Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Car Wash interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Car Wash Interview

Q 1. Describe your experience with different car wash methods (e.g., touchless, self-serve, full-service).

My experience encompasses all major car wash methods. Touchless washes utilize high-pressure water sprays and specialized detergents to clean vehicles without physical contact, minimizing the risk of scratches. This method is efficient but may not be as effective for heavily soiled vehicles. I’ve overseen the operation and maintenance of several touchless systems, including optimizing chemical application for various soil types and adjusting nozzle pressures for different vehicle sizes. Self-serve bays offer customers greater control over the washing process, allowing them to choose their wash options and dwell time. My responsibilities here involved ensuring adequate supplies of detergents, maintaining water pressure and temperature, and addressing any equipment malfunctions promptly. Finally, full-service washes provide a complete cleaning experience, including pre-soaking, washing, drying, and often detailing services. In managing full-service operations, I’ve overseen staff training, optimized workflow to maximize throughput, and implemented quality control measures to ensure consistent service delivery. I’m familiar with various conveyor systems, high-pressure foam applications, and detailing techniques.

Q 2. What are the common types of car wash detergents and their applications?

Car wash detergents vary widely in their composition and purpose. High-pressure foam detergents are often used in the pre-wash stage to loosen dirt and grime. These are typically high-pH alkaline solutions designed to emulsify grease and oils. Wash detergents, applied during the main wash cycle, are lower-pH, but still effective at cleaning the vehicle’s surface. These often contain surfactants to enhance cleaning power and prevent water spotting. Wax-enhanced detergents are frequently used to provide a protective layer, offering a degree of shine and water repellency. Finally, spot-free rinses, typically acidic, help minimize water spots. Selecting the appropriate detergent for each stage of the wash process is crucial for optimal cleaning and minimizing environmental impact. For example, we carefully balance the concentration of each detergent to maximize efficiency while adhering to environmental regulations. This approach not only delivers superior results but also ensures cost-effectiveness and environmental responsibility.

Q 3. How do you handle customer complaints regarding scratches or damage?

Handling customer complaints about scratches or damage is a critical aspect of maintaining customer satisfaction and liability. My approach involves a calm and empathetic response, first actively listening to the customer’s concern and acknowledging their frustration. Next, I’d conduct a thorough inspection of the vehicle, documenting the damage with photographs. If damage is confirmed and attributable to our operations, we offer appropriate compensation, such as a free wash or repair services, depending on the severity of the damage. It’s vital to be transparent and honest with the customer throughout the process. For example, we’ve had instances where damage was pre-existing, and by providing clear documentation, we’ve been able to avoid unnecessary conflict. Good communication is crucial—documenting the process and ensuring a clear understanding between the customer and the establishment. A detailed damage report and a clear resolution strategy are vital elements in this process. We also prioritize staff training to prevent accidents and maintain high standards of care.

Q 4. Explain your experience with maintaining car wash equipment.

Maintaining car wash equipment requires a proactive and systematic approach. This involves daily inspections to identify minor issues before they escalate into major problems, including checking water pressure, detergent levels, and the functionality of all machinery. Preventive maintenance is also key—this includes regular lubrication, filter changes, and belt replacements according to the manufacturer’s recommendations. I’m adept at troubleshooting mechanical and electrical issues, often addressing problems before they disrupt operations. We maintain detailed logs of maintenance activities, which facilitates tracking the equipment’s operational history and anticipating future maintenance needs. For example, we developed a preventative maintenance schedule using software that alerts us to upcoming service requirements, keeping our equipment in top condition. We also leverage data from maintenance logs to evaluate the effectiveness of our maintenance programs and make adjustments as needed.

Q 5. What safety procedures do you follow while operating car wash machinery?

Safety is paramount in a car wash environment. We adhere to strict safety protocols, including requiring all staff to wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toe boots. We emphasize regular safety training, covering safe operating procedures for all machinery and emergency response protocols. We enforce lockout/tagout procedures whenever equipment is being repaired or maintained. Furthermore, we ensure that the car wash facility is well-lit and has clearly marked emergency exits. Regular safety inspections are conducted, addressing any potential hazards promptly. For instance, we regularly check the integrity of electrical wiring and ensure that all safety guards are functioning correctly. Our commitment to safety ensures a secure working environment for our staff and customers.

Q 6. How do you ensure the efficient use of water and cleaning solutions?

Efficient water and detergent usage is crucial for both environmental responsibility and cost-effectiveness. We implement several strategies to achieve this. We utilize water reclamation systems, which recycle and reuse water, significantly reducing our water consumption. Our detergent dispensing systems are precisely calibrated to deliver the optimum amount of detergent for each wash cycle, minimizing waste. We also actively monitor water and detergent usage through metering systems and regularly review our practices to optimize efficiency. For example, we installed low-flow nozzles and water-saving technologies to decrease water consumption without compromising cleaning effectiveness. Regular training for staff on proper chemical handling and water management best practices reinforces responsible usage. This multi-pronged approach helps us significantly minimize our environmental footprint while keeping operational costs in check.

Q 7. What is your experience with inventory management of car wash supplies?

Effective inventory management of car wash supplies is essential for smooth operations. We utilize a computerized inventory management system to track stock levels of all consumables, including detergents, waxes, and other cleaning agents. This system allows us to forecast demand accurately, preventing stockouts and minimizing waste. We set reorder points for each item to ensure timely replenishment. Regular physical inventory counts are conducted to verify the accuracy of the system and identify discrepancies. We analyze consumption data to identify trends and optimize our ordering strategies. For example, we identified seasonal fluctuations in the demand for certain products and adjusted our purchasing accordingly, resulting in significant cost savings. This systematic approach helps maintain the availability of all essential supplies, supporting continuous and efficient car wash operations.

Q 8. Describe your experience with scheduling and managing staff.

Effective staff scheduling and management are crucial for a successful car wash operation. My approach involves a multi-pronged strategy focusing on forecasting, assigning roles, and monitoring performance. I begin by analyzing historical data on customer volume to predict peak and off-peak hours. This helps me create a master schedule that ensures adequate staffing levels at all times. I utilize a staff scheduling software to optimize shifts, considering employee availability and skill sets. For example, experienced detailers are scheduled during peak hours when more intricate services are in demand, while newer team members are assigned to simpler tasks during slower periods. Regular performance reviews and feedback sessions are essential to identify areas for improvement and to motivate the team. I also employ cross-training to ensure staff are versatile and can cover for colleagues when needed.

Q 9. How do you handle peak hours and ensure smooth workflow?

Handling peak hours smoothly requires proactive planning and efficient workflow management. I implement a system of designated roles and stations within the car wash bay. During peak hours, we might add extra staff to expedite the process, for instance, having dedicated staff for pre-washing, washing, drying, and detailing. This division of labor streamlines operations and minimizes wait times. We also employ a queuing system with clear signage to manage customer flow and avoid congestion. Real-time communication between staff is vital; we use walkie-talkies or a dedicated communication system to address immediate needs, such as a clogged nozzle or an unexpected delay. Regular maintenance checks on equipment help prevent unexpected downtimes during peak periods, ensuring the continuous operation of our services.

Q 10. What is your experience with cash handling and POS systems?

I have extensive experience handling cash and utilizing Point-of-Sale (POS) systems. This includes accurately processing transactions, balancing the cash drawer at the end of each shift, and adhering to all relevant financial regulations. I’m proficient with various POS systems, including both traditional cash registers and modern software-based systems. I understand the importance of reconciling daily sales reports with the actual cash and credit card receipts. My experience also involves handling refunds and resolving any discrepancies that may arise. Security is paramount; I follow strict procedures to safeguard cash and prevent theft, including regular cash counts and the use of secure deposit systems. I am comfortable training staff on proper cash handling techniques and POS system usage.

Q 11. How do you maintain cleanliness and organization in the car wash bay?

Maintaining a clean and organized car wash bay is crucial for both operational efficiency and customer satisfaction. My approach involves establishing a comprehensive cleaning schedule and designating specific cleaning tasks to individual team members. This includes regularly cleaning and sanitizing the wash bays, equipment, and customer waiting areas. We use high-pressure cleaning systems to remove debris and prevent buildup. Proper chemical storage and disposal are strictly adhered to, following all safety regulations. We also employ regular preventative maintenance on the equipment to prevent breakdowns and keep everything running smoothly. Visual cues, like color-coded bins for different types of waste, are used to streamline organization and ensure that all team members follow the same cleaning protocols. A checklist ensures that all tasks are completed systematically.

Q 12. How do you identify and resolve common car wash issues (e.g., clogged nozzles, chemical spills)?

Identifying and resolving common car wash issues requires a proactive approach and a strong understanding of the equipment. For example, a clogged nozzle might be addressed by checking for debris and using a high-pressure water jet to clear the blockage. A chemical spill would necessitate immediate action, involving containment of the spill, proper cleanup using designated neutralizing agents, and notifying relevant authorities if necessary. Preventive maintenance, such as regular inspections and lubrication of equipment, drastically reduces the frequency of these issues. Training staff to identify and troubleshoot minor issues themselves empowers the team and increases operational efficiency. I also maintain a detailed log of maintenance and repairs, which helps us track potential problems and identify recurring issues that require more comprehensive solutions.

Q 13. What are your strategies for improving customer satisfaction?

Improving customer satisfaction is a top priority. I focus on several key areas. Firstly, providing excellent customer service is paramount: a friendly greeting, prompt service, and a willingness to answer questions are essential. We regularly solicit customer feedback through surveys and reviews, using this information to identify areas for improvement. Maintaining a clean and well-maintained facility is critical, creating a positive first impression. Offering a variety of services to cater to different customer needs and budgets expands our appeal. Addressing customer complaints promptly and professionally is crucial. For instance, if a customer expresses dissatisfaction with a service, I would offer a complimentary service or a discount on their next visit to rectify the situation. Loyalty programs can incentivize repeat business and foster customer loyalty.

Q 14. What is your experience with detailing techniques (e.g., waxing, polishing)?

My experience in detailing techniques includes a range of processes, from basic washing and drying to advanced techniques like waxing and polishing. I understand the importance of selecting appropriate products for different vehicle types and paint finishes. I’m skilled in using various tools, including buffers and polishers, to achieve a high-quality finish. Waxing protects the paint from environmental damage, while polishing removes minor scratches and imperfections, restoring the car’s shine. I’m also familiar with techniques for cleaning and conditioning leather and vinyl interiors. I maintain a keen eye for detail and strive for excellence in every aspect of the detailing process. I’m capable of training staff in these techniques, ensuring a consistent level of quality across the board.

Q 15. How do you handle difficult customers or confrontational situations?

Handling difficult customers requires a calm and professional approach. My strategy focuses on active listening, empathy, and finding mutually agreeable solutions. I begin by acknowledging the customer’s concerns and validating their feelings, even if I don’t agree with their perspective. For instance, if a customer is upset about a perceived imperfection in their car’s cleaning, I’ll apologize for their dissatisfaction and offer a specific solution, such as a complimentary re-wash or detailing service. I believe in de-escalation through clear and respectful communication. If the situation remains tense, I would involve a supervisor to assist in resolving the conflict. Ultimately, my goal is to convert a negative experience into a positive one, fostering customer loyalty despite initial friction. The key is patience, understanding, and a genuine desire to resolve the issue fairly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with promoting car wash services and packages.

My experience in promoting car wash services and packages has involved a multifaceted approach leveraging both traditional and digital marketing techniques. I’ve successfully implemented loyalty programs, offering discounts for repeat customers and bundled packages for various services (e.g., wash, wax, interior detail). We’ve also utilized targeted social media campaigns showcasing before-and-after photos, customer testimonials, and special offers. Local partnerships with businesses and community events have provided additional avenues for promotion. For example, we partnered with a local auto dealership to offer discounted washes to their customers. Data analysis of our promotional efforts informs future strategies, allowing us to optimize our marketing spend and target our messaging effectively. Tracking customer preferences through surveys and feedback helps us tailor our packages to meet customer demands.

Q 17. Explain your knowledge of different types of car finishes and their care.

Understanding different car finishes and their proper care is critical for providing quality car wash services. Clear coat finishes are common and require gentle washing techniques to avoid scratching. We use microfiber cloths and pH-neutral car wash soaps to ensure we aren’t damaging the protective layer. Matte finishes require even more careful handling, as they are more susceptible to damage. We use specialized products and techniques to clean these finishes without compromising their unique aesthetic. For ceramic-coated vehicles, we understand the importance of preserving the coating’s protective qualities, often using specific cleaning solutions designed for this purpose. Knowledge of different finishes informs our choices in cleaning products and washing techniques, allowing us to offer tailored services to maximize customer satisfaction and protect their vehicles’ appearance.

Q 18. How do you prioritize tasks during a busy day in the car wash?

Prioritizing tasks during a busy day in a car wash requires a systematic approach. I use a combination of methods, including visual cues like a whiteboard to list tasks and a time management system. We prioritize urgent tasks, such as addressing customer needs, ahead of less time-sensitive ones. Teamwork is vital; we assign roles and responsibilities, ensuring everyone understands their priorities. Using a first-in, first-out (FIFO) system for vehicle processing helps maintain a fair and efficient workflow. Real-time communication and adaptability are key; we adjust priorities based on unforeseen circumstances like equipment malfunctions or unexpected influxes of customers. Regular communication and a clear workflow keeps the team organized and focused.

Q 19. What are your methods for training new car wash employees?

Training new car wash employees involves a structured program that combines classroom learning and hands-on experience. We start with safety training, covering the use of equipment and chemicals, and then move on to the various washing techniques. Experienced staff members work alongside new hires, providing mentorship and guidance. Each employee is assessed regularly, ensuring a solid understanding of procedures and a high level of service. We also cover customer service skills, emphasizing respectful communication and conflict resolution techniques. The training is ongoing, with periodic refresher courses and opportunities for advanced training on specialized services. Clear expectations and continuous feedback promote efficient learning and consistent service quality.

Q 20. Describe a time you had to solve a technical problem in the car wash.

One time, our high-pressure washing system malfunctioned, causing a significant backlog. Instead of panicking, I systematically troubleshooted the problem. I first checked the water supply and power, then examined the pump and pressure gauge. I realized the issue was a clogged filter, which I promptly cleaned. This resolved the problem, getting the system back online quickly. To prevent future occurrences, I implemented a regular filter maintenance schedule. This experience highlighted the importance of preventative maintenance and proactive problem-solving skills. This also showed my ability to remain calm and use logical steps to resolve an issue impacting customer service and operational efficiency.

Q 21. How familiar are you with environmental regulations related to car washes?

Familiarity with environmental regulations is paramount in operating a car wash. We adhere strictly to local and state regulations concerning wastewater treatment and disposal. This includes proper use and disposal of cleaning chemicals, ensuring we comply with limits on pollutants. We regularly monitor our water usage and implement water-saving practices where possible, such as using high-pressure, low-flow systems and recycling water. Our facility is equipped with effective filtration systems to minimize environmental impact. We maintain detailed records of chemical usage and wastewater treatment to demonstrate our compliance with environmental regulations. Staying informed about changes in regulations and investing in environmentally friendly technologies are crucial aspects of our operation.

Q 22. How do you ensure the safety of both employees and customers?

Safety is paramount in a car wash environment. We achieve this through a multi-pronged approach encompassing employee training and robust safety protocols.

- Employee Training: All employees receive comprehensive safety training covering the proper use of equipment, chemical handling procedures (including proper PPE usage – personal protective equipment like gloves, eye protection, and aprons), emergency procedures (e.g., handling equipment malfunctions, chemical spills, and first aid), and safe work practices to prevent slips, trips, and falls. This training is regularly refreshed and updated.

- Regular Inspections: We conduct regular safety inspections of the equipment and facility, looking for potential hazards like frayed cords, leaking fluids, or slippery surfaces. Maintenance schedules are strictly adhered to.

- Customer Safety: We clearly mark hazardous areas and provide signage warning customers about potential risks. We encourage customers to remain in their vehicles during the washing process and provide waiting areas that are safely distanced from operational areas. Furthermore, we have clearly defined procedures for handling customer complaints or incidents.

- Emergency Preparedness: We have a detailed emergency plan readily available to all staff members, outlining procedures for various scenarios, including accidents, fires, and severe weather events. We also maintain a well-stocked first-aid kit and regularly conduct emergency drills.

For instance, during training, employees practice using fire extinguishers on a mock fire scenario and learn the precise location of safety equipment throughout the facility. This hands-on approach ensures everyone knows what to do in case of an emergency.

Q 23. What is your experience with using different types of car wash equipment?

My experience encompasses a wide range of car wash equipment, from self-serve bays to fully automated systems.

- Self-Serve Bays: I’m proficient in maintaining and troubleshooting the functionality of individual bay components like high-pressure wands, foam guns, and vacuum systems. Understanding the intricacies of these systems allows for quick repairs and minimizes downtime.

- In-Bay Automatic (IBA) Systems: I’ve worked extensively with IBA systems, familiar with their various components, including conveyor systems, wash brushes, high-pressure nozzles, and drying systems. Troubleshooting issues in these sophisticated systems requires a methodical approach and a detailed understanding of their operational logic. I’m capable of performing preventative maintenance and minor repairs.

- Tunnel Wash Systems: I have experience managing and operating tunnel wash systems, understanding the complex interplay between the various stages of the wash process – pre-soak, wash, rinse, and dry. This includes managing chemical delivery systems, monitoring water usage, and ensuring the overall efficiency and effectiveness of the system.

- Detailing Equipment: I’m also experienced with a variety of detailing equipment such as buffers, polishers, and vacuum cleaners used for post-wash detailing services.

In my previous role, I successfully diagnosed and resolved a recurring malfunction in an IBA system’s conveyor belt, preventing significant downtime and customer inconvenience. This involved identifying a worn roller and replacing it efficiently, showcasing my ability to handle complex mechanical issues.

Q 24. What are your strategies for preventing theft or vandalism at the car wash?

Preventing theft and vandalism requires a layered security approach.

- Surveillance Systems: Utilizing a comprehensive CCTV system with strategically placed cameras covering all key areas of the car wash, both interior and exterior, is critical. Recording capabilities allow for review in case of incidents.

- Security Lighting: Adequate and strategically placed lighting around the premises acts as a powerful deterrent. Motion-sensor lights can be particularly effective in minimizing dark areas.

- Secure Storage: All valuable equipment and chemicals are kept securely locked away in designated storage areas. This reduces the opportunity for theft.

- Employee Training: Staff members are trained to be vigilant and report any suspicious activity immediately. They’re also instructed on secure cash handling procedures.

- Regular Patrols: Especially at night or during low-traffic periods, regular patrols of the premises can significantly deter potential criminals.

- Alarms and Security Systems: A professionally monitored alarm system, possibly in conjunction with motion sensors, will offer an immediate response in case of unauthorized entry or vandalism.

For example, in my previous role, we implemented a motion-sensing security light system which resulted in a significant reduction in vandalism incidents within the first month.

Q 25. How do you track key performance indicators (KPIs) in a car wash?

Tracking KPIs is essential for optimizing car wash operations and profitability. We focus on several key metrics:

- Vehicles Washed Per Hour/Day: This measures the efficiency of the wash process and staff productivity.

- Customer Satisfaction (CSAT): Surveys and feedback mechanisms help gauge customer satisfaction levels and identify areas for improvement.

- Average Revenue Per Vehicle (ARPV): This tracks the profitability of different wash packages and services offered.

- Operating Costs: Monitoring water usage, chemical consumption, and electricity costs helps manage expenses effectively.

- Employee Turnover Rate: Tracking employee turnover indicates the effectiveness of personnel management and work environment.

- Maintenance Costs: Tracking maintenance expenses allows for budgeting and planning for equipment repairs and replacements.

We use a combination of point-of-sale (POS) systems, customer feedback platforms, and spreadsheets to collect and analyze this data. Regular review of these KPIs allows us to identify trends, make data-driven decisions, and implement improvements. For instance, a low CSAT score might indicate a need for improved customer service training or a review of the wash process.

Q 26. Describe your experience with maintaining a clean and safe work environment.

Maintaining a clean and safe work environment is a top priority. This involves a combination of proactive measures and consistent upkeep.

- Regular Cleaning: Implementing a regular cleaning schedule for all areas of the car wash, including equipment, floors, and restrooms, is essential. This prevents the buildup of dirt, grime, and potential hazards.

- Chemical Management: Proper storage and handling of chemicals, including labeling, safety data sheets (SDS) accessibility and adherence to safety procedures are paramount. This ensures the safety of employees and prevents environmental damage.

- Waste Disposal: Adhering to environmental regulations regarding waste disposal is crucial. This includes the proper handling and disposal of wastewater, cleaning solutions, and other waste products.

- Equipment Maintenance: Regular maintenance of equipment helps prevent breakdowns and ensures operational efficiency. It also contributes to a safer working environment.

- Slip and Fall Prevention: Regular cleaning and the use of anti-slip mats in high-traffic areas help to minimize the risk of slips and falls.

- Ergonomic Considerations: Ensuring that workstations are ergonomically designed to minimize physical strain on employees is crucial for a healthy and safe work environment.

For instance, we developed a color-coded system for chemical storage and handling, making it easier for employees to identify and use chemicals safely. This simple change dramatically improved the safety and efficiency of chemical handling processes.

Q 27. How do you handle customer feedback and use it to improve services?

Customer feedback is invaluable for continuous improvement. We actively solicit and analyze feedback through various channels.

- Customer Surveys: We use online surveys and in-person feedback forms to gather customer opinions on their experience.

- Online Reviews: We monitor online reviews on platforms like Google, Yelp, and social media to identify trends and address concerns promptly.

- Comment Cards: Physical comment cards placed at convenient locations allow for immediate feedback collection.

- Direct Communication: We encourage customers to communicate their feedback directly to staff members, providing an opportunity for immediate resolution or clarification.

We analyze the feedback to identify recurring issues, such as long wait times, unsatisfactory cleaning results, or issues with staff friendliness. This data informs decisions on service improvements, process optimizations, employee training, and upgrades to equipment or facilities. For example, customer feedback highlighted slow drying times, leading to an upgrade to our drying system. This resulted in faster service and increased customer satisfaction.

Q 28. What are your salary expectations for this car wash position?

My salary expectations are commensurate with my experience and skills in the car wash industry. Considering my expertise in equipment maintenance, operational management, and customer service, I am seeking a competitive salary within the range of [Insert Salary Range]. I am also open to discussing a compensation package that includes benefits such as health insurance, paid time off, and potential bonuses based on performance metrics.

Key Topics to Learn for Your Car Wash Interview

- Customer Service Excellence: Understanding the importance of providing exceptional customer service in a fast-paced environment. This includes effective communication, handling customer complaints, and exceeding expectations.

- Car Wash Processes & Equipment: Familiarize yourself with the various stages of a car wash process, from pre-wash to detailing. Understand the operation and maintenance of different equipment like conveyor systems, wash bays, and dryers.

- Safety Procedures & Regulations: Demonstrate knowledge of safety protocols related to chemical handling, equipment operation, and workplace hazards. Understanding relevant industry regulations is crucial.

- Teamwork & Collaboration: Highlight your ability to work effectively as part of a team, contributing to a smooth and efficient workflow. Explain how you handle different personalities and collaborate towards shared goals.

- Efficiency & Productivity: Show your understanding of maximizing efficiency within the car wash operation. This includes minimizing downtime, managing workflow, and optimizing resource allocation.

- Inventory Management (if applicable): If the role involves inventory, demonstrate an understanding of stock control, ordering supplies, and minimizing waste.

- Cash Handling & POS Systems (if applicable): If the role involves handling cash, show your experience with cash registers, point-of-sale (POS) systems, and accurate transaction processing.

- Problem-Solving & Quick Thinking: Prepare examples of how you’ve resolved unexpected issues or challenges in previous roles, highlighting your ability to think on your feet and find effective solutions.

Next Steps

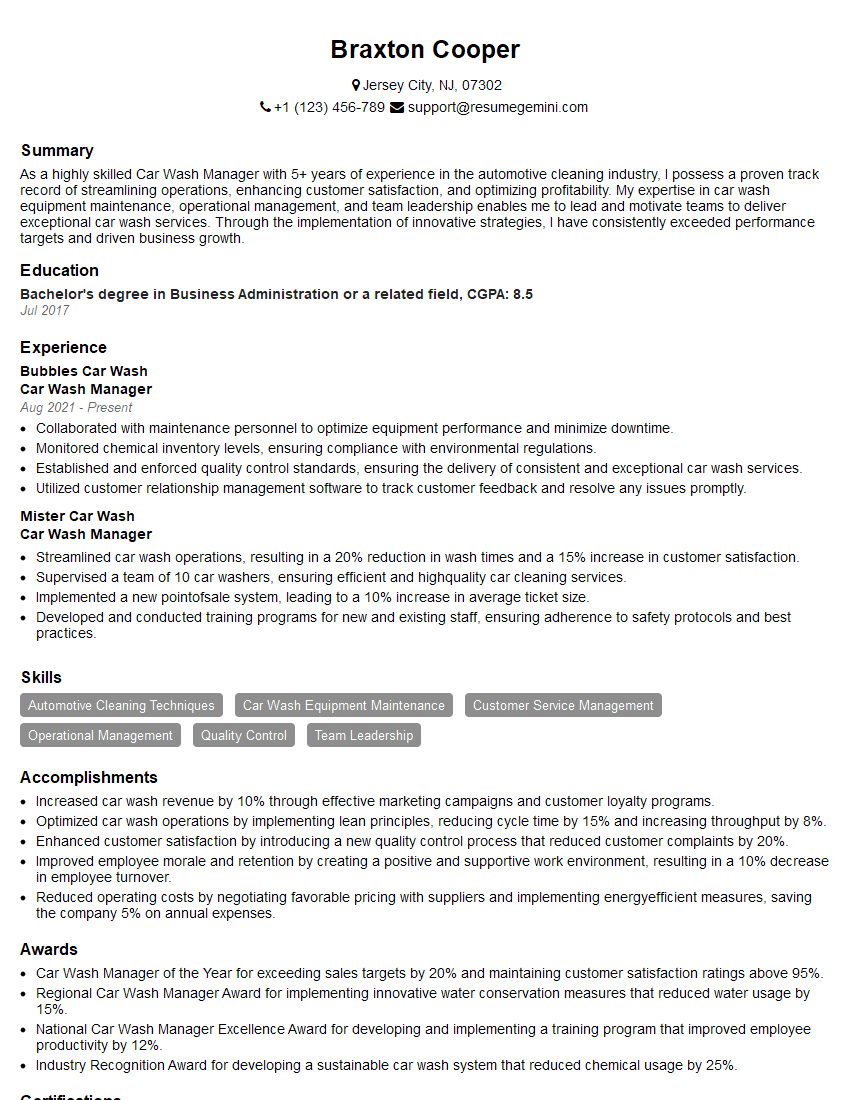

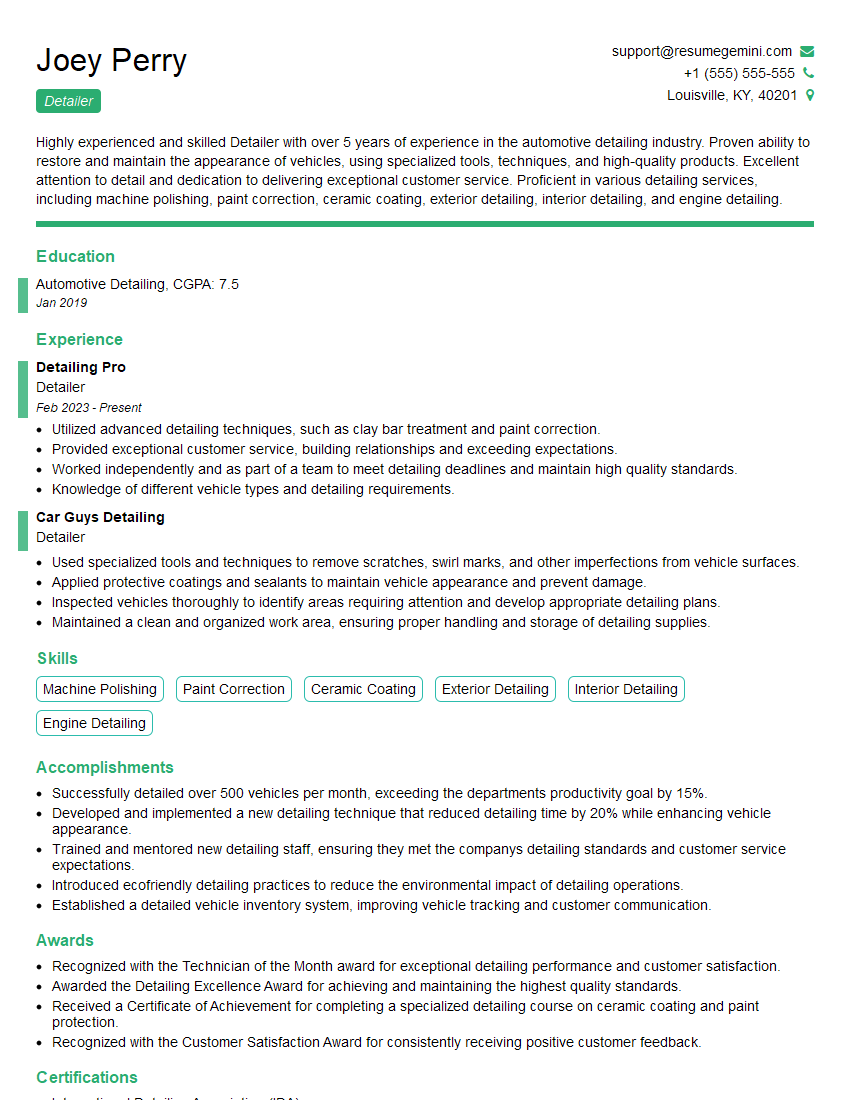

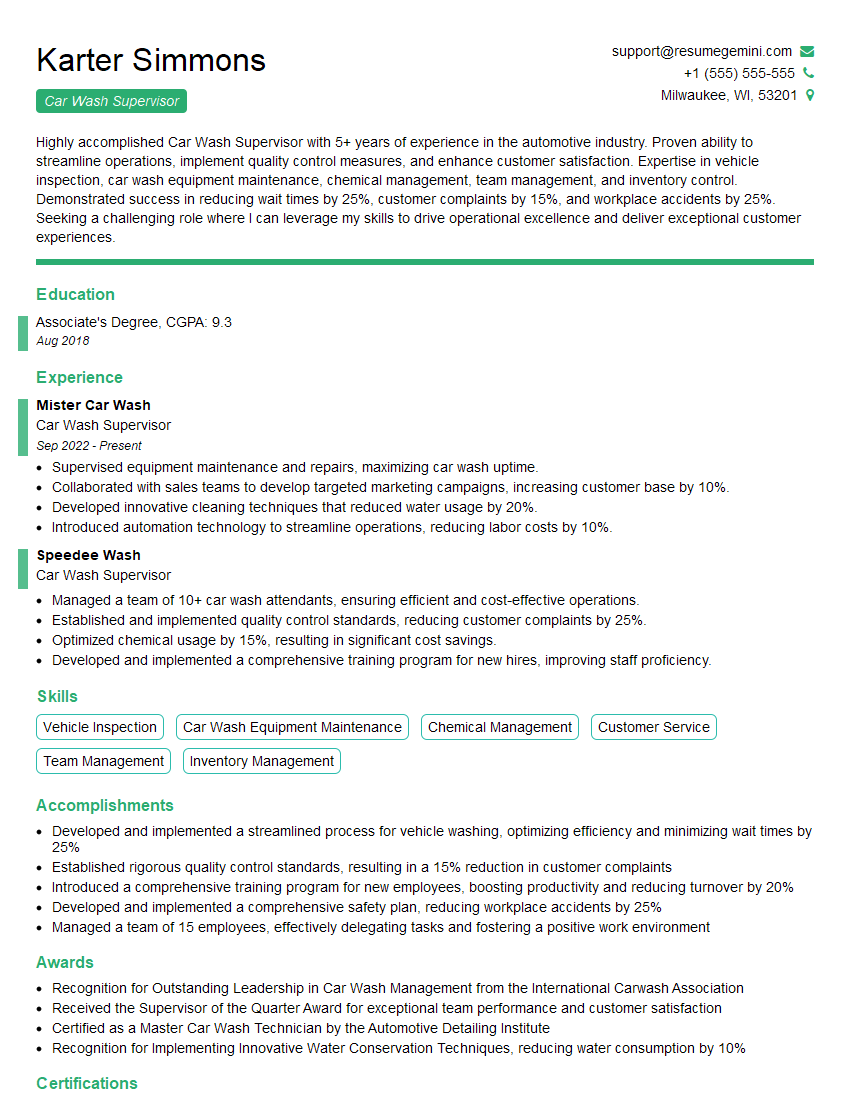

Mastering the key aspects of a car wash operation is vital for career progression within the industry. It demonstrates your commitment to providing excellent service and your understanding of efficient operational practices. To significantly increase your chances of landing your dream job, building an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to the specific requirements of car wash positions. Examples of resumes tailored to the car wash industry are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO