Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Basic knowledge of marine engineering principles interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Basic knowledge of marine engineering principles Interview

Q 1. Explain the principle of operation of a four-stroke diesel engine.

A four-stroke diesel engine is an internal combustion engine that completes its power cycle in four distinct piston strokes: intake, compression, power, and exhaust. Think of it like a four-step dance the piston performs to generate power.

Intake: The piston moves downwards, drawing in a mixture of air into the cylinder. Imagine this like breathing in. The intake valve is open, while the exhaust valve is closed.

Compression: The piston moves upwards, compressing the air to a very high pressure and temperature. This is like squeezing a balloon – the air becomes hot and dense. Both intake and exhaust valves are closed.

Power: Fuel is injected into the highly compressed air, igniting and causing a rapid expansion of gases. This forceful expansion pushes the piston downwards, generating the power stroke. This is the ‘punch’ in the dance, transferring energy to the crankshaft. Both intake and exhaust valves are closed.

Exhaust: The piston moves upwards again, pushing the spent gases out of the cylinder through the open exhaust valve. The intake valve remains closed during this phase. This is like exhaling after a deep breath.

This cycle repeats continuously, providing a rotational force to the crankshaft, which then drives the propeller shaft.

Q 2. Describe the different types of marine propellers and their applications.

Marine propellers come in various designs, each suited to different applications. The key differences lie in their blade shape, number of blades, and overall pitch.

Fixed-pitch propellers: These have a constant pitch (angle of the blades). They’re simple, robust, and cost-effective, ideal for vessels with relatively constant speeds, like smaller boats or tugboats. Think of a basic, reliable fan.

Controllable-pitch propellers (CPP): The pitch of the blades can be adjusted while the propeller is rotating, allowing for efficient operation over a wider range of speeds and maneuvering capabilities. This is like having a gear system for your propeller, providing better control and fuel efficiency at varying speeds, common in larger vessels.

Kort nozzles: These are ducts surrounding the propeller that improve efficiency by increasing thrust and reducing cavitation (formation of vapor bubbles). Imagine a funnel around the propeller, focusing and streamlining the water flow for better propulsion, commonly used in tugboats and icebreakers.

Ducted propellers: Similar to Kort nozzles, these enclose the propeller within a duct, improving thrust and efficiency, often used in smaller vessels and those requiring good maneuverability.

The choice of propeller depends heavily on the vessel’s size, speed requirements, maneuvering needs, and the operational profile.

Q 3. What are the main components of a marine propulsion system?

A marine propulsion system is a complex arrangement of components working together to move a vessel. The main components include:

Main engine: This provides the primary power – usually a diesel engine or gas turbine.

Reduction gearbox: This reduces the high speed of the engine to the slower, more efficient speed of the propeller.

Propeller shaft: This transmits power from the gearbox to the propeller.

Propeller: This converts rotational energy into thrust to move the vessel.

Control systems: These manage engine speed, propeller pitch (if applicable), and overall propulsion.

Auxiliary systems: These include lubricating oil systems, cooling systems, fuel systems, and exhaust systems, all vital for engine operation.

The interaction and efficiency of these components are crucial for optimal vessel performance and fuel economy.

Q 4. Explain the function of a marine boiler.

A marine boiler generates steam under pressure, which is then used for various purposes onboard a vessel. It’s like the heart of the ship, providing essential energy for many functions.

Steam for propulsion: In older vessels, steam turbines were directly driven by the high-pressure steam produced by the boiler.

Heating: Steam provides heat for cabin heating, domestic hot water, and other onboard heating needs.

Power generation: Steam can drive turbines connected to generators, creating electricity for the ship.

Other uses: Steam may be used for cargo handling systems, desalination plants, or other auxiliary functions.

Modern ships often employ diesel-electric propulsion, reducing reliance on boilers, but many older and specialized vessels still utilize steam-based systems.

Q 5. What are the safety precautions for working in an engine room?

Working in an engine room demands strict adherence to safety procedures. One lapse can have serious consequences. Key precautions include:

Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety footwear, hearing protection, eye protection, and flame-resistant clothing.

Lockout/Tagout procedures: Strictly follow lockout/tagout procedures when performing maintenance or repairs on machinery. This prevents accidental energization or startup.

Emergency shutdown procedures: Understand and be familiar with all emergency shutdown procedures for the various systems and machinery in the engine room.

Hot surface awareness: Be mindful of hot surfaces, such as pipes and machinery, to prevent burns.

Ventilation: Ensure adequate ventilation to prevent build-up of harmful gases.

Fire safety: Understand the location and operation of fire extinguishers and other fire safety equipment. Participate in regular fire drills.

Hazardous material handling: Follow proper procedures for handling hazardous materials, such as oils, chemicals, and fuels.

Regular safety training and adherence to company safety policies are vital for a safe working environment.

Q 6. Describe the different types of marine pumps and their applications.

Marine pumps are essential for various onboard functions. Different types cater to specific needs:

Centrifugal pumps: These are the most common type, using a rotating impeller to increase fluid pressure. They are suitable for high flow rates, efficient for transferring seawater, bilge water, and other liquids.

Positive displacement pumps: These pumps displace a fixed volume of fluid with each stroke, ideal for high pressure applications, such as fuel oil transfer and hydraulic systems.

Bilge pumps: These pumps remove water from the bilges (the lowest part of the ship). They are vital for preventing flooding and maintaining the integrity of the vessel.

Fire pumps: These are high-capacity pumps used to supply water to the fire-fighting systems.

Ballast pumps: These pumps control the water ballast in tanks to maintain stability and trim of the vessel.

The selection of the pump depends on the fluid to be pumped, the required flow rate, pressure, and the specific application.

Q 7. Explain the purpose of a marine sewage treatment plant.

A marine sewage treatment plant (MSTP) processes sewage generated onboard a vessel, treating it to an environmentally safe level before discharge into the sea. Think of it as a mini-water treatment plant onboard the ship.

Its purpose is to protect the marine environment by preventing the discharge of untreated human waste and other harmful pollutants. MSTPs typically employ a combination of physical, chemical, and biological processes to remove solids, reduce organic matter, and disinfect the treated effluent before it’s released.

Regulations concerning the discharge of sewage vary, and vessels must comply with international maritime regulations (like MARPOL) to ensure responsible waste management.

Q 8. What is the function of a ballast water management system?

A Ballast Water Management System (BWMS) is crucial for preventing the spread of invasive aquatic species between different bodies of water. Ships use ballast water – water taken on board to maintain stability – and this water can contain a variety of organisms. When the ballast water is released at a destination port, these organisms are introduced into a new environment, potentially causing ecological damage.

The function of a BWMS is to treat ballast water before it’s discharged, eliminating or significantly reducing the number of viable organisms. This treatment can involve various methods, including filtration, UV disinfection, and chemical treatment. The goal is to meet international standards, such as those set by the International Maritime Organization (IMO), ensuring environmentally responsible shipping practices.

Imagine a ship traveling from a tropical region to a colder climate. Without a BWMS, the tropical organisms in the ballast water could outcompete native species, disrupting the local ecosystem. The BWMS prevents this by ensuring that only clean water is released, safeguarding biodiversity.

Q 9. Describe the different types of marine lubricating oils and their applications.

Marine lubricating oils are crucial for reducing friction and wear in various shipboard machinery. Different types are used based on their specific applications and properties.

- Diesel Engine Oils: These oils are formulated to withstand high temperatures and pressures within diesel engines. They provide lubrication, cooling, and cleaning properties, preventing engine wear and extending engine life. Different grades exist, depending on the engine type and operating conditions (e.g., high-speed, low-speed engines).

- Cylinder Oils: Used in the cylinders of large, slow-speed diesel engines, these oils are highly viscous and need to form a protective film on cylinder liners to minimize wear from piston rings. Their resistance to oxidation is crucial.

- Gear Oils: These oils are used to lubricate gears and other rotating components, requiring high viscosity and extreme pressure (EP) additives to prevent wear and damage under heavy loads.

- Turbine Oils: Used in gas turbines, these oils must have excellent oxidation stability and resistance to high temperatures. They require precise viscosity to ensure proper lubrication and efficient turbine operation.

- Hydraulic Oils: Used in hydraulic systems, these oils transmit power and provide lubrication. They need to be resistant to degradation and maintain consistent viscosity across a range of temperatures.

The selection of the appropriate oil depends on the specific machinery’s requirements, considering factors such as operating temperature, load, and speed. Using the wrong type of oil can lead to premature wear, equipment failure, and costly repairs.

Q 10. Explain the principle of operation of a centrifugal pump.

A centrifugal pump operates using the principle of converting rotational energy into fluid energy. It increases the pressure of a liquid by accelerating it using a rotating impeller.

Imagine a spinning wheel with curved blades (the impeller). As the impeller rotates, it pulls the liquid towards its center. The curved blades then throw the liquid outwards, increasing its velocity and consequently its pressure. This pressurized liquid is then discharged from the pump’s outlet.

The impeller is housed within a casing, which directs the flow of liquid. The centrifugal force generated by the rotating impeller is the primary mechanism for increasing the liquid’s pressure. The higher the impeller’s speed, the greater the pressure increase. Centrifugal pumps are commonly used for various applications on ships, including supplying cooling water, transferring ballast water, and handling fuel.

Q 11. What are the different types of marine valves and their applications?

Marine valves are critical components that control the flow of liquids and gases within a ship’s systems. Various types exist, each tailored to specific applications.

- Gate Valves: Used for on/off service, providing a relatively unobstructed flow when open. They’re suitable for larger pipelines.

- Globe Valves: Provide throttling control, allowing for precise regulation of flow. They are better suited for smaller pipelines and where fine control is needed.

- Ball Valves: Simple on/off valves that are quick to operate and provide a tight seal when closed.

- Butterfly Valves: Similar to ball valves in operation but utilize a rotating disc to control flow. They are often used for larger pipelines where rapid on/off control is needed.

- Check Valves: Prevent backflow of fluids in a piping system. They automatically open when flow is in one direction and close when flow reverses.

- Safety Valves: Designed to protect equipment from overpressure by automatically opening and releasing pressure when it exceeds a preset limit.

The choice of valve type depends on factors such as the fluid being handled, the required flow control, the pressure and temperature conditions, and the ease of maintenance.

Q 12. Explain the importance of regular maintenance of marine engines.

Regular maintenance of marine engines is paramount for ensuring safe and efficient operation, preventing costly breakdowns, and maximizing engine lifespan. Neglecting maintenance can lead to catastrophic failures at sea, potentially resulting in significant financial losses and safety hazards.

Regular maintenance involves a combination of scheduled inspections, preventative measures, and timely repairs. This includes tasks such as oil changes, filter replacements, checking fuel systems, inspecting cooling systems, monitoring vibration levels, and regularly testing safety devices. A well-maintained engine operates efficiently, consumes less fuel, produces fewer emissions, and requires fewer unplanned repairs.

Think of a car – regular oil changes and inspections prevent major engine problems. The same logic applies to marine engines, but on a much larger scale with potentially more severe consequences if neglected.

Q 13. Describe the process of engine overhauling.

Engine overhauling is a comprehensive process involving a complete disassembly, inspection, repair, and reassembly of a marine engine. It is typically undertaken after a significant period of operation or when major repairs are required.

The process involves several steps: Disassembly of the engine, thorough cleaning of components, detailed inspection for wear and tear, replacement of worn or damaged parts, repair or reconditioning of components as needed, reassembly of the engine, rigorous testing and adjustments to ensure proper functionality. Overhauling ensures that the engine is returned to its original specifications, restoring its performance and reliability.

Overhauling is a major undertaking that requires skilled technicians and specialized equipment. It’s significantly more involved than routine maintenance and aims to restore the engine to as-new condition or better, extending its service life.

Q 14. What are the common causes of engine malfunction?

Engine malfunctions can stem from various causes, often stemming from a combination of factors. Some common causes include:

- Fuel System Problems: Contaminated fuel, clogged filters, faulty fuel injectors, or problems with fuel pumps can lead to engine misfires, reduced power, or complete engine failure.

- Lubrication System Issues: Insufficient lubrication, low oil pressure, contaminated oil, or faulty oil pumps can cause excessive wear, overheating, and seizure of engine components.

- Cooling System Failures: Leaks in the cooling system, clogged water passages, or malfunctioning cooling pumps can lead to engine overheating, potentially causing significant damage.

- Ignition System Problems (for spark-ignition engines): Faulty spark plugs, ignition coils, or wiring can result in misfires and reduced power.

- Wear and Tear: Over time, components such as piston rings, bearings, and valves wear out, reducing efficiency and leading to malfunction.

- Improper Maintenance: Neglecting routine maintenance significantly increases the risk of engine failure.

Effective diagnostics are crucial for identifying the root cause of engine malfunctions. This usually involves a systematic approach, checking each component and system until the problem is isolated.

Q 15. How to troubleshoot a malfunctioning marine engine?

Troubleshooting a malfunctioning marine engine requires a systematic approach. Think of it like diagnosing a car engine – you need to isolate the problem before fixing it. It starts with observing the symptoms: Is the engine not starting? Is it running rough? Is there excessive smoke or unusual noise?

Here’s a step-by-step approach:

- Safety First: Ensure the engine is shut down and secured. If there’s a fire or other immediate danger, prioritize safety procedures.

- Gather Information: Check engine gauges (oil pressure, temperature, RPM), log book entries, and talk to crew members about when the problem started and what they observed.

- Visual Inspection: Look for obvious problems like loose connections, leaks (fuel, oil, coolant), damaged belts or hoses. This is often where you’ll find simple fixes.

- Systematic Checks: Based on the symptoms, follow a logical sequence of checks. For example, if the engine won’t start, check the battery, starter motor, fuel supply, and ignition system. If it’s running rough, check fuel injectors, air intake, and compression.

- Diagnostic Tools: Use appropriate tools such as multimeters, pressure gauges, and compression testers to gather data and pinpoint the problem.

- Consult Manuals: Refer to the engine’s maintenance and troubleshooting manuals for specific guidance. These manuals are invaluable!

- Seek Expert Advice: If you can’t identify the problem, don’t hesitate to contact a qualified marine engineer or service technician. Attempting a complex repair without sufficient knowledge can cause further damage.

Example: Imagine the engine won’t start. You check the battery and find it’s dead. A simple jump-start might solve the issue. However, if the battery is consistently failing, it points to a charging system problem requiring further investigation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the principle of operation of a refrigeration system.

A marine refrigeration system works on the same basic principle as a household refrigerator – using a refrigerant to absorb heat from one area and release it in another. It’s a closed-loop system involving a compressor, condenser, expansion valve, and evaporator. Think of it as a heat pump that moves heat from the inside of the refrigeration space (making it cold) to the outside (making it warmer).

- Compressor: Compresses the refrigerant gas, raising its temperature and pressure.

- Condenser: The high-pressure, high-temperature refrigerant gas releases heat to the surrounding environment, condensing into a liquid.

- Expansion Valve: The liquid refrigerant passes through a valve, causing it to rapidly expand and evaporate. This expansion reduces the refrigerant’s temperature.

- Evaporator: The cold, low-pressure refrigerant absorbs heat from the refrigerated space, evaporating back into a gas, thus cooling the space. The cycle then repeats.

Practical Application: Marine refrigeration systems are crucial for preserving food, storing medicines, and maintaining comfortable temperatures in crew accommodations. Proper maintenance, including regular cleaning of the condenser coils, is essential for efficient operation.

Q 17. What are the different types of marine air conditioning systems?

Marine air conditioning systems are broadly categorized into several types based on their refrigerant, operation, and capacity.

- Chill Water Systems: These systems use chilled water as a refrigerant, often employing a central chiller unit that cools the water. This cooled water is then circulated through fan coil units located throughout the vessel.

- Direct Expansion (DX) Systems: In DX systems, the refrigerant flows directly through the evaporator coils in each air handling unit (AHU). These are commonly used in smaller vessels due to their simpler design.

- Reverse Cycle Systems (Heat Pumps): These systems can both cool and heat the spaces. In cooling mode, they function similarly to a regular AC system. In heating mode, they reverse the refrigeration cycle to extract heat from outside air and transfer it inside.

- Packaged Units: These are self-contained units including the compressor, condenser, evaporator, and fan. They are often simpler to install and maintain than larger, split systems.

The choice of system depends on the size and type of vessel, the required cooling capacity, and budget constraints. Larger vessels often opt for chill water systems for better control and efficiency, while smaller vessels might use DX systems for their simplicity.

Q 18. Explain the function of a marine fire fighting system.

A marine fire-fighting system’s primary function is to quickly and effectively suppress fires, protect lives, and minimize damage to the vessel and its cargo. It involves a network of fire detection and suppression systems designed to tackle different types of fires in various locations on the ship.

Key components include:

- Fire Detection Systems: Smoke detectors, heat detectors, and flame detectors automatically alert the crew to a fire.

- Fixed Fire Fighting Systems: These include sprinkler systems, foam systems, and CO2 flooding systems, strategically located to combat fires in specific areas (engine room, cargo holds, etc.).

- Portable Fire Fighting Equipment: Fire extinguishers of various types (water, foam, CO2, dry powder) are readily available for immediate response to small fires.

- Fire Pumps and Hydrants: A system of pumps and fire hydrants with hoses and nozzles allows for manual fire suppression.

Example: An engine room fire might be addressed by a fixed CO2 flooding system, while a galley fire could be tackled with a portable fire extinguisher and the ship’s hydrant system.

Q 19. What are the different types of marine safety equipment?

Marine safety equipment is crucial for ensuring the safety of the crew and vessel. It encompasses a wide range of items, categorized by their function:

- Life-saving Appliances: Lifeboats, life rafts, life jackets, immersion suits, and personal locator beacons (PLBs) are designed to keep people alive in an emergency.

- Fire Fighting Equipment: As described earlier, this includes fire extinguishers, hydrants, fire pumps, and fixed suppression systems.

- Navigation Equipment: This includes GPS, radar, compasses, and other navigational aids necessary for safe navigation.

- Personal Protective Equipment (PPE): This includes safety helmets, gloves, eye protection, and specialized clothing to protect from various hazards.

- Emergency Signaling Equipment: This includes flares, distress signals, and emergency lights for attracting attention in an emergency situation.

- First Aid Equipment: A well-stocked first aid kit and trained personnel are essential for dealing with injuries.

The specific equipment required varies greatly depending on the size, type, and operational area of the vessel.

Q 20. Describe the procedures for responding to an engine room fire.

Responding to an engine room fire requires a rapid and coordinated effort. Remember the acronym RACE: Rescue, Alarm, Confine, Extinguish/Evacuate.

- Rescue: Attempt to rescue any personnel in immediate danger, but do not risk your own safety.

- Alarm: Raise the general alarm to alert the entire crew. Sound the ship’s alarm bells and use other communication systems to alert others.

- Confine: Attempt to confine the fire by closing fire doors, hatches, and dampers to prevent its spread. This is crucial to contain the flames and prevent smoke from spreading to other areas.

- Extinguish/Evacuate: Use appropriate fire fighting equipment to attempt to extinguish the fire. If the fire is too large or if attempts to extinguish it fail, evacuate the engine room immediately and proceed with emergency procedures.

Important Considerations: Always follow the ship’s emergency procedures. Use the ship’s fire-fighting systems correctly. Communicate clearly and effectively with other crew members. If the fire is uncontrollable, abandon ship according to the established procedures.

Q 21. Explain the importance of maintaining proper engine room ventilation.

Proper engine room ventilation is critical for several reasons, all directly related to safety and operational efficiency.

- Removal of Harmful Gases: Combustion engines produce exhaust gases like carbon monoxide, which is highly toxic. Adequate ventilation prevents these gases from accumulating to dangerous levels. Imagine being trapped in a small space with a running car engine; proper ventilation is the equivalent of opening the garage door.

- Prevention of Explosions: Flammable fuel vapors can accumulate in poorly ventilated spaces, creating a risk of explosions. Ventilation helps to dilute these vapors and prevents them from reaching explosive concentrations.

- Heat Removal: Engines generate significant heat. Effective ventilation helps to dissipate this heat, preventing overheating of equipment and improving the working environment for the crew. Think of it as cooling down a computer that’s been running for a long time.

- Improved Engine Efficiency: Sufficient air intake is essential for efficient combustion in the engines. A lack of fresh air can lead to poor engine performance.

- Crew Comfort: Proper ventilation ensures a comfortable working environment for the engine room crew, reducing discomfort due to heat, fumes, and humidity.

Regular inspections and maintenance of the ventilation system are crucial to ensure its effective functioning. This includes checking fans, ducts, and filters for obstructions or damage.

Q 22. What are the regulations related to marine pollution prevention?

Marine pollution prevention is governed by a complex web of international and national regulations, aiming to minimize the environmental impact of shipping activities. The most significant international framework is the International Maritime Organization (IMO), a specialized agency of the United Nations. The IMO develops and enforces conventions, such as the MARPOL Convention (Marine Pollution), which is crucial for preventing pollution from ships.

MARPOL 73/78: This convention addresses various pollution sources, including oil, noxious liquid substances, garbage, sewage, and air emissions. It’s divided into Annexes, each dealing with a specific pollutant type. For example, Annex I regulates oil pollution, while Annex V focuses on garbage disposal.

Ballast Water Management Convention: This relatively newer convention aims to prevent the spread of invasive aquatic species through ballast water discharge. Ships must either treat their ballast water or follow specific procedures to manage it safely.

National Regulations: Individual countries often have their own regulations that complement or exceed international standards. These national laws typically address issues like port state control, enforcement, and specific pollution concerns relevant to their coastal waters.

Compliance with these regulations is vital for protecting the marine environment and ensuring the sustainable operation of the shipping industry. Penalties for non-compliance can be substantial, including fines, detention of vessels, and even criminal prosecution.

Q 23. Explain the importance of complying with international maritime regulations.

Compliance with international maritime regulations is paramount for several key reasons. Firstly, it ensures the safety of life at sea. Regulations regarding ship construction, maintenance, and operation are designed to minimize the risk of accidents and casualties. Secondly, it protects the marine environment. As discussed earlier, conventions like MARPOL aim to prevent pollution, preserving delicate ecosystems and marine life.

Thirdly, it facilitates international trade. Uniform standards and regulations enable ships to navigate freely between ports worldwide, avoiding the complexities and delays associated with differing national requirements. Non-compliance can lead to significant delays, port-state control inspections, and potential fines, all of which directly impact the profitability of shipping operations. Finally, it enhances the reputation and credibility of shipping companies. A strong safety and environmental record is crucial for attracting customers and maintaining a competitive edge in the industry.

Imagine a world without international regulations – ships operating with different safety standards, potentially polluting waterways without consequence. The chaos and environmental damage would be catastrophic. International regulations provide a crucial framework for responsible and sustainable shipping practices.

Q 24. Describe your experience with marine engine maintenance and repair.

During my time working on [Name of Vessel/Company, if comfortable sharing; otherwise omit], I gained extensive hands-on experience with marine engine maintenance and repair. My responsibilities included performing routine inspections, servicing various engine components (e.g., fuel injectors, turbochargers, and lubricating systems), and troubleshooting malfunctions. I’m proficient in diagnosing faults using diagnostic tools and conducting necessary repairs, adhering to strict safety protocols.

For example, I once successfully resolved a critical issue with a main engine’s fuel injection system. By systematically analyzing the engine’s performance data and conducting thorough inspections, I identified a faulty injector causing a significant loss of power and increased fuel consumption. After replacing the faulty injector, and performing the necessary adjustments, the engine resumed normal operation. This experience honed my problem-solving skills and emphasized the importance of meticulous attention to detail in engine maintenance. I’m familiar with various engine types, including [mention specific types of engines you’ve worked with, e.g., diesel, gas turbines], and possess a solid understanding of their operational principles.

Q 25. What are your strengths and weaknesses as a marine engineer?

My strengths as a marine engineer include a strong problem-solving aptitude, a meticulous attention to detail, and a proactive approach to maintenance. I’m a quick learner, adept at adapting to new technologies and challenges, and a strong team player capable of collaborating effectively in diverse environments. I’m also comfortable working independently and taking initiative when needed.

One area for improvement is my experience with specific advanced engine control systems. While I possess a fundamental understanding, I’m eager to expand my knowledge and proficiency in this field through further training and hands-on experience. I actively seek opportunities to broaden my skillset and stay current with industry advancements.

Q 26. Why are you interested in a career in marine engineering?

I’ve always been fascinated by the power and complexity of marine engines and the intricacies of maritime operations. The combination of engineering challenges, global travel, and the unique teamwork required onboard vessels strongly appeals to me. I thrive in challenging environments, and the demanding nature of marine engineering provides constant opportunities for growth and learning. The opportunity to contribute to the safe and efficient operation of ships, ensuring both crew safety and environmental protection, is highly rewarding.

Furthermore, I appreciate the sense of responsibility and the critical role marine engineers play in the global maritime industry. The field offers a blend of technical expertise, problem-solving, and international collaboration – aspects that resonate deeply with my personal and professional aspirations.

Q 27. How do you handle pressure and stressful situations?

Marine engineering often involves high-pressure situations, from handling engine malfunctions to responding to emergencies. I handle these by remaining calm and focused, prioritizing systematic problem-solving. I break down complex issues into manageable steps, focusing on identifying the root cause before implementing solutions. I also value clear communication and teamwork, ensuring everyone is informed and contributing effectively under stress.

For instance, during a heavy storm at sea, we experienced a power failure affecting essential ship systems. By maintaining clear communication with the crew and calmly prioritizing repairs, we managed to restore power efficiently and safely, minimizing any risks. My ability to stay calm under pressure is a significant asset in this high-stakes environment.

Q 28. Describe a time you had to solve a complex technical problem.

During a voyage, we encountered a significant issue with the main engine’s cooling system. The engine temperature was rising rapidly, threatening serious damage. The initial diagnosis pointed to a potential leak in the cooling jacket, but locating the precise source proved challenging due to the complexity of the system and limited accessibility in certain areas.

My approach involved a systematic investigation. I first reviewed the engine’s operational logs and checked various pressure and temperature readings. I then conducted a visual inspection, using specialized tools to identify any visible leaks or damage. After carefully isolating different sections of the cooling system, I eventually pinpointed a small crack in a less-accessible part of the cooling jacket. We repaired the crack and subsequently carried out a thorough pressure test to confirm the fix. The successful resolution not only prevented a catastrophic engine failure but also highlighted the value of methodical troubleshooting and attention to detail in complex systems.

Key Topics to Learn for a Basic Marine Engineering Principles Interview

- Marine Propulsion Systems: Understanding different types of propulsion (e.g., diesel engines, gas turbines, electric propulsion), their operational principles, and maintenance requirements. Consider practical applications like troubleshooting common engine malfunctions.

- Ship Stability and Trim: Grasp the principles of buoyancy, center of gravity, and metacentric height. Explore practical applications such as load calculations and their impact on ship stability. Consider problem-solving scenarios involving cargo shifting or flooding.

- Basic Thermodynamics: Familiarize yourself with fundamental thermodynamic cycles (e.g., Rankine cycle, Diesel cycle) and their application in marine engine systems. Understand concepts like heat transfer and efficiency.

- Marine Auxiliary Systems: Gain knowledge of essential auxiliary systems like refrigeration, air conditioning, and fire-fighting systems. Be prepared to discuss their operational principles and maintenance procedures.

- Safety and Regulations: Understand basic maritime safety regulations (SOLAS, MARPOL) and their relevance to marine engineering operations. Consider practical applications, such as emergency procedures and pollution prevention.

- Basic Fluid Mechanics: Understand fundamental principles of fluid flow, pressure, and viscosity, and their application in marine systems such as piping and pumping systems.

- Engine Room Operations: Develop a general understanding of typical engine room layouts, procedures, and responsibilities.

Next Steps

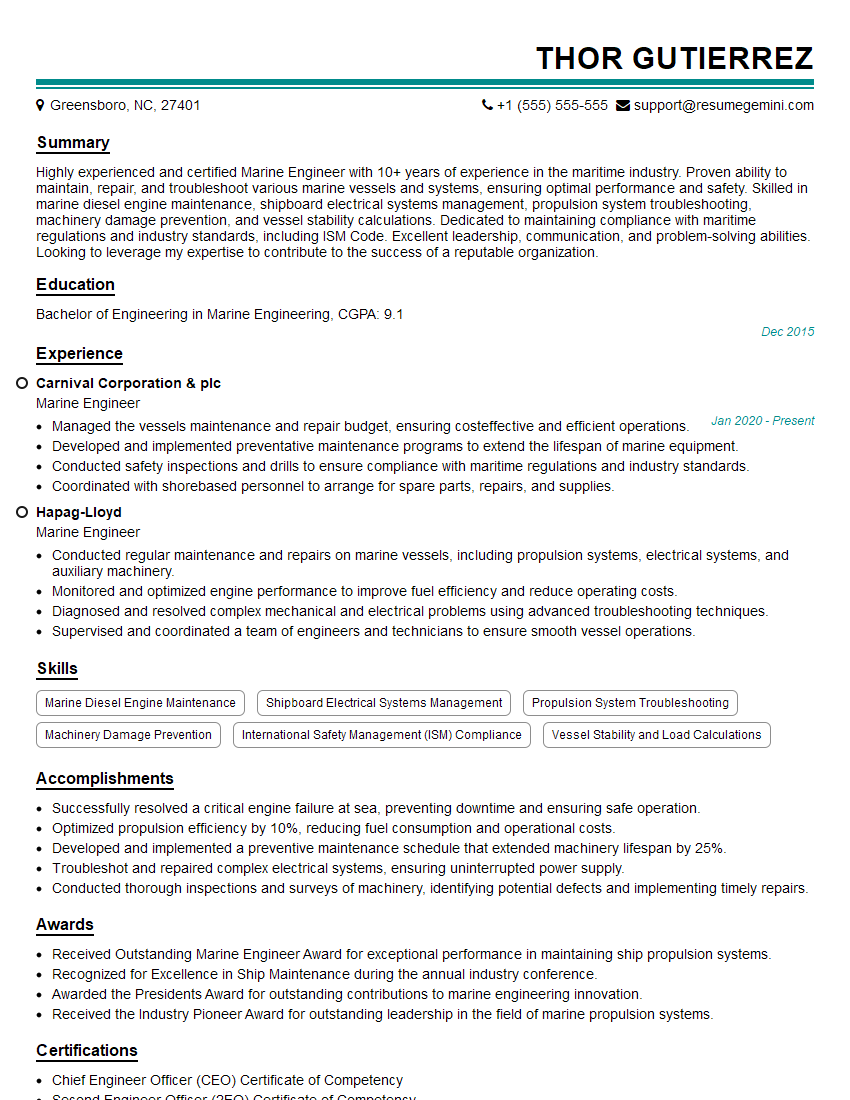

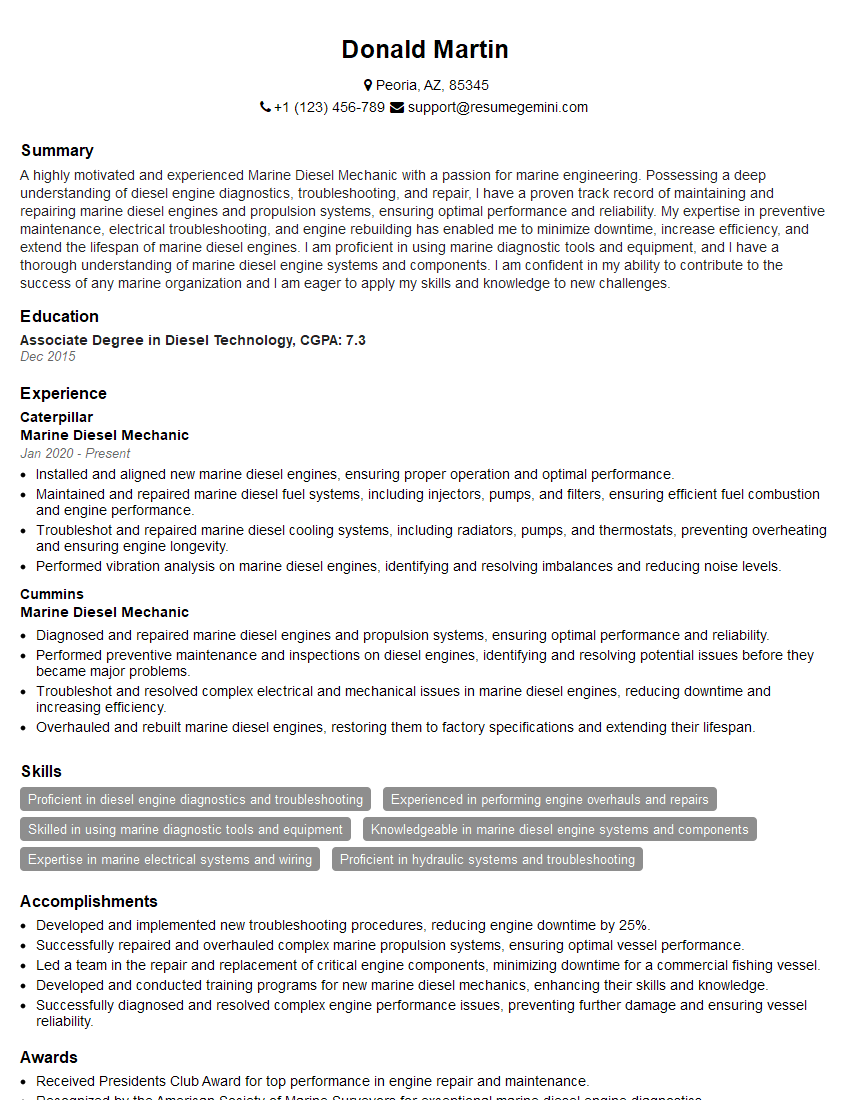

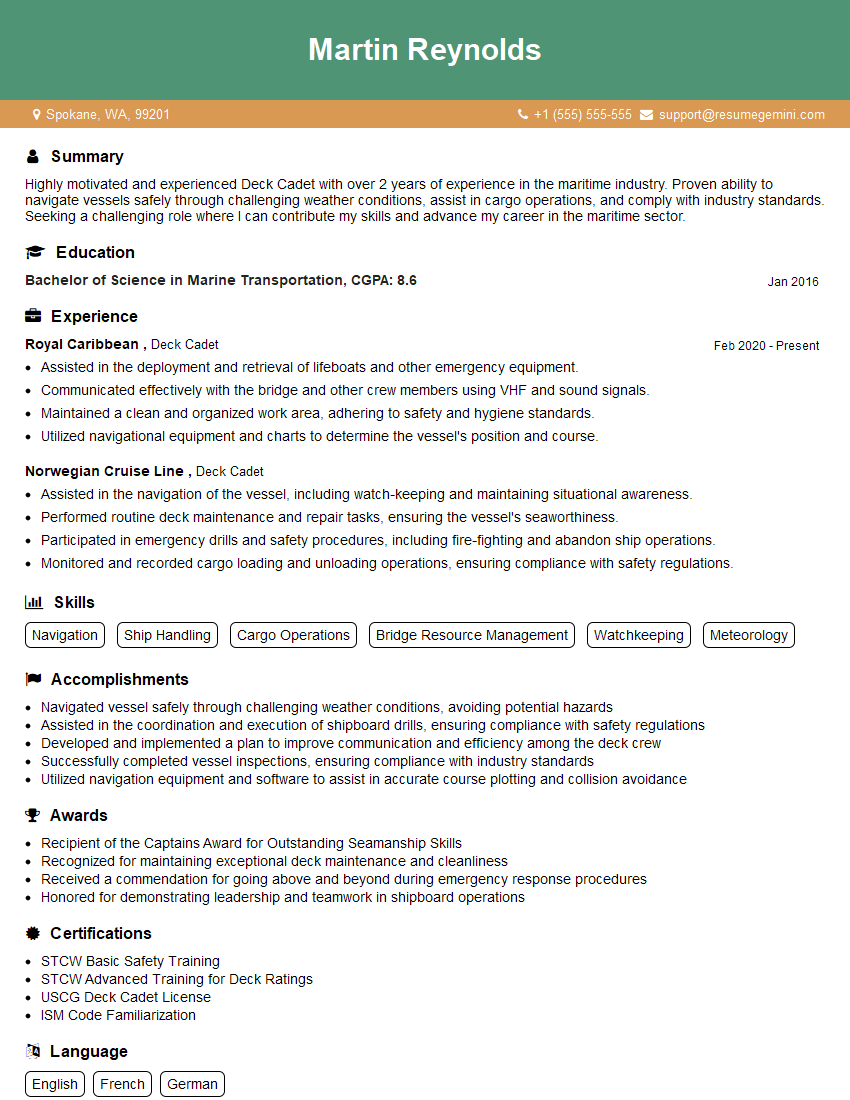

Mastering basic marine engineering principles is crucial for career advancement in this exciting field. A strong foundation in these concepts will significantly improve your interview performance and open doors to various opportunities. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to showcasing basic knowledge of marine engineering principles are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO