Are you ready to stand out in your next interview? Understanding and preparing for Boat Corrosion Removal interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Boat Corrosion Removal Interview

Q 1. Explain the different types of corrosion affecting boat hulls.

Boat hulls are susceptible to various corrosion types, primarily driven by the aggressive marine environment. Understanding these types is crucial for effective prevention and remediation.

- Galvanic Corrosion: This occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (seawater). The more active metal (e.g., zinc) corrodes preferentially to protect the less active metal (e.g., steel). Think of it like a sacrificial anode – one metal rusts to save the other. This is very common in boats with multiple metal components.

- Uniform Corrosion: This is a relatively even corrosion across a metal surface. It’s like a slow, steady wearing away. While less dramatic than other types, it can still significantly weaken the hull over time. This is often seen on steel hulls exposed to seawater without proper protection.

- Pitting Corrosion: This involves the formation of small, localized pits or holes on a metal surface. It’s like tiny, aggressive pinpricks. Pitting is particularly insidious because it can penetrate deep into the metal, compromising structural integrity without being readily apparent on the surface.

- Crevice Corrosion: This occurs in confined spaces or crevices where stagnant water accumulates, leading to localized corrosion. Think of areas where two metal plates overlap, or where marine growth collects. The lack of oxygen in these spaces accelerates the corrosive process.

- Stress Corrosion Cracking (SCC): This happens when a metal is under tensile stress and exposed to a corrosive environment. The combination of stress and corrosion can lead to cracking and potential hull failure. This is more common in areas of high stress, such as welds or hull joints.

Q 2. Describe the process of assessing the extent of corrosion damage on a boat.

Assessing corrosion damage requires a systematic approach, combining visual inspection with more advanced techniques.

- Visual Inspection: Begin with a thorough visual examination of the hull, looking for signs of rust, pitting, discoloration, blistering, or cracking. Pay close attention to areas prone to corrosion: joints, welds, through-hull fittings, and areas where water can accumulate.

- Thickness Measurement: Use a calibrated ultrasonic thickness gauge to measure the remaining metal thickness at various points on the hull. This helps determine the depth of corrosion and assess structural integrity. Comparing these measurements to the original hull thickness reveals the extent of material loss.

- Dye Penetrant Testing: This non-destructive test reveals surface cracks or discontinuities by using a dye that penetrates the cracks and is then revealed by a developer. This is particularly useful for detecting hairline cracks associated with stress corrosion.

- Magnetic Particle Inspection: For ferromagnetic materials like steel, this method can detect surface and near-surface flaws. Magnetic particles are applied to the surface, and defects disrupt the magnetic field, making the flaws visible.

- Documentation: Detailed photographic and written documentation is crucial. This serves as a baseline for future assessments and tracking the effectiveness of repair and preventative measures.

Based on this comprehensive assessment, a decision can be made regarding the necessary repair or replacement work.

Q 3. What are the common causes of galvanic corrosion in marine environments?

Galvanic corrosion in marine environments is primarily caused by the presence of dissimilar metals in contact with seawater, acting as an electrolyte. The seawater facilitates the flow of electrons between the metals, leading to corrosion of the more active metal.

- Dissimilar Metals: The most common cause. Steel propellers on aluminum outdrives, or zinc anodes protecting steel hulls, are classic examples.

- Seawater Conductivity: Saltwater is an excellent conductor of electricity, facilitating the electrochemical reactions that drive galvanic corrosion. The higher the salinity, the faster the corrosion.

- Oxygen Concentration Differences: Differences in oxygen concentration on the surface of different metals can also contribute to galvanic corrosion. Areas with less oxygen become anodic (corroding) relative to areas with more oxygen.

- Temperature: Higher temperatures generally increase the rate of electrochemical reactions and thus the rate of galvanic corrosion.

- Presence of Pollutants: Certain pollutants in the water can accelerate corrosion rates by altering the electrochemical properties of the environment.

Understanding these factors allows for informed decisions in material selection and preventative measures to minimize galvanic corrosion.

Q 4. How do you identify and treat different types of marine corrosion (e.g., pitting, crevice, galvanic)?

Identifying and treating different types of marine corrosion requires careful inspection and appropriate remediation techniques.

- Pitting Corrosion: Identified by small, deep holes. Treatment involves removing the affected areas by grinding, wire brushing, or other mechanical means. After cleaning, the area needs to be primed and repainted with a corrosion-resistant coating.

- Crevice Corrosion: Found in confined areas. Treatment requires thorough cleaning of the crevice, ensuring complete removal of corrosive materials. Applying a sealant or corrosion inhibitor can prevent recurrence.

- Galvanic Corrosion: Identified by corrosion preferentially on one of the dissimilar metals. Treatment focuses on isolating the metals electrically (using insulating materials) or implementing cathodic protection (discussed later).

- Uniform Corrosion: A more even degradation of the surface. Treatment generally involves cleaning the surface and applying a protective coating.

In all cases, proper surface preparation is paramount before applying any coatings. This typically involves cleaning, degreasing, and potentially etching the metal surface to improve adhesion.

Q 5. Explain the principles of cathodic protection and its application in boat corrosion prevention.

Cathodic protection is a widely used technique to prevent corrosion by making the metal structure the cathode in an electrochemical cell. This prevents it from becoming anodic and corroding.

It works by supplying electrons to the protected structure, effectively reversing the corrosion process. Think of it as ‘electronically’ filling in the missing electrons that would otherwise be lost to corrosion.

- Sacrificial Anodes: This is the most common method. More active metals, like zinc or aluminum, are connected to the metal structure. These anodes corrode preferentially, protecting the boat hull. They need to be inspected and replaced periodically.

- Impressed Current Cathodic Protection (ICCP): This involves using an external power source (a rectifier) to supply a controlled current to the structure, making it cathodic. It is more complex but offers better control and is often used for larger vessels.

Proper design and maintenance of the cathodic protection system is crucial to ensure its effectiveness. Regular inspections are essential to verify anode condition and current output (in ICCP systems).

Q 6. What are the various methods for removing corrosion from different boat materials (aluminum, steel, fiberglass)?

Corrosion removal methods vary depending on the boat material.

- Aluminum: Requires careful handling to avoid damaging the surface. Gentle methods such as chemical cleaning and light sanding are preferred. Abrasive blasting should be avoided as it can weaken the material. Specialized aluminum cleaners and primers are available.

- Steel: Often involves more aggressive methods like wire brushing, grinding, or abrasive blasting to remove rust and scale. Surface preparation is key for effective coating adhesion. Rust converters can be used to chemically convert rust into a stable compound before priming and painting.

- Fiberglass: Corrosion typically affects the metal components embedded within the fiberglass. Removing corrosion on these components might involve mechanical cleaning, chemical treatment, and then protecting them with a suitable coating before re-embedding in the fiberglass. The fiberglass itself rarely corrodes.

In all cases, proper safety precautions (protective gear, ventilation, etc.) must be taken during corrosion removal processes.

Q 7. Describe your experience with different types of marine coatings and their applications in corrosion prevention.

My experience encompasses a wide range of marine coatings, each offering unique properties and applications in corrosion prevention.

- Epoxy Primers: Excellent adhesion, chemical resistance, and provide a barrier against corrosion. Often used as the first layer on prepared metal surfaces.

- Polyurethane Coatings: Durable, flexible, and offer good UV and abrasion resistance. Popular choices for topcoats, providing long-term protection.

- Zinc-Rich Primers: Contain high percentages of zinc, acting as sacrificial anodes, providing additional protection against corrosion.

- Ablative Coatings: Designed to erode gradually, carrying away fouling organisms and preventing buildup of materials which can accelerate corrosion.

- Silicone-based Coatings: Offer excellent water repellency and UV resistance, particularly useful in harsh marine environments.

The choice of coating depends on factors like the substrate material, the expected environmental conditions, and the desired lifespan of the coating. Proper surface preparation and application techniques are crucial for optimal performance.

Q 8. How do you select the appropriate cleaning agents and methods for removing corrosion without damaging the underlying material?

Selecting the right cleaning agent and method for boat corrosion removal is crucial to avoid further damage. The choice depends heavily on the type of corrosion, the underlying material (aluminum, steel, fiberglass), and the extent of the damage. Think of it like choosing the right tool for a job – a hammer won’t work for screwing in a screw.

- For light surface corrosion on aluminum, a mild abrasive cleaner and a soft bristle brush often suffice. Avoid harsh chemicals that can etch the aluminum’s surface. I’ve found that a solution of mild soap and water, followed by a thorough rinsing, is often enough for initial cleaning.

- For heavier corrosion on steel, a more aggressive approach may be necessary. Chemical treatments like phosphoric acid-based rust converters can neutralize rust and provide a protective layer. However, always follow manufacturer instructions meticulously and test in an inconspicuous area first. Mechanical methods such as wire brushing or sanding can also be used, but care must be taken to avoid excessive material removal.

- Fiberglass is usually cleaned with a mild detergent and a soft sponge. Avoid harsh chemicals or abrasive cleaners that could scratch the gel coat.

- Electrolysis is a powerful method for removing corrosion from metal boats, especially aluminum. It uses an electric current to safely remove corrosion without harming the underlying metal. This method requires specialized equipment but is highly effective.

Ultimately, a thorough assessment of the damage is paramount. Pictures, close inspection, and even the use of non-destructive testing methods (discussed later) can inform the best choice of cleaning agent and method.

Q 9. What safety precautions are essential when working with corrosion removal chemicals?

Safety is paramount when handling corrosion removal chemicals. These substances can be corrosive, toxic, and flammable. My standard operating procedure always includes:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves (nitrile or neoprene, depending on the chemical), respiratory protection (mask or respirator), and appropriate clothing to prevent skin contact.

- Ventilation: Work in a well-ventilated area or use a respirator to avoid inhaling fumes. Many cleaning agents release harmful gases.

- Chemical Compatibility: Never mix different chemicals unless explicitly instructed by the manufacturer. Mixing incompatible substances can create dangerous reactions.

- Spill Control: Have absorbent materials on hand to deal with any spills. Know how to properly dispose of chemicals according to local regulations.

- First Aid Knowledge: Be familiar with first-aid procedures in case of accidental exposure. Have a first-aid kit readily available.

- Proper Disposal: Always follow the manufacturer’s instructions for proper disposal of used chemicals and cleaning materials. Improper disposal can harm the environment.

I always prioritize safety briefings and ensure everyone on the job site understands and follows these precautions. A safe workplace is a productive workplace.

Q 10. How do you determine the best repair method for corrosion damage (e.g., welding, fiberglass repair, metal replacement)?

Choosing the right repair method for corrosion damage depends on several factors: the extent of damage, the material of the boat, and the location of the damage. It’s a decision that balances cost-effectiveness with longevity and structural integrity.

- Welding: Suitable for repairing holes and significant corrosion damage in steel or aluminum boats. Requires specialized skills and equipment. I have extensive experience with both MIG and TIG welding for marine applications. Proper preparation, including cleaning and grinding the area before welding, is crucial for a strong and lasting repair.

- Fiberglass Repair: Common for repairing damage to fiberglass hulls and decks. Involves grinding the damaged area, applying resin and fiberglass cloth, and sanding to create a smooth finish. This requires expertise in working with different types of resin and fiberglass materials.

- Metal Replacement: Often necessary for extensive corrosion or damage in areas that are critical to the structural integrity of the boat. This might involve cutting out the damaged section and welding in a new piece of metal. Careful measurements and precision fitting are essential to maintain the boat’s original shape and strength.

For example, a small hole in a steel boat hull might be effectively repaired by welding, while extensive corrosion in a critical structural member might require metal replacement. My approach always prioritizes restoring the boat’s structural integrity and safety. I frequently collaborate with structural engineers to assess critical damage scenarios.

Q 11. Describe your experience with non-destructive testing methods used to assess corrosion damage.

Non-destructive testing (NDT) is crucial for assessing the extent of corrosion damage without causing further harm. I’m proficient in several NDT methods:

- Visual Inspection: A fundamental first step, involving careful examination of the surface for signs of corrosion such as rust, pitting, blistering, or discoloration.

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws and measure the thickness of materials. This is invaluable for identifying corrosion that might be hidden beneath the surface.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface cracks and discontinuities in ferromagnetic materials (like steel). It’s effective for finding corrosion-induced cracking.

- Eddy Current Testing (ECT): Uses electromagnetic induction to detect surface and subsurface flaws in conductive materials, such as aluminum and copper. It’s a very sensitive method for detecting corrosion.

For instance, in a recent project, UT revealed extensive corrosion hidden beneath the surface of an aluminum boat hull. This allowed us to plan a more comprehensive repair strategy, preventing potential future problems.

Q 12. How do you manage a corrosion removal project, including planning, execution, and quality control?

Managing a corrosion removal project effectively involves a structured approach focusing on planning, execution, and quality control.

- Planning: This stage includes a detailed assessment of the damage, defining the scope of work, selecting appropriate materials and methods, creating a timeline, and preparing a budget.

- Execution: This involves careful preparation of the work area, implementing the chosen cleaning and repair methods, adhering strictly to safety protocols, and maintaining detailed records of the process.

- Quality Control: Throughout the project, regular inspections and testing (both visual and non-destructive) ensure that the work meets the required standards. This includes checking for any remaining corrosion, ensuring the structural integrity of repairs, and verifying the quality of the final finish.

I use project management software to track progress, manage resources, and maintain communication with clients. Regular progress reports keep stakeholders informed and allow for timely adjustments if needed. Thorough documentation, including photos and reports, is essential for verifying the quality of the work performed and for any future reference.

Q 13. What are your skills in using specialized tools and equipment for corrosion removal?

My expertise extends to a wide range of specialized tools and equipment used in corrosion removal. This includes:

- Power tools: Angle grinders, drills, sanders, and wire brushes for surface preparation and removal of corrosion.

- Welding equipment: MIG and TIG welders for repairing metal structures.

- Electrolysis equipment: For safely removing corrosion from metal boats, especially aluminum.

- Non-destructive testing equipment: Ultrasonic flaw detectors, magnetic particle inspection kits, and eddy current testers.

- Specialized cleaning agents and chemicals: Phosphoric acid rust converters, aluminum cleaners, and fiberglass repair kits.

I am also adept at using various hand tools including chisels, hammers, scrapers, and brushes for more intricate work. I am comfortable working with both traditional and modern technologies to achieve optimal results.

Q 14. Describe your experience with different types of marine metals and their susceptibility to corrosion.

Understanding the different types of marine metals and their susceptibility to corrosion is crucial for effective preventative measures and repair strategies. Different metals have varying levels of corrosion resistance due to their electrochemical properties and interaction with seawater.

- Steel: Susceptible to rusting (oxidation) if not properly protected. Requires regular maintenance and protective coatings like paint or galvanizing.

- Aluminum: More corrosion-resistant than steel but prone to galvanic corrosion when in contact with other metals. Proper isolation and protective coatings are essential.

- Copper alloys (bronze, brass): Generally quite corrosion-resistant in marine environments, but still susceptible to specific forms of corrosion in certain conditions.

- Stainless steel: Highly corrosion-resistant due to the chromium content forming a passive oxide layer. However, different grades of stainless steel have varying resistance, and improper maintenance can compromise this protection.

I’ve worked with all these metals extensively and understand their individual characteristics. For example, when repairing an aluminum boat, I would take extra care to avoid galvanic corrosion by ensuring proper isolation between different metals. This might involve using dielectric materials to prevent electrical contact between dissimilar metals.

Q 15. How do you assess the environmental impact of corrosion removal processes and materials?

Assessing the environmental impact of corrosion removal is crucial for responsible boat maintenance. We must consider the disposal of removed materials, the toxicity of cleaning agents, and the potential impact on marine ecosystems. For example, using abrasive blasting can create dust containing heavy metals that can pollute the surrounding water and air. Similarly, certain chemical treatments can release harmful substances into the environment. A thorough assessment involves identifying the materials being removed (e.g., paint containing lead, zinc, or copper), the volume of waste generated, and selecting environmentally friendly removal and disposal methods. This often involves employing techniques like careful hand-scraping, low-pressure water blasting with bio-degradable detergents, or utilizing specialized electrochemical methods. The ultimate goal is minimizing waste and selecting processes that adhere to local environmental regulations and protect marine life.

We also evaluate the long-term consequences of the chosen method. For instance, while some chemical treatments are effective, their byproducts might harm marine life, requiring careful consideration of the trade-off between effectiveness and environmental impact. A Life Cycle Assessment (LCA) can help quantify the environmental burdens across the entire process, from material sourcing to waste disposal.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key factors to consider when developing a corrosion prevention plan for a boat?

Developing a comprehensive corrosion prevention plan hinges on several key factors. First, a thorough assessment of the boat’s construction materials is needed – aluminum, steel, fiberglass, or wood each require specific approaches. Then, we consider the boat’s intended use and environment. A boat used frequently in saltwater will require far more aggressive prevention than one primarily used in freshwater. Regular cleaning and inspection are essential, identifying corrosion at its earliest stages. The plan should detail a regular maintenance schedule, outlining cleaning, inspection, and repair intervals. Proper application and maintenance of protective coatings, tailored to the materials and environment, is critical. An effective plan also includes considerations for cathodic protection (for metallic hulls), proper ventilation to prevent condensation, and storage practices to minimize exposure to moisture and the elements. It’s like a doctor’s preventative care plan for your boat – regular checkups are key to preventing serious problems down the line.

Q 17. Explain your understanding of different types of marine environments and their impact on corrosion rates.

Marine environments vary significantly in their corrosiveness. Saltwater is highly corrosive due to the presence of dissolved salts and oxygen, accelerating the electrochemical processes that cause corrosion. This is especially true in coastal areas with high salinity and tidal fluctuations. Freshwater is generally less corrosive, but factors like water chemistry (pH, dissolved minerals) and the presence of pollutants still influence corrosion rates. Estuarine environments (where freshwater meets saltwater) are often highly corrosive due to the fluctuating salinity. Tropical climates tend to accelerate corrosion due to high humidity and temperatures, while colder climates can introduce other factors such as ice abrasion. Think of it like this: imagine a piece of metal in a constantly-damp, salty environment versus the same metal in a dry desert – corrosion will be far more pronounced in the former.

Understanding these variations is crucial because the choice of materials, protective coatings, and corrosion prevention strategies must be tailored accordingly. A steel boat in a saltwater environment might require a more robust coating system and potentially cathodic protection compared to the same boat used solely in freshwater.

Q 18. How do you determine the appropriate thickness of protective coatings for different materials and environments?

Determining the appropriate coating thickness involves careful consideration of several factors. The material being protected, the aggressiveness of the environment, the type of coating, and the anticipated service life all play a role. Industry standards and manufacturer specifications provide guidelines, but experience and engineering judgment are crucial. Thicker coatings generally offer more protection but can be more expensive and might not always be necessary. For instance, a less aggressive freshwater environment might require a thinner coating on aluminum compared to the same aluminum material in a harsh saltwater environment. We might use coating thickness gauges to verify application and consider additional factors such as the underlying surface’s condition. The goal is to balance protection with cost and practicality. Sometimes, a multi-layered system with a primer and topcoat might be more effective than a single thick layer.

Q 19. Describe your experience in troubleshooting corrosion-related problems on boats.

Troubleshooting corrosion problems requires a systematic approach. I begin with a thorough visual inspection, identifying the location, extent, and type of corrosion. This might include pinhole corrosion, pitting, crevice corrosion, or galvanic corrosion. Then, I investigate the underlying causes. This may involve analyzing the materials, assessing environmental factors, and examining the coating’s integrity. For example, if I find galvanic corrosion, it suggests that dissimilar metals are in contact, creating an electrochemical cell that accelerates corrosion. I’ve worked on cases where improper grounding in the boat’s electrical system led to significant corrosion. In other cases, a poorly applied coating system failed to provide adequate protection. The solution usually involves addressing the root cause—remedying the electrical issue, replacing deteriorated sections, applying a suitable protective coating, and implementing preventative measures to avoid future problems. Documenting the findings and the steps taken is important for future maintenance.

Q 20. Explain the importance of proper surface preparation before applying corrosion prevention coatings.

Proper surface preparation is paramount to the success of any corrosion prevention coating. A clean and properly prepared surface ensures good adhesion, which is crucial for long-lasting protection. This involves removing all rust, scale, loose paint, and other contaminants. This often includes processes like abrasive blasting, wire brushing, or chemical cleaning, followed by thorough rinsing and drying. Surface profiling might be needed to ensure the correct roughness for optimal adhesion. If this step is skipped or done improperly, the coating will likely peel or blister, leading to rapid corrosion. Imagine trying to paint a wall with dirt and loose paint still on it – the paint won’t stick properly. The same principle applies to boat hulls and components. The time and effort invested in thorough surface preparation far outweigh the cost and disruption of premature coating failure.

Q 21. What are the limitations of different corrosion prevention techniques?

Every corrosion prevention technique has limitations. Protective coatings, while effective, can be damaged by abrasion, impact, or UV degradation. Their effectiveness depends on the proper application and maintenance. Cathodic protection, excellent for metallic hulls, requires a power source and regular maintenance; it doesn’t protect areas not directly connected to the system. Sacrificial anodes, another form of cathodic protection, require periodic replacement as they corrode to protect the boat’s hull. Chemical treatments are effective for removing corrosion products but might be environmentally unfriendly or damage underlying materials if not used correctly. Even regular cleaning and inspection can’t prevent corrosion entirely, just slow it down. Understanding these limitations and employing a combination of techniques is crucial for creating a robust corrosion prevention strategy tailored to the specific boat and its environment.

Q 22. How do you document the corrosion removal and repair process for future reference?

Thorough documentation is crucial for efficient boat repair and future maintenance. My process involves a multi-stage approach. First, I create a detailed photographic record of the corrosion before any remediation begins. This includes close-up shots of the affected areas, noting their size, depth, and location on the vessel. Next, I document the chosen repair method, listing the materials used (e.g., specific type of primer, paint, filler) and their application steps. This information is logged in a comprehensive report which includes dates, times, and the names of personnel involved. Any unexpected findings or changes in the repair plan are also meticulously recorded. Finally, I complete the documentation with post-repair photographs showcasing the finished work and a summary of the process’s effectiveness. This detailed record ensures that future repairs can be accurately assessed and maintained, avoiding costly mistakes.

For example, I recently worked on a sailboat where extensive galvanic corrosion was found on the keel. My documentation included photos showing the extent of the damage, followed by step-by-step pictures detailing the grinding, priming, and application of epoxy coating. A final assessment noted the complete resolution of the corrosion and the absence of any further signs of damage.

Q 23. Explain your experience working with different types of boat designs and their unique corrosion challenges.

My experience spans various boat designs, each posing unique corrosion challenges. Aluminum boats, for instance, are susceptible to pitting and crevice corrosion, particularly in saltwater environments. The complex geometries of these hulls can make access for cleaning and repair difficult. Fiberglass boats, while generally more resistant, are vulnerable to osmotic blistering (water ingress) if the gel coat is compromised, leading to delamination and further corrosion of the underlying layers. Steel boats, on the other hand, are prone to rust and galvanic corrosion if not properly protected with a good zinc anode system. Wooden boats present another set of challenges; moisture penetration can lead to rot and the growth of marine organisms, requiring specialized treatments. Understanding the specific material properties and construction techniques of each design is key to identifying and addressing the specific corrosion concerns.

For example, I once worked on a classic wooden sailboat with significant rot in the transom. This required careful removal of the decayed wood, replacement with marine-grade timber, and sealing to prevent future moisture ingress. The approach differed greatly from my work on an aluminum fishing boat, where I focused on addressing pitting corrosion through meticulous sanding, priming, and painting.

Q 24. How do you handle unexpected corrosion issues during a repair project?

Unexpected corrosion issues are part of the reality of boat repair. My approach is methodical and prioritizes safety and a thorough understanding of the problem before proceeding. When unexpected corrosion is discovered, I first thoroughly document the issue—photographing, measuring, and noting the location. I then investigate the root cause. This might involve inspecting surrounding components, checking electrical systems for shorts, or examining the boat’s history for clues. Once the cause is identified, I develop a revised repair plan, addressing the unexpected issue alongside the original scope of work. This plan includes detailed steps, necessary materials, and potential risks. Crucially, I communicate the changes to the client, outlining the impact on the project timeline and cost. Transparency and clear communication are essential in such situations.

For example, during a routine hull cleaning, we discovered hidden stress cracks near the keel joint which had initiated corrosion. This required a complete assessment of the keel’s structural integrity, a reevaluation of the project plan, and additional resources to address the unexpected problem.

Q 25. Describe your familiarity with relevant industry standards and regulations related to marine corrosion.

My work adheres to several industry standards and regulations. I’m familiar with ISO 12944 (Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems), which provides guidance on selecting and applying protective coatings. I also follow the American Boat and Yacht Council (ABYC) standards, particularly those related to electrical systems and corrosion prevention. These standards outline best practices for grounding and bonding to minimize galvanic corrosion. Furthermore, I am knowledgeable about the regulations pertaining to the handling and disposal of hazardous materials used in corrosion removal and repair, such as solvents and heavy metals. Adherence to these standards ensures the longevity and safety of the repair.

Q 26. How do you communicate technical information about corrosion to non-technical stakeholders?

Communicating complex technical information to non-technical stakeholders requires clear, concise language and visual aids. I avoid jargon whenever possible, using analogies to explain concepts easily. For example, when discussing galvanic corrosion, I might compare it to a battery, explaining how dissimilar metals in contact can create an electrical current that causes one metal to corrode. Diagrams and illustrations are invaluable tools. A simple drawing showing the process of corrosion or a flowchart outlining the repair steps can help non-technical clients understand the situation and proposed solution. Keeping the language straightforward and always being available to answer questions ensures clear understanding and client confidence.

Q 27. Describe a situation where you had to deal with a challenging corrosion problem; what was your approach?

One particularly challenging case involved a vintage wooden yacht with severe hull rot due to prolonged neglect. The extent of the damage was initially underestimated. The traditional approach of simply replacing the affected wood was impractical, due to the widespread decay. My solution involved a phased approach. First, we used a combination of non-destructive testing techniques like ultrasonic scans and moisture meters to map the affected areas precisely. This allowed for targeted removal of rotted wood, minimizing structural compromise. Then we carefully repaired and strengthened the hull using epoxy resin systems and marine-grade plywood. This was followed by an extensive caulking and sealing process to prevent further moisture ingress. The project took considerably longer than anticipated, but the thorough approach ensured the yacht’s long-term structural integrity. The owner was kept informed at each stage, and the final result was a beautifully restored vessel.

Q 28. How do you stay updated on the latest advancements in boat corrosion removal technologies and techniques?

Staying current with advancements in boat corrosion removal is vital. I achieve this through several avenues. I regularly attend industry conferences and workshops, networking with other professionals and learning about new techniques and technologies. I subscribe to relevant trade publications and online journals, keeping abreast of research and development in materials science and corrosion prevention. Active participation in professional organizations, such as the NACE International (formerly the National Association of Corrosion Engineers), provides access to cutting-edge knowledge and networking opportunities. Furthermore, I actively seek continuing education courses focused on new coatings, repair methods, and non-destructive testing techniques. This continuous learning ensures I maintain my expertise and provide the best possible service.

Key Topics to Learn for Boat Corrosion Removal Interview

- Types of Boat Corrosion: Understanding galvanic corrosion, pitting corrosion, crevice corrosion, and their causes in different boat materials (aluminum, steel, fiberglass).

- Inspection and Assessment Techniques: Methods for visually identifying corrosion, using specialized tools (e.g., ultrasonic testing), and interpreting assessment results to determine the extent of damage.

- Corrosion Removal Methods: Familiarization with various techniques including mechanical cleaning (sandblasting, wire brushing), chemical cleaning (acid etching, passivation), and electrochemical methods.

- Material Selection and Protection: Knowledge of corrosion-resistant materials and protective coatings (paints, sealants) to prevent future corrosion.

- Practical Application: Case studies or examples demonstrating the application of different corrosion removal techniques to specific boat types and materials. Understanding the selection criteria for appropriate methods based on severity and location of corrosion.

- Safety Procedures: Safe handling of chemicals, proper use of personal protective equipment (PPE), and environmental considerations during the corrosion removal process.

- Repair and Restoration Techniques: Methods for repairing corroded areas, including welding, fiberglass repair, and fairing techniques.

- Cost Estimation and Project Management: Understanding the factors influencing the cost of corrosion removal projects, and the ability to create realistic project timelines and budgets.

Next Steps

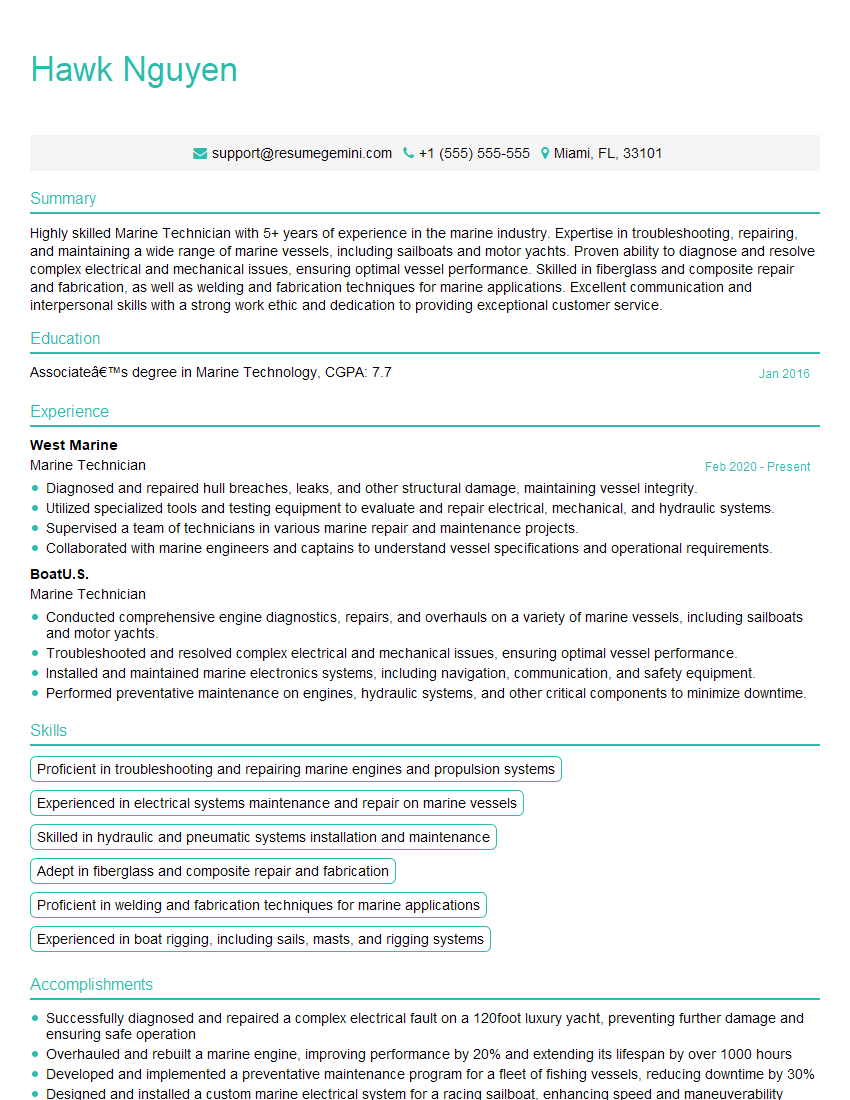

Mastering boat corrosion removal techniques opens doors to rewarding career opportunities in marine maintenance, repair, and restoration. A strong understanding of these concepts is highly valued by employers. To significantly boost your job prospects, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Take advantage of their tools and resources; examples of resumes tailored to Boat Corrosion Removal are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO