Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Disinfection Procedures interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Disinfection Procedures Interview

Q 1. Explain the difference between sterilization, disinfection, and sanitization.

Sterilization, disinfection, and sanitization are all methods of reducing microbial contamination, but they differ significantly in their level of effectiveness and target outcome.

- Sterilization is the complete elimination or destruction of all forms of microbial life, including bacteria, viruses, fungi, and spores. Think of it as achieving absolute cleanliness at a microscopic level. This is often achieved through methods like autoclaving (using high-pressure steam) or using certain chemical sterilants like ethylene oxide.

- Disinfection reduces the number of microbial contaminants to a safe level, but it doesn’t necessarily eliminate all microorganisms. It targets pathogenic (disease-causing) organisms. Think of disinfecting a countertop after preparing raw chicken – you’re aiming to significantly lower the risk of contamination, but not necessarily eliminating every single bacterium.

- Sanitization reduces the microbial load to a level deemed safe by public health standards. This is often a lower level of reduction than disinfection, and is usually performed through cleaning with detergents followed by a low-level disinfectant. For example, sanitizing dishes in a restaurant involves washing them thoroughly and then using a sanitizing rinse.

In essence: Sterilization is the most rigorous, followed by disinfection, and then sanitization.

Q 2. Describe the various methods of disinfection (e.g., chemical, physical).

Disinfection methods can be broadly categorized into chemical and physical methods:

- Chemical Disinfection: This involves using chemical agents to kill or inhibit the growth of microorganisms. Examples include:

- Alcohols (e.g., ethanol, isopropanol): Effective against bacteria and some viruses, but not spores.

- Aldehydes (e.g., formaldehyde, glutaraldehyde): Powerful broad-spectrum disinfectants, effective against a wide range of microorganisms, including spores. However, they are often toxic and require careful handling.

- Chlorine compounds (e.g., bleach): Widely used, inexpensive disinfectants effective against bacteria and viruses, but their effectiveness can be reduced by organic matter.

- Quaternary ammonium compounds (quats): Commonly used in household cleaners and disinfectants, effective against many bacteria and fungi, but less effective against viruses and spores.

- Hydrogen peroxide: Effective against a broad range of microorganisms, including spores. It’s a good choice for environmentally friendly disinfection.

- Physical Disinfection: These methods use physical agents to control microbial growth.

- Heat: Boiling, pasteurization (heating to a specific temperature for a set time), and autoclaving (high-pressure steam) are all effective methods, with autoclaving being the most effective for sterilization.

- Radiation: Ultraviolet (UV) radiation can be used to disinfect surfaces by damaging the DNA of microorganisms. It’s often used in air and water purification systems.

- Filtration: Physical removal of microorganisms from liquids or gases using filters with specific pore sizes. This is commonly used in the pharmaceutical and medical industries.

Q 3. What are the factors influencing the efficacy of a disinfectant?

The efficacy of a disinfectant is influenced by several factors:

- Concentration of the disinfectant: Higher concentrations generally lead to increased efficacy, but this needs to be balanced against safety concerns. Too high of a concentration can be dangerous.

- Contact time: The disinfectant needs sufficient time to act on the microorganisms. Longer contact times generally result in better kill rates. (This is detailed further in question 5)

- Temperature: Higher temperatures often enhance the activity of disinfectants.

- pH: The acidity or alkalinity of the environment can affect the effectiveness of some disinfectants.

- Presence of organic matter: Organic materials (e.g., blood, feces) can interfere with the action of disinfectants and reduce their effectiveness. Thorough cleaning before disinfection is crucial.

- Type and number of microorganisms: Spores are more resistant than vegetative bacteria, and viruses can have varying susceptibilities to disinfectants.

- Surface type: Porous surfaces are more difficult to disinfect than smooth, non-porous surfaces.

Q 4. How do you determine the appropriate disinfectant for a specific surface or situation?

Selecting the appropriate disinfectant requires careful consideration of several factors:

- Target microorganisms: Identify the types of microorganisms you need to control (e.g., bacteria, viruses, fungi, spores). This will determine the type of disinfectant needed. A broad-spectrum disinfectant might be suitable for high-risk areas.

- Surface type: Some disinfectants can damage certain surfaces. For example, bleach can corrode certain metals. Consult the disinfectant’s label for compatibility information.

- Environmental conditions: Temperature and pH can affect the disinfectant’s efficacy. Select a disinfectant that performs optimally under the given conditions.

- Safety concerns: Consider the toxicity of the disinfectant and the safety precautions required for its use. Less toxic options should be prioritized where feasible.

- Regulatory requirements: Follow all relevant regulations and guidelines for the use of disinfectants in your specific setting (e.g., healthcare, food processing).

Often, a combination of cleaning and disinfection is necessary for optimal microbial control. Cleaning removes organic matter, which improves disinfectant efficacy.

Q 5. Explain the concept of contact time in disinfection.

Contact time refers to the length of time a disinfectant must remain in contact with a surface or object to achieve its desired level of disinfection. It’s crucial for effective microbial kill. It’s not simply spraying and wiping immediately; the disinfectant needs time to work. The required contact time is specified by the manufacturer on the product label and varies depending on the specific disinfectant and the target microorganisms. For instance, a disinfectant might require a 10-minute contact time to effectively kill Salmonella bacteria.

Insufficient contact time can lead to incomplete disinfection and potentially increased infection risk. Always follow the manufacturer’s instructions meticulously, ensuring surfaces remain wet with the disinfectant solution for the entire specified contact time.

Q 6. What are the safety precautions to follow when handling disinfectants?

Safety precautions when handling disinfectants are paramount:

- Always read and follow the manufacturer’s instructions carefully. This includes information on dilution, application, contact time, and safety precautions.

- Wear appropriate personal protective equipment (PPE). This may include gloves, eye protection, and a respirator, depending on the disinfectant and the situation.

- Work in a well-ventilated area. Many disinfectants release fumes that can be irritating or harmful if inhaled.

- Avoid skin contact. Wash hands thoroughly with soap and water after handling disinfectants.

- Store disinfectants properly. Keep them in their original containers, out of reach of children and pets, and away from food and drinks. Label containers clearly.

- Dispose of used disinfectants and contaminated materials appropriately. Follow local regulations for the disposal of hazardous waste.

- Be aware of any potential health effects. Some disinfectants can cause skin irritation, respiratory problems, or other health issues. If you experience any adverse effects, seek medical attention immediately.

Q 7. How do you ensure proper dilution of disinfectants?

Accurate dilution of disinfectants is essential for both effectiveness and safety. Using too little disinfectant will be ineffective, while using too much can be wasteful, corrosive, or harmful. Here’s how to ensure proper dilution:

- Use appropriate measuring devices. Use graduated cylinders, pipettes, or other accurate measuring tools, rather than eyeballing it. Inaccurate measurements can significantly impact disinfection efficacy.

- Follow the manufacturer’s instructions precisely. The recommended dilution ratio is usually specified on the product label. This ratio is often expressed as a concentration, e.g.,

1:10dilution (1 part disinfectant to 10 parts water). - Use clean, pre-measured containers. Use clean containers to avoid cross-contamination. Pre-measure the water first, then add the disinfectant to the water, stirring gently to ensure proper mixing. Never add water to the disinfectant, as this can cause splashing and potentially harmful exposure.

- Label containers clearly. Indicate the disinfectant used, the dilution ratio, the date of preparation, and the expiration date (if applicable). This prevents confusion and ensures the solution remains correctly identified throughout its use.

- Regularly check the concentration of disinfectant solutions. Especially for solutions that are stored for extended periods. Many solutions lose their potency over time. If in doubt, discard and prepare fresh solution.

Q 8. Describe the process of cleaning and disinfecting a contaminated surface.

Cleaning and disinfecting a contaminated surface is a two-step process crucial for preventing the spread of infectious agents. Think of it like this: cleaning removes visible dirt and grime, while disinfection targets and kills invisible microorganisms.

- Cleaning: First, physically remove visible soil, debris, and organic matter from the surface using soap and water or a detergent solution. This is done using appropriate cleaning tools like mops, brushes, or cloths, ensuring thorough removal of contaminants. For example, wiping down a countertop with soapy water before disinfecting removes food particles that could shield bacteria from the disinfectant.

- Disinfection: After cleaning, apply an appropriate disinfectant to the surface, following the manufacturer’s instructions carefully. This usually involves a contact time – the period the disinfectant needs to remain wet on the surface to effectively kill microorganisms. For example, a diluted bleach solution might need a 10-minute contact time. The choice of disinfectant depends on the type of microorganisms involved and the surface being treated. For instance, a phenolic disinfectant might be suitable for hard surfaces in a hospital setting, whereas an alcohol-based disinfectant might be preferred for smaller equipment.

Thorough rinsing with clean water might be necessary after disinfection depending on the type of disinfectant used to prevent residue buildup.

Q 9. What are the indicators of effective disinfection?

Indicators of effective disinfection aren’t always immediately visible but require a multifaceted approach. They include:

- Reduced microbial counts: This is best confirmed through microbiological testing, where samples are taken before and after disinfection and analyzed to determine the reduction in microbial load. A significant decrease indicates effective disinfection.

- Absence of visible contamination: While not definitive, the absence of visible organic matter after cleaning and the lack of signs of microbial growth (e.g., mold, discoloration) suggest a successful procedure.

- Confirmation of disinfectant efficacy: Using approved disinfectants with known effectiveness against target microorganisms provides a reasonable assurance of successful disinfection. Always check the disinfectant’s label for its claimed activity against specific pathogens.

- Proper application procedure: Following the manufacturer’s instructions carefully ensures the disinfectant is used at the correct concentration and contact time. Improper application directly impacts effectiveness.

It’s important to remember that visible cleanliness doesn’t guarantee disinfection; microscopic organisms might still remain.

Q 10. How do you monitor and evaluate the effectiveness of disinfection protocols?

Monitoring and evaluating disinfection protocols is essential for ensuring their efficacy and protecting against outbreaks. This involves:

- Regular environmental monitoring: Swabbing and culturing surfaces to check for the presence of microorganisms. This helps identify areas needing improved cleaning and disinfection practices.

- Performance indicators: Tracking factors like the number of disinfection incidents, the time taken for disinfection, and the consumption of disinfectants. Anomalies could point to inefficiencies or inadequacies in the protocol.

- Staff training and competency assessment: Regular training and competency assessments ensure that staff understand and correctly implement disinfection protocols. This includes practical demonstrations and assessments.

- Use of standardized methods: Employing standardized methods for sampling, testing, and data analysis allows for consistent and comparable results over time and between different locations.

- Regular reviews and updates: Disinfection protocols should be regularly reviewed and updated based on the results of monitoring, changes in infection rates, and the emergence of new pathogens.

By employing this systematic approach, institutions can identify areas for improvement and ensure the ongoing effectiveness of their disinfection strategies.

Q 11. What is the role of personal protective equipment (PPE) in disinfection procedures?

Personal Protective Equipment (PPE) is crucial in disinfection procedures to safeguard personnel from exposure to hazardous chemicals and infectious agents. The type of PPE used depends on the specific task and the substances involved. Common PPE includes:

- Gloves: Protect hands from contact with disinfectants, contaminated surfaces, and infectious materials. Choose gloves appropriate for the chemical compatibility of the disinfectant.

- Gowns or aprons: Protect clothing and skin from splashes and spills of disinfectants or infectious materials.

- Eye protection: Goggles or face shields protect eyes from splashes and fumes of disinfectants.

- Respiratory protection: Masks or respirators are necessary when handling highly concentrated disinfectants or materials that could generate airborne particles.

Proper PPE selection and use are non-negotiable to minimize the risks associated with disinfection procedures.

Q 12. Explain the proper disposal of contaminated materials and used disinfectants.

Safe disposal of contaminated materials and used disinfectants is vital for environmental protection and public health. Procedures vary depending on local regulations and the nature of the waste. In general:

- Contaminated materials: Materials like swabs, disposable wipes, and other items that came into contact with infectious materials should be disposed of in designated biohazard waste containers. These containers are typically color-coded (usually red) and sealed before disposal.

- Used disinfectants: Used disinfectants must be handled according to the manufacturer’s instructions and local regulations. Some disinfectants may require neutralization before disposal, while others can be diluted and disposed of through sanitary sewers. Always check the safety data sheet (SDS) for specific guidelines.

- Sharps disposal: Needles, syringes, and other sharps must be disposed of in puncture-resistant containers to prevent injuries.

Proper labelling and documentation are crucial for tracking and managing waste disposal. Always follow established protocols for handling hazardous materials.

Q 13. What are the common types of microorganisms encountered in disinfection procedures?

Disinfection procedures target a variety of microorganisms, including:

- Bacteria: Single-celled organisms that can cause a wide range of infections, including Staphylococcus aureus, Escherichia coli, and Pseudomonas aeruginosa.

- Viruses: Submicroscopic infectious agents that require a host cell to replicate, such as influenza viruses, noroviruses, and coronaviruses.

- Fungi: Eukaryotic organisms including yeasts and molds, some of which can cause serious infections like candidiasis (yeast infection) or aspergillosis (mold infection).

- Protozoa: Single-celled eukaryotic organisms that can cause diseases like malaria, amoebiasis, and giardiasis.

The choice of disinfectant will depend on its effectiveness against the specific types of microorganisms expected in a particular environment.

Q 14. How do you handle spills of infectious materials?

Handling spills of infectious materials requires immediate action to minimize risk and prevent contamination. Follow these steps:

- Isolate the area: Restrict access to the spill area to prevent further contamination.

- Don appropriate PPE: Wear gloves, gown, eye protection, and potentially a respirator, depending on the nature of the spill.

- Absorb the spill: Use absorbent materials like paper towels or spill pads to absorb the spill. Avoid spreading the material.

- Clean and disinfect the area: Thoroughly clean the area with soap and water, followed by an appropriate disinfectant, paying attention to the manufacturer’s instructions for contact time.

- Dispose of contaminated materials: Dispose of all contaminated materials, including absorbent materials and PPE, in appropriate biohazard waste containers.

- Report the incident: Report the spill to the appropriate personnel and document the incident for record-keeping purposes.

The specific procedures will vary depending on the type of infectious material spilled. Always consult safety data sheets and relevant institutional protocols.

Q 15. Describe your experience with different types of disinfectants (e.g., chlorine bleach, quaternary ammonium compounds).

My experience encompasses a wide range of disinfectants, each with its strengths and weaknesses. Chlorine bleach, for instance, is a powerful broad-spectrum disinfectant effective against many bacteria and viruses. However, it’s corrosive, unstable in sunlight, and can damage certain surfaces. Its efficacy is also highly dependent on concentration and contact time. I’ve extensively used it in various settings, always following strict safety protocols and ensuring proper dilution. Quaternary ammonium compounds (quats) offer a different profile. They’re generally less corrosive than bleach and have a longer shelf life, making them suitable for routine disinfection of many surfaces. However, they are less effective against certain viruses and spores. My experience includes evaluating the effectiveness of different quats, considering factors like concentration, contact time, and the presence of organic matter which can significantly reduce their efficacy. I’ve also worked with other disinfectants, such as alcohols (isopropanol, ethanol), hydrogen peroxide, and glutaraldehyde, each chosen based on the specific application and the target microorganisms. Understanding the specific properties of each disinfectant is crucial for safe and effective use.

Career Expert Tips:

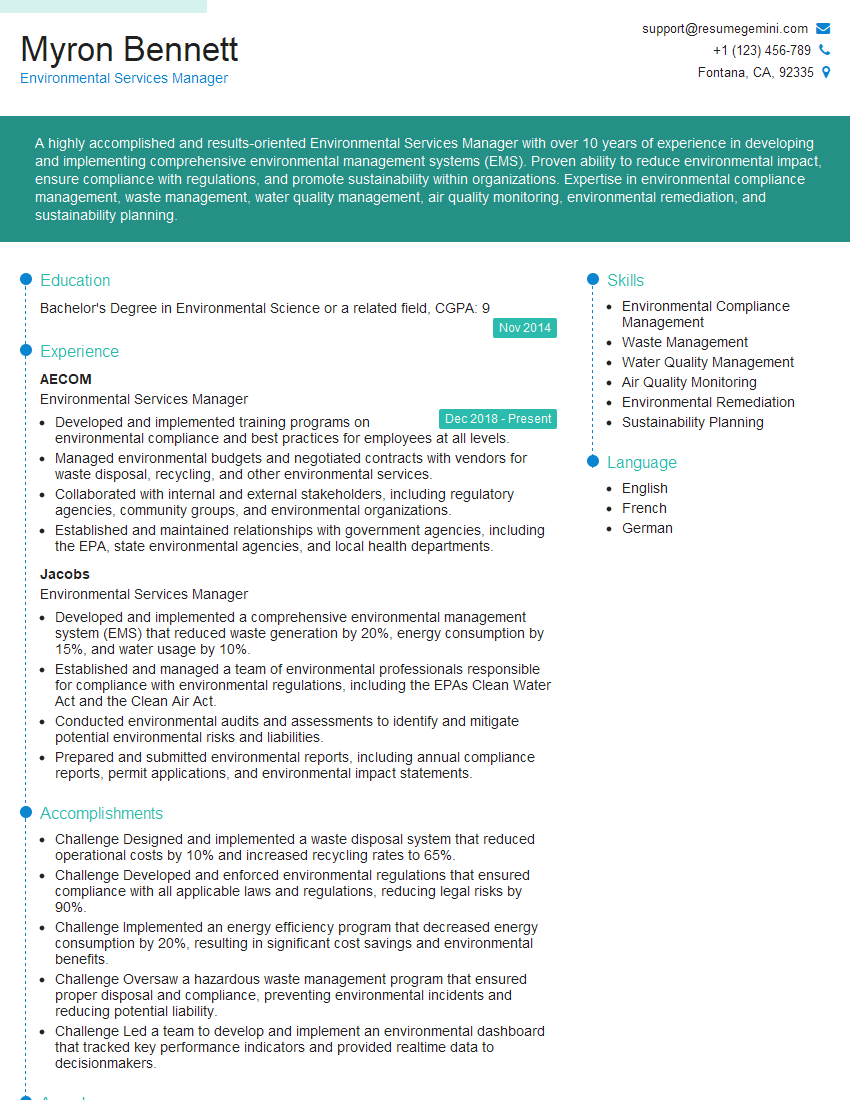

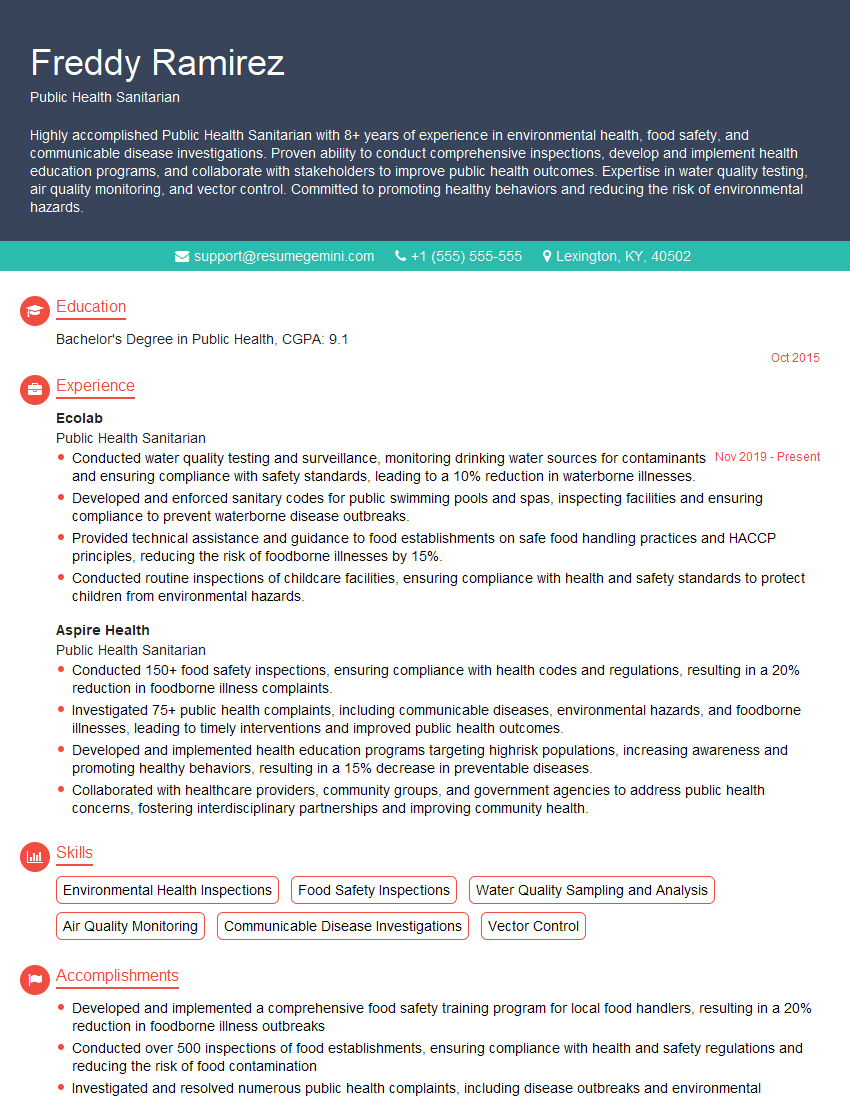

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the regulatory requirements and guidelines for disinfection in your field?

Regulatory requirements and guidelines for disinfection vary depending on the specific setting and the type of microorganisms being addressed. In healthcare settings, for example, adherence to guidelines from organizations like the CDC (Centers for Disease Control and Prevention) and OSHA (Occupational Safety and Health Administration) is paramount. These guidelines outline specific procedures for disinfecting surfaces, equipment, and instruments, often specifying required contact times and concentrations of disinfectants. Similarly, food processing facilities are subject to stringent regulations from agencies like the FDA (Food and Drug Administration) focusing on preventing cross-contamination and ensuring food safety. These regulations often mandate specific disinfection protocols and the regular testing of disinfectant efficacy. In all cases, meticulous record-keeping and employee training are critical components of compliance. Failure to adhere to these guidelines can lead to serious consequences, including outbreaks of infections, product recalls, and legal penalties.

Q 17. How do you document and record disinfection procedures?

Documentation is the cornerstone of effective disinfection. We use a combination of methods to ensure complete and accurate records. This typically involves detailed checklists for each disinfection procedure, including the date, time, area disinfected, disinfectant used, concentration, contact time, and the initials of the person performing the disinfection. These checklists are then filed and stored according to established protocols. For high-level disinfection or sterilization procedures, more comprehensive documentation is required, often including equipment validation and biological indicator results. Digital record-keeping systems can also be very useful for tracking disinfection procedures, allowing for easier data analysis and reporting. Regular audits and inspections verify the accuracy and completeness of the records and ensure adherence to the established procedures. In short, thorough documentation serves as both a record of compliance and a valuable tool for identifying areas needing improvement in our disinfection processes.

Q 18. What are the potential hazards associated with improper disinfection procedures?

Improper disinfection procedures can lead to a range of hazards, most significantly the spread of infections. Insufficient contact time or incorrect dilution of disinfectants can leave surfaces contaminated, allowing pathogens to persist and potentially infect individuals. Using incompatible disinfectants, or mixing them incorrectly, can create toxic byproducts, posing risks to both personnel and the environment. Improper handling of disinfectants, such as ignoring safety data sheets (SDS), can also lead to accidental exposure, resulting in skin irritation, respiratory problems, or even more severe health consequences. Damage to equipment or surfaces due to the corrosive nature of some disinfectants is another potential problem. Finally, inadequate training and a lack of proper protocols increase the likelihood of errors and accidents, compounding the risks associated with ineffective or unsafe disinfection.

Q 19. How do you address resistance to disinfectants?

Addressing disinfectant resistance requires a multifaceted approach. One key strategy is to rotate different types of disinfectants to prevent the development of resistance in microbial populations. This approach works on the principle that microorganisms may develop resistance to one type of disinfectant but not others. Regular environmental monitoring is crucial for identifying the types and levels of microbial contamination, informing the selection of appropriate disinfectants and strategies. Proper cleaning before disinfection is critical; organic matter can interfere with disinfectant action and allow microorganisms to survive. Using disinfectants at the correct concentration and for the recommended contact time is also essential. Finally, implementing strict infection control practices, such as hand hygiene and proper waste disposal, can help to reduce the overall microbial load and minimize the need for relying heavily on disinfectants. A combination of these strategies can help to mitigate the development and spread of disinfectant-resistant microorganisms.

Q 20. Describe your experience with high-level disinfection procedures.

High-level disinfection is crucial for items that come into contact with mucous membranes or non-intact skin but don’t require sterilization. My experience involves working with processes using chemicals like glutaraldehyde or peracetic acid, following strict protocols and safety precautions. This includes preparing the solutions according to manufacturer instructions, ensuring adequate immersion time for the items to be disinfected, and carefully neutralizing the disinfectant after the process, if required. Thorough rinsing is also essential to remove any residual disinfectant. We meticulously document each high-level disinfection cycle, including the specific chemical used, concentration, immersion time, and the results of any efficacy testing conducted. Proper handling and disposal of the used chemicals are also critical to ensure environmental and personal safety. This careful approach ensures items are effectively disinfected while mitigating any risks associated with the use of these powerful chemicals. Regular equipment maintenance and calibration are important aspects of maintaining the reliability and safety of high-level disinfection processes.

Q 21. Explain the importance of hand hygiene in infection control.

Hand hygiene is the single most important infection control measure. Hands are the primary vectors for transmitting pathogens. Effective hand hygiene significantly reduces the spread of infections by removing transient microorganisms (those acquired from contact with contaminated surfaces) and reducing the resident flora (microorganisms normally found on the skin). The proper technique involves washing hands with soap and water for at least 20 seconds, paying attention to all surfaces, including between fingers and under nails. When soap and water aren’t available, alcohol-based hand rubs are a highly effective alternative. Frequent handwashing, particularly after contact with potentially contaminated surfaces or individuals, drastically reduces the risk of infection transmission, protecting both healthcare workers and patients. Regular training and consistent reinforcement of proper hand hygiene techniques are essential for maintaining high levels of infection control in any setting.

Q 22. How do you verify the efficacy of sterilization equipment?

Verifying the efficacy of sterilization equipment is crucial to ensuring patient safety and preventing infections. We employ a multi-pronged approach, combining regular maintenance and testing with biological and chemical indicators.

Biological Indicators (BIs): These are spore-containing strips that are placed within the sterilizer during each cycle. Spores, like those of Geobacillus stearothermophilus for steam sterilization, are highly resistant to heat. After the cycle, the strips are cultured to confirm whether all spores have been killed. A negative result confirms successful sterilization. Failure indicates a problem with the sterilizer’s parameters, requiring investigation and correction before further use.

Chemical Indicators (CIs): CIs change color when exposed to specific sterilization parameters, such as temperature and time. These are simpler and less expensive than BIs, offering a visual check that the sterilizer has reached the required conditions. While useful for monitoring parameters, they don’t confirm sterilization efficacy as effectively as BIs. Different types of CIs exist for different sterilization methods, providing specific feedback on that method’s effectiveness.

Regular Maintenance and Calibration: Sterilizers require regular maintenance, including cleaning, checks of seals, and calibration of temperature and pressure gauges (for autoclaves). These measures ensure the equipment is functioning optimally and consistently achieving the required sterilization parameters.

For example, in a hospital setting, we’d use both BIs and CIs routinely in autoclave cycles and regularly calibrate and maintain equipment according to manufacturer’s instructions and best practice guidelines, creating detailed records to meet regulatory requirements and demonstrate compliance.

Q 23. What are the key principles of a successful infection control program?

A successful infection control program hinges on several key principles, all working in concert to minimize the risk of infection transmission.

- Surveillance and Monitoring: Continuously tracking infection rates, identifying patterns, and investigating outbreaks are essential. This allows for proactive interventions and evaluation of current control strategies.

- Standard Precautions: These encompass basic hygiene practices like hand hygiene, appropriate use of personal protective equipment (PPE), safe injection practices, and proper waste disposal. They apply to all patients, regardless of infection status.

- Transmission-Based Precautions: These are implemented in addition to standard precautions when specific infectious agents are identified or suspected. They vary depending on the mode of transmission (airborne, droplet, contact), ensuring appropriate isolation and environmental controls.

- Environmental Cleaning and Disinfection: Regular and thorough cleaning and disinfection of all surfaces and equipment reduces the microbial load and minimizes the potential for spread.

- Education and Training: Healthcare professionals require regular training on infection control principles and practices. This is paramount in establishing a culture of safety and compliance.

- Policy and Procedure Development: Having well-defined policies and procedures ensures consistency in infection control practices, ensuring everyone understands the protocols and how to implement them effectively.

Imagine a hospital implementing a new protocol for hand hygiene. Careful monitoring of infection rates after the change reveals a decrease, illustrating the program’s success. This approach shows the importance of measuring effectiveness and continuously improving the program based on the data gathered.

Q 24. What is your experience with different types of sterilization methods (e.g., autoclaving, ethylene oxide)?

My experience encompasses a broad range of sterilization methods, each with its own strengths and limitations.

- Autoclaving (Steam Sterilization): This is the most widely used method, employing high-pressure saturated steam to kill microorganisms. It’s effective for a wide range of materials and is relatively quick and cost-effective. However, it’s unsuitable for heat-sensitive items. I’ve extensively used autoclaves in various settings, from hospital operating rooms to research laboratories, adhering to rigorous quality control measures such as BI testing and maintenance logs.

- Ethylene Oxide (EtO) Sterilization: EtO is a gas sterilant used for heat-sensitive medical devices. It’s effective but requires a specialized chamber and careful handling due to its toxicity. EtO sterilization demands strict adherence to safety protocols including ventilation and personnel protection. I’ve been involved in EtO sterilization procedures, carefully following established protocols and regulations to minimize exposure risks and environmental impact.

- Other Methods: I am also familiar with other methods like dry heat sterilization, hydrogen peroxide plasma sterilization, and low-temperature sterilization using gases like formaldehyde. Each method has specific applications based on the materials and risks involved. The choice of method always depends on the type of instrument or equipment, its heat sensitivity, and the level of microbial load expected.

For example, delicate surgical instruments often require EtO sterilization due to their sensitivity to heat and moisture, whereas reusable surgical equipment may be effectively processed through steam sterilization using an autoclave. Selection is based on a thorough risk assessment.

Q 25. How do you manage and prevent the spread of healthcare-associated infections?

Managing and preventing the spread of healthcare-associated infections (HAIs) requires a multi-faceted approach, focusing on both patient care and environmental control.

- Strict adherence to Standard and Transmission-Based Precautions: As mentioned earlier, this is fundamental to reducing the risk of transmission.

- Rapid Identification and Isolation of Infected Patients: Implementing effective infection surveillance systems is crucial for early detection and isolation, preventing further spread.

- Environmental Cleaning and Disinfection: Thorough cleaning and disinfection of patient rooms, equipment, and high-touch surfaces are critical for controlling the spread of pathogens.

- Effective Hand Hygiene: Proper hand hygiene remains the single most important factor in preventing HAIs. This involves consistent use of alcohol-based hand rubs and handwashing with soap and water.

- Appropriate Use of PPE: Appropriate PPE should be worn when there is a risk of exposure to infectious agents.

- Proper Waste Disposal: Appropriate disposal of medical waste prevents further spread of pathogens.

- Continuous Monitoring and Improvement: Regular monitoring of HAI rates and feedback loops allow for continual evaluation and improvement of control strategies.

For example, a surge in a specific HAI in a specific hospital ward triggers an immediate investigation. This might involve enhanced cleaning protocols, revised patient placement strategies, and updated infection control education for staff. This highlights the necessity for ongoing vigilance and adaptation in HAI control.

Q 26. Describe your experience with outbreak management and response related to disinfection.

My experience in outbreak management involves a structured approach rooted in investigation, containment, and prevention. When faced with an outbreak potentially linked to disinfection failures, I follow a detailed protocol.

- Immediate Containment: The first step is isolating affected individuals and restricting access to potentially contaminated areas.

- Epidemiological Investigation: This involves tracing the source of the outbreak, identifying susceptible populations, and determining transmission patterns. This may include reviewing sterilization records, reviewing staff practices, and environmental sampling.

- Environmental Sampling and Analysis: We conduct thorough environmental sampling to identify the causative agent and determine the extent of contamination. This helps guide cleaning and disinfection efforts.

- Enhanced Cleaning and Disinfection: This includes targeted disinfection of affected areas using appropriate disinfectants and implementing strengthened cleaning protocols.

- Staff Education and Training: Strengthening staff education on infection control protocols and disinfection procedures is essential.

- Post-Outbreak Review: A comprehensive review assesses the effectiveness of implemented measures to identify areas of improvement and to prevent future outbreaks.

In one instance, an outbreak of a multi-drug resistant organism was traced back to improper sterilization protocols in a surgical equipment processing unit. Implementing stricter protocols, including enhanced staff training, a comprehensive review of sterilization equipment, and frequent BI and CI testing, successfully halted the spread and prevented further cases.

Q 27. What are the key performance indicators (KPIs) for evaluating disinfection efficacy?

Key Performance Indicators (KPIs) for evaluating disinfection efficacy provide quantitative measures of success. These include:

- Infection Rates: Tracking the incidence of HAIs is a critical measure of the effectiveness of infection control programs. A reduction in infection rates demonstrates the success of disinfection practices.

- Environmental Culture Results: Regular environmental sampling and culturing can detect the presence of pathogens and assess the effectiveness of disinfection procedures in reducing the microbial load.

- Sterilization Indicator Results: The rate of positive and negative results from biological and chemical indicators during sterilization cycles provides direct feedback on the equipment’s effectiveness. High rates of positive BIs necessitate an investigation into potential faults in the sterilizer or in its operation.

- Compliance Rates: Monitoring compliance with hand hygiene, PPE use, and other infection control protocols provides an assessment of the program’s implementation and effectiveness. Low compliance rates will often correlate with high infection rates.

- Staff Knowledge and Competency: Regular assessments of staff knowledge and skills concerning disinfection practices can improve program efficacy.

For instance, if infection rates significantly decrease after implementing a new disinfection protocol, it indicates the effectiveness of that protocol. Conversely, high rates of positive BIs may trigger a review of autoclave maintenance and operation to identify and correct flaws in the system.

Key Topics to Learn for Disinfection Procedures Interview

- Understanding Different Disinfectants: Explore the chemical properties, mechanisms of action, and appropriate uses of various disinfectants (e.g., alcohols, chlorine-based compounds, quaternary ammonium compounds). Consider factors like efficacy against specific pathogens and material compatibility.

- Practical Application of Disinfection Techniques: Review procedures for surface disinfection, equipment sterilization, and hand hygiene. Be prepared to discuss specific techniques like wiping, spraying, immersion, and high-level disinfection. Consider the impact of contact time and concentration.

- Infection Prevention and Control: Understand the principles of infection prevention and control, including standard precautions, transmission-based precautions, and the role of disinfection in minimizing the spread of infectious agents. This includes understanding different types of pathogens and their susceptibility to various disinfectants.

- Safety and Handling of Disinfectants: Discuss the safety precautions associated with handling and using different disinfectants, including personal protective equipment (PPE) requirements, proper storage, and disposal procedures. Be ready to explain potential hazards and mitigation strategies.

- Monitoring and Evaluation of Disinfection Effectiveness: Explore methods for monitoring the effectiveness of disinfection procedures, such as microbial testing and environmental monitoring. Be prepared to discuss how to identify and address deficiencies in the process.

- Regulatory Compliance and Best Practices: Familiarize yourself with relevant regulations and guidelines related to disinfection procedures in your specific industry or field. Understand and be prepared to discuss industry best practices and their rationales.

- Troubleshooting Common Disinfection Challenges: Practice identifying and resolving common problems encountered during disinfection processes. This could involve dealing with resistant microorganisms, equipment malfunctions, or unexpected contamination.

Next Steps

Mastering disinfection procedures is crucial for advancing your career in a variety of fields, ensuring patient safety, and contributing to a healthier environment. A well-crafted resume is key to showcasing your expertise and securing your dream role. Make sure your resume is ATS-friendly to maximize its visibility to potential employers. To help you create a professional and impactful resume, we recommend using ResumeGemini. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to disinfection procedures to guide you through the process. Take the next step toward your career success today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO