Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Dock and Terminal Operations interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Dock and Terminal Operations Interview

Q 1. Describe your experience with different types of cargo handling equipment.

My experience encompasses a wide range of cargo handling equipment, from the most basic to highly specialized machinery. I’m proficient in operating and maintaining various types, including:

- Container handling equipment: This includes reach stackers, which are used to lift and move containers in stacks; rubber-tired gantry cranes (RTGs), which are essential for stacking containers in container yards; and ship-to-shore cranes (STS), gigantic cranes that load and unload containers directly from ships.

- Forklifts: I’m experienced with various forklift types, from counterbalance forklifts for general cargo to specialized forklifts for handling oversized or delicate goods.

- Straddle carriers: These are large vehicles that straddle containers, picking them up and transporting them across the terminal. They are particularly useful in areas with limited space.

- Conveyors and automated systems: I understand the principles behind automated conveyor systems and their role in streamlining cargo movement. I’ve worked with both traditional and modern automated systems, including those controlled by sophisticated software.

- Specialised equipment: My experience also includes handling equipment for specific cargo types, such as specialized cranes for heavy lifts, or equipment for handling breakbulk cargo (cargo not packed in containers).

Understanding the capabilities and limitations of each piece of equipment is crucial for efficient and safe operations. For example, knowing the weight capacity of a forklift is critical to preventing accidents and ensuring smooth operations.

Q 2. Explain your understanding of safety regulations in dock and terminal operations.

Safety is paramount in dock and terminal operations. My understanding of safety regulations is comprehensive, covering all aspects from personal protective equipment (PPE) to hazard identification and risk mitigation. I’m familiar with regulations like OSHA (in the US) and equivalent international standards. Key aspects include:

- PPE: Ensuring all personnel use appropriate PPE, including safety helmets, high-visibility clothing, safety shoes, and hearing protection, is essential.

- Hazard identification and risk assessment: Regularly identifying potential hazards, such as heavy machinery, hazardous materials, and confined spaces, and implementing appropriate control measures is crucial.

- Emergency procedures: Detailed emergency response plans, including fire safety, evacuation procedures, and first aid protocols, must be in place and regularly practiced.

- Load securing: Proper securing of cargo is critical to prevent shifting during transit and potential accidents. I am trained in various load securing techniques.

- Vehicle safety: Strict adherence to traffic regulations within the terminal, proper vehicle maintenance, and operator training are key to preventing accidents.

- Hazardous materials handling: Safe handling, storage, and transportation of hazardous materials require specialized training and adherence to strict regulations. I have experience working with various hazardous materials classifications.

I believe a proactive approach to safety, through continuous training, regular inspections, and open communication, is the best way to minimize risks and ensure a safe working environment. I’ve implemented several safety programs and witnessed firsthand how a strong safety culture leads to significant reduction in accidents and injuries.

Q 3. How do you manage inventory and track cargo movement within a terminal?

Inventory management and cargo tracking are integral to efficient terminal operations. We utilize a combination of technologies and processes to achieve accurate and real-time visibility of cargo movement. This typically includes:

- Terminal Operating Systems (TOS): These sophisticated software systems provide a centralized platform for managing cargo information, tracking its movement throughout the terminal, and generating reports. Examples include Navis N4 and Oracle Transportation Management.

- Radio Frequency Identification (RFID): RFID tags attached to containers allow for automated tracking of their location within the terminal, eliminating manual tracking and significantly improving efficiency.

- Barcode scanning: Barcode scanning of cargo manifests and other documentation allows for quick and accurate data entry into the TOS.

- Global Positioning Systems (GPS): GPS tracking of vehicles and equipment provides real-time location data, improving operational efficiency and optimizing routes.

- Warehouse Management Systems (WMS): For warehousing operations within the terminal, a WMS manages inventory levels, storage locations, and order fulfillment.

The data collected through these systems allows us to monitor inventory levels, track cargo movement, identify potential bottlenecks, and optimize resource allocation. Accurate and timely information is crucial for meeting delivery deadlines and ensuring customer satisfaction.

Q 4. What are your strategies for optimizing space utilization in a warehouse or terminal?

Optimizing space utilization is crucial for maximizing throughput and reducing operational costs. My strategies include:

- Efficient storage layouts: Designing storage layouts that consider cargo size, type, and frequency of access. This may involve using high-bay racking systems or specialized storage solutions for oversized or unusual cargo.

- Block stacking: Optimizing container stacking within the yard by considering container type and destination.

- Inventory optimization: Minimizing excess inventory through efficient forecasting and inventory control techniques. Using data analytics to predict demand and adjust inventory levels accordingly.

- Improved equipment utilization: Scheduling and routing equipment to maximize their efficiency and minimize idle time.

- Vertical space maximization: Making use of vertical space through multi-tiered racking or stacking systems.

- Regular audits and adjustments: Periodically reviewing and adjusting storage layouts to accommodate changes in inventory and operational needs.

I have experience implementing lean manufacturing principles to minimize waste and improve space efficiency. For example, in one previous role, we reduced wasted space by 15% simply by reorganizing the storage layout and implementing a more efficient inventory management system.

Q 5. How do you handle unexpected delays or disruptions in the shipping process?

Unexpected delays and disruptions are inevitable in the shipping industry. My approach to handling them involves a combination of proactive planning and reactive problem-solving.

- Proactive measures: This includes developing contingency plans for common disruptions, such as port congestion, bad weather, or equipment failures. Regular monitoring of potential disruptions through news sources and communication with stakeholders.

- Communication: Maintaining clear and timely communication with customers, suppliers, and other stakeholders about any delays or disruptions. Transparency is key to managing expectations.

- Problem-solving: Identifying the root cause of the disruption and implementing appropriate solutions. This may involve rerouting cargo, finding alternative transportation modes, or negotiating with suppliers or customers.

- Resource allocation: Efficiently allocating resources to address the disruption and minimize its impact. This may involve prioritizing certain tasks or deploying additional equipment or personnel.

- Post-incident review: After the disruption is resolved, conducting a thorough review to identify areas for improvement and prevent similar incidents in the future. This includes identifying weaknesses in the existing plans and adjusting them accordingly.

For instance, during a recent port strike, we were able to mitigate the impact by rerouting some cargo through alternative ports and utilizing our existing relationships with trucking companies to expedite delivery.

Q 6. Describe your experience with implementing and improving operational efficiency.

Improving operational efficiency is a continuous process. My approach involves a combination of data analysis, process improvement methodologies, and technology implementation. I have experience implementing various strategies including:

- Process mapping and optimization: Identifying bottlenecks and inefficiencies in existing processes through process mapping and applying lean principles to streamline operations.

- Technology implementation: Leveraging technology such as TOS, WMS, and RFID to automate tasks, improve data accuracy, and enhance visibility.

- Data analysis: Utilizing data analytics to identify trends, predict potential problems, and measure the effectiveness of implemented improvements.

- Employee training and development: Investing in employee training to improve skills and efficiency.

- Continuous improvement programs: Implementing continuous improvement programs, such as Kaizen or Six Sigma, to foster a culture of innovation and efficiency.

In a previous role, we implemented a new TOS which resulted in a 10% reduction in cargo handling time and a significant improvement in overall throughput. This success demonstrates my ability to effectively plan, implement, and manage operational efficiency improvement initiatives.

Q 7. Explain your knowledge of different types of cargo and their handling requirements.

My knowledge of different cargo types and their handling requirements is extensive. I understand the unique challenges associated with each type and have experience handling:

- Containerized cargo: The most common type, requiring careful handling to avoid damage to containers and their contents.

- Breakbulk cargo: Cargo that is not containerized, requiring careful planning and handling to prevent damage and ensure efficient loading and unloading.

- Bulk cargo: Cargoes such as grains, ores, and liquids, requiring specialized handling equipment and storage facilities.

- Liquid cargo: Requires specialized tanks and handling procedures to prevent spills and contamination.

- Hazardous materials: Requires specialized training, equipment, and procedures to ensure safe handling and storage.

- Refrigerated cargo (reefers): Requires temperature-controlled containers and monitoring systems to maintain product quality.

- Oversized and heavy-lift cargo: Requires specialized equipment and planning for safe handling and transport.

Understanding the specific handling requirements for each type of cargo is crucial to preventing damage, ensuring safety, and maintaining efficient operations. This includes understanding weight limits, fragility, and the need for specific handling techniques or equipment. For instance, handling fragile ceramics requires different techniques and equipment compared to handling steel coils.

Q 8. How familiar are you with international maritime regulations and standards?

My familiarity with international maritime regulations and standards is extensive. I possess a deep understanding of the International Maritime Organization (IMO) conventions, including the SOLAS (Safety of Life at Sea) convention, the MARPOL (Marine Pollution) convention, and the IMDG Code (International Maritime Dangerous Goods Code). I’m also well-versed in the International Ship and Port Facility Security (ISPS) Code, which is crucial for maintaining security within port environments. These regulations cover various aspects, from ship safety and pollution prevention to cargo security and crew welfare. For example, my experience includes ensuring compliance with MARPOL Annex VI regulations concerning air emissions, particularly the sulfur content of ship fuels. I’ve been directly involved in implementing and monitoring these regulations, ensuring our operations remain compliant and environmentally responsible. I understand the nuances of these regulations and how they impact operational decisions daily.

Beyond the IMO conventions, I’m familiar with national and regional regulations that often complement or augment international standards. This understanding allows me to navigate the complex legal landscape of international shipping and ensure all our operations adhere to the highest standards.

Q 9. What is your experience with using terminal operating systems (TOS)?

I have extensive experience with various Terminal Operating Systems (TOS), including Navis N4, Oracle TOS, and TG-System. My experience goes beyond simply using the systems; I understand their underlying logic and how different modules interact. I can effectively utilize these systems for tasks such as vessel scheduling, yard management, gate operations, and equipment tracking. For example, I’ve used Navis N4 to optimize vessel berthing schedules, reducing vessel turnaround times and improving overall terminal efficiency. I’m proficient in configuring and customizing TOS functionalities to meet specific operational needs, and I have experience troubleshooting and resolving system issues. Furthermore, I’m adept at integrating TOS with other systems, such as WMS (Warehouse Management Systems) and ERP (Enterprise Resource Planning) systems, to ensure seamless data flow across the entire supply chain.

In one instance, I identified a bottleneck in the yard truck movements using data analytics within the TOS. By modifying the yard allocation algorithm and implementing a new dispatch system, we reduced truck wait times by 15%, significantly improving operational efficiency and reducing costs.

Q 10. How do you prioritize tasks and manage workload in a fast-paced environment?

In fast-paced dock and terminal operations, prioritization and workload management are critical skills. I utilize a combination of techniques, including:

- Prioritization Matrices: I use methods like the Eisenhower Matrix (urgent/important) to categorize tasks and focus on high-impact activities first.

- Kanban Boards: Visual task management tools help to track progress, identify bottlenecks, and adjust workflows in real-time.

- Real-Time Monitoring: Constant monitoring of vessel schedules, cargo arrival times, and equipment availability allows for proactive adjustments and prevents unforeseen delays. Think of it like air traffic control for cargo.

- Effective Communication: Open communication with all stakeholders—from dockworkers to shipping agents—is crucial for efficient coordination and prevents conflicting priorities.

For instance, during peak season, when multiple vessels arrive simultaneously, I’d prioritize unloading high-priority cargo (perishable goods, time-sensitive shipments) before focusing on others. This requires careful planning and coordination across different teams to ensure smooth operations. Proactive identification of potential delays – weather, equipment malfunctions – and preparing contingency plans is key. This proactive approach ensures that deadlines are consistently met and disruptions are minimized.

Q 11. Describe your experience in managing a team of dockworkers or other terminal staff.

I have extensive experience managing teams of dockworkers, including supervisors, equipment operators, and clerical staff. My leadership style focuses on fostering collaboration, clear communication, and continuous improvement. I believe in empowering my team members by delegating responsibilities according to their skills and providing opportunities for professional development. Regular performance reviews and feedback sessions are crucial for enhancing performance and addressing any issues proactively. I’ve implemented training programs on safety protocols and efficient work methods, resulting in a significant reduction in workplace accidents and increased productivity.

In one particular instance, I identified a communication gap between the yard management team and the gate staff. This resulted in delays at the gate. By introducing daily briefings and a real-time communication system, we significantly reduced the wait times and improved overall gate efficiency.

Q 12. How do you ensure the security and safety of cargo within a terminal?

Ensuring cargo security and safety is paramount in terminal operations. My approach is multi-layered and involves:

- Physical Security Measures: Implementing robust perimeter security, including fencing, access control systems (e.g., gates, CCTV), and regular patrols. This is our first line of defense.

- Cargo Inspection and Monitoring: Thorough cargo inspection procedures at the gate, including X-ray scanning and physical checks for contraband, help prevent smuggling and protect against threats. This also involves the use of technologies to monitor container locations within the terminal.

- Access Control: Strict control over access to the terminal and individual containers, using identification badges and security clearances, restricts entry to authorized personnel only.

- Personnel Training: Regular training programs for all personnel on security protocols, recognizing and reporting suspicious activities, and emergency response procedures are essential.

- Collaboration with Law Enforcement: Maintaining a strong working relationship with local law enforcement agencies for timely responses to security incidents.

A real-world example would be implementing a new container tracking system that uses GPS and RFID technology to monitor the location and movement of every container within the terminal in real-time, enhancing our ability to detect any unauthorized access or movement.

Q 13. How familiar are you with customs procedures and documentation?

I am very familiar with customs procedures and documentation. My experience includes working closely with customs brokers and agents to ensure timely and accurate processing of import and export documentation. I understand the requirements for various customs forms, such as entry manifests, bills of lading, certificates of origin, and other relevant documents. I’m knowledgeable about customs regulations regarding different types of goods, including restricted and prohibited items. This understanding is crucial for ensuring smooth clearance of cargo and avoiding delays or penalties. For example, I’m proficient in using electronic data interchange (EDI) systems to submit customs declarations electronically.

In a specific instance, we successfully navigated a complex customs clearance issue involving misclassified goods by working closely with the customs broker to provide accurate documentation and addressing their concerns promptly. This prevented a significant delay and associated costs.

Q 14. What is your experience with warehouse management systems (WMS)?

While my primary focus has been on terminal operations and TOS, I have experience working with Warehouse Management Systems (WMS) in the context of integrating them with terminal operations. This integration is crucial for efficient cargo handling and tracking, especially for cargo that requires warehousing before final delivery. I understand how WMS helps manage inventory, track goods, and optimize warehouse space. I have utilized WMS to track the movement of goods from the terminal to the warehouse and vice versa, providing real-time visibility into the entire supply chain. This integration minimizes data entry errors, reduces manual processes, and provides a comprehensive view of cargo throughout its journey.

For example, in a previous role, we integrated our TOS with a WMS to optimize the allocation of warehouse space based on the anticipated arrival of containers. This system prevented congestion in the warehouse and improved the overall efficiency of the supply chain.

Q 15. Describe your experience with different types of transportation modes and their integration.

My experience encompasses the seamless integration of various transportation modes, including maritime, rail, trucking, and air freight, within dock and terminal operations. Think of it like a well-orchestrated symphony; each instrument (mode of transport) plays its part to achieve a harmonious outcome – efficient goods movement.

- Maritime: I’ve extensively worked with vessel scheduling, container handling, and port operations, optimizing cargo flow from ships to terminals.

- Rail: My experience includes coordinating rail transport to and from the terminal, leveraging intermodal capabilities for long-distance transport and reducing reliance on solely road-based transport. This is crucial for cost-effectiveness and environmental responsibility.

- Trucking: I’m proficient in managing trucking fleets, optimizing delivery routes, and ensuring timely pickup and delivery of goods at the terminal. This often involves driver management and real-time tracking of shipments.

- Air Freight: While less common for bulk goods handled in typical dock operations, I understand the integration of air freight for high-value, time-sensitive cargo, particularly the procedures for customs clearance and handling.

In practice, integration involves sophisticated planning and real-time coordination. For instance, a delayed vessel arrival needs immediate adjustments to trucking schedules and rail connections to prevent bottlenecks and ensure on-time deliveries to customers. This requires robust communication across different stakeholders and a flexible operational framework.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage and resolve conflicts between different stakeholders?

Conflict resolution between stakeholders – shippers, carriers, customs officials, and internal teams – is a daily occurrence. My approach is rooted in open communication, collaboration, and a focus on finding mutually beneficial solutions. Imagine a traffic jam; everyone is frustrated, but a coordinated effort to redirect flow can clear the congestion.

- Active Listening: I begin by actively listening to each stakeholder’s perspective, acknowledging their concerns and validating their feelings.

- Identifying the Root Cause: Once everyone feels heard, I work to identify the underlying cause of the conflict. Is it a scheduling issue? A communication breakdown? A misunderstanding of procedures?

- Collaborative Problem Solving: I then facilitate a collaborative discussion, brainstorming solutions that address everyone’s needs. This might involve compromise, negotiation, or even arbitration if needed.

- Documentation and Follow-up: Finally, I ensure that agreed-upon solutions are documented clearly and that follow-up actions are assigned and tracked to prevent future conflicts.

For example, a dispute between a shipper and a carrier over damaged goods might be resolved through a thorough investigation, possibly involving insurance claims and collaborative agreement on compensation. Transparency and a fair approach are key to maintaining positive working relationships.

Q 17. How do you handle customer complaints and address their concerns?

Handling customer complaints is crucial for maintaining positive relationships and reputation. I approach each complaint as an opportunity to improve our services. Think of it as customer feedback, not just a complaint.

- Acknowledge and Empathize: I begin by acknowledging the customer’s frustration and empathizing with their situation. A simple ‘I understand your concern’ goes a long way.

- Gather Information: I gather all relevant information about the complaint, including dates, times, and specific details. This might involve reviewing shipping documents, tracking information, and communicating with relevant internal teams.

- Investigate Thoroughly: I conduct a thorough investigation to understand what went wrong. Was there a delay? Was there damage? Was there a communication breakdown?

- Offer a Solution: Based on the investigation, I offer a fair and reasonable solution to the customer. This might involve a refund, a replacement, expedited delivery, or a combination of these.

- Follow Up: Finally, I follow up with the customer to ensure they are satisfied with the resolution and to address any remaining concerns.

For example, a delayed shipment might be resolved by offering a partial refund and providing regular updates on the shipment’s progress. The goal is to restore the customer’s trust and loyalty.

Q 18. What is your experience with reporting and data analysis in dock and terminal operations?

Reporting and data analysis are fundamental to efficient dock and terminal operations. I have extensive experience using various software and tools to track key performance indicators (KPIs), analyze trends, and identify areas for improvement. This isn’t just about numbers; it’s about using data to drive better decision-making.

- KPI Tracking: I track key metrics such as vessel turnaround time, container dwell time, cargo throughput, and on-time delivery rates. These KPIs provide insights into operational efficiency and areas needing attention.

- Data Analysis: I utilize statistical methods and data visualization tools to analyze trends in these KPIs. For example, I might identify patterns of congestion at certain times of day, leading to better scheduling and resource allocation.

- Reporting: I regularly generate reports summarizing key performance indicators, highlighting trends, and recommending improvements. These reports are crucial for monitoring performance, identifying bottlenecks, and making data-driven decisions.

- Software Proficiency: My experience includes proficiency in Terminal Operating Systems (TOS), warehouse management systems (WMS), and various data analysis tools such as Excel, Tableau, or Power BI. (Specific software experience would be detailed in my resume).

For instance, analyzing dwell time data might reveal inefficiencies in yard operations, prompting changes in storage strategies or equipment deployment to reduce costs and improve efficiency. Data-driven decision making is essential in improving operational processes.

Q 19. Explain your understanding of supply chain management principles.

My understanding of supply chain management principles is comprehensive, encompassing planning, sourcing, production, logistics, and customer service. In dock and terminal operations, we are a critical link in this chain, influencing efficiency and overall cost. Think of it as a relay race; a smooth handover at each stage is crucial for success.

- Demand Planning and Forecasting: Accurate forecasting of cargo volumes is critical for efficient resource allocation and effective planning of vessel schedules, terminal space, and equipment.

- Inventory Management: Effective management of container inventory at the terminal is vital to prevent congestion and ensure timely availability of cargo.

- Logistics Optimization: Optimizing transportation routes, modes, and schedules is key to minimizing costs and transit times. This requires coordination across all transportation modes.

- Risk Management: Identifying and mitigating potential risks, such as port congestion, weather disruptions, or security threats, is crucial for maintaining supply chain resilience.

- Customer Service: Providing excellent customer service, including timely communication and efficient handling of queries, is essential for maintaining strong relationships with shippers and carriers.

For example, effective forecasting can help prevent bottlenecks caused by unexpected surges in cargo volume, allowing for proactive adjustments in resource allocation to maintain smooth operations.

Q 20. How familiar are you with various types of containers and their specifications?

I’m very familiar with various container types and their specifications. Containers are the fundamental building blocks of global trade, and understanding their variations is essential for efficient handling and storage.

- Dry Containers: These are the most common type, used for general cargo, ranging from 20-foot to 40-foot lengths and various heights. Variations include standard, high-cube, and open-top containers.

- Refrigerated Containers (Reefer): These maintain a controlled temperature for perishable goods like fruits, vegetables, and pharmaceuticals. They require specialized handling and power connections.

- Special Purpose Containers: These include tank containers for liquids, flat rack containers for oversized cargo, and open-side containers for easy loading and unloading of bulky items.

- Container Specifications: I’m familiar with container dimensions (length, width, height), weight limits (gross, tare, and net), and ISO codes used for container identification. These are critical for safe and efficient stacking and handling.

Understanding these specifications is crucial for efficient loading, stacking, and securing containers on vessels and within terminals. Incorrect handling can lead to accidents, damage, and delays.

Q 21. How do you ensure compliance with environmental regulations?

Environmental compliance is paramount in dock and terminal operations. We must minimize our environmental impact through responsible practices and adherence to regulations. This is not just a legal requirement; it’s also crucial for sustainability and corporate social responsibility.

- Air Emissions: Reducing air pollution from equipment such as trucks and cranes through the use of cleaner fuels and technologies (e.g., electric or hybrid vehicles).

- Water Pollution: Preventing water contamination through proper handling of cargo and waste materials, employing effective oil spill prevention and response plans, and managing stormwater runoff.

- Noise Pollution: Minimizing noise pollution through the use of quieter equipment and adopting noise reduction measures.

- Waste Management: Implementing effective waste management programs to reduce, reuse, and recycle waste materials, minimizing landfill disposal.

- Regulatory Compliance: Staying up-to-date with and adhering to all relevant environmental regulations and permits, including those related to air emissions, water pollution, and waste management.

For instance, we might implement a program to encourage the use of low-sulfur fuels for vehicles operating within the terminal or invest in noise-reducing barriers around loading docks. Continuous improvement is essential in minimizing environmental impact.

Q 22. Describe your experience with budget management and cost control.

Budget management and cost control in dock and terminal operations require a keen eye for detail and a proactive approach. It’s not just about tracking expenses; it’s about strategically allocating resources to maximize efficiency and profitability. My experience involves developing and managing budgets encompassing various operational costs, including labor, equipment maintenance, fuel, and port charges. I utilize various techniques such as:

- Zero-based budgeting: Instead of basing the next year’s budget on the previous year’s, each expense is justified from scratch, ensuring every dollar is contributing to overall goals.

- Variance analysis: Regularly comparing budgeted versus actual costs, investigating significant discrepancies to identify areas for improvement and cost savings. For example, if fuel costs exceed the budget, we’d analyze fuel consumption patterns, explore alternative fuel sources, or optimize equipment usage to reduce consumption.

- Key Performance Indicators (KPIs): Tracking KPIs such as cost per container handled, equipment downtime, and labor productivity helps identify areas needing attention. A sudden spike in equipment downtime, for instance, might signal the need for more robust preventative maintenance programs.

- Negotiation and vendor management: Negotiating favorable rates with suppliers for fuel, equipment parts, and services is crucial. Building strong relationships with vendors helps secure better pricing and timely delivery.

In one instance, by implementing a more efficient scheduling system and optimizing crane usage, I was able to reduce labor costs by 15% within a six-month period, significantly impacting the bottom line.

Q 23. What are your strategies for improving communication and coordination within a team?

Effective communication and coordination are the lifeblood of any successful dock and terminal operation. Teamwork is essential for ensuring smooth workflows and minimizing delays. My strategies focus on:

- Clear and consistent communication: Regular team meetings, daily briefings, and the use of clear, concise language are crucial. This involves actively listening to team members’ concerns and suggestions.

- Open-door policy: Creating an environment where team members feel comfortable approaching their supervisors with problems or suggestions fosters trust and collaboration.

- Utilizing technology: Employing communication tools such as project management software (e.g., Asana, Trello), instant messaging platforms (e.g., Slack), and real-time data dashboards improves transparency and facilitates quick information sharing.

- Cross-training: Cross-training team members allows for greater flexibility and reduces reliance on individual expertise. If one team member is absent, others can step in and ensure operations continue smoothly.

- Conflict resolution: Addressing conflicts promptly and fairly, focusing on solutions rather than assigning blame, is crucial for maintaining a positive team dynamic.

For instance, during a period of high operational demand, implementing a daily operational briefing using a digital whiteboard significantly improved team coordination and reduced delays caused by miscommunication.

Q 24. How do you address and resolve equipment malfunctions?

Equipment malfunctions can cause significant disruptions to terminal operations. My approach involves a structured, multi-step process:

- Immediate assessment: First, we determine the nature and severity of the malfunction. Is it a minor issue that can be addressed on-site, or does it require specialized repair?

- Safety first: Prioritize safety. If the equipment poses a safety hazard, isolate it and ensure the area is secured.

- Troubleshooting: Attempt basic troubleshooting based on the equipment’s manual or documented procedures. This might involve checking power supply, fuses, or fluid levels.

- Contacting maintenance personnel: If the issue cannot be resolved internally, contact specialized maintenance personnel immediately. Clearly communicate the problem and any relevant details.

- Temporary solutions: If the equipment is critical to operations, consider temporary solutions, such as using backup equipment or adjusting the workflow to minimize reliance on the malfunctioning unit.

- Documentation: Thoroughly document the malfunction, troubleshooting steps, repair procedures, and any downtime incurred. This information aids in future preventative maintenance and identifying recurring issues.

For example, a recent malfunction of a gantry crane was addressed by quickly isolating the area, contacting the maintenance team who diagnosed a faulty motor, and completing the repair within 4 hours, minimizing disruption to operations.

Q 25. Explain your experience with preventative maintenance programs for equipment.

Preventative maintenance is key to minimizing equipment downtime and maximizing operational efficiency. My experience includes developing and implementing comprehensive preventative maintenance programs that encompass:

- Regular inspections: Establishing a schedule for regular inspections of all equipment, including visual checks, functional tests, and lubrication.

- Predictive maintenance: Utilizing data analytics and sensors to monitor equipment performance and predict potential failures. This allows for proactive maintenance before a breakdown occurs.

- Planned downtime: Scheduling routine maintenance during periods of low operational demand to minimize disruption.

- Spare parts inventory: Maintaining an adequate inventory of essential spare parts to minimize repair time.

- Training and documentation: Providing training to maintenance personnel on proper maintenance procedures and maintaining comprehensive documentation of maintenance activities.

By implementing a robust preventative maintenance program, we were able to reduce equipment downtime by 20%, leading to significant cost savings and improved operational efficiency.

Q 26. How do you ensure timely and efficient loading and unloading of vessels?

Timely and efficient loading and unloading of vessels is paramount for maintaining smooth operations and satisfying customer expectations. My approach involves:

- Advanced planning: Careful planning of cargo handling operations, including vessel scheduling, cargo allocation, and equipment deployment.

- Optimized workflows: Designing efficient workflows to minimize cargo movement and maximize equipment utilization.

- Real-time monitoring: Utilizing real-time tracking systems to monitor the progress of loading and unloading operations, identify bottlenecks, and make necessary adjustments.

- Effective communication: Maintaining clear and consistent communication between the vessel crew, terminal staff, and other stakeholders.

- Contingency planning: Developing contingency plans to address unforeseen events, such as equipment malfunctions or weather delays.

For example, using a sophisticated scheduling system, we were able to improve vessel turnaround time by 15%, resulting in increased throughput and improved customer satisfaction.

Q 27. Describe your experience with planning and scheduling operations within a terminal.

Planning and scheduling operations within a terminal are crucial for optimizing resource allocation and maximizing efficiency. My experience includes:

- Master scheduling: Developing a master schedule that integrates vessel arrivals, cargo handling, and resource availability.

- Resource allocation: Optimizing the allocation of resources, including cranes, trucks, and personnel, to meet operational demands.

- Capacity planning: Accurately assessing the terminal’s capacity to handle current and future demands and making necessary adjustments.

- Utilizing scheduling software: Employing sophisticated scheduling software to optimize resource allocation and minimize conflicts.

- Continuous improvement: Regularly reviewing and refining scheduling processes to identify areas for improvement.

I successfully implemented a new scheduling system that reduced vessel waiting times by 20%, improving overall efficiency and customer satisfaction.

Q 28. How do you adapt to changing operational demands and priorities?

Adaptability is crucial in dock and terminal operations, where demands and priorities can change rapidly. My approach to adapting to change involves:

- Flexibility: Maintaining a flexible approach to operations allows for quick adjustments in response to unexpected events.

- Effective communication: Open communication ensures that all stakeholders are aware of changes and their impact.

- Proactive problem-solving: Identifying and addressing potential challenges before they escalate.

- Continuous learning: Staying abreast of industry trends and adopting best practices.

- Collaboration: Working collaboratively with other teams and stakeholders to find solutions to unexpected problems.

During a recent port congestion, I quickly adapted by re-allocating resources, implementing a new queuing system, and coordinating with other terminals to alleviate the congestion. This minimized disruption to operations and ensured customer satisfaction.

Key Topics to Learn for Dock and Terminal Operations Interview

- Cargo Handling & Logistics: Understanding different cargo types, handling procedures, storage, and the entire supply chain from vessel to final destination. Consider the impact of various factors like weather and equipment malfunctions.

- Safety Regulations & Procedures: Deep knowledge of OSHA, IMO, and other relevant safety regulations, including hazard identification, risk assessment, and emergency response protocols within a dock environment. Be prepared to discuss practical examples of safety implementation.

- Equipment & Technology: Familiarity with various types of dock equipment (cranes, forklifts, etc.), their operation, maintenance, and technological integrations like automated systems and port management software. Discuss troubleshooting scenarios and preventative maintenance strategies.

- Inventory Management & Control: Understanding inventory tracking systems, optimizing storage space, minimizing losses, and ensuring efficient stock rotation. Be prepared to discuss strategies for improving inventory accuracy and efficiency.

- Scheduling & Planning: Knowledge of optimizing vessel berthing, cargo loading/unloading schedules, resource allocation, and coordination with various stakeholders (shipping lines, customs, trucking companies). Discuss challenges in schedule adherence and problem-solving techniques.

- Communication & Teamwork: Effective communication skills are paramount in dock operations. Be prepared to discuss scenarios requiring clear communication with diverse teams and stakeholders under pressure.

- Operational Efficiency & Optimization: Understanding key performance indicators (KPIs) relevant to dock operations and strategies to improve efficiency, reduce costs, and enhance throughput. Be ready to discuss your approach to identifying bottlenecks and implementing solutions.

Next Steps

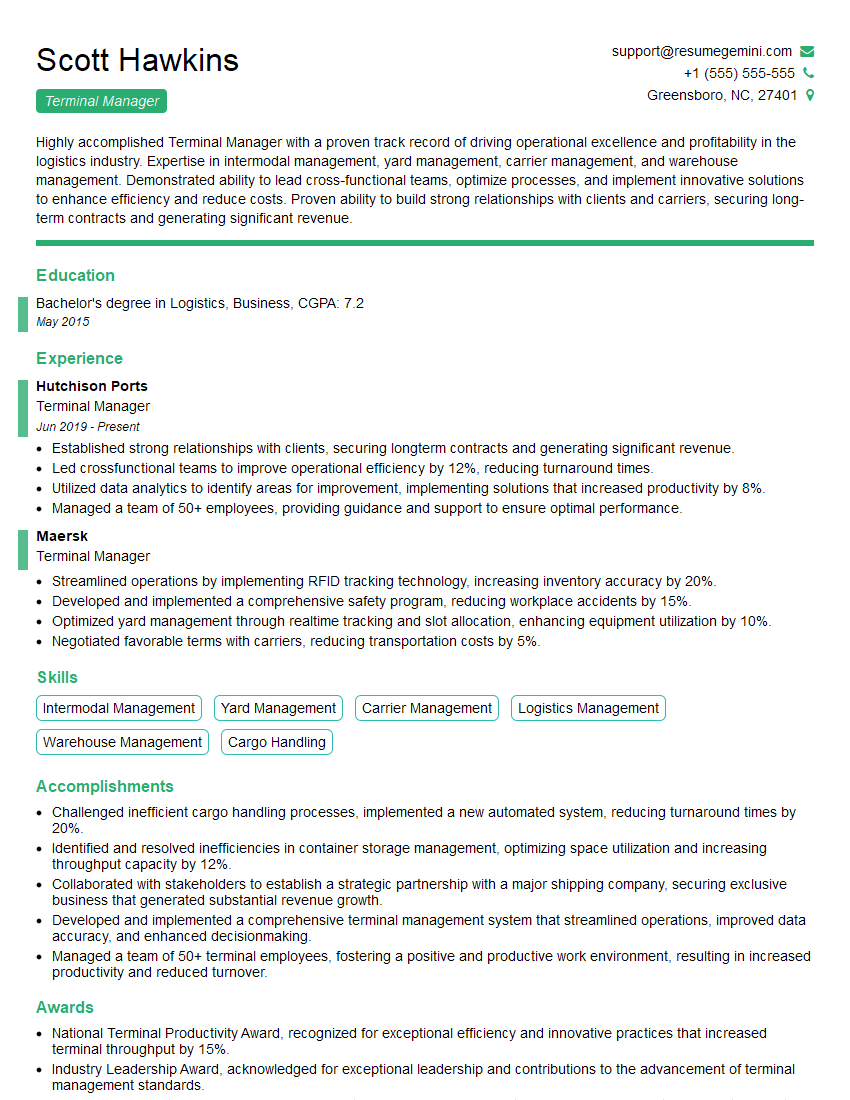

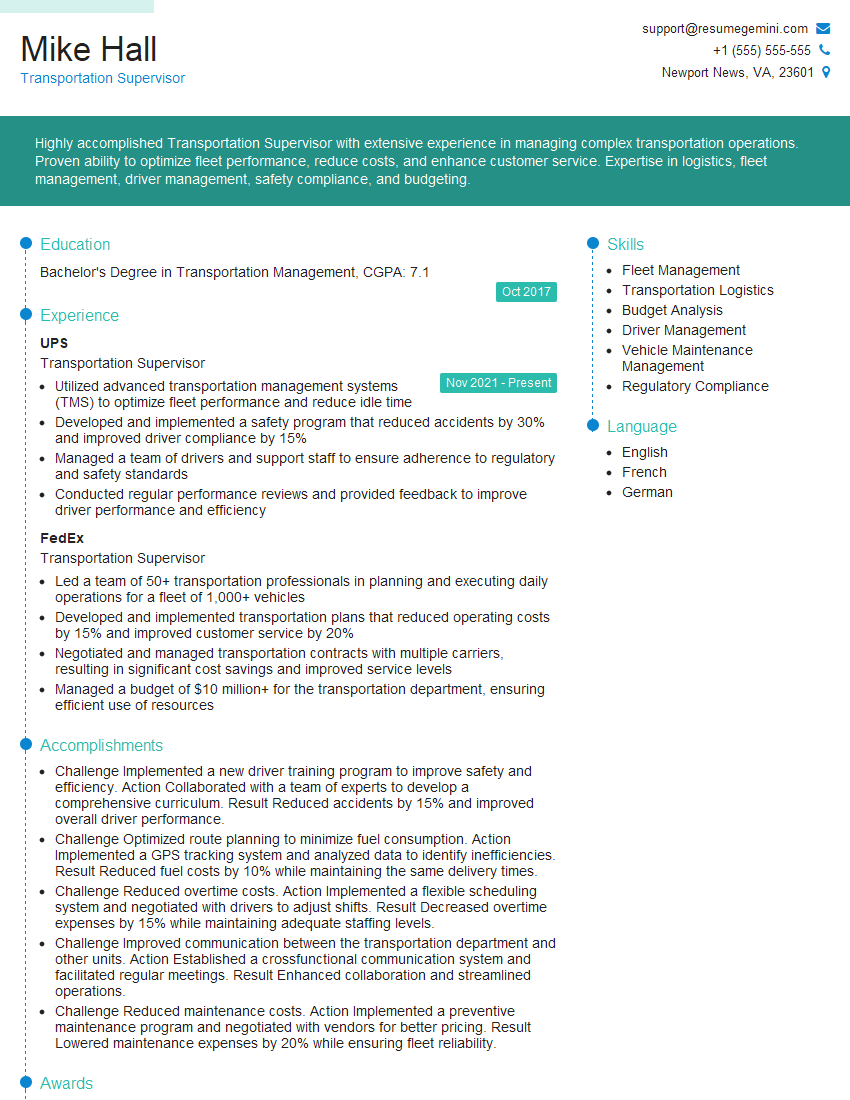

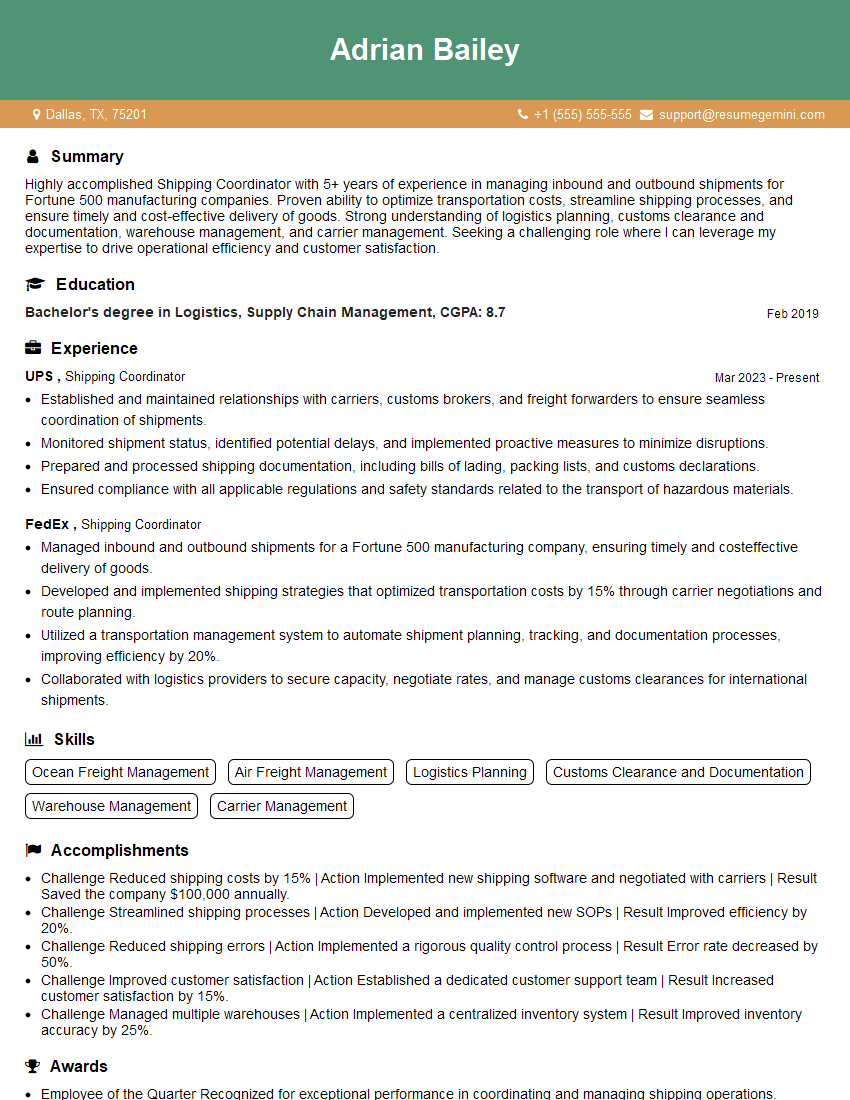

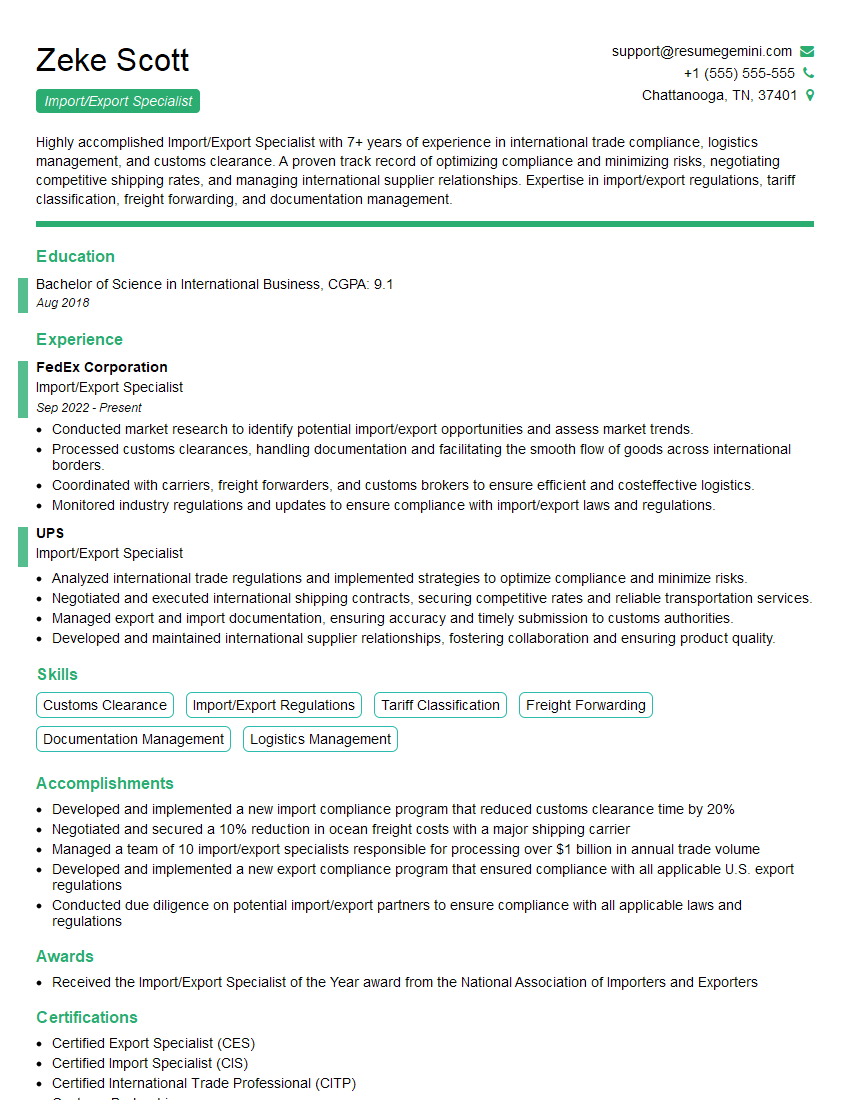

Mastering Dock and Terminal Operations opens doors to a rewarding career with excellent growth potential. These roles are crucial for global trade and offer diverse opportunities for advancement. To significantly increase your chances of landing your dream job, crafting an ATS-friendly resume is paramount. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored specifically to Dock and Terminal Operations to guide you through the process. Invest time in creating a strong resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO