The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Bookbinding and Finishing Equipment Operation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Bookbinding and Finishing Equipment Operation Interview

Q 1. Describe your experience operating perfect binding machines.

My experience with perfect binding machines spans over eight years, encompassing various models from Muller Martini to Horizon. Perfect binding is ideal for softcover books, magazines, and journals. I’m proficient in all aspects, from setup and adjustment to troubleshooting and maintenance. For instance, I’ve successfully resolved numerous production slowdowns caused by incorrect glue application by adjusting the glue temperature and pressure settings based on the paper stock. I understand the importance of maintaining consistent glue application for a strong and aesthetically pleasing spine. I’m also experienced in handling different paper types and thicknesses, ensuring optimal results across varied projects.

I’m adept at pre-press preparation, which includes accurate spine thickness calculation to avoid problems such as spine cracking or insufficient glue coverage. My skills also include regularly scheduled maintenance to prevent breakdowns – this includes cleaning the glue system, checking the rollers, and ensuring accurate cutting and trimming capabilities.

Q 2. Explain the process of saddle stitching.

Saddle stitching is a simple yet effective binding method, perfect for booklets and magazines with a relatively low page count. It involves folding pages in half or multiple times to create signatures. These signatures are then gathered and stitched together through the fold line using wire staples. Imagine folding a piece of paper in half and stapling it – that’s the fundamental principle. The process generally begins with the gathering of pages, following a precise order; then, the folded signatures are placed into a saddle stitcher.

The machine then uses a mechanism to feed the signatures, accurately aligning them before the stapling process. The number of staples and their placement are adjustable, depending on the thickness and size of the publication. For example, a thinner booklet might require only one staple in the center, while a thicker one might need two or even three. After stapling, the finished product is often trimmed to create a neat and professional look. Throughout the process, careful attention is given to ensure accurate signature alignment and consistent stapling, preventing misaligned pages or poorly secured staples which compromises the integrity of the finished product.

Q 3. What are the common issues encountered while operating a three-knife trimmer?

Three-knife trimmers are powerful but require careful handling. Common issues include:

- Blade misalignment: This results in uneven trimming, affecting the overall quality. Regular blade alignment checks are crucial. I always ensure the blades are perfectly aligned before commencing any trimming operation.

- Paper jams: These are caused by improper feeding or paper pile inconsistencies. I address this by carefully checking the paper feed mechanism and ensuring even pressure and accurate stacking of materials.

- Blade dullness: Dull blades cause tearing and uneven cuts. Regular sharpening or replacement is essential to maintain quality. I keep a close eye on blade sharpness by checking for clean cuts throughout my work and schedule blade maintenance proactively based on usage.

- Incorrect settings: Improperly set cutting depths or guides lead to inaccurate cuts. Double-checking settings against the job specifications before starting a run is crucial.

Addressing these issues promptly ensures efficient operation and prevents damage to the equipment and materials.

Q 4. How do you ensure the quality of folded signatures?

Ensuring high-quality folded signatures requires attention to detail at every stage. It starts with the initial sheet feeding – ensuring proper alignment and preventing skew or wrinkles. This is crucial for accurate folding and prevents binding problems down the line. Proper folding depends on machine settings, as well as paper characteristics like weight and moisture content.

Regular maintenance of the folding machine is essential. This includes cleaning the rollers to prevent sticking or jamming and checking for consistent pressure throughout the folding mechanism. Visual inspection of each signature is a critical quality control step, making sure folds are crisp, free from wrinkles or creases, and pages are neatly aligned. Any defects found are addressed immediately to prevent the flawed signature from advancing through the process and causing bigger problems later. A consistent approach to this process helps maintain high-quality outputs.

Q 5. Describe your experience with case binding equipment.

My experience with case binding equipment includes operating various machines for cover and text block preparation, such as Smyth sewing machines, and casing-in machines. Case binding is a robust method used for hardcover books and requires precise operations for a high-quality finish. I’m familiar with the complete case binding workflow, from the initial preparation of the text block to the final casing-in. For example, I understand the precise adjustments needed on a Smyth sewing machine to ensure consistent stitching depending on the thickness and page count of the book. Incorrect adjustments might lead to poor stitching, leading to loose pages or a weakened spine.

I’m proficient in setting up and operating different types of casing-in machines, ensuring the cover is perfectly aligned and glued to the text block. This process requires precision and knowledge to ensure proper adhesion and the structural integrity of the finished book. I meticulously monitor the glue application and pressure to avoid problems like cover detachment or uneven glue coverage. Regular maintenance and cleaning of the equipment are key elements of maintaining its efficiency and the quality of the final product.

Q 6. What safety precautions do you follow while operating bindery equipment?

Safety is paramount when operating bindery equipment. I always follow these precautions:

- Personal Protective Equipment (PPE): I consistently wear safety glasses, cut-resistant gloves, and hearing protection where appropriate.

- Machine guards: I ensure all machine guards are in place and functioning correctly before operation.

- Lockout/Tagout procedures: I strictly follow lockout/tagout procedures for maintenance or repairs to prevent accidental starts.

- Clear workspace: I maintain a clean and organized workspace, free of obstacles to prevent trips and falls.

- Proper training: I’ve received comprehensive training on the safe operation of all equipment I use.

- Emergency procedures: I’m familiar with emergency procedures and the location of emergency shut-off switches and first-aid equipment.

By adhering to these guidelines, I ensure a safe working environment for myself and others.

Q 7. How do you troubleshoot paper jams in a gathering machine?

Troubleshooting paper jams in a gathering machine requires a systematic approach. First, I’d turn off the machine and ensure it’s completely powered down before attempting any troubleshooting. This is crucial for safety. Then, I’d carefully examine the feed tray to ensure the paper is properly stacked and aligned, free of any wrinkles or bent sheets. I check the feeder rollers for any debris or obstructions.

Next, I trace the paper path, checking for any misaligned components, or areas where the paper might be caught. This may involve opening access panels to inspect the internal mechanisms. A common cause of jams is the presence of foreign objects in the gathering mechanism. Once the cause of the jam is identified, I carefully remove the jammed sheets, ensuring I don’t damage the machine in the process. Finally, I visually inspect the entire machine, paying close attention to the paper path before restarting the machine, ensuring the problem doesn’t recur.

Q 8. Explain the different types of binding methods and their applications.

Bookbinding methods are chosen based on the project’s needs, from the number of pages to the desired aesthetic. Let’s explore some common types:

- Perfect Binding: This is the most common method for paperback books. The pages are glued together at the spine, then the cover is wrapped around. Think of your average paperback novel – that’s perfect binding. It’s cost-effective for high-volume printing and works well for books with a relatively low page count.

- Saddle Stitch Binding: This is a simple and economical method suitable for magazines, brochures, or booklets with a low page count (typically under 64 pages). Pages are folded in half and stapled along the spine. It’s quick, efficient, and results in a flat-laying document.

- Spiral Binding (Coil Binding): Plastic or metal coils are inserted through pre-punched holes along the spine. It allows the book to lay flat, making it ideal for calendars, notebooks, and documents that need to be frequently opened. The coil type and size are chosen depending on the thickness of the book.

- Wire-O Binding: Similar to spiral binding, but uses a double-loop wire for a more professional and durable finish. This is often seen in high-quality notebooks and calendars, offering a superior lay-flat capability and a clean, polished look. It’s particularly suitable for books with a higher page count than spiral binding.

- Case Binding: This is a more robust method for hardcover books, often used for high-end publications or textbooks. Sections of pages (signatures) are sewn together, creating a strong and durable spine. The cover boards are then glued to this spine, providing a very sturdy and long-lasting finish.

The choice of binding depends on factors such as the number of pages, budget, required durability, and the overall desired aesthetic. A high-page-count academic textbook would benefit from case binding, while a short brochure might be best suited to saddle stitching.

Q 9. What is your experience with die-cutting machines?

I have extensive experience operating various die-cutting machines, from smaller, manually-fed models to large automated systems. My expertise includes setting up and operating machines from different manufacturers, ensuring accurate die placement, and maintaining optimal cutting pressures to avoid damaging the material. I’m proficient in troubleshooting common issues like blade dulling, misaligned dies, and material jams. For instance, I once resolved a production slowdown by identifying a minute misalignment in a complex die, preventing significant production delays and material waste. I’m also experienced in creating and using custom dies for unique designs and shapes.

Q 10. How do you maintain and clean bindery equipment?

Maintaining bindery equipment is crucial for both productivity and the quality of the finished product. My routine includes daily cleaning to remove dust, paper scraps, and glue residue. I meticulously inspect all moving parts for wear and tear, regularly lubricating mechanisms according to manufacturer guidelines. For example, I use specialized cleaning agents to remove glue from rollers and use compressed air to clear debris. I maintain detailed maintenance logs, recording cleaning schedules, parts replacement, and any necessary adjustments. Preventative maintenance is key; it prevents breakdowns and ensures consistent performance. I also undergo regular training on new equipment and maintenance procedures to stay updated on industry best practices.

Q 11. Describe your troubleshooting experience with folding machines.

Troubleshooting folding machines requires a systematic approach. I start by identifying the problem – is it a misfeed, a crease issue, or a jam? I’ve dealt with various scenarios, from simple paper jams (often caused by humidity affecting paper feed) to more complex mechanical issues like faulty rollers or incorrect adjustments. My troubleshooting process usually involves:

- Visual Inspection: Carefully examine the machine for any obvious problems like debris or misaligned parts.

- Check Paper Settings: Ensure the paper type and size are correctly configured in the machine.

- Test Runs: Perform small test runs to isolate the issue and try different settings.

- Consult Manuals/Experts: If the issue persists, I consult the machine’s operational manual or contact technical support for assistance.

For example, I once resolved a recurring misfolding issue by adjusting the pressure rollers and the knife alignment, resulting in a significant increase in the machine’s efficiency and the quality of the folded products.

Q 12. What are the different types of glues used in bookbinding, and when would you use each?

Different glues serve distinct purposes in bookbinding, and selecting the right one is critical for a quality finish. Here are some common types:

- PUR (Polyurethane Reactive): A strong, flexible adhesive that produces a durable and water-resistant bond. It’s ideal for case binding and other applications where strength and longevity are paramount.

- EVA (Ethylene Vinyl Acetate): A hot melt adhesive that’s easy to use and relatively inexpensive. It’s suitable for perfect binding and other applications where a strong, but not necessarily water-resistant, bond is required.

- Animal Glue: A traditional adhesive known for its flexibility and strength. It’s primarily used in traditional bookbinding techniques and restoration work.

- Polyvinyl Acetate (PVA): A water-based adhesive that’s commonly used for paper-to-paper bonding in less demanding applications. It’s often preferred when the project requires non-toxic options.

The selection depends on factors like the type of binding, paper stock, budget, and the desired durability and flexibility of the final product. For example, PUR glue would be preferred for a high-quality hardcover book, while EVA would suffice for a less demanding paperback.

Q 13. How do you ensure accurate collating?

Accurate collating is essential for producing error-free bound documents. This is achieved through a combination of careful planning, using reliable equipment, and employing quality checks. We utilize automated collating machines for large-scale projects to minimize human error. Smaller projects might be collated manually, using a checklist and counting sheets to verify accuracy at each stage. A crucial step is conducting regular spot checks to confirm the correct sequence of pages. Employing visual cues such as colored markers or page number verification during manual collating can greatly aid accuracy. If errors are found, tracing them back allows us to quickly identify and rectify the problem, preventing large-scale waste.

Q 14. Explain the process of setting up a wire-o binding machine.

Setting up a wire-o binding machine involves several key steps:

- Paper preparation: Ensure that the document is accurately collated and punched to the required specifications (punching hole size and spacing vary depending on wire-o size).

- Wire selection: Choose the appropriate wire size based on the thickness of the document (a thicker document requires a thicker wire). The wire is available in various colors.

- Machine setup: Adjust the wire-o machine to accommodate the paper thickness and wire size. This includes adjusting the clamping pressure and the closing mechanism.

- Wire insertion: Insert the wire into the machine’s feed mechanism.

- Closing and crimping: Clamp the punched document and close the wire around the spine. This must be done with the correct tension to ensure a secure binding. Crimping forms a closed loop, preventing the wire from unwinding.

- Testing: Always test a small section before binding the complete document to ensure proper settings and binding quality.

Proper setup is critical for a professional-looking finish and prevents damage to the document. Incorrect settings can lead to bent wires, uneven binding, and potential damage to the pages.

Q 15. What is your experience with automated bindery systems?

My experience with automated bindery systems spans over ten years, encompassing various models from leading manufacturers like Muller Martini, Horizon, and Duplo. I’m proficient in operating and maintaining high-speed systems for perfect binding, saddle stitching, case binding, and wire-o binding. This includes understanding the intricacies of each machine’s control panel, troubleshooting malfunctions, and performing preventative maintenance. For example, I’ve successfully diagnosed and repaired a recurring paper jam issue on a Muller Martini perfect binder by identifying a misaligned feeder roller using diagnostic software, preventing significant production delays. I also have experience with integrated systems, where multiple binding and finishing processes are automated, increasing efficiency and minimizing human error.

My expertise extends to programming and setting up these automated systems for various job specifications. This involves configuring parameters such as cover thickness, spine width, and glue application for optimal results. I’m comfortable working with different paper stocks and understanding their impact on the binding process, adjusting the machine accordingly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address quality issues in the finished product?

Identifying and addressing quality issues requires a multi-step approach that begins even before the binding process. It starts with a thorough pre-press check of the printed sheets for any defects like misregistration, smudging, or damaged pages. During the binding process, regular checks are crucial – I visually inspect the work at each stage and frequently utilize quality control tools like gauges to measure spine thickness and ensure consistent glue application. For instance, in perfect binding, an uneven spine can indicate issues with the three-knife trimmer or glue application unit.

Addressing these issues involves systematically pinpointing the root cause. This might involve adjusting machine settings, replacing worn parts, or even recalibrating the entire system. If the problem persists, I document the issue, analyze the data, and escalate it to the appropriate technician for more in-depth analysis. For example, if I notice recurring instances of covers coming off, I’ll analyze the glue type, temperature, and application pressure to determine the optimal solution. Maintaining detailed records of quality issues, solutions, and machine settings ensures continuous improvement and helps prevent future recurrence.

Q 17. What is your experience with different types of paper and their suitability for various binding methods?

My experience encompasses a wide range of papers, from lightweight newsprint to heavy-duty cover stocks and specialty papers like textured or coated stocks. Understanding paper properties like weight, grain direction, and moisture content is critical for choosing the appropriate binding method. For instance, lightweight papers are ideal for saddle stitching, while thicker stocks require perfect binding or case binding. Using the wrong paper for a binding method can lead to issues such as tearing, poor adhesion, or an unprofessional finish.

- Saddle Stitch: Best for thin documents printed on lightweight papers.

- Perfect Binding: Suitable for thicker documents using various paper weights and covers.

- Case Binding: Ideal for high-quality books and documents using heavier paper stocks and durable boards.

- Wire-O Binding: Versatile for papers of different thicknesses; great for calendars or notebooks.

I always consider the paper’s absorbency and its interaction with adhesives – choosing the right adhesive is key for a secure bond. Experience helps to anticipate potential problems; for example, coated papers might require a specialized adhesive to ensure proper adhesion.

Q 18. Describe your experience with foil stamping and embossing machines.

I have extensive experience operating both foil stamping and embossing machines. This includes setting up the machines, preparing the dies, and adjusting parameters to achieve the desired results. Foil stamping involves using heat and pressure to transfer metallic or colored foil onto the cover, creating a luxurious and professional look. Embossing creates raised or indented designs without using foil, adding texture and depth. Both processes require precision and attention to detail.

My experience involves working with different types of foil and dies, understanding their properties and limitations. For example, I’ve used different foil types – matte, gloss, holographic – to achieve various aesthetic effects. I’ve also worked with various die materials like brass and polymer, each with its pros and cons regarding durability and cost. Troubleshooting problems like uneven foil transfer or die damage requires a thorough understanding of the machinery and materials, along with a systematic problem-solving approach.

Q 19. How do you calculate the cost of materials for a binding job?

Calculating material costs for a binding job requires a detailed breakdown of all components. I typically begin by obtaining accurate quotes from my suppliers for each material – paper stock, cover stock, boards, adhesives, foil, and any other finishing materials. The quantity of each material is determined based on the job specifications (number of pages, size, binding type, finishing requirements).

The formula is fairly straightforward: Total Material Cost = (Quantity of Material A * Cost per Unit of Material A) + (Quantity of Material B * Cost per Unit of Material B) + ... It’s crucial to factor in waste and overages. I include a buffer of approximately 5-10% for paper and other consumables to account for potential errors and spoilage. Moreover, I maintain updated price lists from my vendors to accurately calculate costs, and I regularly review these costs to ensure competitive pricing. This careful cost calculation ensures accurate job costing and helps prevent unexpected expenses.

Q 20. How do you prioritize tasks in a high-volume bindery environment?

Prioritizing tasks in a high-volume bindery environment involves a structured approach that considers several factors. I use a combination of methods, including job scheduling software and a visual Kanban board. The software allows me to input job details – deadlines, material requirements, and machine needs – to create a prioritized queue. The Kanban board visually tracks the progress of each job, enabling me to identify potential bottlenecks and adjust priorities dynamically.

Urgency and deadlines are key factors in my prioritization. Rush jobs are given precedence, and jobs with tighter deadlines are placed higher in the queue. The complexity of the job, the required machinery, and potential material constraints are also considered. For example, jobs requiring specialized equipment or materials might be scheduled to minimize downtime or potential delays. By utilizing both software and a visual system, I ensure transparency and efficiency in managing the workflow, helping the team smoothly navigate high-volume demands.

Q 21. What is your experience with different types of finishing materials (e.g., cover stock, boards)?

My experience with finishing materials extends across a broad spectrum. Cover stock, the material used for book covers, comes in a variety of weights, textures, and finishes – from lightweight paperboard to heavy-duty chipboard. The choice of cover stock depends on factors like the book’s size, intended use, and desired aesthetic. For instance, a high-end coffee table book might require a thicker, textured cover stock, whereas a paperback novel might utilize a lighter weight.

Boards, particularly used in case binding, are rigid materials providing structural support for the book. I’m familiar with various board types, including binders board, chipboard, and greyboard, each with different strengths and properties. These choices depend on the book size and anticipated use. In addition to cover stock and boards, I’m familiar with various other finishing materials including ribbons, headbands, and endpapers – selection of these depends on the type of binding and the aesthetic goal of the final product. Understanding the properties and suitability of each material allows me to select the appropriate ones to enhance the quality and durability of the finished product.

Q 22. Explain your understanding of job tickets and production schedules.

Job tickets and production schedules are the backbone of efficient bindery operations. A job ticket is a detailed instruction sheet for each project, outlining specifications like the number of books, binding type (e.g., perfect binding, saddle stitch), cover materials, finishing requirements (e.g., embossing, foil stamping), and deadlines. Think of it as a recipe for a book. The production schedule, on the other hand, is a master plan that coordinates all job tickets, assigning them to specific machines and operators, factoring in setup times, run times, and potential bottlenecks. It’s like a conductor orchestrating a symphony of binding operations.

For example, a job ticket might specify 1000 copies of a paperback novel requiring perfect binding, while the production schedule would integrate that job ticket with others, ensuring the perfect binder is utilized efficiently and deadlines are met. Effective scheduling involves considering machine capabilities, operator expertise, and material availability to optimize throughput and minimize downtime.

Q 23. How do you handle unexpected downtime or equipment malfunctions?

Unexpected downtime is unfortunately a common occurrence in any bindery. My approach involves a structured troubleshooting process. First, I’d identify the problem: Is it a mechanical issue, a material jam, or an operator error? Then, I’d consult the equipment’s manual and troubleshoot using the diagnostics. Simple fixes, like clearing a paper jam, are handled immediately. For more complex issues, I’d first attempt repairs based on my experience and training. If that fails, I’d escalate the issue to the maintenance team or supervisor, providing them with detailed information about the malfunction and any steps I’ve already taken. Meanwhile, I’d communicate the delay to the production supervisor and explore options for rerouting work to other machines or operators if possible, minimizing production disruption.

For instance, if a folding machine malfunctions, I’d check for paper jams, ensure the rollers are clean and properly aligned, and verify power supply. If it’s a more serious issue, like a faulty sensor, I’d document the problem and call maintenance while assessing whether work can be re-routed to a secondary folding machine.

Q 24. Describe your experience with quality control procedures in a bindery setting.

Quality control is paramount in bookbinding. My experience encompasses several key aspects. Firstly, I perform in-process checks at each stage of the binding process. This includes verifying the accuracy of cutting, folding, stitching, and binding, ensuring that specifications are met. Secondly, I conduct random sampling checks throughout the production run to monitor consistency and identify any deviations early. Finally, I’m involved in the final inspection, carefully examining a representative sample of finished books for defects like misaligned pages, incorrect cover placement, and any damage to the binding or cover. Documentation of all checks is crucial, including identification of defects and corrective actions taken.

For example, during perfect binding, I’d regularly check the spine thickness and adhesion to ensure the books are sturdy and the pages are securely bound. If I find a consistent problem, I’d immediately adjust the machine settings or inform the supervisor.

Q 25. What are your strengths and weaknesses in operating bindery equipment?

My strengths lie in my proficiency with a wide range of bindery equipment, including perfect binders, saddle stitchers, casemakers, and various finishing machines. I’m adept at troubleshooting equipment malfunctions and possess a strong understanding of quality control procedures. I’m also a quick learner and able to adapt to new technologies. My ability to work efficiently and independently, while also contributing effectively within a team environment, further enhances my capabilities.

An area for development is expanding my expertise with advanced digital finishing techniques. While I possess foundational knowledge, further training in this area would improve my versatility and problem-solving capabilities. I’m actively seeking opportunities to enhance my skills in this area.

Q 26. How do you stay updated on new technologies and advancements in bookbinding and finishing?

Staying updated in this field requires a multi-pronged approach. I regularly subscribe to industry publications like Book Production Industry and attend trade shows such as the PRINTING United Expo. These events showcase new technologies and provide opportunities to network with other professionals. I also actively participate in online forums and communities, engaging with discussions about new developments and best practices. Additionally, I often explore manufacturer websites for updates on their equipment and software. Continuous learning is essential to remain competitive in this dynamic industry.

Q 27. Describe a time you had to solve a complex problem related to bookbinding equipment.

I once encountered a recurring issue with a perfect binder’s glue application. The books were intermittently experiencing poor adhesion, leading to pages falling out. After ruling out simple causes like glue viscosity and paper type, I meticulously investigated the machine’s settings, including the glue roller temperature, pressure, and the timing of application. I discovered that a minor misalignment in the glue roller was the culprit. A small adjustment, documented carefully, resolved the problem, preventing significant waste and delays. This experience underscored the importance of methodical troubleshooting and precise attention to detail.

Q 28. What are your salary expectations for this position?

My salary expectations for this position are in the range of $[Insert Salary Range], commensurate with my experience, skills, and the responsibilities of the role. I’m open to discussing this further and am confident that my contributions will quickly add value to your team.

Key Topics to Learn for Bookbinding and Finishing Equipment Operation Interview

- Understanding Binding Methods: Explore different binding techniques (e.g., perfect binding, saddle stitch, wire-o, case binding) and their applications for various projects. Consider the advantages and disadvantages of each method.

- Equipment Operation and Maintenance: Gain a strong understanding of the operation and basic maintenance of various bookbinding and finishing machines (e.g., cutters, folders, stitching machines, gluing machines). Practice describing your experience troubleshooting common equipment malfunctions.

- Paper Handling and Finishing Techniques: Master the principles of paper handling, including understanding different paper types and their properties. Learn about various finishing techniques such as trimming, creasing, scoring, and perforating.

- Quality Control and Inspection: Develop skills in inspecting finished products for defects and ensuring adherence to quality standards. Be prepared to discuss your experience with quality control procedures and how you ensure accuracy.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols related to operating bookbinding and finishing equipment. Be able to discuss relevant safety regulations and best practices.

- Production Planning and Efficiency: Understand the principles of efficient production planning, including job scheduling, material management, and workflow optimization in a bookbinding environment.

- Understanding Job Tickets and Specifications: Practice interpreting job tickets and technical specifications to ensure accurate execution of bookbinding and finishing tasks.

Next Steps

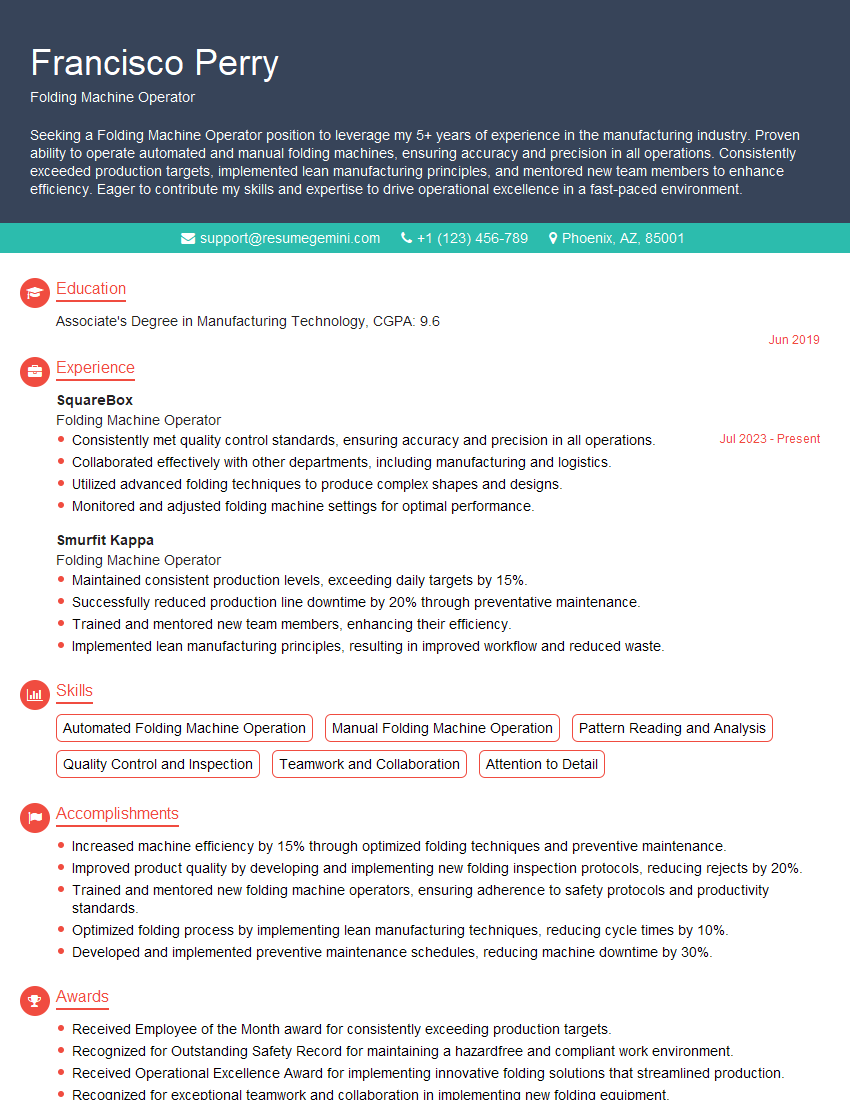

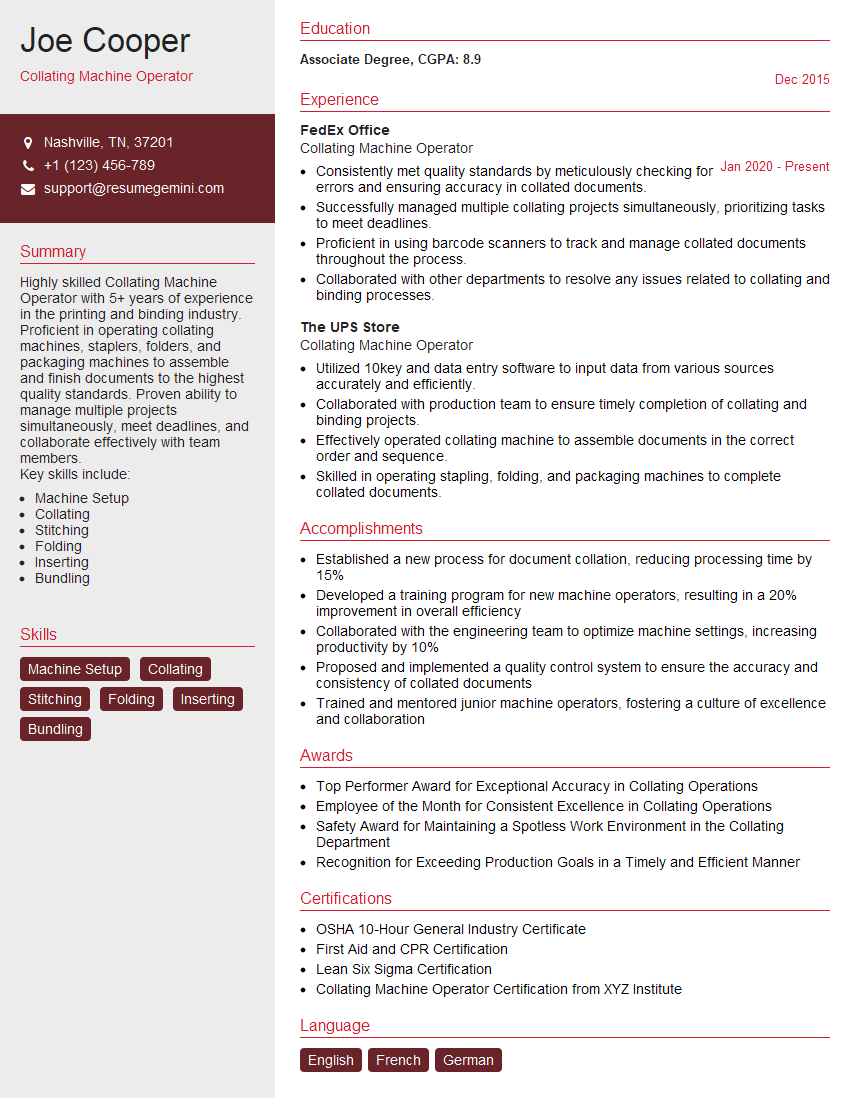

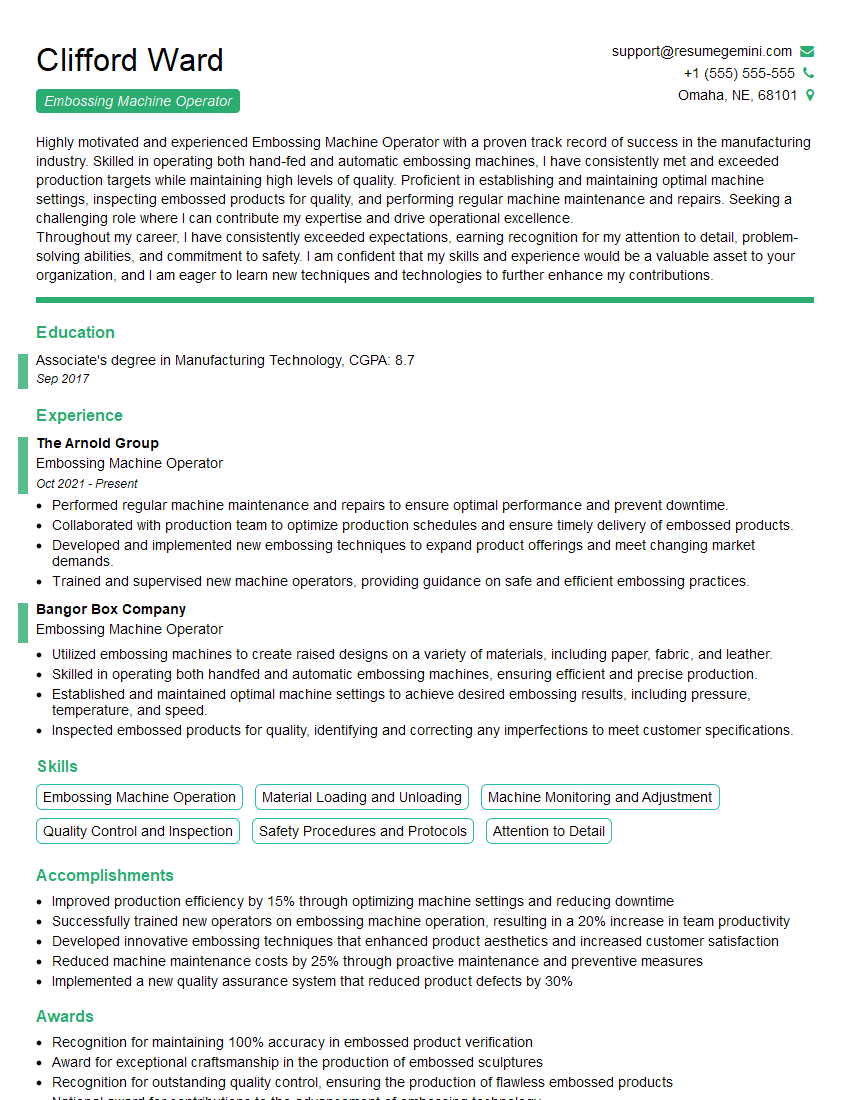

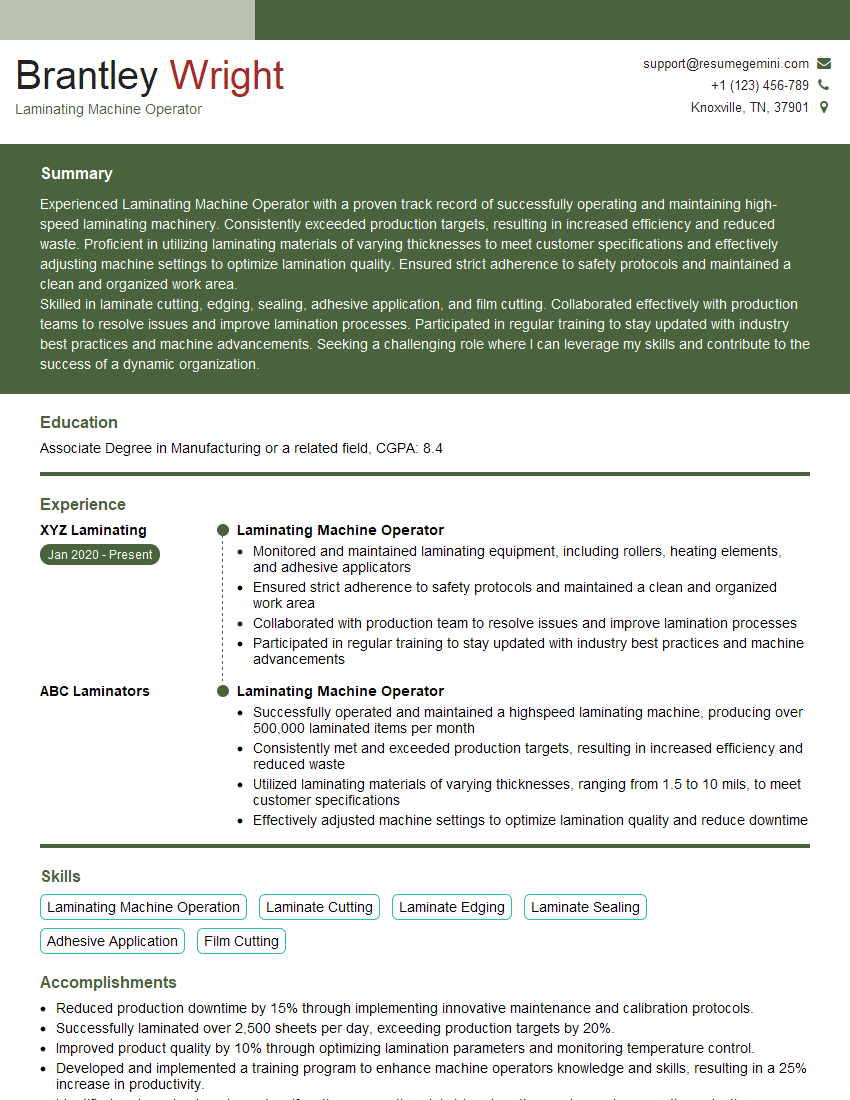

Mastering Bookbinding and Finishing Equipment Operation opens doors to rewarding careers with excellent growth potential. From entry-level positions to more specialized roles, a strong foundation in this field is highly valued. To maximize your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to Bookbinding and Finishing Equipment Operation to guide you through the process. Take the next step toward your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO