Preparation is the key to success in any interview. In this post, we’ll explore crucial Crocheting and Machine Knitting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Crocheting and Machine Knitting Interview

Q 1. Explain the difference between single crochet and double crochet.

The difference between single crochet (sc) and double crochet (dc) lies primarily in the height and thickness of the stitch. Think of it like building a wall: single crochet is like using small bricks, creating a dense, tightly woven fabric. Double crochet uses larger bricks, resulting in a taller, airier fabric.

Single Crochet (sc): You insert your hook into a stitch, yarn over, and pull through a loop. You now have two loops on your hook. You yarn over again and pull through both loops on your hook. This creates one single stitch.

Double Crochet (dc): You insert your hook into a stitch, yarn over, and pull through a loop. Now you have two loops on your hook. You yarn over and pull through one loop. You now have two loops. You yarn over and pull through both loops. This creates a taller stitch.

In essence, a double crochet involves an extra yarn over and pull-through step, leading to a longer, looser stitch compared to a single crochet.

- Sc creates a tighter, denser fabric, ideal for amigurumi or blankets needing structure.

- Dc creates a looser, airier fabric, perfect for shawls, afghans, or items where texture is desired.

Q 2. Describe various machine knitting techniques, such as tuck stitch and intarsia.

Machine knitting offers a variety of techniques to create intricate designs and textures. Two prominent examples are tuck stitch and intarsia.

Tuck Stitch: This technique creates a ribbed, textured fabric by manipulating the needles to create a stitch that’s partially wrapped around another stitch. Imagine creating a slight knot or tuck in the fabric. It gives depth and visual interest without needing multiple colors. The exact method varies depending on the machine, but generally involves using the carriage controls to selectively lift certain needles and create the tucked effect.

Intarsia: Intarsia is a colorwork technique where you knit different colors next to each other, often forming distinct shapes or patterns. Unlike Fair Isle (where you carry the unused colors across the back), intarsia involves introducing a new yarn for each color section. This requires cutting and joining yarns frequently, demanding meticulous planning and execution to avoid holes or gaps in the fabric. Many machines have specific carriages or mechanisms to facilitate intarsia knitting.

Other machine knitting techniques include Fair Isle (carrying multiple colors across the back), slip-stitch patterns, and various lace patterns achieved through needle selection and yarn manipulation. The capabilities are largely dependent on the specific machine model.

Q 3. How do you troubleshoot dropped stitches in crochet?

Dropped stitches in crochet are frustrating but fixable. The key is to identify the dropped stitch and carefully rejoin it to the fabric without creating a noticeable hole or disrupting the pattern.

Troubleshooting Steps:

- Locate the dropped stitch: Carefully examine your work to pinpoint the exact location of the dropped stitch. It’s often a visible gap or a noticeable change in the fabric’s texture.

- Use a crochet hook: Insert your hook into the stitch immediately before the dropped stitch, going from the front of the piece to the back. Grab the dropped stitch loop (usually hanging loosely below), pull it through to the front, and then carefully work the rest of the stitches as you normally would.

- Weave in ends:Once you have repaired the dropped stitch, make sure to weave in the loose yarn ends to secure the repair.

- Steaming or blocking (if necessary): Gently steam or block your crochet piece to even out the stitches and minimize the visibility of the repair.

If the dropped stitch is difficult to retrieve, you may need to unravel a few stitches above to access it properly. Remember, patience is key when repairing dropped stitches.

Q 4. How do you maintain consistent tension in machine knitting?

Maintaining consistent tension in machine knitting is crucial for achieving even fabric and preventing distortions. This is controlled primarily through the machine’s settings and the knitter’s technique.

Techniques for Consistent Tension:

- Correctly adjust the tension dial: This dial controls how tightly the yarn is pulled through the needles. Consult your machine’s manual for recommended settings based on yarn weight and desired fabric drape. Experimentation is key to finding the optimal setting.

- Use a consistent yarn feed: Uneven yarn feed leads to inconsistencies in tension. Keep a steady pace when feeding the yarn.

- Regularly check the yarn path: Ensure the yarn is smoothly flowing through the machine’s path. Any snags or friction can cause uneven tension.

- Use a suitable yarn: Some yarns are better suited for machine knitting than others. Opt for consistent yarns that are not too fluffy or easily pilled.

- Observe your gauge swatch: Regularly knit gauge swatches to check if the tension is consistent. Adjust machine settings until your swatch matches the design specifications.

Consistent tension is the cornerstone of high-quality machine-knitted garments. Regular monitoring and adjustments are paramount.

Q 5. What are the different types of yarn suitable for crochet and machine knitting?

Yarn selection is crucial in both crochet and machine knitting. The type of yarn impacts the final product’s drape, texture, and durability.

Suitable Yarns for Crochet:

- Cotton: Breathable, durable, and easy to care for; great for summer items.

- Acrylic: Affordable, versatile, and comes in a wide range of colors; suitable for beginners.

- Wool: Warm, soft, and naturally insulating; can be itchy for some.

- Merino wool: A softer type of wool, less likely to cause itchiness.

- Alpaca: Luxurious, soft, and warm; known for its hypoallergenic properties.

Suitable Yarns for Machine Knitting:

- Worsted weight yarns: Often recommended for machine knitting, ensuring smooth feed.

- Sport weight yarns: Can be used but require careful machine adjustment for consistent tension.

- Avoid highly textured or bulky yarns: These can clog the machine or create uneven tension.

Always check the yarn label for recommendations regarding machine suitability. Gauge swatches are recommended before starting a large project to ensure compatibility with the machine and pattern.

Q 6. Explain the concept of gauge in crochet and machine knitting.

Gauge refers to the number of stitches and rows (or rounds) per inch (or centimeter). It’s the fundamental measurement that ensures your finished project matches the pattern’s dimensions. An incorrect gauge results in a piece that’s too large or too small.

Gauge in Crochet: To determine your gauge, you crochet a small swatch using the specified yarn and hook size, then measure the number of stitches and rows within a defined area (e.g., 4 inches). If your gauge doesn’t match the pattern’s specified gauge, you need to adjust your hook size or yarn weight to achieve the correct gauge.

Gauge in Machine Knitting: Gauge is determined similarly, knitting a small swatch with the selected yarn and machine settings. You measure the stitches and rows per inch to verify that it matches the pattern. Adjustments to needle size, yarn feed, or tension may be needed.

Accurate gauge is crucial in achieving the correct fit and dimensions. Always knit or crochet a gauge swatch, especially when working with a new yarn or pattern.

Q 7. How do you read and interpret crochet patterns?

Reading crochet patterns might initially seem daunting, but with practice, it becomes straightforward. Patterns use a combination of written instructions, abbreviations, and diagrams.

Understanding Crochet Pattern Components:

- Materials List: Specifies the yarn type, quantity, hook size, and other necessary materials.

- Abbreviations: A key explaining common crochet abbreviations (e.g., sc for single crochet, dc for double crochet, ch for chain).

- Gauge: Provides the number of stitches and rows per inch, crucial for achieving the correct size.

- Instructions: These are the step-by-step directions for creating the project. They often include round-by-round or row-by-row instructions.

- Charts (optional): Visual representations of the pattern, often used for complex designs. They use symbols to represent different stitches.

Tips for Reading Crochet Patterns:

- Read the entire pattern before starting: This helps you understand the overall structure and identify any potential challenges.

- Work through each step carefully: Don’t rush; crochet is a process that requires attention to detail.

- Use stitch markers: These help track your progress and ensure accuracy.

- Don’t be afraid to ask for help: There are many online communities and resources for assistance.

With patience and practice, reading crochet patterns becomes a rewarding aspect of the craft, unlocking countless creative possibilities.

Q 8. How do you create your own crochet patterns?

Designing crochet patterns involves a blend of creativity and technical knowledge. It starts with a concept – perhaps a specific garment or decorative item. I then sketch out the design, noting the desired dimensions and overall shape. Next, I determine the stitch pattern; this could be a simple single crochet or a more complex lace pattern. Crucially, I select a yarn weight appropriate for the project and the chosen stitch pattern. I then work a small swatch to check the gauge (stitches and rows per inch) to ensure the final product will match my design. This is essential for accurate sizing. Once the gauge is correct, I develop the written instructions, including detailed descriptions of each step, stitch counts, and any necessary increases or decreases. I always include a materials list and a visual representation like a chart or schematic for clarity. For example, I might detail a simple granny square pattern, carefully describing each round, including increases, and the final joining technique. For more complex designs, I’ll often create a chart to visually represent the stitch patterns.

I usually create a test piece following my written pattern, noting any needed adjustments before finalizing the pattern for sharing or publication.

Q 9. How do you program different stitch patterns on a machine knitting machine?

Programming stitch patterns on a machine knitting machine involves understanding the machine’s capabilities and using its punch cards or electronic programming system. Most modern machines utilize electronic systems, allowing for complex designs. The process typically begins by selecting the desired stitch pattern. This could be a simple stockinette stitch (knit on one side, purl on the other) or a complex cable or lace pattern. Then, you input the pattern using the machine’s software, defining the sequence of knit and purl stitches, and potentially other actions such as yarn overs or decreases. For example, to program a simple rib pattern, like a 2×2 rib, you would input a repeating sequence: two knit stitches, two purl stitches.

Example (Simplified): K2, P2, repeat.The software often provides libraries of pre-programmed patterns, offering a starting point for modifications. The key is understanding the machine’s stitch structure and how the programmed instructions translate into the finished fabric. Experienced machine knitters can even create their own patterns using specialized software, allowing for intricate and unique designs. I’ve worked extensively with various software platforms and have mastered the art of translating complex hand-knit patterns into machine-knit equivalents, adapting them as needed for the machine’s limitations and capabilities.

Q 10. Describe your experience with various machine knitting machines.

My experience spans several machine knitting machine brands and models, from vintage mechanical machines to modern computerized ones. I’ve worked with single-bed and double-bed machines, each with its unique characteristics and challenges. For instance, I’ve used Brother knitting machines known for their ease of use and accessibility to beginners, and also more advanced models with sophisticated features for intricate patterns. I’m also familiar with the complexities of older hand-cranked machines, which require a higher level of skill and patience but offer a unique texture and tactile experience. Working with different machines has not only honed my technical skills but also broadened my understanding of various knitting techniques. Each machine has its strengths and weaknesses; therefore, selecting the right machine for a project depends on the desired outcome, complexity of the pattern, and personal preference.

Q 11. How do you select the appropriate needle size for different yarn weights?

Selecting the correct needle size for different yarn weights is crucial for achieving the desired gauge and fabric drape. Yarn weight is categorized using standardized systems (e.g., worsted, bulky, super bulky). Each yarn weight has a recommended needle size range. The general rule is that thicker yarns require larger needles, and thinner yarns require smaller needles. For example, a bulky weight yarn will need a size 15 needle or larger, while a fingering weight yarn would be knitted on a size 1 or 2 needle. However, these are just guidelines. The actual needle size can depend on the specific yarn’s fiber content and structure. Always knit a gauge swatch before beginning your project to verify that the chosen needle size yields the desired stitch density. I often use needle size charts to get a sense of the appropriate range, but my personal experience allows me to intuit the correct range more often than not. This also requires careful consideration of the final intended fabric; loose stitch patterns on a bulky yarn need a larger needle than a tight pattern.

Q 12. How do you manage yarn overs and decreases in crochet?

Yarn overs (yo) and decreases are fundamental techniques in crochet used to create increases and decreases in stitches, respectively. A yarn over involves wrapping the yarn around the hook before completing the next stitch, creating an extra loop, thus resulting in an increase in the stitch count. Decreases are achieved by working two or more stitches together as a single stitch, reducing the stitch count. There are several types of decreases, such as single crochet decrease (sc2tog) or double crochet decrease (dc2tog). Each decrease technique results in a slightly different appearance. Managing them effectively is essential for controlling stitch count and creating shaping in crochet projects.

For example, in creating a garment, you’d use yarn overs to increase stitches along the armhole and decreases to shape the neckline or shoulders. Understanding when and how to place yarn overs and decreases is vital for accurate pattern interpretation and the successful completion of complex crochet designs. I often use stitch markers to highlight the places where I need to increase or decrease to prevent mistakes.

Q 13. Explain your understanding of colorwork techniques in crochet and machine knitting.

Colorwork is a captivating technique where multiple colors are incorporated into a project to create patterns or designs. In crochet, colorwork can be achieved through various methods, such as intarsia (carrying multiple yarn strands along the back of the work) or fair isle (carrying multiple yarns and changing colors within rows). Machine knitting offers more streamlined colorwork possibilities using multiple yarn feeders and sophisticated programming. Intricate patterns can be easily achieved with programmed color changes.

For both techniques, careful planning is crucial to avoid color mismatches or yarn tangles. In crochet, I often use colorwork charts to visualize the pattern and keep track of color changes. In machine knitting, I use the machine’s programming interface, carefully defining the color changes within each row of stitches. Colorwork is a very creative process; I’ve often found my own designs evolve and change as I start knitting with various colors.

Q 14. Describe your experience with finishing techniques, such as blocking and seaming.

Finishing techniques are crucial for transforming a completed crochet or machine knitting piece into a wearable or presentable item. Blocking, the process of wetting and shaping knitted fabric, is essential for achieving even stitch definition and the desired size and shape. Blocking techniques vary depending on the fiber content of the yarn and the specific project. I often use blocking boards, pins, and spray bottles for optimal results.

Seaming, the process of joining individual pieces of crocheted or machine-knitted fabric, is also an important skill. I’m proficient in various seaming techniques, such as mattress stitch (an almost invisible seam) and three-needle bind-off (for machine knitting) to ensure a clean and professional finish. Weaving in loose ends is vital to prevent unraveling. These finishing techniques are critical for ensuring a high-quality and professional outcome; they transform a raw knitted or crocheted product into a polished final product.

Q 15. How do you repair holes or damage in knitted or crocheted garments?

Repairing holes or damage in knitted or crocheted garments depends on the size and location of the damage, as well as the yarn type. For small holes, a simple method is to use a darning needle and yarn that closely matches the garment to weave back and forth across the hole, creating a tight weave to fill the gap. This is similar to mending a sock. For larger holes or more significant damage, you might need to use a technique called grafting, which involves seamlessly joining two edges of fabric together to conceal the hole. Alternatively, you could incorporate the damaged area into a design element, such as adding embroidery or decorative stitching around the hole to make it a feature rather than a flaw. The key is to choose a repair method that’s both invisible and structurally sound.

Example: Imagine a small snag in a wool sweater. Using a darning needle and a strand of matching wool, I’d carefully weave back and forth across the snag, using tiny stitches to create a smooth, almost invisible patch. For a larger hole, I might strategically incorporate it into the sweater’s design by adding lacework around the repair area, turning a flaw into a unique decorative detail.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common issues encountered in machine knitting and how do you solve them?

Common issues in machine knitting often stem from yarn problems, tension inconsistencies, or machine malfunctions. Problems like dropped stitches can be caused by uneven yarn feed, incorrect needle selection, or even static electricity. These lead to visible gaps or holes in the fabric. A common solution is to carefully pick up the dropped stitches using a latch hook or crochet hook, re-integrating them into the fabric using the correct stitch.

Another frequent issue is poor tension, resulting in uneven fabric or a distorted finished product. This can be due to incorrect machine settings, using the wrong yarn weight for the selected needles, or simply inconsistent hand movements while feeding the yarn. Adjusting the tension dial on the machine is crucial. You’ll often need trial and error to find the optimal tension for a specific yarn and pattern. Lastly, machine malfunctions, such as broken needles or faulty parts, can disrupt the knitting process. Regular maintenance and prompt attention to any mechanical issues are vital to avoiding larger problems.

Example: If a dropped stitch occurs, I carefully use a crochet hook to gently retrieve the dropped loops and knit them back into the fabric. If tension is off, I’ll adjust the machine’s tension dial, and, if necessary, try a slightly different yarn or needles for better results. Regular cleaning and lubrication of the machine also prevents mechanical issues.

Q 17. Describe your experience working with different types of fibers (e.g., cotton, wool, acrylic).

My experience working with different fibers is extensive. Cotton, for example, is a breathable and versatile fiber ideal for warmer climates and projects requiring durability, like dishcloths or summer garments. However, cotton can be more challenging to work with because it’s less elastic than wool or acrylic, requiring a tighter tension to prevent gaping.

Wool offers warmth, softness, and excellent drape, making it perfect for sweaters and blankets. Different types of wool, from merino to alpaca, have unique properties that affect the final product’s texture and feel. Working with wool requires careful consideration of needle size and tension to achieve the desired result.

Acrylic is a synthetic fiber that is inexpensive, easy to care for, and available in a wide array of colors. It’s a great option for beginners or for projects where cost-effectiveness is paramount. However, acrylic generally lacks the softness and drape of wool and can sometimes be less durable in the long run.

I adapt my techniques based on the chosen fiber. I’d use a looser tension for a flowing wool garment, a tighter tension for a sturdy cotton item, and adjust my needle size and stitch pattern accordingly.

Q 18. How do you determine the yardage needed for a crochet or knitting project?

Determining the yardage needed for a project is crucial for avoiding mid-project yarn shortages. The most accurate way is to use a gauge swatch. A gauge swatch is a small sample of the project knitted or crocheted using the chosen yarn and needles, following the pattern’s stitch pattern. Measuring this swatch will provide the stitches and rows per inch (or cm), which allows calculation of the total number of stitches and rows in the finished project. By multiplying this total by the stitch density in yards per stitch (from yarn label), the total yardage needed can be determined.

Pattern instructions often provide an estimated yardage, but this is only a guideline, and individual gauge and variations in stitch density can significantly affect the actual requirement. It’s always advisable to add extra yarn, ideally around 10-20%, to account for any errors or potential unexpected increases in yarn consumption.

Example: If a pattern estimates 400 yards but my gauge swatch shows that I need more stitches per inch, my calculation will adjust the needed yarn accordingly, and I will likely need more than the estimated amount.

Q 19. How do you adapt patterns to different yarn weights or needle sizes?

Adapting patterns to different yarn weights or needle sizes involves recalculating the gauge and adjusting the number of stitches and rows. Changing needle size significantly affects the finished fabric’s density. Thicker needles create looser fabric, while thinner needles result in tighter fabric. Similarly, different yarn weights have varying thicknesses, directly affecting the number of stitches and rows needed for the same size garment.

To adapt a pattern, one must first determine the new gauge with the changed yarn and needle size. If the gauge significantly deviates from the original pattern, recalculating the total number of stitches and rows becomes essential. This might involve simple proportional changes, increasing or decreasing the number of stitches and rows based on the difference in gauge. Sometimes, substantial modifications require reworking the pattern from scratch.

Example: If a pattern calls for worsted weight yarn and size 8 needles, but I want to use bulky yarn and size 15 needles, I would knit a gauge swatch to determine how many stitches and rows are produced per inch using my chosen materials. The difference in gauge will determine how much I need to increase the stitch and row count to maintain the intended garment dimensions.

Q 20. What software or tools do you use for machine knitting programming or pattern design?

For machine knitting programming and pattern design, several software tools can assist. Many modern knitting machines use proprietary software that aids in creating complex patterns electronically. This usually involves using a computer to input the knitting instructions, creating stitch patterns by programming the needles to knit, purl, or execute other functions.

Design software like KnitPro Designer 7 or other specialized programs allow for the creation and modification of knitting patterns digitally, enabling the designer to see the results on screen before knitting. These programs often offer tools for stitch pattern creation, gauge calculation, and size adjustments. While some advanced programmers might use other coding languages to write their knitting machine controls, most users will find these dedicated design and machine control software options the most accessible.

Q 21. How do you handle complex stitch patterns in crochet or machine knitting?

Handling complex stitch patterns in crochet or machine knitting requires careful planning, attention to detail, and a strong understanding of the fundamental stitches. For crochet, charting is invaluable. A chart visually represents the stitch pattern, making it easier to follow intricate sequences. Each symbol on the chart represents a stitch, allowing the crocheter to easily track their progress.

In machine knitting, complex stitch patterns often require careful programming or utilization of a punchcard system. Each needle movement needs to be precisely controlled to achieve the desired stitch pattern. Detailed written instructions are often insufficient for intricate patterns; the visualization provided by charts or dedicated software is key. It’s crucial to work slowly and methodically, paying close attention to each stitch to avoid errors that could significantly affect the finished project. Practice is essential for mastering complex stitch patterns to ensure accuracy and efficiency.

Example: A challenging crochet cable pattern might require a large chart, broken into smaller, manageable sections, making the task easier. Similarly, a complex lace pattern on a machine might require careful programming, step-by-step checks of the punched cards or software instructions, and even the use of a simulator to preview the result before actually knitting the piece.

Q 22. Explain your understanding of different knitting machine structures and functions.

Knitting machines come in various structures, each designed for specific functionalities and yarn types. The two primary categories are single-bed and double-bed machines. Single-bed machines, like the Brother KH-868, use a single set of needles to create the fabric, often resulting in a simpler structure and easier operation, ideal for beginners. They are excellent for creating basic knits, purls, and simple patterns. Double-bed machines, such as the Passap DUO, boast two needle beds, allowing for more complex stitch patterns and intarsia work (creating images within the fabric). The interaction between the two needle beds creates a wider array of textures and designs.

Further, machines differ in their needle structure. There are latch needles, which are more common in hobbyist machines and are relatively straightforward to use. Bearded needles, often found in industrial settings, create a different stitch structure and are usually part of more robust machines capable of heavier yarns and faster knitting speeds. Understanding these structural differences directly impacts the choice of machine for a particular project. For instance, a complex cable knit would be far easier to produce on a double-bed machine, whereas a simple scarf could be comfortably produced on a single-bed machine.

- Single-bed: Simpler operation, ideal for beginners, suitable for basic stitches and patterns.

- Double-bed: More complex operation, allows for intricate patterns and intarsia, suitable for advanced knitters.

- Latch needles: Common in hobbyist machines, easier to use.

- Bearded needles: Used in industrial machines, capable of heavier yarns and faster knitting.

Q 23. Describe your experience with lacework in crochet or machine knitting.

Lacework presents a unique challenge in both crochet and machine knitting, requiring precision and careful planning. In crochet, I’ve extensively used various techniques like filet crochet (creating patterns using a grid of double crochets and chains), Irish crochet (using motifs joined together), and using lace weights of yarn to create delicate openwork. For example, I recently created a wedding shawl using Irish crochet, meticulously joining individual floral motifs to create a flowing, elegant design. The challenge here lies in maintaining even tension and achieving a consistent, refined look.

With machine knitting, creating lace involves using specialized techniques like tuck stitches, yarnovers, and pattern modifications to create openwork. I’ve experimented extensively with different lace patterns using my Passap machine, employing punched cards and electronic patterning for intricate designs. Achieving a balance between the delicate airy sections and firm structure is key, as overly loose lace can be prone to stretching or snagging.

Q 24. How do you maintain the cleanliness and proper maintenance of knitting machines?

Maintaining a knitting machine is crucial for its longevity and the quality of the finished product. Regular cleaning is paramount. After each use, I always remove any yarn scraps and dust from the needle beds, using a soft brush and compressed air. For a more thorough cleaning, I might use a specialized knitting machine cleaner. It’s important to lubricate moving parts according to the manufacturer’s instructions – this usually involves applying a specific lubricant to the carriage and other mechanisms. Storing the machine in a clean, dry environment, away from direct sunlight and moisture, also helps to prevent rust and damage.

Beyond routine cleaning, preventative maintenance is key. This might involve checking for loose screws or worn parts, and replacing them if necessary. Regularly inspecting the needles for any bends or damage is critical. Addressing small problems early can prevent larger, more expensive repairs down the line. Think of it like servicing a car; regular maintenance keeps it running smoothly and prevents costly breakdowns.

Q 25. What are some common mistakes to avoid when crocheting or machine knitting?

In crocheting, inconsistent tension is a common mistake leading to uneven fabric and distorted shapes. Another frequent error is incorrect stitch counts, causing pattern discrepancies and frustrating results. Beginners often struggle with reading patterns accurately, and not understanding the terminology. Using the wrong hook size also impacts the final product’s gauge. In machine knitting, incorrect tension settings lead to loose or tight fabric. Forgetting to engage the correct needle beds or incorrectly setting the stitch cam can lead to dropped stitches and messy results. Lastly, not pre-treating the yarn correctly can cause unexpected results with fiber type and size inconsistencies. Addressing these issues requires patience, careful attention to detail, and practice.

Q 26. How do you ensure accuracy and consistency in your crochet or machine knitting work?

Accuracy and consistency are paramount. In crochet, using a consistent tension throughout the project is key to achieving even fabric. I use stitch markers to track progress and count stitches carefully. Regularly checking the gauge (stitches and rows per inch) against the pattern ensures consistency. This is especially crucial when working with intricate patterns or when switching yarns. For machine knitting, maintaining consistent tension is automated to an extent but selecting appropriate needle selection, yarn type and cam settings plays a large part. Programming the machine accurately using stitch patterns, and regularly checking the knitting for any errors are important steps. Accurate gauge swatching for both crochet and machine knitting ensures the finished product matches the original design.

Q 27. Describe your experience working within a team on a textile project.

I’ve been part of several collaborative textile projects, most recently the creation of a large-scale tapestry for a community center. We had a team of five, each responsible for a specific section of the design, using both crochet and machine knitting techniques based on individual strengths. Effective communication was vital to ensure the seamless integration of each section, maintaining consistency in yarn type, color, and gauge. We held regular meetings, sharing progress, addressing challenges, and fine-tuning our individual contributions to achieve a cohesive final product. This collaborative process was rewarding, allowing for a diverse range of skills and perspectives to combine and create something truly unique and beautiful. Understanding each team member’s skill set and tailoring their role accordingly is key for successful teamwork.

Q 28. Explain your process for creating a sample garment for a client.

Creating a sample garment for a client involves several steps. First, we discuss their needs and preferences – style, fit, yarn choices, and overall vision. Once this is clear, I create a detailed design sketch, including measurements and stitch patterns. Then, I produce a small gauge swatch using the chosen yarn and needles or machine settings to verify the stitch pattern and gauge. This swatch lets me adjust the pattern as needed to fit the client’s measurements and expectations. Based on the swatch information and design, I create a small sample of the garment, often a sleeve or a section of the front. This allows the client to assess the texture, drape, and overall look and feel of the final piece, providing feedback before starting the full project. This iterative approach guarantees client satisfaction and reduces the likelihood of errors or unwanted changes in the finished garment.

Key Topics to Learn for Crocheting and Machine Knitting Interview

- Crocheting: Fundamental Stitches and Techniques: Mastering basic stitches (single crochet, double crochet, etc.), understanding stitch tension, and applying various increases and decreases.

- Crocheting: Project Planning and Design: Reading and interpreting patterns, calculating yarn requirements, and adapting patterns to create variations.

- Crocheting: Troubleshooting and Problem Solving: Identifying and correcting common errors like dropped stitches, uneven tension, and gauge inconsistencies.

- Machine Knitting: Machine Operation and Maintenance: Understanding the functions of different knitting machines, performing basic maintenance, and troubleshooting common mechanical issues.

- Machine Knitting: Pattern Design and Programming: Creating and modifying knitting patterns using machine-specific software or punch cards, understanding different knitting techniques achievable on the machine.

- Machine Knitting: Yarn Selection and Properties: Choosing the appropriate yarns for different projects, understanding yarn characteristics (weight, fiber content), and their impact on the final product.

- Both Crocheting and Machine Knitting: Yarn Knowledge and Fiber Types: Familiarity with various yarn types (cotton, wool, acrylic), their properties, and suitability for different projects.

- Both Crocheting and Machine Knitting: Finishing Techniques: Weaving in ends, blocking techniques, seaming, and other finishing processes crucial for creating professional-looking garments and items.

- Both Crocheting and Machine Knitting: Design Principles and Aesthetics: Understanding color theory, texture, and design elements to create visually appealing and well-constructed pieces.

Next Steps

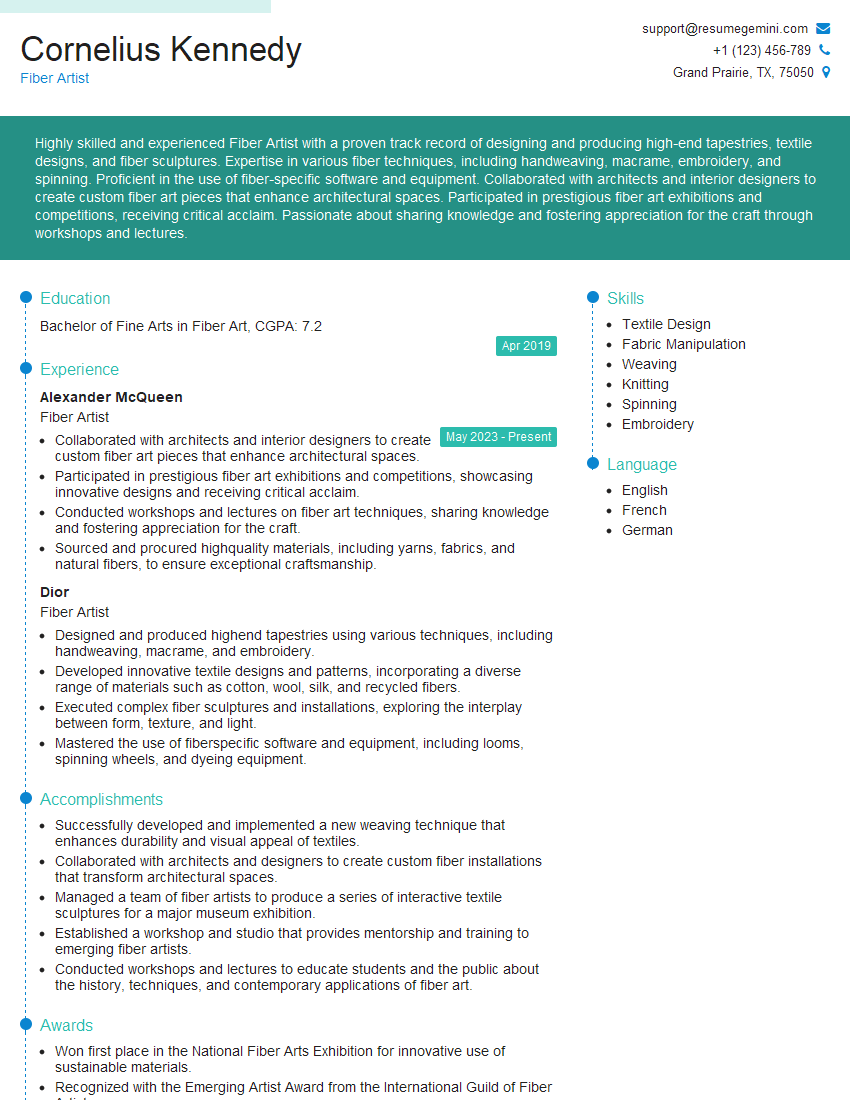

Mastering crocheting and machine knitting opens doors to exciting career opportunities in design, manufacturing, teaching, and more. To significantly improve your job prospects, focus on creating an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They offer examples of resumes tailored to the specific requirements of the crocheting and machine knitting industries, helping you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO