Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important American Welding Society (AWS) interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in American Welding Society (AWS) Interview

Q 1. Explain the difference between AWS D1.1 and AWS D1.3.

AWS D1.1 and AWS D1.3 are both structural welding codes published by the American Welding Society, but they cover different types of structures. Think of them as specialized instruction manuals for welders.

AWS D1.1: This standard focuses on structural steel welding for buildings and bridges. It details requirements for welding procedures, welder qualifications, and inspection of various steel types commonly used in these structures. Imagine building a skyscraper – D1.1 would be your guide for safely and correctly welding the steel framework.

AWS D1.3: This code addresses the welding of sheet and light gauge structures. This could include things like automotive bodies, pressure vessels, or smaller-scale metal fabrications. It’s like having a separate manual for building a car frame instead of a skyscraper. While both deal with steel, D1.3 often deals with thinner materials and potentially different welding processes.

The key difference lies in the application. D1.1 deals with heavier structural applications requiring rigorous strength and stability considerations, while D1.3 covers lighter gauge materials where the design criteria and welding processes might differ.

Q 2. Describe the various types of welding defects and their causes.

Welding defects are imperfections in a weld that compromise its strength, integrity, or appearance. They can stem from various causes, including improper welding technique, faulty equipment, or unsuitable base materials. Think of it like baking a cake – if you don’t follow the recipe or use bad ingredients, the cake will be flawed.

- Porosity: Small holes or voids within the weld metal, often caused by gases trapped during solidification. Imagine tiny bubbles in your weld.

- Cracks: Breaks or fissures in the weld metal, often resulting from stresses created during cooling or from hydrogen embrittlement. Like a crack in a vase, it weakens the structure.

- Undercut: A groove melted into the base metal adjacent to the weld, caused by excessive heat input or improper welding technique. Think of a small channel eroded next to the weld.

- Lack of Fusion: The weld metal fails to completely fuse with the base metal, creating a weak spot. Imagine two pieces of metal only touching at the edges.

- Slag Inclusion: Non-metallic material trapped within the weld metal, originating from the welding process (e.g., flux). Similar to finding pebbles in your cake batter.

- Incomplete Penetration: The weld does not extend fully through the joint, leaving a portion unwelded. Like two pieces of bread with a filling that doesn’t connect them entirely.

Causes of these defects can include incorrect welding parameters (current, voltage, travel speed), poor joint preparation, contaminated base materials, improper shielding gas, or lack of welder skill.

Q 3. What are the different welding processes covered by AWS standards?

AWS standards cover a wide array of welding processes, each with its own strengths and limitations. These processes are chosen based on the material being welded, the joint design, and the desired properties of the final weld.

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, uses a consumable electrode coated with flux to protect the weld from atmospheric contamination.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, uses a continuously fed consumable electrode and a shielding gas (usually argon or CO2) to protect the weld.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, utilizes a non-consumable tungsten electrode and a shielding gas to produce a high-quality weld.

- Flux-Cored Arc Welding (FCAW): Similar to GMAW, but the electrode contains a flux core that provides shielding and deoxidizing properties.

- Submerged Arc Welding (SAW): A high-productivity process where the weld is submerged in a blanket of flux, shielding it from the atmosphere.

The choice of process depends heavily on the application. For example, SMAW is portable and relatively inexpensive, making it suitable for field work, while GTAW provides superior weld quality but demands more skill and precision.

Q 4. How do you interpret a welding symbol?

Welding symbols are a standardized way of conveying detailed welding instructions in a concise graphical format. They provide crucial information about the weld type, dimensions, and other specifications required by the welder. Think of it as a blueprint for the weld.

A typical welding symbol includes:

- Reference Line: The horizontal line from which other elements originate.

- Arrow Side: The side of the joint to which the symbol applies.

- Other Side: Indicates if a similar weld is needed on the opposite side of the joint (often indicated by a tail or a symbol).

- Basic Weld Symbol: Identifies the type of weld (e.g., fillet weld, groove weld).

- Dimensions: Indicates weld size, length, etc.

- Specification: Refers to specific requirements for the weld process, material, and other aspects.

By understanding the components, you can decipher the symbol and ensure proper weld execution. For example, a symbol with a specific dimension near the reference line indicates the size of a fillet weld on the arrow side only, while adding a tail on the other side indicates a similar weld should be applied there. More complex symbols might include specifications such as the required welding process or the type of filler material. Proper interpretation prevents costly rework and safety issues.

Q 5. Explain the importance of pre-heating and post-heating in welding.

Pre-heating and post-heating are crucial steps in many welding operations, particularly when welding thicker materials or those susceptible to cracking. They are thermal treatments applied before and after the welding process to manage residual stresses and prevent defects. Consider them as stress management techniques for metal.

Pre-heating: This involves heating the base metal to a specific temperature before welding. It lowers the cooling rate, reducing the formation of hard, brittle microstructures and the risk of cracking, especially in high-carbon steels. Imagine warming up a metal before bending it to prevent it from breaking.

Post-heating: This involves heating the weldment after welding to reduce residual stresses, preventing cracking and improving toughness. It’s like a relaxing massage for the weld, reducing any internal tension built up during the welding process.

The specific temperatures and durations for pre-heating and post-heating depend on the material, thickness, and welding process. Improper application can lead to defects like cold cracking or other metallurgical issues, highlighting the importance of following the specified procedures. The parameters are often determined based on the specific material and welding process according to AWS recommendations.

Q 6. Describe the different levels of AWS certifications.

AWS certifications demonstrate a welder’s competency and adherence to industry best practices. They are crucial for ensuring consistent quality and safety in welding applications. These certifications are earned through rigorous testing and verification processes.

Levels can vary based on the specific certification (e.g., structural welding, pipe welding), but generally include:

- Welder Certification: Demonstrates a welder’s ability to perform a specific welding process to a specific standard, usually involving practical tests.

- Welding Inspector Certification: Verifies competency in inspecting welds for conformance to codes and standards.

- Senior Welding Inspector Certification: Requires more extensive knowledge, experience, and a proven track record in weld inspection and quality control.

- Welding Engineer Certification: This level requires a detailed understanding of welding metallurgy, design, and engineering principles.

The specific requirements and levels of certification may vary depending on the specific AWS certification program. Higher levels often involve more extensive training, experience requirements, and more rigorous examinations.

Q 7. What are the essential safety precautions for welding?

Welding poses significant safety hazards if proper precautions are not followed. It’s essential to treat welding with the respect it deserves.

- Eye and Face Protection: Always wear appropriate eye and face shields to protect against sparks, spatter, and ultraviolet radiation.

- Respiratory Protection: Welding fumes can be toxic, necessitating the use of respirators in poorly ventilated areas.

- Protective Clothing: Wear flame-resistant clothing to protect against burns and sparks.

- Fire Prevention: Keep flammable materials away from the welding area, and have fire extinguishers readily available.

- Proper Ventilation: Ensure adequate ventilation to remove welding fumes and prevent the buildup of hazardous gases.

- Electrical Safety: Use appropriate electrical grounding and isolation techniques to prevent electrical shock.

- Hot Work Permits: In industrial settings, obtain necessary hot work permits to ensure the area is safe for welding operations.

- First Aid and Emergency Procedures: Be aware of emergency procedures and have a first-aid kit nearby.

Prioritizing safety is paramount in welding. Failure to adhere to safety protocols can lead to severe injuries, property damage, or even fatalities. It’s not just about the right equipment, it’s about the commitment to safety at every step.

Q 8. How do you ensure weld quality and compliance with AWS standards?

Ensuring weld quality and compliance with AWS standards is paramount for safety and structural integrity. It’s a multi-faceted process that starts even before welding begins. We must first select the appropriate AWS standard for the specific application – this dictates the materials, processes, and testing requirements. For example, AWS D1.1 covers structural welding code, while AWS A5.1 covers filler metals.

Next, we meticulously follow the specified procedures, which include:

- Proper Material Selection: Using materials that meet the specified chemical composition and mechanical properties per the AWS standard.

- Qualified Welders and Welding Procedures: Employing welders who have successfully passed AWS-approved tests for the specific welding process and base material. We also must have a qualified welding procedure specification (WPS) that details parameters like amperage, voltage, and travel speed.

- Visual Inspection: This is the cornerstone of weld quality control, inspecting for defects like cracks, undercuts, porosity, and excessive spatter.

- Non-Destructive Testing (NDT): This might involve radiographic testing (RT), ultrasonic testing (UT), or magnetic particle inspection (MPI) to detect internal flaws unseen to the naked eye. The type of NDT depends on the weld’s criticality and the requirements of the relevant AWS standard.

- Documentation: Maintaining comprehensive records of every step, including WPS, welder qualifications, inspection results, and any corrective actions. A well-maintained welding log is essential for traceability and auditing.

Ultimately, adherence to the selected AWS standard and a robust quality control plan assures that the welds meet the necessary strength, durability, and safety requirements. Think of it like building a house – you wouldn’t skimp on inspections or use substandard materials; welding is no different.

Q 9. What are the different types of weld joints and their applications?

Weld joints are the interfaces where two or more pieces of metal are joined together through welding. The type of joint selected depends on factors like the geometry of the parts, the accessibility of the joint, and the required strength. Some common weld joints and their applications include:

- Butt Joint: The edges of the two parts are joined end-to-end. Used extensively in pipelines and structural steel fabrication.

- Lap Joint: The edges of the two parts overlap. Often used in sheet metal work, where full penetration is not always necessary.

- T-Joint: One part is perpendicular to the other, creating a ‘T’ shape. Frequently found in structural welding where members are joined at angles.

- Corner Joint: Two parts meet at a corner, forming a right angle. Commonly used in boxes and containers.

- Edge Joint: The edges of the two parts are joined side-by-side. Frequently employed in joining thin sheets.

Selecting the appropriate weld joint is crucial for optimization of the weld process and overall structure’s performance. For instance, a butt joint provides maximum strength, whereas a lap joint might be chosen for ease of welding.

Q 10. Explain the concept of weld penetration and its significance.

Weld penetration refers to the depth to which the weld extends into the base metal. It’s a critical factor that significantly influences the weld’s strength, integrity, and ability to withstand stress. Sufficient penetration is essential for achieving the required joint strength. Insufficient penetration leads to a weakened weld, making it susceptible to failure.

Think of it like this: imagine trying to join two wooden planks with only a thin layer of glue on the surface. The joint would be weak, likely breaking easily. Full penetration, on the other hand, ensures the planks are fused together throughout their thickness providing robust connection.

Factors affecting weld penetration include the welding process (e.g., GMAW, SMAW), the amperage and voltage settings, the travel speed, and the type of filler metal. AWS standards specify minimum penetration requirements for different applications, and proper procedures and quality control are needed to ensure these requirements are consistently met.

Q 11. Describe the different types of welding filler metals and their uses.

Welding filler metals are crucial materials that fill the gap between the base metals being joined, solidifying to form the weld. The type of filler metal used is selected based on the base metal’s composition and the welding process. Several types include:

- Solid Wire: Available in various diameters and compositions, commonly used in GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding).

- Electrodes (SMAW): Coated rods containing flux and filler metal, used in SMAW (Shielded Metal Arc Welding). The coating provides shielding gas and slag protection.

- Rods: Similar to electrodes but often used in specialized welding processes like gas welding.

- Filler Metal Alloys: Specific compositions are tailored for different base metals and applications, such as stainless steel filler metals for stainless steel joints or high-nickel alloys for high-temperature applications.

AWS provides detailed specifications for filler metals, including their chemical composition, mechanical properties, and approval ratings, ensuring compatibility and consistent weld quality. Choosing the incorrect filler metal can lead to weld defects, poor strength, and corrosion issues. The AWS A5 series of standards provides specific requirements for filler metals of varying types.

Q 12. What is the role of a Welding Inspector according to AWS standards?

According to AWS standards, a Welding Inspector plays a crucial role in ensuring weld quality, safety, and compliance. Their responsibilities include:

- Interpreting Welding Codes and Standards: Understanding the relevant AWS standards and codes to determine the correct requirements for a specific welding job.

- Pre-weld Planning: Reviewing welding procedures and drawings to ensure they meet the necessary standards before welding begins.

- Inspection and Testing: Performing visual inspections and overseeing or conducting NDT methods, such as RT, UT, or MPI, to evaluate weld quality.

- Documentation and Reporting: Maintaining thorough records of inspections, testing results, and any non-conformances.

- Qualification of Welders and Welding Procedures: Verifying that welders possess the necessary qualifications and that welding procedures are properly qualified.

- Corrective Actions: Identifying and recommending corrective actions for non-conforming welds.

The inspector is the gatekeeper of quality, ensuring that all welding activities are executed correctly and meet required standards. They contribute significantly to preventing failures and ensuring structural safety.

Q 13. How do you handle non-conforming welds?

Handling non-conforming welds is a critical aspect of welding quality control. The approach involves a systematic process that begins with identification, followed by investigation, and finally corrective action or repair.

1. Identification: Through visual inspection and NDT, the welding inspector identifies the non-conforming weld. This includes documenting the type and location of the defect.

2. Investigation: The cause of the non-conformity needs to be thoroughly determined. Was it due to improper welder technique, faulty equipment, incorrect material, or a flawed WPS? This investigation is essential for implementing corrective actions and preventing future occurrences.

3. Corrective Action: Depending on the severity and location of the defect, several options exist: repair, rework, or removal and replacement. Repair procedures must be documented, approved, and executed by qualified personnel. For critical welds, the repaired area must be re-inspected and re-tested to ensure it meets the required standards.

4. Documentation: Every step, from identification to repair and reinspection, must be meticulously documented. This documentation is vital for traceability and demonstrates adherence to quality control procedures. The records may be subject to audits.

The process should be compliant with the relevant AWS standard and any company-specific procedures. Failure to address non-conforming welds correctly can lead to structural failures and safety hazards.

Q 14. Explain the different types of destructive and non-destructive testing methods used in welding.

Both destructive and non-destructive testing methods are used to evaluate weld quality. Destructive methods involve the destruction of a sample to determine its properties, while non-destructive methods evaluate the weld without causing damage.

Destructive Testing (DT):

- Tensile Testing: Determines the weld’s strength and ductility by applying a tensile load until failure.

- Bend Testing: Evaluates the weld’s ductility and toughness by bending the sample. Various bend tests, such as side bend, face bend, and root bend, exist, each assessing different aspects of the weld.

- Impact Testing: Measures the weld’s ability to absorb impact energy, essential for welds operating under dynamic loading.

- Hardness Testing: Measures the weld’s hardness, offering insights into its strength and resistance to wear.

Non-Destructive Testing (NDT):

- Visual Inspection (VT): The most fundamental method, involving visual examination of the weld for surface defects.

- Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal defects like cracks, porosity, and slag inclusions.

- Ultrasonic Testing (UT): Employs high-frequency sound waves to detect internal defects and measure weld thickness.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface defects in ferromagnetic materials by magnetizing the sample and applying magnetic particles.

- Liquid Penetrant Inspection (LPT): Detects surface-breaking defects by applying a penetrant that seeps into the defect and is revealed by a developer.

The choice of testing method depends on the weld’s criticality and the type of defects anticipated. Often, a combination of DT and NDT methods is employed to provide a comprehensive assessment of weld quality.

Q 15. What are the common causes of weld porosity and cracking?

Weld porosity and cracking are significant defects that compromise the integrity of a weld. Porosity, the presence of small holes, weakens the weld’s strength and can lead to leaks in pressure vessels or pipelines. Cracking, on the other hand, represents a fracture within the weld metal, drastically reducing its load-bearing capacity. Both issues stem from several interconnected causes.

- Porosity: Often caused by gas entrapment during welding. This can result from insufficient purging of shielding gas, moisture in the base material or filler metal, or the presence of oil or grease. For example, a welder failing to properly clean the joint before welding can introduce contaminants that cause porosity. Another common cause is using an improper shielding gas or insufficient gas flow rate, leading to atmospheric contamination of the weld pool.

- Cracking: Can occur due to high residual stresses in the weld, hydrogen embrittlement, or improper metallurgical transformation of the base material. Residual stresses develop during the cooling process after welding. Hydrogen, a common contaminant in welding, can cause brittle cracking. The improper choice of filler metal, not matching the base metal’s composition, can also lead to cracking. For instance, using a high-carbon filler metal on a low-carbon steel base can result in cracking because of the heat-affected zone’s rapid cooling and associated stresses.

Identifying and addressing the root causes—proper surface preparation, using appropriate shielding gas and flow rates, choosing the right filler metal, and controlling the welding parameters—are crucial to prevent these defects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate welding parameters (voltage, amperage, etc.)?

Selecting appropriate welding parameters is critical for achieving a high-quality weld. These parameters, including voltage, amperage, travel speed, and electrode stick-out, interact in complex ways. The choice depends on several factors including the base material’s thickness and type, the filler material used, and the desired weld profile.

The process generally begins with referencing AWS standards and manufacturer’s recommendations for specific materials. For example, welding thicker sections of steel requires higher amperage and voltage to achieve sufficient penetration. The choice between a higher voltage and lower amperage or vice-versa influences the heat input into the weld. A higher heat input could lead to excessive heat-affected zone and possibly cracking, while a lower heat input could result in insufficient penetration or incomplete fusion.

Practical experience and knowledge of the equipment are crucial. Often a welder begins with a trial weld, adjusting the parameters based on the resulting weld bead. For instance, if the bead is too narrow, the amperage might be increased. If it’s overly wide or has excessive spatter, then the amperage needs to be reduced or the travel speed increased. This iterative process fine-tunes the parameters to yield an acceptable weld profile consistent with the specified requirements.

Q 17. Describe your experience with different types of welding equipment.

My experience encompasses a broad range of welding equipment, from traditional manual processes to advanced automated systems. I am proficient with various types of equipment:

- Shielded Metal Arc Welding (SMAW): Extensive experience using various electrode types (e.g., 6010, 6011, 7018) for different applications, from structural steel to pipe welding.

- Gas Metal Arc Welding (GMAW): Proficient in both short-circuiting and pulsed GMAW, including experience with different shielding gases and wire feeds, suitable for a range of materials including aluminum and stainless steel.

- Gas Tungsten Arc Welding (GTAW): Skilled in both AC and DC GTAW, with experience in precision welding of thin-gauge materials and applications requiring high-quality finishes.

- Flux-Cored Arc Welding (FCAW): Familiar with both self-shielded and gas-shielded FCAW, often employed for outdoor applications due to its robustness.

- Automated Welding Systems: I have worked with robotic welding systems, including programming and setup, for high-volume production welding.

My expertise extends beyond the operation of these systems. I understand the maintenance requirements and troubleshooting procedures associated with each type of equipment.

Q 18. Explain the importance of maintaining welding equipment.

Maintaining welding equipment is paramount for safety, productivity, and weld quality. Neglecting maintenance can lead to equipment failure, resulting in downtime, potential injury, and defective welds. A well-maintained system produces consistent welds, reducing rework and improving efficiency.

- Regular Inspections: Visual inspections are crucial, checking for cable damage, worn parts, and any signs of leakage in gas lines. Regular checks on gas regulators for proper pressure are essential for safety and consistent welding.

- Preventative Maintenance: This involves scheduled cleaning, lubrication, and replacement of worn components, like contact tips and drive rolls. This minimizes the risk of sudden failures and extends the equipment’s lifespan.

- Safety Checks: Regular checks of grounding connections and electrical insulation are critical to prevent electrical shocks. This is especially important for systems operating at high voltages.

- Calibration: Periodic calibration of equipment, such as flow meters and current meters, ensures accuracy and consistency in the welding process. For example, a malfunctioning flow meter could lead to insufficient shielding gas and compromised welds.

A structured maintenance program, following manufacturer’s recommendations, minimizes unexpected issues, contributing to efficient and safe welding operations.

Q 19. How familiar are you with AWS A5.1 and its significance?

AWS A5.1 is a crucial specification covering filler metals for welding and brazing. It details the classification, chemical requirements, and mechanical properties of various filler metals used in a wide range of applications. Its significance lies in ensuring the consistent quality and performance of welds.

The standard provides a comprehensive catalog of filler metals, categorized by their chemical composition and mechanical properties. This allows welders to select the appropriate filler metal based on the base material, the application’s requirements, and the welding process. For example, choosing a filler metal with appropriate tensile strength and impact resistance for a structural application is critical to ensuring its durability and safety.

Compliance with AWS A5.1 is often a contractual requirement for many projects, demonstrating commitment to quality and adherence to industry best practices. It facilitates traceability and ensures that the filler metal used meets the specified performance standards. Understanding and applying this standard is foundational for any professional welder.

Q 20. What is the significance of the WPS (Welding Procedure Specification)?

A Welding Procedure Specification (WPS) is a documented procedure outlining the parameters and techniques for performing a specific weld. It serves as a blueprint, ensuring consistent and high-quality welds across multiple welds and welders. Its significance lies in its role in assuring weld quality and reproducibility.

A WPS typically details the welding process (e.g., GMAW, SMAW), base material type and thickness, filler metal, shielding gas, amperage, voltage, travel speed, pre-heat temperature (if required), and post-weld heat treatment (PWHT) requirements. It also specifies the necessary inspection and testing to validate the weld’s quality. This detailed information ensures that welders consistently produce welds that meet the required standards.

Using a validated WPS is crucial for compliance with industry codes and standards. Many projects require WPS approval as a part of the quality assurance process. Using a pre-qualified WPS is faster and cost effective than creating one from scratch.

Q 21. How do you interpret and apply a PQR (Procedure Qualification Record)?

The Procedure Qualification Record (PQR) documents the results of qualification tests performed to validate a WPS. It provides objective evidence that the welding procedure produces welds meeting the specified mechanical and metallurgical requirements. Essentially, it’s the ‘proof’ that the WPS works as intended.

Interpreting a PQR involves reviewing the test results against the acceptance criteria specified in the relevant codes and standards (e.g., ASME Section IX). Key parameters in a PQR include tensile strength, yield strength, elongation, hardness, and macro/microstructures. These values are compared to the acceptance criteria specified in the WPS.

Applying a PQR means ensuring that future welds made using the corresponding WPS meet or exceed the same qualified performance levels. Any deviation from the PQR’s documented parameters requires requalification of the WPS, which may involve re-testing. The PQR provides the crucial link between the welding process, the expected weld quality, and compliance with industry regulations.

Q 22. Describe your experience with different types of base materials.

My experience encompasses a wide range of base materials, crucial for selecting appropriate welding processes and consumables. This includes various steels – from low-carbon mild steel commonly used in construction to high-strength low-alloy (HSLA) steels found in bridges and pressure vessels; stainless steels, categorized by their chromium content and further differentiated by their austenitic, ferritic, or martensitic microstructures, each requiring specific welding techniques to avoid issues like sensitization or cracking; aluminum and its alloys, requiring specialized procedures due to their high thermal conductivity and susceptibility to porosity; and finally, various non-ferrous metals like titanium and nickel alloys, demanding meticulous control of the welding process due to their reactivity and stringent quality requirements. I’ve worked extensively with AWS specifications, such as AWS A5.1 (Carbon Steel electrodes) and AWS A5.9 (Nickel electrodes), to ensure material compatibility and weld integrity in each application. For instance, when working with stainless steel, I’ve successfully utilized TIG welding with appropriate filler metals to prevent chromium carbide precipitation and maintain corrosion resistance.

- Mild Steel: Extensive experience with GMAW (MIG) and SMAW (Stick) welding.

- Stainless Steel: Proficiency in GTAW (TIG) and GMAW (MIG) with pulsed current techniques for superior control.

- Aluminum: Expertise in GTAW (TIG) using AC current and specialized filler metals.

- High-Strength Low-Alloy Steels: Experience with advanced techniques like FCAW (Flux-cored arc welding) for improved weld quality.

Q 23. How do you select the correct welding consumables for a particular application?

Selecting the right welding consumables is paramount for achieving a strong, reliable, and defect-free weld. The selection process depends entirely on the base material, the desired weld properties, the welding process, and the environmental conditions. It’s a multi-faceted decision, often guided by AWS standards. For instance, the AWS A5.X series specifies filler metals for various applications. I always begin by identifying the base material’s chemical composition and mechanical properties. Then, I consider the required weld strength, toughness, and corrosion resistance. The chosen welding process influences the type of consumable needed; for example, MIG welding will use solid or flux-cored wire, while TIG welding requires specific filler rods. Finally, environmental factors such as exposure to corrosive elements might necessitate using specialized filler metals with improved corrosion resistance. It’s a methodical approach, almost like choosing the right ingredients for a recipe; you wouldn’t use sugar in a savory dish, right? Similarly, incorrect consumable selection can lead to poor weld quality, potential cracking, and failure. A practical example: When welding high-strength low-alloy steel in a sub-zero environment, I’d choose a low-hydrogen electrode (like E7018) to minimize the risk of hydrogen cracking.

Q 24. Explain the importance of proper weld cleaning and surface preparation.

Proper weld cleaning and surface preparation are fundamental for achieving high-quality, reliable welds. Think of it as preparing the ground before building a house; if the foundation is flawed, the entire structure will be compromised. Surface contaminants like oxides, scale, paint, grease, or moisture can significantly weaken the weld metal’s bond to the base material, leading to porosity, cracking, and other defects. AWS D1.1 provides detailed guidance on these aspects. My approach involves a multi-step process: first, removing all visible contaminants using mechanical methods such as wire brushing, grinding, or sandblasting; then, a thorough cleaning with solvents to remove any remaining grease or oil; lastly, sometimes chemical cleaning, such as pickling or etching, may be necessary for specific materials like stainless steel to remove surface oxides. The surface finish must be suitable for the chosen welding process, with appropriate roughness and cleanliness levels. Neglecting this step can lead to catastrophic weld failures. I once encountered a case where insufficient surface preparation on stainless steel led to significant intergranular corrosion, requiring a costly rework.

Q 25. Describe your experience with managing a welding team.

My experience in managing welding teams emphasizes safety, training, and fostering a collaborative environment. I’ve led teams ranging from small, specialized units to larger crews on complex projects. A key aspect of my management style is proactive safety training and enforcement. This includes regular safety meetings, practical demonstrations, and the rigorous adherence to established safety protocols, PPE requirements, and lockout/tagout procedures. Furthermore, I focus on continuous improvement through ongoing skill development. This often involves providing opportunities for training on new welding techniques, certifications (like AWS certifications), and participation in workshops. I strive to create a team environment based on open communication, trust, and mutual respect, where each member feels comfortable contributing ideas and addressing concerns. Motivation and recognition are crucial; acknowledging individual and team achievements promotes a sense of pride and shared responsibility. A successful team, in my view, is one that not only meets project goals but also prioritizes safety and personal growth.

Q 26. How do you handle conflict resolution in a welding environment?

Conflict resolution in a welding environment demands a calm, fair, and decisive approach. Most conflicts stem from misunderstandings, communication breakdowns, or differences in work styles. My approach involves active listening, understanding the root cause of the conflict, and creating a safe space for all parties to express their concerns. I always aim to remain neutral and objective, focusing on finding a solution that addresses everyone’s needs. Sometimes, mediation might be necessary, especially with disagreements involving technical aspects of welding. This involves consulting relevant codes and standards (like AWS D1.1) to ensure the decision is technically sound and aligns with best practices. In cases of serious violations of safety protocols or company policy, decisive and firm action is taken, always ensuring due process and fairness. The goal is to resolve conflicts constructively, improving communication, and building a stronger, more harmonious team.

Q 27. Describe your experience with implementing quality control measures in a welding operation.

Implementing quality control measures is essential for delivering consistently high-quality welds. My approach involves a multi-layered strategy: starting with meticulous planning and process definition. This includes establishing clear welding procedures, specifying the required consumables and parameters, and documenting all aspects of the welding process. During the welding process, regular inspections are conducted to monitor weld quality, ensuring adherence to standards. This includes visual inspections for defects like porosity, cracks, or undercut and using non-destructive testing (NDT) methods such as radiographic testing (RT) or ultrasonic testing (UT) for hidden defects. After welding, destructive testing might be necessary to verify weld strength and other mechanical properties. All inspection results are meticulously documented, creating a comprehensive record of the welding process and ensuring traceability. Continuous monitoring and improvement are key to maintaining high-quality standards, using data analysis to identify trends and improve procedures. This proactive approach prevents defects and minimizes rework, ultimately enhancing the project’s overall quality and efficiency.

Q 28. How would you deal with a critical weld failure in a project?

Dealing with a critical weld failure requires a systematic and thorough investigation to determine the root cause and prevent future occurrences. The immediate step is to secure the affected area and prevent further damage. Then, a detailed investigation is launched, involving a thorough review of welding procedures, inspection records, and NDT results. This might involve consultation with metallurgical experts or failure analysis specialists. Once the root cause is identified (e.g., incorrect consumable selection, inadequate surface preparation, or procedural errors), corrective actions are implemented to address the issue, which may involve re-welding the failed joint or redesigning the component. Lessons learned from the failure are documented and used to improve procedures, training, and quality control systems. This proactive approach turns a setback into an opportunity for improvement. In one instance, a weld failure analysis revealed flaws in the pre-heating procedure, leading to significant improvements in our welding protocols and improved welder training.

Key Topics to Learn for American Welding Society (AWS) Interview

Preparing for an AWS-related interview requires a solid understanding of welding theory and practice. Focus your studies on these key areas to showcase your expertise and impress potential employers:

- Welding Processes: Understand the principles behind various welding processes (SMAW, GMAW, GTAW, etc.), including their applications, advantages, and limitations. Consider exploring the nuances of each process, including arc characteristics and metal transfer mechanisms.

- Welding Metallurgy: Grasp the metallurgical changes that occur during welding, including the formation of different microstructures and their impact on mechanical properties. Be prepared to discuss heat-affected zones (HAZ) and their significance in weld quality.

- Welding Codes and Standards: Familiarize yourself with relevant AWS standards and codes, such as those related to weld symbols, qualifications, and testing procedures. Understanding how these codes ensure safety and quality is crucial.

- Weld Inspection and Testing: Learn about various non-destructive testing (NDT) methods used to assess weld quality, including visual inspection, radiographic testing (RT), ultrasonic testing (UT), and magnetic particle testing (MT). Be ready to discuss the strengths and limitations of each method.

- Safety and Health: Demonstrate a strong understanding of welding safety procedures and personal protective equipment (PPE). Discuss common hazards associated with welding and how to mitigate them effectively.

- Practical Problem-Solving: Prepare to discuss how you approach challenges encountered in welding. Focus on your problem-solving skills, including troubleshooting techniques, analytical thinking, and your ability to find creative solutions to welding defects.

- AWS D1.1 Structural Welding Code: Depending on the role, a deep understanding of this code and its implications might be essential. Focus on sections related to your area of expertise.

Next Steps

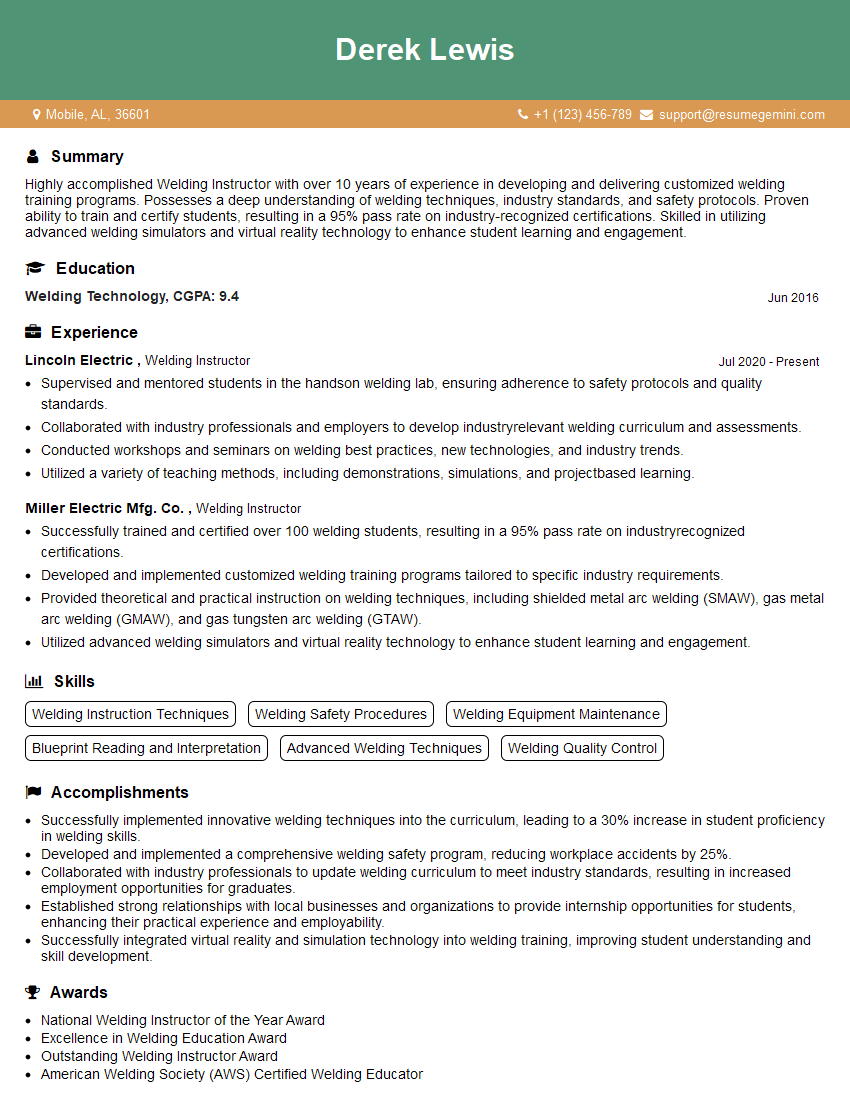

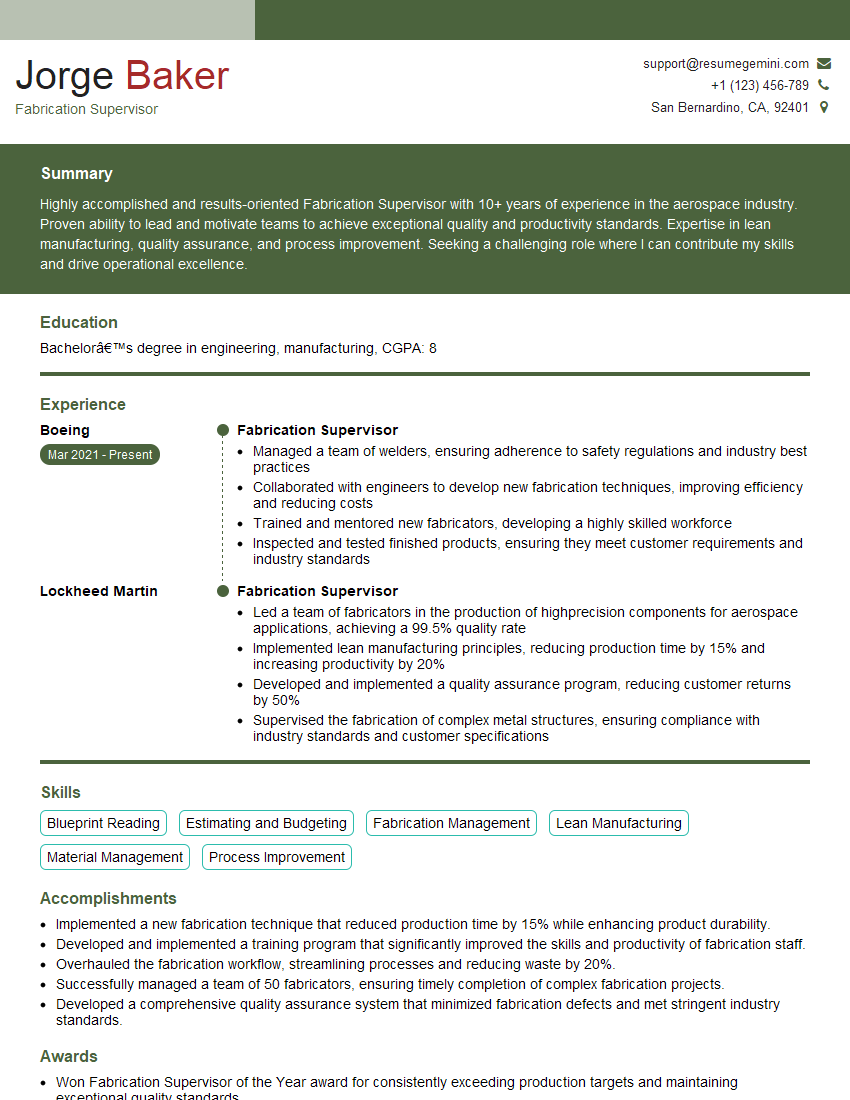

Mastering the principles and applications of the American Welding Society standards is vital for career advancement in the welding industry. It demonstrates your commitment to quality, safety, and professional excellence. To increase your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of the welding industry. Examples of resumes tailored to American Welding Society (AWS) roles are available to guide you. Invest in your professional presentation – it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO