Cracking a skill-specific interview, like one for Appliances, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Appliances Interview

Q 1. Explain the different types of appliance compressors and their applications.

Appliance compressors are the heart of refrigeration and air conditioning systems. They’re responsible for circulating refrigerant, which absorbs heat from the inside of the appliance and releases it outside. There are several types, each suited for different applications:

- Reciprocating Compressors: These are the most common type, using a piston to compress the refrigerant. They’re known for their relatively simple design, durability, and cost-effectiveness. You’ll find these in many household refrigerators and freezers.

- Rotary Compressors: These use a rotating mechanism to compress the refrigerant. They tend to be smaller, quieter, and more energy-efficient than reciprocating compressors, making them popular in smaller appliances like mini-fridges and some air conditioners.

- Scroll Compressors: These use two spiral-shaped components to compress the refrigerant. They are exceptionally quiet, energy-efficient, and reliable, often found in high-end refrigerators and some air conditioners.

- Screw Compressors: These use two intermeshing helical screws to compress the refrigerant. They’re designed for high-volume applications, such as large commercial refrigeration systems and industrial chillers.

- Linear Compressors: These utilize a linear motor to move a piston back and forth. They are extremely quiet and efficient, often found in high-end and energy-efficient appliances.

The choice of compressor depends on factors like the appliance’s size, desired energy efficiency, noise level requirements, and cost considerations. For example, a large commercial freezer would likely utilize a screw compressor for its high capacity, while a residential refrigerator might use a reciprocating or scroll compressor for its balance of performance and cost.

Q 2. Describe the troubleshooting steps for a refrigerator not cooling properly.

Troubleshooting a refrigerator that’s not cooling properly requires a systematic approach. First, check the obvious:

- Is the refrigerator plugged in? This sounds simple, but it’s the first thing to check!

- Is the thermostat set correctly? Make sure it’s turned to a sufficiently cold setting.

- Is the condenser coil clean? Dust buildup restricts airflow, reducing cooling efficiency. Clean the coils with a vacuum cleaner brush attachment.

- Is the door sealing properly? A poorly sealing door lets warm air in, forcing the compressor to work harder. Check for any gaps or damage around the seals.

If these don’t solve the problem, more advanced troubleshooting is needed:

- Check the compressor’s operation: Listen for the compressor to kick on and off. If it’s not running at all, there could be an electrical issue. If it runs constantly, there might be a refrigerant leak or a problem with the thermostat.

- Check the evaporator fan: Make sure the fan inside the freezer compartment is running. This circulates cold air throughout the refrigerator.

- Check the defrost system (automatic defrost models): Ensure the defrost heater and defrost timer are functioning correctly. Inadequate defrosting can lead to ice buildup, hindering cooling.

If you’re not comfortable performing these checks, it’s best to call a qualified appliance repair technician to avoid further damage or injury.

Q 3. How do you diagnose and repair a malfunctioning washing machine drain pump?

Diagnosing and repairing a malfunctioning washing machine drain pump involves several steps:

- Unplug the washing machine: Safety first! Always disconnect the power before working on any appliance.

- Locate the drain pump: This is usually located at the bottom front of the machine, often behind an access panel.

- Check for obstructions: Inspect the pump and the drain hose for clogs. Remove any foreign objects like coins, buttons, or small toys.

- Inspect the pump impeller: The impeller is a rotating part that pumps the water out. Check for damage or blockages. Sometimes, a small item might be lodged behind the impeller.

- Test the pump motor: Use a multimeter to check the pump motor’s continuity. If it’s not functioning, the motor might need replacement.

- Check the drain hose: Ensure the drain hose isn’t kinked or blocked. A partially blocked hose can restrict the flow of water.

Repairing the pump typically involves replacing the faulty component. If the problem is a simple clog, removing the obstruction will suffice. Otherwise, a new drain pump will likely be required. Refer to your washing machine’s service manual for specific instructions and part numbers.

Q 4. What are the common causes of a dishwasher not cleaning effectively?

A dishwasher not cleaning effectively can be frustrating. Here are some common culprits:

- Low detergent levels: Make sure you’re using the correct amount of detergent, according to the manufacturer’s instructions.

- Clogged spray arms: Food particles and debris can clog the spray arms, preventing proper water distribution. Remove and thoroughly clean the spray arms.

- Dirty filter: A dirty filter restricts water flow and reduces cleaning power. Clean the filter regularly, following the dishwasher’s manual.

- Hard water: Hard water leaves mineral deposits that can affect cleaning and contribute to spotting. Consider using a water softener or adding a rinse aid.

- Improper loading: Overloading the dishwasher prevents proper water circulation and cleaning. Ensure dishes are loaded correctly, allowing space between them.

- Faulty heating element: If the water isn’t getting hot enough, the dishes won’t get clean. Test the heating element to see if it’s functioning.

Addressing these issues systematically should improve your dishwasher’s performance. If the problem persists, consult your dishwasher’s service manual or call a repair technician.

Q 5. Explain the safety procedures for working with electrical appliances.

Safety is paramount when working with electrical appliances. Always follow these procedures:

- Unplug the appliance: Before performing any repairs or maintenance, always disconnect the appliance from the power source. This prevents electrical shocks.

- Turn off the water supply: For appliances that use water, such as washing machines and dishwashers, turn off the water supply to prevent leaks and water damage.

- Use appropriate safety gear: Wear safety glasses and gloves to protect against injuries from sharp objects or electrical components.

- Never work on a live appliance: Always ensure the appliance is unplugged and the power is off before attempting any repairs.

- Be aware of potential hazards: Be mindful of sharp edges, hot surfaces, and moving parts. Use caution and take necessary precautions.

- Consult a professional if needed: If you are unsure about any repair procedure, consult a qualified appliance repair technician. Improper repairs can lead to further damage or safety hazards.

Remember, safety should always be your top priority when working with any electrical appliance.

Q 6. How do you handle a customer complaint about an appliance repair?

Handling customer complaints professionally is crucial. My approach involves:

- Active listening: Allow the customer to fully explain their complaint without interruption. Show empathy and understanding.

- Gather information: Ask clarifying questions to understand the problem thoroughly. Get details about the appliance, the issue, and when it started.

- Offer solutions: Depending on the nature of the complaint, propose solutions, such as scheduling a repair, offering a replacement part, or explaining how to resolve a minor issue.

- Set expectations: Be transparent about the timeline for resolving the issue. Keep the customer informed of the progress.

- Follow up: After the issue is resolved, follow up with the customer to ensure they’re satisfied. A simple phone call or email can make a big difference.

- Document everything: Keep detailed records of the complaint, the actions taken, and the outcome. This helps track issues and improve service.

I believe in treating every customer with respect and professionalism, aiming for a positive resolution that leaves the customer feeling valued and heard. Even if the complaint isn’t entirely valid, maintaining a courteous and professional manner is essential.

Q 7. Describe your experience with different types of appliance control systems.

My experience encompasses a wide range of appliance control systems, from simple mechanical controls to sophisticated electronic and microprocessor-based systems. I’ve worked with:

- Mechanical controls: These rely on simple mechanisms like dials, knobs, and timers. While less precise, they are reliable and easy to understand. Common in older appliances.

- Electronic controls: These use electronic components and printed circuit boards to control various functions. They offer greater precision and flexibility in controlling appliance functions.

- Microprocessor-based controls: These utilize microprocessors to manage complex operations, enabling features like self-diagnostics, error codes, and user-friendly interfaces. Common in modern appliances.

- Touchscreen interfaces: These provide intuitive and user-friendly control, with options for customizable settings and advanced functions.

- Smart appliance controls: These allow for remote control and monitoring via mobile apps or smart home systems. They provide enhanced convenience and energy efficiency.

My experience working with these diverse systems enables me to diagnose and repair a broad spectrum of appliance malfunctions effectively. Understanding the underlying control system is crucial for efficient troubleshooting and repair.

Q 8. What are the common causes of a dryer not heating?

A clothes dryer not heating is a common problem, usually stemming from a few key areas. Think of it like a car – it needs fuel (electricity), a spark (ignition), and a properly functioning engine (heating element) to run. In a dryer, these translate to:

- Faulty Heating Element: This is the most frequent culprit. Over time, the heating element, a coil of resistance wire, can burn out or become damaged, preventing heat generation. Think of it as a lightbulb burning out; it simply stops working.

- Bad Thermal Fuse: This safety device protects the dryer from overheating. If it’s blown, it cuts power to the heating element, preventing it from working. It’s a failsafe, kind of like a circuit breaker in your house.

- Defective High-Limit Thermostat: This thermostat monitors the dryer’s temperature. If it malfunctions, it may cut off power to the heating element prematurely or not allow it to turn on at all. It’s like a thermometer that’s reading wrong and causing the system to shut down.

- Problems with the Dryer’s Power Supply: This includes issues with the power cord, outlet, or even house wiring. Make sure the dryer is properly plugged in and receiving power; it’s the most basic yet often overlooked problem.

- Clogged Vent: A blocked vent restricts airflow, preventing the dryer from heating up properly. Lint buildup is a major culprit here. Think of it like a clogged pipe; the air can’t flow through properly.

Diagnosing the exact cause requires careful testing with a multimeter to check for voltage and continuity in the different components. However, a visual inspection of the heating element and vent for obvious damage or blockage is a good starting point.

Q 9. Explain the process of installing a new appliance.

Installing a new appliance is a multi-step process that prioritizes safety and proper functionality. The exact steps vary depending on the appliance, but some general guidelines include:

- Preparation: Read the manufacturer’s installation instructions carefully. Gather the necessary tools (screwdrivers, level, possibly a wrench, etc.). Ensure the area is clear and properly ventilated.

- Unpacking and Inspection: Carefully remove the appliance from its packaging and inspect it for any damage. This step prevents disputes later.

- Location and Connections: Position the appliance in its designated location, ensuring it’s level and has sufficient clearance. Connect the water supply lines (if applicable – for dishwashers or washing machines) tightly, using appropriate fittings and sealing compounds. Secure gas or electrical connections (if applicable) properly.

- Testing: Once everything is connected, turn on the appliance and check its operation. Make sure the water flows correctly and the appliance functions as it should. Listen for any unusual sounds.

- Final Adjustments: Make any necessary fine adjustments to ensure the appliance works optimally and safely. This might include adjusting leveling feet or securing the appliance to the wall (if required).

Remember, safety is paramount! If you are not comfortable with any of the steps, it’s always best to call a qualified appliance installer.

Q 10. How do you ensure the safe disposal of old appliances?

Safe disposal of old appliances is crucial for environmental and safety reasons. Simply tossing them in the trash is not an option; many contain hazardous materials. The most responsible approach is:

- Check for Local Recycling Programs: Many municipalities offer appliance recycling programs that handle the safe disposal of refrigerants, hazardous materials, and recyclable parts. These programs often schedule pick-ups or have designated drop-off locations.

- Contact Appliance Retailers: Some retailers offer appliance take-back programs, which will help dispose of your old appliance responsibly when you purchase a new one. This is a great option for convenience.

- Appliance Recycling Centers: These specialize in dismantling and recycling appliances, separating the valuable materials and properly disposing of hazardous components.

- Charitable Organizations: If the appliance is still functional, consider donating it to a local charity or shelter, giving it a second life.

Before disposal, remove any loose parts and disconnect all power and water supply lines. Proper disposal protects the environment and helps prevent accidental injuries from discarded appliances.

Q 11. What are the different types of appliance motors and their applications?

Appliances utilize various motor types, each suited for specific tasks:

- Universal Motors: These motors are commonly found in vacuum cleaners, blenders, and some hand mixers. They can operate on both AC and DC power, providing high speed and torque. Think of them as workhorses; strong and versatile.

- Induction Motors: These efficient motors are used in refrigerators, washing machines, and dryers. They offer high reliability and relatively quiet operation. They are known for their efficiency and quietness.

- Capacitor-Start Induction Run Motors: These are a variation of induction motors used where high starting torque is needed, like in larger appliances such as compressors in refrigerators or dishwashers. They provide a powerful initial push but then settle into efficient running.

- DC Brushless Motors: These newer motors are becoming more common in high-end appliances due to their efficiency and precise speed control. They offer excellent energy savings and longer lifespan.

The choice of motor depends on factors like required torque, speed control needs, energy efficiency requirements, and noise level constraints. Each motor type has its strengths and weaknesses, making it suitable for specific applications.

Q 12. How do you diagnose and repair a malfunctioning oven heating element?

Diagnosing and repairing a malfunctioning oven heating element involves a systematic approach. Remember, safety is always paramount; disconnect the oven’s power supply before attempting any repairs!

- Visual Inspection: Carefully inspect the heating element for any visible damage such as cracks, burns, or broken wires. A simple visual check can often pinpoint the problem.

- Continuity Test: Use a multimeter to test the continuity of the heating element. If the multimeter reads infinite resistance (no continuity), the element is broken. This confirms whether there is a broken circuit.

- Thermostat Check: Test the oven’s thermostat using the multimeter. A faulty thermostat can prevent the element from receiving power, even if the element itself is fine. You want to ensure it’s correctly registering the temperature and activating the heating element.

- Wiring Inspection: Inspect the wiring connected to the heating element and thermostat for any damage or loose connections. This is where you troubleshoot the power pathway to the element.

- Replacement (if necessary): If the heating element, thermostat, or wiring is faulty, replace it with a compatible part. Refer to the oven’s service manual for detailed instructions and part specifications. This often requires some technical skill and precision.

If you’re not comfortable working with electricity, it’s best to contact a qualified appliance repair technician.

Q 13. Describe your experience with appliance maintenance and preventative care.

Appliance maintenance and preventative care are key to extending their lifespan and ensuring optimal performance. Think of it as regular checkups for your appliances! My experience involves:

- Regular Cleaning: Cleaning the vents of dryers, filters of dishwashers and refrigerators, and ensuring the oven is free of spills prevents build-up that can impede efficiency and lead to malfunction.

- Lubrication: Applying lubricant to moving parts in appliances such as garbage disposals or washing machine doors ensures smooth operation and prevents premature wear. A little lubrication can go a long way.

- Inspection: Periodically inspecting appliances for any signs of wear or damage, paying attention to electrical connections, water lines, and gas connections (if applicable), can prevent small issues from escalating into major problems. Early detection is crucial.

- Calibration: Checking and calibrating temperature controls in ovens, refrigerators, and other appliances can ensure they’re operating within their optimal range, minimizing energy consumption and maximizing performance. Calibration ensures accuracy and efficiency.

Preventative maintenance not only saves money on repairs but also promotes safety and prolongs the appliance’s life. It’s far less costly to prevent problems than to fix them.

Q 14. How do you troubleshoot a malfunctioning garbage disposal?

Troubleshooting a malfunctioning garbage disposal requires a systematic approach. Again, safety first; always turn off the power to the disposal before starting any troubleshooting.

- Check the Power Supply: Ensure the disposal is plugged in and the breaker hasn’t tripped. A simple power outage is often the culprit.

- Check for Obstructions: Many issues arise from clogs. Use tongs to carefully remove any visible obstructions. Never put your hand inside the disposal!

- Reset the Thermal Overload Protector: Most disposals have a thermal overload protector that trips when the motor overheats. Look for a small red reset button underneath the unit and push it.

- Listen for Unusual Noises: Grinding, humming, or unusual sounds indicate a possible mechanical problem. This could signify a more significant issue requiring professional attention.

- Manual Crank (if applicable): Some disposals have a manual crank for clearing minor obstructions. Refer to your disposal’s manual for instructions on how to use it.

- Check for Water Flow: Ensure sufficient water is running while operating the disposal. Water acts as a lubricant and helps flush away waste.

If the problem persists after these steps, a more serious issue might require professional intervention. Don’t attempt repairs beyond your skill level.

Q 15. What are the common causes of a microwave oven malfunctioning?

Microwave oven malfunctions stem from a variety of issues, ranging from simple user errors to complex component failures. Let’s break down some common causes:

- Power Supply Problems: This is often the simplest culprit. A blown fuse, a tripped circuit breaker, or a faulty power cord can all prevent the microwave from operating. Imagine it like a car needing fuel – no power, no operation.

- Magnetron Issues: The magnetron is the heart of the microwave, generating the microwaves. A failing magnetron can lead to reduced cooking power, sparking, or complete failure. This is more of an internal engine problem in our car analogy.

- High-Voltage Diode Problems: This component rectifies the high-voltage electricity needed by the magnetron. A faulty diode will prevent the magnetron from receiving the necessary power.

- Capacitor Issues: Capacitors store electrical energy. A failed capacitor can cause erratic behavior or complete shutdown.

- Control Panel Malfunction: Buttons, the control panel display, or the internal electronics responsible for interpreting inputs can all fail, hindering operation. This is like the dashboard in your car; if it’s not working, you can’t really control much.

- Door Switch Issues: The microwave’s safety mechanism ensures it won’t operate with the door open. A faulty door switch will prevent it from starting, even with the door properly closed. Think of this as the car’s safety lock – it needs to be functioning correctly.

- Overheating: Excessive use or improper ventilation can lead to overheating, potentially damaging internal components. This is akin to overheating your car engine – you have to let it cool down.

Troubleshooting often involves checking these components systematically, starting with the simplest and safest checks (power cord, fuse, circuit breaker) before moving on to more complex internal components.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the different types of appliance wiring and connections.

Appliance wiring and connections vary significantly depending on the appliance type and its power requirements. Understanding these is crucial for safe and effective operation and repair.

- Three-Prong Plugs (Grounded): Most household appliances utilize a three-prong plug that connects to a grounded outlet. The third prong grounds the appliance, providing a path for stray electrical current to safely flow to the earth, preventing electrical shock. This is the standard for most appliances for safety.

- Two-Prong Plugs (Ungrounded): Older appliances may have two-prong plugs, lacking the grounding prong. These should ideally be updated for safety by a qualified electrician.

- Hardwiring: Some appliances, like built-in ovens and ranges, are hardwired directly into the home’s electrical system. This requires careful attention to proper wiring techniques, ensuring correct amperage and voltage ratings. Incorrect hardwiring can lead to serious hazards.

- Wiring Connections: Internal wiring within appliances uses various types of connectors, including wire nuts, crimp connectors, and screw terminals. Proper connection ensures a secure and reliable electrical path. Loose connections can create resistance, leading to overheating and potential fire hazards.

- Low Voltage Circuits: Some appliances, like dishwashers and some refrigerators, might utilize low-voltage circuits (12V DC) for internal components like control boards, even if the main power is 120V AC.

The critical aspect is matching the appliance’s wiring and power requirements to the appropriate outlet and circuit within the home. Improper connection can damage the appliance, trip circuit breakers, or, worse, cause a fire or electrical shock. Always consult the appliance’s installation instructions.

Q 17. How do you determine the appropriate size and type of appliance for a customer’s needs?

Determining the right appliance size and type depends on the customer’s specific needs and lifestyle. It’s a consultative process, not just a sales pitch.

- Needs Assessment: I begin by asking detailed questions about the customer’s household size, cooking habits, storage needs, and budget. For example, a family of four will need a larger refrigerator than a single person.

- Capacity Considerations: For refrigerators, this involves cubic feet of storage space. For washing machines, it’s the weight capacity in pounds. For ovens, it’s the cooking capacity and oven size. I will provide explanations of each measurement and how it relates to practical use.

- Features & Functionality: Customers often have specific needs, such as energy efficiency, special cooking functions (convection, steam), or specific features in a dishwasher or washing machine. This part of the discussion explores exactly what features add value to their lifestyle.

- Space Constraints: The available space must be measured carefully to ensure the appliance fits seamlessly into the kitchen or laundry room. This includes checking for adequate clearances around the appliance for ventilation and usability.

- Budgetary Limitations: Appliances range widely in price. I help the customer find the best balance between features, quality, and budget. This often involves explaining the trade-offs between premium features and more affordable models.

Essentially, it’s about understanding the customer’s lifestyle and translating their needs into specific appliance features and capacities. A well-matched appliance improves daily life significantly. One example, a larger capacity washing machine for a family saves significant time and energy, whilst a smaller capacity suits someone living alone.

Q 18. What are the common safety hazards associated with appliance repair?

Appliance repair presents numerous safety hazards. It is critical to treat each job with respect for safety protocols.

- Electrical Shock: This is perhaps the most significant risk, especially when dealing with high-voltage components in appliances like ovens and washing machines. Always disconnect the power before working on any electrical components.

- Burns: Working with heating elements in ovens and dryers can cause burns. Allow components to cool down completely before handling. I always use appropriate heat-resistant gloves.

- Cuts and Abrasions: Sharp edges and broken glass pose potential hazards. I always wear safety glasses and gloves to protect against cuts.

- Chemical Exposure: Appliances might contain hazardous chemicals like refrigerants. Proper handling and disposal are essential. I am fully trained on the safe handling of refrigerants and follow all regulations strictly.

- Gas Leaks (for gas appliances): Gas leaks can cause explosions or asphyxiation. Thorough inspection and leak detection are vital before starting any repair involving gas appliances.

My approach to minimizing these risks involves always using the appropriate safety gear, following safe work practices, and knowing when to call for professional assistance if the repair exceeds my expertise or safety capabilities. Safety is paramount; if something feels unsafe, I stop and reassess.

Q 19. Describe your experience with appliance repair documentation and reporting.

Detailed documentation and reporting are essential for efficient appliance repair services. This ensures accountability and aids in future repairs.

- Repair Tickets/Work Orders: I use digital repair tickets to record the customer’s information, the appliance details (make, model, serial number), the reported problem, the diagnostic steps taken, the parts replaced (with part numbers), and the solution implemented. This detailed record serves as a historical reference for troubleshooting.

- Photographs and Videos: In complex cases, I capture photographic and video evidence of the problem, the repair process, and the final outcome. This aids in communication with customers and serves as a visual record.

- Parts Inventory Management: I maintain an accurate inventory of parts used and a record of suppliers. This allows for efficient ordering of parts for future repairs.

- Customer Communication Logs: All communication with customers (initial contact, updates, follow-up) is documented carefully to maintain transparency and efficiency.

- Reporting to Management: Regular reports are generated summarizing repair activities, including common issues identified, parts usage, and customer feedback. This assists in identifying trends and improving service efficiency.

My documentation practices ensure that the information is easily accessible, maintainable, and helpful for both the customer and internal operations. This allows for quick reference in the future and promotes seamless collaboration within the team. For example, consistent logging of errors on a particular model allows for proactive communication with suppliers or manufacturers about potential design issues.

Q 20. How do you handle emergency appliance repair calls?

Emergency appliance repair calls require a rapid and efficient response, prioritizing safety and minimizing disruption to the customer.

- Prioritization: Emergency calls, such as a refrigerator malfunction in hot weather or a gas leak, are prioritized over routine repairs. This involves immediate scheduling and deployment of qualified technicians.

- Rapid Diagnosis: Upon arrival, I conduct a quick yet thorough diagnosis to identify the root cause of the problem. This prioritizes safety first; for instance, ensuring gas lines are shut off if there’s a leak.

- Temporary Solutions: In some cases, a complete repair might not be immediately possible. I will implement temporary fixes to minimize inconvenience while awaiting parts or scheduling more complex repairs.

- Safety Precautions: Safety remains paramount. All necessary safety precautions are taken, especially when dealing with potentially hazardous situations. This includes using proper PPE and adhering to all safety regulations.

- Communication: Open and consistent communication with the customer is crucial, updating them on the progress, anticipated repair time, and any costs involved. This helps manage customer expectations and alleviate anxiety.

My experience has shown that a calm, efficient, and communicative approach minimizes stress during emergencies. A clear explanation of the problem and the solution, combined with swift action, ensures customer satisfaction, even in stressful situations. For example, a quick temporary fix to a refrigerator allows food to remain safe until permanent repairs are completed.

Q 21. Explain your experience with various appliance brands and models.

Over the years, I’ve gained extensive experience working with a wide range of appliance brands and models, from budget-friendly options to high-end, specialized appliances.

- Major Brands: I am proficient in repairing appliances from leading manufacturers such as Whirlpool, GE, LG, Samsung, KitchenAid, Maytag, and Electrolux. This includes both built-in and freestanding models.

- Model Variations: I’m familiar with the diverse model variations within each brand, understanding the nuances of different features and technologies. This means I can efficiently troubleshoot problems even with less common or older models.

- Troubleshooting Techniques: My experience allows me to apply various diagnostic and repair techniques depending on the brand and model. I understand the unique design characteristics of various appliance types and brands.

- Component Knowledge: I am knowledgeable about the different components used in various appliances and brands, enabling me to quickly identify and replace faulty parts. This includes understanding the compatibility of parts across different models and brands.

- Parts Sourcing: I have established relationships with reliable parts suppliers to ensure timely access to the necessary components for repair, even for older or less common models.

This broad experience allows me to approach repairs systematically, accurately diagnose problems, and efficiently resolve them regardless of the brand or model. Knowing the quirks of particular brands allows me to preempt potential issues and optimize the repair process. For example, I know that a specific model of washing machine from a certain brand is prone to a certain type of pump failure, allowing for proactive troubleshooting.

Q 22. How do you stay up-to-date on the latest appliance technologies and repair techniques?

Staying current in the dynamic field of appliance repair requires a multi-pronged approach. I actively participate in continuing education opportunities, such as manufacturer-sponsored training workshops and online courses focusing on new technologies and repair techniques. These often cover the latest innovations in smart appliances, energy-efficient designs, and advanced diagnostic methods. For example, I recently completed a course on the intricacies of inverter technology in modern refrigerators, learning how to troubleshoot issues specific to this type of compressor. I also subscribe to industry-specific journals and online forums, where professionals share case studies, best practices, and insights into emerging challenges. Finally, I maintain a strong professional network, attending industry events and exchanging information with colleagues to learn from their experiences and stay ahead of the curve.

Q 23. Describe your experience working with various appliance parts and components.

My experience spans a wide range of appliance parts and components, encompassing major and small appliances. I’m proficient in working with heating elements, compressors, control boards, motors, pumps, and various sensors, including those found in refrigerators, ovens, washing machines, dryers, and dishwashers. For example, I’ve extensively worked with the intricate control boards of high-end dishwashers, troubleshooting communication issues between various modules and performing repairs ranging from simple component replacement to complex circuit board diagnostics. My experience also includes familiarity with different types of motors—from induction motors in washing machines to DC brushless motors in newer refrigerators—allowing me to identify the source of motor-related malfunctions effectively. Furthermore, my expertise extends to understanding the mechanics of water pumps, valves, and thermostats, crucial for accurately diagnosing and fixing issues in washing machines, dishwashers, and other water-dependent appliances.

Q 24. How do you effectively communicate technical information to non-technical customers?

Effective communication with non-technical customers is paramount. My approach involves simplifying complex technical issues into easily understandable terms, avoiding jargon whenever possible. I use analogies and visual aids—such as diagrams or photos—to explain the problem and the proposed solution. For example, instead of saying “the capacitor is faulty,” I would explain that “a component that helps control the power is failing, causing the appliance to malfunction.” I listen actively to the customer’s concerns, ensuring I understand the issue before offering a solution. I always obtain their approval before starting any repair and provide clear, upfront estimates. Furthermore, I prioritize empathy and patience, making sure to address any anxieties the customer may have about the repair process. Clear and concise communication builds trust and ensures customer satisfaction.

Q 25. Explain your experience with using diagnostic tools for appliance repair.

I’m experienced in using a variety of diagnostic tools crucial for efficient appliance repair. This includes multimeters for measuring voltage, current, and resistance; clamp meters for accurately measuring current flow; and specialized appliance testers that help pinpoint specific component failures. I also utilize advanced diagnostic software and handheld devices provided by various manufacturers, enabling me to read error codes and troubleshoot advanced issues in modern appliances. For instance, when working with a smart refrigerator that isn’t cooling properly, I’d use the manufacturer’s diagnostic software to read its internal sensors and identify whether the problem lies with the compressor, the temperature sensor, or the control board. My skill in interpreting these diagnostic readings allows for faster and more accurate repairs, minimizing downtime and reducing unnecessary part replacements.

Q 26. What are your salary expectations for this position?

My salary expectations are in the range of [Insert Salary Range] annually, commensurate with my experience and skills, and reflective of the responsibilities associated with this position. I’m open to discussing this further based on the specifics of the job description and the overall compensation package.

Q 27. What are your strengths and weaknesses as an appliance technician?

One of my greatest strengths is my meticulous attention to detail. I believe that thorough troubleshooting is essential for effective repair, and I meticulously examine each component to ensure accuracy in my diagnosis. Another strength is my problem-solving ability; I’m adept at tackling complex repair challenges and finding creative solutions. A potential area for improvement is time management; while I prioritize quality, I am always working to optimize my workflow to complete tasks more efficiently. I’m actively pursuing strategies like improved task prioritization and more efficient organization to better manage my time.

Q 28. Why are you interested in this appliance-related position?

I’m very interested in this position because of [Company Name]’s reputation for providing high-quality service and its commitment to customer satisfaction. The opportunity to work with a team of experienced professionals and to contribute to a company that values expertise aligns perfectly with my career goals. Furthermore, the prospect of utilizing my skills to resolve challenging appliance repair issues and to consistently exceed customer expectations is particularly exciting. I’m confident that my experience and dedication make me a valuable asset to your team.

Key Topics to Learn for Appliances Interview

- Appliance Functionality & Design: Understanding the mechanical and electrical workings of various appliance types (refrigerators, washing machines, ovens, etc.), including their component parts and operational cycles. Consider exploring energy efficiency standards and design innovations.

- Troubleshooting & Repair: Develop your problem-solving skills by practicing diagnosing common appliance malfunctions. This includes identifying symptoms, using diagnostic tools (if applicable), and suggesting effective repair strategies. Think about how you would approach a scenario with limited information.

- Safety & Regulations: Familiarize yourself with safety protocols related to appliance installation, maintenance, and repair. Understand relevant industry standards and regulations concerning electrical safety, gas appliances, and water usage.

- Installation & Maintenance: Learn the best practices for installing and maintaining different types of appliances. This includes understanding proper connections, testing procedures, and preventative maintenance schedules.

- Customer Service & Communication: Practice explaining technical information clearly and concisely to non-technical audiences. Consider how you would handle difficult customer situations and resolve complaints effectively.

- Sales & Marketing (if applicable): If the role involves sales, familiarize yourself with common appliance features, benefits, and target customer demographics. Understand the competitive landscape and sales techniques.

Next Steps

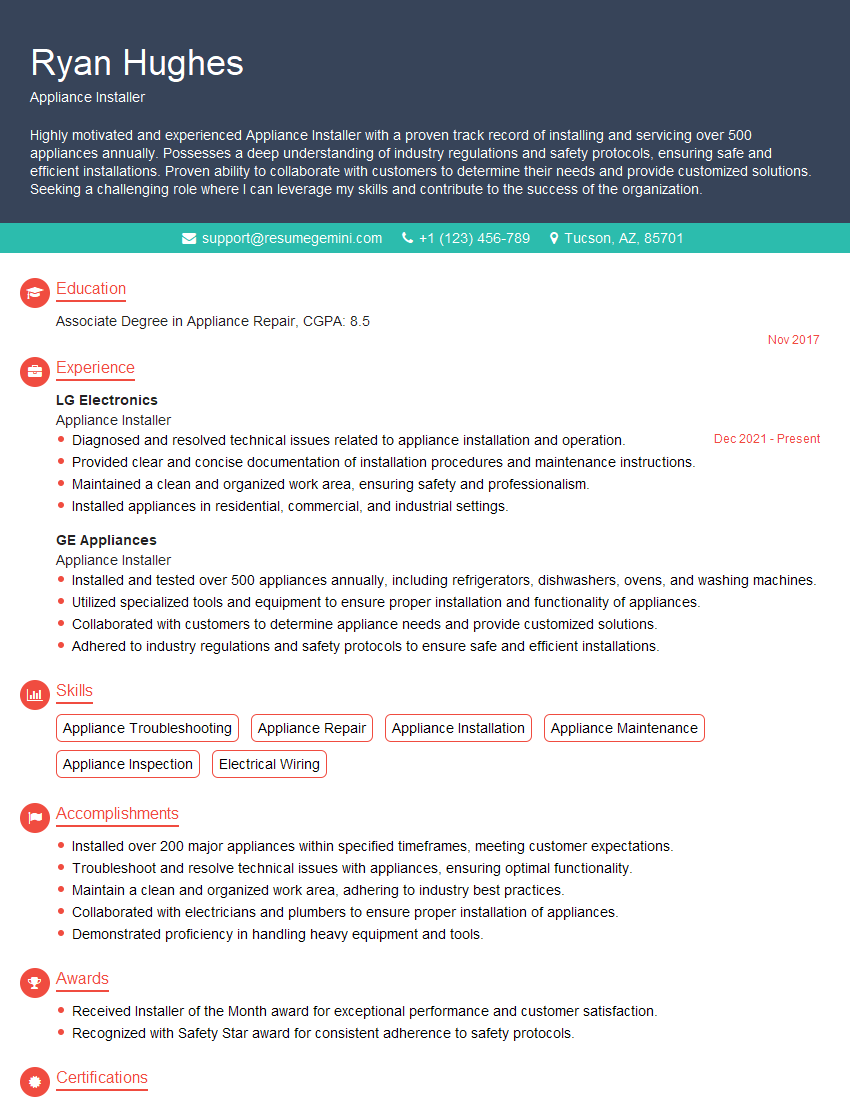

Mastering the intricacies of appliances opens doors to exciting career opportunities within a growing industry. A strong understanding of appliance technology, coupled with excellent problem-solving and communication skills, significantly enhances your employability. To increase your chances of landing your dream job, it’s crucial to have an ATS-friendly resume that highlights your skills and experience effectively. We highly recommend using ResumeGemini to create a professional and compelling resume that showcases your capabilities. ResumeGemini provides helpful tools and even offers examples of resumes tailored to the Appliances industry, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO