The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Coaxial Cable Installation and Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Coaxial Cable Installation and Repair Interview

Q 1. Explain the difference between RG-59, RG-6, and RG-11 coaxial cables.

RG-59, RG-6, and RG-11 are all types of coaxial cables, differing primarily in their size, shielding, and bandwidth capabilities. Think of them like different sized pipes carrying water – some are better suited for certain tasks than others.

- RG-59: This is a thinner cable, typically used for applications requiring less bandwidth, such as older cable television systems or closed-circuit television (CCTV). Its smaller size makes it easier to maneuver in tight spaces, but it’s more susceptible to signal loss over longer distances.

- RG-6: This is a more common and versatile cable, offering better shielding and higher bandwidth than RG-59. It’s ideal for modern cable television systems, satellite dishes, and broadband internet connections. Its thicker construction provides superior signal integrity over longer runs.

- RG-11: This is the thickest and most robust of the three, designed for applications requiring maximum bandwidth and minimal signal loss, such as long-distance cable television distribution or high-definition video transmission. While providing superior performance, its size can make installation more challenging.

In essence, choosing the right cable depends on the specific application and the distance the signal needs to travel. For shorter runs with lower bandwidth needs, RG-59 might suffice. For higher bandwidth needs and longer runs, RG-6 or RG-11 are better choices.

Q 2. Describe the proper methods for terminating coaxial cables.

Proper coaxial cable termination is crucial for optimal signal transmission and minimizing signal loss. Improper termination can lead to signal reflections and poor reception. The process involves carefully stripping the cable, attaching a connector, and ensuring a proper connection with the impedance of the cable and the connected equipment.

There are two main types of coaxial connectors: F-type and BNC. The specific steps may vary slightly depending on the connector type, but the general principles remain the same.

- Strip the outer jacket: Carefully remove the outer jacket of the cable using a cable stripper, exposing the braided shield and the dielectric insulator.

- Prepare the braid: Trim and fold back the braid. This is vital for proper contact and grounding.

- Remove the dielectric: Carefully remove the dielectric material to expose the inner conductor without damaging it.

- Attach the connector: Insert the prepared cable into the connector and firmly crimp it with a crimping tool. Ensure the connector is firmly seated to maintain the proper impedance.

- Test the connection: After crimping, use a multimeter or a signal level meter to ensure a proper connection and check for impedance mismatch.

Always use high-quality connectors and tools to ensure a clean and reliable connection. A poorly terminated cable can be the source of numerous frustrating signal problems.

Q 3. What tools are essential for coaxial cable installation and repair?

A well-equipped technician needs a variety of tools for efficient coaxial cable installation and repair. The list below covers essentials for most scenarios:

- Cable Stripper: For precisely removing the outer jacket of the coaxial cable without damaging the inner conductor.

- Crimping Tool: To securely attach connectors to the cable. Different crimpers are needed for different connector types (F-type, BNC, etc.).

- Coaxial Connectors: A supply of appropriate connectors (F-type are most common) for the cable type being used.

- Multimeter: To test cable continuity and check for shorts or open circuits.

- Signal Level Meter: To measure signal strength and identify potential signal loss points within the coaxial cable network.

- Cable Tester: This specialized tool tests the integrity of the coax cable and identifies potential problems in the cable like impedance mismatches.

- Screwdrivers: Various sizes are needed depending on the type of connectors and equipment being used.

- Wire Cutters/Diagonal Cutters: To cleanly cut the coaxial cable.

- Measuring Tape: To determine the required cable length.

Remember, quality tools are an investment that improves efficiency and ensures professional results.

Q 4. How do you identify and troubleshoot signal loss in a coaxial cable network?

Troubleshooting signal loss in a coaxial cable network requires a systematic approach. The problem could be anywhere from a poor connection at the termination to a damaged section of the cable itself.

- Visual Inspection: Start by visually inspecting the entire cable run. Look for any obvious signs of damage, such as kinks, cuts, or corrosion.

- Check Connections: Examine all connectors for tightness and corrosion. Loose or corroded connections are a common source of signal loss.

- Signal Level Meter Measurements: Use a signal level meter to measure signal strength at various points along the cable run. This helps pinpoint the location of the problem.

- Continuity Test: Use a multimeter to test for continuity in the inner and outer conductors. A lack of continuity indicates a break in the cable.

- Impedance Check: Verify the impedance of the cable and connectors to rule out impedance mismatches. The typical impedance for most coaxial cables is 75 ohms.

- Splitters and Amplifiers: If the problem is more widespread, check splitters and amplifiers for proper operation and signal degradation. Faulty components can introduce significant signal loss.

By systematically checking each element of the system, you can effectively isolate and fix signal loss issues. Remember to replace any damaged components with high-quality equivalents.

Q 5. Explain the concept of impedance matching in coaxial cable systems.

Impedance matching is crucial in coaxial cable systems to ensure efficient signal transmission and prevent signal reflections. Impedance refers to the resistance to the flow of electrical current at a specific frequency. Coaxial cables are designed with a specific characteristic impedance, typically 50 ohms or 75 ohms (75 ohms is common for cable TV and satellite).

When the impedance of the cable, connectors, and equipment is matched, the signal is transmitted effectively from the source to the destination without significant reflections. Think of it like trying to pour water into a pipe. If the pipe’s diameter doesn’t change suddenly, the flow is smooth. If there’s a sudden change in diameter, the flow is disrupted and some water splashes back.

A mismatch in impedance leads to signal reflections, resulting in signal loss and poor quality. Careful selection of components and proper termination are critical to achieving impedance matching. Specialized impedance matching devices may be necessary in certain circumstances.

Q 6. What are the common causes of signal attenuation in coaxial cables?

Several factors contribute to signal attenuation (signal loss) in coaxial cables:

- Cable Length: Longer cables generally experience more attenuation than shorter cables. The signal weakens over distance.

- Cable Quality: Poorly constructed cables with inferior materials and shielding will exhibit greater attenuation.

- Bends and Kinks: Sharp bends and kinks in the cable can damage the inner conductor and increase signal loss.

- Water Ingress: Water inside the cable can significantly degrade the signal.

- Corrosion: Corrosion on connectors or within the cable can lead to increased resistance and signal loss.

- Frequency: Higher frequencies experience greater attenuation than lower frequencies. This is why higher bandwidth signals require better quality cables.

Regular maintenance, proper installation techniques, and the use of high-quality cables and connectors can help mitigate these factors and maintain signal integrity.

Q 7. How do you test for continuity in a coaxial cable?

Testing for continuity in a coaxial cable involves checking for a continuous path for electrical current in both the inner and outer conductors. A simple multimeter can be used.

- Set the multimeter: Set the multimeter to the continuity test setting (usually represented by a diode symbol).

- Test the inner conductor: Connect one multimeter lead to the center conductor at one end of the cable and the other lead to the center conductor at the other end. A continuous beep indicates a good connection.

- Test the outer conductor: Repeat the process, this time connecting the leads to the outer shield of the cable at both ends. Again, a continuous beep signifies a good connection.

If there’s no beep in either test, it indicates a break in the cable requiring repair or replacement. If only one conductor shows continuity, this could mean a short between the inner and outer conductors. Remember that a continuity test only confirms the physical connection; it doesn’t measure signal quality.

Q 8. Describe the process of splicing coaxial cables.

Splicing coaxial cables, while possible, is generally avoided due to the potential for signal degradation and increased signal loss. However, in situations where cable replacement is impractical, a proper splice is crucial. The process involves carefully stripping the outer jacket and shielding, ensuring the center conductor remains intact. A specialized coaxial connector, often a compression connector, is then used to join the two cable ends. This ensures a good electrical connection and maintains the cable’s impedance.

Steps involved in a coaxial cable splice:

- Prepare the Cables: Carefully strip the outer jacket and shielding of both cables, exposing a clean section of the inner conductor and dielectric. Use a cable stripper designed for coaxial cable to avoid damaging the inner conductor.

- Connect the Conductors: Ensure a clean, tight connection between the center conductors. The connection should be continuous and free of any gaps or irregularities.

- Secure the Shielding: Join the outer shielding using a compression connector or specialized splicing technique to maintain electrical continuity and reduce signal loss.

- Seal the Connection: Seal the connection using weatherproof sealant or heat-shrink tubing to protect it from moisture and environmental factors.

Important Considerations: The success of a splice hinges on maintaining the cable’s characteristic impedance. Using the wrong tools or improper techniques can lead to signal reflections and a significant reduction in signal quality. For critical applications, consider using a low-loss splice connector designed to minimize signal attenuation.

Q 9. What safety precautions should be taken when working with coaxial cables?

Safety is paramount when working with coaxial cables. These cables often carry high-frequency signals that can be hazardous under certain circumstances. Here are some essential safety precautions:

- Always de-energize the system: Before working on any coaxial cable system, ensure that the power is completely off and that the system is properly grounded. Confirm with a voltage tester before proceeding.

- Use appropriate tools: Always use tools specifically designed for coaxial cables. Improper tools can easily damage the cable and cause signal loss.

- Wear safety glasses: Protect your eyes from potential debris or sharp objects during cable stripping and connector installation.

- Work in a safe environment: Avoid working near energized equipment or in hazardous conditions. A well-lit and organized workspace is essential for safety.

- Be aware of RF radiation: High-frequency signals can potentially cause health issues with prolonged exposure. Minimize direct skin contact with cables and connectors and use protective gear if necessary.

- Use proper grounding techniques: Proper grounding is crucial to prevent electrical shocks and signal interference. This should always be addressed before energizing the system.

Failure to follow these safety precautions can result in injury, equipment damage, and system malfunctions. Always prioritize safety!

Q 10. How do you properly ground a coaxial cable system?

Proper grounding of a coaxial cable system is crucial for preventing signal interference, protecting equipment, and ensuring personnel safety. Grounding provides a path for stray currents to flow safely to earth, eliminating ground loops and noise. A good coaxial ground uses a low-impedance connection to earth ground.

Grounding techniques often involve:

- Grounding the equipment: Connect the equipment chassis to earth ground using a dedicated grounding wire. This is typically done via a three-prong power cord and a properly grounded power outlet.

- Grounding the cable shield: The shield of the coaxial cable should be grounded at both ends. This often involves using grounding lugs or clamps to connect the shield to earth ground at the equipment and at the source. Continuity should be checked with a multimeter.

- Grounding blocks: Specialized grounding blocks can be used to simplify the grounding process, especially in larger systems, allowing for easy connection and monitoring of the ground connection.

Using a multimeter to test the continuity of the ground path is vital to verify that your system is properly grounded. Poor grounding can lead to increased noise levels, data loss, and potential safety hazards.

Q 11. Explain the importance of proper cable routing and management.

Proper cable routing and management are essential for a well-functioning and long-lasting coaxial cable system. It significantly impacts signal quality, system longevity, and maintainability. Think of it like organizing the wires in your house – messy wiring leads to problems!

Benefits of proper cable routing and management:

- Reduced signal loss: Proper routing minimizes bending, kinking, and stress on the cable, reducing signal attenuation.

- Minimized signal interference: Keeping cables organized reduces the likelihood of electromagnetic interference from other devices or cables.

- Improved system aesthetics: Well-managed cables improve the overall appearance of the installation.

- Enhanced maintainability: Organized cables make troubleshooting and future maintenance much easier.

- Increased system lifespan: Reducing stress on cables leads to extended system lifespan and reduced repair needs.

Best practices include using cable ties, trays, and conduits to route the cables neatly and securely, minimizing sharp bends, avoiding running cables near high-power equipment, and clearly labeling all cables.

Q 12. What are the different types of coaxial cable connectors?

Coaxial cable connectors come in various types, each designed for specific applications and cable sizes. Some of the most common types include:

- F-type connectors: Widely used for television, cable internet, and satellite applications. They are available in various configurations, including compression connectors and crimp-on connectors.

- BNC connectors: Often used in instrumentation and video applications, known for their bayonet-style locking mechanism.

- N-type connectors: Primarily used in high-frequency applications, such as radio frequency (RF) systems.

- SMA connectors: Small, widely used in microwave applications.

- TNC connectors: Threaded connectors offering a robust and waterproof connection.

The choice of connector depends heavily on the application’s frequency range, impedance requirements, and environmental conditions. It’s crucial to select the right connector for the specific coaxial cable type to ensure optimal performance.

Q 13. How do you identify a faulty coaxial connector?

Identifying a faulty coaxial connector can involve a combination of visual inspection and signal testing.

Signs of a faulty connector:

- Visual inspection: Look for obvious signs of damage, such as bent pins, corrosion, loose connections, or damaged cable shielding near the connector.

- Signal testing: Use a signal level meter or spectrum analyzer to measure the signal strength at various points in the system. A significant drop in signal strength near a particular connector indicates a problem.

- Continuity testing: A multimeter can be used to test for continuity between the center conductor and the outer shield of the connector. Lack of continuity signifies a break in the cable or connector.

- Return loss measurement: A high return loss indicates significant reflections at the connector due to an impedance mismatch.

If a faulty connector is suspected, replacing it with a new, correctly installed connector is the most effective solution. Poorly installed connectors are a common source of signal degradation. Remember to always use the correct tools and techniques for installation.

Q 14. What is the purpose of a coaxial cable amplifier?

A coaxial cable amplifier boosts the strength of a weak signal traveling through the coaxial cable. This is crucial in situations where the signal has weakened due to long cable lengths, signal attenuation (loss of signal strength over distance), or signal interference. Imagine a whisper needing to be heard across a vast room – the amplifier acts like a megaphone!

Applications of coaxial cable amplifiers:

- Cable television systems: Used to amplify signals over long cable runs to improve signal quality at the end user.

- Satellite TV systems: Used to boost weak satellite signals received by the satellite dish.

- Wireless communication systems: Amplify signals for improved transmission and reception.

- Instrumentation and test equipment: Used in various test setups and instruments to boost weak signals.

Selecting an appropriate amplifier requires understanding the frequency range of the signal, the desired gain (signal amplification), and the noise figure (amount of noise introduced by the amplifier). Improper amplifier selection can lead to signal distortion and reduced system performance.

Q 15. How do you troubleshoot a problem with a coaxial cable amplifier?

Troubleshooting a coaxial cable amplifier involves a systematic approach. First, visually inspect the amplifier for any obvious damage, loose connections, or signs of overheating. Then, check the power supply – ensure it’s properly connected and functioning. Next, measure the signal strength at the input and output of the amplifier using a signal level meter. A significant drop in signal strength indicates a problem within the amplifier or its connections. If the input signal is weak, the problem might lie upstream, with the cable or source. If the output signal is weak despite a strong input, the amplifier itself may be faulty and require replacement or repair. Finally, check for correct impedance matching (typically 75 ohms) throughout the system. Mismatched impedance can cause significant signal loss.

For example, I once diagnosed a weak signal problem to a faulty grounding connection on an amplifier. Simply tightening the ground connection restored the signal strength.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of coaxial cable testing equipment.

My experience encompasses a range of coaxial cable testing equipment, from simple signal level meters to sophisticated spectrum analyzers. Signal level meters are essential for measuring signal strength in decibels millivolts (dBmV) and checking for signal loss. They’re easy to use and provide a quick overview of signal health. Time Domain Reflectometers (TDRs) are more advanced and allow you to pinpoint faults along the cable’s length by measuring reflections caused by impedance mismatches, breaks, or shorts. They provide an accurate location of the fault, saving time and effort during repair. Spectrum analyzers give a detailed frequency analysis of the signal, helping identify interference sources or other frequency-related problems. Finally, cable testers verify the continuity and impedance of the coaxial cable itself.

I’ve worked extensively with various models from Fluke, Tektronix, and other leading manufacturers, and I’m proficient in interpreting their readings.

Q 17. How do you interpret the results of a coaxial cable test?

Interpreting coaxial cable test results depends on the type of equipment used. A signal level meter will show the signal strength in dBmV. Readings significantly below the expected levels indicate signal loss, potentially due to cable damage, poor connections, or amplifier issues. A TDR will display a waveform showing reflections from impedance mismatches or faults. The time it takes for the reflection to return indicates the distance to the fault. A spectrum analyzer shows the signal’s frequency components, revealing interference from other sources. For instance, a significant peak at a specific frequency might indicate interference from a nearby radio transmitter. It is crucial to understand the expected signal parameters for the specific application (e.g., cable type, frequency band) to accurately interpret the test results.

For example, a TDR might show a significant reflection at 50 meters, indicating a break or connector problem approximately 50 meters from the test point.

Q 18. Explain the process of installing a coaxial cable splitter.

Installing a coaxial cable splitter is relatively straightforward but requires careful attention to detail. First, choose a splitter with the appropriate number of outputs and frequency range. Next, securely connect the input coaxial cable to the splitter’s ‘IN’ port using F-type connectors. Then, connect the output coaxial cables to the splitter’s ‘OUT’ ports, again ensuring secure F-type connections. Finally, carefully tighten all connections to avoid signal leakage. It’s important to use good quality connectors and ensure the cable is properly grounded to minimize signal loss and interference.

It’s crucial to note that each split will result in a signal loss of approximately 3dB, which means using many splitters can significantly reduce the signal strength. I often advise customers to consider the use of amplifiers to compensate for signal loss, especially in longer cable runs or when servicing multiple devices.

Q 19. How do you choose the correct coaxial cable for a specific application?

Choosing the correct coaxial cable depends on several factors, most notably the frequency range of the signal and the cable’s length. High-frequency signals (like those used for satellite TV) require cables with lower attenuation (signal loss) per unit length, typically RG-6 or RG-11. Lower frequency signals (like those used for cable TV) can use slightly lower-grade cables. The application also influences the choice, for example, outdoor installations require weatherproof cables. The cable’s impedance must match the impedance of the connected equipment (typically 75 ohms). Incorrect impedance will cause signal reflections and loss. I always consult specifications to make sure the cable is appropriately rated for the signal strength and environmental conditions of the installation.

For instance, for a long-distance satellite TV installation, I would use RG-6 Quad-Shield cable for its superior shielding and low attenuation properties.

Q 20. What are the common problems encountered during coaxial cable installation?

Common problems during coaxial cable installation include loose or damaged connectors, incorrect impedance matching, poor grounding, and signal leakage. Loose or damaged connectors are a frequent cause of signal loss, and improper grounding can lead to interference and noise. Incorrect impedance matching results in signal reflections and loss. Signal leakage occurs when the cable shielding is compromised, allowing RF signals to escape or enter the cable, leading to interference or signal degradation.

I once encountered a job where the entire system was poorly grounded. Solving this issue required tracing the ground wire throughout the system and ensuring proper grounding at the main distribution point.

Q 21. How do you solve problems with signal interference in coaxial cables?

Solving signal interference problems in coaxial cables requires careful investigation and troubleshooting. First, identify the source of interference using a spectrum analyzer. Then, address the interference source if possible (e.g., moving a nearby appliance). If the interference is from a nearby device, shielding the cable can be effective (e.g., using a shielded cable or adding a metal conduit). Ensure proper grounding practices to eliminate ground loops. Properly installed coaxial connectors that are tight and free of damage are also essential. If the interference is within the cable itself, it may need replacement. Using high-quality connectors and cables, paying attention to details during installation and ensuring proper grounding will prevent most interference issues.

In a situation where a nearby cordless phone was causing interference, rerouting the coaxial cable significantly improved signal quality, avoiding the frequency range used by the phone.

Q 22. Explain your experience with working at heights during coaxial cable installations.

Working at heights is a routine part of coaxial cable installation, especially in MDUs or when dealing with aerial drops. Safety is paramount. My experience includes extensive training in fall protection techniques, including proper harness usage, anchor point selection, and rescue procedures. I’m proficient in using various fall arrest systems, like safety harnesses and lifelines, ensuring compliance with OSHA regulations. For example, when installing cable on a tall building, I meticulously inspect all equipment, ensure proper anchoring, and always work with a spotter. I’ve successfully completed numerous high-altitude installations without incident, prioritizing safety above all else.

Q 23. How do you handle difficult or challenging coaxial cable installations?

Challenging installations often involve navigating difficult terrain, congested spaces, or complex building structures. My approach involves thorough planning, starting with a detailed site survey. I identify potential obstacles and develop a strategy that accounts for these challenges. For example, when faced with limited access in an attic, I might use smaller, more maneuverable tools and employ strategic cable routing to avoid obstructions. If signal interference is a problem, I systematically check for signal leaks using a signal level meter and spectrum analyzer, tracing the source to isolate and fix the issue. I’m adept at problem-solving and adapting to unforeseen circumstances, ensuring the job is completed to the highest standards, even in difficult scenarios.

Q 24. What are your strengths and weaknesses in coaxial cable installation and repair?

My strengths lie in my meticulous attention to detail, my proficiency in troubleshooting, and my ability to work efficiently and safely under pressure. I’m particularly skilled in diagnosing and resolving signal degradation issues, often pinpointing the problem quickly and efficiently. For example, I recently resolved a complex signal issue in a large apartment building by identifying a faulty splitter using a time domain reflectometer (TDR). My weakness, which I’m actively working to improve, is managing multiple projects simultaneously in extremely high-pressure situations. I’m currently implementing time management techniques and project prioritization strategies to overcome this.

Q 25. Describe your experience with working independently and as part of a team.

I’m comfortable working both independently and as part of a team. When working independently, I’m self-motivated and capable of managing my time effectively to meet deadlines. However, I also value the collaborative aspect of teamwork. I believe in open communication and readily share my knowledge and expertise to contribute to the team’s success. For instance, on a recent large-scale MDU project, I collaborated with other technicians, sharing our expertise to resolve a complex network issue efficiently and effectively. The combined skills allowed us to complete the installation well ahead of schedule.

Q 26. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills, and aligned with the industry standards for this role. I am open to discussing a competitive compensation package that reflects my contributions to the team.

Q 27. Do you have any questions for me?

Yes, I have a few questions. First, what are the company’s specific training and development opportunities for employees? Second, could you describe the typical project workflow and the tools and technologies used by the team? Finally, what are the company’s expectations for performance metrics and career progression for this role?

Q 28. Describe your experience with troubleshooting signal degradation in a multi-dwelling unit (MDU) environment.

Troubleshooting signal degradation in an MDU requires a systematic approach. I begin by using a signal level meter to measure the signal strength at various points within the system. I then utilize a spectrum analyzer to identify any interference or noise that might be causing the degradation. A common cause in MDUs is faulty splitters or damaged cabling. I systematically check each splitter and cable run, looking for visual signs of damage or loose connections. If the problem persists, I might use a time-domain reflectometer (TDR) to pinpoint the exact location of a cable fault. This allows for a more precise repair, minimizing downtime. In one instance, I identified a faulty amplifier in the headend of an MDU, causing widespread signal attenuation. By replacing the faulty component, I restored signal quality across the entire building.

Key Topics to Learn for Coaxial Cable Installation and Repair Interview

- Coaxial Cable Types and Properties: Understanding the differences between RG-59, RG-6, and other coaxial cable types, their impedance, and signal characteristics. This includes knowing when to select the appropriate cable for a specific application.

- Signal Transmission and Impedance Matching: Grasping the principles of signal transmission over coaxial cables and the importance of impedance matching to minimize signal loss and reflections. Practical application includes troubleshooting signal attenuation issues.

- Installation Techniques: Mastering proper cable routing, termination techniques (F-connectors, BNC connectors), and the use of tools like cable strippers, crimpers, and multimeters. This includes understanding safety precautions and best practices.

- Troubleshooting and Repair: Diagnosing common problems like signal degradation, intermittent connections, and cable damage. Practical application involves using signal level meters and other testing equipment to pinpoint faults and implementing effective repair strategies.

- Network Topologies: Familiarity with different network topologies (e.g., star, bus) and their relevance to coaxial cable installations, particularly in relation to home entertainment systems and broadband networks.

- Safety Regulations and Best Practices: Understanding relevant safety standards and procedures, including working at heights, handling tools safely, and following proper grounding techniques.

- Testing and Measurement Techniques: Proficiency in using signal level meters, time domain reflectometers (TDRs), and other test equipment to verify cable integrity and signal quality. This includes understanding the interpretation of test results.

Next Steps

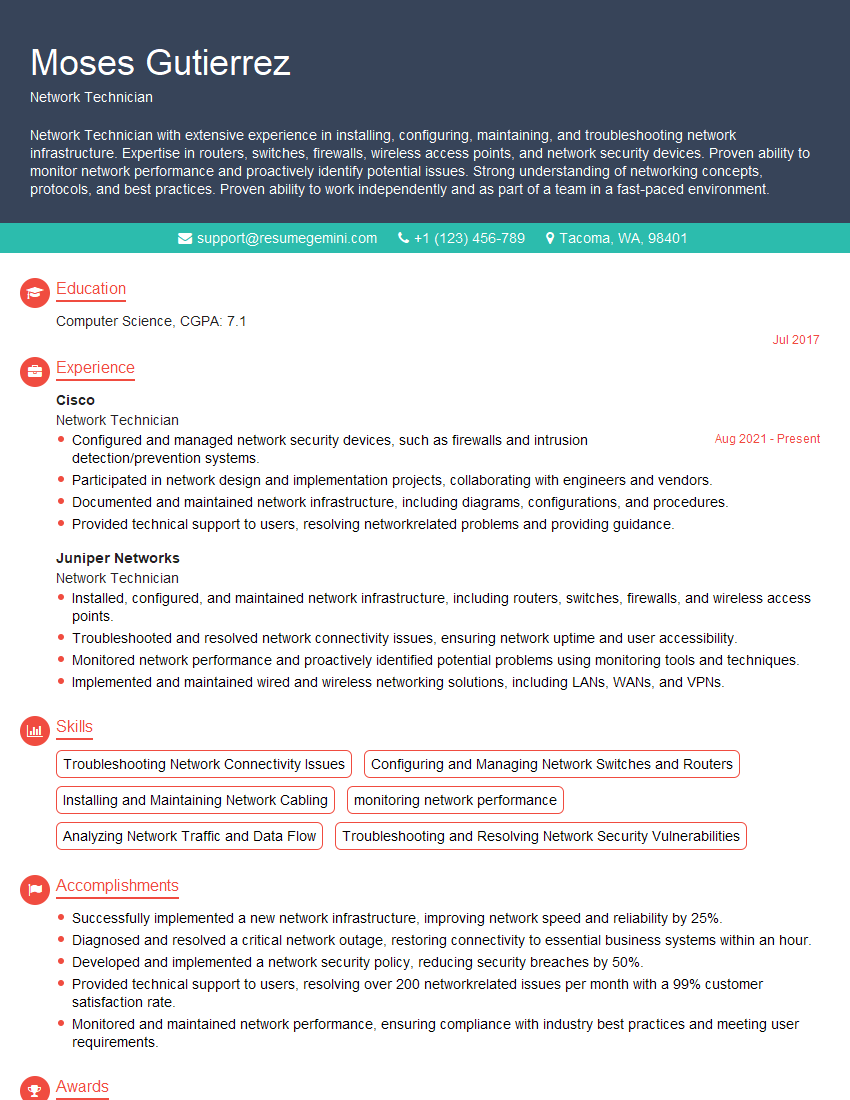

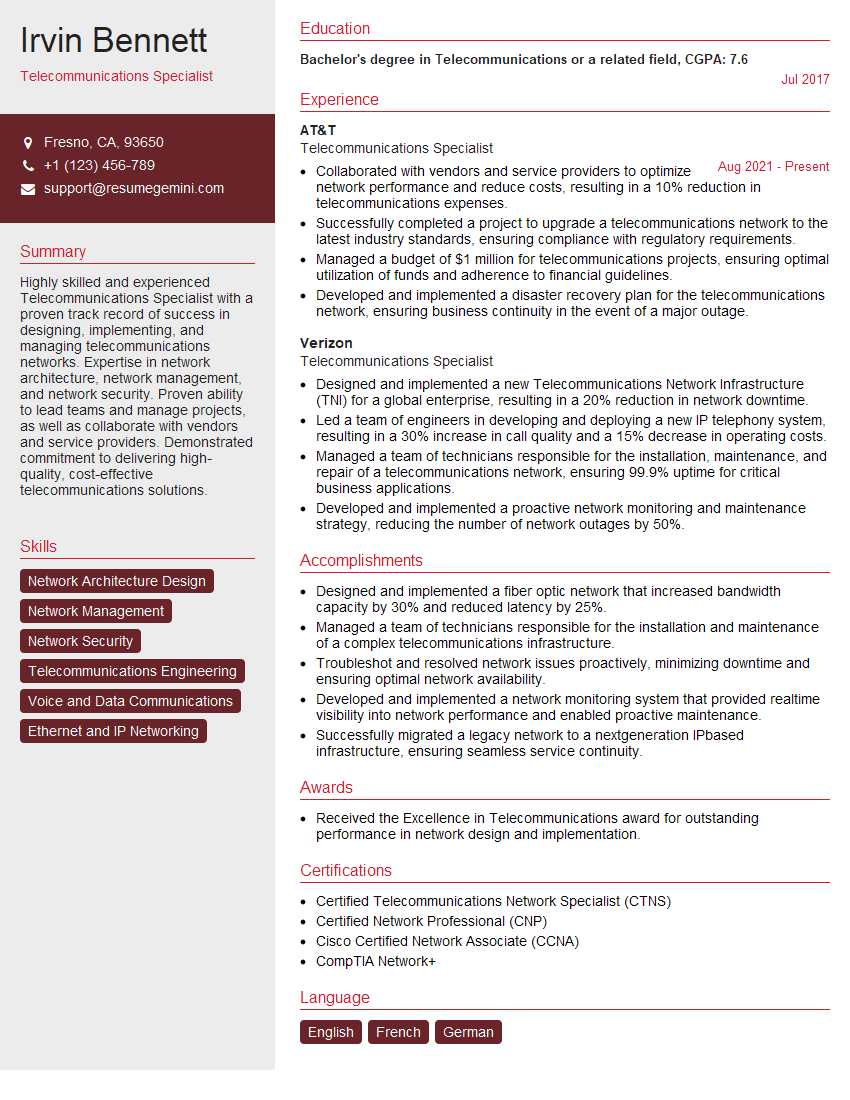

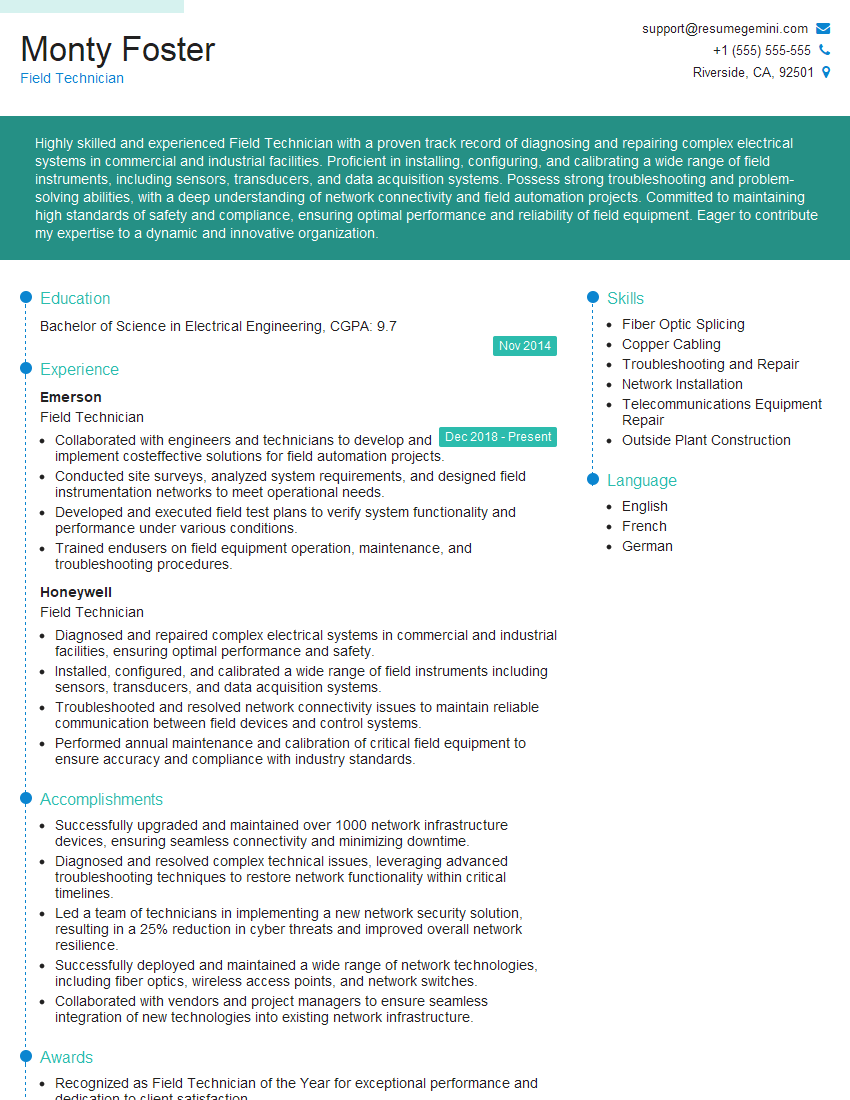

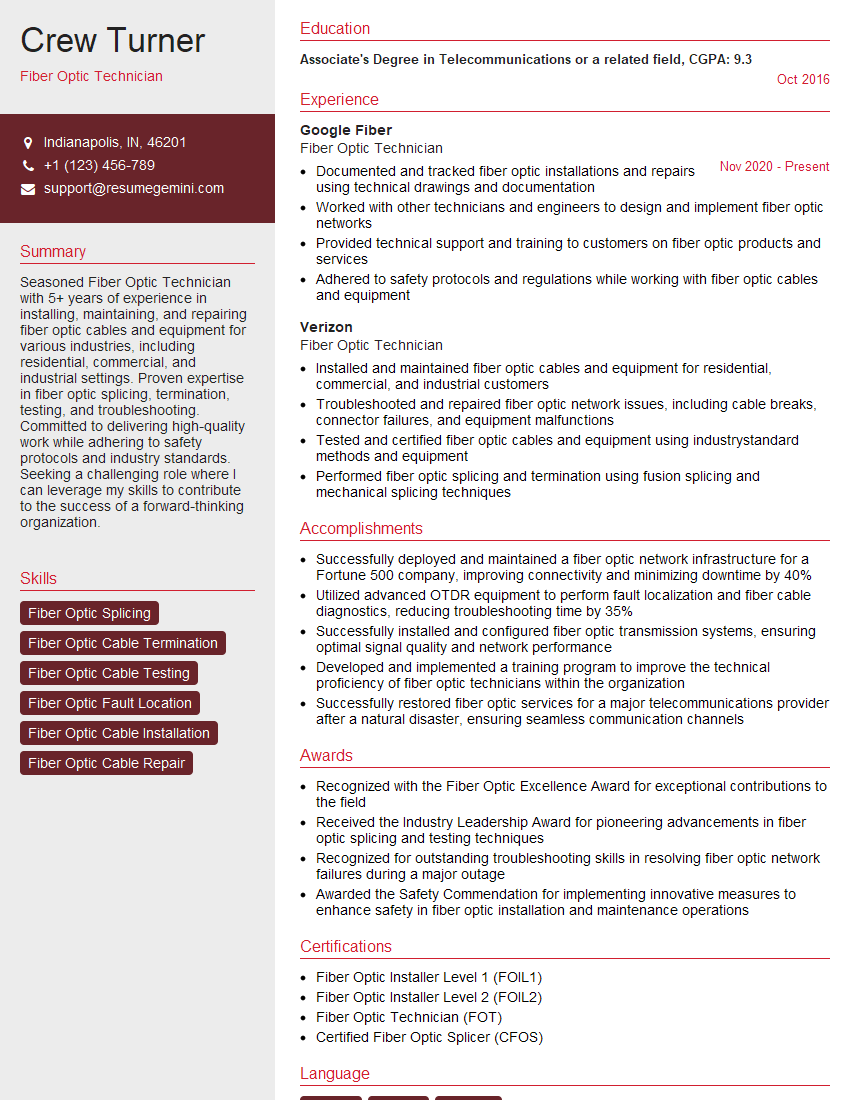

Mastering coaxial cable installation and repair opens doors to exciting career opportunities in telecommunications, cable television, and networking. A strong foundation in these skills positions you for advancement and higher earning potential. To significantly boost your job prospects, create an ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume, maximizing your chances of landing your dream job. Examples of resumes tailored to Coaxial Cable Installation and Repair are available to further guide your efforts.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO