Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Basic Hydraulics and Pneumatics Understanding interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Basic Hydraulics and Pneumatics Understanding Interview

Q 1. Explain Pascal’s Law and its application in hydraulic systems.

Pascal’s Law is a fundamental principle in fluid mechanics stating that a change in pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and to the walls of the containing vessel.

Imagine squeezing a balloon filled with water – the pressure you apply at one point instantly affects the entire balloon. This is Pascal’s Law in action. In hydraulic systems, this principle allows us to multiply force. A small force applied to a small area creates a large pressure, which is then transmitted to a larger area, resulting in a much larger force.

Application in Hydraulic Systems: Hydraulic systems leverage Pascal’s Law extensively. A classic example is a hydraulic jack used to lift heavy objects. A small piston with a small surface area is pushed, generating pressure. This pressure is then transferred through an incompressible fluid (usually oil) to a larger piston with a much larger surface area. The larger piston exerts a much greater force, capable of lifting a heavy vehicle.

Another example is hydraulic braking systems in cars. Pressure applied to the brake pedal is amplified by the hydraulic system, applying substantial stopping force to the wheels.

Q 2. Describe the difference between hydraulic and pneumatic systems.

Hydraulic and pneumatic systems both use fluids to transmit power, but they differ significantly in the type of fluid used and their operating characteristics.

- Hydraulic Systems: Use incompressible liquids, typically oil, to transmit power. They provide high force and precise control, and are well-suited for high-power applications.

- Pneumatic Systems: Use compressible gases, typically air, to transmit power. They are lighter, faster, and safer than hydraulic systems in many applications, but offer lower force and less precise control. They are often preferred for applications requiring speed and ease of control.

Think of it like this: hydraulics is like pushing a column of water; the force is constant and powerful. Pneumatics is like pushing a balloon – it moves quickly but with less consistent force.

Q 3. What are the advantages and disadvantages of hydraulic systems compared to pneumatic systems?

Both systems have their advantages and disadvantages:

Hydraulic Systems:

- Advantages: High power-to-weight ratio, precise control, high force capacity, relatively insensitive to temperature fluctuations.

- Disadvantages: Requires more maintenance (oil leaks, contamination), less safe due to high pressure and flammability of the oil, higher initial cost, potentially messy operation.

Pneumatic Systems:

- Advantages: Safer (air is not flammable or toxic), less maintenance, lower initial cost, faster response time, lighter weight components.

- Disadvantages: Lower force capacity, less precise control, susceptible to temperature and moisture effects, lower efficiency than hydraulic systems.

The best choice depends on the specific application. For instance, a large industrial press might benefit from the high force of a hydraulic system, while an automated assembly line might prefer the speed and safety of a pneumatic system.

Q 4. Explain the function of a hydraulic pump.

A hydraulic pump is the heart of a hydraulic system. Its primary function is to draw fluid (typically oil) from a reservoir, increase its pressure, and deliver it to other components in the system (like actuators and valves).

Imagine it as a water pump in your house: it draws water from a tank, increases its pressure, and delivers it to your taps. Similarly, a hydraulic pump takes oil, increases its pressure, and sends it to the components needing power. The increased pressure allows the hydraulic fluid to move components against a load or resistance.

Q 5. What are the different types of hydraulic pumps?

Several types of hydraulic pumps exist, each with its own characteristics and applications. Common types include:

- Gear Pumps: Simple and robust, suitable for low-pressure applications. They use meshing gears to draw and displace fluid.

- Vane Pumps: Offer higher pressure and flow rates than gear pumps, often used in medium-pressure applications. They utilize vanes that rotate within a circular chamber.

- Piston Pumps: Provide the highest pressure and flow rates. These pumps use reciprocating pistons to displace fluid, suitable for high-pressure applications. They further subdivide into radial piston pumps and axial piston pumps.

The choice of pump depends on factors such as pressure requirements, flow rate, efficiency, and cost.

Q 6. Explain the function of a hydraulic valve.

Hydraulic valves control the flow of hydraulic fluid within a system. They direct, regulate, and stop fluid movement, ensuring that power gets to where it’s needed, when it’s needed, and in the correct amount.

Think of them as traffic lights for hydraulic fluid, managing the flow to avoid congestion and ensuring efficient operation. They are crucial for directing power to actuators, regulating speed, and controlling sequences of operations.

Q 7. What are the different types of hydraulic valves?

Many types of hydraulic valves exist, categorized by function and design:

- Directional Control Valves: Control the direction of fluid flow, often used to start, stop, and reverse actuator movement.

- Pressure Control Valves: Regulate the pressure of the fluid, ensuring consistent operation and protecting system components from overpressure.

- Flow Control Valves: Control the rate of fluid flow, allowing for precise speed and position control of actuators.

- Check Valves: Allow fluid to flow in one direction only, preventing backflow and ensuring the system’s stability.

Each valve type serves a unique purpose, and combinations of these valve types are often used in complex hydraulic systems to achieve intricate control.

Q 8. Explain the function of a hydraulic cylinder.

A hydraulic cylinder is a mechanical actuator that converts hydraulic energy (fluid pressure) into linear mechanical motion. Think of it as a muscle powered by fluid instead of blood. It consists of a cylindrical barrel, a piston rod, and a piston. Fluid, typically oil, is pumped into the cylinder, forcing the piston to extend, creating linear movement. By reversing the flow of fluid, the piston retracts.

How it works: When pressurized fluid enters one side of the cylinder, it pushes against the piston, causing it to move. This movement is transferred to the piston rod, which performs the desired mechanical work. The other side of the piston is connected to a reservoir, allowing for the fluid displacement.

Example: Hydraulic cylinders are commonly used in heavy machinery like bulldozers and excavators to lift, push, or pull heavy loads. Imagine the arm of an excavator; the powerful movement comes from hydraulic cylinders.

Q 9. Describe the function of a pneumatic actuator.

A pneumatic actuator is similar to a hydraulic cylinder but uses compressed air instead of hydraulic fluid to generate linear or rotary motion. It’s a simple, yet powerful way to automate tasks using readily available compressed air. The compressed air, acting as the power source, drives a piston or vane to produce motion.

Key Advantage: Pneumatic systems offer several advantages over hydraulics. They are typically lighter, cleaner, and less expensive. However, they generally have less power and accuracy compared to hydraulic systems.

Example: Think about the automated doors at a supermarket or a car assembly line where pneumatic actuators are used for various automated movements and actions.

Q 10. What are the different types of pneumatic actuators?

Pneumatic actuators come in several types, the most common being:

- Linear Actuators: These convert compressed air pressure into linear motion, similar to a hydraulic cylinder. They are often used for pushing, pulling, or clamping.

- Rotary Actuators: These convert compressed air pressure into rotary motion. They are commonly used for turning or rotating mechanisms. Rotary actuators can be further classified into vane-type and piston-type.

- Diaphragm Actuators: These use a flexible diaphragm to create linear motion. They are often used for smaller applications requiring relatively low force.

The choice depends on the specific application requirements regarding force, speed, and space constraints.

Q 11. Explain the concept of hydraulic pressure.

Hydraulic pressure is the force exerted by a hydraulic fluid per unit area. Think of it like the intensity of the push from the oil in a hydraulic system. A higher pressure means more force is being exerted on a given surface area. This is expressed as:

Pressure = Force / Area

Understanding the Equation: A larger force applied over a smaller area results in higher pressure, while the same force applied over a larger area results in lower pressure. Hydraulic systems leverage this principle to amplify force. A small pressure change in the pump results in a large force at the cylinder, allowing for heavy lifting and powerful movements.

Q 12. Explain the concept of pneumatic pressure.

Pneumatic pressure is similar to hydraulic pressure, but it refers to the force exerted by compressed air per unit area. Instead of oil, it’s air that’s compressed and used to power actuators. The higher the pressure, the more powerful the air will push on components.

Key Difference: While both hydraulic and pneumatic systems use pressure to produce motion, pneumatic systems generally operate at lower pressures than hydraulic systems and utilize compressible air as the medium. This difference has implications for power, control, and the types of applications best suited for each technology.

Q 13. How is hydraulic pressure measured?

Hydraulic pressure is typically measured using a pressure gauge, often displaying pressure in units of pounds per square inch (psi), bars, or Pascals (Pa). These gauges are connected to the hydraulic system at various points to monitor pressure levels. More sophisticated systems use electronic pressure transducers for precise digital readings and data logging.

Calibration and Maintenance: Regular calibration and maintenance of the pressure gauge is crucial to ensure accuracy and prevent malfunctions in hydraulic systems. A faulty gauge can lead to inaccurate readings which can affect the entire system operation.

Q 14. How is pneumatic pressure measured?

Pneumatic pressure is also measured using pressure gauges, often calibrated in psi, bars, or Pascals. These gauges are designed to withstand the pressure levels commonly found in pneumatic systems. Similar to hydraulic systems, electronic pressure transducers are often used for improved accuracy, remote monitoring, and data acquisition.

Safety Considerations: When dealing with pressurized air, safety precautions are paramount. Appropriate safety equipment and training are necessary to prevent potential injury due to burst components or accidental release of compressed air.

Q 15. What is hydraulic fluid and what are its properties?

Hydraulic fluid is the lifeblood of a hydraulic system, a specially formulated liquid that transmits power throughout the system. Think of it like the blood in your body, carrying energy to where it’s needed. Its properties are crucial for efficient and reliable operation. Key properties include:

- Viscosity: This measures the fluid’s resistance to flow. Too low, and it leaks easily; too high, and the system becomes sluggish. It’s temperature-dependent, meaning viscosity changes with temperature.

- Compressibility: Hydraulic fluids should be relatively incompressible to efficiently transmit power. High compressibility leads to power loss and sluggish response.

- Lubricity: The fluid needs to lubricate the moving parts within the system, preventing wear and tear. This extends the lifespan of components.

- Chemical Stability: The fluid must resist degradation over time and not react with system materials like seals and hoses. Degradation can lead to system failure.

- Pour Point: This is the lowest temperature at which the fluid flows freely. A high pour point is undesirable in cold climates.

- Flash Point: This is the temperature at which the fluid’s vapor ignites. A high flash point is crucial for safety.

Different applications might require fluids with specific properties. For instance, a hydraulic system operating in extreme cold needs a fluid with a low pour point, while a high-pressure system demands a fluid with low compressibility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common types of pneumatic fluids?

The most common pneumatic fluid is simply compressed air. Air is readily available, relatively inexpensive, and safe to use compared to other gases. However, other gases like nitrogen can be used in specialized applications where specific properties are needed, such as:

- Nitrogen: Offers better consistency in pressure and temperature than air, making it ideal for precision applications. It also reduces the risk of condensation and oxidation.

- Other inert gases: In applications where air contamination is critical, inert gases like argon or helium may be used.

The choice of pneumatic fluid is usually dictated by factors such as cost, availability, cleanliness requirements, and the specific operating conditions of the pneumatic system.

Q 17. Explain the concept of hydraulic flow.

Hydraulic flow refers to the movement of hydraulic fluid within a hydraulic system. This fluid, under pressure, is used to transmit power, driving actuators like hydraulic cylinders or motors. Imagine it like water flowing through a pipe, but with significantly more power behind it. The flow rate and pressure are critical factors in determining the system’s performance.

Several factors influence hydraulic flow, including:

- Pump capacity: The pump’s displacement determines the maximum volume of fluid it can deliver.

- Pipe diameter: Smaller pipes restrict flow more than larger ones, like a narrow water hose compared to a fire hose.

- System pressure: Higher pressure results in a reduced flow rate due to increased resistance.

- Fluid viscosity: Higher viscosity fluids flow more slowly than lower viscosity fluids.

Understanding hydraulic flow is vital in sizing components correctly to ensure optimal system performance. A poorly designed system can lead to insufficient power, excessive wear, or even catastrophic failure.

Q 18. Explain the concept of pneumatic flow.

Pneumatic flow is the movement of compressed gas, most often air, within a pneumatic system. This flow, driven by a pressure differential, powers pneumatic actuators like air cylinders and air motors. Think of it as a controlled gust of wind powering a mechanism.

Factors influencing pneumatic flow include:

- Compressor capacity: The compressor’s ability to supply compressed air dictates the maximum flow rate.

- Pipe size: Smaller diameter pipes create more resistance and reduce flow, similar to hydraulic systems.

- Pressure drop: Pressure differences across components cause air to flow, but significant pressure drops reduce efficiency.

- Temperature: Air expands when heated and contracts when cooled, affecting both flow rate and pressure.

The compressibility of air is a significant aspect of pneumatic flow. Unlike hydraulic systems, the flow in pneumatic systems is more difficult to control precisely due to air’s compressibility. This compressibility is often managed using various methods like regulators and accumulators.

Q 19. How is hydraulic flow rate measured?

Hydraulic flow rate is typically measured in units of volume per unit of time, such as liters per minute (L/min) or gallons per minute (GPM). Specialized flow meters are used for accurate measurements. These meters can be:

- Variable area flow meters (rotameters): These meters use a tapered tube with a float that rises proportionally to the flow rate. They are simple and inexpensive but less accurate than other types.

- Turbine flow meters: These meters utilize a turbine that spins at a rate proportional to the flow rate. They provide more accurate measurements than rotameters.

- Ultrasonic flow meters: These meters use ultrasonic waves to measure the flow rate without any obstruction in the flow path. They are very accurate and suitable for many applications.

The choice of flow meter depends on the required accuracy, pressure, temperature, and the fluid’s properties. The flow rate is a critical parameter in designing and troubleshooting hydraulic systems. Too low a flow rate results in insufficient power, while too high a flow rate can lead to system instability.

Q 20. How is pneumatic flow rate measured?

Pneumatic flow rate is also usually measured in volume per unit time, often expressed in liters per minute (L/min) or standard cubic feet per minute (SCFM). Standard cubic feet per minute refers to the volume of air at standard temperature and pressure conditions. Similar to hydraulic systems, various flow measurement devices are available:

- Rotameters: As in hydraulic systems, rotameters provide a simple, but less accurate, method for measuring pneumatic flow.

- Orifice plates: These plates with a precisely sized hole create a pressure drop proportional to the flow rate. The pressure drop can be measured to determine the flow rate.

- Thermal mass flow meters: These meters measure the heat transfer across a heated element, which depends on the flow rate of the gas.

The specific method chosen for measuring pneumatic flow will depend on the requirements of the application, such as the desired accuracy and the operating pressure and temperature.

Q 21. Describe different types of hydraulic seals and their applications.

Hydraulic seals are critical components that prevent leakage in hydraulic systems, ensuring efficient operation and preventing environmental contamination. Different types of seals are used depending on the application’s pressure, temperature, fluid type, and speed.

- O-rings: These simple, versatile seals are made of elastomers (rubber-like materials) and provide a reliable seal in many applications. They are relatively inexpensive and easy to install, but might not be suitable for high-pressure or high-speed applications.

- U-cups: These cup-shaped seals are better suited for reciprocating (back-and-forth) motion than O-rings, providing a reliable seal against dynamic pressure. They are commonly used in hydraulic cylinders.

- Lip seals: These seals, often made of rubber or polyurethane, feature a flexible lip that conforms to the shaft, providing a good seal at relatively high speeds and pressures. They are widely used in pumps and other rotating components.

- Hydraulic piston seals: These are more complex seals, often employing a combination of sealing elements to withstand the high pressures and dynamic forces experienced by hydraulic pistons.

- Face seals: These seals employ flat faces that are precisely machined to provide a leak-proof seal. They are commonly used in high-pressure applications where extremely low leakage rates are required.

Selecting the appropriate seal is crucial for the longevity and efficiency of the hydraulic system. Incorrect seal selection can result in leaks, decreased performance, and system failure. Engineers carefully consider the operating conditions to choose the most appropriate seal type and material.

Q 22. Describe different types of pneumatic seals and their applications.

Pneumatic seals are crucial for preventing air leakage in pneumatic systems. Their choice depends heavily on factors like pressure, temperature, and the type of fluid being handled. Several types exist, each with specific applications:

- U-Cup Seals: These are simple and inexpensive, shaped like a U. They are suitable for low-pressure applications and offer good static sealing but can be prone to extrusion at higher pressures. Think of them as a basic rubber gasket providing a tight fit.

- O-Rings: Extremely common and versatile, O-rings provide a radial seal. Their simplicity and effectiveness make them ideal for a wide range of pressures and applications, from small actuators to large cylinders. Imagine them as a simple, reliable rubber donut creating a pressure barrier.

- V-Packings: These consist of multiple V-shaped rings stacked to provide a good seal even under high pressure and reciprocating motion. They’re often used in hydraulic and pneumatic cylinders where a robust seal is needed to withstand significant wear and tear.

- Lip Seals (or Rotary Shaft Seals): Designed to seal rotating shafts, these seals utilize a flexible lip to maintain contact and prevent leakage. They are essential in applications with rotating components, such as air compressors or pneumatic motors. Picture them as a small, spring-loaded lip that wipes against the shaft.

- Wipers: These seals prevent contaminants from entering the system, usually placed before the main seal. They act like a cleaning agent before the main seal makes contact, improving seal life. Think of them as a pre-filter for the main seal.

The selection of a seal involves careful consideration of the operating conditions. For example, a high-pressure application would necessitate a V-packing or a specifically designed high-pressure O-ring, whereas a low-pressure application might only require a simple U-cup seal.

Q 23. Explain the concept of hydraulic filtration.

Hydraulic filtration is the process of removing contaminants from hydraulic fluid. These contaminants – which can include dirt, wear debris from metal components, and water – can severely damage hydraulic components, leading to reduced efficiency, increased wear, and ultimately, system failure. Think of it as regular oil changes for your car, but much more critical due to the high pressures involved.

The filtration process involves passing the hydraulic fluid through a filter element with progressively smaller pore sizes. Common filter types include:

- Suction Filters: These are placed on the suction side of the pump, protecting the pump from large contaminants.

- Pressure Filters: These are placed on the pressure side of the pump, protecting the entire system from smaller contaminants.

- Return Line Filters: These filter the fluid as it returns to the reservoir.

The efficiency of a hydraulic filter is measured by its micron rating, indicating the size of the particles it can remove. A lower micron rating signifies a finer filter capable of removing smaller particles. Regular filter maintenance, including replacement or cleaning according to the manufacturer’s recommendations, is paramount for optimal system performance and longevity.

Q 24. Explain the concept of pneumatic filtration.

Pneumatic filtration serves a similar purpose to hydraulic filtration but focuses on removing contaminants from compressed air. These contaminants—water vapor, oil aerosols, dust, and other particulate matter—can negatively impact the performance and reliability of pneumatic systems. For instance, moisture can cause corrosion in pneumatic components, while particulate matter can lead to premature wear and tear in actuators and valves.

Pneumatic filtration systems typically employ several stages of filtration to achieve the desired level of cleanliness. This usually starts with coalescing filters removing liquid, followed by particulate filters of decreasing pore sizes. A final stage may include desiccant air dryers.

The effectiveness of a pneumatic filter is determined by several factors, including the filter element’s pore size, the filter’s flow rate, and the type of contaminants being removed. Regular maintenance, which might involve filter element changes or scheduled purging of moisture, is essential to ensure a clean and effective pneumatic system. A poorly maintained pneumatic filter can lead to malfunctions such as compressor failure, valve sticking, and corrosion. Regular inspection and maintenance are just as vital as in hydraulic systems.

Q 25. How do you troubleshoot a hydraulic leak?

Troubleshooting a hydraulic leak involves a systematic approach to pinpoint the source and implement the necessary repair. It’s crucial to prioritize safety, as hydraulic systems operate under high pressure and can cause serious injury.

The troubleshooting process typically follows these steps:

- Safety First: Isolate the system and relieve the pressure before attempting any inspection or repair.

- Visual Inspection: Carefully examine all hoses, fittings, seals, and components for visible signs of leakage. Look for wet spots, dripping fluid, or evidence of fluid spraying.

- Pressure Testing: If a leak isn’t immediately apparent, carefully increase the system pressure to better identify the source of a leak. Use caution during this stage.

- Component Isolation: Once the location is identified, isolate the affected component or section to further pinpoint the source of the leak (i.e., specific hose, seal, or fitting).

- Repair or Replacement: Once the source is found, either repair the component or replace it with a new, functioning equivalent.

- System Flush: After the repair, flush the system with clean hydraulic fluid to remove any remaining contaminants.

Remember, always consult the system’s manuals and diagrams for specific procedures and safety precautions. It might be beneficial to document the troubleshooting process with pictures or notes.

Q 26. How do you troubleshoot a pneumatic leak?

Troubleshooting a pneumatic leak is similar to hydraulic leak troubleshooting, but the pressures involved are typically lower. However, even low-pressure leaks can be detrimental to system performance and efficiency over time.

The process usually follows these steps:

- Safety First: Always ensure that the system is depressurized before commencing any investigation or repair.

- Listen for Hissing Sounds: Leaks often produce a characteristic hissing sound. Follow this sound to locate the probable leak.

- Visual Inspection: Carefully examine all connections, fittings, tubing, and seals for signs of leakage (bubbles in water or soapy solution).

- Soap Solution Test: Apply a soapy solution to suspect areas. Bubbles forming will indicate the presence of a leak.

- Pressure Testing (optional): If you cannot identify the leak through visual or auditory means, you might use a pressure gauge to check for pressure drops.

- Tighten Connections: If a leak is found in a loose connection, carefully tighten it. Do not over-tighten.

- Replace Seals or Components: If tightening doesn’t resolve the issue, worn seals or damaged components may be the cause, which should be repaired or replaced.

For persistent leaks, it’s advisable to consult the system’s documentation or seek assistance from a qualified technician. Using compressed air appropriately is key to ensuring safety and efficient leak detection and repair.

Q 27. Describe your experience with hydraulic schematics and diagrams.

I have extensive experience interpreting and creating hydraulic schematics and diagrams. I’m proficient in reading and understanding industry-standard symbols, including those representing pumps, valves, actuators, reservoirs, and various piping configurations. I’ve worked with both simple and complex systems, understanding the flow of hydraulic fluid, pressure variations, and the interaction between different components.

In my previous role at [Previous Company Name], I was responsible for designing and reviewing hydraulic schematics for various applications, including [mention specific application examples, e.g., industrial presses, mobile equipment, etc.]. My experience includes using CAD software to create detailed drawings, ensuring that all components are correctly represented and that the system’s operation is accurately depicted. I frequently use these schematics for troubleshooting, maintenance, and system modifications. I’m familiar with various schematic formats and can adapt to different industry standards.

Q 28. Describe your experience with pneumatic schematics and diagrams.

My experience with pneumatic schematics and diagrams is equally extensive. I’m comfortable working with standard symbols for air compressors, valves (e.g., directional control valves, pressure regulators), actuators (cylinders, air motors), filters, and other pneumatic components. I can decipher the flow of compressed air, pressure regulation, and the control logic of complex pneumatic systems.

At [Previous Company Name or Project], I was involved in [mention specific activities, e.g., designing a pneumatic control system for a packaging machine, troubleshooting a malfunctioning pneumatic system, etc.]. This involved interpreting existing schematics to identify problems and creating new schematics to document modifications or new designs. I’m familiar with different drawing conventions and can adapt my approach based on the specific application requirements. My experience encompasses both simple and sophisticated pneumatic control systems, and I’m comfortable using various software tools for schematic creation and modification.

Key Topics to Learn for Basic Hydraulics and Pneumatics Understanding Interview

- Fluid Properties: Understand density, viscosity, and compressibility and their impact on system performance. Consider how these properties affect pressure and flow.

- Pascal’s Law and its Applications: Explain Pascal’s Law and its crucial role in hydraulic systems. Discuss practical examples like hydraulic presses and lifts.

- Hydraulic Components: Familiarize yourself with pumps, valves (directional control, pressure control, flow control), actuators (cylinders), and reservoirs. Understand their function and interoperability.

- Pneumatic Components: Learn about air compressors, valves (similar to hydraulics but with air specifics), actuators (pneumatic cylinders), and pressure regulators. Understand their differences from hydraulic components.

- Fluid Power Circuits: Practice interpreting and designing simple hydraulic and pneumatic circuits. Understand the flow of fluid and how components interact to achieve desired movement or actions.

- Pressure, Flow, and Force Relationships: Master the fundamental relationships between pressure, flow rate, and force in both hydraulic and pneumatic systems. Be prepared to solve basic calculations.

- Safety Considerations: Discuss common safety procedures and regulations related to hydraulic and pneumatic systems, including pressure relief valves and emergency shut-off mechanisms.

- Troubleshooting and Maintenance: Understand basic troubleshooting techniques for identifying and resolving common issues in hydraulic and pneumatic systems. Discuss preventative maintenance strategies.

- Types of Hydraulic and Pneumatic Systems: Explore different system designs and architectures, such as open-center and closed-center hydraulic systems.

- Practical Applications: Be ready to discuss real-world applications of hydraulics and pneumatics in various industries (e.g., manufacturing, construction, automotive).

Next Steps

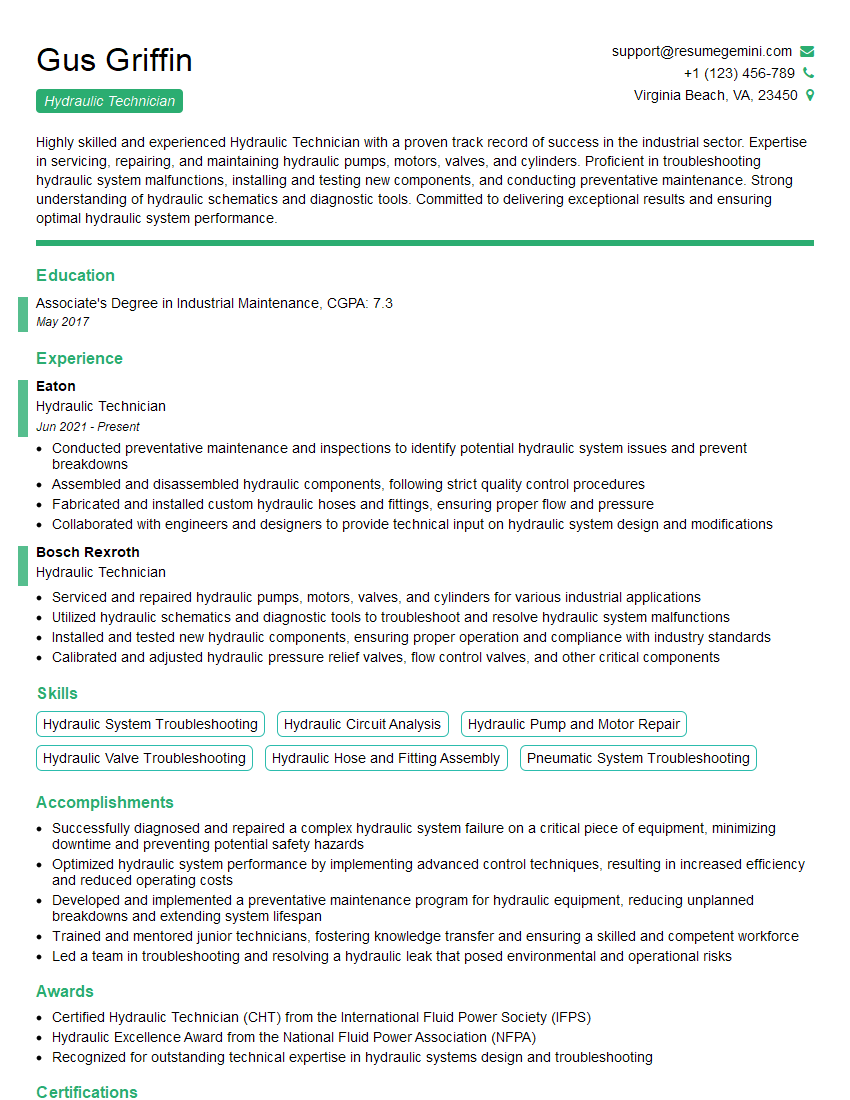

Mastering Basic Hydraulics and Pneumatics Understanding opens doors to exciting career opportunities in diverse sectors. A strong grasp of these principles significantly enhances your employability and positions you for advancement. To maximize your job prospects, create a professional, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume. We provide examples of resumes tailored to Basic Hydraulics and Pneumatics Understanding to guide you through the process. Invest in your future – build a resume that showcases your expertise and lands you your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO