Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top BOM Analysis interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in BOM Analysis Interview

Q 1. Explain the purpose and importance of a Bill of Materials (BOM).

A Bill of Materials (BOM) is a comprehensive list of all the raw materials, components, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. Think of it as a recipe for a product, detailing every ingredient and its amount. Its importance is paramount because it underpins virtually every aspect of product development, manufacturing, and lifecycle management. A precise and accurate BOM is crucial for accurate costing, procurement, manufacturing scheduling, inventory control, and quality assurance. Without a well-maintained BOM, a manufacturer risks delays, cost overruns, and quality issues.

For example, imagine building a bicycle. The BOM would list the frame, wheels (with tires and tubes), handlebars, seat, pedals, gears, brakes, and all the smaller fasteners and components. Each item would have a specified quantity. This allows for accurate ordering of parts, assembly, and ultimately, delivering a finished bicycle.

Q 2. Describe different types of BOM structures (e.g., single-level, multi-level, modular).

BOM structures vary depending on the complexity of the product and the manufacturing process. Here are some common types:

- Single-Level BOM: This lists only the direct components needed to assemble the final product. It’s simple but lacks detail on sub-assemblies. Think of it as a top-level overview of the ingredients. Example: A simple chair might have a single-level BOM listing legs, seat, and back.

- Multi-Level BOM: This provides a hierarchical breakdown of all components, including sub-assemblies and sub-components. It’s more complex but offers a more complete picture. This is like a detailed recipe showing sub-recipes for sauces or pre-made components. Example: A bicycle’s multi-level BOM would show the frame, then the components of the frame, then the components of those components, and so on.

- Modular BOM: This organizes components into modules or assemblies, which are then combined to create the final product. This is useful for products with highly modular designs, simplifying BOM management. Example: A computer with modular components – CPU, motherboard, RAM, graphics card – each having its own sub-BOM.

Q 3. How do you identify and resolve BOM discrepancies or inconsistencies?

Identifying and resolving BOM discrepancies is a critical task. Inconsistencies can stem from errors in design, manufacturing, or data entry. My approach involves a multi-step process:

- Data Comparison: Comparing the BOM with actual production data, engineering drawings, and supplier information. Automated tools can be invaluable here.

- Visual Inspection: Carefully reviewing the BOM for obvious errors, such as missing parts or incorrect quantities. A fresh pair of eyes can often catch mistakes.

- Cross-Referencing: Matching part numbers and descriptions across different sources. Inconsistencies might indicate obsolete parts or data entry errors.

- Root Cause Analysis: Investigating the origin of discrepancies to prevent recurrence. This may involve checking the design specifications, reviewing manufacturing processes, or improving data management systems.

- Corrective Actions: Implementing corrections to the BOM and updating relevant documentation. This might involve revising drawings, adjusting purchasing orders, or training personnel on correct procedures.

For example, if a discrepancy shows a missing component in the assembled product versus the BOM, a thorough investigation may reveal a problem with the assembly process or an outdated BOM.

Q 4. What software or tools are you familiar with for BOM management?

I have extensive experience using various software and tools for BOM management, including enterprise resource planning (ERP) systems like SAP and Oracle, product lifecycle management (PLM) systems such as Siemens Teamcenter and Autodesk Vault, and specialized BOM management software such as Arena Solutions and Agile PLM. I’m also proficient in using spreadsheets (Excel) for smaller projects or specific analysis tasks. The choice of tool depends on the complexity of the product and the overall business requirements.

Q 5. Explain your experience with BOM data cleansing and validation.

BOM data cleansing and validation are crucial for maintaining data integrity. My experience includes developing and implementing processes to identify and correct inconsistencies, such as:

- Duplicate Part Numbers: Identifying and resolving duplicate entries representing the same component.

- Obsolete Parts: Identifying and removing obsolete parts that are no longer used.

- Missing Information: Identifying and filling in missing data fields, such as descriptions, specifications, and supplier information.

- Data Standardization: Ensuring consistency in data formats and units of measure.

- Data Validation: Using automated checks to ensure data accuracy and completeness. This might involve cross-referencing part numbers, validating material specifications, and checking quantity ranges.

I often employ scripting (e.g., Python) to automate data cleansing tasks and improve efficiency. A recent project involved cleansing a BOM with over 10,000 components, reducing errors by over 80% through automated validation and standardization.

Q 6. Describe your process for creating and maintaining accurate BOMs.

Creating and maintaining accurate BOMs is an iterative process. My process typically involves:

- Design Collaboration: Close collaboration with engineering and design teams to ensure the BOM reflects the latest design specifications.

- Data Entry and Validation: Accurate data entry, employing standard naming conventions and robust validation rules.

- Version Control: Using version control to track changes and maintain a history of revisions.

- Regular Audits: Periodically auditing the BOM to identify and correct errors. This might include comparing the BOM to actual production data.

- Continuous Improvement: Continuously evaluating and refining the BOM creation and maintenance process to improve efficiency and accuracy.

Transparency and communication are key. Regular updates and stakeholder input are vital to ensuring everyone works from the same, accurate BOM.

Q 7. How do you handle engineering change orders (ECOs) and their impact on BOMs?

Engineering Change Orders (ECOs) represent modifications to a product’s design or specifications. Managing their impact on the BOM is critical. My process involves:

- ECO Review: Carefully reviewing each ECO to understand its implications for the BOM.

- BOM Update: Updating the BOM to reflect changes in part numbers, quantities, or specifications resulting from the ECO.

- Impact Assessment: Assessing the impact of the ECO on downstream processes, such as procurement, manufacturing, and inventory management.

- Communication: Communicating the changes to all relevant stakeholders, including purchasing, manufacturing, and quality control.

- Version Control: Maintaining clear version control of the BOM to track changes and enable rollback if needed.

A well-defined ECO process, integrated with the BOM management system, minimizes disruptions and ensures a smooth transition to the revised product design.

Q 8. Explain the process of BOM costing and its significance.

BOM costing is the process of determining the total cost of a product by calculating the cost of all its individual components and the manufacturing processes involved. It’s a crucial element in pricing, profitability analysis, and overall business decision-making.

The process typically involves:

- Gathering Data: Collecting costs for each component from the Bill of Materials (BOM), including material costs, labor costs, and overhead.

- Calculating Material Costs: Determining the cost of raw materials, purchased parts, and sub-assemblies.

- Calculating Labor Costs: Estimating direct labor costs for assembly and manufacturing.

- Calculating Overhead Costs: Allocating indirect costs, such as factory rent, utilities, and equipment depreciation, to the product.

- Summing Costs: Aggregating all the costs (material, labor, and overhead) to arrive at the total cost of the product.

- Analyzing Cost Drivers: Identifying the major cost contributors to understand where cost savings could be realized.

Significance: Accurate BOM costing is vital for accurate pricing, identifying areas for cost reduction, evaluating product profitability, and making informed business decisions regarding product development, sourcing, and manufacturing.

For example, imagine we’re manufacturing a bicycle. Accurate BOM costing would detail the cost of the frame, wheels, tires, gears, and labor involved in assembly. This enables us to price the bicycle competitively while ensuring profitability.

Q 9. How do you ensure BOM accuracy and integrity throughout the product lifecycle?

Ensuring BOM accuracy and integrity is paramount. It requires a multi-faceted approach involving robust processes and technology.

- Centralized BOM Management System: Implementing a single source of truth, typically an ERP system, to prevent data inconsistencies across departments. This allows for real-time updates and traceability.

- Data Validation and Verification: Employing automated checks and validations to identify discrepancies in data entry, such as missing or incorrect component information or quantities. Regular audits also play a crucial role.

- Version Control: Implementing a robust version control system that tracks changes to the BOM, including who made the change, when, and why. This facilitates traceability and allows for easy rollback to previous versions if needed. This is particularly important when dealing with engineering changes.

- Engineering Change Orders (ECOs): Using a formal ECO process to manage and track changes to the BOM. This ensures that all relevant departments are notified and changes are implemented consistently across the organization.

- Regular Reconciliation: Periodically comparing the BOM data with actual inventory levels and production data to identify any discrepancies. This helps prevent costly overstocking or shortages.

- Supplier Data Management: Collaborating closely with suppliers to ensure accurate and up-to-date component information. This includes managing supplier part numbers, specifications, and lead times.

Think of it like building a house – using inaccurate blueprints (BOM) would lead to major problems. Our approach ensures the blueprints are accurate, updated, and consistently used throughout the construction (product lifecycle).

Q 10. What are the common challenges in BOM management, and how do you address them?

Common challenges in BOM management include:

- Data Inconsistency: Different departments might maintain their own BOMs, leading to conflicting information.

- Lack of Version Control: Difficulty in tracking changes and identifying the current, accurate version of the BOM.

- Poor Data Quality: Inaccurate or incomplete data can lead to production delays and cost overruns.

- Integration Challenges: Integrating the BOM system with other systems like ERP, PLM, and MES can be complex.

- Communication Gaps: Ineffective communication between departments can lead to errors and misunderstandings.

- Lack of Standardization: Inconsistent naming conventions or part numbering across the organization can make BOM management difficult.

Addressing these challenges involves:

- Centralized System Implementation: Using a robust ERP or PLM system to create a single source of truth for the BOM.

- Establishing Clear Processes and Procedures: Defining clear guidelines for BOM creation, maintenance, and approval.

- Data Governance: Implementing data governance policies to ensure data quality and accuracy.

- Collaboration and Communication: Fostering strong communication and collaboration among departments.

- Training and Education: Providing adequate training to employees on BOM management processes and procedures.

- Regular Audits: Conducting periodic audits to identify and address any issues.

Q 11. How do you collaborate with different departments (engineering, procurement, manufacturing) regarding BOMs?

Collaboration is key to effective BOM management. I facilitate this through:

- Regular Meetings: Scheduling regular meetings with representatives from engineering, procurement, and manufacturing to discuss BOM-related issues and updates.

- Shared Platform: Utilizing a shared platform (e.g., a collaborative ERP system) for accessing and updating BOMs. This ensures everyone works with the most current information.

- Clear Communication Protocols: Establishing clear communication channels and protocols to ensure timely and accurate information flow between departments.

- Joint Problem-Solving: Encouraging joint problem-solving sessions to address BOM-related challenges collaboratively.

- Cross-functional Training: Providing cross-functional training to enhance understanding of the roles and responsibilities of each department in BOM management.

- Data Ownership: Establishing clear data ownership and accountability to ensure responsibility for BOM accuracy and integrity.

For instance, I’ve successfully implemented a process where Engineering releases the initial design BOM, Procurement validates component availability and pricing, and Manufacturing uses the BOM for production planning and scheduling. Regular meetings and a shared ERP system ensure seamless information flow and timely resolution of any discrepancies.

Q 12. Describe your experience using ERP systems for BOM management.

I have extensive experience using ERP systems, specifically SAP and Oracle, for BOM management. I’ve leveraged their functionalities to:

- Centralize BOM data: Maintain a single, accurate BOM database accessible across departments.

- Manage BOM revisions: Track changes, manage different versions, and ensure traceability.

- Automate processes: Streamline tasks like costing, reporting, and data validation.

- Integrate with other systems: Connect the BOM to other systems, like MRP (Material Requirements Planning) for production planning and procurement systems for purchasing.

- Generate reports: Create various reports on cost, inventory, and BOM structure.

In one project, we migrated from a manual BOM system to SAP. This resulted in significant improvements in data accuracy, reduced errors, and improved efficiency in procurement, production, and costing.

Q 13. How do you manage BOM revisions and version control?

Managing BOM revisions and version control is critical for accuracy and traceability. My approach involves:

- Formal Change Management Process: Implementing a formal process for submitting, reviewing, and approving BOM changes. This typically involves Engineering Change Orders (ECOs).

- Version Numbering System: Using a clear and consistent version numbering system to identify different versions of the BOM (e.g., BOM-A-v1.0, BOM-A-v2.0).

- Change History Tracking: Maintaining a detailed history of all changes made to the BOM, including the date, time, author, and reason for the change.

- Document Management System: Utilizing a document management system to store and manage different versions of the BOM securely and accessibly.

- Release Management: Establishing a process for releasing approved BOM revisions to different departments.

For example, if a component is changed due to a supplier issue, the ECO process ensures that the BOM is updated, all relevant parties are notified, and the new version is released, while previous versions are archived, allowing easy tracking of modifications.

Q 14. Explain your understanding of effective BOM standardization processes.

BOM standardization is crucial for efficiency and consistency. It involves creating standardized processes and templates for BOM creation, maintenance, and usage. This includes:

- Standardized Part Numbering System: Implementing a consistent part numbering system across the organization to facilitate easy identification and tracking of components.

- Standardized Units of Measure: Utilizing consistent units of measure for all components and quantities to avoid confusion.

- BOM Structure Standardization: Adopting a consistent structure for BOMs, including the level of detail and the information included in each entry.

- Data Templates: Creating and utilizing standard templates for data entry to ensure consistency and accuracy.

- Classification and Categorization: Establishing a clear classification and categorization system for components to facilitate searching, reporting, and analysis.

Effective standardization reduces errors, simplifies data management, and improves communication and collaboration between departments. Imagine a library with no organization – finding a specific book would be a nightmare. BOM standardization is analogous to organizing that library, making information readily available and reducing search time.

Q 15. How do you handle obsolete or discontinued components in a BOM?

Handling obsolete or discontinued components in a BOM requires a proactive approach involving several key steps. First, we need a robust system for identifying these components. This often involves regular checks against supplier catalogs and industry databases for end-of-life announcements. We then categorize the obsolete parts based on their criticality to the final product. For non-critical components, finding a suitable replacement is usually straightforward. This might involve a direct replacement with similar specifications or a redesign to use a readily available alternative. Documentation is crucial here; we update the BOM with the new part number, specifications, and cost implications. For critical components, the process is more involved. It requires thorough testing and validation of the replacement part to ensure functionality and safety. This might involve a longer lead time and potentially higher costs. In some cases, a complete redesign of the affected product segment might be necessary. Finally, we need a comprehensive change management process to ensure all stakeholders are aware of the changes and that the updated BOM is implemented across all relevant systems. For instance, I once worked on a project where a key microcontroller became obsolete. We successfully identified a suitable replacement, but the process required rigorous testing to ensure compatibility with existing hardware and software, ultimately avoiding a costly product recall.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What metrics do you use to measure the effectiveness of BOM management?

Measuring the effectiveness of BOM management involves a multifaceted approach focusing on key metrics. Accuracy is paramount; we track the percentage of BOMs that are error-free to ensure their reliability in manufacturing and cost calculations. Completeness is another crucial aspect, measured by the percentage of BOMs with all necessary information, including part numbers, descriptions, and quantities. We also monitor lead times, evaluating the average time to procure components from the BOM. This metric reveals potential supply chain bottlenecks. Finally, we track the cost of goods sold (COGS) against the projected cost based on the BOM. Significant discrepancies here highlight areas needing improvement in BOM accuracy or supplier negotiations. A well-managed BOM should minimize discrepancies between projected and actual costs, demonstrating improved cost control and efficient procurement.

Q 17. Explain your experience with BOM analysis for cost reduction initiatives.

BOM analysis is a powerful tool for cost reduction. My experience includes using BOMs to identify high-cost components, evaluate opportunities for standardization (using the same part across multiple products), and explore alternative suppliers offering lower prices. For example, in a previous role, I analyzed the BOM of a complex assembly and identified three components accounting for 60% of the total cost. We then initiated a multi-pronged approach. This involved negotiating better pricing with existing suppliers for two components, and for the third (a relatively common part), we explored alternative, lower-cost suppliers after thorough quality checks. This resulted in a 15% reduction in the overall product cost. The key to successful cost reduction through BOM analysis is not just finding cheaper parts but also ensuring the quality and reliability of the replacements are maintained. Furthermore, it’s essential to consider lifecycle costs, evaluating total cost of ownership over the product’s lifespan.

Q 18. Describe your approach to identifying and mitigating BOM risks.

Identifying and mitigating BOM risks requires a structured approach. We start by identifying potential risks, including supplier reliability, component obsolescence, and geopolitical factors affecting supply chains. This involves regular supplier performance reviews and monitoring industry trends and news. To mitigate these risks, we employ various strategies, such as dual sourcing critical components (having two suppliers for the same part), establishing safety stock levels for high-risk components, and using risk assessment matrices to prioritize mitigation efforts. A risk matrix would visually represent the likelihood and impact of each risk, allowing us to focus on the most critical ones first. For example, if a component has a high likelihood of obsolescence and a significant impact on our product, we’ll prioritize finding a replacement or developing a robust alternative. We also regularly update our BOMs to reflect changes in supplier performance or component availability.

Q 19. How do you leverage BOM data for forecasting and planning purposes?

BOM data is invaluable for forecasting and planning. Accurate BOMs provide a detailed breakdown of the components required for production, allowing us to forecast material needs precisely. This information is crucial for planning procurement, ensuring timely delivery of components and preventing production delays. We use this data in conjunction with sales forecasts to estimate the demand for each component and optimize inventory levels, minimizing storage costs while preventing shortages. For instance, if we predict increased sales in the next quarter, we can use the BOM data to anticipate the increased demand for specific components, proactively ordering them to avoid delays. This proactive approach minimizes disruptions in production schedules and reduces the risk of stockouts.

Q 20. Explain your understanding of different BOM formats and their applications.

Several BOM formats exist, each suited for specific applications. The most common are tabular formats like CSV or spreadsheets (e.g., Excel), which are simple to create and use, especially for smaller projects. More complex projects benefit from structured formats like XML or JSON, offering greater flexibility and enabling easier integration with enterprise resource planning (ERP) systems. These structured formats allow for automated data processing and analysis. Finally, database-driven BOMs offer the highest level of scalability and maintainability, ideal for large organizations managing numerous products and components. The choice of format depends on the complexity of the product, the size of the organization, and the level of integration required with other systems. I’ve worked with all these formats, tailoring my approach to the specific requirements of each project. For instance, a small project might use a simple Excel-based BOM, while a large-scale manufacturing project would leverage a database-driven system for optimal control and integration.

Q 21. How do you ensure data consistency across different BOM systems or platforms?

Ensuring data consistency across different BOM systems is crucial for accurate reporting and efficient operations. This requires a standardized data model to be implemented consistently across all platforms. This includes using consistent part numbering systems, descriptions, and units of measure. Regular data synchronization between systems is also essential. This can be achieved through various methods, including automated data imports and exports using APIs or ETL (Extract, Transform, Load) processes. Data validation rules should be established and enforced to ensure the integrity of the data. These rules might check for duplicate part numbers or inconsistencies in units of measure. Finally, regular data audits should be conducted to identify and correct any discrepancies. For example, we might use a master data management system to act as a single source of truth for component information, ensuring that all other systems access and use consistent and up-to-date data. This systematic approach helps maintain data integrity and minimizes the risk of errors stemming from inconsistencies in different BOM systems.

Q 22. Describe your experience with BOM explosion and implosion.

BOM explosion and implosion are crucial processes in managing a Bill of Materials (BOM). Think of a BOM as a recipe; explosion is like expanding the recipe to list every single ingredient and its quantity needed to make the final dish. Implosion does the opposite – it summarizes the components to show higher-level assemblies.

BOM Explosion: This process starts with a finished product and recursively breaks it down into its sub-assemblies, components, and raw materials. For example, if you’re building a bicycle, explosion would reveal the individual parts: frame, wheels (further broken down into tires, rims, spokes, etc.), handlebars, gears, etc., along with quantities needed for each. The result is a comprehensive list of everything required to manufacture the final product.

BOM Implosion: This is the reverse process. It aggregates components and sub-assemblies into higher-level assemblies. Instead of a detailed parts list, you get a summary of major modules or assemblies. For the bicycle example, implosion might group the wheels, handlebars, and frame into ‘bicycle sub-assemblies’ before finally reaching the ‘complete bicycle’ level. This is useful for high-level planning and cost analysis.

My experience includes extensive use of both processes, leveraging software tools like ERP systems to automate the creation and management of exploded and imploded BOMs, essential for accurate costing, procurement, and production scheduling.

Q 23. How do you handle complex BOMs with numerous components and sub-assemblies?

Managing complex BOMs with numerous components and sub-assemblies requires a structured and systematic approach. Imagine trying to build a complex piece of machinery – you wouldn’t just throw parts together! You need a clear plan.

- Modularization: Breaking down the overall assembly into smaller, manageable modules simplifies the BOM. Each module has its own BOM, making the overall structure more easily understood and manageable.

- BOM Software: Utilizing dedicated BOM management software is critical. These tools offer features such as version control, change management, and automated explosion/implosion capabilities. They often integrate with other systems like ERP and PLM, ensuring data consistency across departments.

- Data Validation and Verification: Implementing rigorous checks and balances to ensure data accuracy is paramount. This includes regular audits, cross-referencing with engineering drawings, and using automated validation rules within the software to flag potential inconsistencies.

- Visualization Tools: Using visual tools, like diagrams or interactive 3D models, helps visualize the relationships between components and sub-assemblies within a complex BOM. This significantly improves comprehension and reduces the likelihood of errors.

For example, in my previous role, we managed a BOM for a complex industrial robot with over 10,000 components. Through modularization and using a robust ERP system, we were able to efficiently manage changes, track inventory, and streamline the manufacturing process.

Q 24. How do you incorporate sustainability considerations into BOM management?

Incorporating sustainability into BOM management is increasingly important. It’s about making environmentally conscious choices throughout the product lifecycle, starting with the design and material selection phases.

- Material Selection: Prioritize sustainable materials with lower environmental impact, such as recycled materials, bio-based materials, or materials with reduced carbon footprints. This requires close collaboration with engineering and procurement.

- Lifecycle Assessment (LCA): Integrate LCA data into the BOM. LCA evaluates the environmental impacts associated with each component throughout its entire life cycle, from raw material extraction to disposal. This helps identify potential hotspots for improvement.

- Waste Reduction: Analyze the BOM to minimize waste generation during manufacturing. This involves optimizing component design for efficient assembly, minimizing material usage, and promoting the use of reusable components.

- End-of-Life Management: Consider the end-of-life management of components and assemblies. Designing for disassembly and recyclability helps minimize environmental impact at the end of the product’s useful life.

For example, we recently incorporated LCA data into our BOM to identify components with high carbon footprints, leading to the substitution of these components with more environmentally friendly alternatives resulting in a 15% reduction in the overall carbon footprint of the final product.

Q 25. Explain your understanding of the relationship between the BOM and other manufacturing documents.

The BOM is the central document in manufacturing, intricately linked with other crucial documents. It acts as the foundation upon which many other processes are built. Think of it as the core of a complex manufacturing system.

- Engineering Drawings: The BOM provides the list of parts, while engineering drawings specify the design and specifications of each part. They are directly linked; changes to one necessitate updates to the other.

- Manufacturing Instructions: The BOM dictates the components required, while manufacturing instructions define how these components are assembled. They must be synchronized to ensure efficient and error-free production.

- Procurement Documents: The BOM drives procurement. It specifies the parts needed, their quantities, and potentially their suppliers, forming the basis of purchasing orders.

- Inventory Management Systems: The BOM integrates with inventory systems to track component availability and plan replenishment.

Maintaining consistency across all these documents is essential for efficient manufacturing. Any discrepancy can lead to delays, errors, and increased costs.

Q 26. How do you use BOM data to improve efficiency and reduce waste in manufacturing processes?

BOM data is a goldmine for improving efficiency and reducing waste. By analyzing this data, we can optimize various aspects of the manufacturing process.

- Inventory Optimization: Analyzing BOM data reveals component usage patterns, enabling better inventory planning. This reduces storage costs and minimizes the risk of stockouts or overstocking.

- Supply Chain Optimization: BOM data enables better supplier selection and management based on factors like cost, lead times, and reliability. This can significantly improve supply chain efficiency.

- Waste Reduction: Analyzing the BOM can highlight areas where material waste is high. This enables process improvements to reduce excess material consumption.

- Production Scheduling: BOM data is essential for accurate production scheduling, allowing better resource allocation and minimizing production delays.

For instance, by analyzing historical BOM data, we identified a component with consistently high scrap rates. By investigating the manufacturing process for this component, we identified and corrected a process flaw, resulting in a 20% reduction in scrap and significant cost savings.

Q 27. Describe a time you had to resolve a critical issue related to a BOM. What was the issue, and how did you solve it?

In a previous project, we faced a critical issue just before a major product launch. A critical component was incorrectly specified in the BOM, leading to incompatible parts being ordered. This was discovered only during the final assembly phase. The issue threatened significant delays and reputational damage.

Problem: The incorrect component specification was due to a lack of robust version control within the BOM management system. The wrong version of the BOM was mistakenly used for procurement, leading to ordering the incorrect part. We could identify the mistake because our software flagged this anomaly.

Solution: We immediately implemented a multi-step solution:

- Emergency Procurement: We expedited the procurement of the correct component from an alternative supplier, minimizing the delay.

- Root Cause Analysis: We thoroughly investigated the root cause – poor version control. The existing software had some features which were not used properly which we updated.

- Process Improvement: We implemented stricter version control procedures, including mandatory review processes and improved training for the team involved in BOM management.

- Communication: We proactively communicated the issue and mitigation plan to all stakeholders, managing expectations and maintaining transparency.

This incident highlighted the criticality of robust BOM management and the importance of stringent version control and process adherence to prevent similar situations. Through swift action and a structured approach, we successfully mitigated the issue, minimizing its impact on the product launch.

Key Topics to Learn for BOM Analysis Interview

- BOM Structure and Organization: Understanding different BOM types (single-level, multi-level, indented), their representations, and how to navigate complex structures.

- Data Analysis and Interpretation: Practical application of extracting key insights from BOM data, such as cost analysis, material requirements planning (MRP), and identifying potential bottlenecks.

- BOM Costing and Pricing: Calculating the total cost of a product based on component costs, labor, and overhead. Understanding the impact of material price fluctuations on the final product cost.

- Change Management and Version Control: Strategies for managing BOM changes efficiently and effectively, including version control systems and change impact analysis.

- Data Integrity and Validation: Techniques for ensuring the accuracy and consistency of BOM data, identifying and resolving discrepancies.

- Software and Tools: Familiarity with common software used for BOM management (ERP systems, spreadsheets, specialized BOM software) and data manipulation techniques.

- Problem-Solving and Optimization: Applying analytical skills to identify areas for improvement in BOM processes, such as reducing material costs, streamlining workflows, or improving efficiency.

- Manufacturing Processes and Supply Chain Integration: Understanding how BOM analysis relates to overall manufacturing processes and supply chain management.

Next Steps

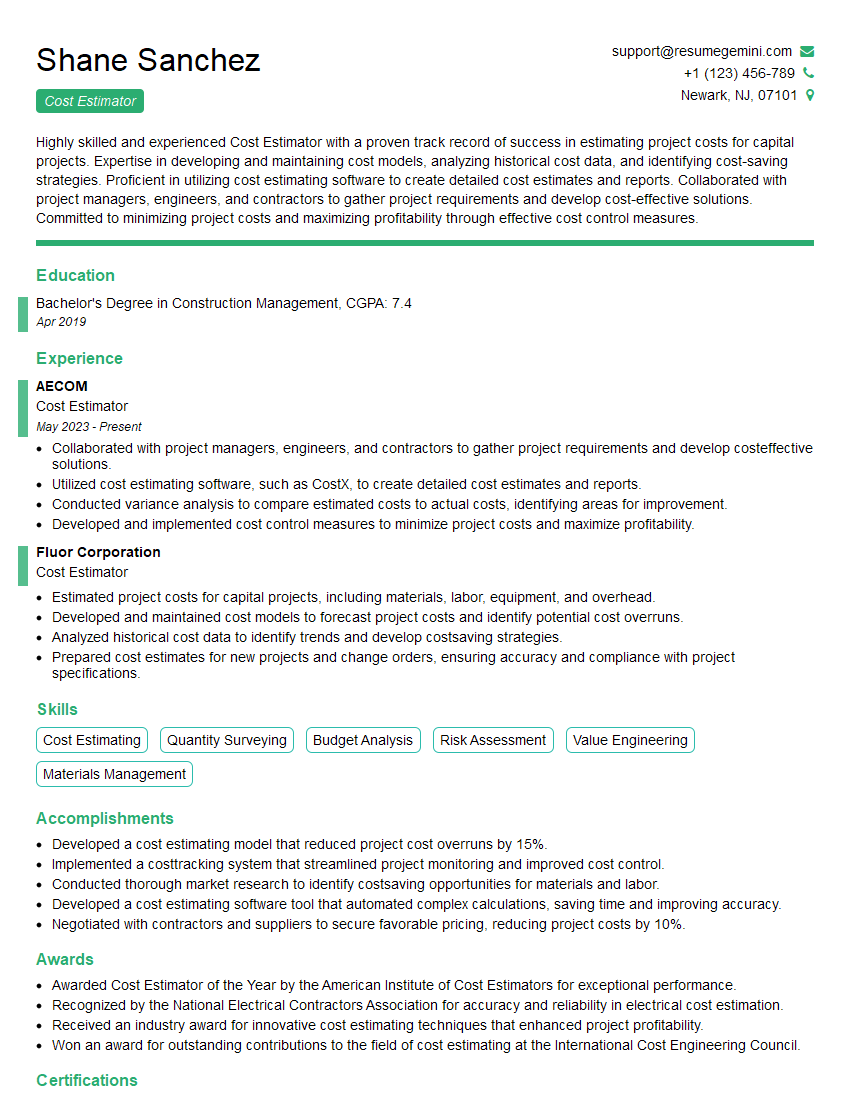

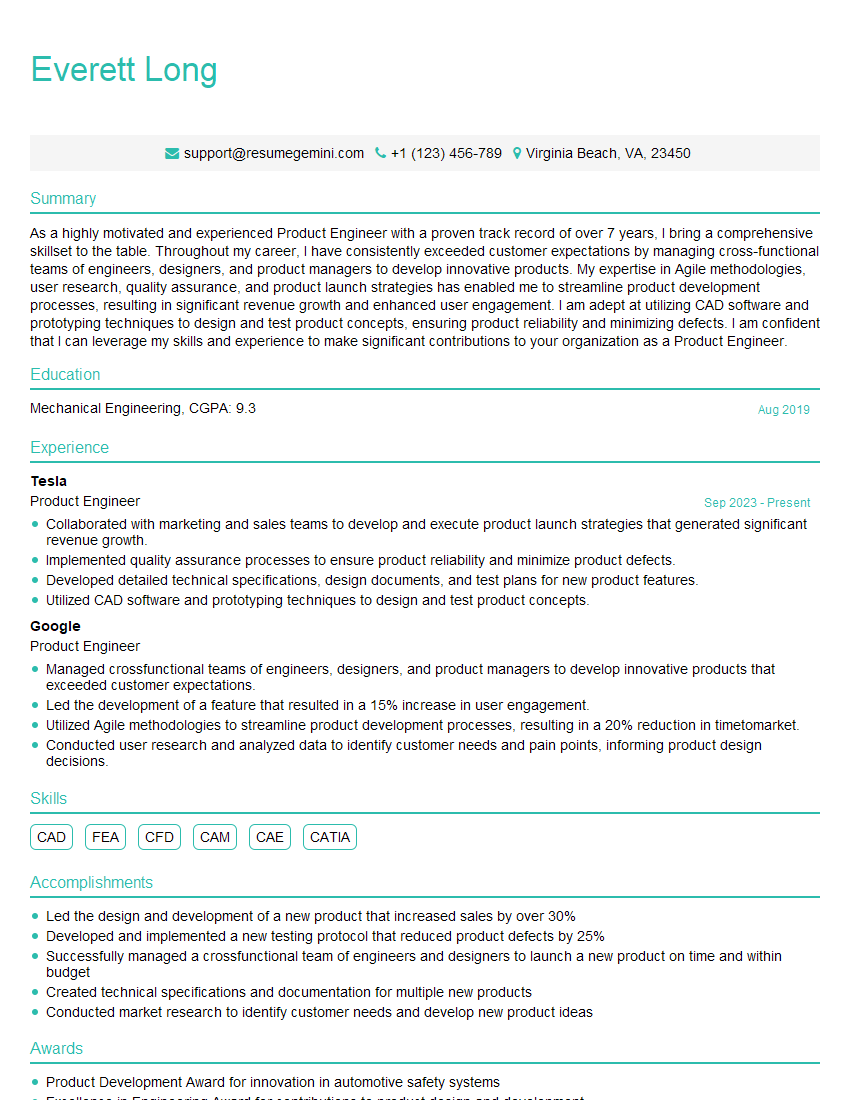

Mastering BOM analysis significantly enhances your value in manufacturing, engineering, and procurement roles, opening doors to exciting career advancements and higher earning potential. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of BOM Analysis positions. Examples of resumes tailored to BOM Analysis roles are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO