The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Custom Furniture Design and Fabrication interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Custom Furniture Design and Fabrication Interview

Q 1. Explain your experience with various wood types and their suitability for different furniture applications.

Choosing the right wood is crucial in custom furniture design. Different woods offer unique properties in terms of strength, durability, grain pattern, and workability. My experience spans a wide range, allowing me to select the ideal material for each project’s specific needs and aesthetic goals.

- Hardwoods (e.g., Oak, Walnut, Mahogany): Known for their strength, durability, and beautiful grain patterns, hardwoods are excellent for high-stress applications like table tops, chair legs, and structural components. Oak, for instance, is incredibly robust and takes stain beautifully, making it ideal for traditional styles. Walnut offers rich, dark tones and a luxurious feel, perfect for contemporary designs. Mahogany’s deep red tones and fine grain are prized for their classic elegance.

- Softwoods (e.g., Pine, Fir, Cedar): Generally more affordable and easier to work with than hardwoods, softwoods are suitable for less-stressful applications or where a more rustic aesthetic is desired. Pine, for example, is commonly used for shelving, drawers, and less-demanding furniture pieces. Its light color and even grain make it versatile for painting or staining. Cedar, with its aromatic scent and natural insect-repellent properties, is often chosen for outdoor furniture or chests.

- Engineered Woods (e.g., Plywood, MDF): Engineered woods are manufactured products offering consistency and cost-effectiveness. Plywood, with its layered construction, is strong and stable, often used for cabinet construction or as a substrate for veneers. MDF (Medium-Density Fiberboard) is excellent for smooth surfaces and intricate details but lacks the inherent strength of solid wood.

For example, I recently designed a dining table where the client desired a rustic yet sturdy piece. I opted for reclaimed oak, whose inherent imperfections added character while its strength ensured the table could comfortably withstand daily use. Another project involved creating sleek, modern nightstands, for which I selected birch plywood for its clean lines and affordability.

Q 2. Describe your process for creating detailed shop drawings from design concepts.

Creating detailed shop drawings is a critical step, bridging the gap between design concept and fabrication. My process involves a meticulous approach to ensure accuracy and clarity.

- Conceptual Sketches: I begin with hand-drawn sketches to explore various design options, focusing on proportions, functionality, and overall aesthetics.

- Digital Modeling: I then translate the chosen design into a 3D model using CAD software (detailed in a later answer). This allows for precise measurements, detailed visualizations, and easy modification of the design before fabrication.

- Orthographic Projections: From the 3D model, I generate detailed orthographic projections (top, front, and side views). These drawings clearly show dimensions, joint types, material specifications, and other essential information for the fabrication team.

- Detailed Sections & Details: Complex joinery or intricate details require separate, enlarged sections and details. These drawings clearly illustrate the construction methods, ensuring consistency and accuracy during assembly.

- Bill of Materials (BOM): A comprehensive BOM is created, listing all the necessary materials with their exact dimensions and quantities. This ensures efficient procurement and reduces waste.

This methodical approach minimizes errors during construction and ensures the final product precisely matches the client’s vision. For instance, a recently completed custom entertainment center required intricate routed details. Detailed sections and 3D renderings were crucial for correctly conveying these design elements to my team.

Q 3. How do you ensure the structural integrity of a custom furniture piece?

Structural integrity is paramount in custom furniture. It’s about understanding the forces acting upon the piece and designing accordingly to ensure longevity and safety.

- Appropriate Wood Selection: Choosing wood species with sufficient strength and stiffness for the intended application is fundamental. Hardwoods generally offer superior strength compared to softwoods.

- Robust Joinery: Utilizing strong joinery techniques (more detail below) is crucial. Mortise and tenon, dovetail, and through-tenons are examples of strong, reliable joints.

- Reinforcement: Where necessary, I incorporate additional reinforcement, such as dowels, screws, or biscuits, to further enhance the structural integrity of joints and critical areas.

- Proper Construction Techniques: Correct glue application, clamping procedures, and assembly sequences ensure the integrity of the piece. Any warping or stress during construction can compromise the overall strength.

- Stress Analysis (for complex designs): For exceptionally intricate or large pieces, I might use finite element analysis (FEA) software to simulate stresses and strains on the structure, optimizing the design for maximum strength and stability.

For example, a large dining table requires careful consideration of the forces acting on the tabletop. I would use robust joinery to connect the legs and apron, and potentially add internal bracing to prevent sagging over time.

Q 4. What are your preferred CAD/CAM software programs, and how proficient are you in them?

Proficiency in CAD/CAM software is essential for efficient and accurate custom furniture design and fabrication. My preferred programs are:

- SketchUp: I use SketchUp primarily for 3D modeling and visualization. Its intuitive interface allows me to quickly create detailed models and generate accurate dimensions.

- AutoCAD: For generating precise 2D drawings, including shop drawings, detailed sections, and technical documentation, AutoCAD is my go-to software.

- V-Carve Pro (CAM Software): For CNC routing, V-Carve Pro facilitates the creation of toolpaths for intricate carvings, shaping, and other CNC operations. This ensures accurate and efficient machining.

My proficiency extends to creating complex 3D models, generating accurate 2D drawings, and producing optimized CNC toolpaths. I am comfortable using these programs to design and fabricate everything from simple shelving units to elaborate, custom-built furniture pieces.

Q 5. Describe your experience with different joinery techniques.

Joinery is the art of joining wood pieces together. My expertise encompasses a variety of techniques, each selected based on the project’s aesthetic and structural requirements.

- Mortise and Tenon: A classic and strong joint where a tenon (projection) fits snugly into a mortise (hole). Variations include through-tenons, blind tenons, and wedged tenons, offering different levels of strength and aesthetics.

- Dovetail Joints: Interlocking finger-like joints known for their exceptional strength and attractive appearance. Commonly used for drawer construction and other high-stress applications.

- Biscuit Joints: Utilizing oval-shaped biscuits (wood wafers) to strengthen edge-to-edge or face-to-edge joints. These joints provide a strong and relatively quick method for assembly.

- Dowel Joints: Simple and effective joints using dowels (cylindrical wooden pins) for alignment and reinforcement. These are suitable for less-stressful applications and are often used in conjunction with other joinery techniques.

- Pocket Hole Joinery: Using a jig to create angled holes, this method is fast and efficient, often used for frame and casework construction.

The choice of joinery depends on factors like the type of wood, the required strength, and the overall design aesthetic. For example, I’d use dovetail joints for a high-end, hand-crafted dresser, while pocket hole joinery might be more appropriate for a simple bookshelf.

Q 6. How do you manage project timelines and budgets for custom furniture projects?

Managing timelines and budgets is critical for successful project delivery. My approach involves a structured process:

- Detailed Project Scope: A clear project scope defines all aspects of the project, including design details, materials, finishes, and any special requirements.

- Time Estimation: Based on the project scope and my experience, I provide a realistic timeline, outlining key milestones and deadlines.

- Cost Estimation: A detailed breakdown of all costs, including materials, labor, and any subcontracted services, is prepared. This provides the client with transparency and ensures accurate budgeting.

- Regular Communication: I maintain consistent communication with the client, providing updates on progress, addressing any concerns, and making necessary adjustments to the timeline or budget as the project progresses.

- Project Management Software: I utilize project management software to track progress, manage tasks, and ensure deadlines are met. This allows for better organization and proactive issue resolution.

By meticulously planning and tracking the project, I ensure timely and cost-effective delivery. For instance, I recently designed a large custom library. Through detailed project planning and ongoing communication with the client, we were able to deliver the project on time and within the agreed budget.

Q 7. Explain your familiarity with different finishing techniques (e.g., staining, painting, lacquering).

Finishing is the final step, enhancing both the appearance and durability of the furniture. My experience includes various techniques:

- Staining: Applying stains to enhance the natural wood grain and color. This involves selecting the appropriate stain color, applying multiple coats for even coverage, and ensuring proper drying time between coats.

- Painting: Applying paint for a uniform, solid color. This requires careful surface preparation, including sanding and priming, to ensure a smooth, even finish. Multiple coats are typically needed for optimal coverage and durability.

- Lacquering: Applying lacquer for a protective and high-gloss finish. Lacquer offers excellent durability and resistance to scratches and moisture. Several thin coats are preferred to prevent runs and sags.

- Other Finishes: I also have experience with oil finishes, which penetrate the wood for a natural look and feel; and wax finishes, providing a subtle sheen and protection.

The choice of finish depends on the client’s preferences and the intended use of the furniture. A high-gloss lacquer finish might be suitable for a formal dining table, while an oil finish might be preferred for a rustic coffee table. I always discuss finish options with clients, ensuring their vision is reflected in the final product.

Q 8. How do you handle client revisions and modifications during the design or fabrication process?

Client revisions are an integral part of the custom furniture design process. We handle them by establishing clear communication channels from the outset. This usually involves regular meetings and detailed documentation, including sketches, 3D renderings, and material samples. We use a collaborative design approach, actively involving clients in the decision-making process at each stage. For example, if a client wants to change the dimensions of a bookcase after the initial design is approved, we’ll discuss the implications on structural integrity and cost, providing updated renderings and estimates. If the change is feasible, we update the design and production schedule accordingly. We emphasize transparency throughout the revision process, keeping clients informed of potential delays or additional costs. We might even create a simple change order form to track all revisions and their associated pricing changes, ensuring everyone is on the same page.

Our goal is to make the revision process as smooth as possible, balancing client satisfaction with project feasibility and timeline.

Q 9. Describe your experience with upholstery techniques and materials.

My upholstery experience spans various techniques and materials. I’m proficient in traditional methods like hand-tufting and buttoning, which lend themselves to classic and bespoke designs. For example, I’ve hand-tufted a Chesterfield sofa using high-quality leather, achieving a luxurious look and feel. I also utilize modern techniques such as pneumatic stapling for efficiency in large-scale projects or when working with more contemporary fabrics. My material expertise includes a wide range: leather (full-grain, top-grain, etc.), various textiles (velvet, linen, cotton blends), microfiber, and even faux leather options. I carefully select materials based on client preferences, durability requirements, and the overall design aesthetic. I understand the importance of proper padding and support, ensuring comfortable and long-lasting pieces. We also test and approve sample swatches before full-scale production, ensuring our clients are completely satisfied with their fabric and texture selections. Understanding the drape and the wear characteristics of various materials is critical to the overall success of a project.

Q 10. What is your experience with CNC machining in furniture fabrication?

CNC machining has revolutionized furniture fabrication, allowing for precise and efficient production. I have extensive experience using CNC routers and other CNC machines to create complex curves, intricate joinery, and repetitive patterns with high accuracy. This is particularly useful for creating customized components that wouldn’t be feasible with manual methods alone. For instance, I’ve used CNC routing to create detailed inlays for a client’s dining table, achieving a level of precision and repeatability that’s simply not achievable by hand. We also use CNC technology for cutting various materials efficiently, optimizing material use and minimizing waste. In terms of software, I’m proficient with industry-standard CAD/CAM software like Vectric Aspire and similar programs, which allow for designing and generating CNC toolpaths. I understand the nuances of tool selection, feed rates, and cutting strategies to ensure optimal results while minimizing wear and tear on the equipment.

Q 11. How do you troubleshoot problems during the construction of a complex furniture piece?

Troubleshooting during the construction of a complex piece requires a systematic approach. My first step is a thorough review of the design plans and construction documents. This helps to identify any potential issues early on. Then, I carefully examine the problem, looking for discrepancies between the design and the actual construction. Sometimes it’s a simple error, like an incorrect measurement, which can be easily corrected. Other times, it may be a more complex issue, such as a structural weakness or a material incompatibility. In these cases, I document the problem with photos or sketches and often discuss options with the team to resolve it effectively. We might need to adjust design elements, switch materials, or employ different construction techniques. One example was when a complex joinery failed during assembly in a large armoire. Through careful analysis, we discovered that the wood was slightly warped, causing the joint to not seat correctly. The solution involved milling a new joint to accommodate the warping and then reinforce it with additional dowels.

Q 12. What are some common challenges in custom furniture design and fabrication, and how do you overcome them?

Challenges in custom furniture design and fabrication are numerous. One common challenge is managing client expectations. Clients often have unique visions, and it’s crucial to effectively communicate the feasibility and potential limitations of their ideas. For example, a client might envision a piece that’s structurally unsound or requires materials beyond their budget. This is addressed through comprehensive consultations, clear communication, and providing realistic alternatives. Another common hurdle is material sourcing. Finding high-quality, sustainable materials that meet both aesthetic and functional requirements can sometimes be difficult. We address this by building strong relationships with reliable suppliers and staying updated on new material trends. Unexpected issues during construction, such as material defects or unforeseen structural problems, also need to be resolved proactively. We handle this through careful planning, quality control, and a contingency plan that allows for adaptation.

Q 13. How do you ensure quality control throughout the entire furniture production process?

Quality control is a continuous process, starting from design and material selection and continuing throughout fabrication and finishing. We use meticulous quality checks at each step. This includes inspecting materials for defects, verifying measurements, and ensuring proper joinery techniques are used. For example, every piece of wood is inspected for knots or cracks before use. During construction, regular inspections are conducted to identify and address any potential flaws. After fabrication, the piece undergoes a final inspection to ensure it meets the design specifications and quality standards. The process involves both visual inspection and functional testing, ensuring the piece is structurally sound, aesthetically pleasing, and durable. We also utilize checklists and detailed documentation to track the progress and to ensure nothing is missed. Our goal is to provide furniture that’s not only beautiful but also built to last.

Q 14. Describe your experience with different types of hardware and their application in furniture.

My experience with furniture hardware is extensive, encompassing various types and applications. I’m familiar with traditional joinery methods, including dovetail, mortise and tenon, and finger joints. For modern furniture, I utilize high-quality drawer slides, hinges, and catches. My selection is guided by factors such as durability, aesthetics, and the specific needs of the project. For example, for a heavy antique-style cabinet, I might opt for robust, traditional hinges with decorative features. For a modern minimalist piece, I’d choose sleek, concealed hinges and soft-close drawer slides. I also have experience working with specialized hardware like lift systems for coffee tables or unique locking mechanisms for cabinets. I understand the importance of choosing the right hardware not only for functionality but also for its contribution to the overall design. We consider factors like material, finish, and style, ensuring everything complements the furniture’s aesthetic.

Q 15. How do you select appropriate materials for a specific furniture project considering budget and design aesthetics?

Material selection is crucial for a successful furniture project. It’s a balancing act between design vision, budget constraints, and material properties. I start by understanding the client’s design preferences – are they looking for a rustic, modern, minimalist, or eclectic style? This informs the choice of wood species (e.g., oak for durability, walnut for richness, pine for affordability), fabrics (linen for breathability, velvet for luxury), or metals (steel for industrial chic, brass for a classic feel).

Next, I analyze the budget. Different materials have vastly different price points. For instance, solid walnut is significantly more expensive than engineered wood. I may suggest alternatives like sustainably sourced reclaimed wood or less expensive hardwoods to maintain the aesthetic while staying within budget. We also discuss the longevity desired. A high-traffic area might necessitate a more durable material like a hard-wearing fabric or a scratch-resistant finish. The project’s functionality also influences material choice; for example, a kitchen table needs heat-resistant properties.

Finally, I consider the environmental impact. I prioritize sustainably sourced materials whenever possible, and discuss eco-friendly finishes and glues. The entire process involves close collaboration with the client to ensure their vision aligns with practical considerations and financial limitations. For example, a client desiring a mid-century modern design might opt for solid walnut legs and a plywood veneer top to meet both aesthetic and budget needs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with ergonomic principles and their application to furniture design?

Ergonomics is fundamental to my design process. I’m intimately familiar with principles like proper posture, support, and reach. This involves considering factors like seat height, backrest angle, lumbar support, armrest placement, and overall comfort. For instance, a chair designed for prolonged use requires different ergonomic considerations compared to a decorative occasional chair.

I use ergonomic guidelines throughout the design phase, from sketching initial concepts to creating detailed 3D models. For instance, designing a kitchen countertop, I ensure adequate knee clearance and a comfortable work height, reducing strain during food preparation. When designing office chairs, I focus on lumbar support to maintain the natural curvature of the spine, preventing back pain. I regularly consult ergonomic resources and best practices to ensure all my designs promote good posture and user well-being. This isn’t just about aesthetics; it’s about creating furniture that is both beautiful and functional in promoting health and comfort.

Q 17. Explain your process for creating a detailed bill of materials for a custom furniture project.

Creating a detailed bill of materials (BOM) is a critical step for accurate costing and efficient project execution. I typically begin by referencing the finalized design drawings and 3D models. This ensures all components are accounted for. The BOM will include:

- Material Description: Precise details like wood species, dimensions, and grade.

- Quantity: The exact number of each component required.

- Unit of Measure: Whether it’s linear feet, square feet, or individual pieces.

- Supplier Information (if applicable): Where the materials are sourced from, particularly for specialized items.

- Cost per Unit: The price of each material component.

- Total Cost: The overall cost for each material.

For example, a BOM for a simple table might include: ‘Solid Walnut, 2”x4”, 4 linear feet, $20/linear foot, Total: $80.’ I utilize spreadsheet software (like Excel or Google Sheets) to manage the BOM, allowing for easy updates and calculations. The accuracy of the BOM is essential; any oversight can lead to cost overruns and project delays. Regular review and adjustments to the BOM are standard procedure, especially during the project’s evolution.

Q 18. How do you maintain a safe and organized work environment in a furniture workshop?

Safety and organization are paramount in a furniture workshop. My approach is multifaceted. Firstly, I implement a strict 5S methodology: Sort, Set in Order, Shine, Standardize, and Sustain. This ensures that all tools and materials have designated places, minimizing clutter and maximizing efficiency. All power tools are regularly inspected and maintained according to manufacturer guidelines.

Secondly, I prioritize personal protective equipment (PPE). Safety glasses, hearing protection, dust masks, and appropriate gloves are mandatory for all workshop activities. I regularly conduct safety training with any employees or assistants, covering the safe operation of all machinery and proper handling of materials. Emergency procedures are clearly defined, and first-aid supplies are readily accessible. Lastly, the workshop is equipped with proper ventilation and dust collection systems to mitigate the risk of respiratory problems. A clean and organized workshop is both safer and more productive.

Q 19. Describe your experience with project management software relevant to furniture manufacturing.

I have extensive experience using project management software tailored to the furniture manufacturing industry. Software like Katana MRP, ShopVox, or JobBOSS are invaluable for managing projects effectively. These platforms allow me to:

- Create detailed project schedules with milestones and deadlines.

- Track material inventory and purchasing.

- Manage production workflows and resource allocation.

- Monitor project costs and profitability.

- Collaborate effectively with clients and teams.

Using these tools, I can generate comprehensive reports on project progress, identify potential bottlenecks, and ensure timely completion of projects within budget. The software’s ability to integrate with other systems like accounting and inventory management software streamlines operations and enhances overall efficiency. I leverage project management tools to optimize workflow, minimize errors, and consistently deliver high-quality results.

Q 20. How do you handle unexpected challenges or delays during a furniture project?

Handling unexpected challenges is a crucial skill in custom furniture making. When faced with a delay or unforeseen issue (e.g., material defect, equipment malfunction), my first step is to thoroughly assess the situation. This involves identifying the root cause of the problem and its potential impact on the project timeline and budget.

Next, I develop a contingency plan. This might involve sourcing alternative materials, adjusting the production schedule, or proposing creative solutions to overcome the obstacle. Open communication with the client is critical. I keep them informed of the issue, the proposed solutions, and the revised timeline. Transparency is key to maintaining trust and managing expectations. For example, if a supplier is late with materials, I communicate this to the client immediately, offering alternative options if available and providing revised delivery timelines.

Throughout the process, I document all changes and updates, ensuring accurate record-keeping for future projects. Problem-solving in this way is not just about fixing the immediate issue; it’s about learning from the experience to improve future processes and minimize similar occurrences.

Q 21. Explain your knowledge of relevant building codes and safety regulations.

I have a comprehensive understanding of relevant building codes and safety regulations pertinent to furniture design and fabrication. This includes knowledge of fire safety standards (e.g., flammability ratings for upholstery materials), dimensional requirements (e.g., clearances for accessibility), and structural integrity guidelines. I ensure all my designs comply with relevant local, state, and national codes, minimizing liability and ensuring the safety of end-users.

Furthermore, I stay up-to-date on the latest regulations through continuous professional development and by consulting with relevant authorities when necessary. This involves familiarity with certifications for materials and construction methods, ensuring both the quality and safety of the finished product. I regularly review these codes to maintain compliance and ensure best practices are integrated into my designs. The client’s safety and satisfaction are my top priorities.

Q 22. How do you prioritize tasks and manage multiple projects simultaneously?

Prioritizing tasks and managing multiple custom furniture projects requires a structured approach. I utilize project management software to track deadlines, resources, and progress. This allows me to visualize the entire workflow, identifying potential bottlenecks early on. I employ a system of prioritization based on deadlines, client urgency, and project complexity. For example, a project with a tight deadline for a high-value client will naturally take precedence over a less time-sensitive project. I break down large projects into smaller, manageable tasks, assigning each task a specific timeframe and responsible party (if applicable, including subcontractors). Regular check-ins with my team and clients ensure everyone is aligned and that any emerging issues are addressed promptly. Think of it like conducting an orchestra – each instrument (task) needs to be played at the right time and with the right intensity to produce a harmonious whole (finished project).

Q 23. Describe your experience with sustainable and eco-friendly materials in furniture making.

Sustainability is paramount in my approach to furniture making. I actively seek out and utilize eco-friendly materials whenever possible. This includes using reclaimed wood, sustainably harvested hardwoods certified by organizations like the Forest Stewardship Council (FSC), and bamboo, which is a rapidly renewable resource. For finishes, I prioritize low-VOC (volatile organic compound) paints and stains, minimizing harmful emissions. I also explore using natural oils and waxes for a more environmentally conscious approach. For example, I recently completed a project using reclaimed barn wood, giving a beautiful piece a second life while reducing the environmental impact of new lumber harvesting. This not only benefits the environment but also often imparts unique character and history to the finished product that appeals to environmentally conscious clients.

Q 24. How do you collaborate effectively with other professionals (e.g., designers, engineers) on custom furniture projects?

Effective collaboration is key to successful custom furniture projects. I foster open communication with designers, engineers, and clients using a combination of methods, including regular meetings, email updates, and project management software. Clear communication of design specifications, material choices, and construction details is paramount. I encourage active listening and feedback from all stakeholders to ensure everyone’s input is valued. For instance, when working with a structural engineer on a complex piece, I provide detailed CAD drawings and material specifications to ensure the design is both aesthetically pleasing and structurally sound. This collaborative approach avoids misunderstandings, streamlines the process, and ultimately leads to higher quality outcomes and happier clients.

Q 25. Describe your experience with different types of wood finishes and their durability.

My experience encompasses a wide range of wood finishes, each with its own unique properties and durability. Oil finishes, like linseed oil or tung oil, offer a natural look and feel, penetrating the wood to enhance its natural beauty while providing moderate protection. They are relatively easy to maintain but require periodic reapplication. Lacquer finishes offer excellent hardness and durability, providing a high-gloss or satin sheen. They are more resistant to scratches and water damage but can be less forgiving of imperfections in the wood surface. Polyurethane finishes are another popular choice, boasting high durability and a wide range of finishes, from matte to high-gloss. They offer excellent protection against scratches and moisture but may yellow over time. The choice of finish depends heavily on the wood type, intended use, and client preferences. I always discuss the pros and cons of each option with clients to ensure the chosen finish aligns with their needs and expectations.

Q 26. What methods do you employ to ensure accurate measurements and cutting in furniture construction?

Accuracy is critical in furniture construction. I employ a multi-step process to ensure precise measurements and cutting. I start with detailed, scaled drawings, typically using CAD software. These drawings serve as blueprints for the project. I then use precise measuring tools, including tape measures, squares, and digital calipers, to meticulously measure and mark the wood. I utilize advanced cutting tools, such as CNC routers and precision saws, for accurate cuts, minimizing waste and ensuring consistent results. Finally, I always double-check measurements and cuts before proceeding to the next stage of construction, employing quality control checks at each step to prevent costly errors down the line. Think of it as building a house – a single inaccurate measurement could lead to structural problems. Our process aims for zero tolerance for errors.

Q 27. Explain your understanding of different furniture styles and periods.

My understanding of furniture styles spans various periods and aesthetics. I’m familiar with classic styles like Queen Anne, characterized by cabriole legs and ornate details, or the clean lines and functionality of mid-century modern design. I’m also versed in contemporary styles, which often incorporate innovative materials and techniques. A deep understanding of these styles allows me to adapt and integrate various elements to create unique and personalized pieces for my clients. For example, a client might request a modern interpretation of a traditional Shaker piece, blending the simplicity of Shaker design with contemporary materials and finishes. This knowledge base ensures I can effectively communicate with clients and translate their vision into reality.

Q 28. How do you balance the client’s vision with your design expertise to achieve a successful outcome?

Balancing client vision and design expertise involves careful communication and collaboration. I begin by actively listening to the client’s needs, preferences, and inspiration, asking detailed questions to fully understand their vision. I then leverage my design expertise to propose solutions that meet those needs while also ensuring the design is functional, aesthetically pleasing, and structurally sound. This might involve suggesting alternative materials, construction techniques, or design elements that enhance the overall outcome. Throughout the process, I provide regular updates and solicit feedback, making adjustments as necessary to refine the design and ensure client satisfaction. Ultimately, the successful outcome is a collaborative effort – a fusion of the client’s ideas and my professional skills to create a truly unique and exceptional piece of furniture.

Key Topics to Learn for Your Custom Furniture Design & Fabrication Interview

- Design Principles & Aesthetics: Understanding fundamental design elements (line, shape, form, color, texture), design styles (e.g., modern, traditional, rustic), and ergonomics for comfortable and functional furniture.

- Material Selection & Properties: Knowledge of various wood types (hardwoods, softwoods), their properties (strength, durability, workability), and other materials like metals, glass, and fabrics. Practical application: Choosing appropriate materials based on project requirements and client preferences.

- Construction Techniques & Joinery: Mastery of different woodworking joints (mortise and tenon, dovetail, etc.), assembly methods, and finishing techniques (staining, painting, sealing). Practical application: Explaining your preferred methods for building specific furniture pieces, demonstrating understanding of structural integrity.

- CAD/CAM Software Proficiency: Familiarity with design software (e.g., SketchUp, AutoCAD) and potentially CAM software for CNC machining. Practical application: Describing your experience using software to create detailed designs and generate manufacturing instructions.

- Project Management & Client Communication: Understanding project timelines, budgeting, material sourcing, and effective communication with clients to manage expectations and address potential issues. Practical application: Describing a past project and how you managed its various aspects.

- Safety Procedures & Shop Practices: Knowledge of safe woodworking practices, tool usage, and shop organization. Practical application: Demonstrating awareness of relevant safety regulations and best practices.

- Problem-Solving & Troubleshooting: Ability to identify and resolve design and fabrication challenges, adapting to unexpected issues. Practical application: Providing examples of how you’ve overcome obstacles in previous projects.

Next Steps

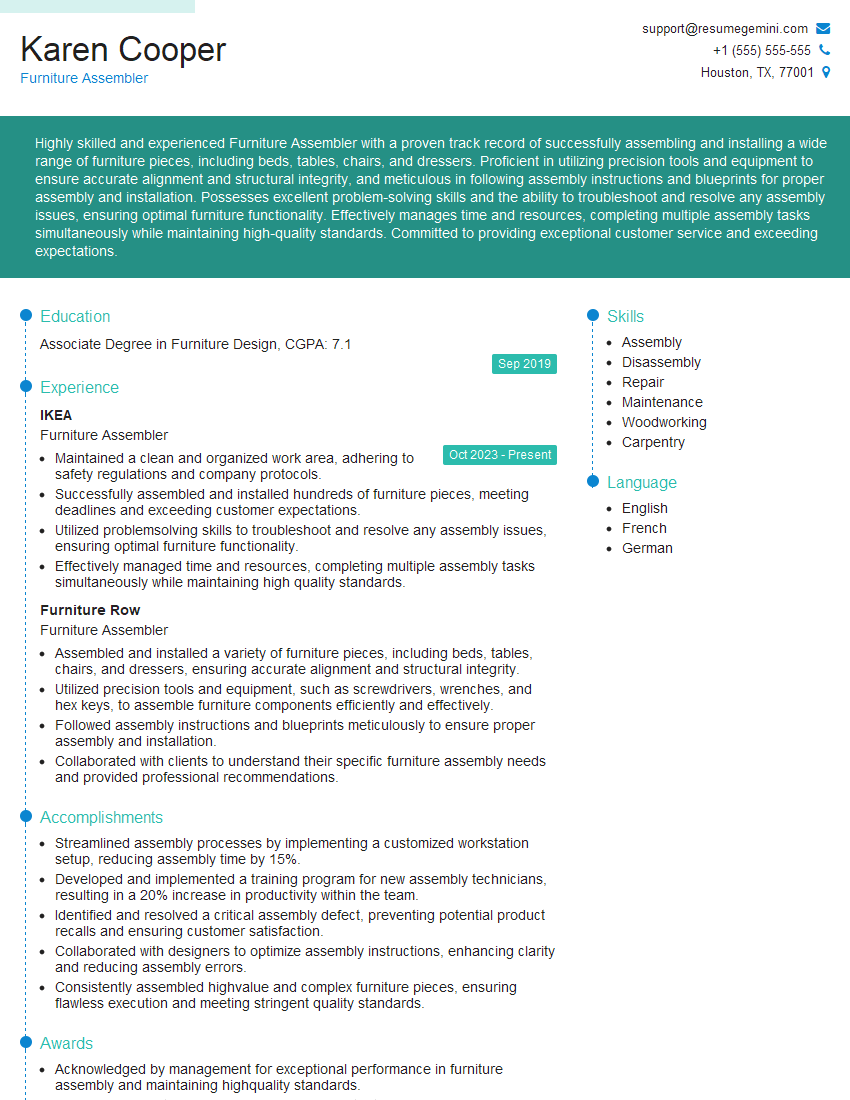

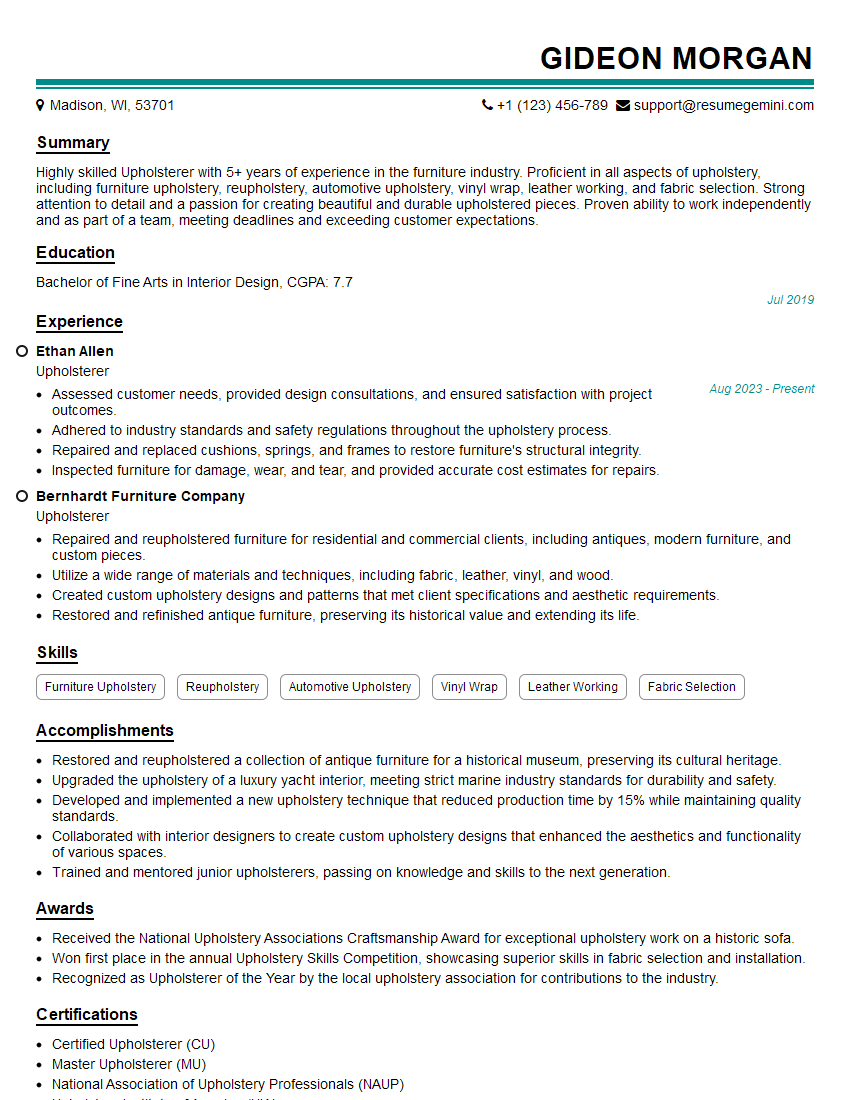

Mastering Custom Furniture Design and Fabrication opens doors to a rewarding career with diverse opportunities for growth and creativity. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you create a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Custom Furniture Design and Fabrication field to guide you. Invest the time to build a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO