Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential CAD Modeling (SolidWorks, Creo, NX) interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in CAD Modeling (SolidWorks, Creo, NX) Interview

Q 1. Explain the difference between wireframe, surface, and solid modeling.

CAD modeling offers three primary representations of a design: wireframe, surface, and solid. Think of them as progressively more complete and realistic representations of your product.

- Wireframe modeling: This is the most basic type. It uses lines and curves to define the edges of an object. Imagine a simple sketch of a cube – just lines showing its outline. It’s good for early conceptual design and quick visualization, but lacks information on the object’s volume or material properties. It’s like seeing the skeleton of a model.

- Surface modeling: Here, we add surfaces to the wireframe. It’s like adding skin to the skeleton. This technique is ideal for creating complex shapes with curved surfaces, often used in automotive or aerospace design. It’s good for visual representation, but lacks information on the object’s volume. Think of a car body – its curves and contours are perfectly represented by surface modeling.

- Solid modeling: This is the most complete representation. It defines the object’s volume, material properties, and geometry. This means you have a true digital 3D representation of the object, allowing for analysis of weight, mass properties, and realistic simulations. It’s like having a fully fleshed-out 3D model of your design, complete with all its details.

In practice, many designs utilize a combination of these techniques. For instance, you might start with a wireframe to define the basic shape, then move to surface modeling to create refined details, and finally use solid modeling for detailed analysis and manufacturing.

Q 2. Describe your experience with SolidWorks, Creo, or NX.

I have extensive experience with all three software packages – SolidWorks, Creo, and NX – accumulating over eight years in professional settings. My expertise spans the entire product development lifecycle, from conceptual design to detailed manufacturing drawings.

In SolidWorks, I’ve mastered features like part modeling, assembly design, and simulations, successfully completing several complex projects, including designing a robotic arm and optimizing its kinematics. I am particularly proficient in using SolidWorks Simulation for stress analysis and fatigue life prediction.

With Creo, I’ve focused on its powerful parametric modeling capabilities, streamlining the design process and facilitating efficient design changes. I have experience using Creo Simulate for thermal analysis and have used its collaboration tools to effectively manage team projects. One notable project involved designing a lightweight chassis for a high-performance vehicle, leveraging Creo’s advanced features for optimization.

My experience with NX includes extensive work with its advanced surfacing tools and its robust CAM capabilities. I’ve leveraged NX’s capabilities to design intricate molds and fixtures for manufacturing processes and have used its integrated simulation tools extensively. I successfully developed a complex injection molding tool using NX, reducing manufacturing costs by 15% by optimizing the mold design.

Across all three platforms, I’m proficient in creating detailed manufacturing drawings, generating bills of materials, and managing data using PDM systems. My skills ensure seamless integration throughout the entire product development cycle.

Q 3. How do you manage large assemblies in CAD software?

Managing large assemblies effectively is crucial for maintaining performance and collaboration. Here’s my approach:

- Component Simplification: Before assembling, I simplify individual components whenever possible. This involves using lightweight components, suppressing unnecessary features, or using representative geometry instead of highly detailed models. Think of it like using a simplified blueprint instead of a highly detailed architectural model for initial project review.

- Component Grouping: I utilize sub-assemblies to logically group related components. This reduces the complexity of the main assembly and improves the overall performance. It’s like organizing a large warehouse into smaller, manageable sections.

- Top-Down vs. Bottom-Up Assembly: I strategically choose the best approach for the specific project. Top-down assembly is better for design intent, while bottom-up is better for managing pre-existing components.

- Lightweight Components: Utilizing lightweight components is a significant way to improve assembly performance. Solidworks offers tools to do this efficiently.

- Large Assembly Management Tools: Each CAD software offers specific tools for managing large assemblies. In SolidWorks, this might involve using the ‘Component Patterns’ or ‘Assembly Constraints’ tools efficiently. In Creo, I leverage similar tools focusing on effective component organization and assembly simplification. NX offers similar functionalities optimized for complex assemblies.

- Design Reuse and Libraries: Creating and utilizing component libraries dramatically improves efficiency by reusing existing, verified components. This helps manage consistency across different projects and significantly reduces modelling time.

By implementing these strategies, I maintain a manageable and efficient workflow even when dealing with extremely complex assemblies.

Q 4. What are the different types of constraints used in CAD modeling?

Constraints are fundamental in CAD modeling; they define the relationships between components in an assembly or the features within a part. They ensure the design behaves as intended and prevent unexpected movements or deformations.

- Geometric Constraints: These define spatial relationships, such as:

Mate: Aligns faces, edges, or points.Distance: Specifies the distance between two elements.Angle: Defines the angle between two elements.Coincident: Makes two points or axes overlap.Concentric: Aligns the axes of two cylindrical features.

- Dimensional Constraints: These specify precise dimensions, such as length, width, diameter, etc. They’re crucial for ensuring the final product meets precise specifications.

- Coupled Constraints: These allow for linked movements or relationships between parts. An example is using a slider-crank mechanism where one part’s motion directly impacts another.

Properly defining constraints is paramount for creating functional and robust designs. Improperly defined constraints can lead to design errors and modeling difficulties. I always prioritize a well-defined constraint strategy to build a stable, predictable, and accurate model.

Q 5. How do you create and manage design configurations?

Design configurations allow for creating multiple variations of a single design, streamlining the process of managing different options or revisions. This is crucial for handling different manufacturing processes, customer requirements, or material options. Each CAD platform offers tools for this.

To create configurations, I typically define different parameters (dimensions, materials, features) and assign them to different configurations. For example, I might create configurations for a product with different materials – one in aluminum, another in steel – or with slightly varying dimensions to meet different customer needs.

Managing configurations involves clear naming conventions and comprehensive documentation. Each configuration needs to be clearly labeled, and changes between them must be meticulously documented to ensure traceability and easy comprehension by other team members. This helps with collaboration and revision management. I frequently use BOM (Bill of Materials) to manage different components for each configuration. This ensures all necessary parts are accounted for in each configuration.

Q 6. Explain your understanding of parametric modeling.

Parametric modeling is a powerful technique that allows defining a design using parameters rather than fixed values. These parameters can be dimensions, materials, or even design choices. Think of it as creating a flexible template or formula for your design.

The key advantage is that changing a single parameter automatically updates the entire model, maintaining consistency and relationships between features. For instance, if you change the diameter of a shaft in a parametric model, the related components (bearings, housings) automatically update to maintain their proper relationships. This drastically speeds up design iteration and error correction.

Using parametric modeling, I’ve streamlined design processes, reduced errors, and greatly improved design efficiency. For example, during the design of a complex gearbox, I used parametric models to easily experiment with different gear ratios and module sizes, significantly speeding up the design optimization phase.

Q 7. How do you handle design changes and revisions?

Handling design changes and revisions is a critical aspect of the design process. I use a structured approach that combines version control, clear communication, and efficient revision management within the CAD software.

- Version Control: Each revision is clearly documented, ideally using a formal revision control system integrated with the CAD software. This allows easy tracking of changes and reverts to previous versions if needed.

- Change Management System: I work within a defined change management process, typically using a formal system or established workflow. This ensures that all changes are reviewed, approved, and implemented systematically.

- Clear Communication: When modifications are necessary, I communicate the changes clearly and thoroughly to the relevant stakeholders. This includes detailed explanations of the changes and their impact on the design.

- Revisions in CAD Software: Each CAD package (SolidWorks, Creo, NX) offers built-in revision tools to manage design history efficiently. I use these tools to keep a meticulous record of changes, including dates, authors, and descriptions. This facilitates review and collaboration.

- Configuration Management: If dealing with variations of the design, configuration management is vital, ensuring that different versions and options are correctly managed and tracked.

By using a combination of these methods, I ensure a well-documented and controlled design process, minimizing errors and maximizing efficiency.

Q 8. What are your preferred methods for creating detailed drawings from 3D models?

Creating detailed drawings from 3D models is a crucial step in the product development lifecycle. My preferred methods leverage the drawing capabilities built into SolidWorks, Creo, and NX, ensuring consistency and accuracy. I start by defining drawing templates with pre-set standards for sheet sizes, title blocks, and annotation styles, promoting uniformity across projects. Then, I utilize the software’s automated features, such as automatic dimensioning and tolerancing, to generate precise measurements and annotations. This not only saves time but also reduces the risk of human error. For complex assemblies, I employ exploded views to clearly illustrate component relationships and create detailed assembly drawings. Finally, I carefully review the generated drawings, checking for completeness, clarity, and adherence to company standards before releasing them. For instance, while designing a complex gear assembly in Creo, I used automated section views to clearly show internal features and critical dimensions, enhancing understanding for manufacturing.

Q 9. How do you ensure dimensional accuracy in your models?

Dimensional accuracy is paramount in CAD modeling. I employ several strategies to maintain precision. Firstly, I meticulously define the base features and constraints of the model, ensuring a well-defined geometry from the outset. This includes using fully defined sketches and appropriate relations between features. Secondly, I consistently use parametric modeling techniques, allowing me to easily modify dimensions and observe their effects on the entire model. This dynamic approach is invaluable for design iterations and changes. Thirdly, I regularly verify my models using various checks such as model analysis for interference detection and mass properties calculations to confirm they align with design specifications. For example, during the design of a precision instrument housing in SolidWorks, I leveraged the software’s simulation tools to check for any potential interference between moving parts. I also used PMI (Product Manufacturing Information) to directly add dimensional tolerances on the model, ensuring manufacturing accuracy and communication. Finally, regular reference to design specifications and thorough documentation of any design changes completes the process.

Q 10. Explain your experience with CAD data management systems.

My experience with CAD data management systems encompasses both centralized and decentralized approaches. I’m proficient in using PDM (Product Data Management) systems like Windchill and Teamcenter. These systems allow for effective version control, change management, and collaboration among team members. I understand the importance of maintaining a well-organized digital vault of CAD models, drawings, and associated documents. This includes implementing robust naming conventions, revision control, and workflow processes. In one project, using Windchill, we were able to manage over 10,000 design files for a large-scale industrial project, ensuring data integrity and accessibility for all team members. This system enabled efficient review cycles and prevented the use of outdated models.

Q 11. Describe your experience with FEA (Finite Element Analysis) integration with CAD.

I have extensive experience integrating FEA (Finite Element Analysis) with CAD. I understand the process of exporting CAD models in suitable formats (like STEP or IGES) for import into FEA software such as ANSYS or Abaqus. I’m comfortable defining mesh parameters, applying boundary conditions, and interpreting the resulting stress, strain, and displacement data. This iterative process allows me to refine the design to optimize performance and reliability while avoiding potential failure points. In a past project involving the design of a high-pressure vessel, I used NX to design the vessel and ANSYS to perform FEA analysis, ensuring the design could withstand the pressure loads and maintain safety standards. This was critical to validating the design prior to manufacturing.

Q 12. How do you optimize CAD models for manufacturing processes?

Optimizing CAD models for manufacturing is critical for cost-effectiveness and efficiency. My approach involves considering several key aspects. First, I employ design for manufacturing (DFM) principles, ensuring the design is manufacturable using the chosen processes (e.g., machining, casting, injection molding). This includes careful consideration of tolerances, draft angles, and accessibility for tooling. Second, I strive to minimize the number of parts and simplify geometries wherever possible, reducing assembly time and cost. Thirdly, I use advanced CAD features like mold design tools in SolidWorks or moldflow analysis to simulate the manufacturing process and identify potential issues before production. In a project involving the design of an injection-molded plastic part, I simulated the filling process in Moldflow, identifying potential sink marks and adjusting the part design accordingly to enhance the quality of the finished product and minimize material waste.

Q 13. What are your methods for troubleshooting modeling errors?

Troubleshooting modeling errors requires a systematic approach. I begin by identifying the nature of the error – is it a geometric error, a topological error, or a constraint error? I then leverage the CAD software’s diagnostic tools, such as error checking functions and debugging aids. If the error is geometric, I meticulously examine the affected features, using visualization tools to identify discrepancies. For topological errors, I typically rebuild the problematic areas of the model or simplify the geometry. Constraint errors are often addressed by carefully reviewing the defined relations and constraints between features, ensuring they are consistent and correctly defined. If the error persists, I often revert to previous stable versions of the model, analyze the modifications made since the last stable state, and pinpoint the source of the error. If necessary, I contact other experienced CAD modelers for collaboration and input, leveraging collective expertise to solve complex issues.

Q 14. Explain your understanding of different file formats used in CAD (e.g., STEP, IGES, STL).

Understanding different file formats is crucial for CAD data exchange. STEP (Standard for the Exchange of Product data) is a widely used neutral format for transferring 3D CAD data between different systems. It preserves much of the model’s design intent. IGES (Initial Graphics Exchange Specification) is another neutral format, but it’s generally less efficient than STEP, potentially losing some detail during translation. STL (Stereolithography) is a widely used format for 3D printing and rapid prototyping. It represents the model as a mesh of triangles, suitable for manufacturing but losing detailed design intent. I use these formats regularly for collaboration with external vendors or to transfer models to different software packages. For example, I often export models as STEP files when collaborating with manufacturing partners to ensure design fidelity is maintained across different platforms. Similarly, when preparing models for 3D printing, I export them as STL files optimized for the specific printer’s capabilities.

Q 15. Describe your experience with rendering and visualization techniques.

Rendering and visualization are crucial for communicating design intent and evaluating aesthetics. My experience encompasses a wide range of techniques across SolidWorks, Creo, and NX. I’m proficient in using photorealistic renderers like PhotoView 360 (SolidWorks), KeyShot, and the built-in rendering capabilities of Creo and NX. I understand the importance of lighting, materials, and camera angles in creating compelling visuals. For instance, while designing a complex automotive part in Creo, I utilized advanced rendering techniques to showcase the intricate details and surface finish, allowing the client to visualize the final product accurately before prototyping. Beyond photorealism, I also leverage animation and walkthroughs to demonstrate functionality and assembly sequences, significantly enhancing stakeholder understanding and approvals.

In addition to software-specific renderers, I’m familiar with exporting models in various formats (like STEP, IGES, STL) for use with external rendering packages offering more advanced features. This flexibility allows me to adapt to different project requirements and client preferences. I consider the choice of rendering techniques a critical aspect of design communication, ensuring clarity and impact for the intended audience.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you utilize design templates and standards in your workflow?

Design templates and standards are fundamental for maintaining consistency, efficiency, and data integrity across projects. My workflow heavily relies on utilizing pre-defined templates that incorporate company-specific standards for sheet sizes, title blocks, layer configurations, and material properties. For example, in SolidWorks, I regularly use custom templates that already include predefined views, annotations, and BOM structures, saving significant time in setting up new projects. In Creo, I leverage the model template functionality to enforce specific design rules and constraints right from the model creation stage.

These templates not only streamline the initial stages of design but also contribute to easier collaboration and data management. Adhering to company standards ensures that all team members work from a common base, minimizing conflicts and misunderstandings. Beyond pre-defined templates, I actively participate in defining and updating standards, ensuring they remain current and effective. This proactive approach helps in standardizing processes and boosting overall design quality.

Q 17. How proficient are you in creating and using custom macros or scripts?

I’m highly proficient in creating and utilizing custom macros and scripts to automate repetitive tasks and enhance productivity. My expertise spans different platforms, including VBA for SolidWorks, and Python for Creo and NX. For example, I developed a VBA macro in SolidWorks to automate the creation of detailed assembly drawings, significantly reducing the manual effort involved in creating standard views, dimensions, and annotations. The macro takes input parameters such as sheet size and scale, making it easily adaptable to various projects.

In NX, I’ve employed Python scripting to streamline complex modeling operations, including the automation of feature creation and model modification based on specific design parameters. These scripts not only save considerable time but also minimize human error associated with manual repetition. Understanding the underlying programming logic involved in these platforms allows me to create customized solutions tailored to specific project needs, increasing efficiency and accuracy in my workflow. I see this as a critical skill in tackling complex designs effectively and consistently.

Q 18. Explain your experience working with different units and systems (e.g., metric, imperial).

Working with different unit systems (metric and imperial) is a commonplace requirement in engineering. I’m adept at seamlessly switching between them within each CAD package. SolidWorks, Creo, and NX all have robust mechanisms for defining and managing units. I understand the importance of selecting the correct units at the project outset and meticulously checking for inconsistencies throughout the design process to avoid errors. I often work with projects requiring both systems, for example, designing a component with metric fasteners integrated into an imperial chassis. Precise unit management is crucial to avoid costly mistakes during manufacturing.

I’m particularly careful when importing models from external sources, verifying their unit systems before incorporating them into the current project to prevent scaling issues. This careful attention to detail is crucial for ensuring accuracy and compatibility across different design phases and collaborators. I routinely employ unit checks within the CAD software and perform manual verification wherever necessary to ensure consistent unit usage across all aspects of the design.

Q 19. How do you handle complex geometric features in your models?

Handling complex geometric features requires a strong understanding of CAD fundamentals and an ability to utilize advanced modeling techniques. I’m adept at employing various techniques like solid modeling, surface modeling, and wireframe modeling depending on the specific requirements of the geometry. For example, to create a complex free-form surface in a consumer product design using SolidWorks, I might leverage techniques like sweep features, lofting, and fill features combined with precise curve manipulation to achieve the desired shape and smoothness. This often involves iterative refinement and careful consideration of the manufacturing process.

In Creo, I utilize advanced surfacing tools to address free-form designs, using techniques such as curve network creation and surface patching. When dealing with complex assemblies, I apply strategies like top-down or bottom-up modeling to manage model complexity, simplifying design creation and modification. Proficient use of constraints, relations, and design tables allows for maintaining design intent and automating updates across the entire assembly. Regularly employing techniques like feature simplification, model cleanup, and utilizing lightweight components ensures optimal performance and maintainability of even the most intricate models.

Q 20. Describe your experience with collaborative design tools.

Collaborative design is essential in modern engineering. My experience includes using various collaborative tools integrated within the CAD software, such as SolidWorks PDM, Windchill (for Creo and NX), and cloud-based solutions like SharePoint. These tools facilitate seamless data management, version control, and concurrent engineering workflows. For example, while working on a multidisciplinary project involving mechanical, electrical, and software teams, utilizing Windchill ensured consistent data access, tracked revisions, and minimized version conflicts. This was essential in maintaining design integrity and keeping all team members on the same page.

Beyond dedicated PDM systems, I’ve utilized cloud storage and collaborative platforms to share and review designs with clients and external stakeholders. These tools enable real-time feedback and quick iteration cycles, significantly improving project efficiency and stakeholder satisfaction. My understanding of these tools and processes allows for smooth integration within collaborative environments, ensuring projects stay on schedule and maintain the highest standards of quality.

Q 21. What is your experience with tolerance analysis and GD&T (Geometric Dimensioning and Tolerancing)?

Tolerance analysis and GD&T (Geometric Dimensioning and Tolerancing) are critical for ensuring manufacturability and functionality. I’m experienced in applying GD&T principles to create robust and reliable designs. I’m proficient in using the GD&T tools within SolidWorks, Creo, and NX to define tolerances, create annotations, and perform tolerance stack-up analysis. Understanding GD&T helps to translate design intent into clear specifications for manufacturing, ensuring that parts fit and function as intended. For instance, designing a precise fitting mechanism for an aerospace component requires careful consideration of tolerances and GD&T to prevent interference and ensure proper functionality under varying conditions. This ensures that manufacturing tolerances align with design requirements.

I’m also familiar with using specialized software for more advanced tolerance analysis, such as CETOL 6σ, which allows for simulating manufacturing variations and predicting potential assembly issues. This proactive approach enables design optimization and cost reduction by mitigating potential manufacturing and assembly problems before they arise. This proactive approach is essential for successful product development and efficient manufacturing processes.

Q 22. How do you perform design reviews and receive feedback?

Design reviews are crucial for catching errors and improving designs before they reach manufacturing. My process typically involves a multi-stage approach. First, I conduct a self-review, meticulously checking for dimensional accuracy, interference issues, and manufacturability concerns. Then, I schedule formal reviews with colleagues and stakeholders, utilizing tools like SolidWorks eDrawings or Creo View to share the model and facilitate collaborative markup. These sessions involve clear communication of design intent, actively listening to feedback, and documenting all changes and decisions. I encourage constructive criticism and actively participate in discussions, weighing different perspectives to optimize the design. For example, during a review of a complex assembly, a colleague pointed out a potential stress concentration in a critical component, leading to a redesign that significantly improved its durability. Feedback is incorporated using a change management system to track revisions and maintain design integrity.

Q 23. Explain your understanding of different modeling techniques (e.g., subtractive, additive).

CAD modeling employs various techniques, but two fundamental approaches are subtractive and additive modeling. Subtractive modeling, like carving a sculpture, starts with a solid block (stock) and removes material to achieve the desired shape. Think of machining a part from a metal block using a CNC mill. This is commonly used in SolidWorks or Creo. Additive modeling, on the other hand, builds the part layer by layer, like 3D printing. This method allows for complex geometries that would be difficult or impossible with subtractive techniques. Software like NX often incorporates this approach for complex free-form surfaces. Both methods have their strengths and weaknesses: subtractive is efficient for simple shapes and allows for high precision, while additive excels in creating intricate and complex geometries. The choice depends heavily on the part’s complexity, material properties, and manufacturing capabilities.

Q 24. What are some common mistakes to avoid when creating CAD models?

Common mistakes in CAD modeling often stem from overlooking fundamental principles. One frequent error is neglecting to properly constrain parts during assembly. This can lead to unpredictable movement and inaccurate simulations. Another common pitfall is over-constraining, resulting in model instability and difficulty in making modifications. Failing to check for interference between parts is another significant issue, potentially leading to manufacturing problems. Poorly defined datums and reference geometry can create ambiguity and inconsistencies. Finally, insufficient attention to detail in creating accurate and complete models can result in errors in downstream processes such as manufacturing and analysis. Regularly employing model checks and utilizing design review processes helps mitigate these risks. For instance, I once encountered a design where a small interference was missed, resulting in a costly rework during prototyping.

Q 25. How do you handle conflicting design requirements?

Conflicting design requirements are inevitable. My approach involves a structured problem-solving process. First, I clearly define and document all requirements, prioritizing them based on criticality and feasibility. Then, I explore potential trade-offs and compromises, using techniques like Pugh matrices to evaluate alternative solutions. This often involves iterative design and simulation to assess the impact of each compromise. Open communication with stakeholders is key – clearly explaining the implications of different choices and collaboratively deciding on the optimal solution. In one instance, a conflict arose between minimizing weight and maximizing strength. Through finite element analysis (FEA), we determined an optimal design that met both requirements sufficiently.

Q 26. Describe your experience with data migration and file conversion between different CAD systems.

Data migration between CAD systems is a common task. My experience includes using various methods, including direct translators (built into the CAD software), neutral file formats like STEP and IGES, and dedicated CAD data migration tools. The choice depends on the complexity of the model and the desired level of fidelity. Direct translators are often the quickest but might lose some data. Neutral formats are more portable but can also lead to minor geometry discrepancies. Specialized tools offer better control and accuracy but can be more expensive. During migration, I always validate the transferred data by comparing key dimensions and features against the original model. I encountered a situation where transferring a complex assembly from SolidWorks to NX required using a dedicated migration tool to maintain the integrity of the design features and associated data.

Q 27. What are your strategies for managing large datasets in CAD?

Managing large CAD datasets necessitates a well-defined strategy. This begins with employing efficient modeling techniques, avoiding unnecessary complexity and utilizing lightweight components where appropriate. Regularly purging unused data and simplifying models reduces file size and improves performance. Using data management software, such as SolidWorks PDM or Windchill, is essential for version control, data organization, and access control. Employing data compression techniques can also contribute to efficient data storage. Furthermore, a well-structured folder system and clear naming conventions aid in organization and retrieval. I often employ techniques like creating smaller sub-assemblies rather than one monolithic assembly to facilitate data management and improve workflow.

Q 28. How familiar are you with simulation and analysis tools within your CAD software?

I have extensive experience using simulation and analysis tools integrated within various CAD packages. In SolidWorks, I’m proficient with Simulation for stress analysis, thermal analysis, and motion studies. Within Creo, I utilize Simulate for similar tasks. NX offers advanced simulation capabilities including finite element analysis (FEA) and computational fluid dynamics (CFD), which I’ve used extensively for complex analyses. Understanding the limitations of each tool and choosing the appropriate analysis type is crucial. For instance, when designing a pressure vessel, I’d utilize FEA in NX to ensure the design can withstand the required pressure without failure. Post-processing and interpretation of simulation results are equally critical to deriving meaningful conclusions for design improvement.

Key Topics to Learn for CAD Modeling (SolidWorks, Creo, NX) Interview

- Part Modeling Fundamentals: Understanding sketching, feature creation (extrusions, revolves, sweeps), and part manipulation. Practice creating complex parts from scratch.

- Assembly Modeling Techniques: Mastering constraints, mates, and configurations. Be prepared to discuss strategies for efficient assembly building and management of large assemblies.

- Drawing Creation and Dimensioning: Proficiency in creating detailed 2D drawings from 3D models, including proper dimensioning and tolerancing techniques. Understand different drafting standards (ANSI, ISO).

- Advanced Modeling Techniques: Explore surface modeling, sheet metal design, and weldments. Familiarize yourself with the specific capabilities of each software (SolidWorks, Creo, NX) in these areas.

- Simulation and Analysis: Demonstrate understanding of basic simulation principles (e.g., stress analysis, motion studies) and how they integrate with the CAD workflow. Knowing the limitations of each simulation type is crucial.

- Data Management and Collaboration: Discuss best practices for file management, version control, and data exchange with other software and team members. Understanding PDM systems is a plus.

- Software-Specific Knowledge: Deepen your expertise in the specific features and functionalities of the CAD software you’re most proficient in (SolidWorks, Creo, or NX). Be ready to discuss your preferred workflows and techniques.

- Problem-Solving and Troubleshooting: Showcase your ability to identify and resolve common modeling challenges. Be prepared to discuss examples where you overcame technical hurdles during a project.

Next Steps

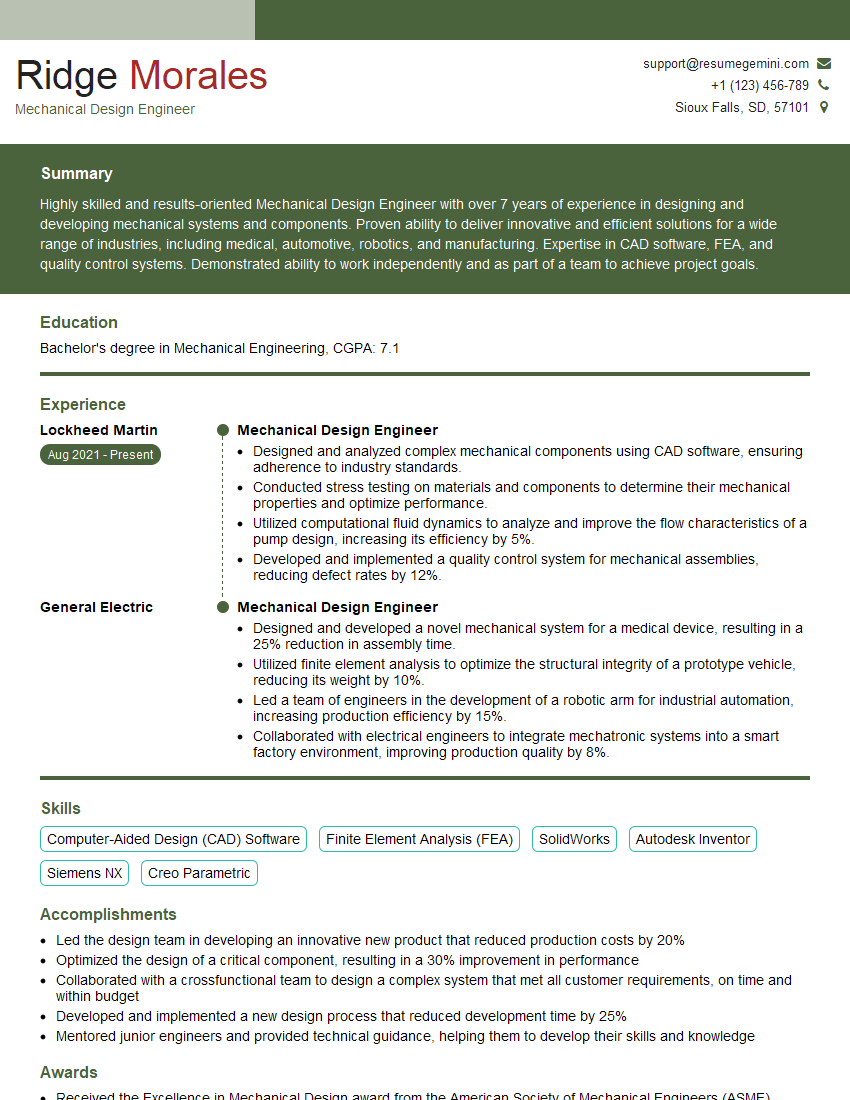

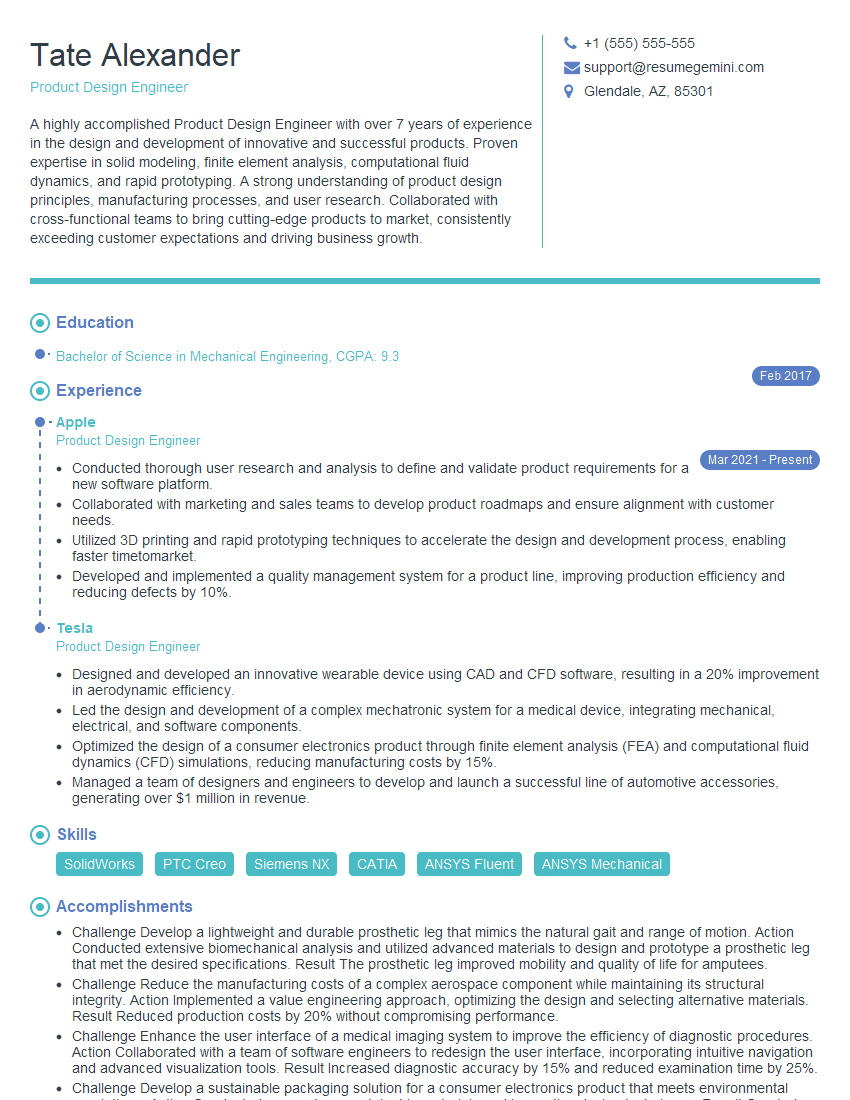

Mastering CAD Modeling (SolidWorks, Creo, NX) is essential for a successful and rewarding career in engineering and design. It opens doors to a wide range of exciting opportunities and allows you to contribute to innovative projects. To maximize your job prospects, crafting a strong, ATS-friendly resume is key. This is where ResumeGemini can help. ResumeGemini provides a powerful platform to build a professional, impactful resume tailored to highlight your CAD modeling skills and experience. Examples of resumes specifically designed for CAD Modeling (SolidWorks, Creo, NX) professionals are available to inspire and guide you. Invest the time to build a standout resume – it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO