Preparation is the key to success in any interview. In this post, we’ll explore crucial CAD/CAM Software (i.e., AutoCAD, SolidWorks, Inventor) interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in CAD/CAM Software (i.e., AutoCAD, SolidWorks, Inventor) Interview

Q 1. Explain the difference between wireframe, surface, and solid modeling.

The three modeling techniques—wireframe, surface, and solid—represent progressively more complete digital representations of a physical object. Think of building a house: wireframe is like the architect’s initial sketch showing only lines and points; surface modeling adds the ‘skin’ or exterior, like siding and roofing; and solid modeling is the fully detailed house, including walls, floors, and interior features.

Wireframe Modeling: This is the simplest form, representing an object using only lines and points (vertices and edges). It defines the object’s basic shape and structure but lacks information about its surface or volume. Useful for early-stage design or conceptual sketches, but unsuitable for analysis or manufacturing processes. Imagine a simple stick figure; that’s a wireframe representation of a human.

Surface Modeling: This method creates a model using mathematical surfaces, defining the object’s exterior but not its internal structure. Think of a car body—the curved panels are surfaces. It’s ideal for objects with complex curves and aesthetics, like car bodies or consumer products. While it provides a visual representation of the object, it doesn’t define its volume, making it unsuitable for simulations involving volume or weight calculations.

Solid Modeling: This is the most advanced technique, creating a complete 3D representation of the object, defining both its surface and volume. It’s akin to a complete digital blueprint, containing data on every aspect of the object, from its geometry to its material properties. It’s the preferred method for engineering and manufacturing, allowing for detailed analysis (e.g., stress analysis, weight calculation), realistic rendering, and direct generation of manufacturing instructions (CAM).

Q 2. Describe your experience with parametric modeling.

Parametric modeling is the cornerstone of modern CAD software. It allows you to define a model using parameters or variables rather than fixed dimensions. Changing a single parameter automatically updates the entire model. For example, if you’re designing a box and define its length, width, and height as parameters, altering any of those parameters will instantly resize the box maintaining all the relationships between the elements. This feature drastically increases design efficiency and allows for easy design exploration.

In my experience, I’ve extensively used parametric modeling in SolidWorks and Inventor to design complex assemblies. For example, I designed a robotic arm using parametric modeling. Changing the length of one segment automatically adjusted the overall reach and required modifications to other components, ensuring consistent functionality. This saved significant time and effort, as manual adjustments would have been incredibly tedious and error-prone.

Q 3. How do you handle large assemblies in SolidWorks/Inventor?

Managing large assemblies requires strategic approaches to improve performance and maintainability. Techniques such as component suppression, lightweight components, and assembly simplification are crucial.

Component Suppression: This allows temporarily hiding components from the assembly, improving performance by reducing the number of parts actively displayed. I often suppress components during initial design reviews to focus on specific areas.

Lightweight Components: These are simplified versions of components that retain geometric information but reduce data size. This is useful for improving performance when working with large assemblies or during simulations.

Assembly Simplification: This involves simplifying the assembly structure using techniques like sub-assemblies. Breaking down a complex assembly into smaller, manageable sub-assemblies helps in organization, analysis, and design changes. For example, I would create sub-assemblies for the engine, transmission, and chassis of a car model.

Efficient Part Design: Well-designed individual components, avoiding unnecessary complexity, significantly improve overall assembly performance. Simplifying component geometry where appropriate can dramatically reduce the total assembly file size.

SolidWorks and Inventor also offer performance-enhancing features like ‘large assembly mode’ which optimizes display and manipulation of extremely large models.

Q 4. What are the different types of constraints used in CAD software?

CAD software utilizes various constraints to define the relationships between different components within an assembly. They are essential for creating accurate and functional designs, ensuring parts fit together properly and move as intended. Constraints can be geometric (defining spatial relationships) or dimensional (specifying precise distances and angles).

Geometric Constraints: Examples include mate constraints (connecting faces), concentric constraints (aligning axes), parallel and perpendicular constraints (aligning planes or edges), and tangent constraints (making surfaces touch smoothly).

Dimensional Constraints: These define specific distances, angles, and radii. They provide precise control over the dimensions and relative positions of components. An example would be specifying the exact distance between two holes.

Using a combination of both geometric and dimensional constraints is critical for creating fully defined and stable assemblies. Over-constraining (too many constraints) can lead to conflicts, while under-constraining (too few constraints) can result in unstable or undefined assemblies.

Q 5. Explain your experience with different CAD file formats (e.g., DWG, STEP, IGES).

Experience with various CAD file formats is vital for collaboration and data exchange. I am proficient in handling:

DWG (AutoCAD Drawing): The native format for AutoCAD, widely used for 2D drawings and some 3D models. Its flexibility makes it a staple in the industry, though compatibility issues sometimes arise with older versions.

STEP (Standard for the Exchange of Product data): A neutral file format, supporting both 2D and 3D data, and widely used for exchanging data between different CAD systems. Its strength is its broad compatibility.

IGES (Initial Graphics Exchange Specification): Another neutral format used for exchanging CAD data, albeit less versatile and commonly used than STEP. It’s primarily used for exporting complex geometry for manufacturing processes.

Other formats: I also have experience with native formats of SolidWorks (SLDPRT, SLDASM) and Inventor (IPT, IAM), along with other less common formats like Parasolid and STL (Stereolithography), which is particularly useful for 3D printing.

Understanding the strengths and weaknesses of these formats allows me to select the best format for a specific purpose, facilitating seamless data transfer between different stakeholders and software.

Q 6. How do you manage revisions and version control in your CAD projects?

Effective revision and version control are paramount to avoid confusion and ensure data integrity. My approach usually involves a combination of software-based version control and a well-structured file naming convention.

Software-based Version Control: I use SolidWorks’ built-in version control features, which allow for tracking changes, restoring previous versions, and managing different iterations of a design. For larger projects or collaborative efforts, I’d integrate with external version control systems like PDM (Product Data Management) systems to ensure thorough change tracking and collaboration management.

File Naming Convention: I implement a structured file naming system, incorporating project name, part number, revision number (e.g., Rev A, Rev B), and date. This allows easy identification and tracking of different versions of a file.

Regular Backups: It is critical to regularly back up all project files in a secure location to mitigate the risk of data loss.

This combination of strategies ensures that all project versions are accounted for, improving project transparency and facilitating efficient collaboration.

Q 7. Describe your experience with CAM software and post-processing.

My experience with CAM software involves generating toolpaths and post-processing to prepare manufacturing instructions. I have used Mastercam and Fusion 360 for this purpose.

Toolpath Generation: This involves defining the cutting operations needed to manufacture a part from a CAD model, considering factors like material properties, machine capabilities, and desired surface finish. I am experienced in generating various toolpaths, including milling, turning, and drilling operations.

Post-Processing: Once the toolpaths are generated, post-processing is crucial to convert the generic toolpath data into machine-specific code. This involves selecting the appropriate post-processor that matches the CNC machine’s controller, ensuring that the generated code runs smoothly and accurately. It requires careful consideration of machine limitations and capabilities to avoid errors or collisions.

Simulation: Before running the actual code on the machine, I always simulate the toolpaths to check for errors or potential collisions. This prevents damage to the workpiece or the machine.

I understand the importance of optimizing toolpaths to minimize machining time and material waste, as this impacts both manufacturing cost and production efficiency. This process requires understanding not only CAM software but also the capabilities of CNC machinery and manufacturing processes.

Q 8. Explain the concept of toolpath generation in CAM.

Toolpath generation in CAM (Computer-Aided Manufacturing) is the process of defining the precise movements of a cutting tool to manufacture a part based on a CAD (Computer-Aided Design) model. Think of it like planning the route of a lawnmower to perfectly cut your lawn – the CAD model is your lawn, and the toolpath is the carefully planned mowing path. This involves selecting appropriate cutting tools, defining feed rates, speeds, and depths of cut, and strategically sequencing these operations to achieve the desired outcome efficiently and accurately.

The process typically involves several steps: firstly, defining the geometry to be machined, which can be a 2D contour or a complex 3D surface. Secondly, choosing appropriate cutting tools; this depends on the material of the workpiece and the desired surface finish. Thirdly, calculating the toolpaths – different algorithms and strategies are used to generate efficient and safe paths. These paths are often visualized as a series of lines or curves that the cutting tool will follow. Finally, optimizing the toolpath for things like minimizing air cutting and ensuring smooth transitions between cuts.

For example, in milling a complex shape, the CAM software might generate multiple toolpaths – a roughing pass using a larger diameter endmill to remove most of the excess material quickly, and a finishing pass using a smaller diameter endmill to achieve a smooth, high-precision surface.

Q 9. What are the different types of machining processes you are familiar with?

I’m proficient in various machining processes, including:

- Milling: This is a very common process where a rotating cutter removes material from a workpiece. I have extensive experience with various milling strategies, including face milling, end milling, and contour milling. For example, I’ve used these techniques to create intricate molds and complex mechanical parts.

- Turning: This process involves rotating a workpiece against a cutting tool to create cylindrical or conical shapes. I’ve worked with both engine lathes and CNC lathes. A recent project involved creating precision shafts using turning operations.

- Drilling: This is used to create holes in workpieces. I have experience optimizing drill paths to minimize cycle time and ensure hole accuracy.

- Lathe turning, and boring: I have extensive experience generating toolpaths for lathe operations including turning, facing, grooving, and boring.

- 3D Milling: I am proficient in creating toolpaths for 3D surfacing and 3D contouring operations.

My expertise extends to programming various machining strategies like adaptive clearing, high-speed machining, and trochoidal milling to maximize efficiency and quality.

Q 10. How do you optimize toolpaths for efficiency and surface finish?

Optimizing toolpaths is crucial for efficient and high-quality machining. This is achieved through a combination of strategies aimed at minimizing machining time, reducing tool wear, and ensuring a superior surface finish.

- Stepover Optimization: Choosing the right stepover (the distance between adjacent tool paths) is critical. A smaller stepover leads to a better surface finish but takes longer. A larger stepover is faster but might leave a rougher surface. The optimal stepover is a balance between these factors, often determined through experimentation and simulation.

- Cutting Parameters: Adjusting parameters like feed rate (how fast the tool moves), spindle speed (how fast the tool rotates), and depth of cut (how much material is removed per pass) significantly impacts efficiency and surface finish. Higher feed rates and spindle speeds generally lead to faster machining but can cause excessive tool wear or vibrations if not carefully chosen.

- Tool Selection: The type of cutting tool (e.g., end mill, drill bit) greatly influences the outcome. Choosing the correct tool with appropriate geometry and material will improve efficiency and finish.

- Toolpath Strategies: Different toolpath strategies exist for various machining operations. For example, using ‘adaptive clearing’ in roughing operations can drastically reduce machining time by efficiently removing material. Likewise, using ‘constant step’ in finishing can improve surface finish uniformity.

- Simulation and Verification: Before machining, I always simulate the toolpath to detect potential collisions or other problems, ensuring the accuracy and safety of the process.

I’ve had successful experiences using these techniques to reduce machining time by up to 20% while simultaneously improving surface finish quality for a variety of projects.

Q 11. Describe your experience with simulation and analysis tools integrated with CAD/CAM.

I have extensive experience with simulation and analysis tools integrated within CAD/CAM software such as SolidWorks CAM, Autodesk Inventor CAM, and Fusion 360. These tools are invaluable for verifying toolpaths, predicting machining times, and detecting potential issues before they occur in the actual machining process.

For instance, in SolidWorks CAM, I routinely use the simulation feature to visualize the toolpath, check for collisions between the tool and the fixture or workpiece, and analyze the material removal process. This allows for the identification and correction of errors in the toolpath programming before any physical machining takes place, saving time, material, and preventing damage to the machine and workpiece.

Furthermore, CAM software often provides tools for analyzing machining time, tool wear, and other crucial performance indicators. This data is used to optimize the machining strategy, select the most appropriate cutting tools, and ultimately improve overall manufacturing efficiency.

Q 12. How do you troubleshoot errors in your CAD/CAM models or programs?

Troubleshooting errors in CAD/CAM models and programs involves a systematic approach. It’s like detective work – identifying clues and piecing them together. Here’s a typical process:

- Verify the Geometry: The first step is to carefully review the CAD model for any geometric errors, inconsistencies, or missing features. Sometimes, a small error in the CAD model can lead to major problems in the toolpath generation.

- Check Toolpath Parameters: Next, I check all the parameters within the CAM software – feed rate, spindle speed, depth of cut, stepover, etc. Incorrect parameters are a frequent source of issues.

- Simulate and Visualize: Using simulation tools, I visualize the toolpath to identify potential problems like collisions, incorrect tool movements, or areas of excessive tool wear.

- Analyze Error Messages: If the software generates error messages, I carefully read and analyze them to get clues about the problem’s source.

- Step-by-Step Debugging: Sometimes, I might need to break down the toolpath generation process into smaller steps, isolating and checking each one individually to pinpoint the precise location of the error.

- Consult Documentation and Support: If all else fails, I consult the software’s documentation or contact technical support.

A recent example involved a toolpath that unexpectedly stopped halfway through a milling operation. By carefully reviewing the simulation, I discovered a small interference between the tool and a clamping fixture that hadn’t been accounted for in the setup.

Q 13. Explain your experience with 2D drafting and annotation.

My experience with 2D drafting and annotation is extensive. I’m proficient in using AutoCAD and other CAD software packages to create detailed 2D drawings from scratch or to modify and update existing drawings. This includes:

- Creating Geometric Shapes and Models: I can create various geometric shapes using precise dimensions and tolerances. This forms the foundation of any engineering drawing.

- Dimensioning and Tolerancing: I’m proficient in applying appropriate dimensioning and tolerancing schemes according to industry standards (e.g., ASME Y14.5).

- Adding Annotations and Text: I can add clear and concise notes, labels, and other annotations to enhance the drawing’s readability and provide essential information.

- Creating Detailed Views and Sections: I know how to create various views (e.g., top, front, side) and sections to clearly convey the shape and details of the object.

- Creating Bills of Materials (BOM): I’m also skilled in creating BOMs, linking drawing components to material specifications.

I’ve used this skill to create various types of technical drawings, including assembly drawings, part drawings, and schematics for a wide range of products. For example, I was recently involved in a project that required creating detailed 2D drawings for a complex mechanical assembly – ensuring proper annotation was key for manufacturing.

Q 14. What are your preferred methods for creating detailed technical drawings?

My preferred methods for creating detailed technical drawings involve a combination of best practices and software capabilities to ensure clarity, precision, and ease of understanding for the manufacturing team.

- Using Standard Drawing Practices: I adhere to industry standards (e.g., ASME Y14.5) for dimensioning, tolerancing, and annotation, ensuring consistent and easily interpretable drawings.

- Layered Drawings: I utilize layers effectively in CAD software to organize the drawing elements logically. This allows for easy selection, modification, and control of individual components within the drawing.

- Detailed Views and Sections: I create detailed views (top, front, side) and sections as needed to clearly illustrate the part’s features, particularly for complex geometries.

- Proper Annotation: I use clear and concise annotation, including dimensions, tolerances, material specifications, surface finishes, and any other relevant information.

- Revision Control: I maintain revision control using methods like numbering and date stamping to keep track of changes made to the drawings.

- Utilizing Templates: I often work with templates to enforce consistency in drawing style, company standards, and common elements.

Creating clear and accurate drawings is critical – a poorly drawn part can lead to costly manufacturing errors. My goal is always to create drawings that are unambiguous and easily understood by anyone involved in the manufacturing process.

Q 15. Describe your proficiency in using different CAD/CAM software packages.

My CAD/CAM software proficiency spans several industry-leading packages. I’m highly proficient in AutoCAD, utilizing its 2D drafting capabilities extensively for detailed drawings, schematics, and annotation. My expertise extends to 3D modeling with SolidWorks and Inventor, where I’ve leveraged their powerful parametric modeling features for complex assemblies, design analysis, and simulation. In SolidWorks, I’m adept at surface modeling and creating complex freeform shapes, while in Inventor, I particularly appreciate its strength in managing large assemblies and creating detailed manufacturing documentation. I’ve used both for projects ranging from simple component design to intricate machine assemblies. For example, in one project, I used SolidWorks to design a custom robotic arm, leveraging its simulation tools to optimize its movement and strength. In another project, I used AutoCAD to create precise shop drawings for a large-scale construction project, ensuring all dimensions and specifications were accurate and easily understandable by the fabrication team. My experience also includes CAM software integration, specifically using post-processors to generate CNC toolpaths from SolidWorks and Inventor models for manufacturing processes.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure dimensional accuracy in your designs?

Dimensional accuracy is paramount in design. I employ several strategies to ensure precision. First, I always start with accurate source data – whether it’s from detailed measurements, specifications, or 3D scans. Within the CAD software, I leverage features like constraints and parametric modeling to maintain relationships between design elements, preventing accidental changes and maintaining overall accuracy. Regular checks and verification steps are crucial. I frequently use the software’s measurement tools to verify dimensions against specifications. For complex geometries, I might employ section views or utilize advanced analysis tools to confirm the design meets all the requirements. Additionally, before finalizing any design, I meticulously review the drawings, checking dimensions, tolerances, and annotations. Think of it like building a house – you wouldn’t just throw up the walls without checking the measurements of the foundation. Similar precision is needed in CAD design. Finally, in collaboration with manufacturing, I utilize tolerance analysis (discussed later) to anticipate potential manufacturing variations and ensure the final product meets specifications.

Q 17. Explain your experience with design for manufacturing (DFM) principles.

Design for Manufacturing (DFM) is an integral part of my design process. It’s about designing products that are not only functional and aesthetically pleasing but also cost-effective and manufacturable. I consider manufacturability from the initial stages of design. This includes selecting appropriate materials, considering manufacturing processes (like casting, machining, injection molding), and ensuring the design is suitable for the chosen process. For example, I avoid sharp internal corners during design to minimize machining time and costs and ensure smooth material flow during molding processes. I’m also familiar with standard manufacturing practices and limitations to avoid designs that are impossible or too expensive to produce. My experience includes working with manufacturing teams to review designs, obtain feedback, and incorporate suggestions for improvement. In a recent project involving the design of a plastic housing, I worked closely with the manufacturing team to select the optimal material and adjust the wall thicknesses to prevent warping and ensure consistent quality during the injection molding process. This collaborative approach reduced manufacturing costs and improved the overall product quality.

Q 18. How do you collaborate with other engineers or designers?

Collaboration is crucial. I utilize various methods to work effectively with other engineers and designers. We often use collaborative platforms like cloud-based data management systems to share design files and track revisions. This ensures everyone has access to the latest version of the design, minimizing confusion and delays. Regular team meetings, where we discuss design progress, address challenges, and coordinate tasks, are a cornerstone of our workflow. For effective communication, we utilize clear and consistent naming conventions for files and components. Additionally, I’m proficient in using version control systems, which allow me to track changes and easily revert to previous versions if necessary. For instance, in a large-scale project involving several engineering disciplines, I used a cloud-based platform to store and share design files, track revisions, and coordinate design reviews with the mechanical, electrical, and software engineering teams. This ensured consistent communication and efficient progress.

Q 19. Describe your experience with creating and managing BOMs (Bill of Materials).

Managing Bills of Materials (BOMs) is a critical aspect of product development. I’m experienced in creating and managing BOMs using both CAD software’s built-in tools and external spreadsheet software. I understand the importance of accurate BOMs for purchasing, inventory control, and cost estimation. I ensure BOMs include all necessary components, their quantities, part numbers, descriptions, and cost information. Using the CAD software’s BOM functionality allows me to automatically generate BOMs based on the assembly structure, ensuring accuracy and reducing errors. I also maintain a clear system for organizing and updating BOMs throughout the product lifecycle. For example, I recently managed a BOM for a complex electromechanical assembly, ensuring that all parts were properly identified, and quantities were updated throughout the design process. This ensured accurate cost estimations and streamlined the procurement process.

Q 20. Explain your understanding of tolerance analysis.

Tolerance analysis is the process of determining the acceptable variations in dimensions and features of a component or assembly. It helps ensure that the final product will meet its functional requirements, even with inherent manufacturing variations. I use several methods for tolerance analysis, including statistical methods and worst-case scenarios. Statistical methods take into account the probability distribution of manufacturing variations to determine the overall tolerance stack-up. Worst-case scenarios assume that all manufacturing variations accumulate in the worst possible combination. These analyses help identify critical dimensions or features where tighter tolerances are needed to prevent assembly issues or performance problems. In a recent project involving a precision mechanism, tolerance analysis helped identify the critical tolerances that needed to be maintained to ensure proper functionality. By using tolerance analysis early in the design process, we were able to avoid costly design revisions later on.

Q 21. How familiar are you with GD&T (Geometric Dimensioning and Tolerancing)?

I’m highly familiar with Geometric Dimensioning and Tolerancing (GD&T). GD&T is a standardized system for specifying the tolerances and geometric characteristics of parts. It provides a more precise and unambiguous way of defining tolerances compared to traditional methods. I understand the various GD&T symbols and their application in specifying tolerances for features like size, form, orientation, location, and runout. Using GD&T in designs ensures clarity and consistency in communication between designers, manufacturers, and inspectors, minimizing misunderstandings and errors. For example, I’ve used GD&T to specify the location and orientation tolerances of critical features in a complex assembly, ensuring that the final product would meet its functional requirements. This improved communication with the manufacturing team and significantly reduced the risk of misinterpretation or manufacturing defects.

Q 22. How do you handle complex geometric shapes and features?

Handling complex geometric shapes and features in CAD/CAM software relies on a combination of strategic modeling techniques and leveraging the software’s advanced capabilities. It’s not just about creating the shape, but doing it efficiently and accurately.

- Feature-based modeling: Instead of directly manipulating surfaces, I utilize features like extrudes, revolves, sweeps, and lofts to build up complex geometry. This parametric approach allows for easy modification later; changing one feature automatically updates the entire model. For instance, if I need to change the diameter of a hole in a complex part, I simply modify the hole feature, not the whole geometry.

- Construction planes and geometry: Complex shapes often require creating auxiliary planes and work planes to define accurate features in 3D space. This is particularly useful for creating complex curves and surfaces. I might use a series of spline curves to define the cross-section of a complex part and then use a sweep to generate the 3D model.

- Boolean operations: These allow me to combine, subtract, or intersect different solid bodies. Imagine designing a complex housing with cutouts for components; Boolean subtraction helps carve out the required spaces precisely.

- Surface modeling: For highly organic or freeform shapes, surface modeling techniques become crucial. I’m proficient in creating and manipulating NURBS (Non-Uniform Rational B-Splines) surfaces to achieve the desired aesthetic and functionality.

By thoughtfully combining these techniques, I can efficiently manage and modify even the most challenging geometric designs, maintaining accuracy and design intent.

Q 23. What are your experience with creating assembly drawings?

My experience in creating assembly drawings is extensive. I’m proficient in assembling multiple parts, managing component relationships, and generating comprehensive assembly drawings that clearly communicate the product’s structure and function.

- Component management: I utilize design management tools to organize and manage numerous parts within an assembly, utilizing techniques like creating part families and using design tables to efficiently modify multiple parts simultaneously.

- Constraints and mates: I skillfully employ constraints (geometric relationships like fixed distances or angles) and mates (more sophisticated relationships defining how components move relative to each other) to precisely position and constrain parts within the assembly. This ensures that the assembly behaves realistically and prevents conflicts. Imagine designing a complex engine; precisely defining the rotational constraints between parts is paramount.

- Exploded views and sectional views: I use these techniques extensively to improve the clarity of assembly drawings, allowing the viewer to easily understand the relationship and interaction between components. An exploded view visually separates parts to highlight assembly sequence, while a sectional view reveals internal components in a clearer way.

- Bill of Materials (BOM): Creating accurate BOMs is a critical aspect. The BOM lists every part, its quantity, and any relevant attributes, making the documentation complete and useful for manufacturing.

My approach to assembly drawings prioritizes clarity, accuracy, and manufacturability, making them valuable resources throughout the product lifecycle.

Q 24. Describe a challenging CAD/CAM project and how you overcame the challenges.

One challenging project involved designing a complex robotic arm with multiple degrees of freedom and intricate cable routing. The challenge lay in ensuring smooth articulation, preventing cable interference, and optimizing the arm’s weight and strength.

- Problem: The initial design led to cable tangling during arm movement, compromising functionality.

- Solution: I employed SolidWorks’ simulation tools to analyze the arm’s movement and cable routing. This allowed me to identify critical areas of interference. By iteratively modifying the arm’s geometry and cable pathways, using simulations and visualizations, I successfully eliminated cable tangling. Further, I used topology optimization to reduce weight without sacrificing structural integrity, leading to a more efficient and robust design.

This project highlighted the importance of iterative design, simulation, and the ability to adapt strategies in response to unexpected challenges. The final design was efficient, robust, and highly functional.

Q 25. What are your strategies for managing large datasets within CAD software?

Managing large datasets in CAD software requires a structured approach. Simply opening a huge assembly can bring even powerful computers to a standstill.

- Component simplification: I frequently utilize simplified representations (lightweight components) for large assemblies during the design process. These simplified models dramatically reduce file size while still allowing for visualization and design decisions. I’ll only work with full detail components when absolutely necessary.

- Data Management Systems (DMS): For large projects, I rely heavily on DMS like Vault or Windchill to efficiently manage and version control the design data. This enables streamlined collaboration and prevents data loss or conflicts.

- Reference models: Instead of embedding entire models within an assembly, I use references or instances of sub-assemblies whenever possible. If a sub-assembly design is modified, the change is reflected across all assemblies referencing it.

- File cleanup: Regularly purging unused data, history, and unnecessary files within the CAD models significantly reduces the file size and improves performance. I also routinely check for and correct geometric errors to improve performance.

By implementing these strategies, I can effectively manage even the largest datasets, ensuring smooth performance and efficient collaboration.

Q 26. How do you ensure the quality and accuracy of your work?

Ensuring the quality and accuracy of my work is paramount. It’s a multi-faceted approach involving both technical proficiency and methodical processes.

- Geometric dimensioning and tolerancing (GD&T): I apply GD&T principles diligently to precisely define the acceptable variations in dimensions and form. This is crucial for manufacturing and ensuring that parts fit together correctly.

- Design reviews: I proactively participate in and conduct design reviews, inviting colleagues to assess the design for potential errors or improvements. A fresh pair of eyes can often catch mistakes.

- Simulation and analysis: Finite Element Analysis (FEA), computational fluid dynamics (CFD), and other simulation tools are employed to verify the structural integrity, thermal performance, and other critical aspects of the design.

- Cross-checking and verification: I meticulously cross-check measurements, tolerances, and assembly constraints to confirm accuracy. I often employ techniques like comparing measured dimensions with CAD model dimensions.

My commitment to precision is reflected in my meticulous attention to detail throughout the entire design process, preventing problems before they occur.

Q 27. What are some of your favorite CAD/CAM tips and tricks?

Over the years, I’ve picked up several time-saving and efficiency-boosting tips and tricks:

- Keyboard shortcuts: Mastering keyboard shortcuts significantly accelerates workflow. Instead of using the mouse for every command, I rely heavily on keyboard shortcuts for faster execution.

- Templates and standards: Creating and utilizing design templates, along with adherence to company standards, maintain consistency and streamline the design process.

- Layer management: Proper layer organization helps to manage model complexity; this is especially vital in large projects.

- Customization: Customizing the software’s interface to my preferences significantly improves productivity, reducing the number of steps it takes to access important tools.

- Using Design Libraries: Creating and using custom design libraries of commonly used parts and components drastically reduces design time and also enhances consistency in a project.

These seemingly small tricks add up to significant time savings and improved design quality over the long term.

Q 28. What are your plans for continuous professional development in CAD/CAM?

My approach to continuous professional development focuses on staying at the cutting edge of CAD/CAM technology and expanding my skillset. This involves a multifaceted strategy:

- Industry certifications: I plan to pursue advanced certifications in relevant CAD/CAM software to formally demonstrate my expertise.

- Online courses and tutorials: Platforms like Coursera, Udemy, and LinkedIn Learning offer a wealth of resources to stay updated on new features, techniques, and industry best practices.

- Workshops and seminars: Attending industry events and workshops is essential to learn from other professionals and explore innovative applications of CAD/CAM technology.

- Mentorship and collaboration: I actively seek mentorship opportunities and collaborative projects to learn from more experienced professionals and share my own knowledge.

- Staying abreast of industry trends: Following industry publications, attending webinars, and networking with professionals in the field will keep me up-to-date on the latest advancements.

My goal is to remain a highly proficient and sought-after CAD/CAM professional throughout my career.

Key Topics to Learn for CAD/CAM Software (i.e., AutoCAD, SolidWorks, Inventor) Interview

- 2D/3D Modeling Fundamentals: Understanding the core principles of creating and manipulating 2D and 3D models. This includes sketching, extrusion, revolution, and other modeling techniques.

- Software-Specific Features: Become proficient in the unique features and functionalities of AutoCAD, SolidWorks, or Inventor, depending on the job description. Focus on commands, shortcuts, and efficient workflows.

- Assembly and Part Design: Practice creating complex assemblies from individual parts, understanding constraints, and managing design configurations.

- Drafting and Documentation: Master creating detailed technical drawings, including dimensioning, annotations, and creating various views.

- Design for Manufacturing (DFM): Learn how to design parts considering manufacturing processes, material selection, and cost-effectiveness.

- Simulation and Analysis: Explore basic simulation techniques like Finite Element Analysis (FEA) or Computational Fluid Dynamics (CFD) to understand the behavior of your designs under various conditions (where applicable to the software and role).

- Data Management and Collaboration: Understand how to manage project data efficiently, utilize version control, and collaborate effectively within a team environment.

- Problem-Solving and Troubleshooting: Practice identifying and resolving common design issues, errors, and unexpected behaviors within the CAD/CAM software.

- Customization and Automation: Explore options for customizing the software environment and automating repetitive tasks using macros or scripting (if relevant to the role).

Next Steps

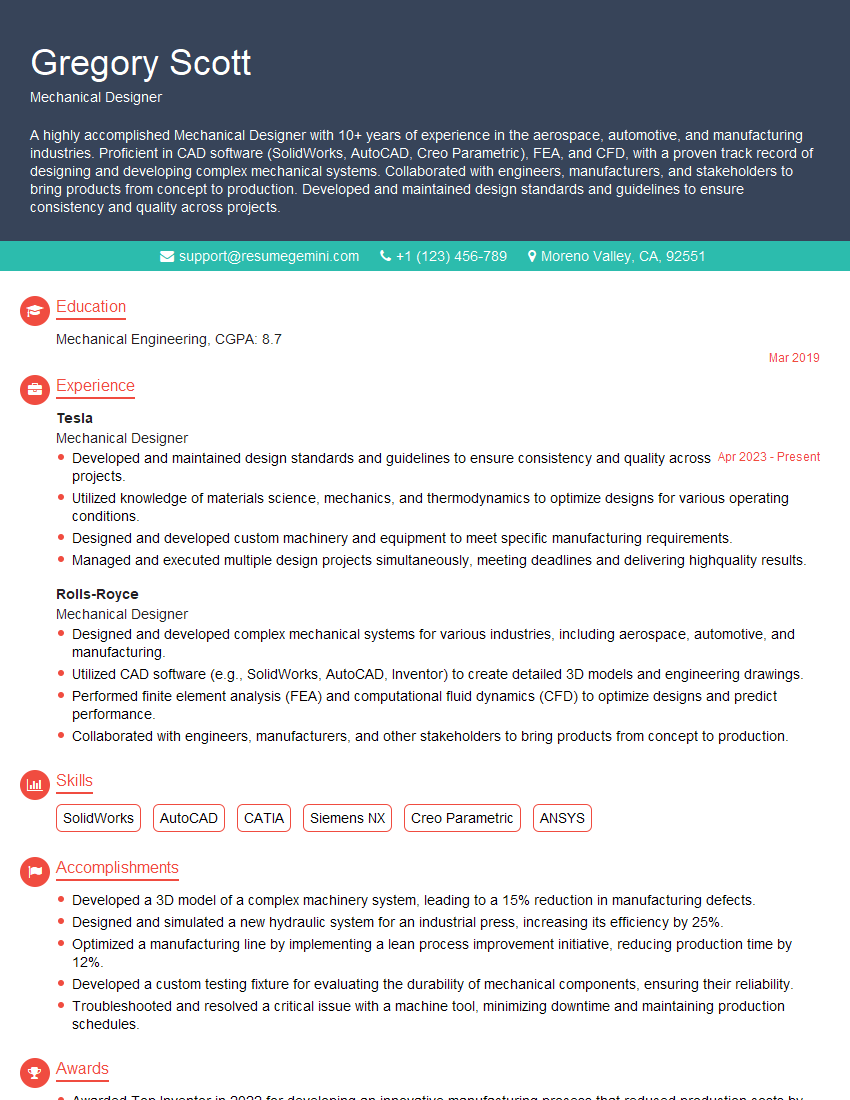

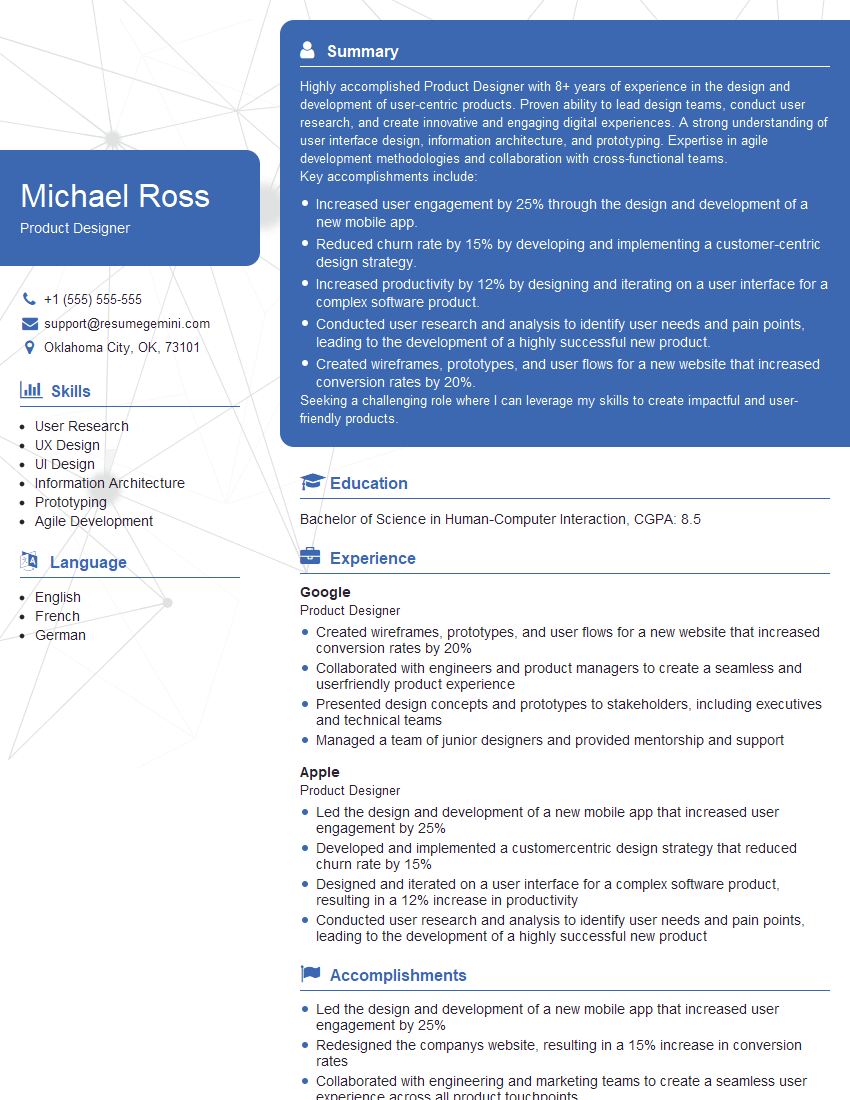

Mastering CAD/CAM software like AutoCAD, SolidWorks, and Inventor is crucial for career advancement in engineering and design. These skills are highly sought after, opening doors to exciting opportunities and higher earning potential. To maximize your job prospects, it’s essential to create an ATS-friendly resume that effectively highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to CAD/CAM software expertise (AutoCAD, SolidWorks, Inventor) are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO