Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Diesel Engine Operation and Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Diesel Engine Operation and Maintenance Interview

Q 1. Explain the four-stroke cycle of a diesel engine.

The four-stroke diesel engine cycle is a fundamental process that converts fuel energy into mechanical work. It’s a cyclical process involving four distinct piston strokes within the cylinder: Intake, Compression, Power, and Exhaust.

- Intake Stroke: The piston moves downwards, drawing in a fresh air charge into the cylinder. Think of it like inhaling – the engine ‘breathes’ in air.

- Compression Stroke: The piston moves upwards, compressing the air to a high temperature and pressure. This is crucial; the heat generated is enough to ignite the fuel later.

- Power Stroke: Fuel is injected into the highly compressed air near the top of the compression stroke. The heat spontaneously ignites the fuel, causing a rapid expansion of gases that pushes the piston downwards, generating power. This is the ‘muscle’ of the engine.

- Exhaust Stroke: The piston moves upwards, pushing the spent combustion gases out of the cylinder through the exhaust valve. It’s like exhaling – clearing out the waste.

This entire cycle repeats continuously, providing a constant stream of power. The precise timing of the valves and the fuel injection is critical for efficient operation.

Q 2. Describe the function of a diesel engine turbocharger.

A turbocharger is a forced induction system that increases the engine’s power output by boosting the air intake. It uses the energy from the exhaust gases to drive a turbine, which in turn compresses more air into the engine’s cylinders.

Imagine a bicycle pump – you’re working hard to push air into the tire (engine cylinders). The turbocharger uses the waste energy from the exhaust (like a clever re-use of energy) to make this pumping action more powerful, allowing more air and fuel to be burned, thereby increasing power.

The increased air density leads to more efficient combustion and hence more power. This is especially important in larger diesel engines found in trucks or ships, where high torque and power are essential. Modern turbochargers often incorporate features like intercoolers to reduce the temperature of the compressed air, further improving efficiency and reducing the risk of detonation.

Q 3. What are the common causes of diesel engine knocking?

Diesel engine knocking, also known as detonation, is a harsh, metallic sound produced by uncontrolled and rapid combustion of the fuel-air mixture. It can be very damaging to the engine.

- Low-Quality Fuel: Fuel with a low cetane number (a measure of how readily the fuel ignites) can cause knocking as it doesn’t ignite smoothly.

- Incorrect Fuel Injection Timing: If the fuel is injected too early or too late, it can lead to uncontrolled burning and knocking.

- High Compression Ratio: Engines with very high compression ratios are more prone to knocking as the air is compressed to extremely high temperatures.

- Over-advanced Injection Timing: An advanced injection timing means the fuel is ignited before optimal, leading to increased pressures and potential knocking.

- Carbon Buildup: Accumulation of carbon deposits in the combustion chamber can alter the combustion process, resulting in knocking.

Knocking can result in severe engine damage if left unchecked, so addressing the root cause is crucial.

Q 4. How do you diagnose a faulty fuel injector?

Diagnosing a faulty fuel injector requires a methodical approach. Symptoms like rough running, poor fuel economy, and excessive smoke are common indicators. We use various diagnostic tools.

- Visual Inspection: Check for leaks or damage to the injector itself and its connections.

- Compression Test: A low compression reading in a particular cylinder might indicate a problem with the fuel injector in that cylinder.

- Fuel Pressure Test: Measuring the fuel pressure will reveal if sufficient pressure is reaching the injector.

- Injector Flow Test: A specialized tool measures the amount of fuel delivered by each injector, helping identify any injector delivering insufficient or inconsistent fuel.

- Leak-Down Test: Checking for leaks in the injector nozzle, often using specialized equipment to pressurize and measure leakage.

- Injector Balance Test: This tests the fuel delivery consistency across all injectors. Uneven fuel delivery can often signify a faulty injector.

Each test provides clues; combining results helps pinpoint the problem injector precisely. Often, a combination of these tests are needed to get to the root cause.

Q 5. Explain the process of performing a diesel engine oil change.

A diesel engine oil change is crucial for maintaining engine longevity and performance. It’s a relatively straightforward procedure but requires care and the right tools.

- Warm-up the Engine: Run the engine briefly to warm the oil, making it flow more easily.

- Locate the Drain Plug: This is typically situated at the bottom of the oil pan.

- Drain the Old Oil: Position a drain pan beneath the plug and carefully remove it. Allow all the oil to drain completely; this can take some time.

- Replace the Drain Plug: Once drained, replace the drain plug and tighten it securely. Don’t overtighten!

- Locate the Oil Filter: This is usually attached to the engine block.

- Remove and Replace the Oil Filter: Use an oil filter wrench to remove the old filter. Lightly lubricate the rubber gasket of the new filter before installing it.

- Add New Oil: Consult your engine’s manual for the correct amount and type of oil. Pour in the new oil through the oil filler cap.

- Check the Oil Level: Use the dipstick to verify the oil level is within the recommended range.

- Run the Engine: Briefly run the engine to circulate the new oil.

- Recheck Oil Level: Once the engine has run for a short while, check the oil level again and top up if necessary.

Always dispose of the old oil responsibly at a designated recycling center.

Q 6. What are the different types of diesel fuel and their properties?

Diesel fuels are categorized by their cetane number, sulfur content, and other additives. Different types are designed for various applications and climates.

- Ultra-Low Sulfur Diesel (ULSD): This is the most common type in many regions, containing very low sulfur levels (typically less than 15 ppm) to reduce emissions and protect the environment. This fuel is used in most modern diesel engines.

- Biodiesel: A renewable fuel made from vegetable oils or animal fats. It can be blended with petroleum diesel, offering a reduced carbon footprint but sometimes requiring adjustments in engine settings.

- High-Sulfur Diesel: Older diesel engines often ran on this fuel, but it’s becoming increasingly rare due to stricter environmental regulations. The high sulfur content leads to increased emissions and greater wear on engine components.

- Arctic Diesel: Formulated with additives to improve cold-weather performance, allowing easy starting in extremely low temperatures. This fuel has a lower pour point and cloud point.

Each fuel type has specific properties regarding its ignition quality, lubricity, and environmental impact. Choosing the correct fuel is crucial for optimal engine performance, longevity, and emission compliance.

Q 7. How do you troubleshoot a diesel engine that won’t start?

Troubleshooting a diesel engine that won’t start involves a systematic approach to eliminate possible causes.

- Check the Fuel System: Ensure there’s enough fuel in the tank and that the fuel lines are free of blockages. Check the fuel filter for contamination; a clogged filter is a very common cause of no-start issues.

- Inspect the Battery: A weak or dead battery is a frequent culprit. Check the battery voltage and terminal connections.

- Verify the Glow Plugs (for cold weather starts): If the engine is cold, faulty glow plugs might prevent starting. Testing them with a multimeter is advisable.

- Examine the Starter Motor: A faulty starter motor will not crank the engine. You might hear a clicking sound if the starter solenoid is at fault.

- Check the Engine’s Compression: Low compression in one or more cylinders indicates significant engine problems and is a major cause of failure to start.

- Inspect the Fuel Injectors: Faulty injectors can prevent the engine from starting. This often requires testing as mentioned earlier.

- Check the Air Intake System: Blocked air intake systems prevent sufficient air from entering the engine.

Working through this checklist methodically will usually identify the root cause of the starting problem. If the issue remains unresolved after these checks, professional assistance from a qualified diesel mechanic might be necessary.

Q 8. Describe the function of the diesel engine cooling system.

The diesel engine cooling system’s primary function is to regulate the engine’s operating temperature, preventing overheating and ensuring optimal performance and longevity. Diesel engines generate significant heat during combustion, and if this heat isn’t effectively managed, it can lead to catastrophic engine failure. The system works by circulating a coolant (typically water or a coolant mixture) through passages within the engine block and cylinder head, absorbing the heat. This heated coolant then flows to a radiator, where a fan and airflow dissipate the heat to the atmosphere. A thermostat regulates the coolant flow, ensuring the engine reaches its optimal operating temperature quickly and maintains it within a safe range.

Think of it like a car’s circulatory system. The engine is the heart, generating heat. The coolant is the blood, carrying away the heat. The radiator and fan are the lungs, releasing the heat into the environment. A malfunctioning cooling system, like a blockage in a blood vessel, can have devastating consequences.

Q 9. Explain the importance of proper lubrication in a diesel engine.

Proper lubrication is absolutely critical for a diesel engine’s health and performance. Diesel engines operate under high pressure and temperature conditions, subjecting moving parts to significant friction and wear. Lubrication serves several vital roles: reducing friction and wear between moving components, preventing seizing and damage, cooling critical parts, cleaning away debris, and sealing combustion gases. The engine oil acts as a barrier between metal surfaces, preventing direct contact and minimizing wear. Without adequate lubrication, metal-to-metal contact can lead to scoring, seizures, and ultimately, engine failure. This is incredibly expensive to repair. Think of it like oiling the hinges on a door – without lubrication, the hinges would quickly wear out and the door would become unusable.

Choosing the correct oil viscosity and ensuring regular oil changes are crucial. Using the wrong oil can lead to increased wear and tear, while neglecting oil changes results in contaminated oil that loses its lubricating properties, accelerating engine wear.

Q 10. What are the safety precautions when working on a diesel engine?

Safety is paramount when working on a diesel engine. The potential hazards include: high temperatures, moving parts, exposure to fuel and oil, and toxic fumes. Here are some crucial safety precautions:

- Always disconnect the battery’s negative terminal before starting any work to prevent accidental electrical shocks or short circuits.

- Allow the engine to cool completely before performing any maintenance or repairs. Hot engine components can cause severe burns.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Consider a respirator if working in poorly ventilated areas.

- Work in a well-ventilated area to avoid inhaling potentially harmful fumes.

- Use proper lifting techniques to avoid injuries when handling heavy engine components. Never work alone; always have a spotter available.

- Be mindful of moving parts. Even after the engine is turned off, some components may still be moving.

- Never work on a running engine unless absolutely necessary and with the appropriate safety measures in place. This includes using specialized tools and taking additional precautions.

- Properly dispose of used oil and other fluids according to local environmental regulations.

Following these precautions will significantly reduce the risk of injury and accidents while working on a diesel engine. A moment’s lapse in attention can lead to severe consequences. Safety should always be the top priority.

Q 11. How do you interpret a diesel engine diagnostic trouble code?

Interpreting a diesel engine diagnostic trouble code (DTC) involves understanding the code’s structure and referencing a diagnostic manual specific to the engine model. DTCs are alphanumeric codes that pinpoint potential problems within the engine’s various systems. They usually consist of a letter (indicating the system, such as ‘P’ for powertrain) followed by a number. For example, a code like ‘P0235’ might indicate a turbocharger boost pressure sensor malfunction.

The interpretation process generally involves:

- Identifying the DTC using an OBD-II scanner or other diagnostic tool.

- Referencing the diagnostic manual to find the specific definition of the code.

- Analyzing the code’s implications to understand the potential causes of the problem.

- Performing further diagnostics (such as checking sensor readings, pressure tests, or visual inspections) to pinpoint the exact source of the issue.

- Implementing the appropriate repair once the root cause is identified.

Using a reliable diagnostic manual is essential, as the same code can have different meanings across different engine models. Proper diagnosis is crucial to fixing the problem efficiently and preventing further damage.

Q 12. Explain the principles of diesel engine combustion.

Diesel engine combustion relies on the principle of self-ignition, unlike gasoline engines that use spark plugs. The process starts with compressing a mixture of air and finely atomized diesel fuel to a high temperature and pressure. This compression raises the air’s temperature to the point where the injected fuel spontaneously ignites, resulting in a controlled explosion that pushes the piston downwards, generating power.

The key stages are:

- Intake Stroke: Air is drawn into the cylinder.

- Compression Stroke: The air is compressed to a high temperature and pressure.

- Combustion: Fuel is injected into the compressed air, igniting spontaneously.

- Power Stroke: The expanding gases from combustion force the piston downwards, producing power.

- Exhaust Stroke: The burnt gases are expelled from the cylinder.

The efficiency of diesel combustion is largely dependent on factors like fuel injection timing, air-fuel ratio, and the quality of the fuel. Improper combustion can lead to incomplete burning, producing excessive smoke, reduced power, and increased emissions.

Q 13. Describe the function of a diesel particulate filter (DPF).

A Diesel Particulate Filter (DPF) is an emission control device designed to trap soot and other particulate matter from the exhaust gases of a diesel engine. These particles are a major source of air pollution, and DPFs significantly reduce their emission. The DPF is essentially a filter made of porous ceramic material with a large surface area, which traps the particles as the exhaust gases flow through it. Over time, the DPF becomes clogged with soot, reducing exhaust flow and engine performance. To regenerate the DPF, the accumulated soot is burned off either passively (through elevated exhaust temperatures during normal operation) or actively (through a controlled process involving fuel injection or other methods).

Think of it as a very advanced air filter for the engine’s exhaust. Regular maintenance and monitoring of the DPF are critical to ensure its proper function and prevent costly replacements or damage to the engine due to blocked exhaust.

Q 14. How do you perform a compression test on a diesel engine?

A compression test measures the pressure inside each cylinder when the piston is at its top dead center (TDC). This test helps diagnose problems related to cylinder leaks, valve issues, piston rings, or head gasket failures. Low compression in one or more cylinders indicates a problem requiring attention.

The procedure typically involves:

- Preparing the engine: Disconnect the battery negative terminal, remove the glow plugs (if applicable), and ensure the engine is cold.

- Connecting the compression tester: Screw the compression tester into the spark plug hole of the cylinder being tested.

- Cranking the engine: Crank the engine for several seconds using the starter motor. The compression tester will display the pressure reading.

- Recording the reading: Note the pressure reading for each cylinder. The readings should be similar across all cylinders. Significant variations indicate potential problems.

- Analyzing results: Compare the results against the manufacturer’s specifications. Low readings in one or more cylinders usually point to internal engine problems.

The specifics of this test can vary depending on engine type and access, but the basic principles remain the same. A thorough compression test is an important part of diagnosing engine performance issues.

Q 15. Explain the different types of diesel engine governors.

Diesel engine governors control the engine’s speed by regulating the fuel supply. Think of it like a cruise control for your car, but for a much more powerful and complex machine. Several types exist, each with its own mechanism:

- Mechanical Governors: These are older, simpler systems using centrifugal weights or flyballs. As engine speed increases, the weights fly outward, acting on a linkage to reduce fuel delivery. They’re robust but less precise than modern systems.

- Hydraulic Governors: These utilize hydraulic pressure to control the fuel rack. They offer smoother control and better responsiveness compared to mechanical governors. Changes in engine speed alter hydraulic pressure, which adjusts the fuel flow.

- Electronic Governors: These are the most advanced, using electronic sensors and a control unit to precisely regulate engine speed. They offer the best accuracy and can incorporate features like speed limiting, load sensing, and electronic diagnostics. They are commonly found in modern diesel engines.

- Pneumatic Governors: Less common now, these systems use compressed air to regulate fuel delivery. They are relatively simple but less responsive than other types.

The choice of governor depends on the engine’s application and required precision. For example, a simple generator might use a mechanical governor, while a high-precision machine in a factory would likely utilize an electronic governor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you adjust the valve clearances in a diesel engine?

Adjusting valve clearances, also known as valve lash, is crucial for maintaining optimal engine performance and preventing damage. Incorrect clearances can lead to poor combustion, reduced power, and even valve damage. The process typically involves:

- Preparation: Consult your engine’s service manual for the correct specifications and procedures. Ensure the engine is cold and safely secured. Gather necessary tools including feeler gauges, wrenches, and possibly a valve spring compressor.

- Access: Remove the valve cover to access the rocker arms or valve adjusters.

- Measurement: Using the appropriate feeler gauge, check the clearance between the valve stem and the rocker arm or adjuster. The manual specifies the required clearance (e.g., 0.2-0.3mm).

- Adjustment: If the clearance is incorrect, adjust it using the adjusting screws or shims as per the engine’s design. This usually involves loosening a locknut, turning the adjusting screw to obtain the correct clearance, then retightening the locknut.

- Verification: Re-check the clearance after adjustment to ensure it’s within the specified range.

- Reassembly: Once all valves are correctly adjusted, reinstall the valve cover and check for leaks.

Incorrect adjustment can lead to burned valves, so accuracy is paramount. If unsure, seek professional assistance.

Q 17. Describe the function of a diesel engine crankshaft.

The crankshaft is the heart of the diesel engine, converting the reciprocating motion of the pistons into rotational motion, which is then used to power various applications. Imagine it as a sophisticated seesaw that rotates. It’s a robust, forged steel component with:

- Crankpins: These connect the connecting rods to the crankshaft, transferring power from the pistons.

- Main Bearings: These support the crankshaft within the engine block, allowing for smooth rotation.

- Counterweights: These help balance the crankshaft, reducing vibration and improving smoothness of operation.

The crankshaft’s design is critical for engine balance and power delivery. Wear or damage to the crankshaft can cause catastrophic engine failure, so regular inspection and maintenance are essential.

Q 18. What are the common causes of diesel engine white smoke?

White smoke from a diesel engine usually indicates unburnt fuel or coolant entering the combustion chamber. Several factors can cause this:

- Injectors: Faulty injectors can lead to incomplete fuel combustion, resulting in white smoke. This could be due to worn-out nozzles, leaks, or incorrect fuel delivery.

- Coolant Leaks: A crack in the cylinder head or head gasket can allow coolant to enter the combustion chamber, leading to white smoke with a sweet smell.

- Worn Piston Rings: Worn piston rings can cause lubricating oil to enter the combustion chamber, producing white smoke.

- Turbocharger Issues: A faulty turbocharger can lead to excessive oil consumption and result in white smoke.

Diagnosing the exact cause requires a thorough inspection of the engine and may involve compression tests, injector testing, and a visual inspection for leaks.

Q 19. How do you troubleshoot a diesel engine with low power?

Low power in a diesel engine can stem from various issues. A systematic approach is needed for effective troubleshooting:

- Fuel System: Check the fuel supply (tank level, fuel lines), fuel filter condition (clogged filter restricts fuel flow), and fuel pump operation. Low fuel pressure is a common cause of low power.

- Air System: Inspect the air filter for restriction. A clogged air filter reduces air intake, leading to incomplete combustion and low power.

- Injection System: Verify injector function. Weak or faulty injectors can severely limit power output.

- Engine Compression: Perform a compression test to assess the health of the cylinders. Low compression indicates potential issues with piston rings, valves, or head gasket.

- Turbocharger: Check for turbocharger boost pressure. A malfunctioning turbocharger can significantly reduce power.

- Governor: Ensure the governor is functioning correctly and is not limiting engine speed.

Remember to consult the engine’s service manual for specific diagnostic procedures and specifications.

Q 20. Explain the function of a diesel engine fuel pump.

The diesel fuel pump is responsible for delivering fuel under high pressure to the engine’s injectors. Think of it as the engine’s heart, ensuring the right amount of fuel reaches the cylinders at the precise moment for combustion. Different types exist:

- In-line Pump: A simpler design, this pump delivers fuel directly to the injectors at a relatively low pressure. Common in older engines.

- Distributor Pump: This type distributes fuel to the injectors at a higher pressure, improving combustion efficiency. Found in many older, larger engines. It times and meters the fuel to each cylinder.

- Common Rail Injection System: This modern system uses a high-pressure pump that supplies fuel to a common rail, which then feeds the injectors. Precise electronic control enables optimal fuel delivery for each injection event. This is very common in modern diesel engines.

Proper pump function is essential for engine power, fuel efficiency, and emissions. Malfunctions can lead to poor starting, rough running, or complete engine failure.

Q 21. What are the common causes of diesel engine overheating?

Diesel engine overheating is a serious problem that can cause significant damage if not addressed promptly. The most common causes include:

- Coolant Leaks: Leaks in the radiator, hoses, water pump, or cylinder head gasket result in insufficient coolant circulation, leading to overheating.

- Faulty Thermostat: A stuck-closed thermostat prevents coolant from circulating, causing the engine to overheat. A stuck-open thermostat can also cause issues, though usually leading to insufficient engine temperature.

- Clogged Radiator: A radiator clogged with debris or scale reduces cooling efficiency.

- Faulty Cooling Fan: A malfunctioning cooling fan (either the clutch or motor) limits the airflow over the radiator.

- Low Coolant Level: Insufficient coolant level restricts heat transfer, leading to overheating.

- Overworking the Engine: Excessive load or prolonged operation under heavy load can cause overheating if the cooling system cannot keep up.

Addressing overheating requires careful diagnosis to identify the root cause. Ignoring overheating can cause serious engine damage, including warped cylinder heads, cracked engine blocks, and blown head gaskets.

Q 22. Describe the procedure for testing a diesel engine glow plug.

Testing a glow plug involves verifying its ability to heat up sufficiently to aid cold-start combustion. A simple, albeit potentially damaging, method involves using a multimeter to check for continuity. A better approach uses a dedicated glow plug tester. These devices accurately measure the resistance and heating capabilities of the plug, providing a reliable indication of its health.

- Visual Inspection: Begin by visually inspecting the glow plug for physical damage like cracks or corrosion. A damaged plug will likely fail the test.

- Resistance Test: Using a multimeter, set it to the ohms setting and carefully touch the probes to the terminals of the glow plug. The resistance value should fall within the manufacturer’s specifications, typically between 0.5 and 3 ohms. A reading outside this range, an open circuit (infinite resistance), or a short circuit (near zero resistance) indicates a faulty glow plug.

- Glow Plug Tester: This is the most accurate method. These tools directly simulate the engine’s electrical environment and measure the glow plug’s heating performance, providing more conclusive results than simple resistance checks. They’ll often indicate whether the glow plug heats to the required temperature within a specified time.

Example: Imagine a reading of 10 ohms. This is significantly higher than expected and points to a faulty glow plug, requiring replacement. If you find a shorted glow plug (near zero resistance), this could indicate internal damage and potential engine damage if left in place.

Q 23. How do you diagnose a faulty diesel engine starter motor?

Diagnosing a faulty diesel engine starter motor requires a systematic approach, eliminating possibilities one by one. It often begins with checking the most likely culprits – the battery, connections, and the starter motor itself.

- Battery Voltage Check: Start by checking the battery voltage. A low voltage can prevent the starter from cranking effectively. Use a multimeter to check the voltage across the battery terminals; it should read around 12.6 volts for a fully charged 12V battery.

- Cable and Connection Inspection: Inspect the battery cables for corrosion or loose connections. Tighten any loose connections and clean corroded terminals. Test the continuity of the cables using a multimeter.

- Starter Motor Testing (In-situ): With the ignition off, use a heavy-duty cable jumper to connect the positive terminal of the battery directly to the positive terminal of the starter motor. Have an assistant turn the ignition key to the start position. If the starter motor cranks, the fault likely lies in the wiring or ignition switch. If not, the starter motor may be defective.

- Starter Motor Testing (Removal and bench testing): Removing the starter motor and bench testing it with a 12V power supply provides a definitive diagnosis. It can be tested for amperage draw, ensuring it’s within the manufacturer’s specifications.

Example: If the battery voltage is low, charging the battery will solve the problem. If the starter only clicks when the key is turned, this may indicate a low battery voltage, a faulty solenoid, or even a problem with the gear engagement mechanism.

Q 24. Explain the principles of diesel engine emissions control.

Diesel engine emissions control focuses on reducing harmful pollutants like particulate matter (PM), nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO). It uses a combination of technologies to achieve this.

- Exhaust Gas Recirculation (EGR): Reduces NOx emissions by recirculating a portion of the exhaust gas back into the combustion chamber, lowering combustion temperatures.

- Diesel Oxidation Catalysts (DOCs): Oxidize HC and CO into less harmful CO2 and water.

- Diesel Particulate Filters (DPFs): Trap PM, reducing particulate matter emissions.

- Selective Catalytic Reduction (SCR): Injects a reducing agent (urea/AdBlue) into the exhaust stream to convert NOx into harmless nitrogen and water.

- Exhaust Gas Temperature (EGT) Sensors and other sensors: These are crucial to monitoring and controlling the emissions system effectively.

Example: DPFs require periodic regeneration (cleaning) to prevent clogging. Failure to regenerate can lead to increased backpressure and reduced engine performance. SCR systems require regular AdBlue replenishment; running the system low on AdBlue can damage the catalyst.

Q 25. Describe the function of a diesel engine EGR system.

The EGR system recirculates a portion of the exhaust gas back into the engine’s intake manifold. This lowers the combustion temperature, significantly reducing the formation of NOx (nitrogen oxides), a major contributor to air pollution.

The amount of EGR is carefully controlled by an EGR valve and regulated by the engine’s control module (ECM) based on engine load, speed, and other factors. The cooler temperatures achieved by EGR also improve engine efficiency and durability but increase the risk of soot buildup which should be monitored.

Example: A faulty EGR valve that’s stuck open can lead to rough running, poor fuel economy, and increased emissions. A stuck-closed EGR valve might lead to NOx emissions exceeding allowable limits.

Q 26. How do you perform a leak-down test on a diesel engine?

A leak-down test measures the amount of compressed air that escapes past the piston rings, valves, or cylinder head gasket during the compression stroke. This helps diagnose the source of compression loss and assess the cylinder’s condition.

- Preparation: Disconnect the glow plugs and fuel injectors. Remove the spark plugs (if applicable). Rotate the engine to top dead center (TDC) on the compression stroke of the cylinder under test.

- Connecting the Tester: Connect the leak-down tester adapter to the cylinder’s spark plug hole (or glow plug hole). Apply compressed air to the tester at the specified pressure (typically around 100 PSI).

- Leak Detection: Listen for air escaping. Feel for air leaking past the piston rings (crankcase), the valves (intake/exhaust), or the cylinder head gasket (between the cylinder head and block). Use a leak-down tester with a pressure gauge to measure the pressure drop over time, indicating the severity of leaks.

- Results Interpretation: A small amount of leakage is normal, but high leakage indicates worn piston rings, faulty valves, or a blown head gasket.

Example: Significant air escaping from the crankcase suggests worn piston rings. Air leaking from the exhaust valve indicates a problem with the exhaust valve or its seating.

Q 27. What are the safety regulations for working with diesel fuel?

Safety regulations for working with diesel fuel are paramount to prevent fire hazards, inhalation of fumes, and environmental damage. Key aspects include:

- Proper Storage: Diesel fuel should be stored in approved containers, away from ignition sources, in a well-ventilated area.

- Spill Prevention and Cleanup: Implement measures to prevent spills, and have appropriate spill cleanup materials readily available. Absorbent materials like spill pads are essential for containing spills.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, eye protection, and respiratory protection, especially when handling large quantities or in poorly ventilated areas.

- No Smoking: Strictly prohibit smoking in areas where diesel fuel is handled or stored.

- Ventilation: Ensure adequate ventilation to prevent the buildup of flammable vapors.

- Disposal: Dispose of used diesel fuel and contaminated materials according to local regulations and guidelines.

- Fire Safety: Have fire extinguishers readily available and know how to use them. Understand the fire hazards associated with diesel fuel and its vapors.

Example: A spill could lead to a fire if an ignition source is present. Inhaling diesel fumes can cause respiratory problems. Improper disposal contaminates the environment.

Q 28. Explain the importance of regular diesel engine maintenance.

Regular diesel engine maintenance is critical for ensuring optimal performance, extending engine life, improving fuel economy, and minimizing emissions. Neglecting maintenance can lead to costly repairs and unexpected downtime.

- Oil Changes: Regular oil changes with the correct grade and amount of oil are vital to lubricate engine components and remove contaminants.

- Fuel Filter Changes: Contaminated fuel can damage injectors and other components. Regular fuel filter replacement ensures clean fuel reaches the engine.

- Air Filter Changes: A clogged air filter restricts airflow, reducing engine power and increasing emissions. Regular replacement is essential.

- Coolant System Maintenance: Regular checks of coolant level and condition (testing freeze point) are important to prevent overheating and corrosion.

- Belt and Hose Inspections: Regularly inspect belts and hoses for wear and tear. Replace any damaged components to prevent failure.

- Component Inspections: Regular inspections of critical components such as injectors, glow plugs, and turbochargers are essential for early detection of potential problems.

Example: Ignoring an oil change can lead to engine seizure due to lack of lubrication. A clogged air filter can lead to poor engine performance and increased fuel consumption.

Key Topics to Learn for Your Diesel Engine Operation and Maintenance Interview

- Engine Fundamentals: Understanding four-stroke and two-stroke cycles, combustion processes, and the role of various engine components (fuel injection system, lubrication system, cooling system, etc.). Prepare to discuss the theoretical principles behind each system.

- Practical Diagnostics and Troubleshooting: Be ready to explain how you’d approach diagnosing common engine malfunctions, using diagnostic tools, and interpreting engine performance data. Consider discussing real-world scenarios and how you’d systematically identify and resolve problems.

- Maintenance Procedures: Detail your knowledge of preventative maintenance schedules, routine inspections, and repair procedures. Showcase your understanding of safety protocols and best practices in a maintenance environment.

- Fuel Systems: Deepen your understanding of fuel injection systems, fuel filters, and fuel delivery mechanisms. Be prepared to discuss common fuel-related issues and their solutions.

- Lubrication Systems: Explain the importance of proper lubrication, different types of engine oils, and how to monitor oil condition. Discuss the consequences of improper lubrication.

- Emission Control Systems: Understand the principles and operation of various emission control technologies (e.g., EGR, DPF, SCR). Be ready to discuss their maintenance requirements and troubleshooting.

- Safety and Regulations: Demonstrate awareness of relevant safety regulations and procedures associated with diesel engine operation and maintenance. This includes personal protective equipment (PPE) and safe work practices.

- Advanced Diagnostics and Data Analysis: Explore your understanding of advanced diagnostic tools and techniques, such as using engine diagnostic software to interpret fault codes and analyze performance data. Discuss how this data informs maintenance decisions.

Next Steps

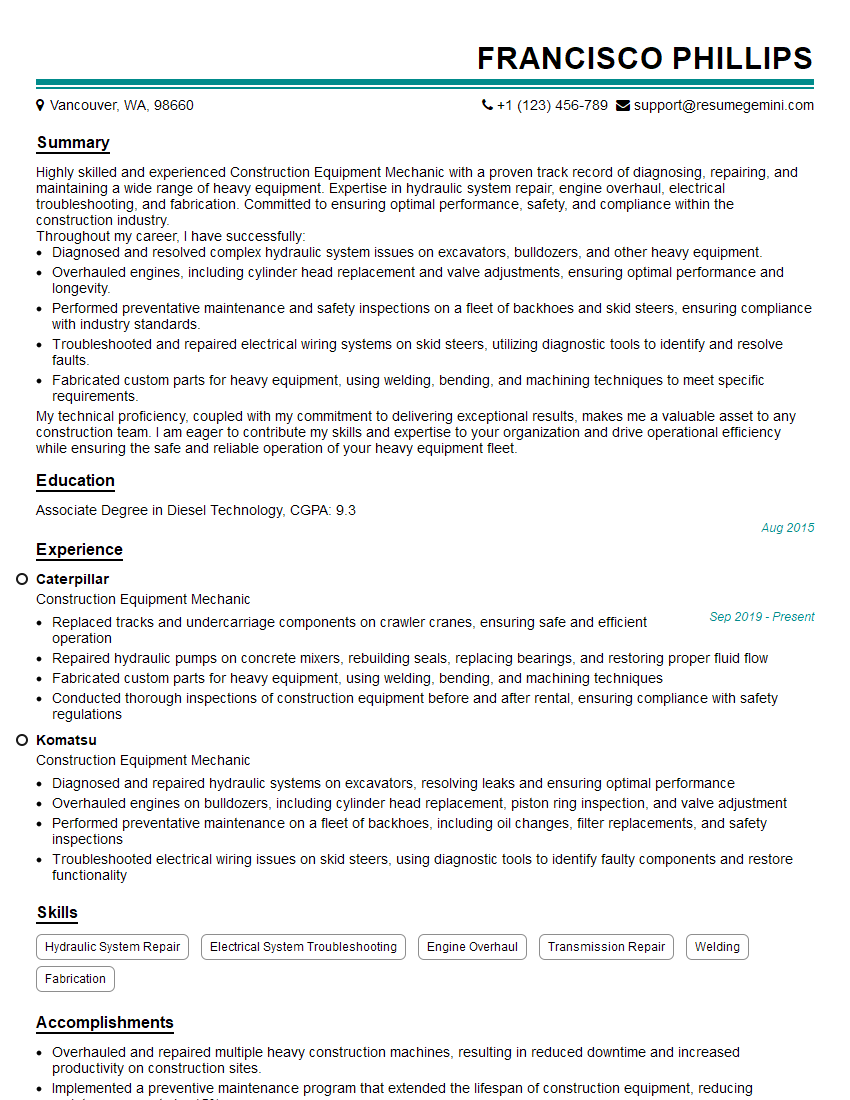

Mastering Diesel Engine Operation and Maintenance opens doors to exciting career opportunities with significant growth potential. A strong foundation in these skills is highly sought after in various industries. To maximize your chances of landing your dream job, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to highlight your expertise. We provide examples of resumes specifically designed for Diesel Engine Operation and Maintenance professionals to help you showcase your skills effectively. Invest time in creating a strong resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO