Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Design for Manufacturing (DFM) Principles interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Design for Manufacturing (DFM) Principles Interview

Q 1. Explain the core principles of Design for Manufacturing (DFM).

Design for Manufacturing (DFM) is a systematic approach to product design that prioritizes ease and cost-effectiveness of manufacturing. Its core principles revolve around optimizing the design to minimize production time, reduce material waste, simplify assembly, and improve product quality. This isn’t just about making things cheaper; it’s about ensuring the product is actually manufacturable and meets its intended functionality reliably.

- Part Simplification: Reducing the number of parts, using fewer features, and simplifying shapes directly lowers manufacturing costs and complexity.

- Material Selection: Choosing appropriate materials based on manufacturability, cost, performance requirements, and environmental impact. For instance, using readily available materials or those easy to machine is crucial.

- Tolerance Optimization: Defining manufacturing tolerances tightly enough to ensure functionality while allowing for flexibility in production and minimizing waste due to rejection.

- Assembly Considerations: Designing for ease of assembly, minimizing the number of assembly steps, and using standardized fasteners to accelerate the production process.

- Manufacturing Process Selection: Choosing the most suitable manufacturing processes (e.g., injection molding, machining, casting) based on the design, material, and volume requirements.

- Testability and Inspection: Designing in features that allow for easy testing and inspection during and after manufacturing to ensure quality control.

Q 2. Describe your experience in applying DFM principles to a specific product design.

In a previous project, we were designing a complex medical device with multiple interconnected parts. Initially, the design was intricate, requiring many small, precisely machined components and a lengthy, multi-step assembly process. Applying DFM principles, we identified several areas for improvement. We consolidated several parts into a single, injection-molded component, significantly reducing the part count and simplifying the assembly. We also redesigned certain features to be easier to manufacture using standard tooling. This resulted in a 30% reduction in manufacturing cost and a 40% decrease in assembly time. We also improved the device’s reliability by incorporating stronger material choices informed by FEA and rigorous material testing.

Q 3. How do you identify potential manufacturing challenges during the design phase?

Identifying manufacturing challenges early in the design phase is crucial. I typically employ a multi-pronged approach:

- Design Reviews with Manufacturing Experts: Involving manufacturing engineers from the outset of the design process provides valuable insights into potential issues and alternative solutions.

- DFM Software and Tools: Using specialized software to simulate manufacturing processes and identify potential problems, such as moldability analysis for injection molding or manufacturability analysis for machining.

- Process Capability Analysis: Assessing the capabilities of the chosen manufacturing processes based on their precision, speed, and cost to ensure they align with the design tolerances and requirements.

- Material Data Analysis: Using material datasheets to understand material properties, processing limitations, and potential challenges like brittleness or warping.

- Failure Mode and Effects Analysis (FMEA): A structured approach to identifying potential failure modes throughout the manufacturing process and assessing their impact on product quality and cost.

Q 4. What are the key considerations for material selection in DFM?

Material selection in DFM goes far beyond simply picking the strongest or cheapest option. Key considerations include:

- Manufacturability: Is the material easily machinable, moldable, or formable using available processes? A strong but difficult-to-machine material might increase manufacturing costs significantly.

- Cost: Consider both the material cost itself and the cost of processing and finishing the material. Sometimes a slightly more expensive material can result in lower overall manufacturing costs if it’s easier to process.

- Performance Requirements: The material must meet the product’s functional requirements concerning strength, durability, temperature resistance, and other relevant properties.

- Environmental Impact: Choosing environmentally friendly materials is becoming increasingly important, considering sustainability and regulatory compliance.

- Availability and Supply Chain: Ensuring the reliable availability of the material throughout the product lifecycle is critical. Supply chain disruptions can halt production.

Q 5. How do you balance design aesthetics with manufacturing feasibility?

Balancing design aesthetics with manufacturing feasibility often involves creative problem-solving and iterative design. The key is to find design solutions that are both visually appealing and manufacturable. This often involves:

- Early Collaboration: Close collaboration between designers and manufacturing engineers is crucial. Designers should understand manufacturing constraints, and engineers should appreciate design intent.

- Alternative Design Solutions: Exploring multiple design options that achieve the desired aesthetic while accommodating manufacturing limitations. For instance, a complex curve might be simplified to a series of simpler shapes.

- Additive Manufacturing (3D Printing): For highly complex or customized designs, additive manufacturing can offer greater freedom in terms of shape and features, potentially bridging the gap between aesthetics and feasibility, though it might not always be cost-effective for high-volume production.

- Compromise and Prioritization: Sometimes, compromises must be made. Ranking design features by importance can help prioritize those that are most critical to maintain while making adjustments to less important features to improve manufacturability.

Q 6. Explain your understanding of tolerance analysis in DFM.

Tolerance analysis is a critical part of DFM, ensuring that the final product functions correctly despite variations in manufacturing processes. It involves analyzing the allowable variations (tolerances) in dimensions and other parameters of individual components to determine their impact on the overall assembly. This is often done using statistical methods, considering the cumulative effect of tolerances on the final product’s functionality. A proper tolerance analysis helps prevent costly rework, rejects, and assembly issues. Tools like GD&T (Geometric Dimensioning and Tolerancing) are crucial for specifying and controlling tolerances effectively. Improper tolerance stack-up analysis could result in parts that don’t fit together or components that function outside acceptable parameters.

Q 7. How do you incorporate DFM principles into the product development lifecycle?

DFM principles should be integrated into every phase of the product development lifecycle. A proactive approach is much more efficient and cost-effective than trying to fix manufacturability issues after the design is finalized. The integration should look like this:

- Concept Phase: Consider manufacturing implications early on. Evaluate different manufacturing processes and material options.

- Design Phase: Collaborate closely with manufacturing engineers. Conduct thorough tolerance analysis and DFM reviews.

- Prototyping Phase: Create prototypes that reflect the final manufacturing process. This helps identify and resolve any potential manufacturing issues early on.

- Production Phase: Monitor manufacturing processes and make any necessary adjustments to optimize efficiency and quality.

By embedding DFM throughout the product lifecycle, companies can minimize manufacturing costs, shorten lead times, and ensure higher product quality.

Q 8. Describe your experience with different manufacturing processes (e.g., injection molding, machining, casting).

My experience encompasses a wide range of manufacturing processes, focusing on how design choices impact manufacturability and cost. I’ve worked extensively with injection molding, machining, and casting, understanding their unique capabilities and limitations.

Injection molding, for instance, is ideal for high-volume production of complex plastic parts. I’ve designed parts considering factors like draft angles (the angle of the wall to allow for easy removal from the mold), gate locations (where the molten plastic enters the mold), and wall thickness uniformity to avoid warping or sink marks. One project involved optimizing the design of a smartphone case to minimize material usage and injection pressure, resulting in significant cost savings.

Machining, on the other hand, offers flexibility for smaller batches and intricate designs in metals or other hard materials. Here, my focus is on ensuring designs are easily machinable, avoiding complex undercuts or features that require excessive tooling. I worked on a project designing a precision metal bracket, carefully selecting material and designing features that minimized machining time while maintaining tight tolerances.

Casting is suitable for creating complex shapes in various materials, often at a lower cost than machining for high-volume production. My experience includes working with both sand casting and investment casting, understanding issues such as part shrinkage, surface finish, and the need for proper draft angles and parting lines. For example, I designed a decorative metal component where the casting process was chosen for its ability to create intricate designs economically.

Q 9. What software tools are you proficient in for DFM analysis?

Proficiency in DFM analysis software is crucial. I’m adept at using several industry-standard tools, including:

- SolidWorks: Not only for CAD modeling but also its integrated simulation tools for stress analysis, mold flow analysis, and tolerance stack-up analysis.

- Moldflow: Specifically for analyzing the injection molding process, predicting potential defects like weld lines, sink marks, and warpage.

- Autodesk Inventor: Similar to SolidWorks, for 3D modeling and its inherent DFM tools for manufacturability checks and design optimization.

- Creo Parametric: Another CAD software with powerful simulation capabilities, crucial for thorough DFM analysis across various manufacturing processes.

Beyond specific software, I’m comfortable using spreadsheets and scripting to automate analysis and reporting, making the DFM process more efficient.

Q 10. How do you collaborate with manufacturing teams to optimize designs?

Collaboration is key in DFM. I believe in a proactive, transparent approach involving manufacturing engineers from the very beginning of the design process. This isn’t just about sending designs over for approval; it’s about a continuous dialogue.

My strategy includes:

- Early Involvement: Bringing manufacturing engineers into design reviews early to provide feedback and identify potential issues before they become major problems.

- Joint Design Sessions: Facilitating workshops where designers and manufacturing engineers work together to explore alternative design solutions and make informed decisions.

- Regular Communication: Maintaining open communication channels to address questions, concerns, and design changes promptly.

- Data Sharing: Using shared online platforms (e.g., project management software) to ensure everyone has access to the latest designs and documentation.

For example, in one project, by involving the manufacturing team early, we identified a design flaw that would have caused significant delays and cost overruns had it been discovered later in the process.

Q 11. How do you handle design changes requested by the manufacturing team?

Design changes requested by the manufacturing team are handled systematically. It’s not about simply accepting or rejecting them, but understanding the rationale behind the request and finding the best solution.

My approach involves:

- Understanding the Rationale: Asking the manufacturing team to explain the reasons for the requested change, including cost, manufacturability, and potential quality implications.

- Impact Assessment: Evaluating the impact of the change on other design aspects, functionality, and performance.

- Feasibility Study: Determining the feasibility of implementing the change, considering time constraints and budget.

- Negotiation and Compromise: Collaborating with the manufacturing team to find acceptable alternatives or compromise solutions that balance design intent with manufacturability.

Documenting all changes and their justifications is essential. This ensures transparency and facilitates future decision-making.

Q 12. What metrics do you use to evaluate the effectiveness of DFM implementation?

Evaluating DFM effectiveness requires quantifiable metrics. I use a combination of:

- Manufacturing Cost: Tracking the cost of manufacturing the product, comparing it against initial estimates and identifying areas for improvement.

- Production Time: Measuring the time required to manufacture the product, striving to reduce lead times and improve efficiency.

- Defect Rate: Monitoring the rate of defects during manufacturing and identifying design-related causes.

- Material Usage: Assessing the amount of material used and finding ways to minimize waste and reduce costs.

- Assembly Time: Measuring the time needed to assemble the product, highlighting areas where design improvements can simplify the assembly process.

These metrics are tracked and analyzed regularly to identify areas for improvement and demonstrate the effectiveness of the DFM process.

Q 13. Explain your approach to identifying and mitigating manufacturing risks.

Identifying and mitigating manufacturing risks is a proactive, multi-step process. It’s like conducting a risk assessment for your product’s journey through the manufacturing pipeline.

My approach includes:

- Failure Mode and Effects Analysis (FMEA): Systematically identifying potential failure modes, their causes, and effects, allowing for proactive mitigation strategies.

- Design for Reliability (DFR): Incorporating reliability considerations into the design process to prevent failures and ensure product longevity.

- Process Capability Analysis: Assessing the capability of the manufacturing process to meet the design specifications and identifying areas for improvement.

- Material Selection: Carefully selecting materials based on their properties, cost-effectiveness, and suitability for the manufacturing process.

- Tolerance Analysis: Analyzing the cumulative effect of tolerances on the final product dimensions and functionality.

By proactively addressing these potential risks, we minimize disruptions and ensure a smoother manufacturing process.

Q 14. How do you ensure design manufacturability during rapid prototyping?

Ensuring design manufacturability during rapid prototyping requires a careful balance between speed and thoroughness. It’s about smart shortcuts, not compromises.

My strategy involves:

- Iterative Prototyping: Building multiple prototypes, each addressing specific manufacturing concerns identified in previous iterations.

- Material Selection for Prototyping: Choosing prototyping materials that mimic the properties of the final production material as closely as possible.

- Simplified Designs: Using simplified geometries during the prototyping phase, focusing on critical features and gradually adding complexity as manufacturability is confirmed.

- Early Manufacturing Feedback: Involving manufacturing personnel in the rapid prototyping process to obtain early feedback on the design’s manufacturability.

- Digital Prototyping: Utilizing software simulation tools to evaluate the manufacturability of the design before physical prototyping.

This approach allows for efficient testing and adjustments, ultimately leading to a more manufacturable final design.

Q 15. Describe your experience with Design for Assembly (DFA) principles.

Design for Assembly (DFA) is a crucial aspect of Design for Manufacturing (DFM), focusing on simplifying the assembly process to reduce costs, improve quality, and shorten lead times. It involves analyzing each component and its interaction during assembly to identify and eliminate unnecessary steps, parts, or complexities.

My experience with DFA spans various projects, from consumer electronics to medical devices. In one project involving a complex electromechanical assembly, we used DFA principles to reduce the number of parts by 30% by integrating multiple components into a single, cleverly designed module. This dramatically reduced assembly time, lowered manufacturing costs, and improved product reliability by decreasing the number of potential failure points.

I’ve also employed DFA techniques like using standardized fasteners, implementing modular designs, and optimizing part orientation for easy handling and insertion. For example, designing parts with self-locating features minimizes the need for skilled labor and specialized tooling during assembly, leading to a faster and more efficient process.

- Part Count Reduction: Aiming to minimize the number of parts needed.

- Simplified Assembly Sequence: Designing parts for easy and intuitive assembly.

- Part Orientation & Handling: Designing parts for easy grasping and placement.

- Modular Design: Breaking down complex assemblies into smaller, manageable modules.

Career Expert Tips:

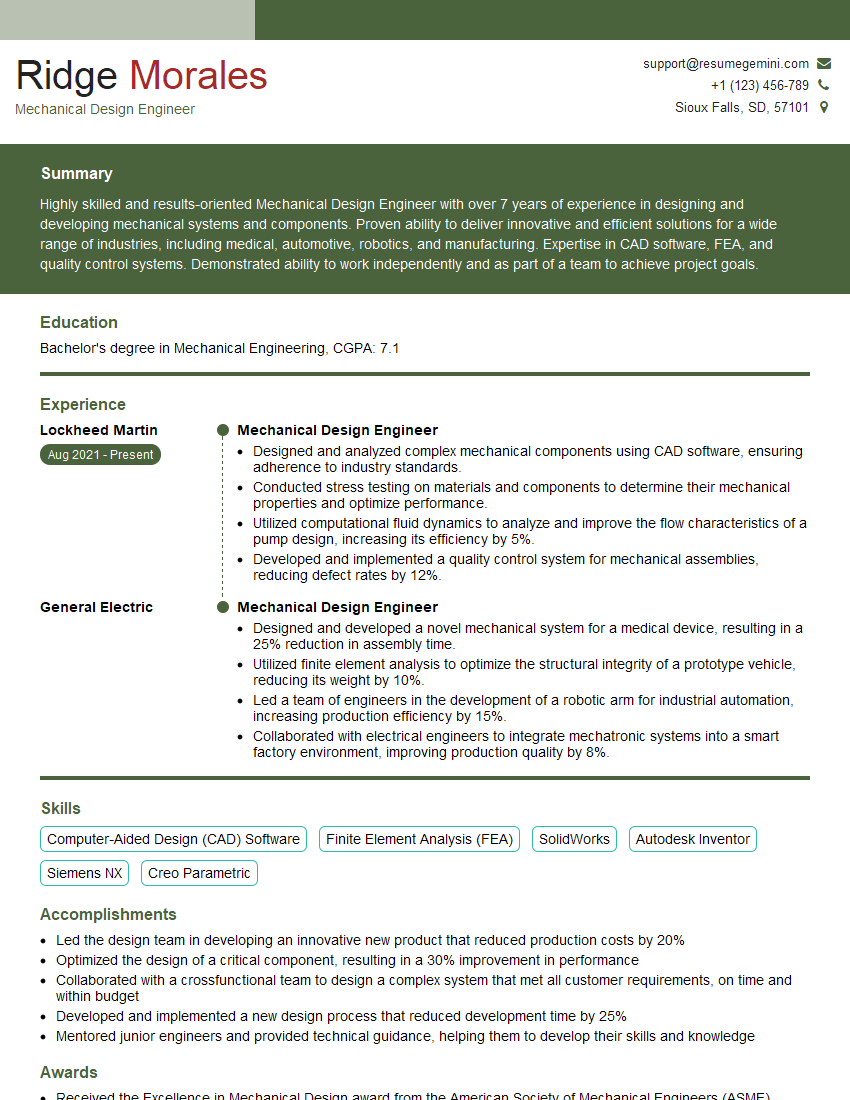

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you consider cost optimization during the design phase?

Cost optimization during the design phase is paramount. It’s far more expensive to correct design flaws after manufacturing has begun. My approach involves a holistic view, considering material costs, manufacturing processes, assembly costs, and potential waste.

I start by selecting cost-effective materials that meet the required performance specifications. This often involves researching alternative materials with similar properties but lower costs. For instance, substituting a high-strength but expensive alloy with a more affordable composite material could significantly reduce costs without compromising product functionality.

Next, I carefully choose manufacturing processes that minimize waste and optimize efficiency. Selecting a simpler process, like injection molding over machining, might yield considerable savings. I also analyze the assembly process to identify opportunities for automation or simplification. For example, designing parts with snap-fits instead of screws can automate assembly and eliminate the need for specialized tools.

Finally, I conduct thorough tolerance analysis to prevent costly rework or scrap caused by assembly errors. Precisely defining tolerances helps ensure that parts fit correctly, reducing the need for manual adjustments or part replacements. Think of it like building with LEGOs; precise dimensions ensure a seamless and efficient build.

Q 17. Explain your understanding of different manufacturing processes and their limitations.

Understanding manufacturing processes and their limitations is fundamental in DFM. My experience encompasses a wide range of processes including injection molding, machining, casting, additive manufacturing (3D printing), and sheet metal forming. Each has its strengths and weaknesses.

- Injection Molding: Excellent for high-volume production of complex plastic parts, but tooling costs are high.

- Machining: Highly versatile for precise parts from various materials but can be time-consuming and expensive for high volumes.

- Casting: Cost-effective for complex shapes and high volumes, but surface finish and dimensional accuracy may be limited.

- Additive Manufacturing: Ideal for rapid prototyping and low-volume production of complex geometries but material properties might be less consistent than traditional methods.

- Sheet Metal Forming: Efficient and cost-effective for creating lightweight sheet metal parts but suitable geometries are limited.

For example, while injection molding is suitable for mass production of a phone case, machining might be more appropriate for a small batch of high-precision medical instruments. Choosing the wrong process can lead to high costs, long lead times, or inferior product quality. Understanding these limitations allows for informed design decisions that optimize manufacturability.

Q 18. How do you evaluate the sustainability of a given design?

Sustainability is a key consideration in modern design. I evaluate a design’s sustainability by focusing on several key aspects:

- Material Selection: Choosing recycled, recyclable, or bio-based materials whenever feasible. This reduces environmental impact and resource depletion.

- Energy Efficiency: Designing products that consume less energy during their lifecycle, whether through improved performance or reduced energy consumption in manufacturing.

- Manufacturing Processes: Selecting manufacturing processes with lower environmental impact, minimizing waste, and utilizing renewable energy sources.

- Product Lifecycle: Designing for durability, repairability, and recyclability to extend product lifespan and reduce waste generation.

- Transportation: Optimizing product packaging and minimizing transportation distances to reduce carbon footprint.

For example, using recycled aluminum in a product significantly reduces the environmental impact compared to using virgin aluminum. Designing for easy disassembly and component reuse also promotes a circular economy, reducing waste and increasing material recovery.

Q 19. How do you handle conflicts between design specifications and manufacturing capabilities?

Conflicts between design specifications and manufacturing capabilities are inevitable. My approach involves a collaborative process of negotiation and compromise.

First, I thoroughly understand the design requirements and specifications. Then, I assess the manufacturing capabilities and limitations of the chosen processes. If a conflict arises, I explore several solutions:

- Design Modification: Minor design adjustments to make the product manufacturable. For example, simplifying a complex geometry or using more readily available materials.

- Process Optimization: Exploring alternative manufacturing processes or techniques that can meet the design specifications more effectively.

- Tolerance Adjustment: Relaxing tight tolerances to reduce manufacturing difficulties. This might require a trade-off in terms of product performance, which needs careful consideration.

- Material Substitution: Finding alternative materials that offer similar properties but are more suitable for the chosen manufacturing process.

The goal is to find the optimal balance between meeting the design requirements and ensuring manufacturability, while maintaining cost-effectiveness and product quality. This often involves communication and negotiation with designers, engineers, and manufacturers.

Q 20. What is your experience with Statistical Process Control (SPC)?

Statistical Process Control (SPC) is a crucial tool for monitoring and improving manufacturing processes. My experience with SPC involves using control charts (like X-bar and R charts) to track key process parameters, identify trends, and detect variations that could lead to defects.

I’ve utilized SPC in several projects to identify sources of variation in the manufacturing process and to improve process capability. For example, in a project producing precision components, we implemented SPC to monitor critical dimensions. By analyzing control charts, we identified a specific machine setting that was contributing to excessive variation. Adjusting this setting significantly improved process consistency and reduced defects.

Beyond basic control charts, I’m familiar with more advanced SPC techniques, such as process capability analysis (Cp, Cpk) and control chart pattern analysis. These techniques help us understand the process’s ability to meet specifications and identify assignable causes of variation, allowing us to make data-driven decisions to optimize the manufacturing process.

Q 21. How do you utilize Design of Experiments (DOE) in DFM?

Design of Experiments (DOE) is a powerful statistical technique used to efficiently investigate the effects of various design parameters on product performance and manufacturability. In DFM, DOE helps optimize designs for ease of manufacturing and reduces the number of prototypes required.

I utilize DOE to study the impact of factors like material properties, process parameters (temperature, pressure, speed), and dimensional tolerances on critical product characteristics. A well-designed DOE experiment can identify the most significant factors influencing the process and determine optimal settings for achieving desired outcomes.

For example, in a project involving injection molding, we used DOE to optimize the molding parameters (injection pressure, mold temperature, cooling time) to minimize warpage and improve surface finish. By systematically varying these parameters and analyzing the results using statistical methods, we identified the optimal settings that significantly improved the quality of the molded parts. This approach allowed us to reduce the number of costly trial-and-error iterations typically involved in optimizing such processes.

Q 22. Explain your experience with Failure Mode and Effects Analysis (FMEA).

Failure Mode and Effects Analysis (FMEA) is a systematic, proactive method used to identify potential failure modes in a system, product, or process and assess their severity, occurrence, and detectability. It’s a crucial tool in Design for Manufacturing (DFM) as it helps prevent problems before they occur, saving time and resources.

In my experience, I’ve led and participated in numerous FMEAs across various projects. This involved collaborating with cross-functional teams – engineers, manufacturing personnel, and quality control – to brainstorm potential failure modes. We’d then use a standardized FMEA worksheet to document each mode, its potential effects, severity rating (how bad the failure would be), occurrence rating (how likely the failure is), and detection rating (how likely the failure would be detected before reaching the customer). A Risk Priority Number (RPN) is calculated (Severity x Occurrence x Detection), helping prioritize which failures require immediate attention. For instance, in a project involving a complex assembly, we identified a potential failure mode of a loose screw leading to component malfunction. Through FMEA, we determined that the severity was high, the occurrence was moderate (due to human error), and detection was low. This high RPN led us to implement corrective actions such as improved assembly instructions and automated screw tightening. The process isn’t just about identifying problems; it’s about implementing corrective actions and verifying their effectiveness. Regular reviews and updates are key to maintaining an effective FMEA.

Q 23. How do you ensure manufacturability when dealing with complex geometries?

Manufacturability for complex geometries hinges on understanding the capabilities of your chosen manufacturing processes. It’s not enough to design a beautiful part; it must be realistically producible at an acceptable cost and quality. Think of it like sculpting – you can design the most intricate statue, but if you lack the tools or skills to carve it, the design is impractical.

My approach involves early collaboration with manufacturing engineers. We explore various manufacturing methods – injection molding, machining, 3D printing – assessing each process’s suitability based on factors such as material choice, tolerance requirements, surface finish, and part complexity. For example, if we’re dealing with undercuts or intricate internal features, injection molding might require expensive tooling and potentially complex mold designs. Alternatively, 3D printing could offer a more cost-effective solution for prototyping or low-volume production. We also consider tooling and fixturing requirements, ensuring the design allows for efficient and reliable manufacturing processes. This might involve simplifying geometries, adding features to aid in manufacturing, or designing for specific clamping mechanisms. Finite Element Analysis (FEA) can be employed to predict stress points and ensure structural integrity under manufacturing stresses like clamping forces.

Q 24. Describe your experience with lean manufacturing principles.

Lean manufacturing principles focus on eliminating waste and maximizing value throughout the production process. My experience involves applying these principles to optimize design and manufacturing flows. This includes concepts like 5S (Sort, Set in Order, Shine, Standardize, Sustain) for workspace organization, and Kanban for managing inventory. I’ve used Value Stream Mapping (VSM) to visualize and analyze the entire production process, identifying bottlenecks and areas for improvement. For example, in one project, VSM revealed a significant delay in the assembly process due to inefficient material handling. By redesigning the layout and implementing a pull system, we significantly reduced lead times and improved overall efficiency.

Furthermore, my experience includes integrating lean principles directly into the design phase. This means considering the manufacturing process implications at the early stages of the design process. For example, designing for modularity allows easier assembly and reduces waste, and designing for ease of access simplifies maintenance and repair.

Q 25. What are some common DFM pitfalls to avoid?

Avoiding DFM pitfalls requires a proactive and collaborative approach. Some common mistakes include:

- Ignoring manufacturing constraints: Designing parts with tolerances too tight for the chosen manufacturing process leads to high costs and rejects.

- Overlooking material selection: Choosing a material that’s difficult to process or incompatible with the intended application results in production issues.

- Lack of early collaboration: Failing to involve manufacturing engineers early in the design process leads to costly redesigns and delays.

- Neglecting tooling and fixturing: Not considering the need for specific tooling and fixturing can lead to inefficient manufacturing processes.

- Complex geometries: Designing excessively complex parts without considering manufacturing limitations results in high costs and difficulties in production.

- Ignoring assembly considerations: Poor design of assembly features can significantly impact efficiency and lead to increased production time.

To avoid these pitfalls, thorough analysis, collaboration, and a focus on simplicity are crucial. Prototyping and testing are also vital for validating design decisions.

Q 26. How do you stay updated with the latest advancements in manufacturing technologies?

Staying current in the rapidly evolving manufacturing landscape is essential. My strategy involves a multi-faceted approach:

- Industry publications and journals: I regularly read publications like Manufacturing Engineering and Modern Machine Shop to stay informed about technological advancements.

- Conferences and workshops: Attending industry conferences and workshops provides valuable insights and networking opportunities.

- Online resources: Utilizing online platforms and webinars offers access to a wealth of information.

- Professional organizations: Membership in organizations like the Society of Manufacturing Engineers (SME) provides access to valuable resources and networking opportunities.

- Collaboration with suppliers: Engaging with suppliers keeps me updated on the latest materials and manufacturing processes.

By combining these methods, I ensure I remain knowledgeable about the latest trends and technologies, allowing me to incorporate cutting-edge solutions into my DFM strategies.

Q 27. Describe a time you had to make a difficult trade-off between design and manufacturing.

In a recent project involving a medical device, we faced a significant trade-off between design aesthetics and manufacturability. The initial design featured a complex, curved surface that was visually appealing but challenging and costly to manufacture using injection molding. The tooling cost was projected to be prohibitively expensive, potentially delaying the product launch.

After careful analysis, we opted for a slightly simplified design that retained most of the aesthetic appeal while significantly improving manufacturability. The modified design reduced the complexity of the mold, decreasing tooling costs by approximately 40%. While the change was subtle, it significantly reduced the manufacturing lead time and overall project cost. This decision was made after thorough analysis, considering the financial implications and the importance of timely market entry. It highlighted the importance of balancing design goals with realistic manufacturing constraints.

Q 28. How do you communicate technical information effectively to non-technical stakeholders?

Effective communication with non-technical stakeholders requires simplifying complex technical information without sacrificing accuracy. I use several strategies:

- Visual aids: Using diagrams, charts, and prototypes helps convey information more effectively than lengthy technical reports.

- Analogies and metaphors: Relatable analogies simplify complex concepts; for example, comparing a manufacturing process to a familiar process like baking a cake.

- Storytelling: Presenting information as a narrative makes it more engaging and memorable.

- Avoiding jargon: Using clear, concise language avoids confusion and ensures everyone understands the message.

- Active listening and feedback: I always make sure I understand the stakeholder’s perspective and incorporate their feedback into my communication.

For example, when presenting a cost analysis to a finance team, I use clear charts and graphs to showcase the cost breakdown rather than focusing on technical manufacturing details. By focusing on the key takeaways and using appropriate visuals, I ensure everyone understands the impact of design decisions on the project budget.

Key Topics to Learn for Design for Manufacturing (DFM) Principles Interview

Acing your Design for Manufacturing (DFM) interview requires a solid understanding of both theory and practice. This isn’t just about memorizing definitions; it’s about demonstrating how you can apply these principles to real-world scenarios. Let’s break down some key areas:

- Material Selection: Understand the trade-offs between material properties (strength, cost, machinability, etc.) and manufacturing processes. Be prepared to discuss how material choices impact manufacturability and product performance.

- Tolerance Analysis: Explore the impact of tolerances on assembly, functionality, and cost. Practice analyzing drawings and identifying potential issues related to tight tolerances or cumulative errors.

- Process Capability: Learn about different manufacturing processes (injection molding, machining, casting, etc.) and their inherent limitations. Discuss how to design parts that are easily and efficiently manufactured using these processes.

- Assembly Considerations: Focus on designing for ease of assembly. Think about factors like part mating, fastening methods, and the overall assembly sequence to minimize cost and time.

- Cost Optimization: Understand how design choices directly impact manufacturing costs. Be prepared to discuss strategies for reducing costs without sacrificing quality or performance.

- Design for Testability (DFT): Discuss how design decisions can make testing and quality control easier and more efficient.

- Sustainability and Environmental Impact: Consider the environmental impact of materials and manufacturing processes. Be prepared to discuss eco-friendly design choices.

Remember to practice applying these concepts to hypothetical scenarios. The ability to problem-solve and think critically is just as important as theoretical knowledge.

Next Steps

Mastering Design for Manufacturing (DFM) Principles is crucial for a successful career in engineering and product development. It demonstrates your ability to create practical, cost-effective, and manufacturable designs. To significantly boost your job prospects, create a strong, ATS-friendly resume that highlights your DFM expertise. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume. We offer examples of resumes tailored specifically to Design for Manufacturing (DFM) Principles to help you get started. Take the next step towards your dream career – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO