Are you ready to stand out in your next interview? Understanding and preparing for Bike maintenance interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Bike maintenance Interview

Q 1. Explain the different types of bicycle brakes and their maintenance.

Bicycle brakes primarily fall into two categories: rim brakes and disc brakes. Rim brakes, the older technology, use pads that squeeze against the rim of the wheel to create friction and slow the bike. Disc brakes, increasingly common, use calipers that squeeze a rotor (a disc) attached to the wheel hub.

- Rim Brakes: These are further subdivided into caliper brakes (the most common type), cantilever brakes (often found on older mountain bikes), and linear-pull (V-brakes) which offer more stopping power. Maintenance involves checking pad wear (replace when worn down to the wear indicators), ensuring the brake cables are properly tensioned (adjusting barrel adjusters or cable tension at the brake lever), and cleaning the brake tracks on the rims (use a dedicated rim cleaner to remove debris and brake dust). Regular cleaning and lubrication of the cable housing is crucial for smooth operation.

- Disc Brakes: These are less prone to weather and dirt affecting performance but still need regular inspection. Maintenance includes checking pad wear (replace as needed), ensuring the rotors are clean and free from warping (which may require professional truing), checking the hydraulic fluid level (for hydraulic disc brakes), and ensuring proper caliper alignment.

Think of rim brakes like a car’s drum brakes—they work well but require more consistent maintenance. Disc brakes, like car disc brakes, are generally more powerful and require less frequent attention to maintenance, but the system is more complex.

Q 2. Describe the process of truing a bicycle wheel.

Truing a wheel involves adjusting the spoke tension to make the rim perfectly round and true (centered in the frame). It’s a skill that requires practice and the right tools. You’ll need a spoke wrench, a truing stand (highly recommended), and potentially a tension meter.

The process generally involves:

- Assessment: Rotate the wheel and observe the rim using the truing stand. Note any lateral (side-to-side) or radial (wobble) deviations.

- Spoke Adjustment: Use the spoke wrench to tighten or loosen individual spokes. Tightening a spoke pulls the rim toward it. Conversely, loosening moves the rim away. Small adjustments are key; make small tweaks, observe the results, and repeat until the rim is true. Lateral truing usually involves opposite spokes, while radial involves spokes in the same area.

- Tensioning: Use a tension meter to measure the tension across the wheel, ensuring consistency to prevent stress on the wheel. Ideally, every spoke should have near-equal tension.

- Final Check: Once true, spin the wheel to ensure smooth rotation and the absence of any wobble or friction.

Truing a wheel is a delicate process. If you’re unsure, it’s best to take it to a professional bike mechanic. A poorly trued wheel can lead to poor handling, decreased efficiency, and even damage to the wheel or frame.

Q 3. How do you diagnose and repair a flat tire?

Diagnosing a flat tire involves visually inspecting the tire for punctures, embedded objects, or signs of damage. Repairing involves:

- Remove the wheel: Unscrew the wheel quick release lever (or use the appropriate wrench for nuts) to detach the wheel from the bicycle frame.

- Deflate the tube completely: Press the valve to release all the air.

- Remove the tire: Use tire levers (plastic is safer for rims) to carefully pry one side of the tire off the rim, then the other. Be careful not to pinch the tube.

- Locate the puncture: Inflate the tube slightly to listen for a hiss, or submerge the tube in water to observe air bubbles escaping at the point of the puncture.

- Patch the tube: If the puncture is small, use a patch kit to clean and apply a patch to the damaged area. Allow it to fully adhere following manufacturer instructions.

- Reinstall the tube and tire: Carefully tuck the tube back into the tire, making sure it is fully seated in the tire cavity. Work the tire bead back onto the rim, using your thumbs to push the bead into the rim channel; you may need to leverage the tire levers to help.

- Inflate the tire: Pump the tire to the recommended pressure (listed on the tire sidewall).

If the tube is beyond repair or the tire is severely damaged, replace both.

Q 4. What are the common causes of derailleur problems and how do you fix them?

Derailleur problems are common, often stemming from cable issues, bent hangers, or worn components.

- Cable Issues: Stretching, fraying, or mis-adjusted brake cables can result in shifting problems. This includes issues with shifting cable tension and the cable housing which may require lubrication.

- Bent Derailleur Hanger: This small component connects the derailleur to the frame. A bent hanger can severely impact shifting performance. Replacement is often necessary.

- Worn Components: Worn chain, cassette, and derailleur pulleys (the small wheels on the derailleur that guide the chain) can lead to inefficient shifting. Replacing the worn parts often solves the issue.

- Limit Screws Adjustment: These screws adjust the range of movement of the derailleur, preventing chain drops. Incorrect adjustment can lead to shifting issues.

Troubleshooting involves visually inspecting the derailleur, checking cable tension and housing, and carefully adjusting the limit screws (following instructions specific to your derailleur). A bent derailleur hanger needs replacement – these are relatively inexpensive parts. A professional bike shop can easily address this issue if you don’t feel comfortable with the process yourself.

Q 5. Explain the process of indexing gears on a bicycle.

Indexing gears involves precisely adjusting the derailleur to shift smoothly and accurately between gears. It ensures each gear shift is clean and precise, rather than slipping or skipping.

The process typically involves:

- Cable Tension Adjustment: This is done using the barrel adjuster on the derailleur or the cable clamp near the shifter. Adjust the tension so you can shift through all gears without skipping or excessive resistance.

- Limit Screw Adjustment: These screws set the derailleur’s range of motion. The high and low limit screws prevent the derailleur from moving too far in either direction. Proper adjustment avoids chain drops.

- Cable Indexing: This varies depending on the type of shifter. Some shifters have cable indexing adjustments that fine-tune shifting precision. This often requires consulting your groupset’s instruction manuals and potentially using a specialized tool.

- Shifting Through Gears: Once initial adjustments have been made, cycle through the gears, noting any inconsistencies in shifting and making incremental adjustments as needed to refine the gear changes.

Indexing gears is a delicate process. It often requires patience, attention to detail, and is greatly simplified using the derailleur’s instruction manual.

Q 6. How do you adjust bicycle brakes for optimal performance?

Optimal brake performance relies on proper adjustment and maintenance. For both rim and disc brakes, the key aspects are:

- Cable Tension: The brake levers shouldn’t feel spongy or require excessive travel before engaging the brakes. Adjust barrel adjusters and cable tension at the brake lever to achieve firm, responsive braking. For hydraulic disc brakes, proper fluid level is critical. Too little fluid can lead to spongy brakes.

- Pad Alignment: Ensure the brake pads contact the rim (rim brakes) or rotor (disc brakes) evenly. Improper alignment can lead to uneven wear and reduced stopping power. Adjust the caliper alignment using the appropriate adjustment mechanisms for the type of brake you have.

- Pad Wear: Regularly check brake pad wear and replace them when worn down to the wear indicators. Worn pads significantly reduce braking efficiency and can lead to accidents.

- Cable Housing: Keep the cable housing clean and lubricated to minimize friction and ensure smooth brake lever action.

The best way to adjust brakes is by going through a systematic procedure for your brake system type. Consult the bike’s maintenance manual and YouTube tutorials specific to the brake type and model.

Q 7. Describe the different types of bicycle chains and their maintenance.

Bicycle chains are primarily made of steel, though some higher-end chains use other materials for weight reduction or increased durability. They are classified by their width and number of speeds (e.g., 8-speed, 10-speed, 12-speed).

- Single-Speed Chains: These are simpler and stronger but not compatible with multi-speed systems.

- Multi-Speed Chains: Designed with narrower plates for smooth shifting between gears. Each speed system requires a specific chain width and design to ensure compatibility with the cassette and chainrings.

Maintenance involves regular cleaning and lubrication. A dirty chain wears out faster and shifts poorly. Clean the chain using a degreaser and chain cleaner, then lubricate using a chain lubricant (wet lube for rainy conditions, dry lube for dry).

Chain wear can be measured using a chain wear tool. Replacing a worn chain is crucial. Riding with an overly worn chain will increase wear on the cassette and chainrings, necessitating more expensive repairs later on.

Think of a chain like the belt in a car engine – it’s constantly under stress. Regular maintenance maximizes its lifespan and ensures smooth and efficient operation.

Q 8. How do you assess the condition of a bicycle frame for cracks or damage?

Assessing a bicycle frame for cracks or damage requires a meticulous visual inspection. Think of it like a doctor’s exam – you need to be thorough and systematic. Start by cleaning the frame, especially around welds and stress points like the head tube, bottom bracket, and chainstays. Then, run your fingers along all surfaces, feeling for any irregularities, bumps, or changes in texture. Pay close attention to areas where the paint is chipped or scratched, as these areas are more susceptible to cracks.

Next, use a bright light at a low angle to illuminate the frame’s surface. This helps highlight even tiny hairline fractures that might otherwise be missed. You can also use a magnifying glass to get a closer look at any suspicious areas. For particularly critical inspections, consider using a dye penetrant test, a professional technique that reveals hidden cracks by drawing a colored liquid into them. If you find any cracks, even small ones, it’s crucial to consult a professional bike mechanic for assessment; continuing to ride a cracked frame is extremely dangerous.

Q 9. What tools are essential for basic bicycle maintenance?

The essential tools for basic bicycle maintenance are surprisingly few but incredibly useful. Think of them as your core toolkit. You’ll want a good set of Allen wrenches (hex keys) in various sizes, a Phillips head screwdriver, and a flathead screwdriver. A chain lubricant and degreaser are vital for keeping your drivetrain smooth. A pump to inflate your tires is a must-have, and a tire lever set makes changing tires easier. Finally, a set of adjustable wrenches is helpful for many tasks, and a multi-tool combines several essential functions into a single compact package. These tools will cover most routine maintenance tasks and are a valuable investment for any cyclist.

Q 10. Explain the procedure for overhauling a bicycle hub.

Overhauling a bicycle hub is a more advanced task, best left to experienced mechanics. It involves completely disassembling the hub, cleaning all the components, inspecting for wear and tear, and reassembling everything with proper lubrication and adjustment. First, you need to remove the wheel from the bike. Then, using specialized tools like cone wrenches, you remove the axle nuts and cones. The bearings and other internal components are then carefully removed, cleaned thoroughly with degreaser, and inspected for damage or excessive wear. Any worn parts should be replaced. Reassembly is the reverse process, ensuring proper bearing preload and axle alignment. Improper adjustment can lead to wheel wobble or premature bearing failure. This is a job best done by someone experienced with hub mechanics, as mistakes can be costly.

Q 11. How do you lubricate a bicycle chain correctly?

Correct chain lubrication is crucial for smooth shifting and extended drivetrain life. Think of it as giving your chain a regular drink of water. Before lubricating, thoroughly clean the chain using a degreaser and a rag or chain cleaning device. Then, apply a small amount of chain lubricant, just a drop or two per link, while slowly rotating the pedals backward. Wipe off any excess lubricant, as excess attracts dirt and grime. Use a dedicated bicycle chain lubricant, as other lubricants might attract dirt or damage seals in your drivetrain components. It’s good practice to lubricate your chain after every few rides or more frequently if you ride in wet conditions. Regular lubrication significantly improves your riding experience and prolongs the life of your chain and other drivetrain components.

Q 12. Describe the process of replacing a bicycle bottom bracket.

Replacing a bottom bracket is a more involved task requiring specialized tools. The type of bottom bracket (e.g., threaded, press-fit) dictates the tools and procedure. First, the crank arms must be removed. Then, using the appropriate tools (like a bottom bracket wrench or press), the bottom bracket is carefully removed. The old bottom bracket is inspected for any signs of wear or damage. The new bottom bracket is then installed, ensuring it’s properly seated and tightened to the manufacturer’s specifications. It’s important to use the correct type of bottom bracket for your frame, and to choose the appropriate tool to prevent damage during installation. This job is best left to those with experience, due to its complexity.

Q 13. How do you identify and repair a broken spoke?

Identifying a broken spoke is usually straightforward – you’ll see a broken or severely bent spoke. Repairing a broken spoke involves several steps. First, you’ll need a spoke wrench, a spoke cutter (if the spoke is severely damaged), and a replacement spoke of the correct length and gauge. The damaged spoke is removed from the hub and the wheel. The new spoke is then threaded through the hub and the nipple is connected. The spoke is then tensioned using the spoke wrench to match the tension of the surrounding spokes. The wheel should then be trued (aligned) to ensure proper functionality. Incorrect tension or truing can lead to wheel wobble or even more damage to the wheel.

Q 14. What are the common causes of bicycle wheel wobble and how do you fix them?

Bicycle wheel wobble, also known as trueness issues, has several common causes. These include loose spokes, bent rims, or damaged hubs. Identifying the cause requires a careful inspection of the wheel. Spin the wheel and observe carefully for any lateral or radial movement. If you see movement in a particular area of the wheel, check for bent spokes or a damaged rim. Loose spokes can often be tightened using a spoke wrench. If the rim is bent, it may require professional repair or replacement. If the hub is damaged, the entire hub may need to be replaced. Trueing a wheel requires experience and specialized tools to achieve accurate results; significant damage may require a professional mechanic’s intervention.

Q 15. How do you adjust bicycle handlebars and stems?

Adjusting handlebars and stems involves changing your riding position for comfort and performance. The stem connects the handlebars to the fork, and its angle and height significantly impact your reach and posture. Handlebar adjustments typically involve rotating them left or right.

Adjusting the Stem: Most stems have a faceplate held by bolts. Loosen these bolts (usually Allen key sizes), then carefully adjust the stem’s angle or loosen and rotate it completely to change the height/reach. Tighten the bolts firmly once in the desired position. Ensure the stem is securely clamped to the steerer tube of the fork; an improperly tightened stem is a serious safety hazard.

Adjusting the Handlebars: Handlebars typically rotate on the stem. Loosen the handlebar clamp bolts (again, usually Allen keys). Rotate the handlebars to your preferred position and tighten the bolts firmly. Always ensure even tightening to avoid stress on the bars or stem. A properly adjusted setup should feel comfortable and give you a stable and responsive feel.

Example: Imagine you’re experiencing neck strain. You might adjust your stem to a slightly higher position or rotate your handlebars back a bit. Always make small adjustments and check your position before making significant changes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of bleeding hydraulic disc brakes.

Bleeding hydraulic disc brakes is essential to remove air bubbles that can impede braking performance. Air in the system compromises braking power and can lead to a spongy brake lever feel. This process requires a bleed kit which typically includes a syringe, tubing, and possibly a specialized bleed block.

Process: 1. Open the bleed port at the caliper. 2. Attach the syringe to the bleed port. 3. Slowly pump the brake lever to push fluid through the system, keeping an eye on the fluid being pushed out of the caliper. 4. Top off the master cylinder reservoir as needed. 5. Repeat this process until all air is removed and consistent, firm lever action is achieved. 6. Close the bleed port and check for leaks.

Important Considerations: Always wear eye protection. Use the correct brake fluid for your system (mineral oil for some systems, DOT fluid for others – never mix). If you are unfamiliar with the process, it’s best to seek professional help or watch a detailed video from a reputable source to ensure proper technique. Incorrect bleeding can cause damage to your brakes. The process can vary slightly depending on the specific brake system, so always check your bike’s manual.

Q 17. How do you install and adjust a bicycle seat post?

Installing and adjusting a seatpost is crucial for a comfortable and efficient riding position. The seatpost connects the saddle to the bicycle frame. Correct installation ensures proper height and fore-aft position.

Installation: 1. Insert the seatpost into the seat tube, making sure the minimum insertion mark is above the top of the frame. 2. Use a seatpost clamp to secure the seatpost in the correct position. 3. Adjust the saddle height and fore-aft position to your preference. 4. Use a torque wrench to tighten the clamp bolts to the manufacturer’s recommended torque to avoid damage. 5. Always make sure the seat post is lubricated with a suitable grease or lubricant before installation for smooth operation and preventing seizing.

Adjusting the Saddle: Adjust the saddle height by adjusting the seatpost; angle and fore/aft positioning by using the saddle clamp bolts. It is important to find a seat height that allows you to comfortably extend your leg without fully locking your knee. Using too much force when tightening the bolts can damage the frame, therefore, use a torque wrench, always.

Example: If you experience knee pain, you may need to raise or lower your saddle slightly. Improperly adjusted seat post is a common cause of cycling discomfort.

Q 18. Describe the different types of bicycle tires and their suitability for various terrains.

Bicycle tires come in a wide variety of types, each suited to different terrain and riding styles. The key differences lie in tread pattern, casing material, and rubber compound.

- Road tires: These feature a smooth tread for low rolling resistance on paved surfaces. They typically have a thinner casing for reduced weight and improved efficiency.

- Mountain bike tires: These boast aggressive tread patterns designed for grip on loose surfaces like dirt, gravel, and rocks. They have thicker, more robust casings to withstand punctures.

- Gravel/All-terrain tires: Offer a blend of features. They feature a tread pattern that handles both paved and unpaved roads, balancing rolling efficiency with grip on varied surfaces.

- Hybrid tires: Somewhere between road and mountain bike tires. Designed for use on paved roads and light trails.

Suitability: Road tires are unsuitable for off-road riding; mountain bike tires are often too heavy and slow on smooth surfaces. Choosing the correct tire is fundamental to optimizing your cycling experience and safety, matching the tire to the terrain ensures maximum performance, grip, and safety.

Q 19. How do you determine the correct tire pressure for a bicycle?

Determining the correct tire pressure is crucial for optimal comfort, efficiency, and safety. The appropriate pressure depends on several factors: tire size, rider weight, and terrain.

Methods: The recommended tire pressure is typically printed on the tire sidewall. This provides a range (e.g., 60-80 psi). You can then adjust the pressure depending on your weight and riding style. Heavier riders will usually require higher pressure, while softer pressures improve comfort on rough surfaces. Tire pressure gauges are readily available to accurately measure inflation levels.

Example: A heavier rider on smoother surfaces might inflate their tires to the higher end of the range. A lighter rider on rougher terrain might prefer the lower end. Always check and adjust tire pressure before every ride.

Important Note: Under-inflation can increase rolling resistance and the risk of pinch flats. Over-inflation reduces comfort and can lead to blowouts.

Q 20. What are the common causes of a squeaky bicycle and how do you fix them?

Squeaky bicycle components are a common problem, often stemming from dry or worn parts. Pinpointing the source requires systematic investigation.

- Brakes: Dry brake pads rubbing against the rims or rotors are a primary culprit. Cleaning the brakes and applying a suitable lubricant can resolve this.

- Seatpost: A dry seatpost rubbing against the frame is another common source. Lubricating the seatpost usually solves the squeak.

- Chain/Drivetrain: A dry chain or dirty chain is a typical source of squeaks. A clean and lubricated chain is essential.

- Pedals: Similarly, dry or worn pedal components can also squeak. Check these components for wear and lubricate accordingly.

Fixing Squeaks: Use a suitable lubricant (such as a bicycle-specific chain lubricant, grease or WD-40 (only for metal-to-metal contact, otherwise not recommended)) to lubricate the identified component. Always clean the component thoroughly before lubrication. Sometimes, replacing worn parts is necessary. For stubborn squeaks, consider using a specialized bicycle lubricant or seeking help from a bike mechanic.

Q 21. Explain the process of cleaning and lubricating a bicycle drivetrain.

Cleaning and lubricating a bicycle drivetrain (chain, cassette, derailleurs) is fundamental maintenance for smooth shifting and efficient power transfer. Regular cleaning and lubrication extends the life of the components and prevents premature wear.

Cleaning: 1. Use a degreaser to remove old lubricant and grime from the chain, cassette, and derailleurs. 2. Use a chain cleaning tool or brush for thorough cleaning. 3. Wipe down all components with a clean rag.

Lubrication: 1. Apply a bicycle-specific chain lubricant to each link of the chain, ensuring the lubricant reaches the inner rollers. 2. Wipe off any excess lubricant to avoid attracting dirt and grime. 3. Rotate the pedals to distribute the lubricant.

Frequency: The frequency depends on riding conditions. In muddy or wet conditions, cleaning and lubrication might be needed after every ride. In drier conditions, it’s advisable to perform this maintenance weekly or bi-weekly. Regular cleaning and lubrication will make all the difference between a well-maintained drivetrain and one in need of immediate replacement.

Q 22. How do you identify and address chain wear?

Identifying chain wear is crucial for preventing costly drivetrain damage. The most common method is using a chain wear tool, which measures the chain’s elongation. A worn chain stretches, causing poor shifting and increased wear on the cassette and chainrings. A chain checker tool typically uses a gauge to measure the distance between pins. If the chain exceeds the manufacturer’s specified limit (usually 0.75% to 1%), replacement is necessary.

Visually, you can also look for signs of wear such as stiff links, rusty or damaged rollers, and overall dullness. A shiny, new chain will be smooth and flexible. A worn chain will feel rough and stiff, and you might notice kinks or bent links.

Addressing chain wear involves replacing the chain. It’s generally advisable to replace the cassette and chainrings at the same time if the chain is excessively worn, to avoid premature wear on these new components. Replacing all three simultaneously ensures optimal drivetrain performance and longevity.

Q 23. Describe the different types of bicycle pedals and their maintenance.

Bicycle pedals come in various types, each with specific characteristics and maintenance requirements:

- Flat pedals: These offer a large platform for the feet, providing stability and comfort. Maintenance is minimal; just keep them clean and lubricate the axle periodically if they feel stiff.

- Clip-in pedals (SPD, Look, etc.): These require special cycling shoes with cleats that clip into the pedals, offering efficient power transfer. Regular cleaning is essential to remove mud and grit. Cleats should be checked for wear and replaced when necessary. The pedal’s release mechanism should be lubricated periodically to ensure smooth engagement and disengagement. Sometimes, cleats might need adjustment to optimize release angle.

- One-sided clipless pedals: One side offers a flat platform while the other side is clipless. This combination provides flexibility for different riding styles and situations.

Regardless of the pedal type, it is important to regularly check the axle for play and tightness. Over-tightening can damage the threads, while loose axles can be dangerous.

Q 24. How do you assess the condition of bicycle cables and housing?

Assessing the condition of bicycle cables and housings is vital for safe and efficient shifting and braking. Inspect both the outer housing and the inner cable for signs of damage or wear.

- Housing: Look for kinks, cracks, cuts, or excessive dirt and grime buildup. Housing that’s crushed or damaged can restrict cable movement, leading to poor shifting or braking performance. Inspect the ends of the housing for fraying or splitting.

- Cables: Check for corrosion, fraying, or kinks in the inner cable. Rust or frayed cables can weaken and break. Inspect the cable ends where they are attached to the levers and derailleurs for burrs or damage.

If you find any of these issues, replace the affected cable and/or housing. Regular cable lubrication using a specialized cable lube will help prevent corrosion and maintain smooth operation. Replacing them proactively can prevent unexpected failures during rides, potentially resulting in accidents.

Q 25. What are the safety precautions you take when performing bicycle repairs?

Safety is paramount when performing bicycle repairs. I always prioritize the following precautions:

- Work in a well-lit, organized area: This minimizes the risk of dropping tools or parts and ensures clear visibility.

- Use appropriate tools: Using the correct tool for each job prevents damage to the bike and ensures proper repairs.

- Wear safety glasses or goggles: This protects against flying debris during tasks like cutting cables or removing parts.

- Use gloves: To protect hands from grease and sharp edges.

- Work on a stable work stand: A work stand securely holds the bike, freeing your hands and preventing accidental drops.

- Never work on a bike that is in motion: This is an obvious but crucial rule.

- Properly dispose of hazardous waste: Always follow local regulations regarding disposal of lubricants, solvents, etc.

By consistently following these steps, I ensure both my safety and the safety of the bike during any repair procedure.

Q 26. Describe your experience with different bicycle frame materials (steel, aluminum, carbon fiber).

I have extensive experience working with various bicycle frame materials:

- Steel: Steel frames are known for their durability, ride comfort, and repairability. They can be easily welded and repaired, making them a good option for customization and longevity. However, they are heavier than aluminum or carbon fiber.

- Aluminum: Aluminum frames offer a good balance of strength, weight, and cost-effectiveness. They are stiffer than steel, providing efficient power transfer. However, they can be more susceptible to damage from impacts and are less easily repaired.

- Carbon fiber: Carbon fiber frames are known for their incredibly high strength-to-weight ratio. They offer superior stiffness and responsiveness but are expensive, more difficult to repair, and require specialized tools and knowledge to work with.

My experience encompasses diagnosing and addressing issues specific to each material, from dents and cracks in steel and aluminum to more complex composite repairs in carbon fiber frames. I am proficient in using different repair techniques suitable for each frame material, including welding (steel), brazing (steel), and specialized carbon fiber repair kits.

Q 27. How do you handle customer complaints regarding bicycle repairs?

Handling customer complaints is crucial for maintaining customer satisfaction. I approach complaints with empathy and professionalism. I begin by actively listening to the customer, allowing them to fully explain their concerns without interruption. I ask clarifying questions to understand the issue comprehensively. Once I understand the problem, I explain the process and steps to address it transparently.

If the issue stems from a repair I performed, I will thoroughly investigate and assess the situation. I will take ownership of any mistakes, and if the issue is due to my error, I will strive to provide a satisfactory solution, such as a free repair or a partial refund. If the issue is due to unforeseen circumstances or factors beyond my control (e.g., component failure), I will explain this clearly and offer solutions that balance fairness and my capabilities. I always maintain a calm and professional demeanor, ensuring customers feel heard and understood. Keeping detailed records of all repairs and communications is crucial for effective complaint resolution.

Q 28. Explain your experience with e-bike specific maintenance and repair.

E-bike maintenance and repair requires specialized knowledge beyond traditional bicycle repair. I am experienced in working with electric bicycle systems, including:

- Battery maintenance: This includes checking battery voltage, assessing charging cycles, and identifying and addressing any charging or power issues. Proper battery care is crucial for its longevity.

- Motor diagnostics and repair: Troubleshooting motor malfunctions, including issues with power delivery, unusual noises, or overheating. This can involve using diagnostic tools to identify the root cause of the problem.

- Controller and wiring inspection: Checking for loose connections, frayed wires, and potential short circuits within the electrical system, as well as diagnosing any issues with the controller unit itself.

- Display unit and sensor maintenance: Checking the functionality of the display unit, speed sensors, and other electronic components that comprise the e-bike system.

My expertise extends to identifying and sourcing replacement parts specific to e-bike systems, understanding the safety precautions involved in working with high-voltage batteries, and properly disposing of e-bike batteries at end-of-life.

Key Topics to Learn for Your Bike Maintenance Interview

- Wheel Maintenance: Understanding truing, spoke tension, and wheel building techniques. Practical application: Diagnosing and repairing a wobbly wheel. Consider exploring different wheel types and their maintenance needs.

- Drivetrain Systems: Knowledge of chain lubrication, cleaning, and replacement; cassette and freewheel maintenance; derailleur adjustment and troubleshooting. Practical application: Performing a complete drivetrain overhaul. Explore different drivetrain technologies (e.g., 1x vs. 2x).

- Braking Systems: Familiarity with different brake types (rim, disc, cantilever), pad replacement, cable adjustment, and bleeding hydraulic brakes. Practical application: Troubleshooting brake squeal and ensuring proper braking performance. Explore the differences in maintenance between different brake types.

- Fork and Suspension Maintenance: Understanding basic suspension principles, servicing air forks and shocks (including lubrication and seal replacement), and diagnosing common suspension issues. Practical application: Identifying and addressing a suspension leak. Explore different types of suspension and their maintenance requirements.

- Bike Frame and Component Inspection: Ability to identify cracks, corrosion, and other damage to the frame and components; understanding material properties and their impact on durability. Practical application: Conducting a thorough pre-ride inspection. Consider the implications of different frame materials (e.g., steel, aluminum, carbon fiber).

- Basic Repair and Tool Usage: Proficiency with common bike tools (e.g., Allen wrenches, torque wrenches, chain whip) and ability to perform basic repairs (e.g., tube changes, tire patching). Practical application: Quickly and efficiently resolving common roadside repairs. Explore advanced tool usage and specialized repair techniques.

- Troubleshooting and Diagnostics: Ability to identify the source of mechanical issues and implement effective solutions. Practical application: Systematically diagnosing a bike that is shifting poorly. Develop a structured approach to troubleshooting mechanical problems.

Next Steps

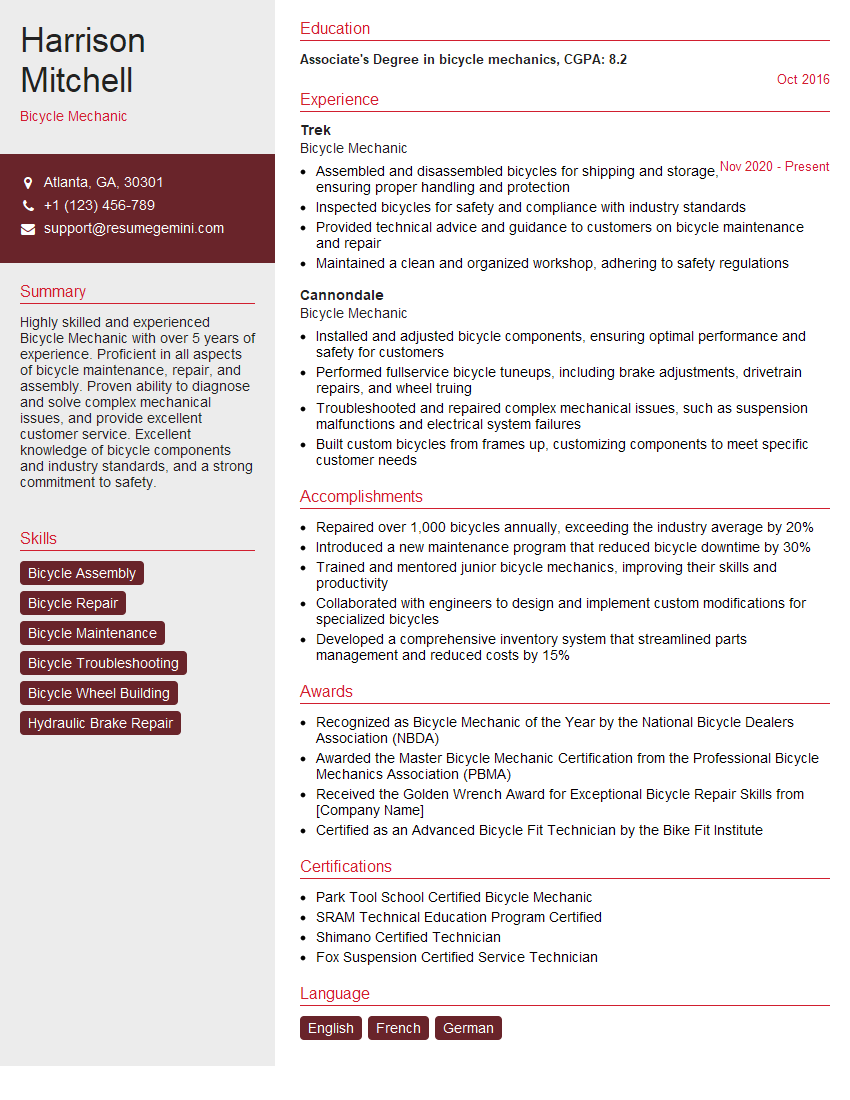

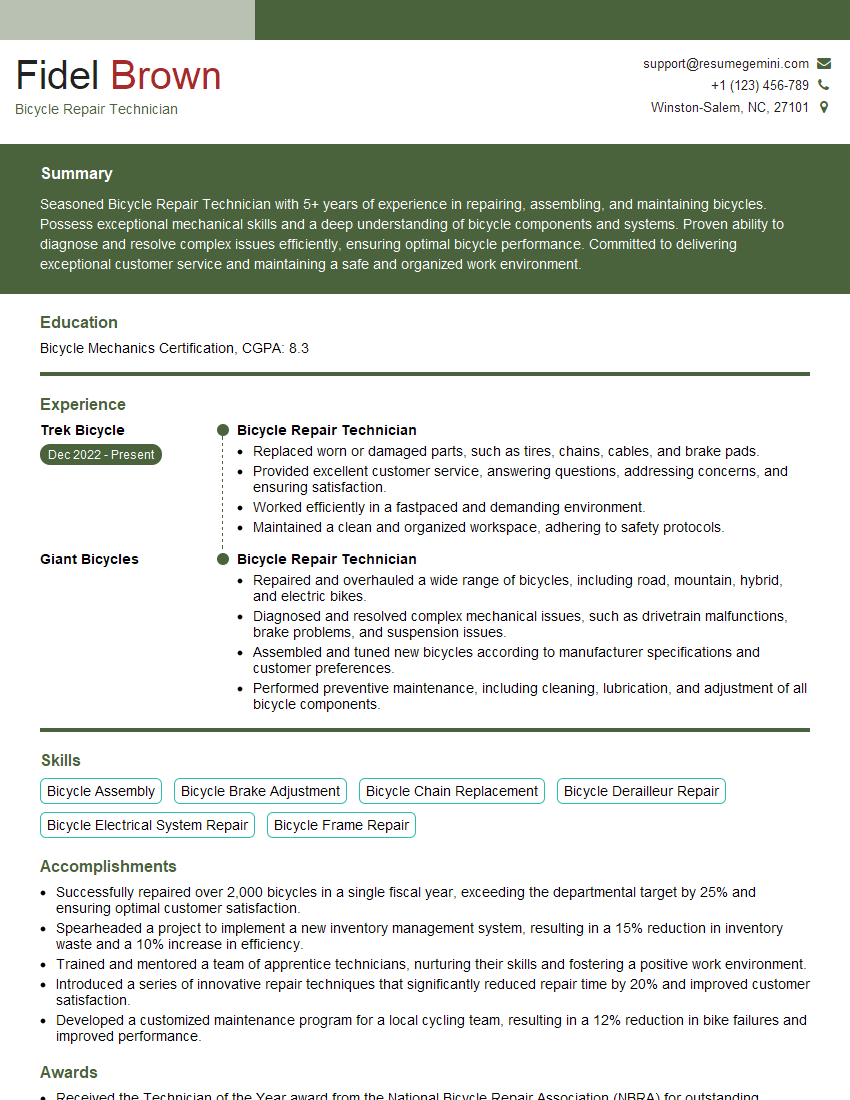

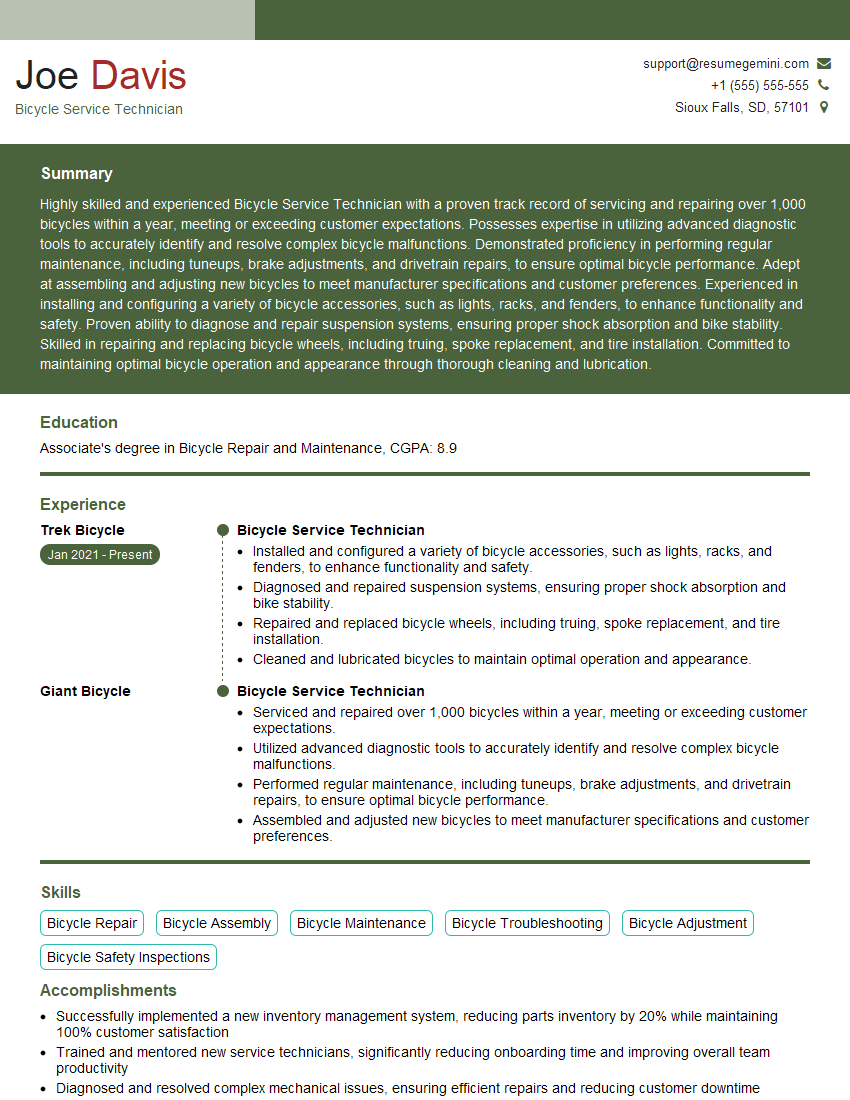

Mastering bike maintenance opens doors to exciting career opportunities in the cycling industry, offering diverse roles and growth potential. A strong resume is key to showcasing your skills and experience to potential employers. To maximize your chances, create an ATS-friendly resume that highlights your technical abilities and relevant experience. ResumeGemini is a trusted resource that can help you build a professional and effective resume. Examples of resumes tailored specifically for bike maintenance professionals are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO