Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Calibration and Instrument Verification interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Calibration and Instrument Verification Interview

Q 1. Explain the difference between calibration and verification.

Calibration and verification are both crucial for ensuring the accuracy and reliability of measuring instruments, but they differ in their scope and purpose. Calibration is the process of adjusting an instrument to match a known standard, effectively correcting its inaccuracies. Think of it like adjusting a watch to match an atomic clock—you’re actively changing the watch to improve its accuracy. Verification, on the other hand, is the process of confirming that an instrument is performing within its specified tolerances. It doesn’t necessarily involve adjustment; instead, it confirms that the instrument is ‘fit for purpose’. Imagine testing a thermometer against a known temperature – if it’s within the acceptable range, it’s verified, even if it’s not perfectly accurate. In short: calibration corrects, verification confirms.

For example, a laboratory balance might be calibrated using certified weights to ensure it accurately measures mass. Following the calibration, a verification check might involve weighing a known standard weight several times to ensure that the balance readings consistently fall within its specified tolerance.

Q 2. What are the different types of calibration standards?

Calibration standards are crucial for ensuring the accuracy and traceability of measurements. They fall into several categories:

- Primary Standards: These are the most accurate standards, often maintained by national metrology institutes (NMIs) like NIST (National Institute of Standards and Technology) or equivalent organizations. They define the base units of measurement and are usually not directly used for routine calibration.

- Secondary Standards: These are calibrated against primary standards and are used to calibrate working standards. They offer a higher level of accuracy than working standards.

- Working Standards: These are used for everyday calibration of measuring instruments in laboratories or industrial settings. They are calibrated regularly against secondary or, in some cases, primary standards.

- Reference Standards: These are standards used to check the accuracy of other standards or to support specific calibration procedures. They may not always meet the same strict traceability requirements as the other categories.

The choice of standard depends on the application and the required level of accuracy. A high-precision analytical balance might require calibration against a secondary standard, while a simple thermometer could use a working standard.

Q 3. Describe your experience with various calibration methods (e.g., gravimetric, volumetric).

Throughout my career, I’ve had extensive experience with various calibration methods. Gravimetric calibration, for example, involves using mass standards to calibrate instruments like analytical balances. I’ve used this extensively in pharmaceutical quality control, ensuring precise measurement of active ingredients. The process includes meticulous cleaning, precise weighing, and careful record-keeping to maintain traceability and minimize errors. Volumetric calibration, on the other hand, is used to calibrate instruments that measure volume, such as pipettes, burettes, and volumetric flasks. I’ve utilized this method in environmental labs, calibrating instruments used in water quality analysis. This often involves measuring and verifying the dispensed volume using high-precision balances and careful temperature control. Beyond these, I’m also experienced in electrical calibration (using calibrated voltage and current sources), temperature calibration (using temperature baths and fixed-point cells), and pressure calibration (using deadweight testers).

In each case, I strictly adhere to documented procedures, utilize appropriate software and equipment, and maintain comprehensive records for auditing and traceability.

Q 4. How do you determine the appropriate calibration interval for an instrument?

Determining the appropriate calibration interval is crucial for maintaining instrument accuracy and reliability, and involves careful consideration of several factors:

- Instrument Type and Stability: A stable instrument might require less frequent calibration than one prone to drift or degradation.

- Usage Frequency: Instruments used heavily are more likely to require more frequent calibration than those used infrequently.

- Environmental Conditions: Harsh environments (extreme temperatures, vibration, humidity) can affect instrument stability and shorten the calibration interval.

- Measurement Uncertainty Requirements: Higher accuracy demands more frequent calibration.

- Manufacturer’s Recommendations: Manufacturer guidelines often provide initial recommendations, but these need to be reviewed in light of operational experience.

- Regulatory Requirements: Some industries have regulatory requirements governing calibration intervals.

A risk assessment is a vital part of establishing the calibration frequency. By evaluating the potential impact of an instrument’s inaccuracy, we can determine the acceptable risk and tailor the calibration interval accordingly.

Q 5. What are the key elements of a calibration certificate?

A valid calibration certificate is a critical document, serving as proof of the instrument’s accuracy and reliability. Key elements include:

- Unique Identification of the Instrument: Serial number, model number, and other identifying marks.

- Calibration Date and Time: Precise record of when the calibration was performed.

- Calibration Methods and Procedures: Description of the methods used and standards applied.

- Calibration Results: Detailed measurements and comparisons to the standards used.

- Uncertainty of Measurement: Quantification of the uncertainty associated with the calibration results. This is crucial for understanding the reliability of the reported values.

- Calibration Standards Used: Identification and traceability of the standards used in the calibration process.

- Calibration Due Date: Date indicating when the next calibration is required.

- Calibration Laboratory Accreditation: Indication that the laboratory is accredited according to a recognized standard (e.g., ISO 17025).

- Signature and Credentials of the Calibrator: Confirmation of the technician’s competence and responsibility.

A complete and well-documented certificate provides complete assurance of the instrument’s reliability and allows for easy verification of its accuracy.

Q 6. Explain the concept of traceability in calibration.

Traceability in calibration means establishing an unbroken chain of comparisons to national or international standards. It ensures that the calibration results are reliable and can be compared to other measurements worldwide. This chain starts with the primary standards maintained by NMIs, which are then used to calibrate secondary standards, which in turn are used for working standards, and finally, for calibrating instruments. This unbroken chain allows anyone to confidently understand the accuracy of a measurement by tracing it back to its fundamental definition.

Imagine a chain of custody in a crime investigation. Traceability in calibration works similarly; we need to know the source of each link in the chain to have confidence that the final calibration is valid. Lack of traceability weakens the reliability of calibration results and casts doubt on the accuracy of measurements.

Q 7. How do you handle out-of-tolerance instruments?

Handling out-of-tolerance instruments requires a systematic approach to ensure accuracy and safety:

- Immediate Removal from Service: Out-of-tolerance instruments should be immediately removed from service to prevent the use of inaccurate measurements that could affect quality, safety, or regulatory compliance.

- Investigation of the Cause: A thorough investigation is needed to identify the reason for the instrument’s failure. This could involve checking for physical damage, environmental effects, or improper usage.

- Repair or Replacement: Depending on the cause and the cost-effectiveness, the instrument may be repaired or replaced. Calibration records provide vital insights for troubleshooting.

- Re-calibration: After repair or replacement, the instrument must be recalibrated to verify its accuracy and restore it to service.

- Documentation: All actions taken, including the findings of the investigation, repair details, and re-calibration results, must be meticulously documented. Non-conformance reports are often necessary.

- Impact Assessment: If the instrument was used while out-of-tolerance, an impact assessment should be performed to evaluate any potential consequences and determine corrective actions.

The priority is to prevent the use of faulty measurements and take corrective actions to maintain the quality and reliability of results.

Q 8. What is the significance of uncertainty in calibration?

Uncertainty in calibration is a crucial concept that quantifies the doubt associated with a measurement result. It essentially tells us how much confidence we can have in the reported value. A smaller uncertainty indicates higher confidence, meaning the true value is likely closer to the reported value. Imagine trying to hit the bullseye on a dartboard; a low uncertainty means your darts consistently cluster tightly around the center, while a high uncertainty implies they’re scattered widely.

In calibration, uncertainty is expressed as a range around the measured value. For example, a calibrated weight might be reported as 100g ± 0.1g. This means the true mass is likely between 99.9g and 100.1g. Understanding uncertainty is critical because it directly impacts the reliability of measurements used in various applications, from manufacturing processes to scientific research. Without considering uncertainty, we risk making faulty conclusions based on potentially inaccurate data.

Q 9. Describe your experience with different types of calibration equipment.

My experience encompasses a wide range of calibration equipment, including:

- Dimensional Measurement Equipment: This includes micrometers, calipers, height gauges, and coordinate measuring machines (CMMs). I’ve worked on calibrating these instruments using traceable standards and ensuring their accuracy within specified tolerances. For example, I’ve calibrated CMMs using artifact standards and laser interferometry for the most demanding precision applications.

- Mass and Weight Equipment: I have extensive experience calibrating analytical balances, precision balances, and even large floor scales, using certified weights and implementing appropriate procedures to minimize environmental influences like air buoyancy.

- Temperature Measurement Equipment: This covers various instruments, such as thermocouples, RTDs (Resistance Temperature Detectors), and thermometers, calibrated using temperature baths and reference standards. I’m proficient in performing both fixed-point and interpolation calibrations.

- Pressure Measurement Equipment: I’ve calibrated pressure gauges and transducers using deadweight testers and other precision pressure sources, accounting for factors like temperature and altitude.

- Electrical Measurement Equipment: My experience includes calibrating multimeters, oscilloscopes, and signal generators using precision standards and specialized calibration software.

In each instance, I meticulously follow established procedures, maintain detailed records, and analyze results to ensure traceability and compliance with relevant standards.

Q 10. Explain your understanding of ISO 17025.

ISO 17025 is an internationally recognized standard that outlines the general requirements for the competence of testing and calibration laboratories. It establishes criteria for ensuring the quality and reliability of laboratory results, thus building trust and confidence in their findings. Think of it as a rigorous quality manual for labs. Compliance means demonstrating competence in all aspects of laboratory operations.

My understanding of ISO 17025 encompasses:

- Management System Requirements: This includes aspects like organizational structure, quality policy, and resource management.

- Technical Requirements: This covers method validation, calibration procedures, measurement traceability, and the handling of nonconformities.

- Personnel Competence: It mandates that laboratory personnel have the appropriate qualifications, training, and experience to perform their tasks effectively.

- Equipment Management: Proper calibration and maintenance of all testing and calibration equipment is crucial for compliance.

- Quality Assurance: Regular internal audits and quality control measures are essential for continuous improvement and compliance.

In practice, ISO 17025 helps ensure that calibration results are accurate, reliable, and traceable to national or international standards, enhancing the credibility and trustworthiness of the laboratory’s services.

Q 11. How do you manage calibration records and data?

Managing calibration records and data is critical for maintaining traceability and demonstrating compliance. We use a robust, computerized system that includes:

- Calibration Management Software: This software tracks calibration schedules, instrument information, calibration results, and certificates. It sends automated alerts for upcoming calibrations, preventing equipment from becoming overdue.

- Electronic Data Storage: All calibration records, including certificates and raw data, are stored electronically in a secure, auditable system that complies with data integrity regulations, making retrieval and analysis seamless.

- Version Control: The system incorporates version control to manage revisions and prevent unintentional overwriting of data. Every change is tracked and documented.

- Data Backup and Recovery: Regular data backups and disaster recovery plans are in place to protect against data loss.

- Access Control: Access to the system is restricted based on user roles, ensuring data security and integrity.

This systematic approach ensures that our calibration records are complete, accurate, readily available, and meet regulatory requirements. A well-maintained system is essential for audits and demonstrating compliance with ISO 17025 or other relevant standards.

Q 12. What are some common sources of error in calibration?

Common sources of error in calibration can be broadly categorized as:

- Environmental Factors: Temperature, humidity, and pressure fluctuations can significantly affect measurement results. For example, a slight change in temperature can affect the reading of a resistance thermometer.

- Instrument Drift: Instruments can exhibit drift over time, leading to inaccuracies. Regular calibration helps to detect and correct this drift.

- Operator Error: Incorrect reading, improper handling, or incorrect application of procedures can introduce errors. Proper training and standardized procedures are crucial to mitigate this.

- Calibration Standard Errors: Calibration standards themselves may have inherent uncertainties. Traceability to national standards minimizes this.

- Equipment Wear and Tear: Physical wear and tear of equipment, such as damage to components, can lead to inaccurate readings.

- Improper Maintenance: Lack of proper maintenance or cleaning can contribute to measurement errors.

Addressing these sources of error involves careful planning, meticulous execution, and regular maintenance and calibration checks of equipment and standards.

Q 13. Describe your experience with statistical process control (SPC) in calibration.

Statistical Process Control (SPC) plays a vital role in ensuring the consistency and reliability of our calibration processes. We utilize control charts, such as X-bar and R charts, to monitor calibration data over time and identify potential trends or shifts that may indicate issues with our calibration processes or equipment. For example, we might monitor the results of calibrating a specific type of instrument over multiple calibration cycles. If the data points consistently fall outside pre-defined control limits, it signals that an investigation is needed.

By employing SPC, we can:

- Early Detection of Problems: Identify potential problems early, before they affect the accuracy of our calibration results.

- Improved Process Control: Make adjustments to our processes to minimize variation and improve accuracy.

- Reduced Waste: Avoid unnecessary recalibrations by identifying and addressing problems promptly.

- Data-Driven Decision Making: Make data-driven decisions regarding instrument maintenance, calibration frequency, and process improvement.

SPC is an essential tool in maintaining the quality and consistency of our calibration operations, ensuring that our results are reliable and trustworthy.

Q 14. How do you ensure the accuracy and integrity of calibration results?

Ensuring the accuracy and integrity of calibration results is paramount. We achieve this through a multi-layered approach:

- Traceability to National Standards: All our calibration standards are traceable to national or international standards, ensuring that our measurements are comparable and reliable.

- Regular Calibration of Standards: Our calibration standards themselves are calibrated at regular intervals by accredited laboratories to maintain their accuracy and validity.

- Validated Calibration Procedures: We use validated calibration procedures that are documented, reviewed, and approved to minimize errors and ensure consistency.

- Environmental Control: We maintain controlled environments whenever necessary to minimize the impact of environmental factors on our measurements.

- Qualified Personnel: Our personnel undergo thorough training and competency assessment to ensure they can perform calibrations accurately and efficiently.

- Regular Audits and Reviews: Internal audits and regular reviews of our calibration procedures and records help to identify areas for improvement and maintain compliance with relevant standards.

- Data Integrity Management: Rigorous data management procedures, including version control and electronic record keeping, ensure the integrity and authenticity of our results.

This comprehensive approach provides a high level of confidence in the accuracy and reliability of our calibration results, ensuring that our clients receive high-quality, trustworthy data they can confidently rely upon.

Q 15. Explain your experience with different calibration software.

My experience with calibration software spans a variety of platforms, from simple spreadsheet-based systems to sophisticated, purpose-built software packages. I’m proficient in using software that manages calibration schedules, tracks instrument history, generates reports compliant with industry standards (like ISO 17025), and performs statistical analysis on calibration data. For example, I’ve extensively used Fluke Calibration’s MET/CAL software for managing and analyzing data from various instruments like multimeters and thermometers. This software allows for automated data acquisition, efficient report generation, and robust data management, streamlining the entire calibration process. I’ve also worked with simpler systems, utilizing spreadsheets to track calibrations for less complex instruments and developing custom macros to automate repetitive tasks. My experience extends to cloud-based calibration management systems, offering benefits such as enhanced collaboration and remote access to calibration data. Choosing the right software always depends on the complexity of the instrumentation, the size of the operation and regulatory requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot instrument malfunctions related to calibration?

Troubleshooting instrument malfunctions after calibration requires a systematic approach. I begin by reviewing the calibration report to identify any anomalies or trends. For instance, if a pressure gauge consistently reads low after calibration, the problem might be a faulty sensor, a leak in the system, or an incorrect zero adjustment. Next, I visually inspect the instrument for any signs of physical damage, such as cracks or loose connections. I then check the instrument’s power source and any external connections. If the problem persists, I’ll perform more specific tests, depending on the instrument type. For example, with a thermometer, I might compare readings against a known standard using a different method (e.g., a reference thermometer). With a pressure gauge, I’d test for leaks using a specialized testing equipment. Documentation throughout this process is critical, meticulously recording each step and observation, including any corrective actions taken. A failure to resolve the issue may necessitate sending the instrument for repair or replacement.

Q 17. Describe your experience with different types of instruments (e.g., pressure gauges, thermometers).

My experience encompasses a broad range of instruments, including pressure gauges (both analog and digital), thermometers (various types: thermocouples, RTDs, liquid-in-glass), multimeters, balances, and various other precision measuring devices. I’m familiar with the principles of operation, calibration methods, and potential sources of error for each instrument type. For instance, I’ve calibrated pressure gauges using deadweight testers, ensuring accuracy by verifying the gauge’s reading against a known pressure standard. Similarly, I’ve calibrated thermometers using dry-block calibrators, reference thermometers, or comparison baths, depending on the temperature range and accuracy requirements. My work also involves understanding the specific uncertainties associated with different calibration methods and instrument types, which is critical for accurate reporting.

Q 18. What are the legal and regulatory requirements related to calibration in your field?

Legal and regulatory requirements for calibration vary depending on the industry and the specific instruments involved. In many sectors, compliance with ISO 17025 (General requirements for the competence of testing and calibration laboratories) is essential. This standard dictates requirements for quality management systems, personnel competence, equipment calibration, and traceability to national standards. Furthermore, specific industries may have additional regulatory requirements. For example, in the pharmaceutical industry, calibration procedures must adhere to Good Manufacturing Practices (GMP). In safety-critical industries like aerospace or nuclear power, calibration procedures and documentation are often subject to even stricter regulations. My work consistently prioritizes maintaining accurate records, ensuring traceability, and adhering to all applicable legal and regulatory guidelines to guarantee the validity and reliability of calibration results.

Q 19. How do you maintain a clean and organized calibration laboratory?

Maintaining a clean and organized calibration laboratory is crucial for accurate and reliable results. This involves establishing a system for managing instrument storage, ensuring a climate-controlled environment (temperature and humidity), and implementing a robust cleaning protocol. Instruments are organized based on type and calibration schedule, allowing for quick and easy access. Work surfaces are kept clean and free of debris. We utilize designated areas for specific tasks, such as cleaning and calibration, to minimize cross-contamination. A regular cleaning schedule is implemented, including cleaning equipment and work surfaces using appropriate cleaning agents. Proper waste disposal procedures are followed, and all calibration equipment is stored according to manufacturer recommendations. This organized system ensures efficiency, minimizes errors, and helps maintain the integrity of the calibration process.

Q 20. Describe your experience with calibration procedures and protocols.

My experience with calibration procedures and protocols is extensive. I’m well-versed in developing and implementing calibration procedures that align with industry best practices and regulatory requirements. These procedures are documented and readily accessible to all personnel involved in the calibration process. A typical calibration procedure includes a detailed description of the equipment, the calibration method, the required standards, the acceptance criteria, and the reporting requirements. The procedures also incorporate quality control measures to ensure accuracy and traceability. For example, a calibration procedure for a pressure gauge would outline the use of a deadweight tester, the specific steps for applying pressure, recording readings, and calculating uncertainties. Regular reviews of these procedures are conducted to ensure their continued relevance and accuracy. This ensures consistency and quality in our calibration services.

Q 21. How do you handle discrepancies in calibration results?

Discrepancies in calibration results require a thorough investigation. The first step is to verify the accuracy of the calibration process itself, checking the calibration standards, the equipment used, and the procedures followed. Potential sources of error are identified and evaluated. For example, a discrepancy might be due to a faulty calibration standard, a problem with the equipment being calibrated, or a mistake in the calibration procedure. If the error is identified within the calibration process, corrective actions are taken to prevent future occurrences. If the discrepancy is outside of the acceptable tolerance, the instrument may require repair or replacement. All discrepancies are documented, including the investigation process, corrective actions, and the final resolution. Maintaining detailed records and conducting thorough investigations are essential for maintaining the integrity of our calibration services. A thorough root-cause analysis is conducted to prevent recurrence.

Q 22. What is your experience with root cause analysis in calibration?

Root cause analysis (RCA) in calibration is crucial for preventing recurring calibration failures and improving the overall accuracy and reliability of our measurement systems. It’s not just about fixing a problem, but understanding why it occurred. My approach typically involves using a structured methodology like the '5 Whys' or a Fishbone diagram.

For example, if a pressure gauge consistently reads low, I wouldn’t just adjust it. I’d systematically ask 'why' repeatedly: Why is it reading low? (Perhaps due to a leak). Why is there a leak? (Maybe a damaged diaphragm). Why is the diaphragm damaged? (Possibly due to excessive pressure during a previous use). Why was the pressure excessive? (Perhaps operator error or faulty pressure regulator).

This process helps identify the root cause—in this case, possibly operator training or a faulty pressure regulator—allowing for corrective actions beyond a simple recalibration.

Q 23. How do you prioritize calibration tasks?

Prioritizing calibration tasks involves a risk-based approach. I consider several factors including the criticality of the instrument to the process (e.g., a critical safety device needs more frequent calibration than a less critical one), the instrument’s stability (an unstable instrument might need more frequent checks), the frequency of use, and regulatory requirements. I often use a prioritization matrix that maps these factors against calibration frequency.

For instance, instruments directly impacting product quality or safety are given high priority, with shorter calibration intervals. Instruments with a history of instability or frequent out-of-tolerance readings are also bumped up. I use a computerized maintenance management system (CMMS) to schedule and track these tasks efficiently, generating automated alerts for upcoming calibrations.

Q 24. Explain your experience with preventative maintenance related to calibration instruments.

Preventative maintenance (PM) is paramount to ensuring the longevity and accuracy of calibration instruments. This involves regularly scheduled checks, cleaning, and minor repairs to prevent major failures. My experience includes developing and implementing PM schedules for various instruments. These schedules typically include cleaning procedures, visual inspections for damage or wear, functional tests, and lubrication (where appropriate).

For example, I create PM schedules for temperature calibrators that include checks for proper sensor function, cleaning the internal components with compressed air, verifying the accuracy of the reference standards, and inspecting for any signs of physical damage. This proactive approach extends the lifespan of the equipment, minimizes downtime, and ultimately, ensures accurate calibrations.

Q 25. Describe your familiarity with different calibration techniques for specific instruments.

My experience encompasses various calibration techniques across several instrument types. For example, I’m proficient in calibrating pressure gauges using deadweight testers, thermometers using traceable temperature baths, and electrical instruments using precision multimeters. The calibration technique depends greatly on the instrument type and its intended use.

For instance, calibrating a digital multimeter involves comparing its readings to those of a calibrated reference multimeter across various voltage, current, and resistance ranges. Calibrating a torque wrench may involve applying known torques and comparing them to the wrench’s readings using a calibrated torque transducer. I always ensure traceability to national or international standards throughout the calibration process.

Q 26. How do you ensure compliance with industry standards and regulations in calibration?

Ensuring compliance with industry standards and regulations is non-negotiable in calibration. We adhere to standards like ISO 17025 (for calibration laboratories) and any industry-specific regulations (e.g., GMP, FDA). This involves maintaining detailed calibration records, using traceable reference standards, employing qualified personnel, and regularly reviewing our processes for compliance.

Our laboratory maintains a comprehensive quality management system that documents all procedures, ensuring traceability of all calibrations, and performing internal audits to verify our compliance with the relevant standards. We also participate in proficiency testing programs to assess our competence and identify any areas needing improvement.

Q 27. What are your strengths and weaknesses in performing calibrations?

My strengths lie in my methodical approach to calibration, my attention to detail, and my ability to troubleshoot complex issues. I’m also adept at training others and implementing efficient calibration processes.

However, like everyone, I have areas for improvement. One area I’m actively working on is enhancing my knowledge of the latest advancements in calibration technologies and software. I believe continuous learning is crucial in this field to stay abreast of the ever-evolving standards and techniques.

Q 28. Describe a time you had to troubleshoot a complex calibration issue.

I once encountered a situation where a high-precision balance consistently produced readings that were slightly off, despite numerous recalibrations. Initial troubleshooting suggested a problem with the balance itself. However, after meticulously checking environmental factors, I discovered that subtle vibrations from nearby machinery were affecting the balance’s readings.

This wasn’t immediately obvious. I employed a systematic approach, isolating potential sources of error one by one. Finally, using a vibration analyzer, I pinpointed the source, leading to the relocation of the equipment and the resolution of the issue. This experience highlighted the importance of considering seemingly minor environmental factors that can significantly impact calibration accuracy.

Key Topics to Learn for Calibration and Instrument Verification Interview

- Measurement Uncertainty: Understanding sources of error, propagation of uncertainty, and expressing results with confidence intervals. Practical application: Analyzing measurement data to determine if instruments meet required accuracy specifications.

- Calibration Standards and Traceability: Knowledge of national and international standards (e.g., NIST, ISO 17025), and how to establish a traceable calibration chain. Practical application: Selecting appropriate calibration standards and documenting the traceability of measurements.

- Calibration Methods and Techniques: Proficiency in various calibration methods (e.g., comparison, substitution, in-situ) and techniques specific to different instrument types (e.g., pressure gauges, temperature sensors, balances). Practical application: Performing a calibration procedure according to established methods and documenting the results accurately.

- Instrument Verification and Validation: Understanding the differences between calibration and verification, and how to validate instrument performance against specified requirements. Practical application: Developing and implementing a verification program for a specific instrument or set of instruments within a production environment.

- Data Analysis and Reporting: Ability to analyze calibration data, identify trends and outliers, and generate clear and concise calibration reports. Practical application: Interpreting calibration results to determine if instruments require adjustment or repair, and communicating findings to stakeholders.

- Good Calibration Practices (GCP): Familiarity with best practices for maintaining calibration records, managing calibration schedules, and ensuring compliance with relevant regulations. Practical application: Implementing a robust GCP system to ensure the quality and integrity of calibration data.

- Troubleshooting and Problem Solving: Ability to identify and resolve common calibration problems, such as instrument drift, inaccurate readings, and calibration failures. Practical application: Diagnosing instrument malfunctions and implementing corrective actions to restore accurate measurement capabilities.

Next Steps

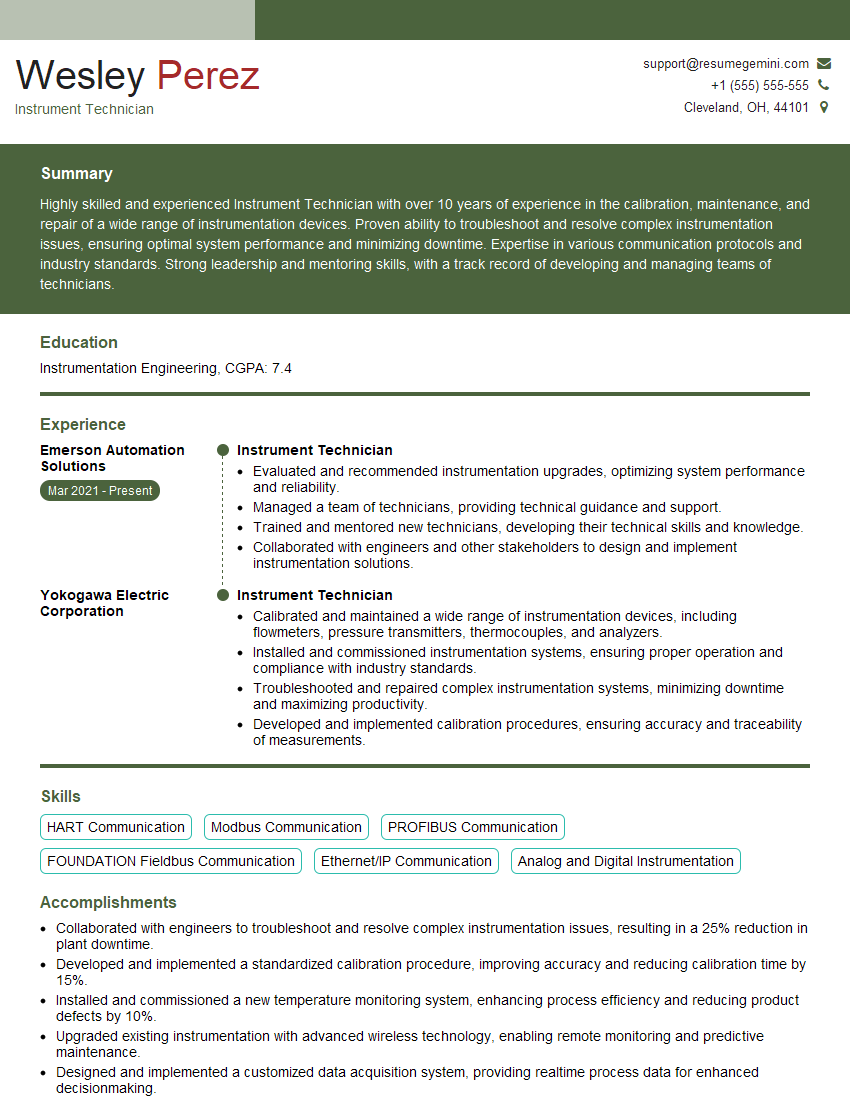

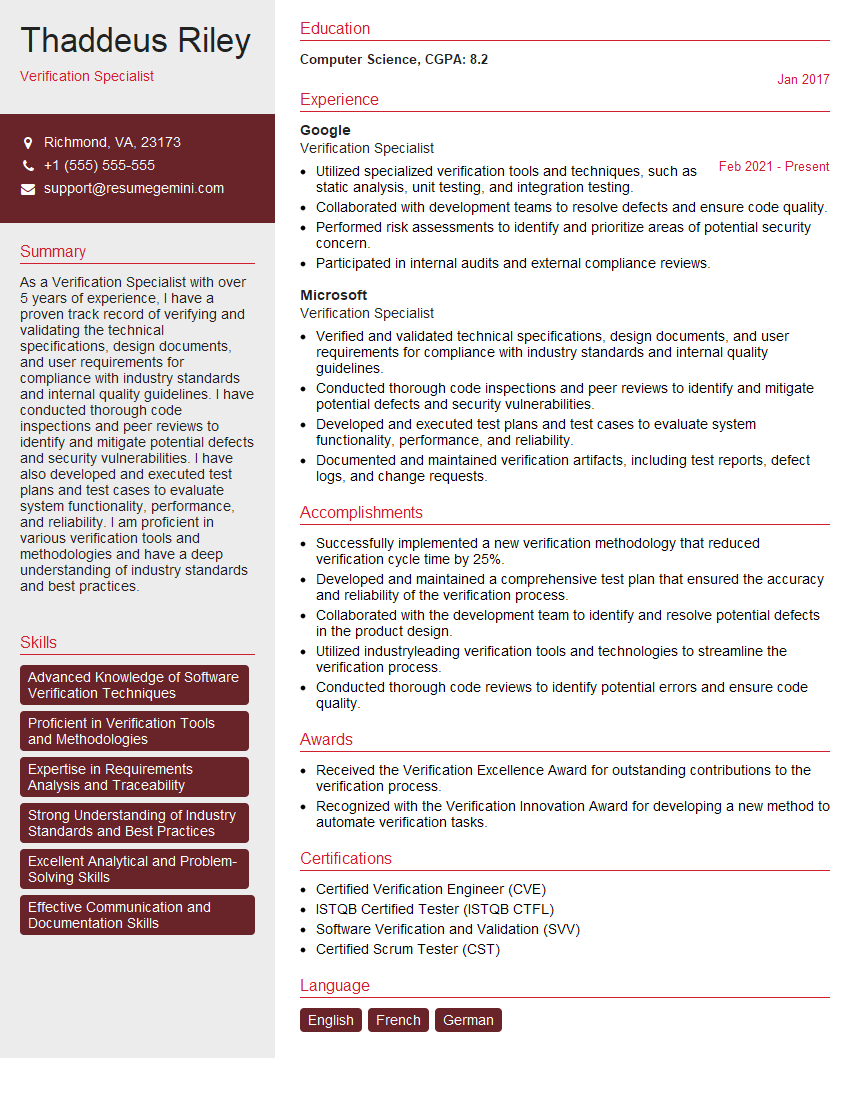

Mastering Calibration and Instrument Verification is crucial for career advancement in various industries, offering opportunities for increased responsibility and higher earning potential. An ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. To significantly improve your job prospects, we strongly encourage you to build a compelling resume using ResumeGemini. ResumeGemini provides a powerful and intuitive platform to create professional, ATS-optimized resumes, and we offer examples tailored specifically to Calibration and Instrument Verification roles to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO