Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Crane Control interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Crane Control Interview

Q 1. Describe your experience operating different types of cranes.

Throughout my career, I’ve operated a variety of cranes, each demanding unique skills and knowledge. This includes tower cranes, commonly used in high-rise construction projects; mobile cranes, offering versatility on various terrains; and overhead cranes, prevalent in industrial settings. My experience with tower cranes involved precise maneuvering of loads at significant heights, necessitating a keen understanding of wind conditions and structural limitations. Operating mobile cranes required adapting to uneven ground and understanding the limitations of outriggers. With overhead cranes, the focus was on smooth and efficient movement within a defined workspace, often involving complex load handling procedures. Each type presented different challenges; for example, the sheer scale of a tower crane operation versus the rapid, repetitive movements demanded by an overhead crane.

Q 2. Explain the different types of crane hooks and their applications.

Crane hooks come in various designs, each suited to specific applications. The most common is the ‘open hook,’ simple and versatile but prone to load slippage if not correctly secured. This is often used for general lifting tasks. Then there are ‘grab hooks,’ designed to grip irregular loads, particularly valuable in demolition or scrap handling. ‘Clevis hooks’ offer a more secure attachment with a pin, preventing accidental slippage, useful when high precision is needed. Finally, ‘special hooks’ are designed to handle specialized loads like magnets or containers. The choice depends on the load’s shape, weight, and material properties. For example, a grab hook would be ideal for handling bundles of scrap metal, while a clevis hook would be preferred for lifting a precisely machined part to avoid damage.

Q 3. What are the common causes of crane accidents and how can they be prevented?

Crane accidents stem from several common causes. Improper rigging and load handling is a major culprit; using incorrect slings or failing to secure the load adequately can lead to drops. Mechanical failure, due to lack of maintenance or overloading, is another significant factor. Operator error, such as exceeding load capacity or operating in unsafe conditions (high winds, poor visibility), is also common. Environmental factors like weather conditions significantly influence safe operation. Preventing accidents involves rigorous pre-operational checks, regular maintenance, strict adherence to load limits, and thorough operator training. Implementing a robust safety program, including regular inspections and safety meetings, is crucial in minimizing risks. Furthermore, clear communication between the crane operator and the signaling personnel is paramount.

Q 4. How do you ensure the safe rigging and slinging of loads?

Safe rigging and slinging are paramount. It begins with selecting the appropriate slings – wire rope, chain, or synthetic webbing – based on the load’s weight, shape, and material. The sling angle must be considered to avoid exceeding the sling’s working load limit. The load must be evenly distributed to prevent damage or slippage. Proper hitching techniques, ensuring the load is balanced and secure, are critical. I always use checklists and visual inspections to verify the rigging’s integrity before initiating a lift. For instance, I’d never use a damaged sling or a sling with excessive wear, and I’d ensure proper hitching methods are applied according to the manufacturer’s recommendations, always double checking and documenting my procedures. This meticulous attention prevents accidents and ensures load stability.

Q 5. Describe the pre-operational checks you perform on a crane.

My pre-operational checks are thorough and follow a strict checklist. This includes verifying the crane’s structural integrity, checking all mechanical components (hoist, brakes, and swing mechanisms) for damage or wear. I inspect the load-bearing components, paying close attention to the hook, sheaves, and ropes. I confirm the operational status of safety devices, such as limit switches and emergency stops. Fluid levels (hydraulic oil, etc.) are checked, and I verify the calibration of the load indicator. Furthermore, I examine the surrounding area, assessing the ground conditions, obstructions, and environmental factors, like wind speed, which could affect the operation. Documentation of each check is crucial for traceability and accountability. Think of this as an aircraft pilot’s pre-flight checklist; it’s not just a procedure, it’s a critical safety measure.

Q 6. Explain the different types of crane signals and their meanings.

Crane signals are crucial for safe operation, ensuring clear communication between the crane operator and the signal person. Hand signals are often used, where specific hand gestures represent actions like hoisting, lowering, swinging, or stopping. Radio communication provides a more efficient and safer alternative, especially in noisy environments. These systems use standardized signals, often supplemented with visual cues. For example, a hand signal indicating a slow, controlled hoist is easily understood by the operator, whereas a radio call might specify the exact lifting speed and direction. Understanding and following these signals is non-negotiable for safe and efficient crane operation. Inconsistency can be very dangerous.

Q 7. How do you handle emergency situations during crane operation?

Emergency situations demand swift and decisive action. If a load starts to swing uncontrollably, I’d immediately stop all crane movements and assess the situation, considering the potential impact zone. If a mechanical failure occurs, I’d engage the emergency brakes and follow established emergency protocols, contacting the appropriate personnel and securing the area. In the event of a load drop, I’d clear the hazard zone and report the incident. My training emphasizes clear emergency procedures and the importance of calm, decisive action in such events. Regular training simulations and drills help reinforce these skills and ensure that everyone on site is prepared to react effectively. The key is to prioritize safety above all else.

Q 8. What are the limitations of your crane operating experience?

While my crane operating experience is extensive, encompassing various crane types and lifting scenarios, my experience is limited in operating specialized cranes like offshore cranes or those used in particularly hazardous environments such as nuclear power plants. My expertise lies primarily in the operation of tower cranes, mobile cranes, and overhead cranes in typical construction and industrial settings. I am always eager to learn and expand my skill set, and I am confident in my ability to quickly adapt to new types of equipment and challenges with proper training.

Q 9. What are the safety regulations and standards you adhere to while operating a crane?

Safety is paramount in crane operations. I strictly adhere to all relevant OSHA (Occupational Safety and Health Administration) regulations and ANSI (American National Standards Institute) standards. This includes, but isn’t limited to, pre-operation inspections, understanding and adhering to load limits, maintaining a safe working radius, proper signaling procedures with the crane signal person, and ensuring the work area is free from obstructions. I always wear appropriate Personal Protective Equipment (PPE) such as hard hats, safety glasses, and high-visibility clothing. Furthermore, I understand and follow all site-specific safety rules and regulations provided by the employer or project manager. For example, I always ensure that the crane is properly secured before commencing any lifting operations. I regularly check the surrounding environment for power lines or other obstacles that might affect the crane’s operation. I also understand and practice emergency shutdown procedures for various situations such as equipment malfunctions or unexpected events.

Q 10. How do you determine the safe working load (SWL) of a crane?

Determining the Safe Working Load (SWL) is crucial for safe crane operation. The SWL is the maximum load a crane can lift safely under specified conditions. It’s not a single number; it depends on several factors. First, I consult the crane’s data plate, which is permanently affixed to the crane and specifies the manufacturer’s stated SWL. However, this is often a general figure. Then, I account for factors like the crane’s configuration (boom length, jib position, radius), the type of load (its shape and distribution of weight), wind speed and direction, and the condition of the crane itself. For example, a longer boom length reduces the SWL. Furthermore, if the crane is operating near its maximum capacity, I will reduce the working load to create a safety margin. I will always err on the side of caution and never exceed the calculated SWL. Finally, I also consider any limitations mentioned in the crane’s load charts (discussed further in the next question). If I’m unsure, I will consult the manufacturer’s specifications or a qualified crane inspector before proceeding.

Q 11. Explain the concept of load charts and their importance.

Load charts are diagrams or tables that provide the SWL for a crane under various configurations. They are essential for safe operation because they account for the complex interplay of factors affecting the crane’s capacity. Think of it like a detailed instruction manual for safe lifting. Each chart depicts the safe working load based on the boom angle, radius, and other relevant factors. For example, a load chart might show that with a 100-foot boom at a 45-degree angle and a 50-foot radius, the SWL is 5 tons, but if the boom angle is increased to 60 degrees, the SWL might reduce to 4 tons. Ignoring these charts can lead to overloading and catastrophic failures. I always check the load chart before any lift to ensure the operation is within the safe parameters. I always ensure I am using the correct chart for the specific crane model and configuration. Any discrepancies or unclarity would necessitate obtaining clarification from the manufacturer or a competent engineer before continuing.

Q 12. What are the different types of crane inspections and their frequency?

Crane inspections are vital for safety and maintaining the operational efficiency of the equipment. There are several types, each with its own frequency:

- Daily Inspections: Performed by the crane operator before each shift, these checks focus on the immediate operational readiness. This includes examining brakes, hooks, cables, and overall mechanical functionality. Any issues are reported immediately.

- Weekly Inspections: More thorough examinations, often by a designated inspector, cover a wider range of components and functions. These might include more detailed assessments of structural elements and safety systems.

- Monthly Inspections: More in-depth checks usually performed by a qualified inspector. They cover more complex systems and components.

- Annual Inspections: Comprehensive checks, often involving external inspection companies. These are usually mandated by regulations and involve a rigorous examination of the entire crane, including non-destructive testing of critical components.

The frequency varies according to regulations, the type of crane, and its usage intensity. Any issues found during inspections are documented and addressed promptly to prevent accidents.

Q 13. How do you identify and report potential hazards during crane operations?

Identifying and reporting potential hazards is a continuous process during crane operation. I use a multi-pronged approach:

- Pre-operational checks: I thoroughly inspect the crane and the surrounding area to identify any potential obstacles, such as power lines, underground utilities, or unstable ground.

- Ongoing vigilance: During operation, I maintain constant awareness of my surroundings, watching for changes in weather conditions (like strong winds) or the appearance of unexpected hazards (people or equipment entering the work area).

- Communication: I maintain clear communication with the crane signal person and other personnel on the ground to prevent misunderstandings and ensure everyone is aware of the crane’s movements.

- Reporting: Any identified hazards, even minor ones, are immediately reported to my supervisor or the site safety officer. This includes documenting the hazard, its potential impact, and any immediate corrective actions taken.

Example: If I notice a weakened support structure near the crane’s operating radius, I would immediately stop operations, report the hazard, and request a structural engineer’s assessment before resuming work.

Q 14. Describe your experience with load moment indicators (LMIs).

Load Moment Indicators (LMIs) are crucial safety devices that continuously monitor the load weight, radius, and boom angle to calculate the load moment. This is a measure of the stress on the crane. The LMI displays this information, preventing overload situations. My experience with LMIs is extensive. I understand how to interpret their readings and how to respond to warnings or alarms. For example, if the LMI indicates that the crane is approaching its maximum load moment, I would immediately reduce the load or adjust the boom angle to stay within the safe operating limits. I understand that LMIs are critical preventative measures against crane accidents and are a key part of safe crane operation, and I always rely on their feedback to ensure I maintain safe and effective operations.

I also understand that different LMIs may have varying features and functionalities, and I adapt my operating procedures accordingly. Regular calibration and maintenance of the LMI system is vital and I’m well-versed in recognizing when the device may require service.

Q 15. Explain the importance of maintaining accurate load charts.

Accurate load charts are paramount for safe and efficient crane operations. They provide crucial information on the crane’s lifting capacity under various conditions, such as boom length, radius, and load configurations. Without accurate load charts, operators risk exceeding the crane’s limits, leading to catastrophic structural failure, potential injury, or even death. Think of it like this: a load chart is the crane’s ‘instruction manual’ for safe lifting. Ignoring it is like ignoring the speed limit – you might get away with it sometimes, but the consequences of exceeding the limits can be devastating.

Maintaining accuracy involves regular inspections and updates. This includes verifying the crane’s structural integrity, checking for any wear and tear, and accounting for environmental factors such as wind speed and temperature, which can affect the crane’s capacity. Any modifications or repairs to the crane necessitate an updated load chart to reflect the changes. For instance, if a new hoist is installed, the load chart must be recalculated to reflect its increased capacity (or any limitations it might impose).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your preferred methods for communication during crane operations?

Clear and unambiguous communication is fundamental to safe crane operations. My preferred methods involve a combination of visual and audible signals. The primary method is hand signals, standardized and understood by all personnel involved. These are supplemented by a radio communication system for longer distances or situations where hand signals might be obscured. For complex lifts, I prefer pre-lift meetings to clarify the plan, the sequence of operations, and emergency procedures. This ensures everyone understands their roles and responsibilities.

I always emphasize the importance of confirmation. Before every lift, I verbally confirm the weight of the load, the intended lifting point, and the designated placement location with the signal person and any other relevant parties. This confirmation process significantly reduces the chances of miscommunication leading to accidents.

Q 17. How do you manage challenging weather conditions during crane operation?

Weather significantly impacts crane stability and operational safety. High winds, heavy rain, snow, or ice can drastically reduce a crane’s lifting capacity and increase the risk of accidents. My approach involves a multi-pronged strategy. First, I constantly monitor weather forecasts and reports. If conditions deteriorate, I immediately communicate with the site supervisor and decide whether to suspend operations or implement mitigating measures. This might involve reducing the load capacity, adjusting the boom angle, or using additional rigging equipment for improved stability.

In extreme weather, delaying or halting operations is always the safest option. For instance, if wind speeds exceed the crane’s operational limit specified in the manufacturer’s guidelines, halting the operation is mandatory. Safety always supersedes deadlines and productivity goals.

Q 18. Describe your experience with different types of crane control systems.

Throughout my career, I’ve gained experience with a variety of crane control systems, ranging from traditional mechanical lever-operated systems to advanced computer-controlled systems. Mechanical systems provide a direct, tactile feel for the crane’s movements, offering a high degree of control in simpler operations. However, they lack the precision and data logging capabilities of modern systems.

Modern computer-controlled systems provide significant advantages. They offer features like load moment indicators (LMIs) which prevent overloading by calculating the crane’s stability in real-time. These systems also facilitate remote monitoring, allowing for precise control and optimized lifting techniques. I’m proficient with both types of systems and can adapt to new technologies quickly. My experience includes systems using PLC (Programmable Logic Controller) based control, and I’m comfortable interpreting data from sensors and displays within those systems.

Q 19. How do you handle communication breakdowns with the signal person?

Communication breakdowns are a serious concern in crane operations. If I notice a misunderstanding or lack of clarity with the signal person, I immediately halt the operation and address the issue directly. I might ask the signal person to repeat their signals or instructions to ensure I understand correctly. If the misunderstanding persists, I’ll clarify the instructions using alternative communication methods, such as verbal confirmation or drawing diagrams. If the problem continues, I’ll seek clarification from the supervisor. Safety protocols dictate that in case of doubt, the operation is immediately stopped.

For example, if I see the signal person giving a signal that contradicts the previously agreed upon plan, I would stop the lift and discuss it to make sure we are both on the same page. This proactive approach ensures a safe working environment for everyone involved.

Q 20. What is your understanding of different types of crane lifting techniques?

Crane lifting techniques vary depending on the load’s characteristics, the crane’s capabilities, and the environment. Some common techniques include:

- Straight Lift: Lifting a load directly vertically.

- Swing Lift: Lifting a load and then swinging it to a different location.

- Derrick Lift: Utilizing a derrick crane for specialized lifting tasks in confined spaces.

- Pick and Carry: Lifting a load and moving it short distances.

- Tandem Lift: Using two or more cranes to lift a single, exceptionally heavy load.

My experience encompasses all these techniques, and I select the most appropriate method based on a thorough risk assessment. For instance, a tandem lift requires meticulous coordination and communication between crane operators and spotters to ensure a safe and controlled operation.

Q 21. How do you ensure the stability of the crane during lifting operations?

Ensuring crane stability is paramount. This involves several crucial steps. First, I always check the ground conditions to ensure the crane is on a stable, level surface, with sufficient load-bearing capacity. Next, I carefully assess the load’s weight, center of gravity, and rigging configuration to avoid unbalanced loads. The load must be properly secured and balanced to prevent swaying or shifting. I use the LMI (Load Moment Indicator) constantly, which provides real-time data on the crane’s load and stability. The boom angle and radius are adjusted as needed to maintain optimal stability, and I always adhere to the crane’s specified operational limits.

Furthermore, I take wind speed and direction into account, understanding that high winds can significantly impact the crane’s stability. I incorporate outriggers when appropriate for additional support, particularly on uneven ground or during high-wind conditions. Consistent vigilance and adherence to safety protocols ensure the crane remains stable throughout the lifting operation.

Q 22. Explain your experience working with different types of rigging equipment.

My experience with rigging equipment spans a wide range, encompassing various types used in diverse lifting operations. I’m proficient with different slings, including wire rope slings (which require careful inspection for kinking or damage), synthetic web slings (known for their flexibility and lighter weight), and chain slings (durable but susceptible to wear and elongation). I’m also experienced with shackles, hooks, and other connecting hardware. Proper selection of rigging equipment is crucial; the choice depends on the load’s weight, shape, and material, as well as environmental conditions. For example, a delicate glass panel would require a soft sling like a web sling, while a heavy steel beam might necessitate a stronger chain sling. Safety is paramount, and I always meticulously inspect all rigging components before each lift, adhering to manufacturer’s guidelines and industry best practices.

- Wire Rope Slings: I’m adept at recognizing signs of wear and tear, such as broken wires, kinking, or corrosion.

- Synthetic Web Slings: I understand the limitations of these slings, including susceptibility to UV degradation and chemical exposure.

- Chain Slings: I can identify stretched links, excessive wear, and damage that could compromise load security.

Q 23. Describe your experience with crane maintenance and troubleshooting.

Crane maintenance and troubleshooting are integral parts of my expertise. My experience includes preventative maintenance schedules, which are critical for extending the lifespan of the crane and preventing catastrophic failures. This involves regular inspections of all mechanical, electrical, and hydraulic components, lubrication of moving parts, and thorough documentation of any findings. I’m also skilled in diagnosing and resolving various issues, from hydraulic leaks and electrical faults to problems with the load-indicating devices and braking systems. For instance, I once diagnosed a slow swing speed on a tower crane by systematically checking the hydraulic system, eventually identifying a malfunctioning pressure relief valve. Replacing the valve restored full functionality. Detailed record-keeping is key; it allows me to track maintenance history, anticipate potential problems, and ensures compliance with safety regulations.

Q 24. How familiar are you with the OSHA regulations for crane operation?

I possess a thorough understanding of OSHA regulations (specifically 29 CFR 1926 Subpart CC) pertaining to crane operation and safety. This includes regulations regarding crane inspections, operator qualifications, load capacity calculations, rigging procedures, and signalpersons. I’m familiar with the requirements for pre-operational inspections, daily inspections, and periodic thorough inspections. My knowledge extends to the regulations surrounding crane certification and licensing, ensuring that all personnel involved meet the necessary qualifications. Understanding these regulations isn’t simply about compliance; it’s fundamentally about ensuring the safety of everyone on the worksite.

Q 25. What are your strategies for preventing crane collisions?

Preventing crane collisions requires a multi-faceted approach. Firstly, establishing clear communication protocols is crucial. This includes using standardized hand signals or two-way radios to ensure that all personnel involved in the lift – crane operators, riggers, and signalpersons – are on the same page. Secondly, implementing a robust site layout and planning process is vital. This involves carefully considering the workspace, identifying potential hazards, and establishing exclusion zones around the crane’s swing radius to prevent workers from entering dangerous areas. Thirdly, effective load charts and calculations are essential. Accurately determining the crane’s load capacity and staying within those limits prevents overloading and reduces the risk of accidents. Finally, regularly reviewing and updating safety procedures and providing ongoing training to personnel are essential.

Q 26. Describe a time you had to make a quick decision to ensure safety during crane operation.

During a high-rise construction project, I noticed a sudden increase in wind speed while a heavy steel beam was being lifted. The crane was already significantly extended, and the wind could have easily caused the load to swing uncontrollably. My quick decision was to immediately halt the lift, despite the pressure to continue. I instructed the crane operator to lower the load slowly and carefully, and I redirected nearby workers to safe areas. Although it caused a temporary delay, this decision prevented a potentially disastrous accident that could have resulted in serious injury or property damage. Prioritizing safety, even when it means facing temporary setbacks, is always my top priority.

Q 27. How do you stay updated on the latest industry best practices and regulations for crane operation?

Staying updated on industry best practices and regulations is an ongoing process. I actively participate in professional organizations like the Association of Crane and Rigging Professionals (ACRP) to network and learn from experienced colleagues. I regularly attend industry conferences and seminars to learn about new technologies and safety advancements. I subscribe to relevant trade publications and online resources that keep me abreast of changes in regulations and best practices. Moreover, I maintain a commitment to continuous learning through online courses and certifications, ensuring my knowledge base remains current and comprehensive.

Q 28. How do you calculate the radius and swing of a crane load?

Calculating the radius and swing of a crane load involves understanding the crane’s specifications and the geometry of the lift. The radius is the horizontal distance from the crane’s center of rotation to the load’s center of gravity. The swing is the arc described by the load as the crane rotates. The calculation is often based on the boom length, the angle of the boom, and the distance from the hook to the load’s center of gravity. The load chart provided by the crane manufacturer is a vital tool in this calculation, as it gives the maximum allowable radius for different loads and boom configurations. For instance, a load chart may show that with a certain boom length and load weight, the maximum allowable radius is 25 meters. Exceeding this radius could lead to instability or an accident. Accurate calculations are not just about numbers; it is about ensuring stability and avoiding catastrophic failures.

Example: Radius = Boom Length * cos(Boom Angle) + Horizontal Distance from Hook to Load Center.Key Topics to Learn for Crane Control Interview

- Crane Types and Operations: Understanding the mechanics and operation of various crane types (tower, mobile, overhead) is fundamental. This includes knowing their limitations and safe operating procedures.

- Load Handling and Stability: Learn how to assess load weight, center of gravity, and potential hazards. Practice calculating safe lifting capacities and understanding stability factors.

- Safety Regulations and Procedures: Familiarize yourself with relevant safety regulations, emergency protocols, and pre-operational checks. Demonstrate a strong understanding of risk assessment and mitigation.

- Signal Communication and Hand Signals: Mastering effective communication with ground personnel is critical. Understand standard hand signals and radio communication procedures.

- Troubleshooting and Maintenance: Be prepared to discuss common crane malfunctions and basic troubleshooting techniques. Understanding preventative maintenance schedules is also beneficial.

- Legal and Regulatory Compliance: Demonstrate knowledge of relevant legislation and regulations pertaining to crane operation and safety in your region.

- Technological Advancements: Stay updated on modern crane technologies, such as load moment indicators (LMIs), anti-collision systems, and remote control systems.

Next Steps

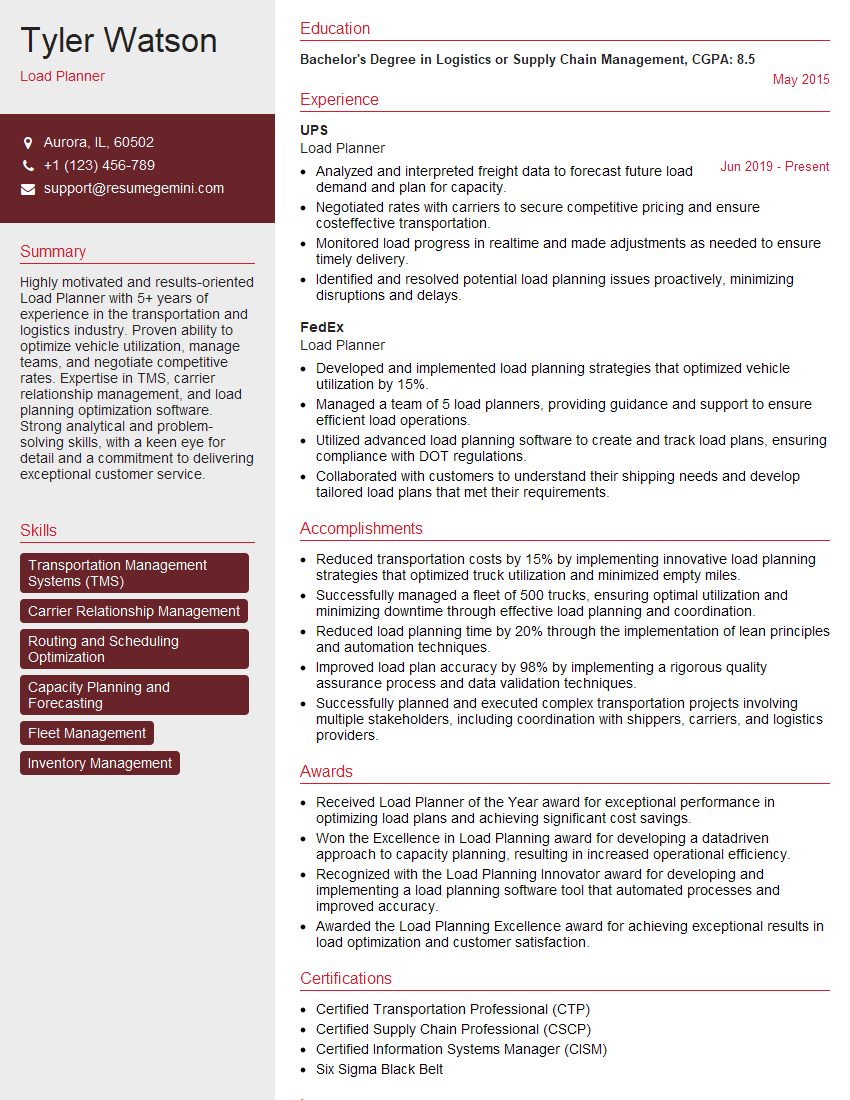

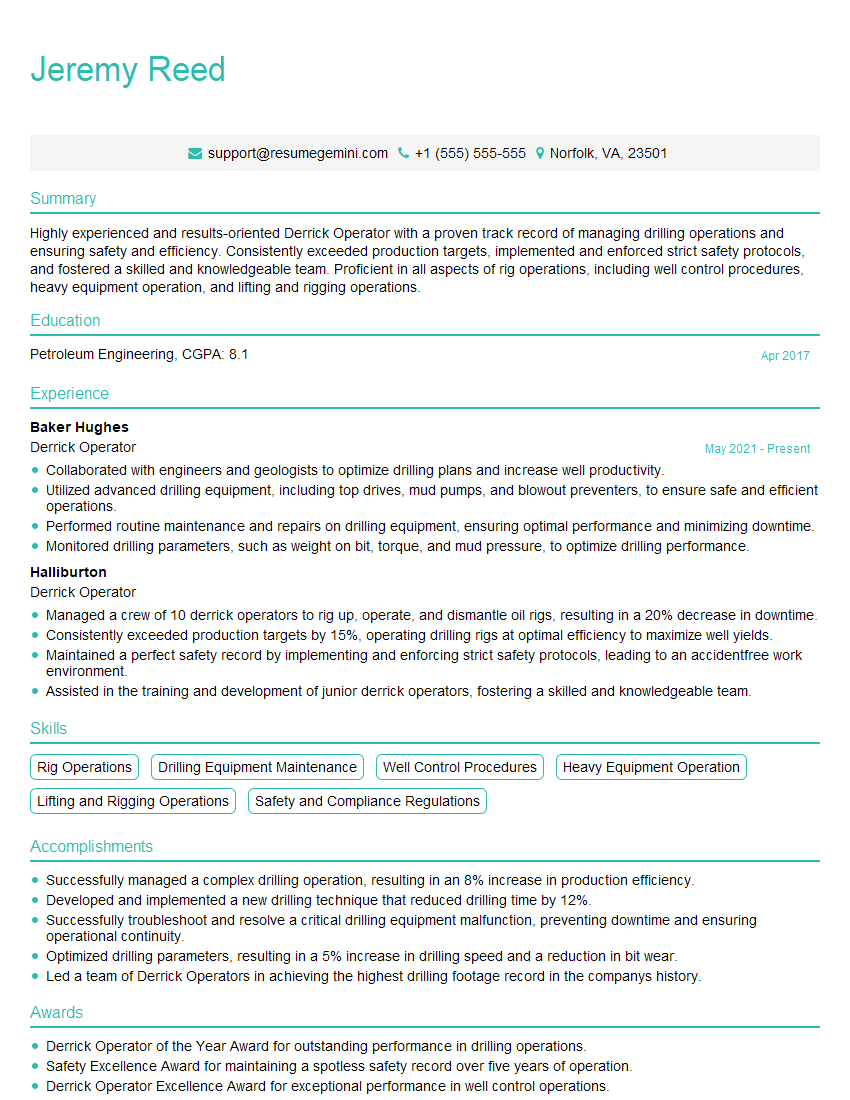

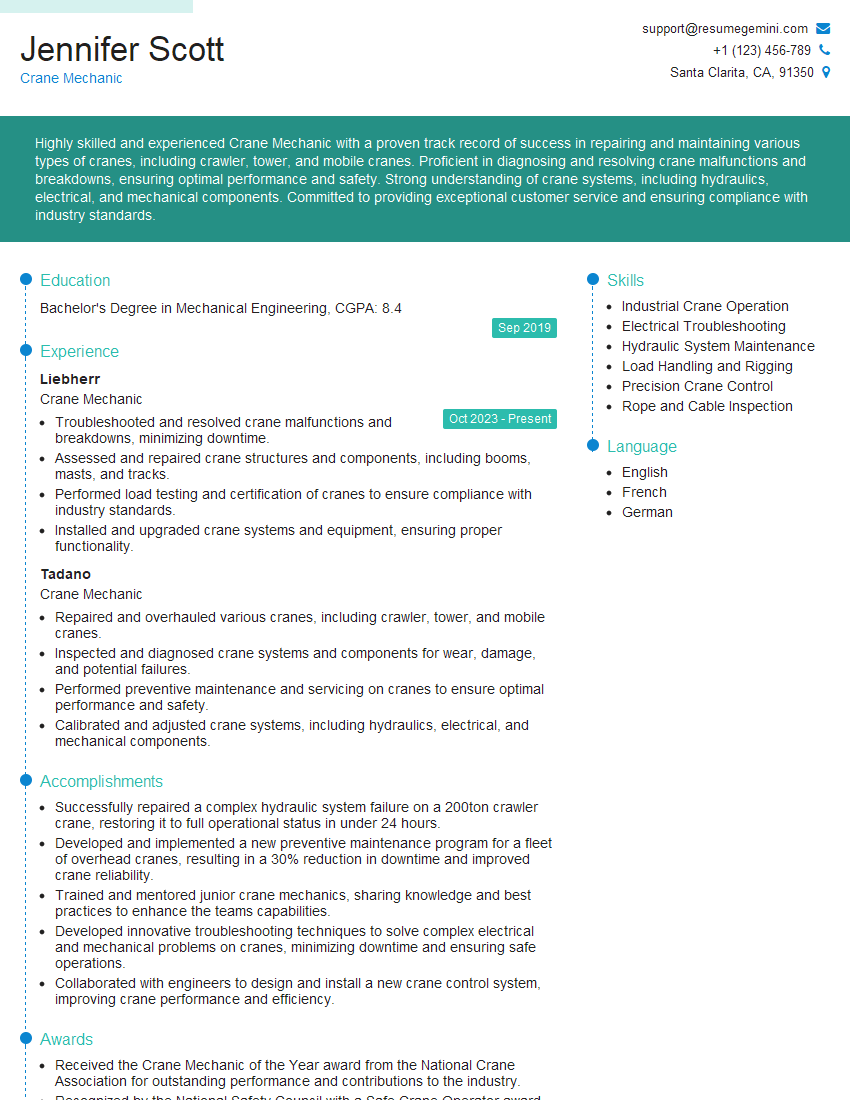

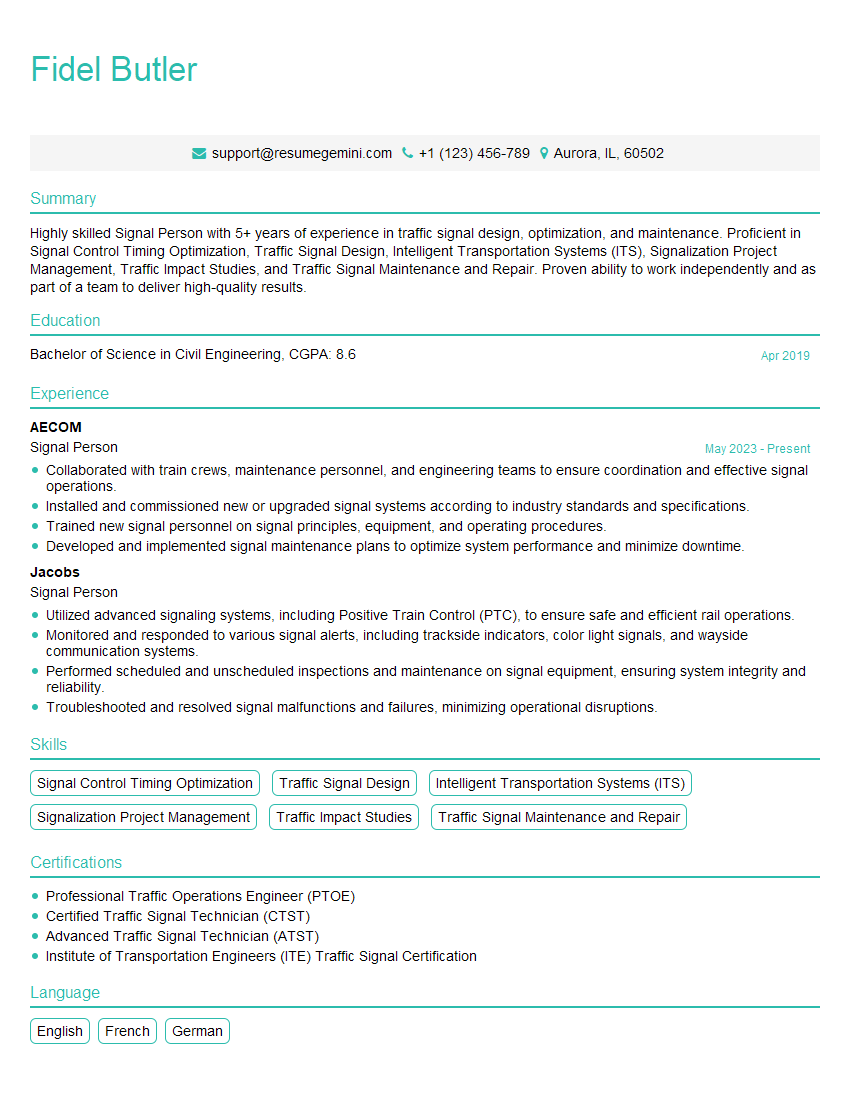

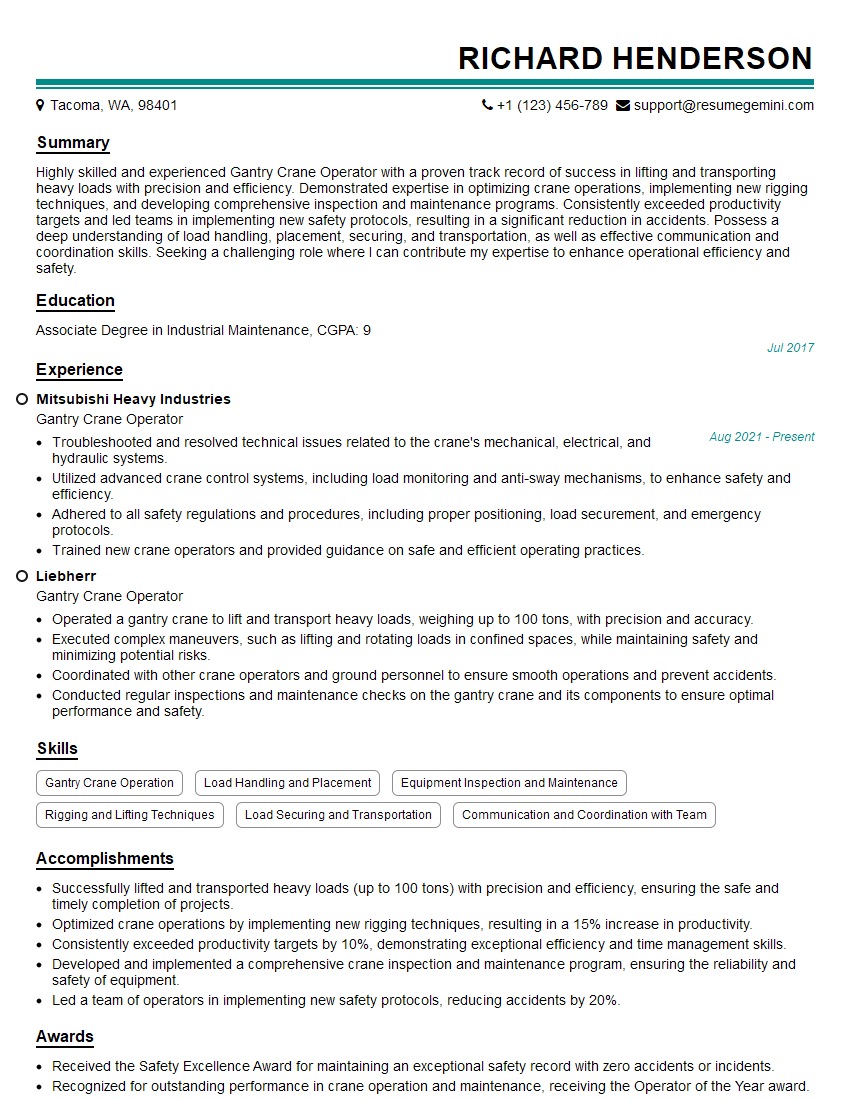

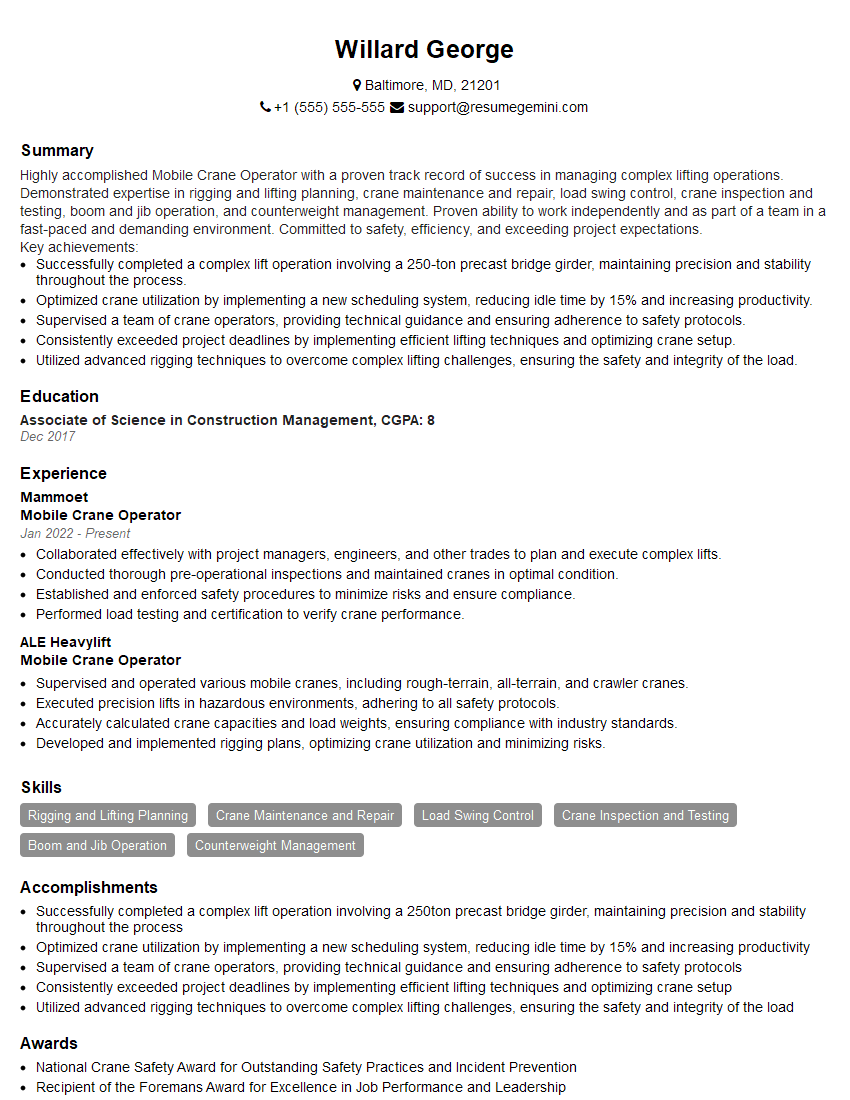

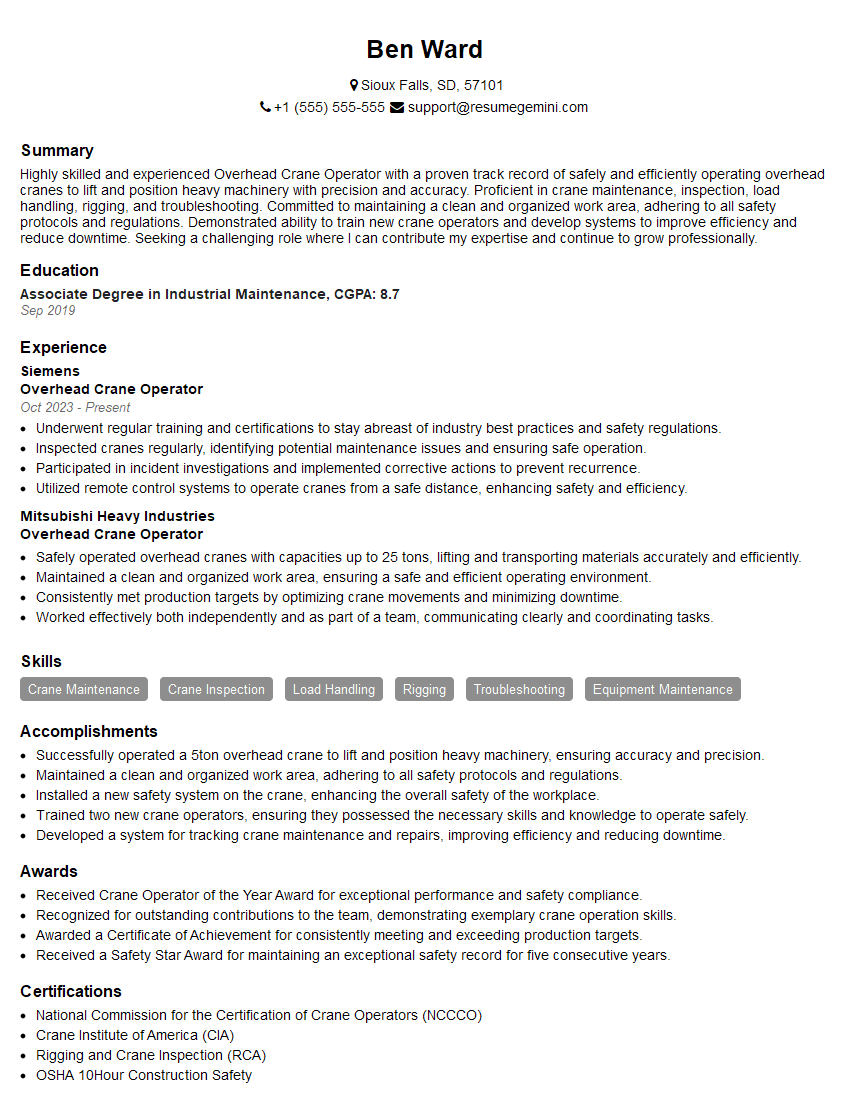

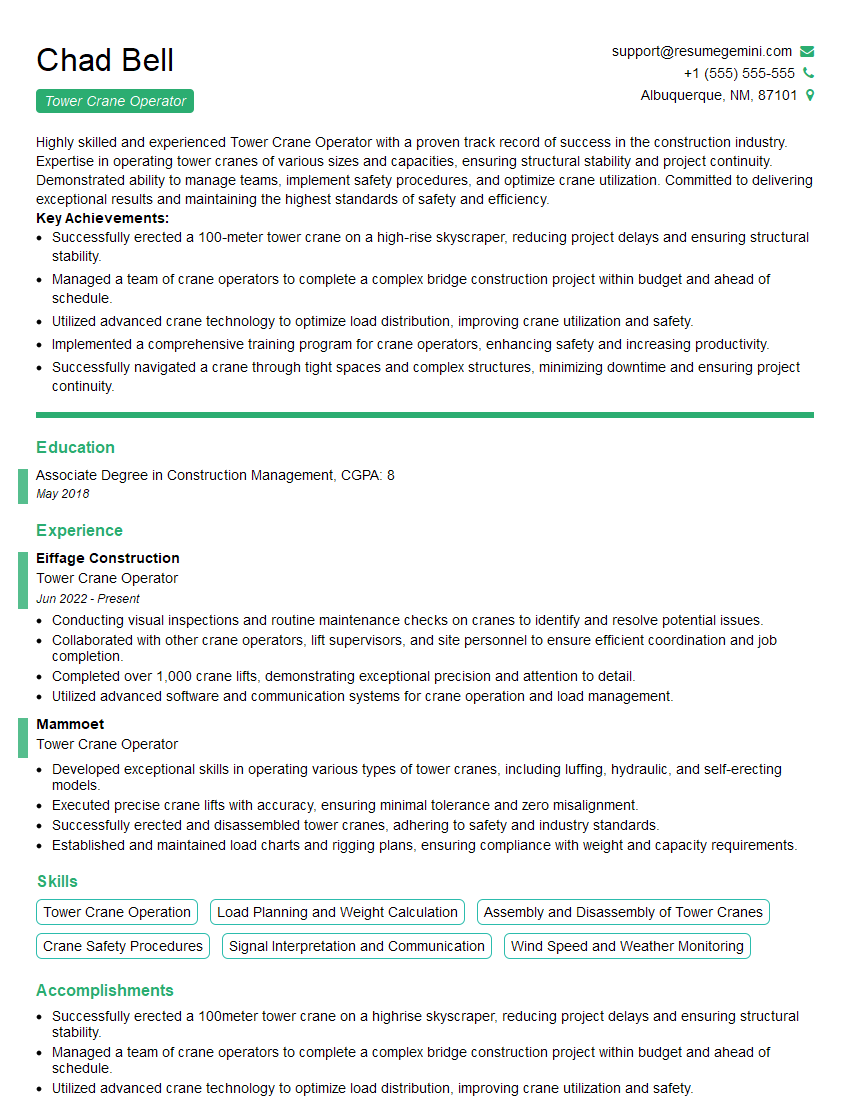

Mastering crane control opens doors to rewarding and well-compensated careers in construction, manufacturing, and logistics. Your expertise in safe and efficient crane operation will be highly valued. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Crane Control field to guide you in showcasing your qualifications. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO