The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Bilge Pumping and Dewatering interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Bilge Pumping and Dewatering Interview

Q 1. Explain the different types of bilge pumps and their applications.

Bilge pumps are crucial for removing accumulated water from a vessel’s bilge – the lowest part of a ship’s hull. Several types exist, each suited to different applications:

- Centrifugal Pumps: These are the most common type, using a rotating impeller to create centrifugal force, pushing water outwards and through a discharge pipe. They’re efficient for handling large volumes of relatively clean water and are generally robust and easy to maintain. Think of a common household water pump – the principle is similar.

- Eductor Pumps: These utilize the Venturi effect. High-pressure water is injected into a nozzle, creating a vacuum that sucks bilge water into a suction pipe. They are simple, relatively low-maintenance, and have no moving parts prone to wear, making them reliable in harsh environments but less efficient than centrifugal pumps for large volumes.

- Diaphragm Pumps: These use a reciprocating diaphragm to pump water. They excel at handling thicker liquids containing solids or debris, making them ideal for handling bilge water with oil or sludge. They are typically slower than centrifugal pumps but offer better self-priming capabilities.

- Submersible Pumps: These are designed to be fully submerged in the bilge water. They are compact and efficient, ideal for smaller vessels or confined spaces but require careful selection to prevent damage from debris.

The choice of pump depends on factors like vessel size, bilge water characteristics (cleanliness, viscosity), required flow rate, and budget. Larger vessels often utilize a combination of pumps for redundancy and to handle varying bilge conditions.

Q 2. Describe the process of bilge water treatment and disposal.

Bilge water treatment and disposal is crucial for environmental protection and regulatory compliance. The process typically involves:

- Oil Separation: Oil separators remove oil from bilge water using gravity or coalescence. This is critical as oil spills are highly damaging to marine environments.

- Filtration: Filters remove solids and other debris from the water, improving the efficiency of the subsequent treatment stages and ensuring smoother pump operation.

- Treatment (Optional): Depending on the regulations and the nature of the bilge water, additional treatments might be needed. This can include biological treatment to reduce biological oxygen demand (BOD) or chemical treatments to remove specific contaminants.

- Monitoring: Continuous monitoring of oil content and other parameters is essential to ensure that the treated water meets discharge standards. This often involves automatic analyzers and logging systems.

- Discharge: Treated bilge water can be discharged overboard, but only if it meets the stringent regulations set by the International Maritime Organization (IMO) and other relevant authorities (often requiring an oil content below 15 ppm). In some cases, it might need to be collected and disposed of in designated facilities.

The specific treatment methods will vary depending on the vessel’s size and type, the nature of its operations, and the local regulations. For example, a cruise ship will have much more sophisticated treatment capabilities than a small fishing boat.

Q 3. What are the safety procedures for operating bilge pumps?

Safety is paramount when operating bilge pumps. Key procedures include:

- Proper Training: All personnel involved in bilge pump operation should receive thorough training on the specific equipment they operate.

- Regular Inspection: Pumps and associated systems should be regularly inspected for leaks, wear, and damage. This includes checking hoses, fittings, and electrical connections.

- Personal Protective Equipment (PPE): Appropriate PPE, such as gloves, eye protection, and protective clothing, should always be used when handling bilge water, which can contain hazardous substances.

- Emergency Shutdown Procedures: All personnel should be aware of the emergency shutdown procedures for the bilge pump system, including isolating valves and power cut-offs.

- Ventilation: Adequate ventilation is crucial in bilge spaces to prevent the accumulation of hazardous gases.

- Confined Space Entry Procedures: If entering a bilge space, follow the strict confined space entry procedures. This involves testing for hazardous atmospheres before entry and using appropriate respiratory protection if necessary.

A safety checklist should be implemented and strictly followed to minimize risks.

Q 4. How do you troubleshoot common bilge pump malfunctions?

Troubleshooting bilge pump malfunctions involves a systematic approach. Here’s a common strategy:

- Check Power Supply: Ensure the pump is receiving adequate power. Check fuses, circuit breakers, and power connections.

- Inspect Inlet and Outlet Lines: Look for blockages, kinks, or leaks in the suction and discharge lines. Clear any blockages and repair or replace any damaged sections.

- Examine Impeller (Centrifugal Pumps): Check the impeller for damage or wear. A worn impeller can significantly reduce pumping efficiency. Replace if necessary.

- Check Valves: Examine suction and discharge valves for proper operation. They might be stuck or clogged.

- Check Priming (If Applicable): Some pumps require priming before operation. Make sure the pump is properly primed.

- Listen for Unusual Sounds: Unusual noises, like grinding or knocking, often indicate mechanical problems that require professional attention.

- Check Automatic Controls: If the pump has automatic controls (e.g., float switch), verify they are functioning correctly.

If the problem persists after these checks, contacting a qualified marine engineer or pump technician is crucial to prevent further damage or safety hazards.

Q 5. What are the regulations regarding bilge water discharge?

Regulations regarding bilge water discharge are stringent and vary depending on location and the type of vessel. The International Maritime Organization (IMO) sets international standards, often adopted and supplemented by national and regional authorities. Key aspects include:

- Oil Content Limits: Strict limits are imposed on the oil content of discharged bilge water (often 15 ppm or less).

- Monitoring and Recording: Vessels must maintain records of bilge water monitoring and treatment procedures.

- Discharge Restrictions: Discharge may be prohibited in certain areas, such as environmentally sensitive zones or near coastlines. Discharge is often permitted only beyond a specified distance from shore.

- Certification and Inspections: Vessels often require certification to demonstrate compliance with bilge water discharge regulations, and they undergo regular inspections by port state control authorities.

- Illegal Discharge Penalties: Penalties for illegal discharge of untreated bilge water can be substantial, including fines, detention of the vessel, and legal action.

Staying up-to-date on the specific regulations applicable to the vessel’s area of operation is crucial for avoiding legal and environmental consequences.

Q 6. Explain the difference between eductor and centrifugal bilge pumps.

Both eductor and centrifugal pumps are used for bilge pumping, but they operate on different principles:

- Centrifugal Pumps: Use a rotating impeller to generate centrifugal force, accelerating the water and pushing it through the discharge pipe. They are generally more efficient for large volumes of relatively clean water and are commonly used on larger vessels.

- Eductor Pumps: Utilize the Venturi effect. High-pressure water is injected into a nozzle, creating a vacuum that sucks the bilge water into a suction pipe. They are simpler, have no moving parts (less maintenance), and are effective in handling some debris but are less efficient than centrifugal pumps for large volumes and require a separate high-pressure water source.

Think of it like this: a centrifugal pump is like a high-powered fan that blows the water out, while an eductor pump is like a powerful vacuum cleaner that sucks the water in.

Q 7. Describe the process of dewatering a flooded compartment.

Dewatering a flooded compartment involves a systematic approach, prioritizing safety and efficiency. The process typically involves:

- Assess the Situation: Determine the extent of the flooding, identify potential hazards (electrical, chemical, structural), and ensure the safety of personnel.

- Isolate the Compartment: If possible, isolate the flooded compartment from the rest of the vessel to prevent further spread of water.

- Ventilation: Adequate ventilation is crucial to remove any hazardous gases that may have accumulated.

- Select Appropriate Pumps: Choose pumps suitable for the volume of water, the nature of the water (clean or contaminated), and the space available. Submersible pumps are often ideal for this application.

- Pumping Operations: Begin pumping operations, monitoring the water level and pump performance. Consider using multiple pumps for faster dewatering.

- Debris Removal: Once the major volume of water is removed, remove any remaining debris that might hinder further dewatering or cause damage.

- Drying and Inspection: After the compartment is dewatered, allow it to dry thoroughly and conduct a thorough inspection for any damage caused by the flooding.

Dewatering a flooded compartment can be challenging and requires careful planning and execution to ensure the safety of personnel and the vessel’s structural integrity. Improper procedures could lead to additional hazards.

Q 8. How do you select the appropriate dewatering pump for a specific job?

Selecting the right dewatering pump hinges on understanding the specific job requirements. Think of it like choosing the right tool for a job – a screwdriver won’t work if you need a hammer. We need to consider several factors:

- Volume of water: How much water needs to be removed? This dictates the pump’s flow rate (gallons per minute or liters per minute).

- Head pressure: How high does the water need to be pumped? This depends on the vertical distance and any frictional losses in the piping. A higher head pressure requires a pump with more power.

- Water characteristics: Is the water clean or contaminated with solids? Slurry or highly viscous fluids require pumps designed to handle abrasive materials. For example, a submersible pump works well for clean water in a flooded basement, while a diaphragm pump is better suited for pumping sludge.

- Power source: Is electricity available, or is a gasoline or diesel-powered pump necessary?

- Accessibility: Is there easy access to the area where the pump will operate, or are there space constraints? This will influence the choice between a submersible, portable, or stationary pump.

- Budget: Different pumps vary in cost, so budgeting plays a role in selection.

For example, in a construction site dewatering pit, I’d likely specify a high-capacity submersible pump capable of handling sediment, powered by electricity from a nearby generator. In contrast, for a smaller, emergency dewatering situation in a flooded vessel’s bilge, a smaller, portable submersible pump might suffice.

Q 9. What are the potential hazards associated with bilge pumping and dewatering?

Bilge pumping and dewatering present several hazards. Safety is paramount!

- Electrical hazards: Working with pumps near water significantly increases the risk of electric shock. Proper grounding and insulation are critical.

- Mechanical hazards: Rotating parts of pumps, such as impellers, pose a risk of injury. Regular maintenance and proper lockout/tagout procedures are essential.

- Chemical hazards: Bilge water often contains pollutants or chemicals that can be harmful. Protective gear such as gloves, eye protection, and respirators may be necessary, depending on the contaminants.

- Entrapment/suffocation: Entering a confined space like a bilge without proper ventilation and safety precautions can lead to asphyxiation due to oxygen deficiency or exposure to toxic gases.

- Fire hazards: Flammable materials or vapors in the bilge can ignite, leading to a fire or explosion. Proper ventilation and avoidance of sparks are vital.

- Ergonomic hazards: Handling heavy pumps and hoses can cause back injuries and strains. Using lifting aids and proper lifting techniques is crucial.

A real-world example: I once witnessed a near-miss where a worker received a minor electric shock while using a submersible pump due to a faulty grounding connection. This emphasized the crucial need for diligent checks before commencing operations.

Q 10. How do you ensure the proper maintenance of bilge pumping systems?

Proper maintenance of bilge pumping systems is crucial for safe and efficient operation. A regular maintenance schedule should include:

- Visual inspections: Regularly check for leaks, corrosion, damage to hoses and pipes, and wear on pump components.

- Regular cleaning: Remove debris and obstructions from the pump intake and discharge lines to prevent clogging and reduce wear.

- Lubrication: Lubricate pump bearings according to the manufacturer’s recommendations to minimize friction and prolong pump life.

- Fluid checks: For pumps with oil lubrication, check the oil level regularly.

- Functional testing: Periodically test the pump to ensure it’s operating at its designed capacity and efficiency.

- Documentation: Keep detailed records of maintenance activities to track performance and identify potential problems.

Think of it like regular car maintenance – preventative measures can prevent major breakdowns and costly repairs down the line. Neglecting this can lead to system failure during critical moments.

Q 11. Explain the importance of regular inspections of bilge pumps and associated piping.

Regular inspections of bilge pumps and associated piping are vital for several reasons:

- Preventative maintenance: Early detection of issues, such as corrosion or leaks, allows for timely repairs, preventing costly breakdowns and downtime.

- Safety: Identifying potential hazards, like leaks that could lead to electrical shock or spills, is critical for preventing accidents.

- Environmental protection: Detecting leaks early helps prevent the discharge of pollutants into the environment.

- Operational efficiency: Ensuring the system is operating optimally maximizes pump efficiency and reduces energy consumption.

- Compliance: Regular inspections are often a regulatory requirement to maintain compliance with environmental and safety regulations.

A cracked pipe, if left undetected, could lead to a significant environmental spill or damage to the vessel itself. Regular checks ensure that these problems are caught early, before they escalate.

Q 12. What are the environmental concerns related to bilge water disposal?

Bilge water often contains oil, grease, chemicals, and other pollutants. Improper disposal poses significant environmental risks:

- Water pollution: Discharge of untreated bilge water can contaminate waterways, harming aquatic life and ecosystems.

- Oil spills: Oil contamination can cause extensive damage to marine environments and wildlife.

- Chemical contamination: Toxic chemicals in bilge water can accumulate in the food chain, posing risks to human health.

Regulations often mandate that bilge water be treated before disposal, to reduce the environmental impact. Oil water separators and other treatment systems are used to remove pollutants before discharging the water.

Q 13. Describe your experience with different types of dewatering pumps (e.g., submersible, diaphragm).

My experience encompasses various dewatering pump types. Each has its strengths and weaknesses:

- Submersible pumps: These are excellent for clean water applications, particularly in flooded basements or pits. They are efficient and relatively easy to install, but they can be damaged by abrasive solids. I’ve used these extensively in construction dewatering projects.

- Diaphragm pumps: These are very effective for handling slurry, sludge, and other viscous fluids containing solids. Their ability to handle abrasive materials makes them ideal for applications involving contaminated water. I’ve used these in wastewater treatment and industrial applications where pumping contaminated liquids is a necessity.

- Centrifugal pumps: High-volume applications often benefit from centrifugal pumps. However, they are less effective with high-viscosity fluids and solids. I’ve utilized these in larger-scale dewatering projects where high flow rates are a priority.

- Trash pumps: These pumps are designed to handle large debris and solids, often used in construction or emergency situations. Their rugged design makes them capable of handling the most challenging materials.

Choosing the appropriate pump requires careful consideration of the specific fluid being pumped and the overall application. I always assess the situation before making a recommendation.

Q 14. How do you calculate the required pumping capacity for a dewatering project?

Calculating required pumping capacity involves several steps:

- Determine the volume of water: This could be estimated from the dimensions of the area to be dewatered or from flow rate measurements.

- Estimate the inflow rate: If water is continuously entering the area, this inflow rate needs to be factored in.

- Calculate the required discharge rate: The pump’s discharge rate must exceed both the volume to be removed and the inflow rate to ensure effective dewatering. This is often expressed in gallons per minute (GPM) or liters per minute (LPM).

- Determine the head pressure: This involves calculating the vertical lift height plus the frictional losses in the piping system. Frictional losses depend on pipe diameter, length, and the fluid’s viscosity.

- Select a pump: Choose a pump with a discharge rate and head pressure that meets or exceeds the calculated requirements.

For example, if a construction pit has a volume of 1000 cubic meters and an inflow rate of 100 liters per minute, and we aim to dewater it within 8 hours (28,800 seconds), the required discharge rate would be (1000 m³ + (100 L/min * 28800s)) / 28800s = approximately 104 liters per minute. Head pressure calculations would then be used to finalize the pump selection.

Q 15. What are the factors that influence the efficiency of a bilge pump?

The efficiency of a bilge pump is a multifaceted issue, depending on several interacting factors. Think of it like a water pump in your garden – its effectiveness depends on both the pump itself and the system it’s part of. Primarily, we consider:

- Pump Capacity (GPM): The pump’s rated gallons per minute directly impacts how quickly it removes water. A higher GPM means faster dewatering.

- Head Pressure: This refers to the vertical distance the water needs to be lifted. Higher head pressure requires a more powerful pump or a multi-stage system. Imagine pumping water to a higher floor – it takes more effort.

- Suction Lift: The distance from the water level to the pump intake affects the pump’s ability to draw water. A long suction lift reduces efficiency and can cause cavitation (formation of vapor bubbles).

- Piping System: Clogged, corroded, or improperly sized piping significantly restricts flow and reduces efficiency. Think of a narrow hose versus a wide one – the wide one allows for faster water flow.

- Viscosity of the Bilge Water: The thickness of the bilge water influences the pump’s ability to move it. Thick, oily bilge water will slow the process.

- Pump Maintenance: Regular maintenance, including impeller checks and cleaning, is crucial. A worn impeller will significantly reduce flow rate.

- Number and Placement of Pumps: For larger vessels, multiple pumps strategically placed ensure redundancy and faster dewatering.

Understanding these factors allows for optimizing bilge pump selection and maintenance for maximum efficiency.

Career Expert Tips:

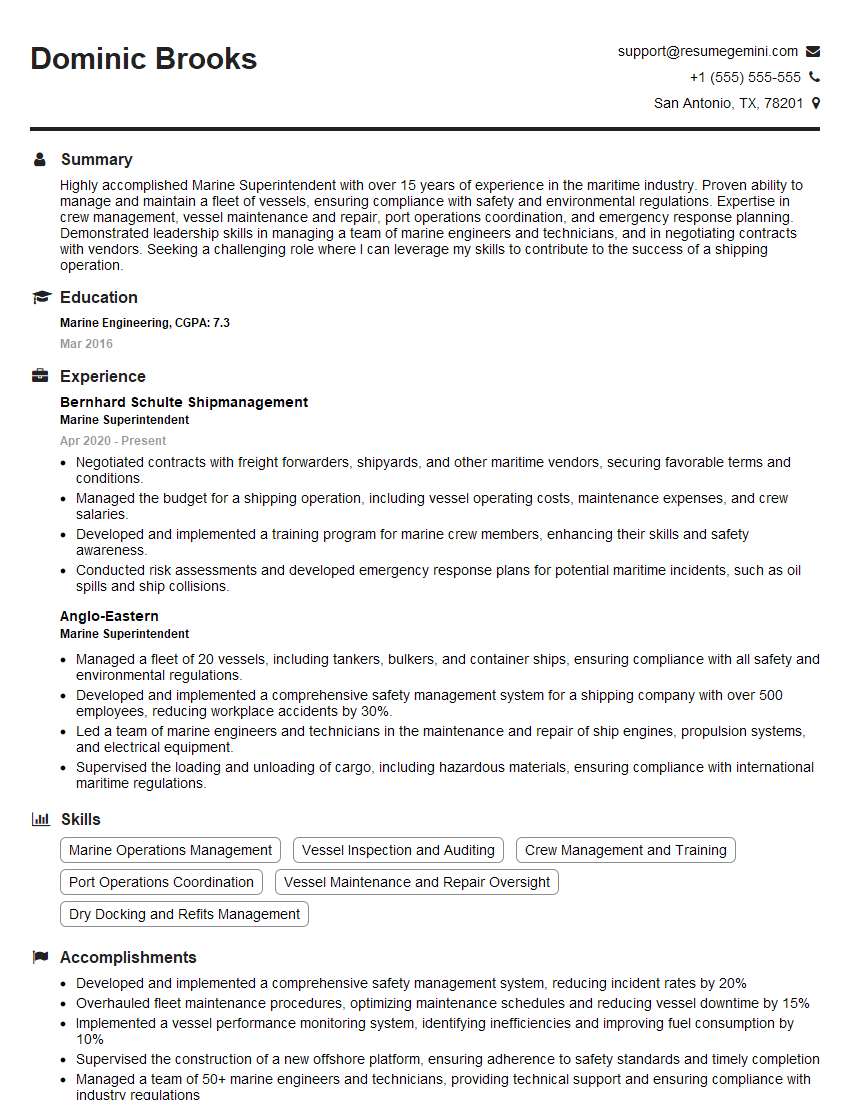

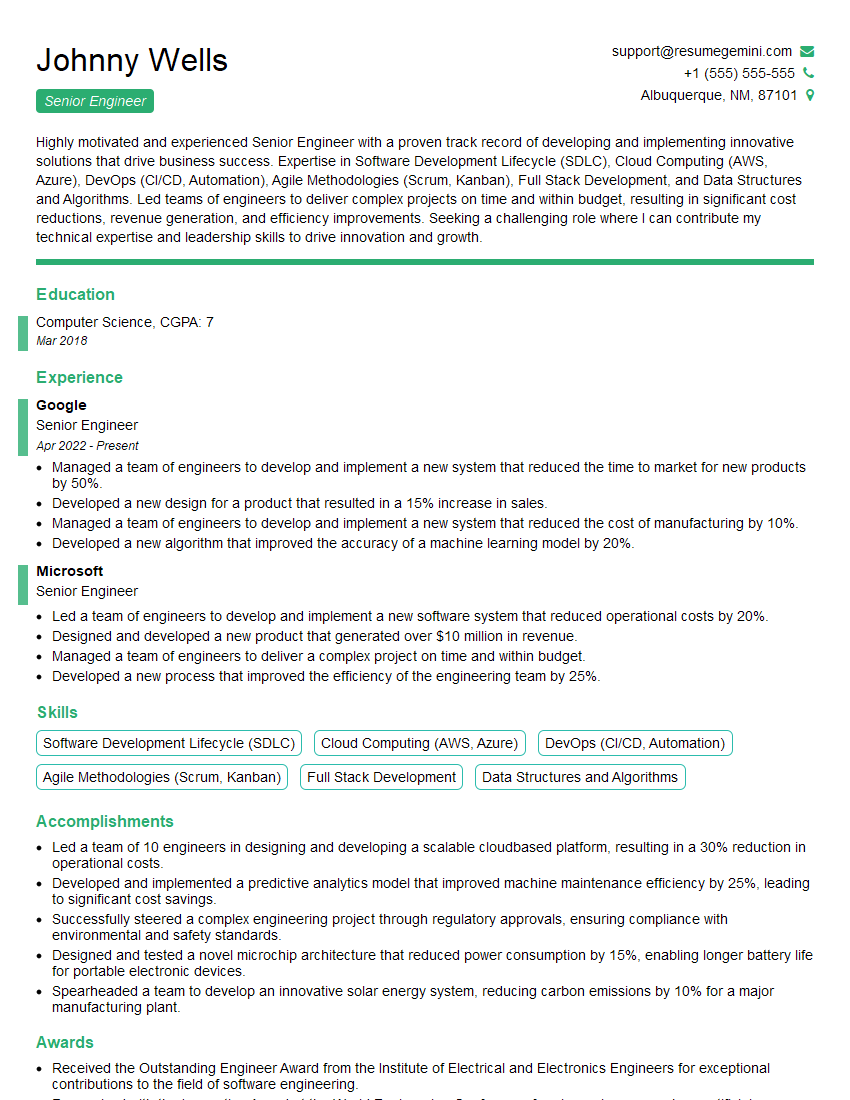

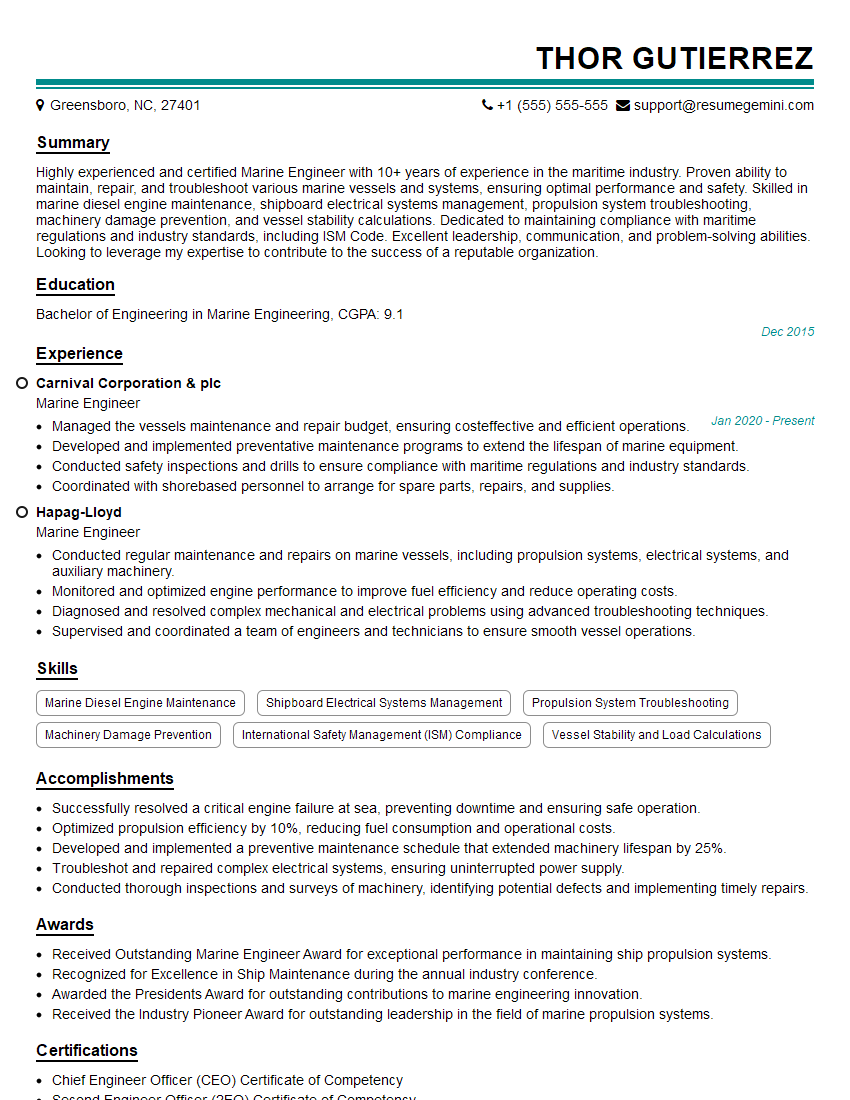

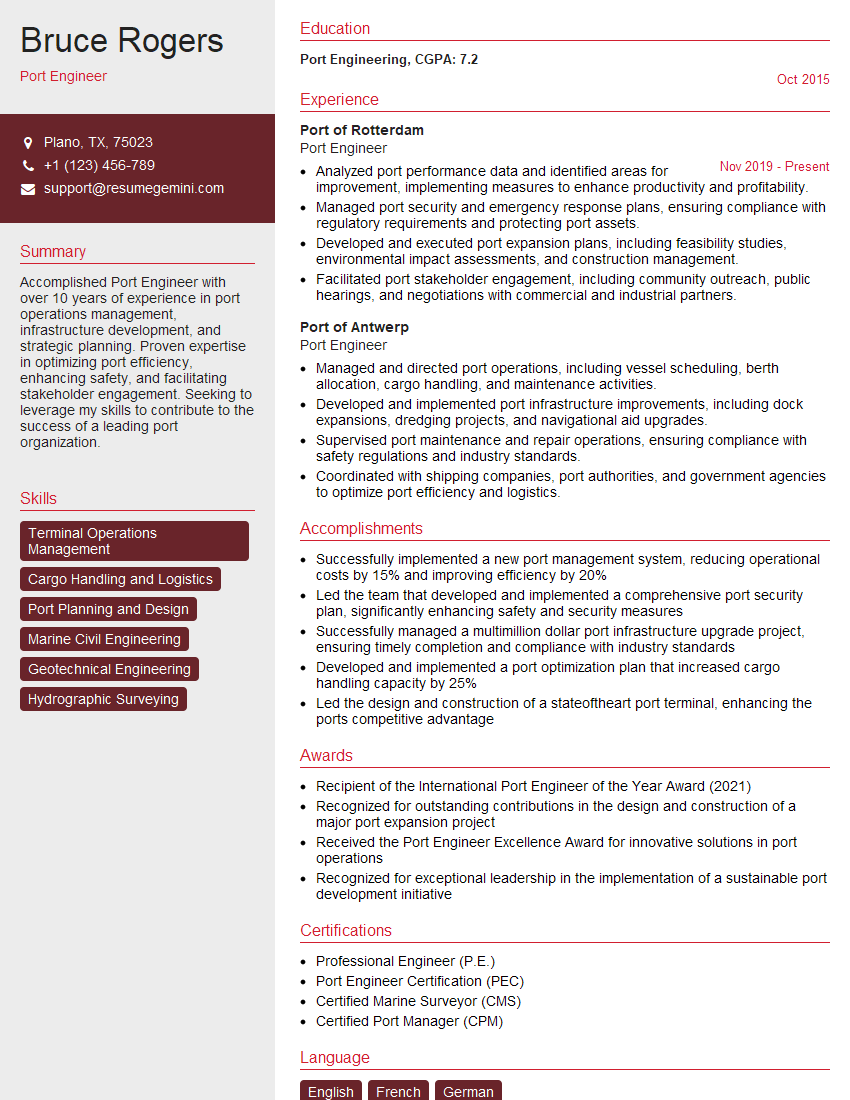

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting electrical issues in bilge pump systems.

Troubleshooting electrical issues in bilge pump systems involves a systematic approach. I always prioritize safety first, ensuring the power is disconnected before any work begins. My approach usually follows these steps:

- Visual Inspection: Checking for loose connections, damaged wiring, and corrosion is the first step. Often, the problem is as simple as a loose wire.

- Voltage Testing: Using a multimeter to check voltage at different points in the circuit helps identify whether the power is reaching the pump motor. A lack of voltage points to a problem in the wiring or power supply.

- Continuity Testing: Checking for continuity in the wiring helps identify any breaks in the circuit. This is where the multimeter is invaluable.

- Motor Testing: If the voltage reaches the motor but the pump doesn’t run, the motor itself may be faulty. Specialized motor testing equipment might be required here.

- Switch and Control Panel Checks: Checking the functioning of the bilge pump switches and the control panel helps identify issues within the control circuitry.

- Circuit Breaker or Fuse Checks: A tripped circuit breaker or a blown fuse is a common cause of pump failure. Replacing the fuse or resetting the circuit breaker (after identifying the cause of the trip) often solves the problem.

For example, I once worked on a vessel where a bilge pump failed to activate. After a thorough check, I found a corroded connection in the wiring harness which was causing a high resistance and preventing sufficient current flow. A simple cleaning and tightening of the connection restored functionality.

Q 17. How do you deal with a bilge pump failure in an emergency situation?

Bilge pump failure is a serious emergency, especially in situations where flooding threatens the vessel. My response is immediate and methodical, prioritizing safety and damage control:

- Assess the Situation: Determine the extent of the flooding and the rate at which the water is rising.

- Activate Emergency Procedures: Initiate the ship’s emergency plan related to flooding, involving the crew in the appropriate tasks.

- Manual Bilge Pumping: If there are manual pumps available, immediately deploy them to mitigate the flooding. This buys critical time.

- Utilize Secondary Pumping Systems: Activate any redundant bilge pumps or other emergency pumping systems.

- Damage Control: If possible, identify and address the source of the flooding (e.g., leak repair).

- Contact External Assistance: If the situation is beyond control, contact emergency services or salvage assistance.

- Post-Incident Review: After the emergency, perform a thorough post-incident review to determine the root cause of the failure and implement corrective measures to prevent future occurrences.

In one instance, a critical bilge pump failed during a storm. By swiftly deploying a secondary pump and patching the initial leak, we prevented the vessel from sinking. The incident underscored the importance of redundancy and immediate response protocols.

Q 18. Explain the importance of proper valve operation in bilge pumping systems.

Proper valve operation is paramount in bilge pumping systems. Valves control the flow of water, ensuring the bilge pump directs water to the proper location and prevents unwanted backflow. Think of valves as traffic controllers for water.

- Isolation Valves: These allow for isolating sections of the bilge system for maintenance or repair without shutting down the entire system. Like isolating a section of road for repairs.

- Non-Return Valves (Check Valves): These prevent water from flowing back into the bilge once it’s pumped out, maintaining efficient pumping. Think of a one-way valve in a water pipe.

- Seacocks: These valves control the discharge of bilge water overboard. Proper operation is crucial for preventing pollution and maintaining vessel stability.

- Manual Valves vs. Automatic Valves: Manual valves require human intervention, while automatic valves open and close based on pre-set parameters (like water level). Both have their place in a robust system.

Failure to operate valves correctly can lead to inefficient pumping, waterlogging, system damage, or even environmental pollution. Regular valve inspections and maintenance are critical to ensure their smooth and reliable operation.

Q 19. What are the different types of bilge alarms and their functions?

Bilge alarms provide critical warnings of rising water levels in the bilge, preventing serious damage or even sinking. There are several types:

- High-Level Alarms: These are triggered when the bilge water reaches a pre-determined high level. They typically sound an audible alarm and may also illuminate a visual indicator.

- Low-Level Alarms: Less common, these alert when the bilge water level falls below a certain point, possibly indicating a leak or malfunction.

- Pump Running Alarms: These indicate when a bilge pump is running, useful for monitoring operations and detecting pump failures (if the pump is running but the level doesn’t fall).

- High-Temperature Alarms: These monitor the temperature of the bilge water. High temperatures may indicate a fire or other dangerous condition.

These alarms are often part of an integrated monitoring system, providing comprehensive information to the crew. Regular testing of the alarms is essential to ensure their reliability.

Q 20. How do you maintain accurate records of bilge pumping operations?

Maintaining accurate records of bilge pumping operations is crucial for compliance, maintenance planning, and troubleshooting. These records typically include:

- Date and Time: Precise timestamp of each pumping event.

- Duration of Pumping: How long the pump(s) ran.

- Amount of Water Pumped (if measurable): This may be estimated based on pump capacity and duration.

- Location of Bilge Water: Which bilge compartment was pumped.

- Pump(s) Used: Specific pump(s) employed.

- Any Associated Issues or Events: Notes on any problems encountered during the pumping.

- Crew Member(s) Involved: Those responsible for the operation.

These records can be kept in a dedicated logbook, a computerized system, or a combination of both. Digital records provide easier access and analysis. The accuracy of these records is vital, as they can be essential for post-incident investigations or compliance audits.

Q 21. Describe your experience with different types of piping systems used in bilge pumping.

Bilge pumping systems utilize various piping materials depending on factors like cost, durability, corrosion resistance, and the specific application. Some common types include:

- PVC (Polyvinyl Chloride): Relatively inexpensive and lightweight, suitable for less demanding applications. However, it’s less durable than other options and may not withstand high pressures or temperatures.

- CPVC (Chlorinated Polyvinyl Chloride): A stronger and more heat-resistant alternative to PVC, suitable for higher temperatures and pressures.

- ABS (Acrylonitrile Butadiene Styrene): A tough and impact-resistant material, often used in areas prone to physical damage.

- Stainless Steel: Highly durable and corrosion-resistant, making it ideal for saltwater environments and high-pressure applications. It’s also more expensive.

- Ductile Iron: Strong and durable, often used for larger diameter pipes and high-pressure systems.

The design of the piping system is crucial. It must be appropriately sized to minimize friction losses and ensure adequate flow rate. Regular inspection and maintenance of the piping system are essential to prevent leaks, corrosion, and blockages, preserving the efficiency and safety of the bilge pumping system. I’ve personally worked with all these types, selecting the most suitable material for the specific needs of the project.

Q 22. What are the safety precautions to take when working with high-pressure bilge pumps?

High-pressure bilge pumps pose significant safety risks if not handled correctly. The immense force of the water jet can cause serious injury. Therefore, a multi-layered safety approach is crucial.

- Personal Protective Equipment (PPE): This is paramount. Always wear safety glasses, hearing protection, and sturdy, closed-toe footwear. High-visibility clothing is also recommended in busy areas. In some cases, protective gloves and full body suits might be necessary depending on the fluid being pumped.

- Pressure Relief Valves: Ensure pressure relief valves are properly installed and functioning. These valves prevent excessive pressure buildup, which could lead to system failure and potential injury.

- Regular Inspection and Maintenance: Regularly inspect hoses, fittings, and the pump itself for wear and tear. Replace any damaged components immediately. Proper maintenance schedules, including lubrication and cleaning, are essential.

- Lockout/Tagout Procedures: Before any maintenance or repair, always follow strict lockout/tagout procedures to prevent accidental start-up. This is crucial for preventing serious injury.

- Emergency Shutdown Procedures: All personnel should be fully aware of the location and operation of the emergency shut-off switch. Regular drills can reinforce this knowledge and ensure swift response in emergencies.

- Confined Space Entry Procedures: If working in a confined space near a bilge pump, strict confined space entry protocols must be followed, including atmospheric monitoring and standby personnel.

For example, during a recent project involving a large cargo vessel, I insisted on a full safety briefing before commencing bilge pump operations. We meticulously checked all PPE, confirmed the functionality of safety valves, and ran a practice emergency shutdown drill. This proactive approach ensured a safe and productive operation.

Q 23. How do you identify and address potential leaks in bilge piping systems?

Identifying leaks in bilge piping systems requires a systematic approach combining visual inspection and pressure testing. Small leaks can easily go unnoticed but eventually lead to significant problems.

- Visual Inspection: Start with a thorough visual inspection of all pipes, fittings, and connections. Look for signs of wetness, staining, or corrosion. Pay close attention to areas where pipes are joined or supported.

- Pressure Testing: After a visual inspection, conduct a pressure test. Isolate sections of the piping system and pressurize them with air or water. Monitor the pressure for any drop, indicating a leak. The use of specialized leak detection equipment, such as ultrasonic detectors, can improve the accuracy of leak identification.

- Dye Testing: In some cases, dye testing can be very effective. A non-toxic dye is added to the bilge water. Leaks will be visible as the dye emerges.

- Listening for Leaks: Sometimes, you can actually hear a faint hissing sound indicating a leak, especially with pressurized air systems.

During a marine dewatering project, we discovered a slow leak in a seemingly insignificant weld on a pipe fitting using a combination of visual inspection and dye testing. Repairing this small leak prevented a much more significant problem later on.

Q 24. What are your experiences with various types of dewatering applications (e.g., construction, marine)?

My experience in dewatering spans various applications, including marine and construction. Each presents unique challenges and demands tailored approaches.

- Marine Dewatering: This often involves removing water from ship bilges, ballast tanks, or flooded compartments. The environments are typically confined and potentially hazardous, requiring stringent safety protocols and specialized equipment such as submersible pumps and effluent management systems. The fluids encountered might contain oil or other contaminants requiring specific handling procedures.

- Construction Dewatering: This typically involves removing groundwater or surface water from construction sites to allow excavation and foundation work. Applications can range from small trench dewatering to large-scale projects involving deep excavations and complex pumping systems. Considerations here include soil conditions, potential environmental impacts, and regulatory compliance.

In one particular marine project, we used a combination of centrifugal and submersible pumps to dewater a flooded engine room, ensuring the removal of contaminated bilge water while adhering strictly to environmental regulations. In a recent construction project, we utilized a series of deep well pumps and a sophisticated network of sumps and pipes to dewater a large excavation in challenging soil conditions.

Q 25. Explain your understanding of the interaction between bilge pumping and fire safety.

Bilge pumping and fire safety are intrinsically linked. Effective bilge pumping is critical for fire prevention and suppression.

- Preventing Fuel Spillage: Efficient bilge pumps remove accumulated water and oil, preventing the build-up of flammable materials that could ignite.

- Reducing Fire Hazards: A build-up of flammable liquids in the bilges is a serious fire hazard. Regular and effective pumping minimizes this risk.

- Access to Firefighting Equipment: In some cases, bilge pumps might need to be turned off to facilitate access to fire suppression equipment.

- Firefighting Water Supply: In emergency situations, the bilge system may be utilized to assist with the supply of firefighting water.

For instance, I recall a training scenario that emphasized the importance of immediately shutting down bilge pumps in the event of a fire to prevent the spread of the flames by avoiding the dispersion of flammable materials in the bilge water.

Q 26. How do you ensure compliance with relevant safety standards and regulations while performing bilge pumping and dewatering operations?

Compliance with safety standards and regulations is non-negotiable. We always adhere to regulations such as those outlined by the Occupational Safety and Health Administration (OSHA) in the United States, or their international equivalents.

- Risk Assessments: Prior to any operation, we conduct thorough risk assessments to identify potential hazards and develop mitigation strategies.

- Permitting: We obtain all necessary permits and approvals before commencing work, especially for projects involving discharges into waterways.

- Record Keeping: Meticulous record-keeping is essential, documenting all activities, safety measures, and any incidents or near misses.

- Training: All personnel involved receive comprehensive training on safe operating procedures, emergency response, and relevant regulations.

- Regular Audits: We conduct regular internal audits to ensure continued compliance and identify areas for improvement.

For example, in a recent project involving the discharge of bilge water, we ensured that all discharge procedures strictly adhered to the MARPOL Annex I regulations. We meticulously documented the process and ensured all involved personnel were adequately trained.

Q 27. Describe your experience with using different types of submersible pumps in dewatering applications.

Submersible pumps are frequently used in dewatering applications due to their versatility and ability to operate in flooded areas. Different types cater to various needs.

- Centrifugal Submersible Pumps: These are efficient for handling large volumes of relatively clean water. They’re ideal for construction site dewatering or removing water from large sumps.

- Vortex Submersible Pumps: These pumps are capable of handling slurries and solids, making them suitable for applications with contaminated water or significant debris. They are often used in sewage and wastewater applications.

- Diaphragm Submersible Pumps: They’re known for their ability to handle abrasive and viscous fluids. These are useful in situations where the pumped liquid contains solids or has high viscosity.

I’ve personally used all three types extensively. For instance, during a project involving the removal of contaminated water from a flooded basement, the robustness of a vortex pump proved invaluable as it successfully handled the debris present in the water. In another project involving clean water drainage from a construction site, the high flow rate of a centrifugal pump was ideal for efficient and rapid dewatering.

Q 28. How would you handle a situation where a bilge pump is overloaded or malfunctioning?

An overloaded or malfunctioning bilge pump requires immediate action to prevent damage and ensure safety.

- Identify the Cause: Determine whether the pump is overloaded due to excessive inflow or if it has a mechanical failure. Check the intake strainer for blockages.

- Reduce Inflow (If Overloaded): If the pump is overloaded due to excessive inflow, attempt to reduce the inflow rate by temporarily diverting water or addressing the source of the excess water.

- Isolate the Pump: Isolate the pump from the system to prevent further damage and potential flooding. This typically involves closing valves.

- Inspect and Repair: Carefully inspect the pump for mechanical problems. This might involve checking the impeller, motor, seals, or wiring. Repair or replace faulty components.

- Use a Backup Pump: If the pump cannot be quickly repaired, use a backup pump to continue the dewatering process.

- Call for Assistance: If the problem is beyond your expertise, immediately contact qualified personnel for assistance.

I once encountered a situation where a bilge pump became overloaded during a heavy storm. Following our established protocol, we quickly identified the blocked intake strainer, cleared the blockage, and then resumed operation with minimal disruption. Had this not been addressed promptly, it could have led to significant flooding.

Key Topics to Learn for Bilge Pumping and Dewatering Interview

- Bilge Pump Systems: Understanding different types of bilge pumps (electric, pneumatic, hand), their operating principles, and maintenance procedures.

- Dewatering Methods: Familiarize yourself with various dewatering techniques, including gravity drainage, vacuum extraction, and the use of submersible pumps, and their applications in different contexts.

- Safety Regulations and Procedures: Mastering relevant safety protocols, including lockout/tagout procedures, personal protective equipment (PPE) usage, and hazard identification in bilge pumping and dewatering operations.

- Troubleshooting and Maintenance: Develop your ability to diagnose common issues in bilge pump systems and dewatering equipment, perform routine maintenance, and implement effective repair strategies.

- Fluid Dynamics and Hydraulics: Grasp the fundamental principles of fluid flow, pressure, and head loss as they relate to the efficiency and effectiveness of bilge pumping and dewatering systems.

- Environmental Considerations: Understand the environmental impact of bilge water discharge and proper disposal methods to comply with regulations.

- Emergency Response Procedures: Be prepared to discuss your knowledge of handling spills and leaks, and implementing emergency shutdown procedures.

- Calculations and Estimations: Practice calculating pump flow rates, pressure, and power requirements based on given scenarios.

- Practical Applications: Prepare examples from your experience (if any) demonstrating your proficiency in troubleshooting, maintenance, and operation of bilge pumping and dewatering systems in diverse environments (e.g., marine, construction, industrial).

Next Steps

Mastering Bilge Pumping and Dewatering opens doors to exciting career opportunities in maritime, construction, and industrial sectors, offering excellent growth potential. A strong resume is crucial for showcasing your skills and experience effectively to potential employers. Building an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to create a professional and impactful resume tailored to the specific requirements of Bilge Pumping and Dewatering roles. ResumeGemini provides examples of resumes specifically designed for this field to help you get started. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO