Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ceramic Coatings interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ceramic Coatings Interview

Q 1. Explain the chemical composition of a typical ceramic coating.

Ceramic coatings are primarily composed of silicon dioxide (SiO2), often in a nano-form. Think of it like incredibly tiny, microscopic glass particles. However, the precise chemical composition can vary significantly depending on the manufacturer and the specific product. Many high-end coatings incorporate other metal oxides, such as titanium dioxide (TiO2), zirconium dioxide (ZrO2), or aluminum oxide (Al2O3), to enhance properties like hardness, UV resistance, or hydrophobicity. These additional components are usually present in smaller percentages, acting as modifiers to fine-tune the overall performance of the coating.

For instance, the addition of TiO2 can boost the coating’s UV resistance, helping to protect the underlying surface from sun damage. These complex mixtures are precisely engineered to achieve a balance of desirable characteristics, such as durability, gloss, and self-cleaning properties.

Q 2. Describe the different types of ceramic coatings available (e.g., SiO2, Si02/TiO2).

Ceramic coatings are broadly classified based on their primary chemical components and performance characteristics. The most common type is based on SiO2 (silicon dioxide), offering excellent hardness and hydrophobicity (water repellency). Many coatings incorporate additional components, creating hybrid variations:

- SiO2 (Silicon Dioxide): This is the foundational component of most ceramic coatings. It provides superior hardness, scratch resistance, and hydrophobic properties, creating a slick surface that repels water and dirt.

- SiO2/TiO2 (Silicon Dioxide/Titanium Dioxide): The addition of TiO2 enhances UV resistance, protecting the underlying surface from sun damage and fading. This combination often results in a slightly increased gloss and improved self-cleaning capabilities.

- Multi-component Coatings: Many advanced ceramic coatings incorporate multiple metal oxides such as ZrO2 and Al2O3, further enhancing specific properties. For example, ZrO2 can increase scratch resistance and Al2O3 can improve chemical resistance.

The variations in composition lead to differences in durability, gloss, hydrophobicity, and other performance characteristics. Choosing the right coating depends heavily on the application and desired outcome.

Q 3. What are the key benefits of using ceramic coatings compared to traditional waxes?

Ceramic coatings offer several significant advantages over traditional waxes:

- Durability: Ceramic coatings are significantly more durable, lasting for months or even years, compared to waxes which need to be reapplied every few weeks. This longevity translates to substantial time and cost savings.

- Hydrophobicity: Ceramic coatings exhibit superior water beading and repellency, making cleaning easier and reducing water spotting. Think of it like the difference between a duck’s feathers and a wet dog – the coating makes the surface drastically easier to clean.

- Gloss and Shine: Ceramic coatings often enhance the gloss and shine of the surface, creating a deeper, more reflective finish compared to waxes.

- UV Protection: Many ceramic coatings offer superior UV protection, mitigating the effects of sun damage and preventing fading.

- Chemical Resistance: Ceramic coatings provide better resistance to chemicals and environmental contaminants, keeping the surface cleaner for longer.

In essence, ceramic coatings offer a far more protective and longer-lasting solution than traditional waxes, justifying their higher initial cost through long-term savings and enhanced protection.

Q 4. Explain the surface preparation process before applying a ceramic coating.

Thorough surface preparation is crucial for achieving optimal adhesion and performance of a ceramic coating. Think of it as preparing a canvas for a painting – a poorly prepared surface will lead to a disappointing result. The process typically involves these steps:

- Washing: A thorough two-bucket wash using a designated wash mitt and high-quality car wash soap is essential to remove loose dirt and grime. This prevents contaminants from being embedded under the coating.

- Decontamination: This step removes embedded contaminants like iron particles (from brake dust) and tar using dedicated iron remover and tar remover products. This is often overlooked but is vital for optimal bond strength and durability.

- Drying: The surface needs to be completely dry before proceeding. Using a high-quality drying towel or air blower is recommended.

- Panel Wipe Down: A final wipe down with an isopropyl alcohol solution helps to remove any remaining residue and ensures a clean, perfectly prepared surface.

- Defect Correction (Optional): For a truly flawless finish, addressing imperfections like swirl marks and scratches through polishing is highly recommended.

Skipping any of these steps can significantly compromise the adhesion, durability, and overall appearance of the ceramic coating.

Q 5. What are the proper techniques for applying a ceramic coating?

Applying a ceramic coating requires precision and attention to detail. The specific instructions will vary depending on the manufacturer’s recommendations, but the general process involves:

- Preparation: Ensure the surface is perfectly clean and dry as described in the previous step.

- Application: Apply the coating in thin, even layers using an applicator pad. Work in small sections (2×2 feet, for instance) to avoid the coating drying out prematurely.

- Spread and Wipe: Spread the coating evenly across the surface and then, within the manufacturer’s recommended time frame, use a clean microfiber towel to wipe away any excess coating.

- Inspection: Carefully inspect the surface to ensure even coverage and the absence of streaks or high spots.

- Curing: Allow the coating to cure according to the manufacturer’s instructions. This is crucial for achieving maximum hardness and durability.

It’s crucial to follow the manufacturer’s instructions closely, as application techniques may vary depending on the specific coating.

Q 6. How do you ensure even coating application and avoid streaks?

Achieving an even coating application and avoiding streaks requires careful attention to several factors:

- Thin Layers: Applying thin, even layers is paramount. Too much coating in one area can lead to uneven drying and streaks.

- Proper Technique: Use a consistent application technique with light pressure, spreading the coating evenly across the surface.

- Applicator Pad: Use high-quality applicator pads designed for ceramic coatings, ensuring they’re clean and free from debris.

- Working Time: Work within the recommended working time of the coating to avoid premature drying.

- Microfiber Towels: Use high-quality, lint-free microfiber towels for wiping off excess coating. Folding the towel frequently during the wiping process helps maintain a clean wiping surface.

- Lighting: Work in good lighting to easily spot any unevenness or streaks during the application and wiping stages.

Practice and attention to detail are key to achieving a flawless, streak-free finish. If streaks do appear, gently reapply a thin layer and wipe again before the coating fully cures.

Q 7. What are the different curing methods for ceramic coatings?

Curing methods for ceramic coatings vary depending on the specific product, but generally fall into these categories:

- Air Drying: Most consumer-grade ceramic coatings cure through air drying. This process typically involves letting the coating sit undisturbed for a specified period (often several hours or even days) to allow it to fully harden.

- Forced Air Drying: Some professional-grade coatings can benefit from forced air drying using fans to promote even curing and reduce the overall cure time.

- Heat Curing (Less Common): A few advanced coatings might require heat curing to accelerate the chemical reactions and achieve optimal hardness and durability. This is usually done with specific equipment and should strictly follow the manufacturer’s instructions.

It is extremely important to follow the manufacturer’s instructions precisely regarding curing time and environment to ensure the coating achieves its maximum potential performance.

Q 8. How do you handle imperfections or defects in the coating application?

Handling imperfections in ceramic coating application is crucial for achieving a flawless, durable finish. Imperfections can range from minor surface blemishes like dust nibs or orange peel to more significant issues like runs or pinholes. My approach is multi-faceted and depends on the severity of the defect.

- Minor Imperfections (Dust Nibs, Orange Peel): These are often addressed through meticulous polishing after the coating has fully cured. A multi-stage polishing process, starting with coarser compounds and progressing to finer ones, can effectively remove these minor blemishes without compromising the coating’s integrity. Imagine sanding down a slightly bumpy surface to achieve a smooth finish; the principle is similar.

- Significant Imperfections (Runs, Pinholes): For more serious defects, the affected area may need to be carefully removed using a dedicated coating remover, ensuring not to damage the underlying surface. Once the area is prepped correctly, a fresh application of the coating can then be applied.

- Prevention is Key: Proper surface preparation is paramount to prevent defects in the first place. This includes thorough cleaning, decontaminating the surface, and ensuring optimal environmental conditions (temperature and humidity) during application.

Careful attention to detail throughout the entire process, from preparation to application and curing, minimizes the need for corrective measures. A trained eye and experience are vital in identifying and handling these issues efficiently.

Q 9. What is the expected lifespan of a typical ceramic coating?

The lifespan of a ceramic coating is highly variable and depends on several factors, including the quality of the coating itself, the application process, the vehicle’s environment, and the level of maintenance. A high-quality, professionally applied ceramic coating can last anywhere from 2 to 5 years, sometimes even longer.

However, factors like frequent exposure to harsh weather (acid rain, extreme temperatures, UV radiation), regular washing with abrasive materials, and the frequency of contact with contaminants all contribute to the coating’s degradation. Think of it like protecting your car with a high-quality shield – the better the shield and the more careful you are, the longer it will last. A less durable coating or improper application will shorten the lifespan significantly.

Therefore, providing an exact number is impossible without detailed information about these factors. Regular inspections and maintenance are essential to accurately assess its condition and remaining lifespan.

Q 10. How do you maintain a ceramic coating after application?

Maintaining a ceramic coating involves a proactive approach designed to preserve its shine, hydrophobic properties, and overall durability. Regular maintenance is crucial for maximizing the lifespan of the coating and preventing premature degradation.

- Regular Washing: Wash your vehicle frequently (every 1-2 weeks) using a pH-neutral car wash soap and a soft wash mitt or sponge. Avoid harsh chemicals or abrasive materials that could scratch the surface.

- Drying: Use a high-quality microfiber drying towel or air dry to prevent water spots. Water spots can etch into the coating over time, diminishing its clarity.

- Periodic Decontamination: Periodically (every 3-6 months), use a detailing spray and a clay bar to remove embedded contaminants that may build up on the surface, preventing them from damaging the coating.

- Protection from Harsh Elements: Park your car in a garage whenever possible, away from direct sunlight, acid rain, and bird droppings. Use a quality car cover for additional protection.

- Professional Detailing: Consider a professional detailing service every 1-2 years for a more thorough cleaning and inspection.

Following these simple maintenance procedures will significantly extend the life and enhance the beauty of your ceramic coating.

Q 11. Describe the different levels of hardness in ceramic coatings.

Ceramic coatings are rated based on their hardness, typically measured on the Mohs Hardness Scale or similar testing methods. The hardness indicates the coating’s resistance to scratching and abrasion. Generally, higher hardness equates to greater durability and scratch resistance. However, extreme hardness doesn’t always guarantee superior performance. There is a balance between hardness and flexibility.

- Low Hardness (e.g., 2H-4H): These offer moderate protection and are often used as sealants or lower-end ceramic coatings. They are more susceptible to scratching.

- Medium Hardness (e.g., 6H-7H): These provide good protection against everyday scratches and are commonly used in mid-range ceramic coatings.

- High Hardness (e.g., 9H): These are the hardest coatings, offering superior scratch resistance. They are typically found in high-end ceramic coatings.

It’s crucial to note that the reported hardness often varies between manufacturers and testing methods. Understanding the specific properties of the coating and its application is vital to assess its actual protective capabilities. A 9H rating doesn’t automatically make a coating superior; other factors like chemical resistance, UV protection, and overall formulation matter.

Q 12. Explain the concept of gloss and its relation to ceramic coatings.

Gloss refers to the shine or reflective quality of a surface. Ceramic coatings are designed to enhance gloss, providing a deep, brilliant shine to the vehicle’s paint. The level of gloss achieved depends on several factors, including the type of coating, the application technique, and the underlying paint condition.

High-quality ceramic coatings typically improve gloss significantly, creating a smoother, more reflective surface. They fill in minor imperfections in the paint, reducing the scattering of light, and thus enhancing the reflective qualities. Imagine comparing a polished mirror (high gloss) to a dull, scratched surface (low gloss). The ceramic coating acts similarly, filling imperfections for a more mirror-like reflection. Some coatings are specifically formulated to enhance gloss levels more than others.

However, excessive gloss may sometimes indicate a thicker-than-necessary coating layer, potentially affecting the coating’s longevity or even leading to problems during curing.

Q 13. How do you determine the appropriate coating thickness?

Determining the appropriate coating thickness is crucial for optimal performance and longevity. Too thin a coating may offer insufficient protection, while a coating that’s too thick can lead to issues during curing, potentially causing imperfections or cracking. The ideal thickness varies depending on the specific coating and the manufacturer’s recommendations.

There’s no universal standard; some coatings might recommend a specific wet film thickness (e.g., 2-3 microns), which is measured using specialized tools, during the application process. These tools help professionals ensure an even layer and correct thickness. Many high-quality coatings are self-leveling, which helps to some extent. However, the manufacturer’s instructions should always be strictly followed.

In practice, I rely on a combination of experience, product-specific guidance, and careful monitoring during the application process. This involves practicing the correct application techniques to achieve consistent and even spreading, along with the use of specialized tools to monitor thickness.

Q 14. What are the safety precautions involved in handling and applying ceramic coatings?

Safety is paramount when handling and applying ceramic coatings. These products contain chemicals that, if mishandled, can cause irritation or damage. The following precautions are crucial:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and a respirator, to prevent skin and respiratory irritation. Many ceramic coatings have solvents or other potentially harmful chemicals.

- Proper Ventilation: Work in a well-ventilated area or use a respirator to avoid inhaling fumes. This is especially important when working indoors.

- Surface Preparation: Always thoroughly clean and prepare the surface before application, avoiding the generation of excessive dust. Dust particles can embed themselves in the coating, causing imperfections.

- Material Handling: Handle the coating and related materials carefully, following the manufacturer’s instructions precisely.

- Waste Disposal: Dispose of any waste materials, including rags, applicators, and leftover coating, according to local regulations. Some coatings require special disposal methods.

- First Aid: Be prepared for accidental exposure. Know the proper first aid procedures and have appropriate materials readily available.

Prioritizing safety and following proper procedures ensures a safe and effective ceramic coating application process.

Q 15. What are the environmental considerations related to ceramic coating application?

Environmental considerations in ceramic coating application primarily revolve around the volatile organic compounds (VOCs) present in some coatings and the disposal of waste materials. Many modern ceramic coatings are formulated to be low-VOC or even VOC-free, minimizing air pollution during application. However, proper ventilation is always crucial to ensure worker safety. Waste products, including used applicators, cloths, and any coating residue, must be disposed of responsibly according to local environmental regulations. This often involves using specialized waste collection services to handle hazardous materials if necessary. Failure to adhere to these guidelines can result in environmental damage and legal repercussions.

For example, we always use certified VOC-compliant coatings and maintain meticulous records of waste disposal. We also educate our staff on proper ventilation techniques and safe handling procedures. This proactive approach minimizes our environmental footprint and demonstrates our commitment to sustainability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle customer complaints regarding ceramic coating application?

Handling customer complaints is crucial for maintaining a positive reputation. We begin by actively listening to the customer’s concerns, showing empathy and understanding. Next, we thoroughly inspect the coated surface, documenting any visible imperfections with photos and detailed notes. We then compare our findings to our application checklist and service agreement to identify potential causes of the issue. These could include improper surface preparation, environmental factors during curing, or product defects.

If the complaint is valid and attributable to our work, we offer appropriate remediation, which could involve re-coating the affected area or offering a partial refund. Transparency is key; we communicate clearly with the customer throughout the process, setting realistic expectations for timelines and outcomes. For instance, a recent complaint involved minor water spotting; after investigation, we identified it as a result of insufficient drying post-application, a detail we now emphasize more strongly in our aftercare instructions. Excellent communication and a willingness to rectify issues build trust and customer loyalty.

Q 17. Explain the difference between single-layer and multi-layer ceramic coatings.

The key difference between single-layer and multi-layer ceramic coatings lies in their thickness, durability, and hydrophobic properties. A single-layer coating offers a basic level of protection and gloss enhancement. Think of it like a single coat of paint – it provides some protection but isn’t as robust. Multi-layer coatings, on the other hand, involve applying several thin layers successively. Each layer builds upon the previous one, creating a thicker, more durable, and more hydrophobic shield. This is similar to building a brick wall – each brick adds strength and stability.

Multi-layer coatings typically offer enhanced protection against scratches, UV damage, and chemical etching, providing longer-lasting performance and a deeper, more intense shine compared to single-layer counterparts. The choice between single or multi-layer depends on the customer’s budget, desired level of protection, and the specific application. High-end vehicles or those frequently exposed to harsh elements might benefit greatly from a multi-layer system.

Q 18. What are the common challenges faced when applying ceramic coatings?

Applying ceramic coatings presents several common challenges. One major hurdle is achieving proper surface preparation. Contaminants like dust, oils, and previous waxes must be completely removed to ensure proper adhesion. Inadequate surface preparation can lead to coating failure. Another challenge is environmental conditions. Temperature, humidity, and even direct sunlight can significantly impact curing and the final outcome. For instance, applying a coating in direct sunlight might cause it to cure too quickly, leading to unevenness. Application technique also plays a critical role. Uneven application or insufficient spreading can result in inconsistent coverage and visible defects.

Furthermore, proper product selection and understanding the specific properties of the coating are crucial. Some coatings require specific curing times and environmental conditions for optimal performance. Careful attention to detail throughout the entire process, from preparation to application and curing, minimizes the risk of encountering these common challenges.

Q 19. How do you address issues like water spotting or etching on a coated surface?

Water spotting and etching on a coated surface are often caused by mineral deposits in hard water, acidic contaminants, or improper washing techniques. To address water spotting, a thorough cleaning with a pH-neutral car wash soap and a high-quality microfiber towel is usually sufficient. For more stubborn spots, a dedicated water spot remover can be used, following the manufacturer’s instructions carefully. Etching, which is a more serious issue, may require more intensive correction.

This could involve using a polishing compound and a polishing machine (following appropriate safety measures). However, aggressive polishing can remove some of the coating’s thickness. Therefore, preventing water spotting and etching through proper washing and drying techniques is crucial. Using a dedicated drying towel or blower to remove excess water immediately after washing helps avoid these issues entirely. Remember, always consult the coating manufacturer’s recommendations for cleaning and maintenance procedures.

Q 20. What are the different types of tools and equipment used in ceramic coating application?

The tools and equipment used in ceramic coating application vary depending on the scale of the operation and the specific coating being used. However, some essential items include:

- Microfiber applicators (various sizes and types): These are used for applying the coating evenly and precisely.

- Microfiber towels: High-quality microfiber towels are crucial for removing excess coating and for cleaning.

- Isopropyl alcohol (IPA): Used for cleaning and degreasing the surface before application.

- Surface prep tools: These might include clay bars, detailing brushes, and polishing compounds to achieve perfect surface preparation.

- Measuring devices (graduated cylinders, scales): Precise measurement ensures correct mixing ratios if required by the product.

- Protective gear: Gloves, eye protection, and respirators to ensure worker safety.

- Optional equipment: Orbital polishers or buffer machines can improve application quality for larger surfaces.

Q 21. How do you clean and maintain your application tools?

Maintaining clean application tools is critical for preventing contamination and ensuring consistent coating quality. After each use, microfiber applicators and towels should be washed separately using a gentle detergent and thoroughly rinsed. Do not use fabric softener, as this can impact the absorbency and performance of the microfiber. Allow them to air dry completely before storing to prevent mold and mildew.

Tools like measuring cylinders and spray bottles should be rinsed thoroughly with clean water and allowed to air dry. For more stubborn residues, a mild detergent can be used, followed by a thorough rinsing. Proper cleaning and storage extend the lifespan of our tools and maintain the highest standards of hygiene and professionalism. Regular inspection of tools for wear and tear is also crucial to ensure consistent application quality.

Q 22. How do you identify the correct type of ceramic coating for a specific substrate?

Choosing the right ceramic coating depends heavily on the substrate material and its intended use. Think of it like choosing the right paint for a project – you wouldn’t use house paint on a car. For example, a coating designed for automotive paint might not be suitable for ceramic tiles, and vice versa.

- Material Compatibility: The coating’s chemical composition must be compatible with the substrate. Some coatings bond better with certain materials like glass, paint, or metal. The manufacturer’s specifications will clearly state which substrates are compatible.

- Durability Requirements: Consider the level of protection needed. A coating for a show car will require a different level of scratch and UV resistance than a coating for everyday use.

- Gloss Level & Finish: Do you prefer a high gloss, satin, or matte finish? Different coatings offer different aesthetic outcomes.

- Application Method: Some coatings are easier to apply than others, requiring different levels of skill and tools.

For instance, if I’m coating a client’s high-end sports car, I’ll carefully choose a coating known for its excellent scratch resistance, UV protection, and hydrophobic properties, ensuring its compatibility with automotive clear coat. For a less demanding application, such as coating a kitchen countertop, I would choose a coating prioritized for chemical resistance and ease of cleaning, potentially foregoing features like extreme hardness or high gloss.

Q 23. Describe the process of removing old ceramic coating before reapplying.

Removing an old ceramic coating is crucial before applying a new one to ensure proper adhesion. A thorough cleaning and preparation process is critical for optimal results. A poorly prepared surface will lead to poor bonding and a shorter lifespan for the new coating.

- Assessment: First, I carefully inspect the existing coating’s condition. Is it damaged or failing in areas? Knowing this informs the appropriate cleaning method.

- Degreasing: Using an appropriate degreaser, the surface is thoroughly cleaned to remove any contaminants like dirt, oil, or wax. This step is paramount to ensure the new coating adheres effectively.

- Decontamination: This often involves using a clay bar or iron remover to remove embedded contaminants. This is like deep cleaning the surface, removing any microscopic particles hindering good adhesion.

- Mechanical Removal (if necessary): If the old coating is significantly damaged or failing, it may require mechanical removal using a dedicated ceramic coating remover or a very fine abrasive compound. This step is done with extreme caution to avoid scratching the underlying substrate.

- Final Cleaning and Inspection: After removal, the surface is meticulously cleaned again to remove any residue. A thorough inspection under bright light ensures a perfectly clean surface before the new coating is applied.

For example, I recently encountered a vehicle with a failing ceramic coating. It had numerous scratches and the protective qualities were diminished. After thorough cleaning and decontamination, we carefully used a coating remover to remove the old coating before preparing the surface for the new, higher-quality product. The result was a flawless finish with much-improved protection.

Q 24. What are your experiences with different brands of ceramic coatings?

I’ve worked with a wide range of ceramic coating brands, each having its own strengths and weaknesses. My experience is based on factors like ease of application, durability, gloss, and longevity. It’s important to note that ‘best’ is subjective and depends heavily on the application.

Some brands are known for their exceptional hardness and scratch resistance but can be more challenging to apply. Others are easier to work with but might offer slightly less protection. I consider factors like cost-effectiveness, customer reviews, and manufacturer support when making brand selections. I don’t endorse specific brands publicly, as preferences can change with product updates and individual needs.

In my professional practice, I focus on understanding the specific properties of each coating to best match it with the client’s needs and expectations. A detailed consultation allows me to leverage the strengths of each brand to optimize the outcome.

Q 25. Explain how the temperature and humidity affect the curing process.

Temperature and humidity significantly impact the curing process of ceramic coatings. Think of it like baking a cake – you need the right oven temperature and humidity for the best results. Extreme deviations can compromise the coating’s integrity.

- Temperature: Ideally, curing occurs within a specific temperature range recommended by the manufacturer. Temperatures that are too low can cause slow curing and potentially incomplete hardening. Conversely, temperatures that are too high can cause the coating to cure too quickly, potentially leading to imperfections or even damage.

- Humidity: High humidity can hinder proper curing by interfering with the evaporation of solvents in the coating. This can lead to a hazy or cloudy finish. Low humidity can cause the coating to dry too quickly, potentially resulting in pinholes or unevenness.

For optimal curing, I always consult the manufacturer’s instructions and carefully monitor the environmental conditions. In extreme weather conditions, I might use additional measures such as climate-controlled environments (garage) or adjust application schedules to ensure ideal curing parameters. Documenting the conditions ensures accountability and helps troubleshoot potential issues later on.

Q 26. Describe your experience with color correction techniques before coating application.

Color correction is often a crucial step before applying a ceramic coating. It’s like preparing a canvas before painting a masterpiece – imperfections will show under the new coat. A properly prepared surface enhances the coating’s appearance and overall longevity.

My experience encompasses various color correction techniques, including:

- Polishing: Using various grades of polishing compounds to remove scratches, swirl marks, and other imperfections. This step significantly enhances the shine and smoothness.

- Compounding: This more aggressive approach is used to remove deeper scratches and defects, providing a foundation for polishing.

- Paint Correction: Advanced techniques are sometimes used to address more challenging imperfections, such as deep scratches or holograms. This can involve several levels of compounding and polishing.

The choice of technique depends heavily on the existing paint condition. For example, on a heavily swirled car, I might begin with compounding, followed by multiple stages of polishing to achieve a flawless surface. For a vehicle with minimal imperfections, polishing alone may suffice. The goal is always to create the perfect base for the ceramic coating to adhere to and showcase its full potential.

Q 27. How do you ensure proper ventilation during application?

Proper ventilation is crucial during ceramic coating application due to the volatile organic compounds (VOCs) present in many coatings. These compounds can be harmful if inhaled in high concentrations.

My approach to ensuring proper ventilation includes:

- Open Air Application: Whenever possible, I prefer outdoor application in well-ventilated areas. This allows for natural airflow to dissipate the VOCs.

- Ventilation Systems: In indoor settings, I utilize exhaust fans and ventilation systems to create a strong airflow, drawing out fumes and replacing them with fresh air.

- Respiratory Protection: I always use appropriate respiratory protection, such as an organic vapor respirator, to minimize the inhalation of VOCs. This is crucial for the applicator’s health and safety.

- Safety Precautions: Safety glasses and gloves are always worn to avoid skin and eye contact with the coating.

Neglecting proper ventilation can lead to health issues and can also impact the quality of the coating application due to the presence of particulates in the air.

Q 28. How do you handle the disposal of waste materials related to ceramic coating?

Responsible disposal of waste materials is critical for environmental protection and worker safety. The disposal methods depend on local regulations and the specific materials.

- Waste Classification: I carefully classify waste materials according to their chemical composition. This determines the appropriate disposal method.

- Hazardous Waste Disposal: Certain solvents and cleaning agents used in the process are hazardous wastes and require specialized disposal facilities. These facilities handle the disposal process in compliance with environmental regulations.

- Recycling: Where possible, I recycle materials like containers and packaging.

- Proper Labeling: All waste containers are clearly labeled to prevent accidental misuse or misidentification.

- Compliance with Regulations: I strictly adhere to all local, state, and federal regulations regarding the disposal of hazardous materials and waste generated during ceramic coating application.

Ignoring proper disposal methods can lead to environmental contamination and potential health hazards. It’s paramount to follow all safety and regulatory guidelines for the protection of the environment and the community.

Key Topics to Learn for Your Ceramic Coatings Interview

- Chemical Composition and Properties: Understand the different types of ceramic coatings (e.g., sol-gel, sputtering, dip coating), their chemical compositions, and how these compositions affect their properties (hardness, durability, thermal resistance, etc.).

- Application Methods and Techniques: Familiarize yourself with various application methods like spraying, dipping, brushing, and spin coating. Understand the pros and cons of each method and their suitability for different substrates and applications.

- Surface Preparation and Pretreatment: Master the importance of proper surface preparation before coating application. Learn about cleaning techniques, surface treatments (e.g., etching, sanding), and their impact on adhesion and coating performance.

- Quality Control and Testing: Understand the different methods used to test the quality of ceramic coatings, such as thickness measurement, hardness testing, adhesion testing, and corrosion resistance testing. Be prepared to discuss quality control procedures in a manufacturing environment.

- Failure Analysis and Troubleshooting: Learn to identify common causes of ceramic coating failure, such as poor adhesion, cracking, delamination, and corrosion. Practice troubleshooting techniques and problem-solving approaches.

- Industry Applications and Case Studies: Explore the various applications of ceramic coatings across different industries (automotive, aerospace, medical, etc.). Research specific case studies to demonstrate your understanding of real-world applications.

- Emerging Trends and Technologies: Stay updated on the latest advancements in ceramic coating technology, such as self-healing coatings, superhydrophobic coatings, and high-temperature resistant coatings.

Next Steps: Elevate Your Career in Ceramic Coatings

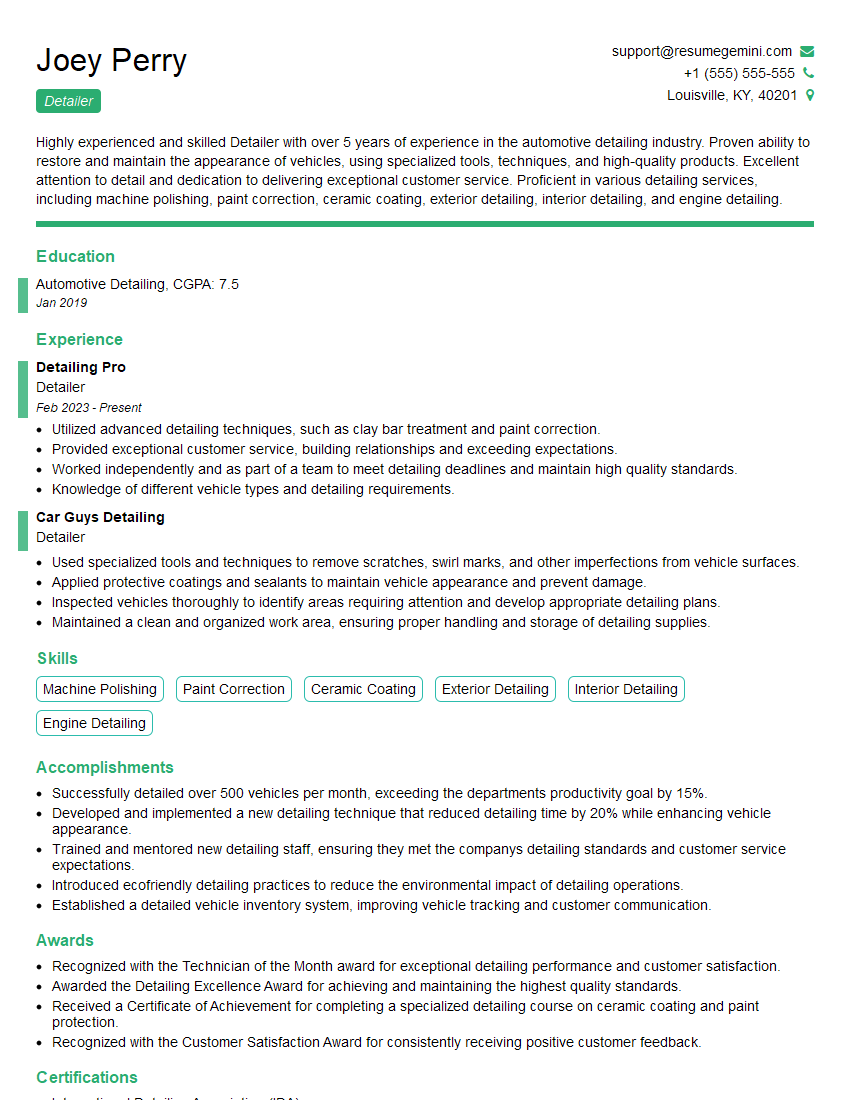

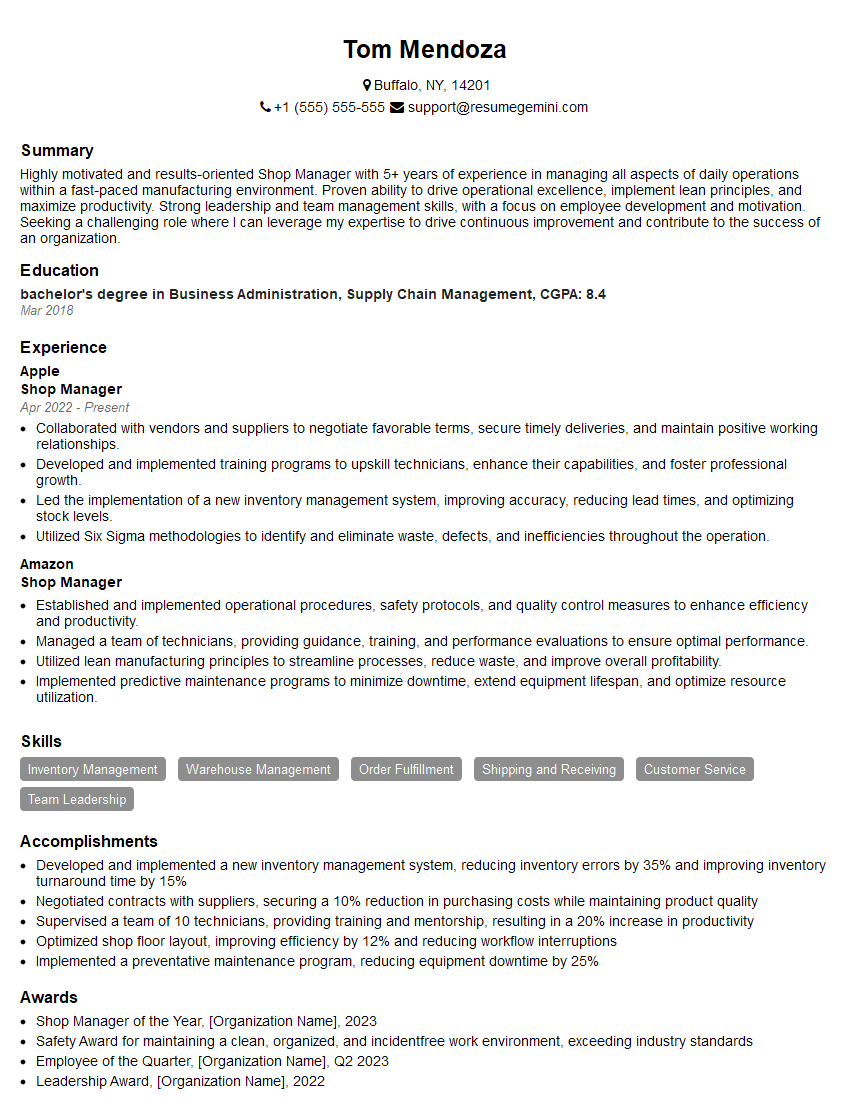

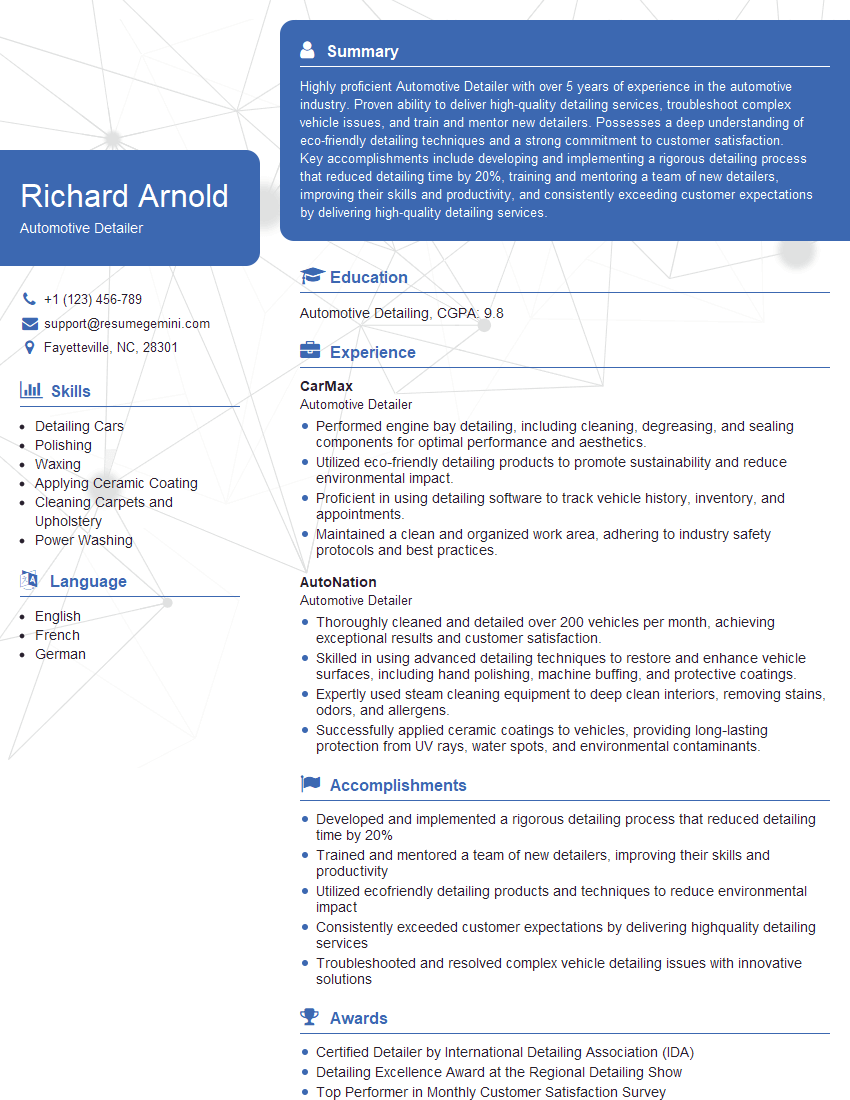

Mastering the fundamentals of ceramic coatings is crucial for career advancement in this dynamic field. A strong understanding of the theoretical concepts and practical applications will set you apart from other candidates. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, tailored to the specific requirements of ceramic coatings roles. Examples of resumes tailored to the Ceramic Coatings industry are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO