The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Car Audio Installation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Car Audio Installation Interview

Q 1. Explain the difference between a single-DIN and double-DIN head unit.

The difference between single-DIN and double-DIN head units lies primarily in their size and features. Think of it like comparing a standard-sized microwave (single-DIN) to a slightly larger, more feature-rich model (double-DIN). A single-DIN head unit occupies a single standard-sized slot in your car’s dashboard, typically about 2 inches tall and 7 inches wide. These usually offer basic features like AM/FM radio, CD player, and potentially Bluetooth connectivity. A double-DIN head unit, however, is twice the height, providing more space for a larger screen, more advanced features such as navigation, touchscreen interfaces, and more sophisticated audio controls. For example, many modern infotainment systems are double-DIN units, offering Apple CarPlay or Android Auto integration.

In essence, double-DIN offers more screen real estate and advanced functionality, often at a higher price point, while single-DIN provides a more compact and budget-friendly solution for basic audio needs.

Q 2. Describe the process of installing a car amplifier.

Installing a car amplifier involves several steps that require careful planning and execution. First, you’ll need to choose a suitable location, ideally one that’s well-ventilated to prevent overheating. Next, securely mount the amplifier using appropriate hardware. Wiring is crucial and begins with running a power wire from the battery to the amplifier, ensuring it’s adequately fused for protection. A ground wire connects the amplifier to a clean, bare metal surface on the car’s chassis for a stable ground. Then, you need to run RCA cables from the head unit’s preamp outputs to the amplifier’s inputs to carry the audio signal. Finally, connect speaker wire from the amplifier’s outputs to your speakers. Always ensure proper polarity (+ and -) is maintained throughout the wiring process. Poor grounding, for instance, will lead to significant noise and distortion. Using quality wire and connectors is essential for optimal performance and longevity.

It’s a good idea to consult your amplifier’s manual for specific wiring diagrams and instructions, and if you’re unsure about any step, it’s best to seek professional help.

Q 3. How do you wire a subwoofer for optimal performance?

Wiring a subwoofer for optimal performance hinges on understanding impedance and amplifier compatibility. Most subwoofers are either dual-voice coil (DVC) or single-voice coil (SVC). An SVC subwoofer has a single voice coil, limiting the wiring configurations. A DVC subwoofer has two voice coils, offering flexibility. For example, a DVC subwoofer with 4-ohm voice coils can be wired in series (8 ohms total) or parallel (2 ohms total). The amplifier must be capable of handling the resulting impedance.

For instance, if you have a 2-ohm stable amplifier and a DVC 4-ohm subwoofer, wiring the coils in parallel will provide a 2-ohm load, matching the amplifier’s specifications. However, wiring them in series would result in an 8-ohm load, potentially causing underpowering. Always check your subwoofer and amplifier specifications before connecting them, and using the wrong configuration can damage your equipment.

Proper grounding and using high-quality wiring, just like with the amplifier installation, contribute significantly to optimal sound quality and prevent interference.

Q 4. What are the different types of car speakers and their characteristics?

Car speakers come in various types, each with unique characteristics. Coaxial speakers are the most common, integrating a woofer and tweeter in a single unit. They’re relatively simple to install and offer a balanced sound. Component speakers offer separate woofers and tweeters, allowing for more precise placement and potentially better sound staging. This is especially important for listeners who value a wider, more spacious audio image. Full-range speakers attempt to cover a broad frequency range, often found in less demanding applications. Finally, there are subwoofers, specialized speakers designed for low-frequency reproduction, providing the bass in your audio system.

The choice of speaker type depends on your budget, installation complexity preferences, and desired audio quality. Component systems generally offer superior sound quality compared to coaxial speakers but require more complex installation.

Q 5. Explain the importance of impedance matching in car audio systems.

Impedance matching is crucial in car audio systems because it ensures efficient power transfer from the amplifier to the speakers. Impedance is the resistance to the flow of electrical current, measured in ohms (Ω). If the amplifier’s output impedance doesn’t match the speaker’s impedance, the amplifier may not deliver its full power, leading to reduced volume, distortion, or even damage to the amplifier.

For example, if you connect a 4-ohm speaker to an amplifier designed for 8-ohm speakers, the amplifier might overheat and fail. Conversely, connecting an 8-ohm speaker to a 4-ohm stable amplifier would be fine. Always consult the specifications of both your amplifier and speakers to ensure they are compatible to avoid issues and prevent damage.

Q 6. How do you troubleshoot a system with poor sound quality?

Troubleshooting poor sound quality requires a systematic approach. Start by checking all connections – loose or corroded wires can cause significant issues. Next, verify the impedance matching, as mentioned earlier. Then, assess the source material – is the problem with the audio file or the system itself? If the sound is distorted, the problem might be the amplifier or speakers. If it’s too quiet, the issue could be with the head unit’s volume, the amplifier’s gain settings, or the wiring.

A common problem is poor grounding. A bad ground connection can introduce significant noise and hum into the system. Checking the ground wire and ensuring a secure connection to a clean metal surface is often an effective solution. Sometimes, the problem lies with the head unit itself. If everything else checks out, testing with a known good head unit or replacing the current one may be required. A systematic approach and elimination help pinpoint the problem and resolve it quickly.

Q 7. Describe your experience with different types of wiring harnesses.

My experience encompasses a wide range of wiring harnesses, from basic ISO connectors found in many European vehicles to vehicle-specific harnesses designed for seamless integration with factory radios. I’ve worked with aftermarket harnesses that adapt to various car models and provide custom solutions for complex installations. Some harnesses are simple, offering basic power and speaker connections, while others incorporate advanced features like CAN-bus integration for advanced communication between the head unit and the vehicle’s computer system. For example, I’ve had to troubleshoot a system where the factory harness was incompatible with the new head unit and had to build a custom interface using a combination of different connectors and wires to maintain all the car’s original functionality while integrating the new system.

Understanding different harness configurations is essential for efficient and error-free installations. Knowing how to identify various connectors, wire gauges and colors, and understanding signal pathways are crucial for successful installations. Incorrect wiring can lead to system malfunctions and potential damage.

Q 8. What are the safety precautions you take when working with car electrical systems?

Safety is paramount when working with car electrical systems. Before I even begin, I always disconnect the negative terminal of the car battery. This is the single most important step to prevent accidental shorts and shocks. I then use insulated tools to avoid direct contact with metal parts, particularly around the battery and wiring harnesses. I also make sure the area is well-lit and ventilated to avoid potential hazards. Protecting my eyes is also crucial; I always wear safety glasses to prevent debris or sparks from causing injury. Finally, I consult the vehicle’s wiring diagram to understand the system’s layout and identify potential hazards before starting any work. Think of it like this: treating the car’s electrical system with respect is like treating a live wire – caution and proper procedure are non-negotiable.

Q 9. How do you determine the correct gauge of wire for a given application?

Choosing the right wire gauge is critical for reliable performance and safety. Too thin a wire will overheat and potentially cause a fire, while too thick a wire is unnecessary and bulky. I determine the correct gauge using a wire gauge chart, taking into account the amperage draw of the component (amplifier, subwoofer, etc.). For example, a high-power amplifier might require 4-gauge wire, while a smaller amplifier might only need 10-gauge or 12-gauge wire. The chart indicates the current carrying capacity for each gauge. I also consider the length of the wire run – longer runs necessitate slightly thicker wire to compensate for increased resistance. It’s not just about the chart though; experience helps. I’ve learned that it’s always better to err on the side of caution and go with a slightly thicker gauge to ensure a safe and reliable installation.

Q 10. Explain the concept of sound deadening and its benefits.

Sound deadening involves applying specialized materials to the interior surfaces of a vehicle to reduce unwanted noise and vibrations. These materials, typically butyl rubber or bitumen-based, absorb sound waves and dampen vibrations, leading to a cleaner, more accurate audio experience. The benefits are significant: reduced road noise, less engine noise, and significantly improved bass response from the car audio system. Imagine trying to listen to your favorite song in a metal bucket compared to a well-insulated room – the sound deadening material acts like that insulation, creating a much more controlled and enjoyable audio environment. This not only enhances listening pleasure but also allows your speakers and subwoofer to perform at their optimal levels, preventing distortion due to unwanted resonances.

Q 11. What experience do you have with installing aftermarket navigation systems?

I have extensive experience installing aftermarket navigation systems. This involves integrating the system with the vehicle’s existing electrical system, often requiring custom wiring and interfacing with the car’s existing infotainment system. I’m proficient in working with various interfaces, including CAN bus systems, to ensure seamless integration. I also know how to correctly route the wiring to avoid interference with other systems and maintain a clean, professional installation. One memorable project involved installing a high-end navigation system in a classic car – it required creative problem-solving to integrate the modern technology while preserving the car’s original aesthetics and functionality. This included using custom mounting solutions and a careful approach to routing the wiring.

Q 12. Describe your experience with working with different types of amplifiers (Class A, B, D).

My experience encompasses all three amplifier classes: Class A, Class B, and Class D. Class A amps are known for their high fidelity but are less efficient and generate more heat. Class B amps offer a good balance between efficiency and sound quality, while Class D amps are highly efficient but can sometimes lack the refinement of Class A or even Class B. I understand the strengths and weaknesses of each class, allowing me to recommend and install the best type for a client’s specific needs and budget. For instance, a client aiming for ultimate sound quality in a smaller vehicle might benefit from a Class A amplifier, while a system focused on high power in a larger vehicle could optimally use a Class D amplifier because of their size and efficiency.

Q 13. How do you handle customer requests that are outside of your expertise?

If a customer requests something outside my expertise, I’m always upfront and honest. I will clearly explain what I can and cannot do. I prioritize transparency and will never attempt a job I’m not qualified for. If the task is beyond my capabilities, I’ll research and refer them to a specialist who can provide the needed service. Honesty builds trust, and sometimes, referring a client to another skilled professional is the best way to serve them and maintain my own reputation for quality work. This builds rapport and ensures long-term customer satisfaction.

Q 14. How familiar are you with different audio file formats (MP3, FLAC, WAV)?

I am very familiar with various audio file formats. MP3 is the most common, offering a good balance between file size and audio quality (though lossy compression results in some information loss). FLAC (Free Lossless Audio Codec) provides lossless audio, maintaining all the original data for superior sound quality, but the files are significantly larger. WAV (Waveform Audio File Format) is another lossless format, often used for studio-quality audio. Understanding these formats allows me to advise clients on the best format for their needs, balancing sound quality with storage space and playback compatibility in their car audio systems. For instance, I recommend FLAC for those with high-capacity storage and a high-fidelity system, while MP3 is a practical choice for listeners who prioritize smaller file sizes.

Q 15. What tools and equipment are essential for car audio installation?

A successful car audio installation requires a comprehensive toolkit. Think of it like a surgeon’s kit – you need the right tools for the job to ensure a clean, professional, and safe installation. Essential tools include:

- Wiring tools: Wire strippers, crimpers, soldering iron (with solder and flux), wire cutters, and a multimeter (for voltage and continuity checks) are absolute necessities. Properly crimping connectors is vital for reliable connections; soldering offers a more secure, long-lasting bond, especially for high-power applications.

- Installation tools: This includes various sizes of screwdrivers (Phillips and flathead), panel removal tools (to avoid scratching the interior), a drill with various drill bits (sometimes needed for speaker mounting), and zip ties for cable management. Proper panel removal tools are crucial to avoid damage during disassembly.

- Measurement and testing tools: Besides the multimeter, a ruler, measuring tape, and possibly a signal generator (for advanced troubleshooting) will ensure accurate component placement and signal verification.

- Safety equipment: Safety glasses and work gloves are non-negotiable to protect against sharp edges, electrical shocks, and potential injuries.

Having the right tools not only speeds up the installation process but also minimizes the risk of damage to the vehicle and the components being installed. I always prefer quality tools; they’re an investment that pays off in the long run.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with installing backup cameras and parking sensors.

I’ve installed numerous backup cameras and parking sensors, ranging from simple wired systems to more advanced wireless setups with integrated displays. The process typically begins with carefully routing the camera cable, often using existing pathways to keep the installation neat and discreet. For example, I’ve run cables through the rubber grommets in the firewall, often tucked along the side of the vehicle’s interior trim. Wiring to the reverse light circuit is critical; the camera only activates when the car is in reverse.

Parking sensor installation involves carefully mounting the sensors in the bumper, ensuring even spacing and proper alignment. This requires precision drilling, which I always do with a pilot hole to avoid cracking the bumper. The control module then needs to be wired to the vehicle’s power and potentially the reverse light circuit, again using an appropriate fuse and relay for protection. The sensor setup often requires calibrating the system for optimal performance and to avoid false triggers. I always test the system thoroughly, ensuring all functionalities work correctly before completing the installation. One memorable instance involved adapting a rearview camera to an older vehicle that didn’t originally have one, which required creative routing and wiring solutions but resulted in a very satisfied client.

Q 17. How do you ensure proper grounding in a car audio installation?

Proper grounding is paramount in car audio. A poor ground can lead to noise, poor signal quality, and even damage to components. Think of a ground as the return path for the electrical current; it needs to be low-resistance and reliable.

My approach involves finding a clean, unpainted metal surface on the vehicle’s chassis, preferably near the audio components being installed. I thoroughly clean the surface to remove paint, rust, or any other contaminants that could affect conductivity. Then, I use a ring terminal appropriately sized for the ground wire, securing it firmly to the chassis with a bolt. The bolt should be adequately tightened to maintain a good connection, but be careful not to over-tighten and strip the threads. I always check the connection with a multimeter, ensuring low resistance between the ground point and the negative battery terminal. A bad ground often presents itself as intermittent noise or hum in the audio system, which immediately highlights the need to reassess grounding.

Q 18. Describe your experience with installing Bluetooth and hands-free systems.

Installing Bluetooth and hands-free systems is a common task, and I’ve handled everything from simple aftermarket kits to integrated factory systems. The process usually involves connecting the Bluetooth module to the head unit and the vehicle’s power supply. Proper antenna placement is important for optimal reception. For hands-free calling, integrating the microphone is key—proper placement ensures clear voice transmission and reception. I often use microphone mounting kits to blend the installation seamlessly into the vehicle’s interior.

Troubleshooting Bluetooth issues often involves checking the module’s power supply, verifying the connection with the head unit, and ensuring proper pairing with the smartphone. Antenna placement is usually the first place I check for problems with reception. I have experience with various Bluetooth protocols and can work with a wide range of head unit types and aftermarket kits. I also prioritize ensuring the installed system does not interfere with the vehicle’s other electrical systems.

Q 19. What are your troubleshooting skills related to electrical problems in vehicles?

Troubleshooting electrical problems requires a systematic approach. I always start by using a multimeter to test voltages, currents, and resistances at various points in the circuit. I’ll check fuses and relays first, as these are common points of failure. I also check for shorts or blown components. My approach is similar to diagnosing a medical problem – I start with the most common issues, then narrow down the possibilities based on test results.

For example, a common problem is a flickering dome light. I’d check the dome light switch, the wiring harness, and the fuse to identify the root cause. A systematic approach often involves visual inspections to detect broken or frayed wires, corrosion, or other signs of damage. I’ve used circuit diagrams extensively, and my experience has taught me how different vehicle systems interact, which is key to effective troubleshooting.

Q 20. Explain your understanding of signal processing and equalizers.

Signal processing and equalizers are crucial for optimizing audio quality. Think of it like a sound sculptor – you’re shaping the audio signal to suit your preferences and compensate for the car’s acoustics. An equalizer (EQ) allows you to adjust the level of different frequency bands, boosting or cutting certain frequencies to improve clarity, balance, or bass response.

Signal processing often includes features like crossovers (discussed later), time alignment (delaying audio signals to create a more unified soundscape), and dynamic processing (compression and limiting to control volume variations). For instance, I might use an EQ to boost bass frequencies slightly in a car with poor low-frequency response or cut harsh high-frequencies to reduce listener fatigue. Understanding frequency responses and how they relate to the car’s interior is vital for successful sound tuning.

Q 21. How familiar are you with different types of crossovers?

Crossovers are essential components in multi-speaker systems. They act as filters, directing specific frequency ranges to different speakers (woofers, mid-range, tweeters) to optimize sound quality. There are different types of crossovers:

- Passive crossovers: These use passive components like capacitors, inductors, and resistors to filter the signal. They are simpler to install, but can impact amplifier efficiency and power handling capacity.

- Active crossovers: These use active circuitry (amplifiers) to filter the signal. This allows for better signal control and usually results in more precise frequency separation, but it does necessitate more amplifier channels.

The choice of crossover type depends on the system design, including the type and quality of the amplifiers and speakers being used. I always choose a crossover type that is compatible with the overall system’s specifications and the desired sound characteristics. Understanding how different crossover slopes (such as 6dB, 12dB, 18dB per octave) affect the frequency response is vital for tuning a system correctly. For example, a steeper slope provides more precise separation, but might result in a less smooth transition between frequency bands if not carefully designed and implemented.

Q 22. Describe the process of installing a factory-matched replacement speaker.

Installing a factory-matched replacement speaker is a relatively straightforward process, but precision is key to ensuring optimal sound and a clean finish. It involves several steps:

- Preparation: First, disconnect the vehicle’s battery to prevent short circuits. Then, carefully remove the existing speaker. This usually involves unscrewing it from the mounting bracket or popping it out of the dashboard. Take photos as you go to help with reassembly.

- Harness Check: Examine the wiring harness of the old speaker. You might need to adapt the new speaker’s wiring to match. Sometimes, factory harnesses require small adjustments – color-coding is your best friend here. This is where a wiring diagram can be a lifesaver.

- Speaker Installation: Carefully mount the new speaker in the existing bracket, ensuring a tight and secure fit. Use provided screws, and avoid over-tightening to prevent damage. Pay attention to the polarity (+ and -). Connecting the wires incorrectly will result in an out-of-phase sound, which affects the overall audio quality significantly.

- Testing and Reassembly: Reconnect the battery and test the speaker. Play a range of audio frequencies to check for any distortion or imbalance. Once you’re satisfied, carefully reassemble all panels and trim pieces.

Example: I once installed a factory-matched speaker in a 2015 Honda Civic. The original speaker had a specific mounting depth that I needed to match precisely; otherwise, the speaker wouldn’t fit flush, affecting both the sound quality and the overall aesthetics.

Q 23. What are your experience with diagnosing and fixing faulty components?

Diagnosing faulty car audio components requires a systematic approach. I start by visually inspecting the components for any obvious damage, loose connections, or corrosion. Then, I use a multimeter to check voltage, current, and continuity to pinpoint the problem.

Example: I recently had a case where a customer’s amplifier was producing a distorted sound. After inspection, I found a loose ground connection which, when properly secured, resolved the issue completely. In other cases, faulty capacitors inside the amplifier or speaker can be the culprit, often requiring component-level repair.

For complex systems, a proper understanding of signal flow is crucial. Tracing the signal path, from the source unit to the amplifier, and then to the speakers, allows me to isolate the faulty component. I use test tones and an oscilloscope to precisely identify the problem. Specialized tools like a signal generator and spectrum analyzer are invaluable for high-end systems.

Q 24. Describe how you maintain a clean and organized work area.

Maintaining a clean and organized workspace is paramount. This ensures efficient workflow, prevents damage to components, and promotes safety. My approach includes:

- Designated Areas: I have designated areas for tools, parts, and materials, keeping similar items grouped together. I use tool organizers and labeled bins for small parts.

- Cleanliness: I clean my work surface regularly, wiping away dust and debris to prevent short circuits. I use anti-static mats to protect sensitive electronic components from electrostatic discharge (ESD).

- Cable Management: I use zip ties and cable clips to manage and bundle wires to prevent tangling and keep things neat. This is particularly important in car audio installations where wiring can become extensive.

- Waste Disposal: Proper disposal of waste, including packaging materials and old parts, is essential. Keeping the workspace clean and tidy improves efficiency and prevents accidental damage.

A clean workspace is a reflection of professionalism and results in more accurate and efficient work. It reduces the chance of errors and creates a more pleasant and productive work environment.

Q 25. How do you handle challenging installations or unique customer requests?

Challenging installations require adaptability and problem-solving skills. I approach them by:

- Thorough Planning: I carefully assess the customer’s request and the vehicle’s specific characteristics. This may involve taking detailed measurements and reviewing technical documentation.

- Creative Solutions: If a straightforward solution isn’t available, I explore creative options. This might involve custom fabrication, adapting existing components, or integrating new technologies.

- Research and Development: I may research alternative solutions or consult with other professionals. Forums and online communities specializing in car audio are great resources.

- Customer Communication: Maintaining open and honest communication with the customer throughout the process is vital. This keeps them informed about any challenges or unexpected delays.

Example: I once had a customer who wanted a custom subwoofer enclosure installed in a classic car with limited space. After thorough planning and custom fabrication, I was able to create a solution that met their expectations without sacrificing the vehicle’s integrity.

Q 26. What are the best practices for ensuring optimal sound quality in a vehicle?

Optimal sound quality in a vehicle involves a holistic approach focusing on several key areas:

- Proper Speaker Selection: Choosing speakers appropriate for the vehicle’s size and acoustic properties is crucial. Larger speakers generally offer more bass response, while smaller speakers are often better suited for higher frequencies. Component sets, which typically consist of separate woofers and tweeters, offer better control and sound staging.

- Sound Damping: Sound damping materials help reduce unwanted noise and vibrations, creating a cleaner and more accurate sound. This is especially beneficial in older vehicles or those with significant road noise.

- Amplifier Selection: An appropriately sized amplifier will provide sufficient power to the speakers, preventing distortion and enhancing clarity. The power output of the amplifier should be matched to the sensitivity and power handling capabilities of the speakers.

- Signal Processing: An equalizer or digital signal processor (DSP) can be used to adjust the frequency response of the audio system to compensate for the vehicle’s acoustics and personal preferences.

- Proper Installation: Careful installation of all components, including proper grounding and wiring, is essential for optimal performance. Poor installation can lead to a variety of issues including hum, buzz, or distortion.

Addressing each of these aspects ensures a significant improvement in overall audio quality.

Q 27. Explain your experience with high-end audio systems (e.g., high-end amps, processors)

My experience with high-end audio systems includes working with amplifiers from brands like JL Audio, Audison, and Mosconi, and processors from brands like Helix and Alpine. These systems require a higher level of technical expertise and precision in installation and tuning. I have extensive experience integrating these components into complex systems, often involving multiple amplifiers, DSPs, and signal processing.

Example: I recently installed a high-end system in a luxury SUV using a combination of Audison amplifiers, a Helix DSP, and Focal Utopia speakers. This involved meticulous tuning of the DSP to optimize the sound stage and frequency response within the car’s cabin. Careful cable management and precise component placement were vital for achieving the best possible results. Working with high-end systems demands meticulous attention to detail and advanced knowledge of audio engineering principles.

Key Topics to Learn for Your Car Audio Installation Interview

- System Design & Planning: Understanding client needs, choosing appropriate components (head units, speakers, amplifiers, subwoofers), and designing a system that meets performance and budget requirements. Practical application: Sketching system diagrams and explaining component choices for different vehicle types and customer preferences.

- Wiring & Connections: Knowledge of different wire gauges, proper grounding techniques, understanding amplifier wiring configurations (mono, bridged, stereo), and safe installation practices to avoid electrical shorts. Practical application: Troubleshooting wiring diagrams and explaining the importance of using appropriate fuses and wire protection.

- Speaker Installation & Sound Tuning: Understanding different speaker types (coaxial, component), proper speaker placement for optimal sound staging and imaging, and techniques for sound tuning (EQ adjustments, time alignment). Practical application: Describing the process of installing speakers in different locations within a vehicle and explaining how to adjust settings to improve sound quality.

- Amplifier Installation & Configuration: Understanding amplifier specifications (power handling, impedance), proper mounting and ventilation, and configuration settings (gain, crossover, EQ). Practical application: Explaining the process of selecting and installing an amplifier suitable for specific speakers and describing different amplifier connection methods.

- Subwoofer Installation & Enclosure Design: Understanding different subwoofer types (sealed, ported), designing or selecting appropriate subwoofer enclosures, and proper installation techniques to optimize bass response. Practical application: Explaining how enclosure design affects subwoofer performance and describing the importance of proper sealing and bracing.

- Troubleshooting & Diagnostics: Identifying and resolving common car audio installation problems, using diagnostic tools (multimeters, signal generators), and understanding fault finding techniques. Practical application: Describing your approach to diagnosing a system with no sound, distortion, or intermittent power issues.

- Safety & Best Practices: Understanding safety regulations regarding car audio installations, proper tool use, and adhering to professional installation standards. Practical application: Explaining how to safely work with car electrical systems and the importance of using appropriate safety equipment.

Next Steps

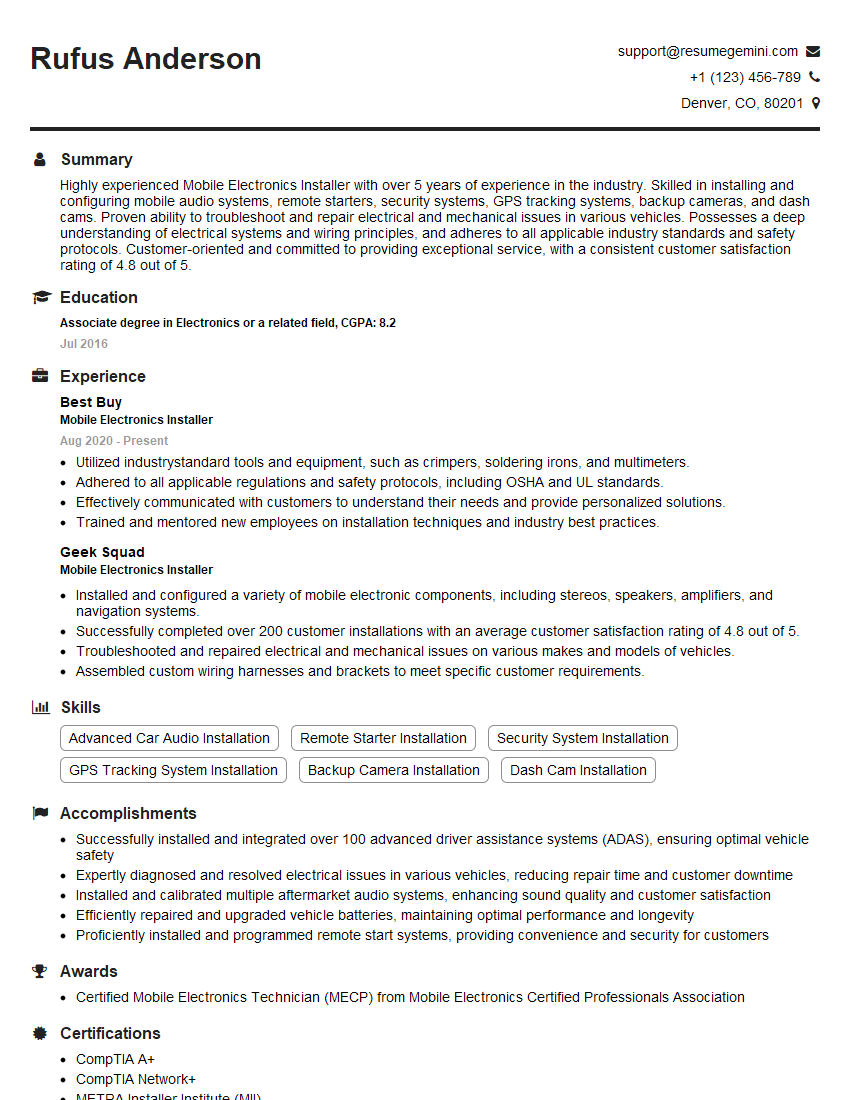

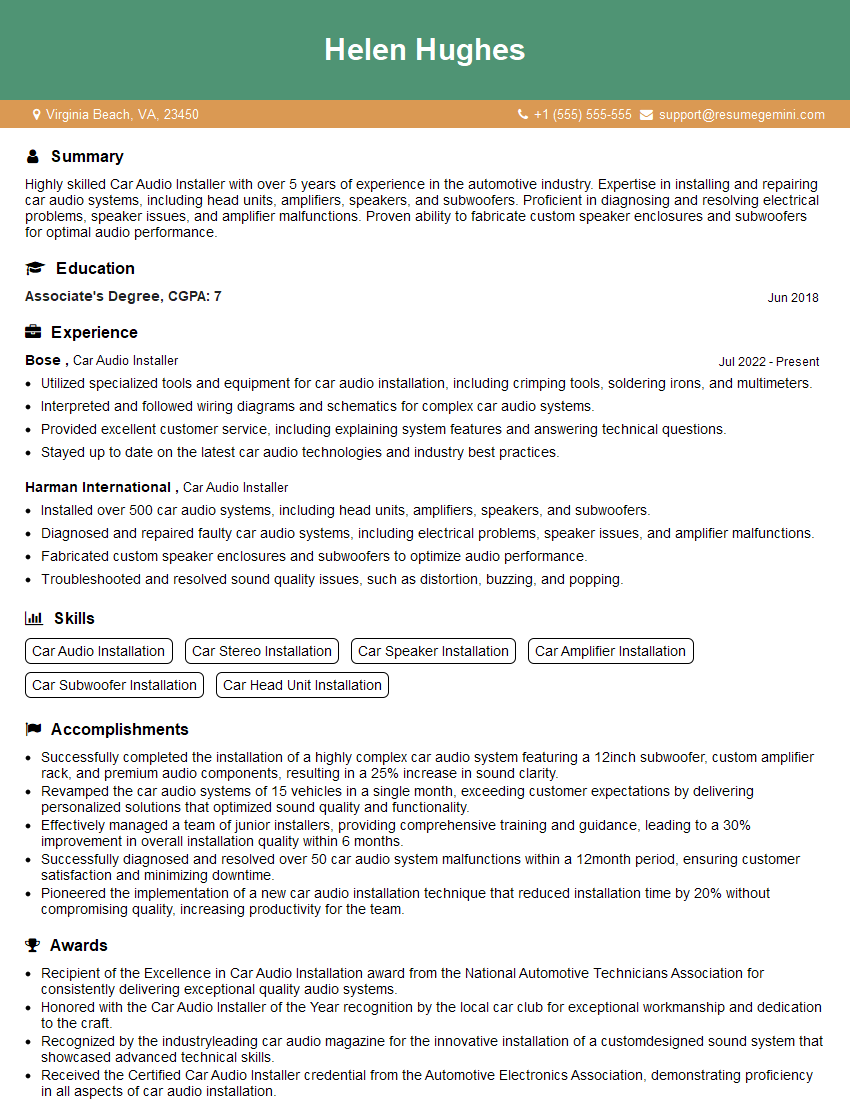

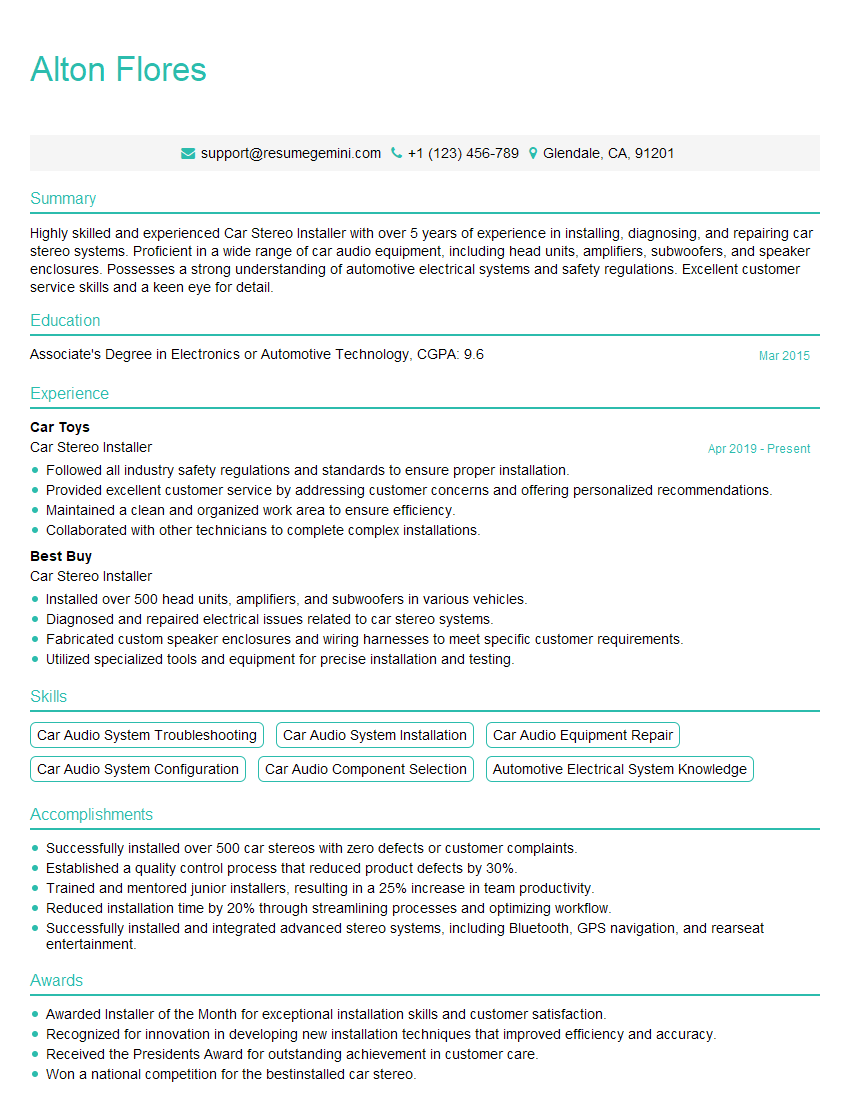

Mastering car audio installation opens doors to a rewarding career with excellent growth potential. You can specialize in high-end systems, mobile electronics, or even start your own business. To stand out, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that catches the eye of recruiters. They offer examples of resumes tailored specifically to Car Audio Installation, giving you a head start in your job search. Invest in your future – build a strong resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO