Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Boat Engine Maintenance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Boat Engine Maintenance Interview

Q 1. Describe the process of troubleshooting a failed engine start.

Troubleshooting a failed engine start involves a systematic approach. Think of it like a detective investigating a crime scene – you need to gather clues and eliminate possibilities. First, ensure the battery is charged and the connections are clean and tight. A weak battery is the most common culprit. Next, check the fuel system: Is there fuel in the tank? Is the fuel line clear? Is the fuel filter clogged? A clogged filter prevents fuel from reaching the engine. Then, examine the ignition system – are the spark plugs clean and properly gapped? Is there spark at the plugs? A weak or absent spark will prevent ignition. Finally, check the engine’s starting mechanism itself – is the starter motor engaging? If it isn’t, you could have a faulty starter or solenoid. If you’ve checked all these and the engine still won’t start, it’s time to consult a qualified marine mechanic.

- Step 1: Check Battery and Connections

- Step 2: Inspect Fuel System (Tank, Lines, Filter)

- Step 3: Examine Ignition System (Spark Plugs, Wires)

- Step 4: Test Starter Motor and Solenoid

For example, I once had a boat that wouldn’t start due to a corroded battery terminal. A simple cleaning solved the problem, highlighting the importance of regular maintenance.

Q 2. Explain the function of a carburetor in an outboard engine.

The carburetor in an outboard engine is the heart of the fuel delivery system. It’s responsible for mixing the correct ratio of air and fuel to create a combustible mixture for the engine to run. Think of it as a precise chef, meticulously measuring ingredients. It does this by drawing in air and using a venturi effect (a narrowing of the airflow) to create a vacuum. This vacuum draws fuel from the fuel tank through jets, atomizing it into a fine mist. The mixture then flows to the engine’s cylinders for combustion. Different types of carburetors exist, each with its specific mechanism for controlling the air-fuel mixture based on engine speed and load. Regular cleaning and adjustment are vital for optimal engine performance and fuel efficiency.

A poorly adjusted or dirty carburetor can lead to rough idling, poor acceleration, and excessive fuel consumption. Imagine trying to bake a cake with the wrong amount of ingredients – the result wouldn’t be good. That’s similar to what happens when the carburetor is not working correctly.

Q 3. What are the common causes of overheating in a marine diesel engine?

Overheating in a marine diesel engine is a serious issue that can cause significant damage. The most common causes include problems with the cooling system itself, such as insufficient coolant flow, a clogged heat exchanger, or a faulty impeller. Other causes include a faulty thermostat, which prevents the coolant from circulating effectively, and scaling or corrosion within the cooling system. Blockages in the cooling system, possibly due to marine growth or debris, can also restrict water flow and cause overheating. Finally, inadequate lubrication (low oil level or poor oil quality) can also contribute to overheating. Think of it as the engine’s circulatory system – if it’s blocked or compromised, the engine overheats.

- Insufficient Coolant Flow: Clogged heat exchanger, faulty impeller

- Faulty Thermostat: Prevents proper coolant circulation

- Scaling or Corrosion: Restricts water flow

- Blockages: Marine growth, debris

- Inadequate Lubrication: Low oil level, poor oil quality

Q 4. How do you diagnose a problem with a boat’s fuel system?

Diagnosing fuel system problems requires a methodical approach. Start by checking the fuel tank – is it empty? Is the fuel clean and free of contaminants? Next, examine the fuel lines for cracks, leaks, or blockages. A visual inspection is often sufficient. Then, test the fuel filter – is it clogged? A clogged filter dramatically reduces fuel flow. Next, check the fuel pump; does it operate correctly and deliver sufficient fuel pressure? Use a fuel pressure gauge to check this. Finally, check the injectors or carburetor – are they delivering fuel properly? If everything appears okay, and the engine still isn’t running smoothly, there may be air in the fuel lines, requiring bleeding. A simple analogy is a clogged water pipe – no water gets through. Similarly, a problem anywhere in the fuel system halts fuel delivery to the engine.

Q 5. Explain the importance of regular oil changes for marine engines.

Regular oil changes are crucial for the longevity and performance of marine engines. Engine oil acts as a lubricant, reducing friction between moving parts and preventing wear and tear. It also acts as a coolant, carrying away heat. Over time, oil degrades, losing its lubricating properties and accumulating contaminants. This contaminated oil can damage engine components, leading to reduced performance, increased fuel consumption, and costly repairs. The harsh marine environment – salt, moisture, and vibration – accelerates oil degradation, making regular changes even more important. Think of it as changing the oil in your car; neglecting it will lead to significant engine problems down the road. Following the manufacturer’s recommended oil change intervals, using the correct grade of marine oil, and properly disposing of used oil are vital steps in maintaining your marine engine.

Q 6. What are the safety procedures for working on a boat engine?

Safety is paramount when working on a boat engine. Always disconnect the battery’s negative terminal before starting any work to prevent accidental electric shock. Ensure the engine is completely cool to avoid burns. Work in a well-ventilated area to prevent exposure to harmful fumes. Use appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Never work alone; have someone nearby to assist in case of an emergency. If you’re unsure about any procedure, consult a qualified marine mechanic. Consider using a fire extinguisher nearby and understanding its use. If you are working on any fuel system components, ensure the area is well ventilated and free of ignition sources. Remember, a small mistake can lead to serious injury or even death.

Q 7. Describe the different types of marine engine cooling systems.

Marine engines employ different cooling systems to maintain optimal operating temperatures. The most common are raw water cooling and closed-loop cooling. Raw water cooling uses seawater directly to cool the engine. This is simple and effective, but it’s susceptible to corrosion and requires regular maintenance due to marine growth and debris. Closed-loop cooling uses a coolant (like antifreeze) that circulates through the engine and a heat exchanger, where heat is transferred to the seawater. This method is better at preventing corrosion and requires less maintenance but adds complexity. A less common but increasingly popular system is a hybrid system combining aspects of both, providing the best of both worlds. Think of it like human blood circulation; it needs to flow efficiently and effectively to keep the body working correctly, and similarly, engine cooling is crucial for reliable operation.

- Raw Water Cooling: Uses seawater directly

- Closed-Loop Cooling: Uses coolant and a heat exchanger

- Hybrid Cooling Systems: Combines aspects of both

Q 8. How do you identify and repair a cracked engine block?

Identifying a cracked engine block can be tricky, as cracks can be hidden. A visual inspection is the first step. Look closely for any visible cracks, especially around the cylinder head, freeze plugs, and water jacket areas. Pay attention to any signs of coolant leakage or discoloration. However, smaller, internal cracks are harder to spot.

To detect hidden cracks, pressure testing is crucial. This involves pressurizing the cooling system with a specialized tool. Any leaks indicate a crack. Dye penetrant testing is another effective method; a dye is applied to the engine block, and after a period, a developer is sprayed on. Cracks will appear as bright lines.

Repairing a cracked engine block depends on the severity and location of the crack. Small, surface cracks can sometimes be repaired with welding by a qualified marine engine mechanic. Larger cracks, or cracks in critical areas, usually necessitate a block replacement, a significantly more expensive and time-consuming option. A professional assessment is crucial to determine the best course of action and to avoid potentially catastrophic engine failure.

Q 9. What are the signs of a faulty impeller?

The impeller is a vital component in your engine’s cooling system. It pumps water through the engine to prevent overheating. A faulty impeller manifests in several ways. One of the most common signs is overheating. The engine temperature gauge will climb significantly, and you might even notice steam or hot water escaping.

Reduced water pressure is another key indicator. A weak or damaged impeller can’t generate the required water flow, resulting in lower pressure. You might notice this by checking the tell-tale or pressure gauge. If the pressure is considerably lower than usual, it points towards impeller issues.

You might also hear unusual noises, such as squealing, rattling, or grinding sounds coming from the engine area. Lastly, check the impeller itself; access it by removing the impeller cover. A worn-out, damaged, or missing impeller will be obvious on inspection.

Q 10. How do you test the compression in a marine engine?

Testing compression is a fundamental diagnostic procedure for internal combustion engines, helping to assess the condition of cylinders and rings. A compression tester, specifically designed for the size of your engine’s spark plugs, is essential. Ensure the engine is cold, the battery is fully charged, and all spark plugs are removed.

For each cylinder, screw the compression tester into the spark plug hole, crank the engine until the gauge reading stabilizes, and record the reading in PSI (pounds per square inch). Compare the readings across all cylinders. Significant variations (more than 10-15%) suggest problems within that cylinder, such as worn piston rings, leaky valves, or a blown head gasket. Low readings across all cylinders could indicate a more widespread issue, such as a vacuum leak.

Always refer to your engine’s specific manual for the expected compression range. The manual will specify the ideal PSI for your engine type. Compression testing is a crucial preventative maintenance step.

Q 11. Explain the function of a marine alternator.

The marine alternator is the heart of your boat’s electrical system. Its primary function is to generate DC (direct current) electricity to charge the battery bank while the engine is running. This power then supplies electricity to all your onboard systems – lights, navigation equipment, electronics, and any other electrical appliances. Think of it as the power source that keeps everything running when you’re out on the water, ensuring a reliable power supply separate from shore power.

A well-functioning alternator maintains the battery charge level, prevents discharge during operation, and ensures enough power for your boat’s various electrical needs. If it fails, you could find yourself stranded without power or with a dead battery.

Q 12. Describe the process of winterizing a boat engine.

Winterizing a boat engine is crucial to prevent damage from freezing temperatures. The process involves removing water from the engine’s cooling system, fuel system, and any other water-containing components. This prevents cracks from forming in the engine block, hoses, and other components as water expands upon freezing.

The process typically involves running antifreeze (propylene glycol-based, never automotive antifreeze which is toxic) through the cooling system until it’s completely circulated. This step protects the engine from freezing. Emptying the fuel tank, or adding fuel stabilizer, is also needed to prevent fuel degradation. Disconnect the battery to prevent discharge. Additionally, protect components from the elements by covering exposed areas to stop corrosion.

Every engine is slightly different, so always consult your engine’s owner’s manual for detailed instructions. Proper winterization ensures your engine will be ready for the next boating season.

Q 13. What are the common causes of excessive fuel consumption?

Excessive fuel consumption can have several root causes. One major culprit is a faulty fuel injection system (if applicable). Clogged injectors or low fuel pressure lead to inefficient fuel delivery, resulting in more fuel being used to achieve the same power output. This is like trying to run a car with a partially blocked fuel line—it requires more fuel to keep going.

Another common cause is a malfunctioning carburetor (in older engines). A dirty or improperly adjusted carburetor will cause a rich fuel mixture, meaning the engine receives too much fuel. Problems with the engine’s air intake system, such as leaks or a dirty air filter, can also lead to increased fuel use. The engine needs the proper air/fuel ratio to function optimally. A poorly tuned engine, meaning incorrect ignition timing or a problem with the spark plugs, also significantly increases fuel consumption.

Regular engine maintenance and tune-ups can help address many of these issues before they lead to excessive fuel consumption.

Q 14. How do you troubleshoot a problem with a boat’s steering system?

Troubleshooting a boat’s steering system requires a systematic approach. First, visually inspect the entire system from the steering wheel to the rudder. Look for any obvious signs of damage, such as loose connections, leaks, or worn cables. A loose nut or a broken cable is relatively easy to identify and fix.

Check the steering cable for proper tension and freedom of movement. If the cable feels stiff or binds, lubrication or cable replacement may be needed. Next, examine the rudder itself. Ensure it’s free to move without obstruction. Any blockage from marine growth or damage would hinder its motion.

If the problem persists, you might need to check the hydraulic steering system (if equipped). Examine the hydraulic fluid level and look for any leaks. If you are not comfortable diagnosing these issues yourself, consult a qualified marine mechanic. Correct diagnosis is important before making any repairs to avoid further damage.

Q 15. Explain the difference between two-stroke and four-stroke outboard engines.

The key difference between two-stroke and four-stroke outboard engines lies in their combustion cycles. Think of it like this: a two-stroke engine is like a simpler, faster running engine, while a four-stroke is more refined and fuel-efficient.

- Two-stroke: Completes one power stroke per two piston strokes. The intake and exhaust processes happen within the same stroke, requiring a mixture of fuel and oil to be pre-mixed. They are generally lighter, simpler, and more compact, but less fuel-efficient and produce more emissions. Imagine a quick, punchy motorbike engine – that’s the feeling you get with a two-stroke outboard.

- Four-stroke: Completes one power stroke per four piston strokes. Each stroke has a dedicated function: intake, compression, power, and exhaust. They use separate fuel and lubricating oil systems, making them cleaner and more fuel-efficient. Think of a smooth, powerful car engine – that’s the feel of a four-stroke outboard. They’re generally more robust and longer-lasting.

Choosing between the two depends on your needs. Two-strokes are often preferred for smaller, lightweight boats where simplicity and affordability are prioritized. Four-strokes are better suited for larger boats where fuel efficiency, longevity, and reduced emissions are paramount.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of replacing a fuel filter.

Replacing a fuel filter is a crucial maintenance task that prevents contaminants from reaching your engine’s delicate fuel system. Here’s how to do it safely:

- Safety First: Disconnect the battery’s negative terminal to prevent accidental sparking.

- Locate the Filter: The fuel filter is usually located in a readily accessible spot along the fuel line, often near the fuel tank or engine.

- Prepare Materials: Gather rags or shop towels, a container to catch spilled fuel, and a new fuel filter of the correct type and specifications for your engine.

- Release Fuel Pressure: Some systems require releasing fuel pressure before disconnecting the lines; consult your engine’s manual for the proper procedure.

- Disconnect Fuel Lines: Carefully loosen and remove the fuel line clamps on either side of the filter. Have your collection container ready to catch any residual fuel.

- Replace the Filter: Install the new filter, ensuring the arrows indicating fuel flow direction match the fuel line orientation.

- Reconnect Fuel Lines: Securely reattach the fuel lines, making sure the clamps are properly tightened.

- Reconnect Battery: Reconnect the battery’s negative terminal.

- Check for Leaks: Carefully inspect all connections for leaks. Start the engine and check for proper operation.

Remember always consult your engine’s owner’s manual for specific instructions and safety precautions. Improper fuel filter replacement can lead to engine failure.

Q 17. What are the common causes of propeller damage?

Propeller damage is a common occurrence, often caused by striking submerged objects or encountering debris. Here are the primary causes:

- Striking Obstacles: This is the most frequent cause. Hidden rocks, logs, sandbars, or even debris on the lakebed can severely damage or bend propellers.

- Running Aground: Running your boat aground on sand, mud, or rocks can easily damage or crack the propeller.

- Foreign Objects: Fishing lines, plastic bags, or other debris can wrap around or become entangled with the propeller, causing damage.

- Excessive Cavitation: While not directly physical damage, excessive cavitation (formation of vapor bubbles around the propeller) can erode the propeller blades over time.

- Corrosion: Prolonged exposure to saltwater can lead to corrosion and weakening of the propeller material, increasing its susceptibility to damage.

Regular propeller inspections and avoiding shallow waters can greatly reduce the chances of damage. Consider using a propeller guard in areas known for debris.

Q 18. How do you diagnose and repair a leaking exhaust manifold?

A leaking exhaust manifold is a serious issue that needs prompt attention. Here’s how to diagnose and repair it:

- Visual Inspection: Carefully inspect the manifold for cracks, corrosion, or any signs of leakage. Look for discoloration, rust, or evidence of water stains around the joints.

- Pressure Test (if possible): Some manifolds can be pressure-tested to pinpoint leaks more precisely. This often requires specialized equipment.

- Identify the Leak Source: Once the leak is located, determine whether it’s a crack in the manifold itself or a problem with the gaskets or bolts.

- Repairing Cracks (minor): Small cracks might be repairable through welding (by a qualified professional). However, extensive damage usually necessitates replacement.

- Replacing Gaskets: If the leak originates from the gaskets, replace them with new ones. Ensure that the mating surfaces are clean and free of debris.

- Tightening Bolts: Check and tighten all bolts connecting the manifold sections, but avoid over-tightening, which can cause damage.

- Replacement (major): For extensive damage or repeated leaks, replacing the entire exhaust manifold might be the most effective solution.

Exhaust manifold leaks can be dangerous due to carbon monoxide poisoning. Always prioritize safety and seek professional assistance if you’re unsure about any aspect of the repair.

Q 19. What are the different types of marine engine lubricants?

Marine engine lubricants are specifically formulated to withstand the harsh conditions encountered in marine environments. The most common types include:

- Mineral-based oils: These are less expensive and offer good protection but have a shorter lifespan compared to synthetic oils.

- Synthetic oils: These are more expensive but offer superior protection, extended service intervals, and better performance at extreme temperatures. They are particularly beneficial in high-performance engines or those operating in harsh conditions.

- Semi-synthetic oils: These are a blend of mineral and synthetic oils, offering a balance between cost and performance.

The choice of lubricant depends on the engine type, operating conditions, and manufacturer’s recommendations. Always refer to your engine’s manual for specific viscosity and type specifications.

Beyond the base oil type, marine lubricants also often contain additives to prevent corrosion, reduce wear, and enhance overall performance in salty environments.

Q 20. Explain the function of a trim tab.

Trim tabs are small, hydraulically or electrically actuated flaps located on the transom of a boat. Their primary function is to control the boat’s attitude (the angle of the hull in relation to the water) and improve handling.

By adjusting the trim tabs, you can:

- Reduce bow rise (porpoising): At high speeds, trim tabs can help lower the bow, preventing the boat from bouncing excessively.

- Improve planing efficiency: By adjusting the trim, you can achieve better planing (getting the boat up on the surface) and improve fuel efficiency.

- Enhance handling in turns: Trim tabs can improve responsiveness and stability during turns, reducing yaw (side-to-side movement).

- Reduce draft (reduce the depth of the boat in the water): This can make it easier to navigate shallow waters.

Imagine trim tabs as adjustable spoilers on a plane’s wings, but for a boat. They allow the boat’s handling to be optimized for different conditions and speeds.

Q 21. How do you check the voltage output of a marine battery?

Checking the voltage output of a marine battery is a simple way to assess its health and charging system. Here’s how:

- Use a Voltmeter: Use a reliable digital voltmeter to get an accurate reading.

- Ensure the Engine is Off: The engine should be completely off during this process.

- Connect the Voltmeter: Connect the voltmeter’s leads to the battery terminals. The red lead goes to the positive (+) terminal, and the black lead to the negative (-) terminal.

- Read the Voltage: A fully charged 12-volt marine battery should typically read between 12.6 and 13.2 volts. Readings below 12.2 volts generally indicate a low charge. Readings below 11.5 volts may signify a dead battery. Note that voltage might vary slightly based on battery temperature and type.

Regular voltage checks, combined with other battery maintenance practices, are essential for ensuring your boat’s electrical system performs optimally.

Q 22. What are the safety precautions when working with fuel and batteries?

Working with fuel and batteries on a boat demands utmost caution. Fuel is highly flammable, and batteries produce explosive gases. Here’s a breakdown of essential safety precautions:

- Ventilation: Always work in a well-ventilated area. Fuel fumes are heavier than air and can accumulate in low-lying spaces, creating a fire hazard. Similarly, battery gases (hydrogen) can ignite.

- Fire Extinguisher: Keep a readily accessible fire extinguisher (rated for Class B and C fires) nearby. Know how to use it!

- Personal Protective Equipment (PPE): Wear safety glasses to protect your eyes from splashes, gloves to prevent skin contact with fuel or battery acid, and closed-toe shoes.

- Fuel Handling: Never fill fuel tanks while the engine is running or hot. Avoid smoking or sparking near fuel. Use a dedicated fuel funnel to prevent spills. Wipe up any spills immediately.

- Battery Handling: Wear protective gloves and eyewear when handling batteries. Never short-circuit terminals. When disconnecting batteries, always disconnect the negative (-) terminal first and reconnect it last. Be mindful of potential sparks when working near batteries.

- Grounding: Ensure that you are properly grounded to prevent static electricity buildup which can cause sparks that ignite fuel fumes.

Remember, a moment of carelessness can have severe consequences. Safety should always be your top priority.

Q 23. Describe the different types of marine propellers and their applications.

Marine propellers come in various designs, each optimized for different applications. The choice depends on the boat type, intended use, and hull design.

- Right-Handed vs. Left-Handed: This refers to the direction the propeller rotates when viewed from the stern. Most boats have right-handed propellers.

- Fixed Pitch Propellers: These are the simplest and most common type. The pitch (angle of the blades) is fixed, resulting in a single speed for a given engine RPM. They are cost-effective and easy to maintain but less efficient than other types.

- Controllable Pitch Propellers (CPP): These allow you to adjust the blade angle while the engine is running, offering greater control over speed and efficiency. This is especially useful in maneuvering and varying conditions but increases cost and complexity.

- Folding Propellers: These blades fold flat against the hub when the engine is in reverse, reducing drag while in reverse. They are popular on sailboats and other vessels that need improved reverse performance and reduced drag while sailing.

- Feathering Propellers: Similar to folding propellers, these rotate the blades to a low-drag position when not in use, maximizing efficiency.

For example, a high-speed powerboat might use a fixed-pitch propeller optimized for speed, whereas a trawler might benefit from a controllable pitch propeller for better maneuverability at low speeds. Choosing the right propeller is crucial for optimal performance and efficiency.

Q 24. How do you troubleshoot an engine that is losing power?

Loss of engine power can stem from various issues. A systematic approach is crucial for effective troubleshooting:

- Check Fuel Supply: Ensure the fuel tank is adequately filled and that there are no obstructions in the fuel line. Look for leaks, filter blockages, or a faulty fuel pump.

- Inspect Air Intake: Clogged air filters restrict airflow, reducing engine power. Clean or replace the filter if necessary.

- Examine Spark Plugs (for gasoline engines): Inspect for fouling, corrosion, or damage. Replace as needed. Weak sparks lead to incomplete combustion and power loss.

- Check for Compression (for gasoline and diesel engines): Low compression indicates a problem with pistons, rings, or valves. A compression test is essential for accurate diagnosis.

- Inspect the Exhaust System: Blockages in the exhaust can impede engine performance. Ensure there are no obstructions.

- Check Fuel Filters: A clogged fuel filter reduces fuel flow to the engine, leading to a decrease in power. Replacing the filter will often solve this issue.

- Check the Carburetor/Fuel Injectors (if applicable): These components are responsible for delivering the correct fuel-air mixture. Cleaning or rebuilding the carburetor or checking the fuel injectors might be necessary.

- Consider the Propeller: A damaged, bent, or fouled propeller can lead to a significant loss of engine power. Inspect for any issues.

Remember to consult your engine’s manual for specific troubleshooting steps. Document your checks, and if the problem persists, seek professional assistance.

Q 25. What is the importance of regular maintenance on a boat engine?

Regular maintenance is paramount for the longevity, reliability, and safety of your boat engine. Neglecting maintenance can lead to costly repairs, breakdowns at inconvenient times, and even safety hazards.

- Extended Engine Life: Regular servicing prevents premature wear and tear, maximizing the engine’s lifespan.

- Improved Performance and Efficiency: A well-maintained engine runs smoothly and efficiently, delivering optimal power and fuel economy.

- Enhanced Safety: Regular inspections identify potential problems before they become serious safety risks. This prevents engine failure while underway.

- Reduced Repair Costs: Addressing small problems before they escalate significantly reduces repair costs in the long run.

- Peace of Mind: Knowing your engine is in good working order provides peace of mind and confidence when you’re out on the water.

Think of it like regular check-ups for your health – preventative care is far better and cheaper than emergency treatment.

Q 26. Explain the process of performing a basic tune-up on an outboard motor.

A basic tune-up for an outboard motor typically involves these steps:

- Check and Adjust Spark Plug Gaps: Use a spark plug gap tool to ensure the correct gap according to the manufacturer’s specifications. Incorrect gaps can lead to misfires and reduced performance.

- Inspect and Clean Spark Plugs: Inspect the plugs for fouling, corrosion, or damage. Clean them with a wire brush if necessary or replace them if severely damaged.

- Inspect and Replace Air Filter: A dirty air filter restricts airflow and reduces engine performance. Clean it if reusable or replace it with a new one.

- Check and Adjust Carburetor (if applicable): If your outboard has a carburetor, inspect it for cleanliness and proper adjustment. A dirty carburetor can lead to a poor fuel-air mixture.

- Inspect Fuel Lines and Filter: Check the fuel lines for cracks, leaks, or kinks. Replace the fuel filter if necessary. A clogged filter restricts fuel flow.

- Lubricate Moving Parts: Lubricate linkages and other moving parts as recommended in the engine manual. This ensures smooth operation and prevents wear.

- Check for Loose Bolts and Connections: Inspect the engine for loose nuts, bolts, or connections. Tighten them as needed to prevent problems from developing.

- Check and Replace Gearcase Oil (if applicable): Check the oil level in the lower unit (gearcase) and replace the oil as recommended in the owner’s manual. This is crucial for lubricating the gears and bearings.

Always refer to your specific outboard motor’s manual for detailed instructions and torque specifications. This ensures you perform the tune-up correctly and safely.

Q 27. How do you troubleshoot and repair a failed starter motor?

Troubleshooting a failed starter motor involves a systematic approach:

- Check Battery Voltage: Use a multimeter to check the battery voltage. A low voltage indicates a battery problem that needs addressing before testing the starter.

- Test Battery Connections: Ensure the battery terminals are clean, tight, and properly connected. Corrosion can prevent proper current flow.

- Check the Starter Solenoid: The solenoid is responsible for activating the starter motor. You can usually hear a click from the solenoid when you turn the key. If there’s no click, the solenoid may be faulty.

- Test the Starter Motor Itself: You can use a multimeter to test the starter motor windings for continuity and shorts. If the starter doesn’t engage, it might need repair or replacement.

- Check Wiring: Inspect the wiring between the battery, solenoid, and starter motor for any damage or loose connections. Ensure that the starter motor receives power.

- Inspect the Bendix Gear (if applicable): The Bendix gear is responsible for engaging the starter with the flywheel. If it’s stripped or damaged, it can prevent the engine from starting.

Repairing a failed starter motor often involves replacing it. In some cases, the solenoid can be replaced separately, but a faulty starter motor usually requires replacement. A professional mechanic can diagnose the precise problem and carry out necessary repairs or replacement.

Q 28. What are your experience in diagnosing and repairing marine diesel engine issues?

My experience with marine diesel engines encompasses a wide range of issues, from minor tune-ups to major overhauls. I’m proficient in diagnosing and repairing problems related to:

- Fuel Systems: I can troubleshoot fuel delivery problems, including issues with fuel pumps, injectors, filters, and lines. This includes diagnosing issues like air leaks, clogged filters, and injector malfunctions. I understand the specifics of diesel fuel injection systems.

- Engine Lubrication: I’m adept at identifying and addressing issues related to oil pressure, leaks, and filter blockages. This involves understanding the oil pressure regulation and the impact of incorrect oil viscosity.

- Cooling Systems: I can troubleshoot issues with both raw water and coolant systems, diagnosing leaks, blockages, and pump malfunctions. This includes understanding the importance of impeller replacements in raw water cooling systems.

- Exhaust Systems: I have experience diagnosing and repairing exhaust system blockages and leaks, recognizing the implications of exhaust gas recirculation in diesel engines.

- Turbochargers: I understand the workings of turbochargers and can diagnose issues such as turbine shaft play and oil leaks. Understanding their function is crucial for diesel efficiency.

- Electrical Systems: I can troubleshoot electrical problems in marine diesel engines, including issues with starting systems, alternators, and sensors. This involves proper testing and diagnostics techniques.

I have worked on a variety of diesel engines, from small recreational engines to larger commercial applications. My approach emphasizes thorough diagnosis, using appropriate tools and techniques to ensure accurate and efficient repairs.

For example, I recently worked on a boat with a diesel engine that experienced a sudden loss of power. Through systematic testing, I pinpointed a faulty fuel injector and replaced it, restoring the engine’s performance. My approach is to pinpoint the cause of the issue before making any significant repairs.

Key Topics to Learn for Boat Engine Maintenance Interview

- Inboard/Outboard Systems: Understanding the differences, common components, and maintenance schedules for both inboard and outboard engines. Practical application: Diagnosing a problem based on engine type and symptoms.

- Fuel Systems: Theory: Fuel injection vs. carburetors, fuel filters, and fuel lines. Practical application: Troubleshooting fuel delivery issues, identifying causes of poor engine performance related to fuel.

- Lubrication Systems: Theory: Oil types, oil pressure, and the importance of regular oil changes. Practical application: Interpreting oil analysis reports, identifying signs of lubrication system failure.

- Cooling Systems: Theory: Different cooling systems (raw water, closed-loop), thermostat function, and troubleshooting overheating. Practical application: Diagnosing and repairing cooling system leaks, maintaining impeller health.

- Electrical Systems: Theory: Starting systems, charging systems, and electrical troubleshooting. Practical application: Diagnosing starting problems, testing battery health, understanding wiring diagrams.

- Preventive Maintenance: Theory: Importance of regular inspections, preventative maintenance schedules, and logbook maintenance. Practical application: Creating and following a preventative maintenance plan for various engine types.

- Troubleshooting and Diagnostics: Theory: Using diagnostic tools, interpreting engine codes, and systematic troubleshooting techniques. Practical application: Identifying and resolving common engine problems using logical diagnostic steps.

- Safety Procedures: Understanding safe working practices around boat engines, including personal protective equipment (PPE) and emergency procedures.

Next Steps

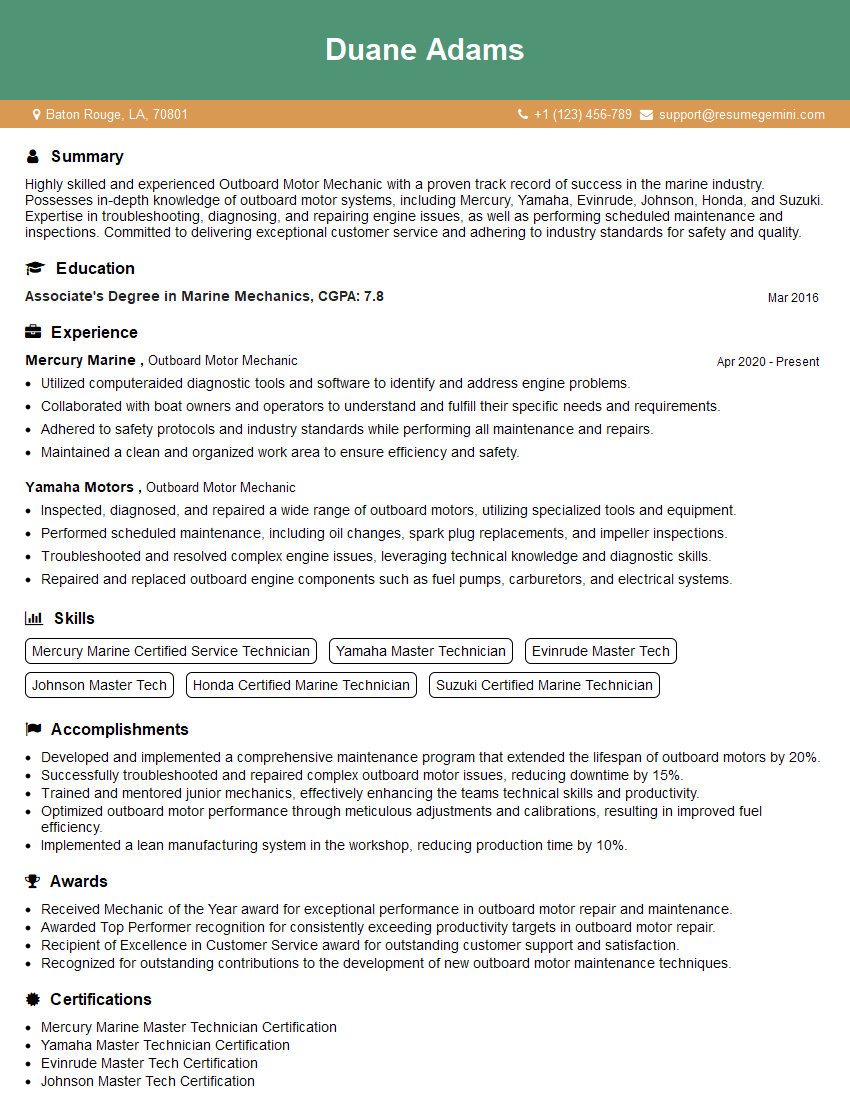

Mastering boat engine maintenance opens doors to exciting career opportunities in the marine industry, offering excellent earning potential and job satisfaction. To stand out from the competition, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Boat Engine Maintenance, allowing you to craft a compelling application that showcases your expertise. Take the next step in your career journey and create a resume that reflects your dedication and passion for boat engine maintenance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO