Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Air Rotary Drilling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Air Rotary Drilling Interview

Q 1. Explain the principle of air rotary drilling.

Air rotary drilling utilizes compressed air as the primary drilling fluid to break up rock and remove cuttings. Instead of using a heavy mud-based fluid like in mud rotary drilling, compressed air is pumped down the drill string, through the drill bit, and then back up the annulus (the space between the drill string and the borehole wall), carrying cuttings to the surface. The high-velocity air stream also provides cooling and lubrication to the bit.

Imagine using a powerful air hose to blast away dirt – that’s the fundamental principle. The rotating drill bit breaks the rock, and the air forcefully removes the resulting fragments. The process is highly effective in certain geological formations.

Q 2. What are the advantages and disadvantages of air rotary drilling compared to mud rotary drilling?

Air rotary drilling offers several advantages over mud rotary drilling, particularly in specific applications.

- Faster Penetration Rates: In formations that are relatively unconsolidated or easily fractured, air can often achieve faster penetration rates due to reduced friction and lower hydrostatic pressure.

- Lower Cost: Air drilling typically requires less equipment and infrastructure compared to mud drilling systems which reduces upfront costs and ongoing operational expenses.

- Environmental Friendliness: Air drilling produces less waste and can be more environmentally friendly, especially where water is scarce.

However, there are significant disadvantages:

- Hole Stability: Air drilling is prone to hole instability, particularly in formations that are prone to caving. The lack of hydrostatic pressure provided by mud can cause the borehole to collapse.

- Limited Application: It’s not suitable for all geological formations. It generally fails in unconsolidated formations, where formations are water saturated, or when encountering high-pressure zones.

- Cuttings Removal Challenges: Efficient cuttings removal can be challenging, especially in deep holes or when drilling through harder rock formations. Fine particles can remain in the hole, hindering drilling progress.

The best choice depends entirely on the specific project – the geology, budget, and environmental considerations.

Q 3. Describe the different types of air compressors used in air rotary drilling.

Various air compressors are used in air rotary drilling, the selection driven by factors like required air volume, pressure, and portability. Common types include:

- Reciprocating Compressors: These are piston-based compressors, relatively simple and robust but can be noisy and less efficient at higher pressures.

- Rotary Screw Compressors: Employ rotating screws to compress air, offering higher efficiency and less noise compared to reciprocating compressors. These are frequently used for larger-scale operations.

- Centrifugal Compressors: Ideal for high-volume, moderate-pressure applications. They’re more complex and usually found in very large-scale drilling projects.

- Portable Air Compressors: These smaller, mobile units are essential for remote locations and smaller-scale projects, frequently used for smaller-diameter boreholes.

Choosing the correct compressor is critical for optimal drilling performance; insufficient air supply can severely impede progress while an oversized compressor may be unnecessarily expensive to operate.

Q 4. How do you determine the appropriate air pressure and flow rate for a specific drilling operation?

Determining the right air pressure and flow rate requires careful consideration of various factors. It’s not a simple calculation but rather an iterative process involving field experience and engineering judgment.

- Formation Type: Harder formations require higher air pressure to effectively break up the rock. Softer formations may require less pressure to avoid excessive hole enlargement.

- Hole Diameter and Depth: Larger diameter holes and greater depths require higher air flow rates to effectively remove cuttings and maintain efficient cooling.

- Bit Type and Design: Different bits have different air requirements. The bit design impacts the way the air is used.

- Drilling Rate: The desired drilling rate will influence the required air pressure and flow rate.

In practice, drilling engineers often begin with estimated values based on experience and then adjust parameters based on real-time observations like drilling rate, cuttings size and the amount of cuttings being carried to surface. Data logging and analysis provide crucial feedback for optimization.

Q 5. Explain the role of cuttings removal in air rotary drilling.

Efficient cuttings removal is paramount in air rotary drilling. The high-velocity air stream is the primary mechanism for lifting cuttings to the surface. However, achieving this can be challenging, particularly in deeper holes or formations with sticky clay.

Factors influencing cuttings removal effectiveness include air flow rate, pressure, bit design, and hole geometry. Problems like bridging (cuttings forming a blockage in the hole) can significantly slow or stop drilling. Mitigation strategies include:

- Optimizing Air Flow and Pressure: Adjusting these parameters based on real-time monitoring helps to ensure effective cuttings transport.

- Proper Bit Selection: Choosing a bit design that optimizes the air flow and cuttings ejection is crucial.

- Periodic Hole Cleaning: Techniques may include using specialized tools to dislodge cuttings that have accumulated in the hole.

Inefficient cuttings removal can lead to reduced drilling rates and even bit damage. Monitoring cuttings size and volume is crucial for detecting potential problems.

Q 6. What are the challenges associated with air drilling in different geological formations?

Air drilling faces distinct challenges in various geological formations:

- Consolidated Formations: Harder rocks may require excessively high air pressures, potentially leading to equipment limitations or increased wear and tear. Efficient cuttings removal also becomes more difficult.

- Unconsolidated Formations: These are particularly problematic as the lack of hydrostatic pressure from mud can cause the hole walls to collapse, leading to hole instability and potentially sticking or losing the drill string.

- Water-Saturated Formations: The influx of water into the borehole can significantly reduce the efficiency of the air lift, making cuttings removal difficult and hindering drilling progress.

- Fractured Formations: While air drilling can be effective in some fractured formations, excessive fracturing can lead to unstable hole conditions and potential losses of drilling fluids.

Proper geological assessment and planning are crucial before commencing air drilling to mitigate these formation-specific challenges. Careful selection of drilling parameters and the use of appropriate drilling techniques are essential.

Q 7. How do you manage hole stability issues during air rotary drilling?

Hole instability is a major concern in air rotary drilling. The absence of a hydrostatic pressure column provided by drilling mud means the borehole walls are less supported, making them susceptible to caving or sloughing.

Several strategies are employed to manage hole stability:

- Proper Hole Cleaning: Efficient removal of cuttings minimizes the risk of bridging and ensures the borehole remains open.

- Optimized Air Pressure and Flow Rate: This can help prevent excessive erosion of the hole walls.

- Use of Stabilizing Agents: In certain cases, specialized foams or other additives can be used to temporarily improve hole stability.

- Casing: The installation of casing is frequently required to stabilize unstable sections of the borehole.

- Reduced Rotation Speed and Weight on Bit: This can reduce the stresses on the hole walls.

Careful monitoring of hole conditions and proactive management strategies are vital to prevent costly complications due to hole instability. A thorough understanding of the geological formation being drilled is paramount.

Q 8. Describe the various types of air drilling bits and their applications.

Air drilling bits are designed to efficiently break up rock formations using compressed air. The choice of bit depends heavily on the geological formation being drilled. Here are some common types:

- Roller Cone Bits: These bits use rotating cones with teeth or inserts to crush and grind the rock. They’re effective in hard, abrasive formations but have a shorter lifespan than other types. Think of them as powerful rock crushers.

- PDC (Polycrystalline Diamond Compact) Bits: These bits use durable diamond inserts that cut through the rock. They’re ideal for softer formations and offer longer operational life compared to roller cone bits. Imagine them as extremely sharp, diamond-tipped scalpels for rock.

- Hybrid Bits: These bits combine features of both roller cone and PDC bits, offering a balance of performance and lifespan in various formations. They are versatile tools offering the best of both worlds.

- Air Hammer Bits: These bits utilize a piston-driven impact mechanism to break up the rock. They are particularly effective in hard, fractured formations and can be used in smaller diameter holes. They work like tiny jackhammers within the drill string.

The application of each bit type depends entirely on the specific drilling conditions: the hardness of the rock, the desired rate of penetration, and the overall drilling objectives. For example, a PDC bit would be preferred in soft shale formations while a roller cone bit might be more suitable for hard sandstone.

Q 9. What safety precautions are crucial during air rotary drilling operations?

Safety is paramount in air rotary drilling. Here are crucial precautions:

- Rig Site Safety Procedures: Strict adherence to established rig site safety rules and regulations, including regular safety meetings and toolbox talks.

- Personal Protective Equipment (PPE): Mandatory use of hard hats, safety glasses, hearing protection, and appropriate clothing at all times.

- Pressure Control Systems: Thoroughly inspect and maintain all pressure control systems to prevent blowouts or uncontrolled pressure surges. Regular checks and maintenance are essential here.

- Emergency Shutdown Procedures: All personnel must be thoroughly trained in emergency shutdown procedures and know the location of all shut-off valves.

- Compressed Air Safety: The quality and pressure of compressed air must be consistently monitored. Air lines must be inspected for damage or leaks regularly.

- Confined Space Entry: If drilling requires confined space entry, proper permits and procedures must be followed, including adequate ventilation and gas monitoring.

- Regular Inspections: The drilling equipment should undergo regular inspections to identify and fix potential problems before they become safety hazards.

Ignoring safety precautions can lead to serious injuries or fatalities. Regular safety training and a strong safety culture are critical to prevent accidents.

Q 10. How do you monitor and control the air pressure and flow rate during drilling?

Monitoring and controlling air pressure and flow rate are crucial for efficient and safe drilling operations. This is typically accomplished through a combination of instrumentation and skilled operator intervention:

- Pressure Gauges: Multiple pressure gauges are installed at various points in the system, including at the compressor, mud pump (if applicable), and the wellhead. They provide real-time pressure readings.

- Flow Meters: Flow meters measure the volume of air passing through the system per unit of time. This data helps determine the efficiency of the air delivery.

- Control Valves: Control valves allow the operator to adjust the air pressure and flow rate based on drilling conditions and the type of formation being drilled.

- Data Acquisition Systems (DAS): Modern drilling rigs often incorporate DAS that automatically record and display pressure, flow, and other relevant parameters. This provides a detailed record of the drilling process for analysis and optimization.

The operator uses this information to maintain optimal drilling parameters, adjusting pressure and flow based on the resistance of the rock and other factors. For example, if the rate of penetration slows down, the operator might increase the air pressure or flow rate to increase the cutting efficiency of the bit.

Q 11. Explain the process of tripping in and out of the hole during air rotary drilling.

Tripping in and out of the hole refers to the process of lowering (tripping in) and raising (tripping out) the drill string.

Tripping In: The drill string, including the drill pipe, drill collars, and bit, is lowered into the hole under controlled conditions. The process involves careful monitoring of the weight on the bit to avoid damage to the drill string or the wellbore.

Tripping Out: The drill string is carefully retrieved from the hole. The process involves disconnecting sections of drill pipe and stacking them on the rig floor, ensuring proper handling and minimizing the risk of accidents.

Safety is paramount during tripping operations. Procedures must be meticulously followed to prevent damage to the drill string, stuck pipe incidents, and injuries to personnel. Clear communication between the driller and the crew is crucial. A good analogy is threading a very long and delicate needle – every step needs precision and careful control.

Q 12. How do you handle well control issues during air rotary drilling?

Well control issues in air rotary drilling, such as kicks (influx of formation fluids), are addressed by immediately shutting down the drilling operation and implementing established well control procedures.

- Shut-in procedures: This involves immediately closing the surface valves to prevent further influx of formation fluids.

- Weighting up the drill string: Additional weight is added to the drill string to counteract the pressure of the formation fluids.

- Circulation: If circulation is possible, the air is circulated to remove the formation fluids.

- Pressure monitoring: Continuous pressure monitoring is maintained to track the well’s pressure and stability.

- Mud System Transition (if applicable): If the well control situation necessitates a transition, the air may be replaced with drilling mud to effectively manage the situation.

The specific actions taken depend on the severity of the kick and the geological conditions. A well control specialist or a team of experts may be consulted to assist in resolving the issue. Training and preparedness are vital for handling well control issues effectively and safely.

Q 13. Describe the different types of air drilling fluids and their properties.

While air is the primary drilling fluid in air rotary drilling, other fluids can be added to enhance performance or address specific challenges. These are usually used in conjunction with air, not as a complete replacement.

- Water: Adding small amounts of water can help reduce dust generation, improve cuttings removal, and lubricate the bit. However, excessive water can cause problems with hole stability.

- Foams: Foams are mixtures of air and liquid that provide better cuttings transport than air alone and can be less damaging to the formation. They provide improved hole cleaning and stability.

- Polymer solutions: These solutions can improve hole stability, reduce fluid loss, and improve cuttings removal. They are valuable for difficult formations.

The properties of these fluids, such as viscosity, density, and stability, are carefully considered to optimize drilling performance and to maintain wellbore stability. The choice of additive depends on the specific geological conditions and drilling objectives. Finding the right balance is crucial for maximizing efficiency and maintaining a safe operation.

Q 14. How do you perform a well integrity test after air rotary drilling?

A well integrity test after air rotary drilling aims to verify the condition of the wellbore and ensure no damage has occurred during the drilling process. Common methods include:

- Pressure testing: A pressure test involves pressurizing the wellbore with air or nitrogen and monitoring pressure changes over time. This helps detect leaks or other integrity issues.

- Temperature surveys: Temperature logging can be used to identify any unusual temperature gradients that might indicate issues with casing integrity or formation fluid flow.

- Cement bond logging: Cement bond logging is performed to verify the quality and effectiveness of the cement job, ensuring that the casing is properly cemented in place.

- Leak detection surveys: Specialized tools can be used to detect the presence of small leaks or fractures in the wellbore.

The specific tests conducted will depend on the drilling program and regulatory requirements. A successful well integrity test confirms that the wellbore is safe and ready for subsequent operations, such as casing installation or completion.

Q 15. What are the environmental considerations during air rotary drilling?

Environmental considerations in air rotary drilling are paramount. We’re talking about minimizing the impact on air quality, noise pollution, water resources, and the overall ecosystem. Dust suppression is a major concern; the drilling process generates significant airborne dust particles, which can be harmful to both workers and the environment. This is often addressed through techniques like water sprays, dust collectors, and the use of dust suppressant chemicals. Another key factor is noise pollution. Air rotary drills are inherently noisy, so we often employ noise barriers and schedule operations to minimize disruption. Water usage, while often minimal, needs careful management, especially in arid regions. Responsible waste disposal of drilling fluids and cuttings is also critical. For example, we might employ settling ponds to separate solids from liquids and carefully manage the disposal of both components following all applicable environmental regulations. Finally, habitat disruption needs to be carefully considered during site selection and operation planning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of maintaining drilling equipment during air rotary drilling.

Maintaining drilling equipment is absolutely crucial for safety, efficiency, and cost-effectiveness in air rotary drilling. Regular maintenance prevents costly breakdowns and ensures optimal performance. Think of it like a high-performance car – regular servicing keeps it running smoothly and prevents major problems down the line. We follow a rigorous preventative maintenance schedule, checking and lubricating components such as bearings, seals, and the compressor regularly. This includes inspecting hoses for wear and tear and checking for leaks. A well-maintained air compressor is essential, as it’s the heart of the system. Regular inspections can detect issues like valve wear, which could lead to a loss of efficiency or even catastrophic failure. We also conduct thorough inspections after each drilling run to identify and address any damage or wear. Proactive maintenance prevents downtime, extends the lifespan of equipment, and significantly reduces overall operational costs.

Q 17. How do you troubleshoot common problems encountered during air rotary drilling?

Troubleshooting in air rotary drilling involves a systematic approach. Let’s say we experience a sudden drop in the rate of penetration (ROP). We’d first check the air pressure and flow rate; a reduction in either suggests a problem with the compressor or the air delivery system. Next, we’d examine the drill bit; dull or worn bits dramatically reduce ROP. We might check for any obstructions in the hole, such as collapsed formations or stuck drill cuttings. Another common issue is problems with the rotary head itself, such as bearing failure or damage to the drive mechanism. These failures might manifest as unusual noises or vibrations. I usually follow a diagnostic flow chart; it guides me through checking various components, starting with the simplest and most likely causes. If the problem persists, we often resort to using specialized diagnostic equipment and can involve senior engineers or manufacturers for support if needed. Detailed records are always kept to aid in future troubleshooting and to ensure consistent maintenance practices.

Q 18. What are the limitations of air rotary drilling?

Air rotary drilling, while versatile, has certain limitations. It’s generally not suitable for very deep drilling or drilling in highly consolidated rock formations. The energy transfer mechanism, relying solely on compressed air, can be inefficient compared to mud rotary drilling in these scenarios. Also, air rotary drilling can be challenging in formations prone to caving or collapse, as the air flow can destabilize them. Another limitation is the difficulty in controlling cuttings in open holes – there is not a contained fluid column. This is because the cuttings are largely carried by the air flow to the surface. Consequently, accurate geological sampling is more challenging compared to mud drilling techniques. Furthermore, borehole stability can be an issue in some formations. Finally, air rotary drilling is often less effective in soft formations where the air pressure may not be sufficient to maintain the borehole stability and may lead to significant hole enlargement.

Q 19. How do you calculate the rate of penetration (ROP) during air rotary drilling?

Rate of penetration (ROP) is a crucial metric in drilling, indicating the speed at which the drill bit penetrates the rock formation. It’s typically calculated by measuring the depth drilled over a specific time interval. For example, if a drill penetrates 10 meters in 30 minutes, the ROP is 20 meters/hour (10 meters / 0.5 hours). The calculation is quite straightforward: ROP = Depth Drilled / Time Taken. However, accurate measurement requires careful recording of the start and end depths and the corresponding times. It’s also important to note that ROP can fluctuate significantly depending on factors such as rock hardness, bit type, air pressure, and drilling parameters. A drilling engineer will use the ROP data to optimize drilling parameters, predict drilling times, and assess overall drilling performance. Changes in ROP can indicate issues, such as bit wear or changes in the subsurface rock properties.

Q 20. Explain the role of a drilling engineer in air rotary drilling operations.

The drilling engineer plays a pivotal role in air rotary drilling operations, essentially overseeing all aspects of the drilling process from planning to completion. Their responsibilities include planning the drilling program, selecting appropriate drilling parameters (air pressure, rotary speed, bit type), and monitoring drilling performance. They must ensure compliance with safety regulations and environmental standards. They’re responsible for the proper management and maintenance of drilling equipment and overseeing the work of drilling crews. During drilling operations, the drilling engineer continuously monitors data such as ROP, air pressure, and torque. They make real-time decisions to optimize performance and to mitigate issues, which is crucial for the success of the project. A good drilling engineer is not just technically competent; they’re excellent problem solvers with strong leadership and communication skills.

Q 21. Describe the process of selecting the appropriate drilling parameters for different rock formations.

Selecting appropriate drilling parameters for different rock formations is a key aspect of successful air rotary drilling. Each formation has unique properties such as hardness, abrasiveness, and fracturing, affecting the best drilling techniques. For example, hard, dense rock requires high air pressure and a robust drill bit designed to withstand the stress. Softer formations might require lower air pressures to prevent excessive hole enlargement and bit wear. The choice of drill bit is also critical; roller cone bits are often preferred for harder formations, while drag bits might be more suitable for softer formations. The rotary speed also needs adjustment. A faster rotary speed might be efficient for softer formations, while slower speeds might be necessary for harder formations to prevent premature bit wear. Factors such as the presence of groundwater or potential for caving are also taken into account. The drilling engineer uses geological data, experience, and often specialized software to simulate and determine the optimal drilling parameters for each formation encountered. The process involves careful consideration of several factors, and adjustments might be made during the process based on real-time observations.

Q 22. How do you manage the disposal of drilling cuttings in air rotary drilling?

Managing drilling cuttings in air rotary drilling is crucial for environmental protection and operational safety. The process primarily involves separating the cuttings from the air stream and disposing of them responsibly. This is typically achieved using several methods:

Cyclone Separators: These are the most common method, using centrifugal force to separate the heavier cuttings from the airflow. The separated cuttings then fall into a collection bin.

Dust Suppression Systems: These systems, often involving water or foam injection, reduce the amount of airborne dust, making the operation cleaner and safer. This is particularly important in arid regions.

Cuttings Handling and Transportation: Once collected, cuttings must be transported to designated disposal sites. This might involve using trucks, conveyor belts, or other methods, depending on the site conditions and volumes involved.

Disposal Methods: Disposal methods vary depending on local regulations and the nature of the cuttings. This could include safe landfill disposal, beneficial reuse (e.g., road construction fill), or specialized treatment if the cuttings contain hazardous materials.

Effective cuttings management minimizes environmental impact, reduces health risks associated with dust inhalation, and ensures compliance with environmental regulations. In my experience, regular maintenance of cyclone separators and dust suppression systems is vital to their efficiency.

Q 23. What is the significance of air velocity in air rotary drilling?

Air velocity in air rotary drilling is a critical parameter influencing several key aspects of the operation. Think of it like the wind’s speed: a gentle breeze might not move much, but a strong gust can carry significant material. In air drilling, the air velocity directly affects:

Rate of Penetration (ROP): Higher air velocities provide greater cuttings removal efficiency. This means the cuttings are cleared away from the bit more quickly, allowing for faster drilling speeds.

Hole Cleaning: Sufficient air velocity is essential for effective hole cleaning. If the velocity is too low, cuttings can accumulate at the bottom of the hole, hindering the bit’s performance and potentially causing problems like bit balling.

Bit Life: Optimal air velocity minimizes the abrasive wear on the drill bit, prolonging its lifespan and reducing operational costs. Too low, and the bit may wear prematurely; too high, and it could lead to excessive bit damage.

Compressor Selection: The required air velocity dictates the size and capacity of the air compressor needed for the operation. Insufficient compressor capacity can significantly reduce ROP.

Therefore, determining the ideal air velocity involves careful consideration of formation characteristics, bit type, and the desired ROP. It’s a balancing act – high enough for efficient cleaning and penetration but not so high as to cause excessive wear and tear.

Q 24. Describe your experience with different types of air drilling rigs.

My experience encompasses a range of air drilling rigs, from small, portable units to large, sophisticated systems. I’ve worked with:

Truck-mounted rigs: These are versatile and mobile, ideal for various locations and formations. They are commonly used in shallow to moderate depth drilling.

Trailer-mounted rigs: Similar to truck-mounted rigs but offering greater capacity and often used for larger-scale projects.

Self-contained rigs: These incorporate all essential components (compressor, mud pumps if used in conjunction with air drilling, etc.) in a single unit, making them convenient for remote locations.

Top-drive rigs: These utilize a top-drive system for rotating the drill string, offering precise control and improved efficiency. These are usually coupled with larger compressors to drive the air to the bottom hole.

Each rig type presents unique operational considerations. For example, maintenance procedures and safety protocols differ slightly. Understanding the specifics of each rig is crucial for efficient and safe operation. My experience allows me to adapt readily to different rig types and optimize operations based on the rig’s capabilities and the project’s requirements.

Q 25. How do you optimize drilling parameters to improve ROP and reduce costs?

Optimizing drilling parameters to improve ROP and reduce costs is a continuous process of refinement and adjustment. It’s a delicate balance, much like finding the perfect recipe. Key parameters include:

Air Pressure: Higher pressure generally improves ROP, but excessively high pressure can damage the bit and formations.

Air Flow Rate: Similar to pressure, higher flow rates improve cuttings removal, but excessive flow can be wasteful and inefficient.

Rotary Speed: The rotational speed of the drill string influences the bit’s performance. The optimal speed varies depending on the bit type and formation.

Weight on Bit (WOB): WOB is the force applied to the bit. Balancing WOB is crucial – too much can cause premature bit wear; too little results in slow penetration.

Bit Selection: Choosing the correct bit type for the formation is fundamental. Using an inappropriate bit can significantly impact ROP and bit life.

Optimization involves systematically adjusting these parameters, monitoring their effect on ROP, and making iterative changes. Data logging and analysis are critical for this process. Cost reduction comes from maximizing ROP, minimizing bit wear, and optimizing air compressor usage. My approach involves a combination of experience, data analysis, and a willingness to adapt to changing conditions.

Q 26. Explain your understanding of air drilling automation and its impact on efficiency.

Air drilling automation is transforming the industry, enhancing efficiency and safety. Automation involves using advanced control systems and sensors to monitor and control various drilling parameters. This results in:

Improved ROP: Automated systems can optimize drilling parameters in real-time, maximizing penetration rates.

Reduced Costs: By optimizing parameters and minimizing downtime, automation leads to significant cost savings.

Enhanced Safety: Automation reduces human intervention in hazardous operations, minimizing risks.

Improved Data Collection and Analysis: Automated systems collect and process vast amounts of data, providing valuable insights for future optimization.

Examples include automated systems that adjust air pressure and flow rate based on real-time feedback from downhole sensors or systems that automatically control the weight on the bit based on pre-programmed algorithms. In my opinion, the impact of automation is profound, leading to safer, more efficient, and ultimately, more cost-effective air drilling operations.

Q 27. Describe a challenging situation you faced during air rotary drilling and how you resolved it.

During a project in a challenging desert environment, we encountered a severe dust storm that significantly reduced visibility and affected the operation of the cyclone separator, causing cuttings to accumulate in the vicinity of the rig and creating a hazardous situation. The primary problem was the compromised visibility which limited our ability to effectively manage the cuttings and the risk of equipment damage from the sand and dust.

My approach involved a multi-pronged solution:

Immediate Suspension of Operations: Safety was the priority; we immediately halted drilling to minimize risks to personnel and equipment.

Emergency Dust Suppression: We deployed additional dust suppression equipment to control the dust cloud and improve visibility.

Cyclone Separator Maintenance: Once the storm subsided, we thoroughly inspected and serviced the cyclone separator to ensure it was functioning correctly.

Safety Briefing: We conducted a safety briefing to review the incident and emphasize the importance of safety procedures during adverse weather conditions.

This situation highlighted the importance of having contingency plans for unforeseen events and the critical role of proactive safety measures in air rotary drilling. Through a combination of decisive action and careful planning, we safely resolved the situation, minimizing potential damage and ensuring the continued safety of the team.

Q 28. What are your future goals and aspirations in the field of air rotary drilling?

My future goals in air rotary drilling involve continuous learning and advancing the field. I am particularly interested in:

Furthering my expertise in automation: I want to contribute to the development and implementation of advanced automation technologies for enhanced safety, efficiency, and sustainability.

Exploring sustainable drilling practices: Reducing the environmental footprint of air drilling is crucial, and I’m keen on investigating and implementing eco-friendly techniques.

Mentoring and training: Sharing my knowledge and experience to foster the next generation of air drilling professionals is a key aspiration.

Research and development: I hope to contribute to research efforts focused on improving drilling techniques and equipment, driving innovation within the industry.

Ultimately, my aspiration is to contribute to the advancement of a safer, more efficient, and environmentally responsible air rotary drilling industry.

Key Topics to Learn for Air Rotary Drilling Interview

- Fundamentals of Air Rotary Drilling: Understanding the basic principles, equipment components, and operational procedures. This includes the differences between air and mud rotary drilling.

- Air Compressor Systems: Knowledge of various compressor types, their capacities, and maintenance requirements. Practical application includes troubleshooting common compressor issues and optimizing air delivery.

- Drill String Dynamics: Analyzing the behavior of the drill string under different operating conditions, including bit selection, weight on bit, and rotational speed. Problem-solving involves recognizing and addressing issues like vibrations and stuck pipe.

- Hole Cleaning and Formation Evaluation: Understanding the importance of efficient cuttings removal and the techniques employed. This includes interpreting air pressure readings and identifying potential formation issues.

- Safety Procedures and Regulations: Deep understanding of safety protocols, emergency response plans, and regulatory compliance related to air rotary drilling operations. This is crucial for both practical application and interview success.

- Environmental Considerations: Familiarity with environmental regulations and best practices for minimizing the environmental impact of air rotary drilling operations. This demonstrates a commitment to responsible operations.

- Data Acquisition and Interpretation: Understanding how data is collected during drilling operations (e.g., air pressure, rate of penetration) and how to interpret this data to optimize drilling performance and efficiency.

Next Steps

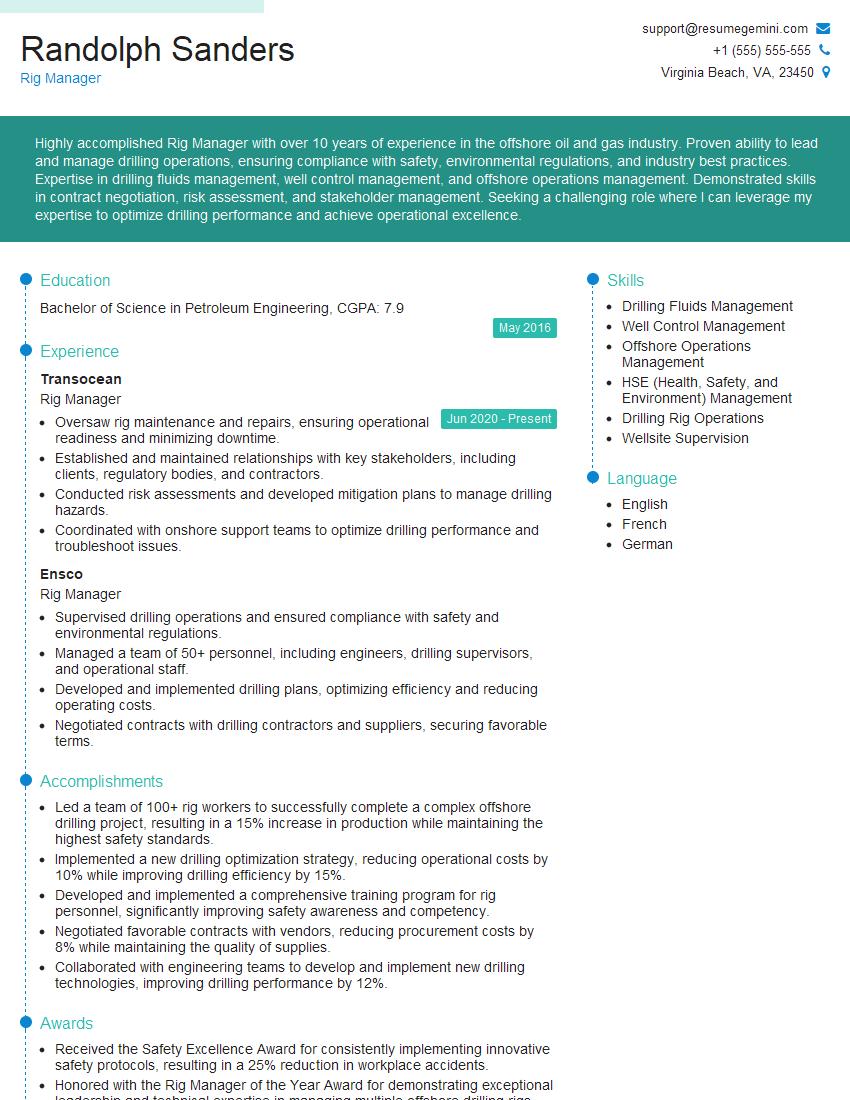

Mastering Air Rotary Drilling opens doors to exciting career opportunities in the energy sector, offering competitive salaries and chances for professional growth and advancement. To maximize your job prospects, it’s crucial to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can help you build a professional resume that stands out to recruiters. We offer examples of resumes tailored specifically to the Air Rotary Drilling industry to give you a head start. Invest time in crafting a compelling resume – it’s your first impression and a critical step in landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO