Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Bike repair interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Bike repair Interview

Q 1. Explain the different types of bicycle brakes and their maintenance.

Bicycle brakes are crucial for safety. There are primarily two main types: rim brakes and disc brakes. Each has its own maintenance needs.

- Rim Brakes: These brakes use pads that squeeze against the rim of the wheel to slow or stop the bike. Maintenance involves checking pad wear (replace when worn down to the wear indicator), ensuring the pads are correctly aligned, and keeping the rims clean and free from debris. Regularly inspect the brake cables for fraying or corrosion and lubricate them as needed. If the brakes feel spongy, bleeding the brake system might be necessary (though this is less common with rim brakes).

- Disc Brakes: These use a rotor attached to the wheel and calipers with pads that squeeze the rotor. Disc brake maintenance is more involved. You’ll need to check pad wear regularly, clean the rotors with a dedicated disc brake cleaner (avoid using degreaser), and occasionally bleed the hydraulic system if the brakes feel soft or unresponsive. This requires specialized tools and knowledge.

Regular inspection and proactive maintenance are key for both types of brakes. Ignoring maintenance can lead to dangerous brake failure.

Q 2. Describe the process of truing a bicycle wheel.

Truing a wheel involves adjusting the spoke tension to make the wheel perfectly round and true (meaning the rim is centered and doesn’t wobble). It requires a truing stand for optimal results.

The process involves using spoke wrenches to tighten or loosen spokes. By carefully adjusting the tension of individual spokes, you can correct lateral and radial wobbles. Lateral wobble is a side-to-side movement of the rim, while radial wobble is an up-and-down movement. It’s a skill that takes practice and patience; starting with small adjustments is crucial. A poorly trued wheel can affect your bike’s handling, ride quality, and tire wear.

Improper truing can lead to broken spokes or a damaged rim. If you lack experience, it’s best to have a professional true your wheel. Watching videos and practicing on old wheels before attempting it on your main bike is highly recommended.

Q 3. How do you diagnose and repair a flat tire?

Diagnosing a flat is usually straightforward: you’ll feel a loss of air pressure in the tire. Repairing it involves these steps:

- Remove the wheel: Detach the wheel from the bike frame.

- Deflate the tire completely: Release any remaining air.

- Remove the tire from the rim: Use tire levers carefully to pry one side of the tire off the rim, then the other. Be gentle to avoid pinching the tube.

- Locate the puncture: Inflate the tube slightly and listen or feel for hissing air. You can also submerge the tube in water to find the leak.

- Repair or replace the tube: Use a patch kit to repair the puncture, or replace the tube with a new one (easier and often more reliable).

- Reinstall the tube and tire: Seat the tire bead into the rim evenly. Make sure the tube isn’t twisted and inflate the tire.

- Check tire pressure: Use a pump with a pressure gauge to inflate the tire to the manufacturer’s recommended PSI (pounds per square inch).

Carrying a spare tube, tire levers, and a pump are essential for any cyclist.

Q 4. What are the common causes of derailleur problems and how do you fix them?

Derailleur problems often stem from cable tension, cable wear, bent hangers, or shifting mechanism issues.

- Cable Tension: Incorrect cable tension prevents smooth shifting. Adjust the barrel adjuster on the derailleur to fine-tune tension.

- Cable Wear: Frayed or corroded cables hinder shifting. Replace worn cables and housing.

- Bent Derailleur Hanger: A bent derailleur hanger (the part that attaches the derailleur to the frame) misaligns the derailleur. This often requires replacement.

- Shifting Mechanism: Worn pulleys, bent derailleur components, or other mechanical issues may hinder shifting. This might need professional attention.

Proper lubrication of the derailleur and cables is important for smooth operation.

Troubleshooting involves systematically checking these components. Start with the simplest solutions (adjusting cables) before moving to more complex repairs.

Q 5. Explain the different types of bicycle gears and their shifting mechanisms.

Bicycle gears provide different ratios between the pedals and the rear wheel, making it easier to climb hills or maintain speed on flat surfaces. There are two main types of gear systems:

- Derailleur Gears: These use derailleurs (front and rear) to move the chain between different sprockets (cogs) on the crankset (front) and cassette (rear), changing the gear ratio. This system offers a wide range of gears.

- Internal Hub Gears: These use a mechanism inside the rear hub to change gears. They are typically more durable and require less maintenance but offer fewer gear options than derailleurs.

Shifting mechanisms involve cables and levers (shifters) which pull the derailleurs or actuate the internal hub mechanism to change the gear ratio. The interaction between the shifters, cables, derailleurs, and sprockets/hub mechanism is essential for precise and efficient shifting. Proper adjustment and lubrication are key for optimal shifting performance.

Q 6. How do you adjust bicycle brakes for optimal performance?

Optimal brake adjustment ensures the brakes engage effectively and consistently, providing maximum stopping power without excessive lever travel or rubbing.

For rim brakes, adjust the brake cable tension using the barrel adjuster. The pads should be close enough to the rim to engage, but not rub continuously. Ensure the pads are evenly spaced and centered.

For disc brakes, the adjustment is usually done by adjusting the calipers. There are often specific adjustments for pad clearance and alignment. If the brakes feel spongy, bleeding the hydraulic system is often necessary (this requires specific tools and knowledge).

Properly adjusted brakes are crucial for safety. If you are uncertain about making these adjustments, consult a bicycle mechanic.

Q 7. Describe the process of replacing a bicycle chain.

Replacing a bicycle chain is a fairly straightforward process, but requires some basic tools.

- Measure the chain: Use a chain checker tool to determine if the chain needs replacing (typically when it stretches beyond a certain length).

- Remove the old chain: Use a chain tool to remove the master link (the quick-release link) connecting the chain.

- Install the new chain: Connect the new chain, ensuring that it’s properly meshed with the cassette and chainrings.

- Install the master link: Join the ends of the new chain using the master link provided.

- Check shifting: After installation, test the shifting to ensure smooth operation. Adjustments might be needed to the derailleur cables.

A chain that’s worn or stretched can lead to poor shifting and accelerated wear on other drivetrain components. Regularly check the chain’s condition and replace it as needed.

Q 8. How do you inspect and maintain a bicycle’s bottom bracket?

Inspecting and maintaining a bicycle’s bottom bracket is crucial for smooth pedaling and efficient power transfer. The bottom bracket is the bearing system that allows the crank arms to rotate. There are several types, including threaded, cartridge, and press-fit. Inspection involves checking for play, noise, and smoothness of rotation.

- Visual Inspection: Look for any obvious damage, scratches, or corrosion on the bottom bracket shell and the crank arms.

- Play Check: Gently rock the crank arms from side to side. Excessive movement indicates worn bearings or a loose bottom bracket.

- Rotation Check: Rotate the crank arms, feeling for any roughness, grinding, or stiffness. Smooth rotation is ideal.

Maintenance depends on the bottom bracket type. Cartridge bottom brackets are generally easier to replace, while threaded ones might require more specialized tools. Regular cleaning and lubrication, typically with a specialized grease, will extend the life of any bottom bracket. If you detect play or noise, replacement is often necessary. This process usually involves removing the crank arms, extracting the old bottom bracket, and installing a new one, ensuring proper torque.

For example, I once had a client whose bike was making a horrible grinding noise. After inspecting the bottom bracket, I found significant play and corrosion. Replacing the cartridge bottom bracket solved the problem, restoring smooth and quiet pedaling.

Q 9. What are the signs of a worn-out bicycle cassette?

A worn-out bicycle cassette, the cluster of gears at the rear wheel, shows several tell-tale signs. These signs impact shifting performance and overall drivetrain efficiency.

- Worn Teeth: Examine the teeth closely. Rounded or hooked teeth indicate significant wear. The edges should be sharp and well-defined. If the teeth are significantly worn, they may even be visibly shorter than their counterparts.

- Difficult Shifting: Worn cassettes often make shifting difficult, leading to chain skipping or slipping. This is because the worn teeth no longer mesh properly with the chain.

- Increased Noise: A worn cassette often produces a clicking or grinding noise while pedaling, especially under load. This is due to the poor meshing between the chain and worn teeth.

- Chain Wear: Note that chain wear is directly related to cassette wear. A stretched chain will accelerate cassette wear.

If you notice any of these signs, replacing the cassette is recommended. Continued use of a worn cassette will further damage the chain and rear derailleur.

Q 10. How do you identify and address spoke issues in a bicycle wheel?

Identifying and addressing spoke issues is essential for wheel trueness and safety. Spoke problems can manifest in various ways, affecting the wheel’s structural integrity.

- Broken Spokes: This is visually obvious. A broken spoke will be completely detached from the hub or rim. It necessitates immediate repair or replacement.

- Loose Spokes: These can be detected by gently squeezing the spoke near the nipple. Excessive play indicates a loose spoke that needs tightening. This can be done with a spoke wrench.

- Bent Spokes: Bent spokes will cause the wheel to be out of true, resulting in a wobble or hop. A bent spoke should be replaced.

- Trueing Issues: If the wheel is noticeably out of true – indicating a lateral or radial deviation – multiple spoke issues may be the cause. A wheel truing stand is needed for accurate spoke adjustments.

Addressing spoke problems often requires using a spoke wrench and a wheel truing stand for more complex adjustments. If unsure, seeking professional help from a bike mechanic is advisable, as improper adjustments can damage the wheel. I’ve seen wheels damaged due to amateurs trying to true wheels without proper equipment and knowledge.

Q 11. Explain the proper procedure for lubricating a bicycle chain.

Lubricating a bicycle chain is a fundamental maintenance task to ensure smooth shifting and reduce wear. The process involves applying a suitable lubricant to the chain’s rollers and links.

- Clean the Chain: Before lubricating, thoroughly clean the chain with a degreaser and a chain cleaning tool or rag. This removes dirt, grime, and old lubricant, preventing the accumulation of grit that damages the chain and drivetrain.

- Apply Lubricant: Use a chain lubricant designed for bicycles. Apply a small amount of lubricant to the inner rollers of the chain while slowly rotating the pedals backwards. Too much lubricant will attract dirt and make the bike messy.

- Wipe Excess Lubricant: After applying the lubricant, use a rag to wipe off any excess. This prevents dirt from adhering to the excess lubricant.

- Allow to Dry: Let the lubricant set for a short period before riding. This allows the lubricant to penetrate into the chain links.

Different types of chain lubricants are available for varying weather conditions. For example, wet lubes are more suitable for rainy conditions, while dry lubes are ideal for dry environments. Regular chain lubrication is important, typically every 100-200 miles depending on riding conditions.

Q 12. Describe the process of overhauling a bicycle headset.

Overhauling a bicycle headset involves a complete disassembly, cleaning, and reassembly of the components responsible for steering. The headset allows the fork to rotate smoothly within the head tube.

- Disassembly: Use the correct tools to remove the headset components, including the top cap, stem, and headset bearings. This will likely involve specialized tools like a headset wrench or press.

- Cleaning: Thoroughly clean all components, removing old grease, dirt, and rust. Pay attention to removing any debris from the head tube and the headset cups.

- Inspection: Inspect the bearings, races, and cups for wear or damage. Replace any worn or damaged parts.

- Reassembly: Apply fresh grease to the bearings and races. Reassemble the headset components, ensuring proper alignment and torque. The headset should turn smoothly with minimal play.

The process involves understanding the type of headset (threaded, threadless, integrated) to use the correct tools and procedure. An improperly adjusted headset can lead to imprecise steering or even dangerous handling.

Q 13. How do you identify and fix a bent bicycle frame?

Identifying and fixing a bent bicycle frame is a challenging task. Minor bends might be manageable, but significant damage usually requires professional assessment.

Identifying a bent frame involves careful inspection for any misalignments, noticeable kinks, or cracks. Check for alignment issues, like the rear dropouts or the head tube being out of alignment. If you detect visible cracks or significant bends, immediate repair or frame replacement is necessary. Minor dents or bends might be repairable by professional frame builders using specialized equipment. Attempting to straighten a frame yourself is highly risky and can cause further damage.

In most cases, a severely bent frame should be replaced. The structural integrity of a frame is crucial for safety and performance, and attempting to fix a severely bent frame can compromise safety. For example, I once saw a customer attempt to straighten a bent top tube with a pipe wrench – this only resulted in further damage and made the bike unsafe to ride.

Q 14. What are the common causes of bicycle wheel wobble and how do you fix it?

Bicycle wheel wobble, or lateral instability, can stem from several issues, affecting the smooth rolling of the wheel. It’s crucial to identify the root cause for a safe and efficient ride.

- Spoke Problems: Loose, broken, or bent spokes are common culprits, causing the rim to deviate from its true position. These can be addressed by tightening loose spokes or replacing damaged ones, using a spoke wrench and often a truing stand.

- Bent Rim: A bent rim will obviously cause the wheel to wobble. The severity determines whether the rim can be trued or needs replacement. Minor dents might be corrected with a truing stand; major dents require rim replacement.

- Damaged Hub: A damaged hub, specifically a bent or damaged axle, can also lead to wheel wobble. This requires hub maintenance or replacement.

- Loose Wheel Bearings: If the wheel bearings are loose, the wheel will wobble noticeably. Adjusting or replacing the wheel bearings might resolve this.

Fixing wheel wobble often requires wheel truing skills and specialized tools. For complex issues, it’s best to consult a professional bicycle mechanic. Ignoring wheel wobble can lead to further damage, poor performance, and potential safety hazards.

Q 15. How do you adjust bicycle derailleurs for precise shifting?

Adjusting bicycle derailleurs for precise shifting involves fine-tuning the derailleur’s position relative to the cassette (rear gears) and chainrings (front gears). This ensures smooth transitions between gears without skipping or chain rub. It’s a process that combines visual inspection with small adjustments.

High and Low Limits: First, you’ll set the high and low limits. The high limit prevents the derailleur from shifting past the largest cog on the cassette, while the low limit stops it from shifting past the smallest. This is usually done via barrel adjusters (small screws) on the derailleur itself.

Cable Tension: Next, you’ll adjust cable tension. Too loose, and shifting will be sluggish or inaccurate. Too tight, and shifting might be difficult or the derailleur might not move freely. This is often adjusted via a barrel adjuster on the shifter itself or by adjusting the cable clamp bolt on the derailleur.

Indexing: This step involves making very fine adjustments to perfectly align the derailleur with each cog. You’ll shift through all the gears, and make small adjustments to the cable tension or the derailleur’s position to ensure each gear is engaged smoothly and precisely. This is often done using the shifter barrel adjuster to fine tune each gear engagement.

Visual Inspection: Throughout the process, regularly inspect the derailleur’s alignment and the chain’s path to ensure it’s running smoothly and cleanly.

Think of it like tuning a musical instrument; small adjustments make a big difference in the final result.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the different types of bicycle tires and their applications.

Bicycle tires are categorized by several key factors, primarily their construction and intended use. Different terrains demand different tire characteristics.

Clincher Tires: These are the most common type. They have a bead that fits inside the rim and are inflated with a tube inside. They’re relatively easy to change and are suitable for various applications.

Tubular Tires: These tires are sewn onto a tube; there’s no separate inner tube. They offer a lighter weight and smoother ride, frequently favored in professional road racing but require specialized tools and techniques for changing.

Tubeless Tires: These tires seal directly to the rim using a sealant. They offer the advantages of both clincher and tubular tires; easier changes than tubular but lighter and offering superior puncture resistance than clincher tires. They are growing in popularity.

Tire applications:

Road Tires: Typically have a thin tread and are designed for smooth pavement; they prioritize speed and efficiency.

Mountain Bike Tires: Feature aggressive treads for traction on dirt, rocks, and roots. Width and tread pattern vary depending on the type of riding (cross-country, trail, downhill).

Gravel Tires: Designed for mixed surfaces; a blend of road and mountain bike tire characteristics. They have a wider tread than road tires but are smoother than mountain bike tires.

Choosing the right tire is crucial for optimal performance and safety.

Q 17. Describe the process of repairing a punctured bicycle tire using patches.

Repairing a punctured tire with a patch involves several steps. Safety and cleanliness are paramount.

Deflate and Remove the Wheel: Completely deflate the tire and remove the wheel from the bicycle. It’s far easier to work on the tire while off the bike.

Remove the Tire: Using tire levers (carefully to avoid damaging the rim), remove the tire from the rim.

Locate the Puncture: Inflate the tube slightly to find the hole. Submerge the tube in water to help pinpoint the leak; you’ll see bubbles escaping at the puncture site.

Prepare the Tube and Patch: Roughen the area around the puncture site with sandpaper or a special patch preparation tool. This ensures proper adhesion.

Apply the Patch: Peel off the protective covering from the patch and firmly press it onto the prepared area of the tube. Ensure complete adhesion.

Reinstall the Tube: Carefully insert the patched tube back into the tire, ensuring it’s not twisted. Then, re-install the tire back onto the rim. Make sure both beads are seated properly.

Inflate and Inspect: Inflate the tire to its proper pressure and check for leaks. Use soapy water if necessary to check the area around the patch.

Reinstall the Wheel: Once confident the tire is holding air, reinstall the wheel onto the bicycle.

Using the right tools and techniques prevents further damage and ensures a reliable repair.

Q 18. How do you assess the condition of bicycle cables and housing?

Assessing bicycle cables and housing is crucial for safe and efficient shifting and braking. The condition of these components directly impacts performance and safety.

Visual Inspection: Look for fraying, kinking, or corrosion on the outer housing. Feel the housing for stiffness or cracks. Check the cables for corrosion, fraying, or stretching.

Flexibility Test: Gently bend the cables and housing. Excessive stiffness indicates internal corrosion or damage. Housing should flex easily without cracking.

Movement Test: Check cable movement within the housing. It should slide freely without sticking or binding. If there’s resistance, the cable or housing may need replacing.

Shifting/Braking Performance: Pay attention to how smoothly the shifting and braking mechanisms work. Sluggish performance often signals issues with cables and housing.

Regular inspection and timely replacement are key to preventing potential problems and maintaining optimal performance. Ignoring these small issues can lead to catastrophic failures.

Q 19. What are the safety precautions involved in bicycle repair?

Bicycle repair involves several safety precautions:

Eye Protection: Always wear safety glasses to protect your eyes from flying debris.

Gloves: Wear gloves to protect your hands from grease, sharp edges, and potential cuts.

Proper Work Area: Work in a clean, well-lit area with adequate ventilation.

Tool Use: Use the correct tools for the job and handle them safely to prevent injury.

Cable Tension: Be cautious when working with cables; sudden release of tension can cause injury.

Wheel Removal: Be careful when removing and installing wheels to avoid pinching fingers or damaging components.

Disposing of Materials: Dispose of old parts and chemicals according to local regulations.

Following these precautions ensures a safe and injury-free repair experience. Safety first is always the rule.

Q 20. How do you properly torque bicycle components?

Properly torquing bicycle components is essential for safe and reliable operation. Over-tightening can strip threads or break parts, while under-tightening can lead to components loosening and potential failure. This is where a torque wrench becomes invaluable.

A torque wrench measures the amount of force applied to a bolt or nut, ensuring it’s tightened to the manufacturer’s specifications. These specifications are typically found in a workshop manual specific to your bike frame or component.

Procedure:

Consult the Manual: Find the recommended torque values for each component in your bike’s manual or the component’s manual.

Use a Torque Wrench: Set the torque wrench to the correct value before tightening.

Tighten Gradually: Tighten the bolt or nut gradually until the torque wrench clicks or reaches the specified value. Do not overtighten.

Double Check: Double-check the torque after tightening.

Using a torque wrench prevents damage to components and ensures their longevity. It is a critical skill for any serious bike mechanic.

Q 21. Describe the process of indexing bicycle shifters.

Indexing bicycle shifters ensures crisp and accurate shifting between gears. This involves aligning the shifter’s mechanism with the derailleur’s movement so each gear click corresponds to a precise position on the cassette or chainrings.

Indexing is typically done using the limit screws (H and L limits) on the derailleurs and the barrel adjusters on the shifters themselves. It’s an iterative process of shifting through gears and making small adjustments.

Procedure:

Set High and Low Limits: First, adjust the high and low limit screws on the derailleur to prevent overshifting.

Shift Through Gears: Shift through all the gears, noting any sluggishness or missed shifts.

Fine Tune: Make minor adjustments to the barrel adjuster on the shifter for each gear to ensure smooth and precise engagement. This process is sometimes called “gear indexing.”

Repeat: Repeat steps 2 and 3 until all shifts are smooth and accurate.

Properly indexed shifters provide a smooth, precise and efficient shifting experience; a crucial factor for rider comfort and performance.

Q 22. What tools are essential for performing basic bicycle repairs?

A basic bicycle repair kit should include tools for addressing common issues. Think of it like having a well-stocked first-aid kit for your bike.

- Tire levers: Essential for removing and installing tires.

- Pump: To inflate tires to the correct pressure (check your tire sidewall for the recommended PSI).

- Screwdrivers (Phillips and flathead): For adjusting components like seat height, handlebars, and derailleurs.

- Adjustable wrench: Useful for tightening various bolts and nuts, especially on brakes and components.

- Allen wrenches (hex keys): A set covering various sizes is crucial for most bike adjustments.

- Chain lubricant: Keeps your chain running smoothly and extends its lifespan.

- Patch kit: For repairing punctures quickly.

- Multi-tool: A handy combination tool with various wrenches and screwdrivers.

Having these tools allows for addressing punctures, adjusting brakes, and performing minor component adjustments. For example, a flat tire can be fixed using tire levers, a patch, and a pump. Loose handlebars can be tightened with an Allen wrench. This foundational set enables quick roadside fixes and extends the life of your bike through preventative maintenance.

Q 23. Explain the importance of proper bicycle wheel tension.

Proper wheel tension is critical for a bike’s performance, safety, and longevity. Imagine a wheel as a drum; if the tension is off, the drum won’t sound right, and might even break. A wheel with improper tension will be prone to trueness issues (wobble), reduce responsiveness, and potentially cause catastrophic failure.

Optimal spoke tension ensures the wheel is strong, stiff, and runs true. Uneven tension can lead to the wheel becoming untrue, causing the rim to wobble and potentially causing the wheel to collapse under stress. This can lead to a dangerous ride and damage to other components. Wheel truing is an essential skill for maintaining proper spoke tension; it involves carefully adjusting individual spokes using a spoke wrench to make sure the rim is perfectly centered and running straight.

A properly tensioned wheel is safer, rides smoother, and lasts longer. Regular checks are part of preventative maintenance, and a professional wheel build guarantees optimal tension from the outset.

Q 24. How do you diagnose and repair a broken bicycle spoke?

Diagnosing a broken spoke involves visually inspecting the wheel. Look for any obviously broken or severely bent spokes. A broken spoke will often show a clear break in the metal, sometimes with the ends slightly separated. A bent spoke might appear out of alignment with the others.

Repairing involves replacing the broken spoke. This requires the correct replacement spoke, a spoke wrench, and potentially a spoke nipple driver. Here’s a basic process:

- Identify the broken spoke: Note its position and the type (length and gauge).

- Remove the broken spoke: Unscrew the nipple from the rim using the spoke nipple driver. Be careful not to damage the nipple or the rim.

- Install the new spoke: Thread the new spoke through the hub and the rim holes, mimicking the original spoke’s path.

- Tighten the nipple: Use the spoke wrench to tighten the nipple gradually, ensuring even tension across the wheel.

- True the wheel: After replacing the spoke, carefully true the wheel using a truing stand to ensure the wheel is running straight. This may involve adjusting other nearby spokes.

Improper repair can lead to further damage, so seeking professional help is advisable if you lack experience.

Q 25. How do you maintain and care for different types of bicycle brakes?

Bicycle brake maintenance depends heavily on the brake type: rim brakes, disc brakes (mechanical or hydraulic), and drum brakes (less common on modern bikes). Regular maintenance is essential for safe braking.

- Rim Brakes: These require cleaning the rim braking surface, ensuring the brake pads are aligned correctly, and replacing worn-out pads. Check for proper cable tension to ensure effective braking.

- Mechanical Disc Brakes: These need regular cable adjustment, cleaning of the brake rotors and calipers, and eventual pad replacement. Lubricating the cable can improve smooth operation.

- Hydraulic Disc Brakes: These require less frequent maintenance but need occasional bleeding to remove air bubbles from the lines, potentially every few years depending on use. Inspect the pads regularly, and replace them as they wear down.

Worn-out brake pads reduce braking performance, while a contaminated braking surface (e.g., oily rim) drastically reduces braking effectiveness. Regular checks and proactive maintenance are crucial for safety.

Q 26. Describe your experience working with various bicycle frame materials.

I have extensive experience working with various bicycle frame materials, each with its unique properties and challenges. My experience spans across:

- Steel: Durable, repairable, and relatively inexpensive, but heavier than other options. I’ve worked with various steel alloys, understanding their differences in strength and weldability.

- Aluminum: Lightweight and stiff, but prone to fatigue cracks if mishandled during repairs or damaged. Precise welding and repair techniques are crucial.

- Carbon Fiber: Extremely lightweight and stiff, offering superior performance, but notoriously difficult and expensive to repair. Repairs often require specialized tools and expertise, and are sometimes impractical.

- Titanium: Exceptional strength-to-weight ratio, highly durable, and resistant to corrosion, but challenging and expensive to work with, requiring specialized welding techniques.

Understanding the properties of each material helps me choose the correct repair approach or determine if a repair is even feasible. For example, a deep crack in a carbon fiber frame might be beyond repair, while a minor dent in a steel frame can often be successfully addressed.

Q 27. Explain your process for troubleshooting complex bicycle problems.

Troubleshooting complex bicycle problems requires a systematic approach. I use a process similar to a mechanic diagnosing a car issue. It often starts with listening to the customer describe the problem, and then goes through these steps:

- Gather Information: Clearly define the issue, when it started, and any relevant conditions (e.g., weather, terrain).

- Visual Inspection: Carefully inspect all relevant components, checking for obvious damage, wear, or misalignment.

- Systematic Testing: Test individual components (e.g., brakes, gears, wheels) to isolate the problem. This might involve test rides or specialized diagnostic tools.

- Research and Diagnostics: If needed, consult manuals, online resources, or other experts to narrow down the possibilities.

- Repair and Testing: Implement repairs, one step at a time, ensuring each fix is tested before proceeding to the next. This prevents making further unnecessary changes.

- Documentation: Keep detailed records of the problem, diagnostics, and the implemented solution. This is beneficial for both future troubleshooting and warranty purposes.

This structured approach minimizes guesswork and ensures a thorough investigation, leading to effective repairs and happy customers.

Q 28. How do you handle customer inquiries and concerns regarding bicycle repairs?

Handling customer inquiries and concerns requires patience, clear communication, and empathy. I always approach a customer with respect and a willingness to understand their needs.

My process involves actively listening to their concerns, explaining the problem in clear and understandable terms (avoiding technical jargon), providing realistic repair estimates, and clearly communicating any potential delays. I always follow up with the customer after the repair is completed, ensuring their satisfaction and addressing any residual concerns. Open communication and transparency build trust, contributing to positive customer relationships.

For example, if a customer is upset about an unexpected repair cost, I clearly explain the necessary work, showing them the damaged parts if possible, and exploring alternative solutions if feasible. Building a rapport based on trust and understanding is key to resolving any issues effectively.

Key Topics to Learn for Your Bike Repair Interview

- Bicycle Frame Geometry & Materials: Understanding different frame materials (steel, aluminum, carbon fiber), their properties, and how geometry impacts bike performance is crucial. Practical application: diagnosing frame issues and recommending appropriate repairs or replacements.

- Drivetrain Systems: Mastering the intricacies of derailleurs, shifters, cassettes, and chainrings. Practical application: troubleshooting shifting problems, performing accurate adjustments, and identifying worn components.

- Wheel Building & Maintenance: This includes truing wheels, replacing spokes, and understanding hub maintenance. Practical application: assessing wheel damage, performing repairs, and ensuring proper wheel tension.

- Brake Systems: Familiarize yourself with different brake types (rim brakes, disc brakes), their maintenance, and proper adjustment. Practical application: bleeding hydraulic brakes, adjusting cable tension, and identifying brake pad wear.

- Suspension Systems (if applicable): Understanding the mechanics of forks and shocks, including servicing and maintenance. Practical application: diagnosing suspension issues, performing basic servicing, and recommending advanced repairs.

- Basic Tool Knowledge & Usage: Demonstrate familiarity with common bike repair tools and their appropriate applications. Practical application: Explaining your approach to a given repair task and selecting the correct tools.

- Troubleshooting & Diagnostics: Develop your ability to systematically diagnose mechanical issues, identifying the root cause rather than just addressing surface-level symptoms. Practical application: explaining your methodical approach to fault finding and problem-solving.

- Safety Procedures & Best Practices: Highlight your understanding of safe workshop practices and procedures for handling tools and components. Practical application: Explaining how you ensure a safe working environment and adhere to safety regulations.

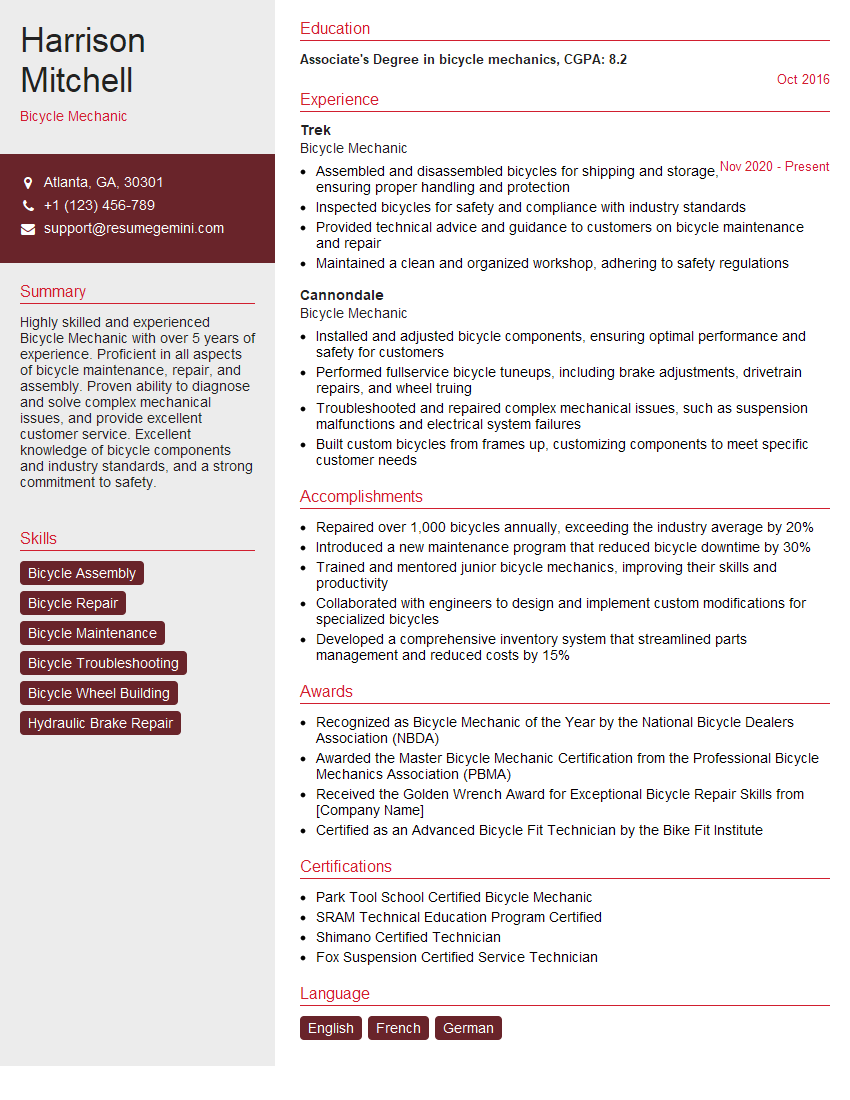

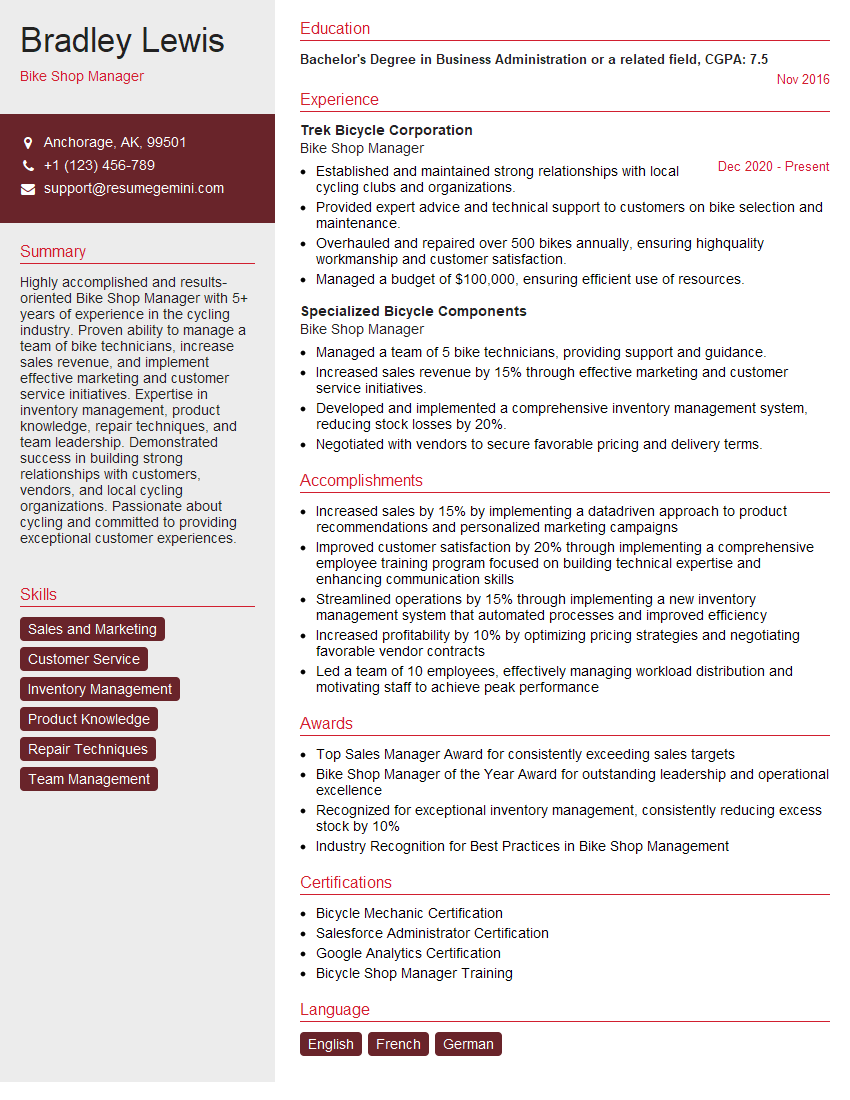

Next Steps

Mastering bike repair opens doors to a rewarding career with diverse opportunities for growth, from independent shop ownership to specialized roles within larger companies. To maximize your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini can help you create a professional and effective resume that highlights your skills and experience in the best possible light. They offer examples of resumes tailored specifically to bike repair professionals, giving you a head start in presenting yourself to potential employers. Take the next step towards your dream career – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO