The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Binding and Finishing Operations interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Binding and Finishing Operations Interview

Q 1. Describe your experience with different binding methods (e.g., perfect binding, saddle stitching, case binding).

My experience encompasses a wide range of binding methods, each suited to different project needs. Let’s consider three key examples:

- Perfect Binding: This is ideal for books with a substantial page count, such as novels or textbooks. The process involves gluing the edges of the pages together to create a block, then applying a cover to the spine. I’ve worked extensively with perfect binding, optimizing the glue application for various paper stocks and ensuring a strong, durable bond. For example, I once helped a client transition from a standard adhesive to a PUR (polyurethane reactive) adhesive, which significantly improved the durability and lay-flat capabilities of their high-page-count technical manuals.

- Saddle Stitching: This method uses wire staples to fasten pages together through the fold. It’s best for magazines, brochures, or booklets with a lower page count (typically under 64 pages). My experience includes troubleshooting misaligned staples, adjusting the machine settings to accommodate different paper weights, and ensuring consistent stitching quality throughout large print runs. I once managed a project where we used saddle stitching for a promotional booklet with intricate folded elements. We had to carefully adjust the machine settings to accommodate the folds without causing jams.

- Case Binding: This is a more robust and sophisticated method used for high-quality books, often featuring a sewn or adhesive-bound text block encased in a separate cover (the ‘case’). This process requires precision and attention to detail. I’ve been involved in several case binding projects, overseeing the entire process from text block preparation to cover attachment. In one project, we used hand-sewing for the text block to achieve a high-end, archival-quality finish.

Q 2. Explain the process of three-knife trimming.

Three-knife trimming is a crucial post-binding process to achieve a clean, square finish. It uses three synchronized blades to trim the three edges (head, tail, and fore-edge) of a book block or stack of sheets simultaneously. The process generally involves:

- Feeding: The trimmed book block is carefully loaded onto the machine’s feed table, ensuring precise alignment.

- Trimming: The three blades move precisely, cutting all three edges of the block at once to the required dimensions.

- Delivery: The trimmed block is then neatly stacked onto an output tray.

Precision is paramount; even slight misalignments can lead to uneven trimming, affecting the overall quality and appearance of the finished product. Regular blade maintenance and careful calibration of the machine are essential to ensure consistent accuracy.

Q 3. How do you troubleshoot common issues with a folding machine?

Troubleshooting folding machines involves systematic investigation. Common issues include paper jams, misfeeds, and inaccurate folds. Here’s a systematic approach:

- Identify the problem: Pinpoint the specific issue – is it a consistent jam in one location, inaccurate folding, or something else?

- Inspect the machine: Check for obvious obstructions (e.g., paper scraps, debris), misaligned components (e.g., rollers, feeders), and worn parts.

- Adjust settings: Verify that the machine settings (e.g., paper thickness, fold type, speed) are appropriate for the current job. Incorrect settings can be a major cause of problems.

- Check the paper: Ensure the paper is of the correct type and quality; wrinkled or damp paper is more prone to jamming. Also, make sure that the paper stack is properly aligned and free of any defects.

- Maintenance: Regular cleaning and lubrication are crucial. Accumulated dust and debris can hinder proper machine operation.

If the problem persists, consult the machine’s manual or seek assistance from a qualified technician.

Q 4. What are the key quality control checks for a perfect bound book?

Quality control for a perfect-bound book involves several key checks:

- Spine Alignment: Verify that the spine is straight and the pages are properly aligned. Any misalignment will create an uneven or unprofessional look.

- Glue Adhesion: Ensure the glue is evenly applied and provides sufficient adhesion to hold the pages together securely. The binding should withstand reasonable stress without the pages separating.

- Cover Adhesion: The cover should be firmly attached to the text block without wrinkles or gaps. A poorly attached cover compromises the book’s structural integrity.

- Trim Accuracy: The edges of the book should be cleanly trimmed, with uniform margins. Uneven trimming detracts from the overall aesthetic quality.

- Page Registration: Check for accurate page alignment throughout the book. Any significant misalignment can disrupt the reader’s experience.

- Visual Inspection: Carefully examine the entire book for any imperfections, such as smudges, creases, or damaged pages.

These checks help identify potential defects early on, minimizing waste and ensuring customer satisfaction.

Q 5. Describe your experience with different types of finishing equipment (e.g., laminators, die cutters).

My experience with finishing equipment is extensive. I’m proficient with various machines:

- Laminators: I’ve worked with both thermal and cold-lamination machines. Thermal lamination provides a more durable, glossy finish, while cold lamination is suitable for projects requiring a matte finish or protection without excessive gloss. I understand the importance of proper temperature and pressure settings for different film types and paper stocks.

- Die Cutters: This is crucial for creating unique shapes and designs. I have experience with both flatbed and rotary die cutters. I understand the importance of die-making precision to achieve accurate cuts and clean edges. I once managed a project where custom die cutting was critical for the product’s aesthetic appeal, creating an intricate design that demanded perfect registration and pressure.

- Foil Stampers: These add a touch of elegance and sophistication to many products. My experience includes setting up and operating foil stamping machines, selecting appropriate foils and controlling temperature and pressure for consistent results.

Proficiency with this equipment allows me to create a wide variety of high-quality, finished products.

Q 6. How do you ensure the accuracy of die cutting?

Ensuring die-cutting accuracy is critical. This is achieved through a multi-step process:

- Die Design and Creation: A precise die must be created based on the required design. This often involves using computer-aided design (CAD) software.

- Die Setup and Alignment: The die needs to be meticulously positioned on the die-cutting machine, precisely aligned with the material to be cut.

- Material Handling: The material must be carefully fed into the machine to ensure proper registration. Any misalignment can lead to inaccuracies.

- Pressure and Speed Control: The machine’s pressure and speed settings must be carefully adjusted to optimize the cutting process. Insufficient pressure can lead to incomplete cuts, while excessive pressure may damage the material.

- Regular Maintenance: Regular maintenance of the die-cutting machine and the die itself ensures consistent quality and prolongs the life of the equipment.

- Quality Checks: Regular quality checks throughout the process are essential to identify and correct errors early on. This may include visual inspection of the cut pieces and comparison against the design.

Precise techniques and diligent attention to detail are crucial for consistently accurate die cutting.

Q 7. What is your experience with different types of paper and their suitability for various binding methods?

The choice of paper significantly impacts the success of various binding methods. Different paper types have varying thicknesses, weights, and finishes, each with implications for the overall book’s look and feel. Here’s a brief overview:

- Perfect Binding: This method works well with a variety of papers, but heavier stocks may need scoring to prevent cracking during folding. The spine also needs sufficient flexibility for the glue to bond properly.

- Saddle Stitching: Thinner papers are ideal for saddle stitching, as heavier papers can create thicker staples, potentially damaging the stitching mechanism.

- Case Binding: Case binding is often used with higher-quality papers, including those suitable for hand-sewing, which requires stronger paper. The paper choice influences the book’s overall durability and aesthetic.

My experience includes working with a vast range of paper types, from lightweight newsprint for high-volume publications to heavier art papers for high-end books, each selected based on the specific binding method and project requirements. I understand how different paper finishes (coated, uncoated, textured) impact the aesthetics and durability of the finished product. I can advise clients on the best paper choices based on budget, desired outcome, and the chosen binding method.

Q 8. Explain the importance of pre-flighting in the bindery process.

Preflighting in the bindery is like a pre-flight checklist for an airplane – crucial for a smooth and successful operation. It’s a critical step before any binding operation begins, ensuring all elements are in place and consistent with the job specifications. This prevents costly errors and delays further down the line.

A thorough preflight check involves verifying several key aspects:

- File integrity: Checking for missing pages, incorrect page order, and image resolution issues.

- Imposition: Confirming that pages are correctly arranged for printing and binding. For example, a perfect-bound book requires specific imposition to ensure the spine’s proper alignment.

- Color consistency: Ensuring consistent color across all pages, especially important for projects needing precise color matching.

- Trim size and bleeds: Verifying that the document is set up correctly for trimming and that bleeds extend beyond the trim line to prevent white margins after cutting.

- Finishing specifications: Reviewing and confirming the specifications of all finishing elements, like cover stock, binding type, and any special effects like embossing or foil stamping.

Without preflighting, you risk discovering significant issues only after significant time and resources have been invested in printing. This leads to rework, delays, and ultimately, cost overruns.

Q 9. How do you maintain the efficiency and productivity of your bindery team?

Maintaining a productive and efficient bindery team requires a multifaceted approach that combines effective leadership, clear communication, and the right tools and training. It’s all about creating a well-oiled machine.

- Cross-training: Empowering team members to handle multiple machines and tasks increases flexibility and reduces downtime when one person is absent or a particular machine is unavailable.

- Regular maintenance: Preventative maintenance on equipment is crucial. Scheduled servicing reduces the risk of unexpected breakdowns and costly repairs, maintaining a consistent workflow.

- Clear communication: Open and honest communication about production schedules, challenges, and priorities is vital. Daily huddles or team meetings ensure everyone is aligned.

- Performance tracking: Using metrics to monitor efficiency and productivity – like pages per hour or jobs completed per day – helps identify areas for improvement and celebrate successes.

- Incentive programs: Introducing rewards systems or bonuses to recognize and motivate the team increases morale and productivity.

- Ergonomic workstations: Ensuring the bindery has ergonomically designed workstations minimizes the risk of repetitive strain injuries and keeps the team comfortable and healthy.

For example, in one bindery I managed, implementing a cross-training program resulted in a 15% increase in overall productivity within three months.

Q 10. Describe your experience with job costing and budget management within a bindery.

Job costing and budget management in a bindery are essential for profitability. It’s about accurately tracking expenses and revenue to understand the cost of each job and to ensure the bindery remains financially sound.

My experience involves using a job costing system that includes:

- Material costs: Tracking the cost of paper, adhesives, covers, and other materials used in each job.

- Labor costs: Accounting for the time spent by each team member on a specific job, using hourly rates or pre-determined job times.

- Machine costs: Calculating the cost of running equipment, including electricity, maintenance, and depreciation.

- Overhead costs: Including rent, utilities, and administrative expenses in the overall cost calculation.

I use this data to create detailed job quotes, monitor profit margins, and identify areas where costs can be reduced without sacrificing quality. Regularly reviewing these numbers against the budget allows for proactive adjustments and prevents financial surprises. Software like specialized bindery management systems or even spreadsheets are essential for accurate tracking.

Q 11. How do you handle unexpected issues or production delays in the bindery?

Unexpected issues happen in any bindery. My approach involves a structured problem-solving process to minimize disruption and ensure timely delivery.

- Identify the issue: Quickly assess the problem’s nature and scope.

- Communicate effectively: Inform relevant parties (clients, team, management) transparently about the delay and potential impact.

- Develop solutions: Brainstorm potential solutions, considering the urgency and available resources. This might involve shifting priorities, reallocating resources, or finding alternative solutions.

- Implement solutions: Execute the chosen solution, focusing on efficiency and minimizing further delays.

- Monitor and adjust: Continuously monitor the implemented solution’s effectiveness and make necessary adjustments to ensure smooth operation.

For example, if a critical machine breaks down, I’d immediately assess the damage, contact a repair technician, and potentially reallocate tasks to other team members using alternative equipment to keep the workflow moving. Transparent communication with the client regarding expected delivery delays is key to maintain the relationship.

Q 12. What safety procedures do you follow while operating bindery equipment?

Safety is paramount in a bindery environment. We have comprehensive safety procedures in place that are strictly enforced.

- Machine guarding: All bindery equipment has proper safety guards in place to prevent accidental contact with moving parts.

- Personal Protective Equipment (PPE): Team members are required to use appropriate PPE such as safety glasses, gloves, and hearing protection, depending on the task.

- Lockout/Tagout procedures: Strict lockout/tagout procedures are followed during machine maintenance or repairs to prevent accidental start-ups.

- Regular training: Employees receive comprehensive training on safe operating procedures, emergency response, and hazard identification.

- Emergency response plan: A well-defined emergency response plan is in place to deal with accidents or emergencies effectively.

- Clean and organized workspace: Maintaining a clean and organized workspace minimizes the risk of slips, trips, and falls.

Regular safety inspections and toolbox talks are crucial to reinforce safe work practices and address potential hazards proactively. We aim for a zero-accident workplace.

Q 13. How familiar are you with different types of adhesives and their applications in binding?

I’m very familiar with various adhesives and their applications in binding. The choice of adhesive depends heavily on the type of binding, the materials being used, and the desired finish.

- Hot melt adhesives: Commonly used in case binding and perfect binding for their fast drying time and strong bond. Different types offer varying degrees of flexibility and tack.

- PUR (Polyurethane Reactive) adhesives: Offer superior adhesion to a wide range of substrates, including low-surface-energy materials like plastics. They are ideal for high-quality books and demanding applications.

- EVA (Ethylene Vinyl Acetate) adhesives: Thermoplastic adhesives providing a strong, flexible bond. Often used in saddle-stitching.

- Animal glues: Traditionally used but less common today. Offer a strong bond but can be more time-consuming to apply.

Understanding the properties of each adhesive is crucial to achieve optimal results. For instance, PUR is excellent for demanding projects requiring a durable bond and flexible spine, while hot melt is ideal for high-speed, automated applications.

Q 14. What is your experience with different types of covers and their construction?

My experience encompasses a wide range of cover types and their construction techniques.

- Casebound covers: These are rigid covers consisting of a cover board wrapped in paper or other material. They are durable and suitable for high-quality books and journals. The construction involves carefully adhering the cover board to the text block using adhesives and ensuring a tight, clean spine.

- Perfect-bound covers: These covers are wrapped around the edges of the text block, which is then glued to the cover. The flexibility of the spine makes it suitable for magazines, softcover books, and brochures.

- Saddle-stitched covers: These covers are folded and stitched directly to the pages. Simple and cost-effective, often for small booklets or magazines.

- Spiral-bound and wire-o-bound covers: These involve using metal coils or wire to bind pages and are suitable for documents that need to lie flat, like notebooks or calendars. The cover can be customized for different branding requirements.

The choice of cover material also plays a significant role in the overall product quality and visual appeal. Factors to consider include durability, printability, and aesthetic value. Materials range from paperboard and coated papers to cloth, leather, and synthetic materials.

Q 15. How do you ensure consistent quality throughout the entire binding and finishing process?

Ensuring consistent quality throughout the binding and finishing process is paramount. It’s achieved through a multi-pronged approach focusing on standardization, meticulous quality control checks, and proactive problem-solving.

- Standardization of Processes: We establish detailed Standard Operating Procedures (SOPs) for every step, from pre-press checks to final packaging. This ensures every operator follows the same procedure, minimizing variations. For instance, our perfect binding SOP specifies exact glue application temperature and pressure to prevent spine cracking.

- Regular Quality Control: We implement a multi-level QC system, including in-process checks at each stage and final inspection before shipment. This involves visual checks for defects like crooked stitching or misaligned covers, as well as functional tests – like page integrity in a bound book. A crucial element is using calibrated measuring tools and visual aids for consistent evaluation.

- Proactive Problem Solving: Data analysis plays a vital role. We track defect rates, identify recurring issues, and implement corrective actions using root cause analysis techniques. For example, if we see a spike in saddle-stitched booklets with misaligned signatures, we’ll investigate machine settings, paper stock quality, or operator training to address the issue at the source.

- Employee Training: Continual training and upskilling ensures that our staff is well-versed in the latest techniques and quality standards. Regular refresher courses and cross-training reduce operational errors and ensure consistency in output.

By integrating these elements, we create a robust system that delivers consistently high-quality binding and finishing results, exceeding customer expectations every time.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of finishing techniques (e.g., embossing, foil stamping).

I possess extensive experience across various finishing techniques, including embossing, foil stamping, die-cutting, and UV coating. Each adds unique value to a product and requires specialized knowledge.

- Embossing: I’ve worked with both blind embossing (creating a raised impression without ink) and registered embossing (combining embossing with printing). For instance, I oversaw a project where we embossed a company logo onto a luxury invitation suite, adding a tactile and sophisticated feel.

- Foil Stamping: This technique allows for the addition of metallic or colored foil to highlight elements like logos, titles, or decorative patterns. I’ve handled various foil types—from hot foil stamping with metallic finishes to cold foil stamping for special effects. A memorable project involved foil stamping a complex design onto a limited-edition book cover, showcasing exquisite detail.

- Die-Cutting: Creating custom shapes and forms using die-cutting adds visual appeal and functionality. I’ve managed projects involving intricate die cuts for packaging, greeting cards, and promotional materials. Precision and accuracy are key; we work closely with die-makers to ensure perfect alignment.

- UV Coating: UV coating provides protection and enhances the visual appeal of printed materials by adding gloss or matte finishes. I have experience with spot UV (applying coating to specific areas) and full UV coating. We utilize this often to protect high-end brochures or product packaging.

My experience encompasses different machine operation, setup, troubleshooting, and ensuring high quality and consistency throughout the processes. I’m adept at adapting these techniques to the specific requirements of each project.

Q 17. How do you handle customer complaints regarding binding quality?

Handling customer complaints regarding binding quality requires a systematic and empathetic approach. The goal is not just to fix the immediate problem but also to retain customer trust and prevent future issues.

- Acknowledge and Empathize: I begin by acknowledging the customer’s concern and expressing understanding of their frustration. A simple, “I understand your concern about the binding quality, and I apologize for the inconvenience” can go a long way.

- Gather Information: I carefully gather all relevant information, including specifics about the defect, the quantity affected, and any relevant order details. I may ask for photos or samples of the faulty product.

- Investigate and Analyze: This is where my expertise in the binding process is crucial. I analyze the problem to determine the root cause—was it a machine malfunction, operator error, or a materials issue? I review QC records and production logs to assist the investigation.

- Develop a Solution: Based on the root cause analysis, I develop a solution. This might include reprinting and rebinding the affected items, offering a discount on a future order, or implementing process improvements to prevent recurrence.

- Communicate and Follow Up: I communicate the solution to the customer promptly, clearly outlining the steps being taken to resolve the issue and prevent it from happening again. I always follow up to ensure the customer is satisfied.

By following this structured approach, I’ve successfully resolved numerous binding quality complaints, turning dissatisfied customers into loyal clients.

Q 18. What are your experience with different types of inks and coatings?

My experience with inks and coatings is extensive, spanning various types and applications. Understanding their properties is vital for achieving optimal print quality and durability.

- Inks: I have worked with different ink types—including UV-curable inks for faster drying times and vibrant colors, water-based inks for environmentally friendly options, and conventional solvent-based inks for cost-effectiveness. The selection depends on factors like substrate, desired finish, and environmental considerations.

- Coatings: I’m familiar with various coatings—matte, gloss, and satin UV coatings to protect and enhance the visual appeal of printed materials, and aqueous coatings for a more eco-friendly alternative. I’ve also worked with specialized coatings like those providing scratch resistance or water resistance, for example, on food packaging.

Understanding the interaction between inks and coatings is critical for successful printing and finishing. For example, selecting the wrong coating can lead to ink bleeding or a poor surface finish. My experience enables me to choose the optimal ink and coating combination for any given project, ensuring the highest quality output.

Q 19. What is your experience with automated bindery systems?

I’ve worked extensively with automated bindery systems, including high-speed perfect binding lines, saddle-stitching machines, and automated booklet makers. Automation significantly increases efficiency and consistency.

- Perfect Binding: I’ve operated and maintained high-speed perfect binding lines, including those with automated three-knife trimming, gluing, and cover feeding systems. This experience includes managing the intricate calibration of these systems to maintain precision and high throughput.

- Saddle Stitching: I’ve worked with automated saddle stitchers that handle large volumes of booklets efficiently, including those with sophisticated features for collating, stitching, and folding. Regular maintenance and preventative measures are critical to maintaining optimal performance.

- Automated Booklet Makers: I’ve utilized systems that automate the entire booklet making process from folding and gathering to stitching and trimming. These systems require careful setup and regular monitoring to ensure smooth operation and high quality.

My experience extends beyond basic operation; I’m proficient in troubleshooting common issues, performing routine maintenance, and optimizing machine settings for maximum efficiency and minimal downtime. Automation allows us to meet tight deadlines while maintaining the quality expected from our bindery.

Q 20. Explain the role of quality control in the bindery process.

Quality control (QC) is the backbone of a successful bindery operation. It’s a proactive process that ensures the final product meets the specified quality standards. In our bindery, QC isn’t just a final check; it’s integrated throughout the entire process.

- In-process checks: At every stage, from paper handling and printing to cutting, stitching, and binding, we have in-process checks to catch defects early. This prevents large batches of faulty products and reduces waste.

- Visual Inspection: Trained personnel perform thorough visual inspections at each step, looking for issues like misaligned signatures, crooked stitching, glue imperfections, or cover defects. We use standardized checklists and tools to maintain consistency.

- Measurement and Testing: We use calibrated measuring devices to ensure dimensions meet specifications. We also conduct functional tests, like page integrity in bound books, to guarantee the product is as expected.

- Data Analysis: We track defect rates and analyze trends to identify potential problems and implement corrective measures. This data-driven approach helps improve overall quality and efficiency.

- Documentation: Complete documentation, including QC checklists, reports, and photos of any detected defects, is maintained to provide traceability and accountability.

A robust QC system not only guarantees consistent quality but also allows for continuous improvement. By actively identifying and addressing potential problems at each stage, we can create a more efficient and reliable bindery process. The goal is zero defects, but a strong QC system helps us get as close as possible.

Q 21. How do you calculate the cost of different binding options?

Calculating the cost of different binding options involves considering several factors. It’s not just about the direct material and labor costs but also includes indirect costs like machine depreciation and overhead.

- Material Costs: This includes the cost of binding materials such as glue, thread, cover stock, and any special finishing materials like foil or embossing dies. The quantity required varies depending on the binding type and the number of products.

- Labor Costs: The labor cost includes the time spent on each stage of the process, from setup and operation to quality control. Highly automated systems reduce labor costs, but the initial investment is higher.

- Machine Costs: Depreciation, maintenance, and repair costs of binding machinery are significant factors. More advanced machines are more expensive to maintain.

- Overhead Costs: These include indirect costs such as rent, utilities, and administrative expenses, which are allocated to each binding project.

- Waste Factor: The potential for waste (material and time) due to errors or machine malfunctions must be factored into the cost calculation. A robust QC system helps minimize waste.

We use a detailed cost breakdown template for each binding type. This allows us to provide accurate quotes to our clients, compare the cost-effectiveness of different binding options, and identify areas for cost optimization. For example, a client might choose perfect binding for a high-volume book project due to its lower per-unit cost compared to case binding, even if the initial investment in materials is higher.

Q 22. What are some common challenges in bindery operations and how have you overcome them?

Bindery operations face numerous challenges, often stemming from the intricate interplay of machinery, materials, and deadlines. One common issue is paper jams, particularly with complex folding or stitching processes. I’ve overcome this by implementing rigorous preventative maintenance schedules, including regular cleaning of rollers and feeders, and proactively addressing any signs of wear. Another challenge is meeting tight deadlines while maintaining quality. I’ve tackled this by using project management tools to track progress, optimize workflow, and identify potential bottlenecks early on. In one instance, we faced a significant delay due to a faulty stitching machine. By quickly diagnosing the problem as a worn-out needle plate and replacing it, we were able to minimize downtime and avoid missing a crucial delivery date. Finally, material inconsistencies can cause significant issues. Differences in paper thickness or texture can affect folding, cutting, and binding. To mitigate this, I’ve developed a system of rigorous quality checks of incoming materials, ensuring that any deviations are identified and addressed before they impact production.

- Preventative maintenance: Regularly cleaning and lubricating machinery.

- Project management tools: Utilizing software to track progress and identify bottlenecks.

- Quality checks: Inspecting materials to identify inconsistencies.

Q 23. Describe your experience with maintaining and troubleshooting bindery equipment.

My experience with bindery equipment maintenance and troubleshooting is extensive. I’m proficient in performing both preventative and corrective maintenance on a wide range of machinery, including saddle stitchers, perfect binders, three-knife trimmers, and folder-gluers. This involves everything from routine lubrication and cleaning to complex repairs requiring specialized tools and knowledge. For instance, I once diagnosed a recurring paper misfeed on a high-speed folder-gluer. By systematically checking the feeder rollers, sensors, and air pressure settings, I pinpointed the issue to a faulty sensor. Replacing this sensor resolved the problem and prevented further production delays. I’m also familiar with safety procedures and regulations surrounding bindery equipment, ensuring a safe work environment for myself and my team. I regularly consult manuals and online resources to stay updated with the latest troubleshooting techniques and best practices.

Q 24. How do you ensure accurate job setup and execution?

Accurate job setup and execution are paramount in bindery operations. I ensure this through a multi-step process. First, I carefully review the job specifications, paying close attention to details like paper size, type, quantity, binding style, and finishing requirements. Next, I configure the bindery equipment accordingly, adjusting settings such as cutting dimensions, folding patterns, and stitching configurations. Before starting the main run, I conduct a thorough test run using a sample set of materials. This allows me to identify and rectify any potential problems – such as incorrect settings or material issues – before processing the entire job. Throughout the process, I maintain meticulous records, tracking materials usage, machine settings, and production progress. This documentation facilitates quality control and aids in troubleshooting if issues arise. Think of it like baking a cake: you wouldn’t start without checking your recipe, prepping ingredients, and doing a test run to ensure the oven is at the right temperature.

Q 25. What are your experience with different types of paper finishes?

I have extensive experience with various paper finishes, including:

- Embossing and Debossing: Creating raised or indented designs to add texture and visual interest. I’ve worked with both hot foil stamping and blind embossing techniques.

- Die-cutting: Precision cutting of intricate shapes and designs, often used for creating unique packaging or promotional materials.

- Foil Stamping: Applying metallic or colored foil to create striking visual effects. I’m familiar with different types of foils and their application methods.

- Laminating: Coating paper with a protective film to enhance durability and water resistance; both gloss and matte finishes are familiar.

- Varnishing: Applying a protective or decorative coating. I understand the difference between aqueous, UV, and spot varnishes and their appropriate uses.

Understanding the limitations and capabilities of each finish is crucial for achieving the desired aesthetic and functional qualities of a printed product. For example, foil stamping on a delicate paper might require adjusting the pressure to avoid damaging the substrate.

Q 26. Explain the importance of understanding the specifications of a particular print job before starting the binding process.

Understanding the print job specifications before beginning the binding process is critical to avoid costly errors and delays. The specifications dictate every aspect of the binding operation, from the type of binding (e.g., perfect binding, saddle stitching, wire-o) to the required finishing touches (e.g., laminating, embossing). Failing to understand these specifications can lead to mismatched materials, incorrect settings, and ultimately, a finished product that doesn’t meet the client’s expectations. For example, if the specifications call for a specific paper weight, using a lighter or heavier paper could lead to problems during the folding or stitching process. Similarly, if the binding style is incorrect, it could result in a poorly bound book that is difficult to handle or use. I always prioritize a thorough review of the specifications, clarifying any ambiguities with the client or print production manager before commencing any binding work.

Q 27. How familiar are you with industry-standard quality metrics for binding and finishing?

I’m very familiar with industry-standard quality metrics for binding and finishing. These metrics often include:

- Accuracy of cuts and folds: Measured in millimeters or inches, ensuring precise dimensions.

- Bindery adhesion strength: Tested using specialized equipment to ensure the binding holds securely.

- Number of defects per 1000 pieces: A measure of overall quality, tracking issues like misaligned pages or damaged covers.

- Throughput rate: Measuring production efficiency in pieces per hour or minute.

- Waste rate: Tracking the percentage of materials lost due to errors or defects.

Using these metrics, I can monitor the quality of our output, identify areas for improvement, and demonstrate our commitment to delivering high-quality products that meet industry standards. Regular monitoring of these metrics helps maintain consistent quality and efficiency in the binding process.

Key Topics to Learn for Binding and Finishing Operations Interview

- Pre-Press Preparation: Understanding file preparation, imposition, and color management for optimal finishing results. Practical application includes troubleshooting pre-press issues that could impact binding.

- Different Binding Methods: Gain a thorough understanding of various binding techniques (e.g., perfect binding, saddle stitch, wire-o, case binding) including their strengths, weaknesses, and suitable applications. Be prepared to discuss the selection process based on project requirements and budget.

- Finishing Techniques: Explore diverse finishing options such as die-cutting, embossing, foil stamping, laminating, and UV coating. Consider the impact of each technique on the final product’s quality and cost-effectiveness.

- Equipment Operation and Maintenance: Familiarize yourself with the machinery used in binding and finishing (e.g., folding machines, stitching machines, cutting machines). Discuss basic troubleshooting and preventative maintenance procedures. This demonstrates practical experience and problem-solving skills.

- Quality Control and Inspection: Understand the importance of quality control throughout the entire process. Be prepared to explain your approach to identifying and resolving defects in a timely manner. This shows your attention to detail and commitment to producing high-quality work.

- Workflow and Production Management: Discuss your understanding of optimizing workflows to ensure efficient production and on-time delivery. Be prepared to discuss scheduling, prioritization, and problem-solving in a high-pressure environment.

- Health and Safety Regulations: Demonstrate your awareness of relevant safety procedures and regulations related to machinery operation and handling of materials in the Binding and Finishing environment.

Next Steps

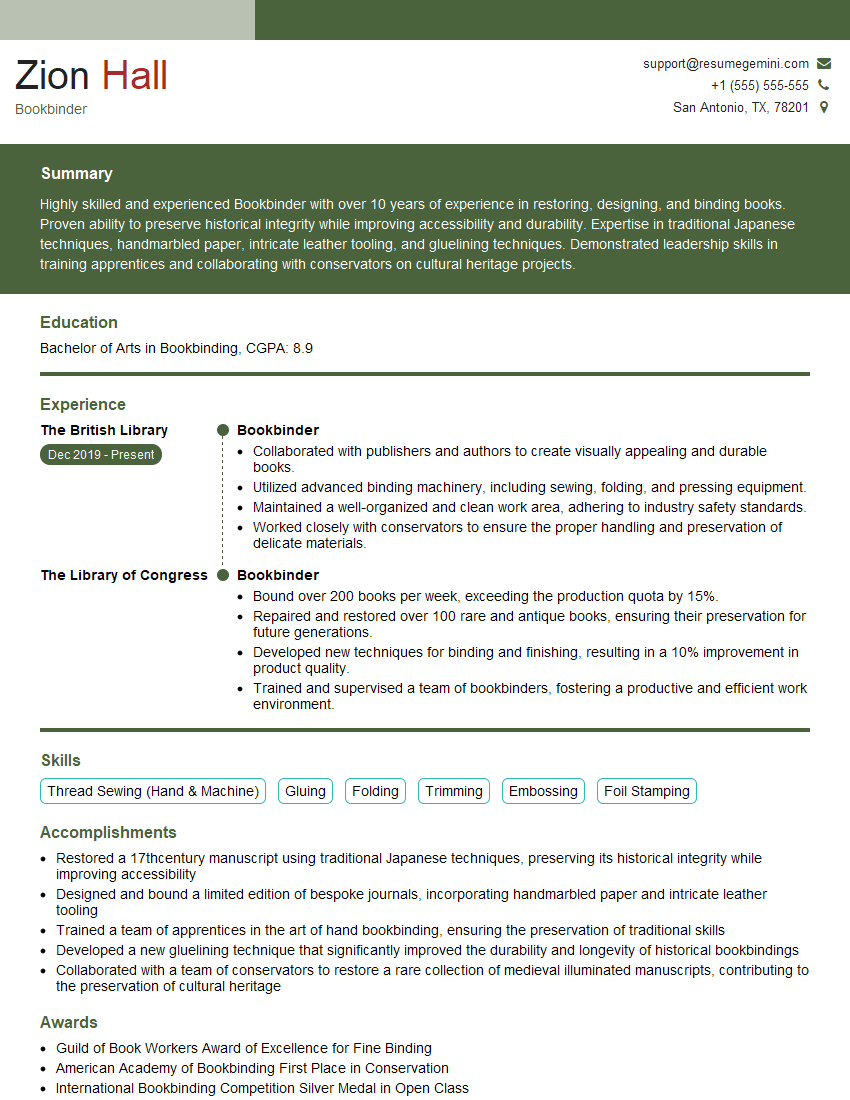

Mastering Binding and Finishing Operations is key to unlocking exciting career opportunities and advancing your expertise in the printing and publishing industry. A strong understanding of these processes will significantly improve your chances of landing your dream role. To maximize your job prospects, it’s crucial to present yourself effectively to potential employers. Create an ATS-friendly resume that highlights your skills and experience in a clear and concise manner. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Binding and Finishing Operations are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO