Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Brake Fluid Inspection interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Brake Fluid Inspection Interview

Q 1. What are the common causes of brake fluid contamination?

Brake fluid contamination is a serious issue that can significantly compromise braking performance and safety. It occurs when unwanted substances mix with the brake fluid, altering its properties and reducing its effectiveness. This contamination can stem from several sources:

- Moisture Absorption: Brake fluid is hygroscopic, meaning it readily absorbs moisture from the air. This moisture reduces the fluid’s boiling point, leading to vapor lock (explained further in answer 5).

- Contamination from the Atmosphere: Dust, dirt, and other airborne particles can enter the brake system through damaged seals or improperly maintained components.

- Internal Corrosion: Rust and corrosion within the brake lines or master cylinder can contaminate the fluid.

- Improper Servicing: Using dirty tools or containers during brake fluid changes can introduce contaminants.

- Damaged Seals and Components: Worn-out seals in the calipers, master cylinder, or wheel cylinders can allow the entry of outside contaminants.

Imagine it like this: your brake fluid is like the clean oil in an engine. If dirt or water gets in, it won’t run smoothly, and could cause serious damage.

Q 2. How often should brake fluid be inspected and replaced?

The frequency of brake fluid inspection and replacement depends on several factors, including vehicle type, driving conditions, and manufacturer recommendations. However, a good rule of thumb is to inspect the fluid at least annually and replace it every 2-3 years, or as recommended in your vehicle’s owner’s manual. More frequent replacement might be necessary in harsh conditions, such as frequent hard braking or extreme temperatures. Regular inspections can prevent major issues down the line.

Think of it like changing the oil in your car – even if it looks okay, the fluid degrades over time and needs to be replaced for optimal performance.

Q 3. Describe the proper procedure for checking brake fluid level.

Checking brake fluid level is straightforward but requires careful attention. First, consult your owner’s manual to locate the brake fluid reservoir, usually a transparent plastic container. Always ensure the engine is off. Then:

- Clean the area: Wipe away any dirt or debris around the reservoir to avoid introducing contaminants.

- Check the level: The reservoir will have minimum and maximum fill lines. The fluid level should be between these marks.

- Inspect the fluid: Look at the fluid’s color and clarity (more on this in answer 4).

- Do not overfill: Overfilling can cause problems. If the level is low, consult a mechanic before adding fluid yourself as this might be a sign of a leak.

Remember: Never open the reservoir cap while the engine is running to avoid spraying hot, pressurized fluid.

Q 4. What are the visual indicators of contaminated brake fluid?

Contaminated brake fluid typically exhibits several visual clues. Fresh brake fluid is usually clear and amber or light brown in color. Contamination will change this appearance:

- Dark Color: A dark brown or black color indicates significant contamination, possibly due to moisture, old fluid, or corrosion products. This is a serious sign of degradation.

- Cloudy Appearance: A cloudy or milky appearance strongly suggests water contamination, significantly lowering the fluid’s boiling point and increasing the risk of brake failure.

- Presence of Particles: Any sediment, particles, or discoloration indicates contamination and should be investigated.

Imagine pouring a glass of perfectly clear water. If someone adds dirt or mud, it’s immediately obvious – the same principle applies to brake fluid.

Q 5. What is the significance of the brake fluid’s boiling point?

The boiling point of brake fluid is critically important for brake system safety. Brake fluid’s primary function is to transmit force from the pedal to the calipers, stopping the vehicle. When brake fluid boils, it turns into vapor, which is compressible. This vaporization, known as vapor lock, creates a spongy brake pedal and significantly reduces braking efficiency or even complete brake failure. The higher the boiling point, the greater the resistance to vaporization under high temperatures generated by repeated or hard braking. Many modern brake fluids have high boiling points (often over 500°F or 260°C) for increased safety.

Think of it as a pressure system: if the pressure decreases because the fluid boils, so will the braking power.

Q 6. How does brake fluid affect brake system performance?

Brake fluid is the lifeblood of the braking system. Its properties directly affect braking performance and safety. Contaminated or degraded brake fluid can:

- Reduce Boiling Point: Leading to vapor lock and reduced braking effectiveness, especially during hard braking or high temperatures.

- Cause Corrosion: Contaminated fluid can accelerate corrosion in brake system components, leading to leaks and failures.

- Hinder Fluid Flow: Particles and contaminants can clog brake lines and restrict fluid flow, further impairing braking response.

- Damage Seals: Some contaminants can damage rubber seals in the brake system, leading to leaks.

- Lead to Brake Failure: In severe cases, brake fluid contamination can lead to complete brake failure, resulting in serious accidents.

Maintaining the quality of your brake fluid is crucial for safe and reliable braking.

Q 7. What are the safety precautions when handling brake fluid?

Brake fluid is corrosive and harmful to the skin and eyes. Always take necessary precautions when handling it:

- Wear protective gear: Use gloves, eye protection, and possibly a respirator to avoid inhalation or skin contact.

- Work in a well-ventilated area: Brake fluid fumes can be harmful.

- Clean up spills immediately: Brake fluid can damage paint and other surfaces. Use a suitable absorbent and clean the area thoroughly.

- Proper disposal: Brake fluid should be disposed of responsibly, according to local regulations. Do not pour it down the drain.

- Avoid contact with painted surfaces: Brake fluid can damage paint.

Remember that safety is paramount when working with any automotive fluids. Following these precautions will minimize the risk of injury and property damage.

Q 8. What are the consequences of using the wrong type of brake fluid?

Using the wrong type of brake fluid can have serious consequences, potentially leading to brake failure. Different DOT classifications (DOT 3, DOT 4, DOT 5.1) have varying boiling points and chemical properties. Mixing incompatible fluids can cause them to react, creating sludge that clogs the brake system’s components. This sludge reduces braking efficiency and can even cause complete brake failure. For instance, using DOT 5 (silicone-based) in a system designed for DOT 3 or DOT 4 is especially dangerous because it’s not compatible and can damage seals. Furthermore, using a fluid with a lower boiling point than the system requires can result in vapor lock under heavy braking, meaning the fluid boils, creating vapor bubbles that significantly reduce braking power. This is incredibly dangerous and could lead to accidents. Always adhere strictly to the vehicle manufacturer’s specifications for the correct brake fluid type.

Q 9. How do you identify different brake fluid types (DOT 3, DOT 4, DOT 5.1)?

Brake fluid types are identified by their DOT (Department of Transportation) classification. You’ll typically find this clearly labeled on the container.

- DOT 3: This is a glycol-ether based fluid, offering a good balance of performance and cost. It’s commonly used in many vehicles, but its boiling point is relatively lower than other types.

- DOT 4: Also glycol-ether based, DOT 4 has a higher wet and dry boiling point than DOT 3, making it suitable for higher-performance vehicles and those subjected to more demanding braking conditions. It offers improved resistance to moisture absorption which reduces the risk of boiling.

- DOT 5.1: This is another glycol-ether based fluid and represents the highest performance standard readily available. It has the highest boiling points and provides excellent braking performance even under extreme conditions. It’s crucial to understand that DOT 5.1 is *not* silicone-based.

- DOT 5 (Silicone-based): This is a completely different type of brake fluid and is *not* interchangeable with DOT 3, 4 or 5.1. It has different properties and requires a completely separate braking system that is designed to work with it.

Q 10. Explain the process of bleeding brakes.

Bleeding brakes is the process of removing air from the brake lines. Air in the lines compromises braking performance significantly, leading to a spongy brake pedal or even complete brake failure. The process typically involves:

- Preparation: Gather necessary tools (see question 4). Have a helper to operate the brake pedal.

- Locate Bleeder Valves: These are usually located on the brake calipers at each wheel.

- Attach Hose and Container: Attach a clear hose to the bleeder valve and submerge the other end in a container filled with brake fluid.

- Open Bleeder Valve: Have your helper slowly and firmly pump the brake pedal several times. Open the bleeder valve to release fluid and air. Close the valve before your helper releases the pedal.

- Repeat: Repeat steps 3 and 4 until only clean fluid (free of air bubbles) is coming from the bleeder valve. Repeat for each wheel, typically starting with the furthest wheel from the master cylinder.

- Check Fluid Level: Ensure the brake fluid reservoir remains topped up during the process to prevent air from entering the system.

- Test Brakes: After bleeding all wheels, carefully test the brakes several times to ensure a firm pedal and consistent braking performance.

Bleeding brakes is best done by a professional, especially if you’re unfamiliar with the process. Incorrect bleeding can introduce more air into the system, worsening the issue.

Q 11. What tools are necessary for brake fluid inspection and replacement?

Essential tools for brake fluid inspection and replacement include:

- Brake Fluid: The correct DOT-rated fluid for your vehicle.

- Fluid Reservoir Inspection Tool: A clear tube or similar tool to check fluid condition and level without opening the reservoir.

- Syringe or Pump: For safely extracting old brake fluid from the reservoir.

- Wrench: To open the bleeder valves.

- Clear Hose: To connect the bleeder valve to a fluid container.

- Container: To collect the old brake fluid (preferably transparent to see air bubbles).

- Gloves and Safety Glasses: To protect yourself from corrosive brake fluid.

- Shop Rags or Paper Towels: To clean up any spills.

- Torque Wrench (Optional but Recommended): To ensure bleeder valves are tightened to the correct specification.

Remember, brake fluid is corrosive and can damage paint. Always take precautions to avoid spills.

Q 12. How do you diagnose a low brake fluid level?

A low brake fluid level is typically diagnosed by visually checking the brake fluid reservoir. The reservoir is usually a transparent container located under the hood near the master cylinder. The reservoir will have minimum and maximum fill lines. A level below the minimum line indicates a low level. However, don’t solely rely on the visual check. A low level doesn’t just mean low fluid, it can point to several issues. A low level can be caused by brake fluid leaks from the system (brake lines, calipers, wheel cylinders), wear on brake pads, a failed master cylinder, or a leak in the system. Always inspect the entire braking system thoroughly for any signs of leaks or damage. If the fluid level is low, addressing this immediately is crucial for safety.

Q 13. What is the role of the master cylinder in the brake system?

The master cylinder is the heart of the hydraulic braking system. It’s a hydraulic pump that converts the force applied to the brake pedal into hydraulic pressure. When you press the brake pedal, the master cylinder’s piston pushes brake fluid through the brake lines to the wheel cylinders (drums) or calipers (discs), actuating the brakes. The master cylinder contains a reservoir which holds the brake fluid, and this reservoir must always be kept at a sufficient level to ensure proper braking function. A malfunctioning master cylinder can lead to poor braking performance or even complete brake failure. Regular inspection is essential.

Q 14. How do you inspect brake lines for leaks?

Inspecting brake lines for leaks involves a visual check and sometimes a pressure test. For a visual inspection:

- Clean the lines: Start by cleaning the brake lines to remove dirt and debris to better see any potential leaks.

- Examine for wetness: Look carefully at all brake lines, connections, and components for any signs of wetness or fluid stains. Brake fluid leaves a distinctive wet spot that will darken over time. This can be especially noticeable on a light-colored background.

- Check for cracks and corrosion: Inspect the brake lines for any signs of cracks, corrosion, or damage to the metal lines or rubber hoses. Rust or deteriorated rubber are clear indicators of potential leaks.

- Use a pressure test (if necessary): For a more thorough inspection, a professional pressure test can reveal leaks that might not be visually apparent. This test involves applying pressurized air to the system and observing for pressure drops.

Remember, even small leaks can eventually lead to brake failure, so addressing any leak, however minor, promptly is paramount. If you find any leaks, have a qualified mechanic repair the problem immediately.

Q 15. What are the signs of a failing brake caliper?

A failing brake caliper can manifest in several ways, often indicating a problem with its ability to effectively grip and release the brake rotor. Think of the caliper as a clamp – if the clamp is stuck, you’ll have problems.

- Dragging brakes: One of the most common signs. A wheel might feel hot to the touch after driving, even without heavy braking. This is because the caliper piston is not fully retracting, causing constant friction.

- Pulled to one side during braking: If one caliper is seizing or sticking, it will apply more braking force to that wheel than the others, causing the vehicle to pull to one side.

- Reduced braking performance: The overall stopping power of the vehicle may be compromised. This happens because the affected caliper isn’t contributing its full share of braking force.

- Squealing or grinding noises: A seized or worn caliper can produce these sounds as metal parts rub against each other.

- Brake fluid leaks: A damaged caliper seal can leak brake fluid, resulting in a noticeable reduction in brake fluid level in the reservoir.

For instance, imagine driving and noticing your car pulling to the left every time you brake. This is a classic symptom of a potentially failing caliper on the right side. It’s vital to address these issues immediately for safety reasons.

Career Expert Tips:

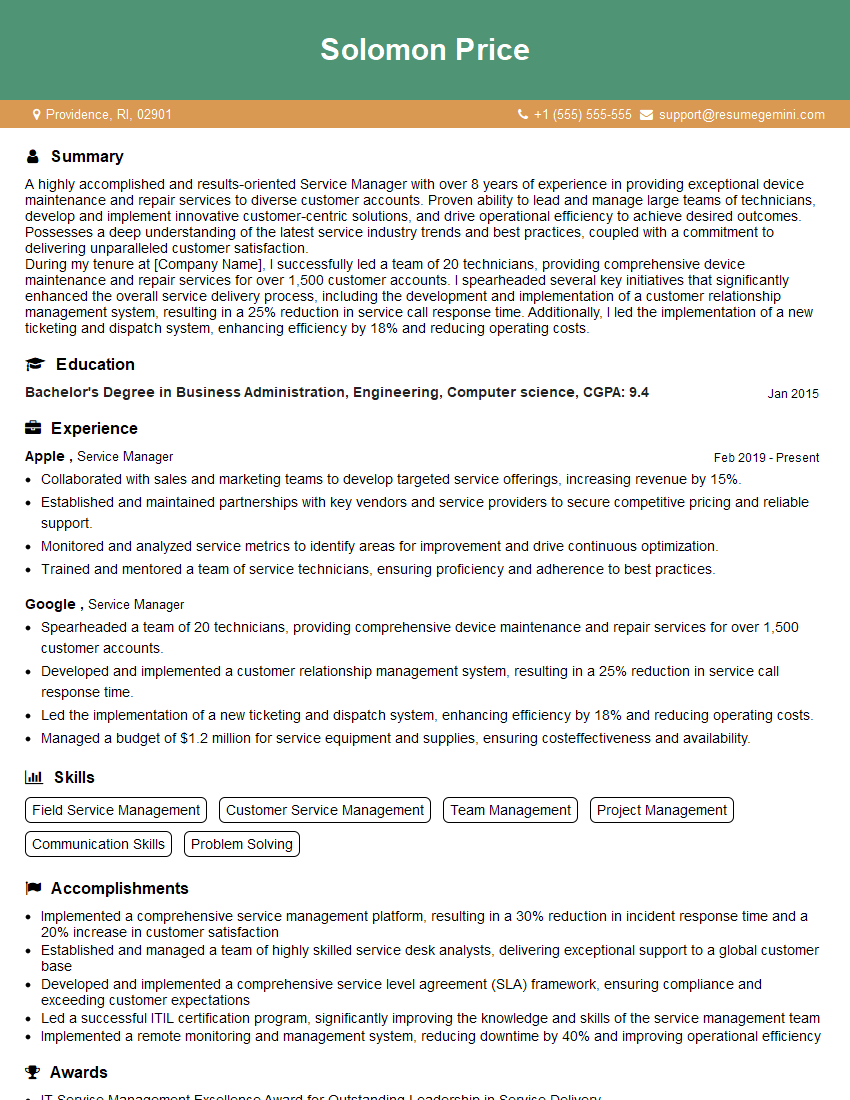

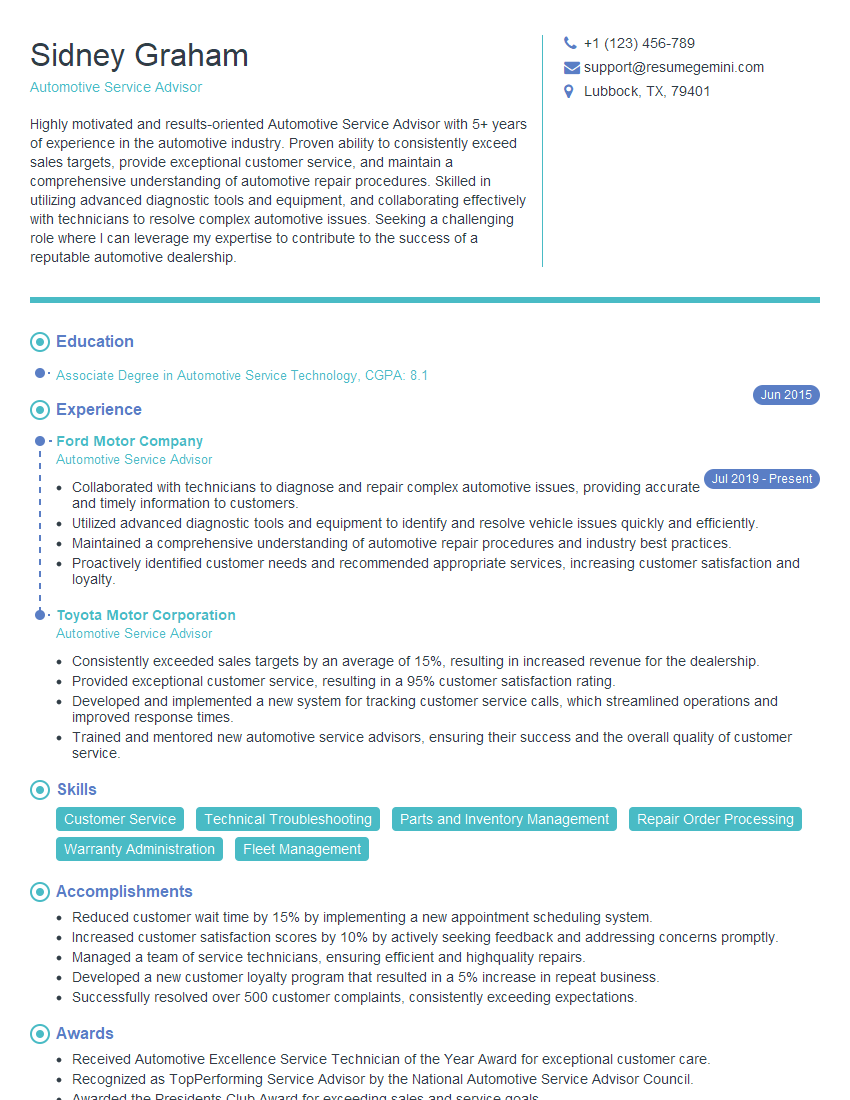

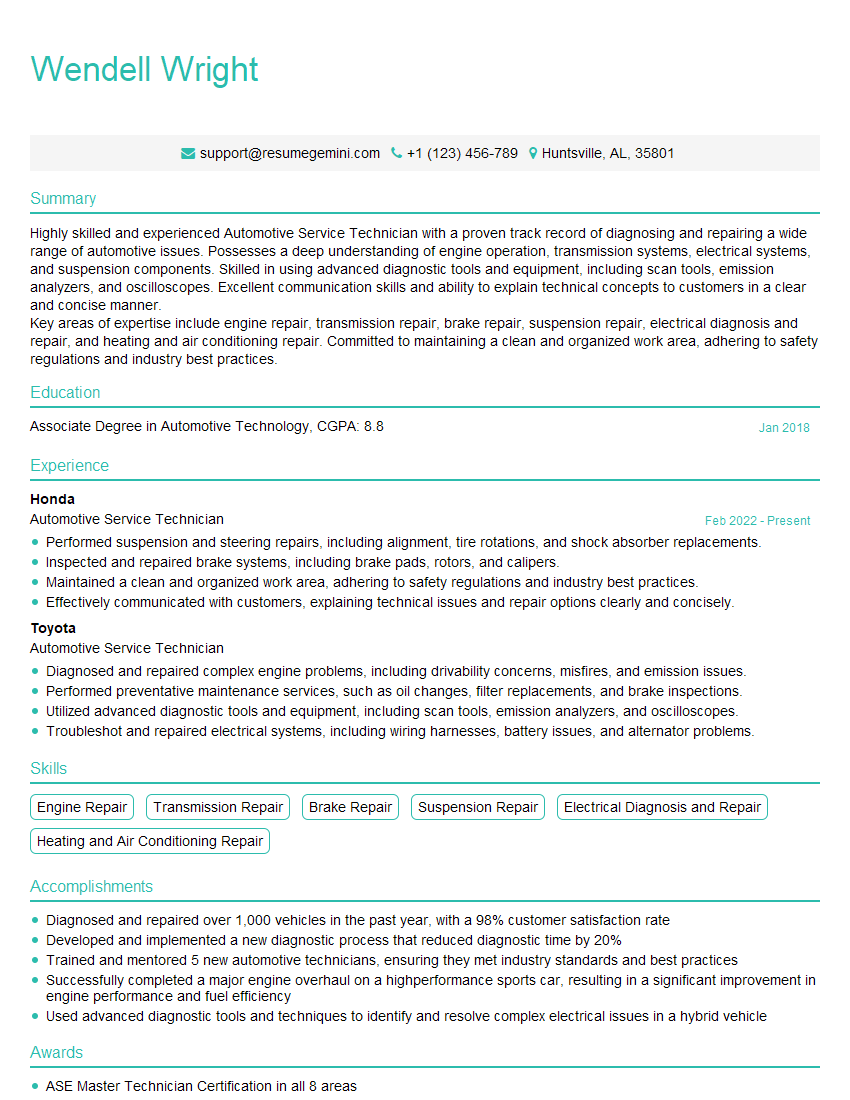

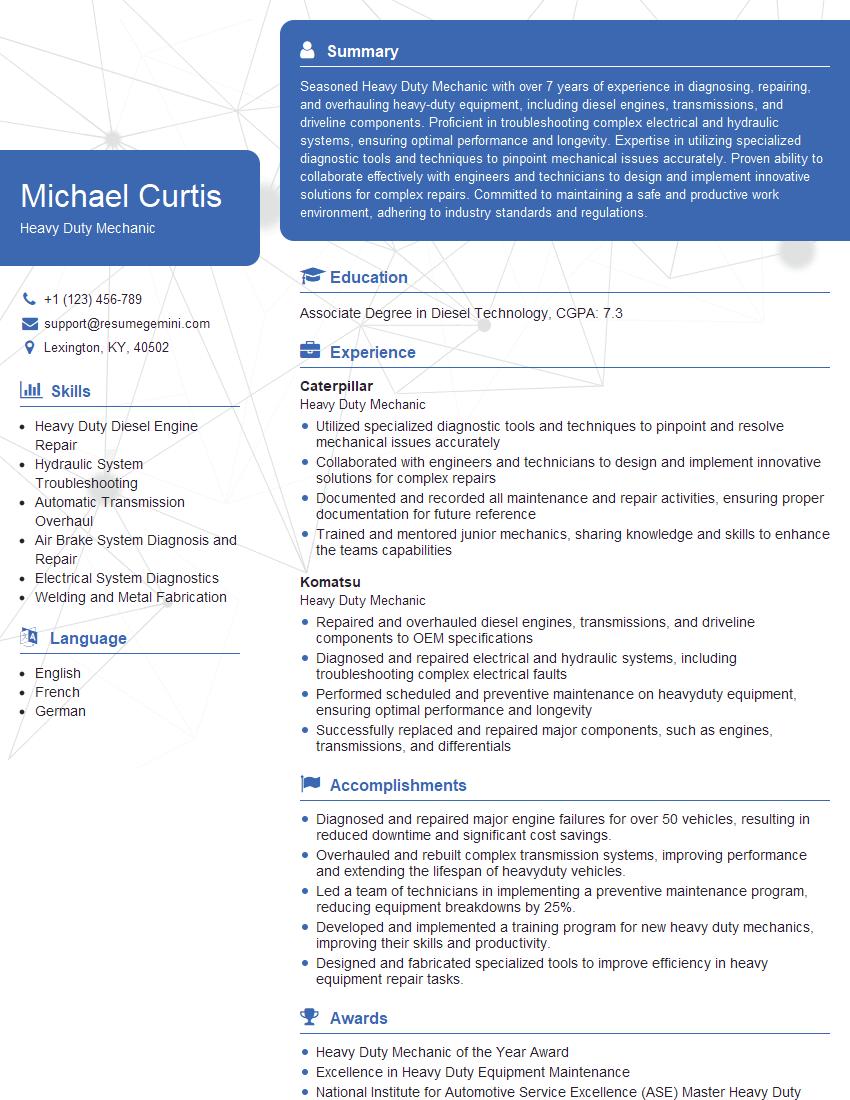

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does moisture affect brake fluid performance?

Moisture is the brake system’s worst enemy. Brake fluid is hygroscopic, meaning it readily absorbs water from the atmosphere. This absorbed moisture lowers the fluid’s boiling point significantly. Imagine a pot of water on a stove – the more salt (in this case, moisture) you add, the lower the boiling point.

The consequence? When you brake hard, the increased heat can cause the brake fluid to boil, forming vapor. Vapor is compressible unlike the liquid, leading to a spongy brake pedal feel, or even complete brake failure. This is extremely dangerous and should never be taken lightly.

Water also corrodes the internal components of the braking system, leading to premature wear and failure of calipers, master cylinders, and other crucial parts. This corrosion can also clog brake lines, further impairing braking performance.

Q 17. What is the impact of air in the brake lines?

Air in the brake lines is detrimental because it’s compressible, unlike brake fluid. When you press the brake pedal, the air compresses instead of transferring hydraulic pressure directly to the calipers. This results in:

- Spongy or soft brake pedal: The pedal feels mushy and requires more travel to achieve the same braking force.

- Reduced braking effectiveness: The brake system’s ability to stop the vehicle is significantly impaired.

- Uneven braking: If air is trapped in one line, the brakes on that wheel might be less effective than the others, potentially causing the vehicle to pull in one direction during braking.

- Pedal pulsation: As the air bubbles move around in the lines, it can cause a noticeable pulsing or vibration in the brake pedal.

Think of it like trying to inflate a bicycle tire with a leaky pump. Some air gets in, but a significant portion escapes, making it difficult to achieve the desired pressure. Similarly, air in the brake lines reduces the system’s overall effectiveness.

Q 18. Explain the importance of proper brake fluid storage.

Proper brake fluid storage is paramount to maintaining its quality and preventing contamination. Brake fluid is highly susceptible to moisture absorption and degradation. Therefore, storage should follow these guidelines:

- Use airtight containers: The container should be sealed tightly to prevent exposure to moisture and air.

- Store in a cool, dry place: Extreme temperatures and humidity accelerate degradation.

- Avoid direct sunlight: UV radiation can break down the fluid’s chemical components.

- Keep away from contaminants: Prevent contact with dirt, grease, or other foreign materials that can compromise the fluid’s purity.

- Use only original factory containers: These are designed to be airtight and protect against degradation. Never use recycled containers.

Imagine using old, contaminated brake fluid. It’s like adding sand to your car’s engine oil; it will severely damage internal components and compromise performance and safety. Proper storage protects against such situations.

Q 19. How do you dispose of used brake fluid responsibly?

Used brake fluid is hazardous waste and requires responsible disposal. Never pour it down the drain, onto the ground, or into your trash. Here’s the correct approach:

- Collect the used fluid in a sealed, leak-proof container: Use a designated container specifically for used brake fluid.

- Label the container clearly: Indicate the contents as “Used Brake Fluid” to avoid accidental misuse or ingestion.

- Locate a local hazardous waste disposal facility: Many communities have designated centers for responsible disposal of automotive fluids.

- Follow local regulations: Check your municipality’s guidelines on disposing of hazardous waste. They may offer specific collection days or locations for this purpose.

Improper disposal contaminates the environment and poses a health risk. Your local municipality usually provides information on correct waste disposal practices and facilities.

Q 20. Describe the different types of brake systems.

There are various types of brake systems, primarily differentiated by their actuation mechanism. The most common are:

- Hydraulic Brake Systems: These use brake fluid under pressure to transfer force from the master cylinder to the wheel cylinders or calipers. This is by far the most prevalent type in modern vehicles.

- Pneumatic Brake Systems: These employ compressed air to actuate the brakes. They’re more commonly found in heavy-duty vehicles such as trucks and buses.

- Vacuum-assisted Brake Systems: These systems use engine vacuum to assist in applying the brakes, making it easier for the driver to stop the vehicle. Many modern cars utilize vacuum assistance for hydraulic brakes.

- Anti-lock Braking Systems (ABS): This is not a separate brake system type, but rather a safety feature incorporated into most modern hydraulic systems. ABS prevents wheel lockup during braking, improving steering control and stopping distance.

Understanding the different types of braking systems allows for a targeted approach to maintenance and troubleshooting. For example, diagnosing problems in a pneumatic system would require a different skillset compared to hydraulic systems.

Q 21. What is the difference between hydraulic and pneumatic brake systems?

The key difference lies in the medium used to transfer force:

- Hydraulic Brake Systems use an incompressible liquid (brake fluid) to transfer force. The pressure applied to the brake pedal is directly translated into clamping force at the wheels. Hydraulic systems are efficient, reliable, and relatively simple to maintain.

- Pneumatic Brake Systems use compressed air to actuate the brakes. Air is compressible, so a larger volume of air is required to achieve the same braking force as a hydraulic system. Pneumatic systems offer advantages in terms of their ability to generate high braking forces, essential for stopping heavy vehicles, and having components distributed throughout the vehicle. However, they’re more complex to maintain, and leaks can lead to significant performance degradation.

Think of it like this: Hydraulic systems are like a rigid rod transferring force directly; pneumatic systems are more like a series of interconnected air chambers that need more volume to exert the same force. The choice between hydraulic and pneumatic systems depends largely on the vehicle’s size and weight.

Q 22. How do you interpret a brake fluid test strip result?

Brake fluid test strips are designed to quickly assess the moisture content in your brake fluid. They’re usually color-coded, and you simply dip the strip into the fluid and compare the resulting color to the chart provided on the packaging. A darker color indicates a higher percentage of water.

For example, a strip might show a green color for low moisture, yellow for moderate moisture, and red for high moisture. A red result indicates the brake fluid needs immediate replacement because moisture significantly reduces its boiling point, leading to brake failure. Always follow the manufacturer’s instructions on the specific test strip you’re using, as slight variations exist.

Q 23. What are the common symptoms of brake fluid problems?

Several warning signs could point towards brake fluid problems. A spongy or soft brake pedal is a major red flag, suggesting air in the lines or fluid contamination. A high-pitched squeal or grinding noise when braking usually indicates worn brake pads, but it’s important to check the fluid level concurrently, as low fluid can exacerbate the problem. Brake fluid leaking from the system, which can be seen as stains on the wheels or under the car, is a serious issue. Finally, a low brake fluid level itself is a crucial warning sign; always check your reservoir.

Imagine driving and suddenly your brake pedal feels unusually soft and sinks close to the floor. That’s a classic symptom indicating a problem and should never be ignored.

Q 24. What are the safety implications of neglecting brake fluid maintenance?

Ignoring brake fluid maintenance carries serious safety implications. Contaminated brake fluid, especially with excessive water, dramatically lowers its boiling point. When brakes are applied repeatedly under heavy stress (like emergency braking or prolonged downhill driving), the fluid can overheat and vaporize. Since vapor is compressible unlike liquid, the brake pedal will go to the floor, leading to complete brake failure. This situation can have catastrophic consequences, potentially causing serious injury or even death.

Think of it like this: brake fluid is the lifeblood of your braking system. If you neglect its health, you’re compromising your safety and the safety of everyone on the road.

Q 25. How do ABS systems affect brake fluid maintenance?

Anti-lock Braking Systems (ABS) don’t directly change the frequency of brake fluid maintenance, but they do introduce a few factors to consider. ABS systems utilize more brake fluid components and lines, increasing the potential points of leakage. Regular inspections become even more critical with ABS systems to detect these potential issues. Additionally, the added complexity might mean a more extensive bleeding procedure if the system needs to be flushed and refilled.

In essence, while the basic principles of brake fluid maintenance remain the same, the higher complexity of an ABS-equipped vehicle necessitates a more vigilant approach to inspections.

Q 26. How do you troubleshoot a spongy brake pedal?

A spongy brake pedal indicates a critical issue. The first step is to visually inspect the brake fluid reservoir; a low fluid level points towards a leak. If the fluid level is fine, air in the brake lines is the most likely culprit. This necessitates bleeding the brakes, a procedure that involves systematically removing air from the brake lines. If bleeding doesn’t resolve the problem, it suggests a more complex issue, possibly a faulty master cylinder or a leak within a caliper or wheel cylinder, requiring professional attention.

Trying to drive with a spongy brake pedal is extremely dangerous. It’s akin to driving with partially deflated tires – the brake response is unreliable, and it drastically increases your stopping distance.

Q 27. How do you handle brake fluid leaks during an inspection?

Discovering brake fluid leaks during an inspection requires immediate attention. Safety is paramount; do not attempt to drive the vehicle. First, mark the location and severity of the leak precisely. Then, take photos as evidence. If possible, identify the source (a leaking hose, caliper, or master cylinder). Report the findings immediately to the vehicle owner and strongly advise against driving the vehicle until the leak is professionally repaired. Thoroughly document the situation, including the location, date, and time of discovery.

Think of brake fluid leaks as a critical emergency, similar to a major engine coolant leak. Both demand immediate action to prevent further damage and maintain safety.

Q 28. What are your troubleshooting steps if a brake fluid level is unexpectedly low?

An unexpectedly low brake fluid level signals a potential problem. The first step is to carefully inspect the brake system for any signs of leakage around the calipers, wheel cylinders, brake lines, and the master cylinder. If a leak is found, repair is crucial before further operation. If no visible leak is evident, internal leakage within the master cylinder or a wheel cylinder is suspected. Another potential issue might be worn brake pads, though this generally results in a slower fluid consumption than an outright leak. A thorough investigation and possibly a pressure test of the system might be necessary to pinpoint the problem.

Never top off the brake fluid without investigating the cause of the low level. Simply adding fluid masks the problem and can delay necessary repairs that could compromise safety.

Key Topics to Learn for Brake Fluid Inspection Interview

- Brake Fluid Properties and Composition: Understanding the chemical makeup, boiling point, and hygroscopic nature of brake fluid, and its impact on braking performance.

- Visual Inspection Techniques: Mastering the identification of contamination (water, air, debris) through color, clarity, and the presence of particulates. Practical application: Describing your experience in visually inspecting brake fluid reservoirs and lines for signs of degradation.

- Fluid Level and Reservoir Condition: Assessing the fluid level in the master cylinder reservoir and identifying potential leaks or damage to the reservoir itself.

- Testing Brake Fluid: Familiarizing yourself with methods for testing brake fluid moisture content and understanding the implications of high moisture levels. Practical application: Explaining the procedure and interpretation of results from a brake fluid moisture tester.

- System Bleeding and Flushing: Understanding the process of bleeding air from the brake system and the importance of regular fluid flushing to maintain optimal performance. Practical application: Detailing your experience in performing brake system bleeding and flushing procedures on different vehicle types.

- DOT Standards and Regulations: Awareness of relevant Department of Transportation standards regarding brake fluid specifications and maintenance requirements.

- Troubleshooting Brake System Issues: Developing the ability to identify and diagnose common brake system problems related to brake fluid, such as spongy brakes, low pedal feel, or brake fluid leaks. Practical application: Describing your approach to troubleshooting a brake system with low fluid levels.

- Safety Procedures: Emphasizing the importance of safety precautions when handling brake fluid and working on brake systems.

Next Steps

Mastering brake fluid inspection is crucial for advancing your career in automotive maintenance and repair. A strong understanding of this critical aspect of vehicle safety demonstrates competence and attention to detail, highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. Examples of resumes tailored to Brake Fluid Inspection expertise are available, providing you with valuable templates to adapt and personalize.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO