Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Climate Control Systems Repair interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Climate Control Systems Repair Interview

Q 1. Explain the difference between a heat pump and a furnace.

The primary difference between a heat pump and a furnace lies in how they produce heat. A furnace generates heat by burning fuel (natural gas, propane, or oil), converting chemical energy into thermal energy. Think of it like a controlled bonfire – it directly creates heat. A heat pump, however, moves heat rather than generating it. It uses a refrigeration cycle to absorb heat from the outside air (even in cold temperatures) and transfer it inside, warming your home. In essence, a furnace creates heat, while a heat pump relocates it.

Consider this analogy: imagine you have two buckets, one hot and one cold. A furnace is like filling the cold bucket with hot water directly from a kettle. A heat pump is like using a pump to move the heat from the hot bucket to the cold bucket, warming the cold bucket without generating new heat. Heat pumps are generally more energy-efficient than furnaces, especially in milder climates.

Q 2. Describe the refrigeration cycle in detail.

The refrigeration cycle is the heart of a heat pump and air conditioner. It’s a continuous loop that involves four key components: the compressor, condenser, expansion valve (or capillary tube), and evaporator coil. The process works like this:

- Compressor: Compresses refrigerant gas, raising its temperature and pressure. This is like squeezing a bike pump; the air inside gets hotter and more pressurized.

- Condenser: The high-pressure, high-temperature refrigerant releases heat to the outside air, condensing into a liquid. This is analogous to sweating; your body releases heat to cool down.

- Expansion Valve: The liquid refrigerant passes through a valve, causing a sudden drop in pressure and temperature. This is like releasing the pressure in a spray can; the refrigerant gets much colder.

- Evaporator Coil: The low-pressure, low-temperature refrigerant absorbs heat from the inside air, evaporating back into a gas. This is similar to the cooling effect of sweating again; evaporation absorbs heat.

This cycle continues, moving heat from one location to another. In cooling mode, heat is extracted from inside and released outside. In heating mode, the process reverses, absorbing heat from outside and releasing it inside.

Q 3. How do you diagnose a malfunctioning compressor?

Diagnosing a malfunctioning compressor requires a systematic approach. First, check for obvious signs like unusual noises (loud clicking, grinding, or humming). A failing compressor might be unusually hot to the touch. Next, use a multimeter to check the compressor’s voltage and amperage draw. If the voltage is normal but the amperage is significantly higher than the manufacturer’s specifications, it indicates a potential problem within the compressor itself. A low voltage reading can indicate electrical issues elsewhere in the system. Furthermore, you’ll want to check the refrigerant pressure; low pressure is often associated with compressor issues. If the refrigerant pressure is low despite a functional compressor, you have other problems that must be addressed first. Finally, if the compressor is running continuously without reaching the set temperature, the compressor itself may be failing, or there might be a refrigerant leak or other system problem.

Q 4. What are the common causes of low refrigerant?

Low refrigerant is a significant problem in climate control systems. Several factors contribute to it:

- Leaks: The most common cause. Small holes or cracks in the refrigerant lines, connections, or the compressor itself can lead to slow refrigerant loss over time. These leaks are often hard to detect visually and require specialized leak detection equipment.

- Improper Installation: Faulty installation can damage components, leading to leaks or other refrigerant loss. Using a system with insufficient refrigerant during installation is a common mistake.

- Component Failure: A failing compressor or expansion valve can lead to refrigerant loss.

Identifying the source of the leak is crucial before recharging the system, otherwise you’ll just be wasting refrigerant.

Q 5. Explain the function of a condenser and evaporator coil.

The condenser coil and evaporator coil are critical components in the refrigeration cycle, working together to transfer heat. The condenser coil, typically located outdoors in an air conditioner or heat pump, releases heat from the high-pressure refrigerant to the outside air. The refrigerant is in a gaseous state and needs to get rid of this heat so it can change phase to a liquid.

The evaporator coil, usually located indoors, absorbs heat from the inside air. The low-pressure refrigerant absorbs this heat and changes phase from a liquid to a gaseous state. Think of it as the reverse process: it gets energy from the air to transition from liquid to gas. Both coils are critical for heat transfer and proper system operation.

Keeping these coils clean is essential for optimal performance; dirt buildup restricts airflow, reducing efficiency. Clogged evaporator coils may freeze and damage the system.

Q 6. How do you troubleshoot a system with no cooling?

Troubleshooting a system with no cooling requires a systematic approach:

- Check the power supply: Ensure the system is properly powered and the circuit breaker hasn’t tripped.

- Examine the thermostat: Verify the thermostat is set correctly to ‘Cool’ and the temperature is set lower than the current room temperature.

- Inspect the air filter: A clogged air filter restricts airflow, impacting cooling capacity. Replace if necessary.

- Check the refrigerant level: Low refrigerant is a major cause of poor cooling. Use pressure gauges to verify the charge and detect leaks if needed.

- Assess the condenser coil: Clean the condenser coil to ensure proper heat dissipation. A dirty condenser significantly reduces cooling capacity.

- Check the compressor: Listen for unusual noises and check the compressor’s amperage draw. Excessive amperage usually indicates a problem.

- Inspect the fan motor: Make sure the condenser fan motor is working correctly; a malfunctioning fan inhibits heat dissipation.

If the problem persists after these checks, a professional HVAC technician is needed for further diagnosis and repair.

Q 7. What are the safety precautions when handling refrigerants?

Handling refrigerants requires strict safety precautions due to their potential hazards:

- Eye and Skin Protection: Always wear safety glasses and gloves to prevent contact with refrigerant. Liquid refrigerant can cause severe frostbite.

- Ventilation: Work in a well-ventilated area to prevent the buildup of refrigerant vapor, which can displace oxygen and cause asphyxiation. Many refrigerants are also flammable or toxic.

- Proper Equipment: Use appropriately sized and calibrated gauges and tools designed for refrigerant handling. Avoid using makeshift tools.

- Recovery and Recycling: Never release refrigerant into the atmosphere. Use recovery equipment to capture and recycle refrigerant during maintenance or repair.

- Training and Certification: Proper training and EPA certification are essential for handling refrigerants legally and safely. Improper handling can result in serious injury or environmental damage.

Always follow the manufacturer’s instructions and relevant safety regulations when handling refrigerants. It’s essential to treat this carefully as it is vital for your safety.

Q 8. Explain the different types of expansion valves.

Expansion valves are crucial components in refrigeration and air conditioning systems, regulating the flow of refrigerant from a high-pressure liquid state to a low-pressure vapor state. Different types offer varying levels of control and adaptability.

- Thermostatic Expansion Valves (TXV): These are the most common type. They use a temperature sensor to sense the evaporator temperature and adjust the refrigerant flow accordingly. Think of it like a smart faucet; if the evaporator is too cold, the valve restricts flow; if it’s too warm, the valve opens more.

- Capillary Tubes: These are simpler, less expensive alternatives, essentially a precisely sized tube that acts as a restrictive orifice. They provide basic refrigerant metering, but offer little to no adjustment. Imagine a fixed-size straw – you can’t control the flow rate easily.

- Electronic Expansion Valves (EEV): These are sophisticated valves controlled by electronic signals, allowing for precise and dynamic refrigerant flow regulation. They offer superior control and are often used in more complex systems. These are like electronically controlled valves in a car’s fuel injection system – precise and adaptable.

- Automatic Expansion Valves (AEV): These valves utilize pressure differences to control refrigerant flow. Less common than TXVs, they are suitable for simpler systems. Think of them as a pressure-sensitive gate regulating liquid flow.

The choice of expansion valve depends on factors like system complexity, cost, and required level of precision.

Q 9. How do you perform a proper system evacuation?

Proper system evacuation is critical for removing air, moisture, and other non-condensables from an HVAC system before charging it with refrigerant. These contaminants can severely reduce system efficiency and damage components. The process typically involves these steps:

- Connect vacuum pump: Securely attach a properly sized vacuum pump to the system’s access ports (usually on the liquid line and suction line).

- Evacuate: Start the vacuum pump and monitor the gauge. The system should reach and hold a deep vacuum (typically below 500 microns or 0.5 torr) for at least one hour, or longer depending on system size and moisture content. This ensures complete removal of contaminants.

- Monitor gauge: Continuously monitor the vacuum gauge throughout the process. A rising pressure indicates a leak in the system. If this happens, additional leak detection is required before proceeding.

- Check for leaks: After achieving the desired vacuum, it’s a good idea to shut off the vacuum pump and monitor the vacuum gauge for 30 minutes to ensure that there are no leaks that slowly introduce contaminants back into the system.

- Charge refrigerant: Once a proper vacuum is achieved and held, the system can be charged with the correct amount and type of refrigerant.

Failing to properly evacuate a system can lead to reduced efficiency, compressor damage, and potential system failure.

Q 10. What tools and equipment are essential for HVAC repair?

Essential tools and equipment for HVAC repair are diverse and depend on the specific task. However, a well-equipped technician will have:

- Refrigerant gauges (manifold): To measure system pressures and temperatures.

- Vacuum pump: To evacuate air and moisture from the system.

- Refrigerant recovery/recycling equipment: Environmentally responsible handling of refrigerant is mandatory.

- Leak detectors: To find refrigerant leaks quickly and efficiently (electronic leak detectors are usually preferred for their sensitivity).

- Various hand tools: Screwdrivers, wrenches, pliers, etc., in various sizes.

- Multimeter: To test electrical components and circuits.

- Manometer: For accurate pressure measurements.

- Brazing equipment (torch and solder): For repairing refrigerant lines.

- Safety glasses and gloves: Protection from potential hazards like refrigerant and sharp tools.

Beyond these essentials, specific tools for specialized tasks may also be needed.

Q 11. Describe your experience with different types of HVAC systems (split, package, etc.)

My experience encompasses a wide range of HVAC systems, including:

- Split Systems: These systems are the most common in residential and light commercial applications. I’m proficient in troubleshooting and repairing both heat pumps and air conditioners within these configurations, including diagnosing issues with the indoor and outdoor units, refrigerant lines, and electrical connections.

- Package Units: These self-contained units are simpler to maintain than split systems, combining all components in one casing. I have experience with various package units, including rooftop units and smaller units typically used in commercial settings. These usually have some more complex control boards.

- VAV (Variable Air Volume) Systems: I’ve worked on systems featuring VAV boxes, which allow for precise control of airflow to different zones. These require a deeper understanding of airflow dynamics and control systems.

- Chillers: While less frequent in my daily tasks, I possess knowledge of chiller systems which are common in larger commercial and industrial settings. This includes water-cooled and air-cooled chiller systems and understanding their cooling towers and pumping systems.

My experience enables me to effectively diagnose and repair a wide array of HVAC problems across various system types.

Q 12. How do you interpret a wiring diagram?

Interpreting a wiring diagram involves understanding the symbols, colors, and connections represented. It’s like reading a map of the electrical system.

First, I identify the components – compressors, fans, capacitors, thermostats, etc. – and their respective symbols. Next, I trace the paths of the wires, noting the color codes (which usually follow industry standards), and determine the voltage and current flow. I check for any connections to transformers, relays, contactors, and other electrical devices that are typically included.

For example, a simple diagram will show the connection between a thermostat’s terminals (often labelled R, W, G, Y, etc.) and the corresponding terminals on a furnace or air handler. By following these connections, we can understand the signals which cause the furnace to engage.

A solid understanding of electrical theory and safety precautions is essential for accurately reading and applying information from wiring diagrams.

Q 13. Explain the role of a thermostat in a climate control system.

The thermostat acts as the brain of the climate control system, enabling users to set desired temperatures and initiate system operation. It senses the room temperature and compares it to the setpoint. Based on this comparison, it sends signals to the HVAC system to turn the heating or cooling on or off, or adjust the fan speed. Modern smart thermostats also offer advanced features like programmable scheduling, remote control, and energy efficiency monitoring.

Think of it as a feedback loop: the thermostat ‘feels’ the room temperature, ‘decides’ whether to activate heating or cooling, and sends instructions to the system to maintain the user’s comfort level.

Q 14. How do you troubleshoot a system with insufficient heating?

Troubleshooting insufficient heating involves a systematic approach:

- Check thermostat settings: Ensure the thermostat is set to ‘heat’ mode, the temperature is appropriately high, and the system is not accidentally set to ‘off’ or ‘auto’. A common oversight!

- Inspect air filters: Clogged filters restrict airflow, significantly reducing heating efficiency. Replace or clean the filters as needed.

- Examine airflow: Check for restricted airflow through vents or ducts. Obstructions or blockages will reduce heating.

- Check the heating element or heat pump: In systems with a heating element, inspect the element itself and ensure that it is functioning correctly. With a heat pump, verify the heat pump is operating correctly and in the correct mode.

- Inspect the blower motor: Check to ensure the fan is circulating air properly; a weak or faulty fan motor can greatly reduce heating performance.

- Verify fuel supply (if applicable): For systems using gas or propane, inspect the fuel supply lines and ensure sufficient fuel supply.

- Inspect the flame sensor or igniter (if applicable): This is usually for gas systems. A faulty flame sensor or igniter will prevent ignition.

- Check for frozen coils or refrigerant issues: Low refrigerant charge can significantly impair heating capacity in a heat pump.

By following this sequence, the root cause of insufficient heating can often be identified and addressed.

Q 15. What are the common causes of frozen evaporator coils?

A frozen evaporator coil is a common problem in air conditioning systems, usually stemming from insufficient airflow or refrigerant issues. Think of it like this: the evaporator coil is like the ice-making part of your refrigerator. If the air doesn’t circulate properly, or there isn’t enough refrigerant to absorb the heat, the coil freezes up.

- Restricted Airflow: A dirty air filter is the most frequent culprit. A clogged filter restricts airflow over the evaporator coil, preventing it from absorbing heat effectively. Other causes include blocked vents, dirty or damaged coils themselves, or a blower motor issue reducing airflow.

- Low Refrigerant: Insufficient refrigerant means the system lacks the necessary substance to absorb heat efficiently. Leaks in the system, improper charging during installation, or a malfunctioning compressor can all lead to low refrigerant levels.

- Faulty Refrigerant Flow: Even with sufficient refrigerant, issues like a clogged expansion valve or a malfunctioning metering device can prevent the refrigerant from flowing properly through the system, causing freezing.

- Defective Fan Motor: A weak or malfunctioning evaporator fan motor can compromise airflow, leading to freezing.

Troubleshooting involves checking the air filter, inspecting the coils for cleanliness and obstructions, checking refrigerant levels (this requires specialized equipment and should only be done by trained professionals), and verifying the functionality of the blower motor and associated components.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different types of air filters.

My experience encompasses a wide range of air filters, from basic fiberglass filters to high-efficiency particulate air (HEPA) filters. Each type has its strengths and weaknesses.

- Fiberglass Filters: These are the most common and least expensive. They are effective at catching larger dust particles but allow smaller particles to pass through. They require frequent replacement.

- Pleated Filters: These offer a larger surface area than fiberglass filters, leading to increased efficiency and longer lifespan. They are better at capturing smaller particles.

- HEPA Filters: These are high-efficiency filters capable of capturing up to 99.97% of particles 0.3 microns in size or larger. They are ideal for individuals with allergies or respiratory sensitivities but can restrict airflow, requiring more powerful blower motors.

- Electrostatic Filters: These filters use static electricity to attract and trap airborne particles. They often have a longer lifespan than fiberglass filters, but their effectiveness can diminish over time.

In my experience, filter selection depends on the specific needs of the system and the occupants. For instance, a home with allergy sufferers may benefit greatly from a HEPA filter, even if it requires more frequent blower maintenance. Conversely, a system in a less demanding environment might only require a pleated filter for cost-effectiveness.

Q 17. How do you calculate the appropriate refrigerant charge?

Calculating the appropriate refrigerant charge is crucial for optimal system performance and efficiency. It’s not a simple matter of filling the system until it’s ‘full.’ It requires precise measurement and an understanding of several factors. Incorrect refrigerant charge can lead to reduced cooling capacity, inefficient operation, and even damage to the compressor.

The process typically involves using specialized equipment like electronic scales, pressure gauges, and temperature sensors. The manufacturer’s specifications for the specific system model provide the starting point. We need to consider factors such as:

- System Type: Different system types (split systems, package units, etc.) have different refrigerant requirements.

- Refrigerant Type: The type of refrigerant (R-410A, R-22, etc.) impacts the charging procedure.

- System Capacity: The larger the system’s cooling capacity, the more refrigerant it generally requires.

- Ambient Temperature: The surrounding temperature affects the refrigerant pressure and charge calculations.

- Subcooling and Superheat: These are critical parameters monitored during the charging process to ensure the system operates within its optimal range.

Accurate refrigerant charging often involves a combination of weighing the refrigerant and using pressure-temperature charts. Subcooling and superheat measurements further refine the process to ensure the system is correctly charged. The process requires training and experience, and improper handling of refrigerants is dangerous; thus, only certified technicians should perform this task.

Q 18. What is your experience with preventative maintenance on HVAC systems?

Preventative maintenance is the cornerstone of a long-lasting and efficient HVAC system. Think of it as regular checkups for your home’s heart. I’ve been performing preventative maintenance on a wide range of HVAC systems for many years, and my approach includes a thorough inspection and cleaning of key components.

- Coil Cleaning: Evaporator and condenser coils accumulate dirt and debris, reducing efficiency. Regular cleaning using appropriate solutions ensures optimal heat transfer.

- Air Filter Replacement: Regular filter replacement is crucial for maintaining proper airflow.

- Blower Motor Inspection: Checking the blower motor for proper function prevents premature failure.

- Refrigerant Level Check: Monitoring refrigerant levels helps identify leaks early, preventing costly repairs.

- Electrical Connections: Inspecting electrical connections prevents shorts, fires, and system malfunctions.

- Belt Inspection: Checking drive belts (where applicable) for wear and tear ensures the proper operation of components.

- Condenser Fan Inspection: Ensuring proper condenser fan operation promotes efficient heat dissipation.

A detailed report is typically provided to the customer outlining the findings, recommendations for repairs, and estimated costs. This proactive approach often prevents major problems down the line, saving the customer money and ensuring reliable system performance.

Q 19. Describe your troubleshooting process for a system with unusual noises.

Unusual noises in an HVAC system are often indicators of underlying problems. My troubleshooting process for such issues is systematic and methodical. I start by identifying the type of noise (rattling, banging, hissing, etc.) and when it occurs (during startup, shutdown, or continuous operation).

Step-by-step process:

- Visual Inspection: I visually inspect the system for loose components, obstructions, or damage.

- Listen Carefully: I carefully listen to the sounds to pinpoint their origin, using a stethoscope if necessary.

- Check for Loose Parts: I check for loose screws, belts, or other parts that could be causing rattling or banging noises.

- Inspect the Blower Motor and Fan: These components are common sources of unusual sounds.

- Check for Refrigerant Leaks: Hissing sounds can indicate leaks in the refrigerant lines. This requires the use of leak detection equipment.

- Verify Compressor Operation: Unusual compressor noises could indicate bearing wear or other internal problems.

- Check for Obstructions: Sounds like rattling or grinding could indicate something is obstructing the fan blades.

By systematically investigating these potential sources, I can typically identify the root cause of the unusual noises and recommend the necessary repair. Safety is paramount, and if I’m unsure of the cause, I will recommend further diagnostics.

Q 20. How do you handle emergency HVAC repair situations?

Handling emergency HVAC repair situations requires quick thinking and prioritization. My approach emphasizes safety, efficiency, and customer satisfaction.

- Prioritize Safety: I always prioritize safety, ensuring the area is secure before beginning any work. This involves turning off power to the system where appropriate and taking necessary precautions to avoid electrical shocks, refrigerant exposure, and other hazards.

- Rapid Assessment: I perform a rapid assessment of the situation to understand the nature of the problem and the level of urgency. Is it a complete system failure or a minor issue?

- Temporary Solutions: In situations where immediate repair isn’t feasible, I may implement temporary solutions to alleviate the problem (e.g., opening windows for ventilation if cooling is lost).

- Efficient Repairs: I prioritize efficiency, focusing on the necessary repairs to restore functionality. Unnecessary repairs are avoided, saving the customer time and money.

- Communication: I communicate regularly with the customer, updating them on the progress and anticipated completion time.

I understand the urgency and stress associated with HVAC emergencies (especially during extreme weather). My goal is to swiftly and effectively resolve the issue while providing clear and reassuring communication to the customer.

Q 21. Explain your understanding of building codes related to HVAC systems.

Building codes related to HVAC systems are crucial for ensuring safety, efficiency, and proper operation. My understanding of these codes is thorough and up-to-date, and I ensure all my work complies with relevant regulations.

Key areas of building codes that I regularly refer to include:

- Refrigerant Handling: Codes dictate proper handling and disposal procedures for refrigerants to prevent environmental harm and worker safety.

- Ventilation Requirements: Codes specify minimum ventilation requirements to ensure adequate airflow and prevent the buildup of harmful gases.

- Electrical Safety: Codes address electrical wiring, grounding, and safety devices to minimize electrical hazards.

- Fire Safety: Codes incorporate fire safety measures for HVAC equipment, including proper clearances and fire-resistant materials.

- Energy Efficiency: Codes often mandate minimum energy efficiency standards to promote energy conservation.

- Accessibility: Codes ensure that HVAC equipment is accessible for maintenance and repair.

Staying current with these codes is an ongoing process that involves continuous learning and review. Compliance is not only essential for legal reasons but also ensures the safety and well-being of building occupants. I regularly attend industry workshops and training sessions to stay informed about code updates and best practices.

Q 22. What is your experience with various control systems (e.g., programmable thermostats)?

My experience with various control systems is extensive, encompassing everything from basic mechanical thermostats to sophisticated programmable and smart thermostats. I’m proficient in installing, configuring, and troubleshooting a wide range of systems, including those using different communication protocols like Wi-Fi, Zigbee, and BACnet. For example, I’ve recently worked on a project integrating a Nest Learning Thermostat into a legacy HVAC system, requiring careful consideration of wiring compatibility and system limitations. I’ve also extensively worked with commercial-grade programmable thermostats, understanding the nuances of scheduling, occupancy sensing, and energy-saving features. My experience extends to understanding and repairing the underlying wiring and connections that allow these control systems to interface correctly with the HVAC unit itself, ensuring proper operation and preventing problems down the line.

- Programmable Thermostats: I’m skilled in setting up various programming schedules, optimizing energy efficiency based on occupancy patterns, and troubleshooting programming errors.

- Smart Thermostats: I’ve worked with several brands, understanding their unique features and integration capabilities, and resolving issues related to network connectivity and app functionality.

- Commercial Control Systems: My experience includes working with larger building management systems (BMS) and understanding their integration with HVAC control systems.

Q 23. How do you ensure the safety and comfort of occupants during repairs?

Ensuring occupant safety and comfort during repairs is paramount. I always begin by assessing the situation, de-energizing the system where necessary, and clearly communicating the repair process to the occupants. This includes explaining potential noises or disruptions during the repair. I utilize appropriate safety equipment, such as gloves and eye protection, and ensure proper ventilation to prevent exposure to refrigerants or other hazardous materials. For example, when working with a gas furnace, I’d always check for carbon monoxide leaks using a specialized detector before and after the repair. I focus on minimizing downtime and keeping the environment as comfortable as possible while working, whether it’s adjusting the temperature to a comfortable setting or minimizing disruption.

In cases of emergency repairs, such as a complete system failure on a hot summer day, I prioritize finding a temporary solution to restore basic cooling or heating as quickly and safely as possible, while still following proper safety procedures.

Q 24. Describe your experience with ductwork inspection and repair.

Ductwork inspection and repair is a significant part of my expertise. I use specialized tools such as cameras and leak detectors to thoroughly inspect ductwork for leaks, blockages, and damage. Common problems include loose connections, gaps in the ductwork, and corrosion. I’m experienced in repairing leaks using metal tape or sealant for metal ducts and mastic sealant for flexible ducts. I also address blockages using specialized brushes and vacuum systems. For instance, I recently repaired a significant leak in a residential system by replacing a section of damaged flex duct, sealing all joints with mastic, and then carefully insulating the repaired area to prevent heat loss.

Larger commercial projects often involve extensive ductwork, requiring thorough documentation, planning, and potentially specialized equipment for access and repair. This includes using negative air pressure to control dust during repair work.

Q 25. What are the common causes of high energy consumption in HVAC systems?

High energy consumption in HVAC systems can stem from several common causes. These include:

- Inefficient Equipment: Older systems or those that haven’t been properly maintained are significantly less efficient.

- Dirty Air Filters: A clogged filter restricts airflow, forcing the system to work harder.

- Duct Leaks: Leaky ducts lose conditioned air, increasing energy demand. This is often overlooked but can be a major cause of inefficiency.

- Improper Thermostat Settings: Inconsistent or overly ambitious temperature settings contribute to higher energy use.

- Refrigerant Leaks (in cooling systems): Low refrigerant levels reduce cooling efficiency, requiring the compressor to run longer and consume more power.

- Problems with the Blower Motor: A malfunctioning blower motor may cause inconsistent airflow and increased energy usage.

Addressing these issues often involves a combination of preventative maintenance, system upgrades (like replacing an old system or fixing duct leaks), and improved user practices, such as adjusting the thermostat appropriately for the time of year and ensuring regular filter changes.

Q 26. Explain your experience working with different types of motors (e.g., PSC, ECM).

I have extensive experience with various types of HVAC motors, including Permanent Split Capacitor (PSC) and Electronically Commutated (ECM) motors. PSC motors are simpler and typically less expensive but less efficient. ECM motors are more advanced, offering variable speed control for enhanced efficiency and quiet operation. I understand the differences in their wiring diagrams, control circuits, and troubleshooting techniques. For instance, diagnosing a problem with a PSC motor might involve checking the capacitor and windings, whereas troubleshooting an ECM motor may involve checking the control board signals and motor current.

My experience allows me to assess which motor type is best suited for a specific application, considering factors like budget, efficiency requirements, and noise levels. I’m also well-versed in the safety precautions necessary when working with these motors, including proper grounding and avoiding electrical shock.

Q 27. How do you diagnose and repair issues with blower motors and fans?

Diagnosing and repairing issues with blower motors and fans typically starts with a visual inspection, checking for obvious damage, loose connections, or obstructions. I then use a multimeter to measure voltage, current, and resistance to identify problems such as faulty windings, bearings, or capacitors. A common issue is a worn-out motor bearing, causing noise and eventually motor failure. In such cases, the bearings might need replacement or the entire motor might need to be replaced. Fan issues can also include problems with the fan blades themselves, such as imbalances or damage.

I’ll carefully check the airflow, ensuring no obstructions exist within the ductwork that could limit airflow and put extra stress on the blower motor. When dealing with a complex system, I often check the control board signals to the motor, ensuring the motor is receiving the correct commands to operate as intended.

Q 28. Describe your experience with electronic control boards and troubleshooting their failures.

Troubleshooting electronic control boards requires a systematic approach. I begin with a visual inspection, checking for burnt components, loose connections, or signs of overheating. Then, using a multimeter and sometimes an oscilloscope, I check for voltage and signal integrity at different points on the board, comparing them to the manufacturer’s specifications or schematics. This allows me to isolate faulty components such as transistors, capacitors, or integrated circuits (ICs).

I use my knowledge of electronic circuits to trace the signal paths, understanding the interaction between different components. In many cases, replacing the faulty component resolves the issue. However, some situations might require more advanced techniques, such as checking for software errors in programmable control boards or replacing the entire control board. Safety is paramount when working with these boards; I always ensure the system is de-energized before handling the electronics.

Key Topics to Learn for Climate Control Systems Repair Interview

- Refrigerant Handling and Safety: Understanding different refrigerants (e.g., R-410A, R-32), proper handling procedures, leak detection methods, and safety regulations. Practical application: Diagnosing and repairing refrigerant leaks in various systems.

- Compressor Systems: Understanding compressor types (reciprocating, scroll, centrifugal), operation principles, troubleshooting common compressor failures (e.g., overheating, seizing), and replacement procedures. Practical application: Identifying and resolving compressor issues based on system performance and diagnostic readings.

- Electrical Systems: Knowledge of wiring diagrams, electrical components (e.g., capacitors, contactors, relays), troubleshooting electrical faults, and safety practices related to electrical work. Practical application: Diagnosing and repairing electrical malfunctions in HVAC systems, ensuring safe operation.

- Airflow Dynamics: Understanding how airflow impacts system efficiency, troubleshooting issues related to ductwork, filters, and fans. Practical application: Optimizing airflow for improved system performance and energy efficiency.

- Control Systems: Familiarity with thermostats, controllers, and sensors. Understanding how these components interact and troubleshoot malfunctions in control circuits. Practical application: Programming and calibrating thermostats and resolving control system issues.

- Troubleshooting and Diagnostics: Mastering diagnostic techniques using various tools (e.g., multimeters, pressure gauges, temperature sensors). Applying systematic troubleshooting methodologies to identify and resolve system malfunctions. Practical application: Effectively diagnosing and repairing a wide range of system faults.

- Preventive Maintenance: Understanding the importance of preventative maintenance procedures for extending system lifespan and optimizing performance. Practical application: Developing and implementing a preventative maintenance plan for various climate control systems.

Next Steps

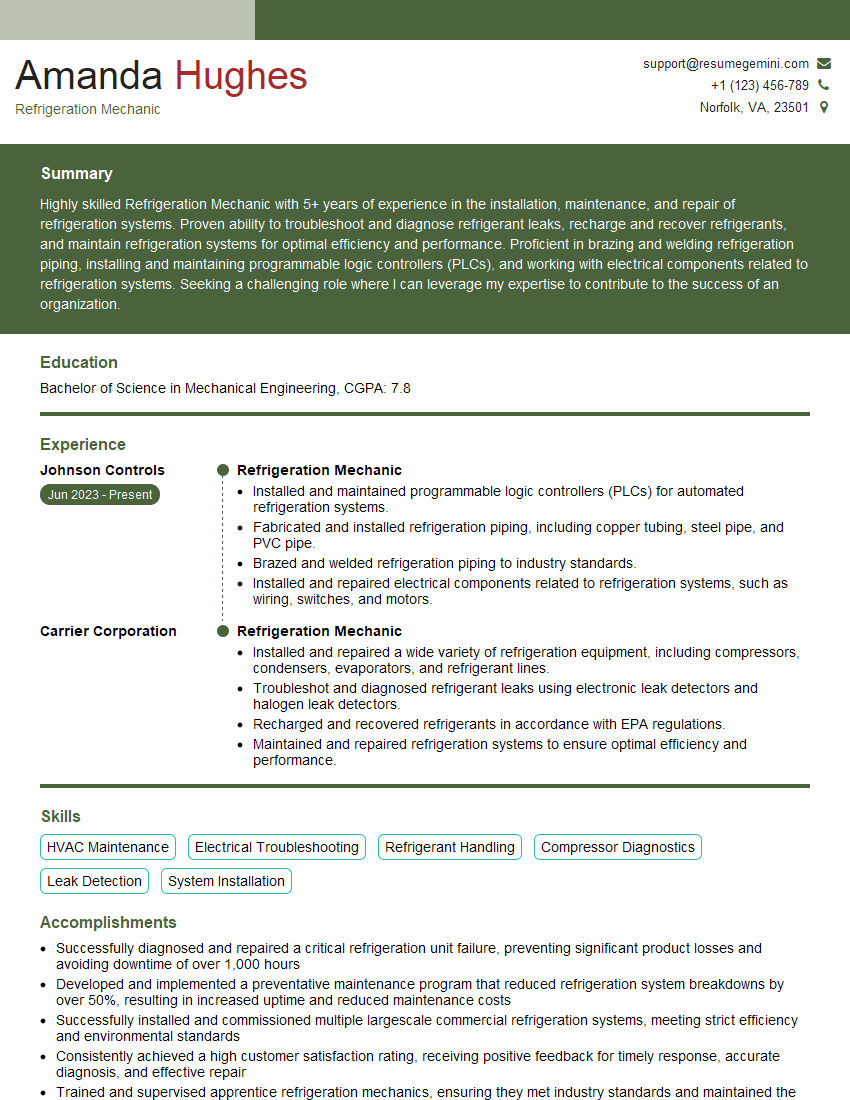

Mastering Climate Control Systems Repair opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization and advancement. To significantly increase your job prospects, it’s crucial to create a professional and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a powerful resume that stands out. They provide examples of resumes tailored to Climate Control Systems Repair, ensuring your application makes a lasting impression on potential employers. Take advantage of these resources to build your best career path.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO