- Smart Thermostats: These connect to Wi-Fi, allowing remote control and monitoring via smartphone apps. They can learn your preferences and optimize energy use through advanced algorithms. Many smart thermostats offer features like geofencing (automatic adjustment based on your location) and energy reporting.

- Building Management Systems (BMS): Large commercial buildings utilize BMS to monitor and control HVAC systems across the entire building, optimizing efficiency and comfort across multiple zones.

My experience includes troubleshooting, installation, and programming of various control systems. I am comfortable working with different communication protocols and system integrations. This allows me to help clients optimize their HVAC system operation and potentially save energy.

Q 22. How do you handle a customer complaint about an HVAC system?

Handling customer complaints is paramount in HVAC. My approach is systematic and focuses on empathy and effective problem-solving. First, I actively listen to understand the customer’s concerns, validating their feelings. I avoid interrupting and ensure they feel heard. Then, I ask clarifying questions to pinpoint the issue: Is the system not cooling properly? Is there unusual noise? What were the conditions leading to the problem? This helps me diagnose the problem accurately. Once the issue is identified, I explain the problem clearly, in non-technical terms whenever possible, outlining the proposed solution and its cost. Transparency is key. I always provide options, weighing the pros and cons of each. Finally, I follow up after the repair to ensure complete customer satisfaction. For example, a recent customer complained about weak airflow. After investigation, I discovered a clogged air filter and a partially restricted return vent. Addressing these minor issues resolved the problem efficiently.

Q 23. What is your experience with troubleshooting electrical issues in HVAC systems?

Troubleshooting electrical issues in HVAC systems requires a thorough understanding of electrical safety and HVAC principles. I’m proficient in diagnosing problems using multimeters to check voltage, amperage, and continuity. I can identify faulty components like capacitors, relays, and control boards. I’m also experienced in working with various wiring diagrams and troubleshooting low voltage controls. I always prioritize safety, following all relevant electrical codes and using appropriate personal protective equipment (PPE) like insulated tools and safety glasses. For instance, I recently resolved a system failure traced to a shorted capacitor in the compressor’s start relay. Replacing the capacitor restored proper system operation. It is crucial to identify the source of any electrical problem and implement corrective measures rather than masking symptoms.

Q 24. How familiar are you with different types of ductwork and their installation?

I have extensive experience with various ductwork materials and installation techniques. I’m familiar with flexible ductwork, typically used for shorter runs and areas requiring flexibility, and rigid metal ductwork, which offers better durability and airflow for larger systems. I also understand the importance of proper sealing and insulation to minimize air leaks and energy loss. Different materials have different properties and suitability. For instance, flexible ductwork might be adequate for a small addition, but rigid metal ductwork is essential in a larger commercial setting. Incorrect installation can lead to reduced efficiency, uneven air distribution, and increased energy bills. My experience ensures proper sizing, sealing, and insulation of ductwork to guarantee optimal system performance. A well-designed and installed duct system can significantly improve the overall efficiency of an HVAC system.

Q 25. Explain the importance of proper ventilation in HVAC systems.

Proper ventilation is critical for indoor air quality and the efficient operation of an HVAC system. It involves the controlled intake and exhaust of air to remove pollutants, moisture, and stale air. Inadequate ventilation can lead to a buildup of pollutants like carbon monoxide, mold, and allergens, negatively impacting health and comfort. Furthermore, it can cause condensation within the ductwork, leading to corrosion and other problems. Proper ventilation prevents the buildup of moisture, minimizing the risk of mold growth and improving the overall efficiency of the HVAC system by ensuring proper air circulation and preventing issues such as high humidity or condensation. I consider ventilation design during every installation and service. For example, we always verify proper exhaust venting for gas furnaces and appliances to prevent dangerous gas buildup.

Q 26. What is your experience with preventative maintenance programs?

Preventative maintenance programs are essential for extending the lifespan and optimizing the performance of HVAC systems. My experience encompasses developing and implementing tailored maintenance plans for various systems. These plans typically include regular inspections, cleaning, filter replacements, and functional checks to identify potential problems early. This proactive approach helps prevent costly repairs and ensures the system operates efficiently. For example, a thorough inspection might reveal a refrigerant leak before it causes major damage. A well-maintained system also improves indoor air quality and reduces energy consumption. We build strong relationships with our clients, providing regular updates, clearly communicating findings, and recommending any needed services.

Q 27. Describe your experience working with different brands of HVAC equipment.

I have extensive experience working with a wide array of HVAC equipment brands, including Carrier, Trane, Lennox, Rheem, and Goodman. My knowledge spans various technologies, including heat pumps, air conditioners, furnaces, and boilers. This broad experience allows me to diagnose and repair diverse systems effectively. I understand the unique characteristics and common issues associated with each brand, allowing for quicker troubleshooting and more efficient repairs. For instance, I know the specific diagnostic codes for a Lennox furnace and am comfortable servicing the unique components of a Carrier heat pump. The experience includes both residential and light commercial applications, ensuring I can handle a variety of system sizes and complexities.

Key Topics to Learn for Your Air Conditioning and Heating Repair Interview

- Refrigerant Systems: Understanding different types of refrigerants, their properties, and safe handling procedures. Practical application: Troubleshooting refrigerant leaks and performing proper charging.

- HVAC System Components: Thorough knowledge of compressors, condensers, evaporators, expansion valves, and their functions. Practical application: Diagnosing malfunctions based on component behavior and understanding their interdependencies.

- Electrical Systems: Familiarity with wiring diagrams, voltage measurements, and troubleshooting electrical faults in HVAC equipment. Practical application: Identifying and resolving electrical issues causing system malfunctions.

- Troubleshooting and Diagnostics: Mastering systematic diagnostic techniques using tools like multimeters and pressure gauges. Practical application: Accurately diagnosing the root cause of system failures and proposing effective solutions.

- Safety Procedures: Adherence to safety regulations and best practices for handling refrigerants, electricity, and working at heights. Practical application: Explaining your safety protocols and demonstrating your commitment to a safe work environment.

- Air Quality and Filtration: Understanding the importance of air filters, air purification systems, and their impact on indoor air quality. Practical application: Explaining the benefits of regular filter changes and recommending appropriate air filtration solutions.

- Energy Efficiency: Knowledge of energy-efficient practices and technologies in HVAC systems. Practical application: Discussing how to optimize system performance for maximum efficiency and cost savings.

- Customer Service and Communication: Effective communication skills to explain technical issues to non-technical customers. Practical application: Describing a situation where you successfully communicated a complex problem to a client.

Next Steps

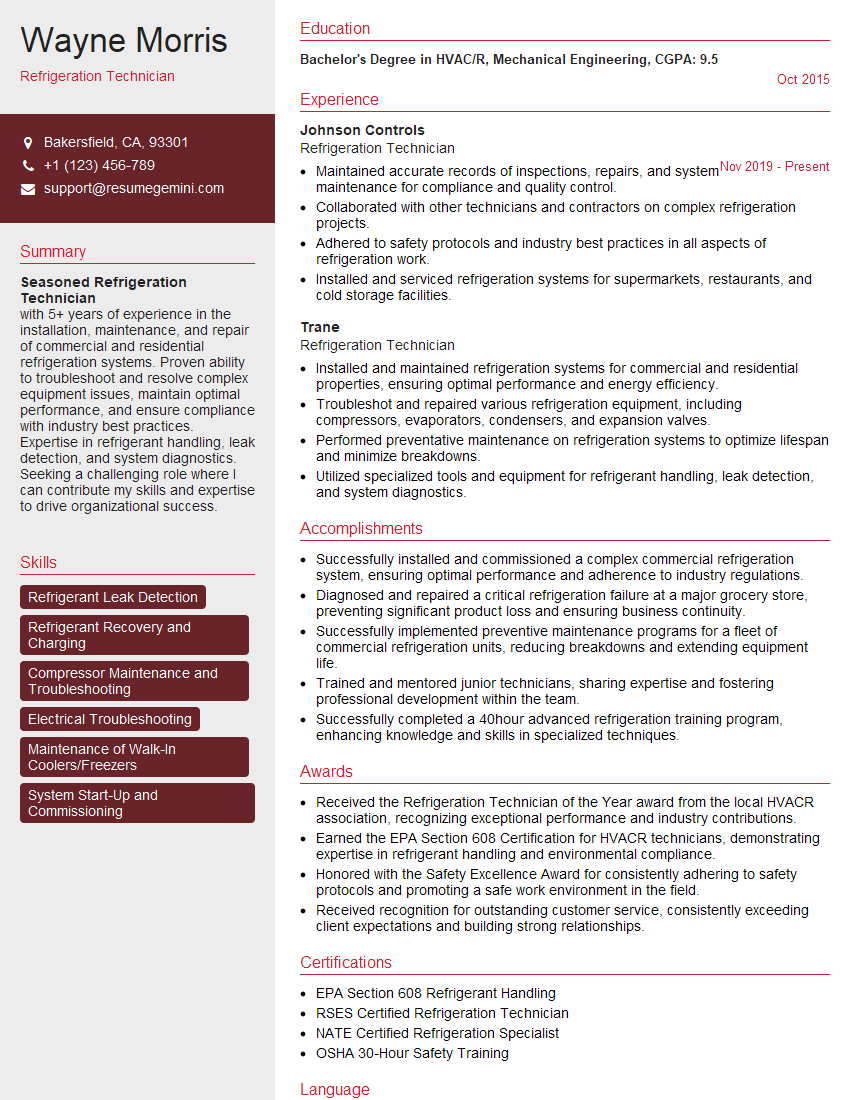

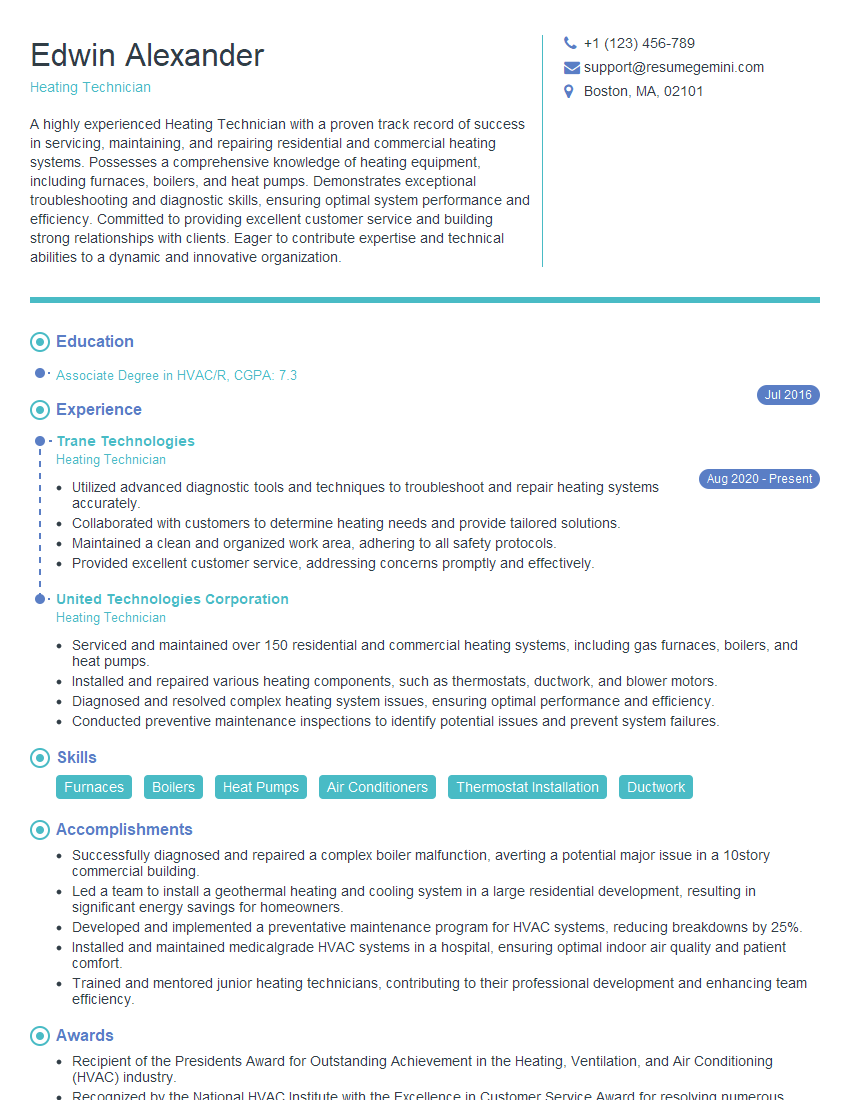

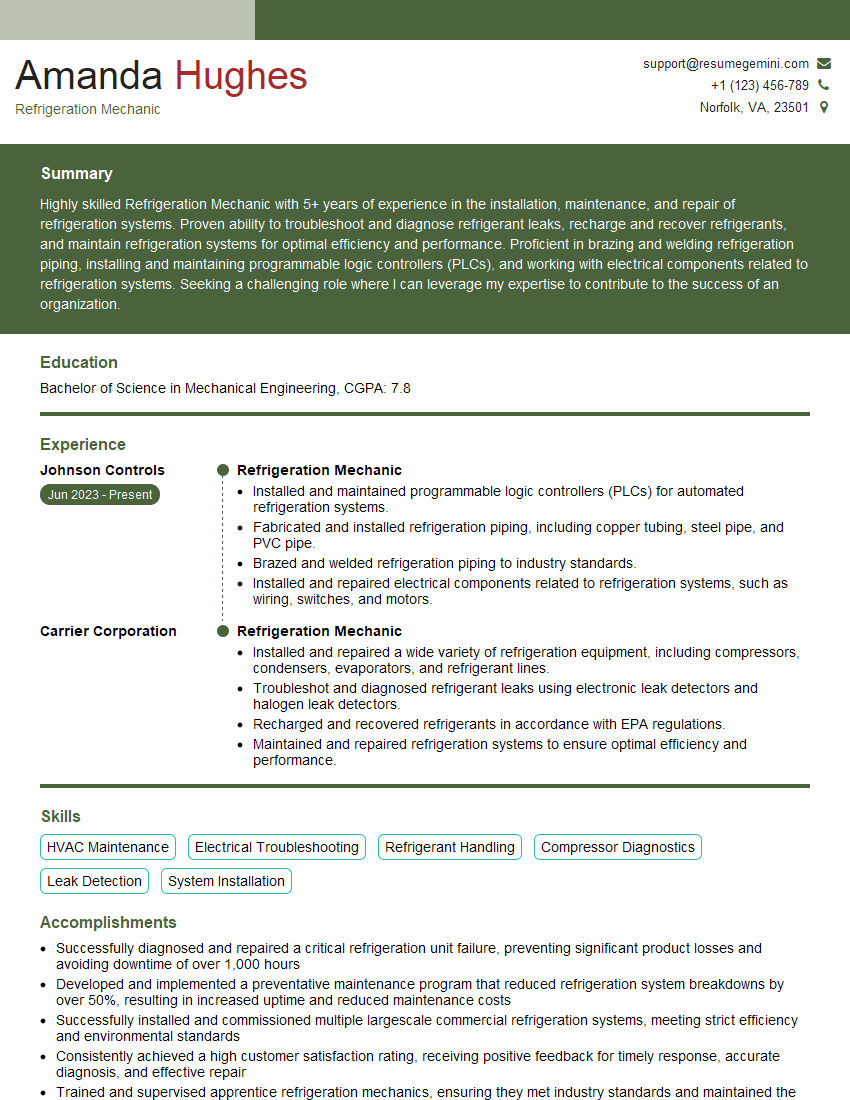

Mastering Air Conditioning and Heating Repair opens doors to a rewarding and stable career with excellent growth potential. To maximize your job prospects, a strong, ATS-friendly resume is crucial. ResumeGemini can help you create a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to the Air Conditioning and Heating Repair industry, giving you a head start in crafting a compelling application that gets noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO