Are you ready to stand out in your next interview? Understanding and preparing for Electrical Codes interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Electrical Codes Interview

Q 1. What is the NEC and why is it important?

The NEC, or National Electrical Code, is a widely adopted set of standards for the safe installation of electrical wiring and equipment in the United States. Think of it as the rulebook for electrical safety. It’s incredibly important because it protects people and property from electrical hazards like fires, shocks, and electrocution. The NEC isn’t a law itself, but it’s often adopted by local governments as a legal requirement, meaning that electrical work must comply with its provisions. Its importance stems from its detailed guidelines that cover everything from wiring methods and overcurrent protection to grounding and bonding techniques, ensuring a consistent level of safety across all electrical installations.

Q 2. Explain the difference between grounding and bonding.

Grounding and bonding are distinct but related concepts crucial for electrical safety. Grounding connects non-current-carrying metal parts of electrical equipment to the earth, providing a path for fault currents to flow safely to the ground. This effectively minimizes the risk of electric shock. Imagine it like a safety valve, allowing excess electricity to escape harmlessly. Bonding, on the other hand, connects non-current-carrying metal parts within a system to each other. This helps to equalize the potential between these parts, preventing voltage differences that could lead to dangerous electrical shocks or arcing. Think of bonding as creating a uniform electrical potential, eliminating the possibility of dangerous voltage differentials. Both grounding and bonding are integral to preventing hazardous situations.

Q 3. Describe the requirements for branch circuit protection.

Branch circuit protection is essential for preventing overcurrent conditions, which can lead to overheating, fires, and equipment damage. The NEC dictates that every branch circuit must have overcurrent protection, typically in the form of a circuit breaker or fuse, whose rating cannot exceed the ampacity of the conductor supplying the circuit. For example, a 15-ampere circuit should have a 15-ampere circuit breaker or fuse. The correct sizing is crucial; a breaker rated too high can’t prevent overheating, while a breaker rated too low will trip frequently and disrupt operation. Selecting the appropriate ampacity for the wire and the protective device is critical and requires careful calculation based on the load and wire gauge.

Q 4. What are the requirements for GFCI protection?

GFCI, or Ground Fault Circuit Interrupter, protection is mandated in specific locations to safeguard against electrical shock hazards caused by ground faults. Ground faults occur when a live wire comes into contact with a grounded surface, creating a path for current to leak to ground. GFCIs are designed to quickly detect these small leakage currents and interrupt the power, preventing potentially fatal shocks. The NEC requires GFCI protection for outlets in wet locations (bathrooms, kitchens, outdoors), near water sources, and in garages. In addition, many jurisdictions mandate GFCI protection for all outdoor receptacles.

Q 5. Explain the purpose of AFCI protection.

AFCI, or Arc-Fault Circuit Interrupter, protection is designed to detect and interrupt potentially dangerous arcing faults within a circuit. Arcing faults occur when electrical current jumps across a gap, often resulting in sparks and heat. This can cause fires that might go undetected by traditional circuit breakers. AFCIs are particularly important in circuits supplying bedrooms, which are considered high-risk areas. The NEC requires AFCI protection for these circuits, improving safety by preventing fires caused by arcing faults that traditional overcurrent protection might miss.

Q 6. What are the requirements for wiring methods in different locations (e.g., wet locations)?

Wiring methods must be suitable for the environment in which they’re installed. The NEC specifies different requirements for various locations. For example, in wet locations like bathrooms or outdoors, wiring must be protected from moisture to prevent short circuits and potential hazards. This might involve using conduit, armored cable, or other water-resistant methods. In dry locations, the requirements are less stringent, allowing for a wider range of wiring methods. In damp locations, considerations are between those of wet and dry locations. Always consult the NEC for specific requirements; proper cable selection based on location and potential exposure is paramount to long-term safety and code compliance.

Q 7. How do you calculate the voltage drop in a circuit?

Voltage drop is the reduction in voltage between the source and the load in an electrical circuit. It’s calculated using the formula: Voltage Drop = (2 * I * L * R) / 1000, where:

Iis the current in amperesLis the length of the conductor in feet (one-way)Ris the resistance of the conductor in ohms per 1000 feet

The result is the voltage drop in volts. Excessive voltage drop can reduce the efficiency and performance of equipment, and it is important to keep it within acceptable limits (usually 3% for branch circuits and 5% for feeders), as specified in the NEC. This calculation is vital in determining the appropriate conductor size for a given circuit to ensure sufficient voltage reaches the load. A larger conductor will have a lower resistance and therefore a lower voltage drop.

Q 8. What are the requirements for service entrance conductors?

Service entrance conductors are the wires that bring electricity from the utility company’s power lines to your electrical panel. Their requirements are crucial for safety and depend heavily on the building’s electrical load and the amperage of the service. These requirements are typically specified in the National Electrical Code (NEC) and local jurisdiction’s adoption thereof. Key considerations include:

- Ampacity: The conductors must have sufficient ampacity (current-carrying capacity) to handle the building’s total electrical demand. Undersized conductors can overheat and cause fires. For example, a home with a high-load appliance like an electric stove will necessitate thicker gauge wires than a smaller apartment.

- Material: Common materials include copper and aluminum. Copper is preferred for its higher conductivity, but aluminum is often used due to its lower cost. However, aluminum conductors require special connectors and installation techniques to prevent corrosion and connection failures.

- Insulation: The insulation must be appropriate for the voltage and operating temperature. The NEC specifies minimum insulation types based on installation location and potential environmental factors, such as exposure to moisture or direct sunlight.

- Number of Conductors: The number of conductors (hot, neutral, and ground) must be sufficient for the service, with adequate spacing maintained to prevent overheating.

- Installation Methods: Conductors must be properly secured, protected from physical damage, and installed in accordance with NEC guidelines to prevent shorts, grounds, or other hazardous conditions. This might include using conduits, cable trays, or other protective means.

Imagine trying to power a large home with thin, poorly insulated wires – the wires would overheat, potentially leading to a fire. Properly sized and installed service entrance conductors are fundamental to a safe and reliable electrical system.

Q 9. Explain the requirements for overcurrent protection devices.

Overcurrent protection devices, such as fuses and circuit breakers, are designed to prevent damage to electrical equipment and prevent fires by interrupting the flow of electricity when current exceeds a safe level. The NEC dictates specific requirements for their selection and application. Key aspects include:

- Correct Amperage Rating: The device must be rated for the appropriate amperage of the circuit it protects. A circuit breaker rated for 15 amps should not be used on a circuit designed for 20 amps and vice-versa. Oversizing the protection device can allow dangerous overcurrents to flow, while undersizing it can lead to nuisance tripping.

- Type of Device: Fuses and circuit breakers are common choices, each with its own characteristics. Circuit breakers can be more convenient to reset than fuses, but fuse selection often reflects the complexity and specific requirements of a circuit.

- Location: Overcurrent protection devices must be easily accessible and located in accordance with the NEC. For example, they must be easily accessible for inspection and replacement.

- Coordination: In larger systems, multiple overcurrent protection devices must be coordinated to ensure that the appropriate device trips in the event of a fault. This prevents cascading failures, protecting the entire system.

For example, imagine a short circuit in a lighting circuit. The circuit breaker, properly sized, should trip quickly to isolate the fault and protect the wiring from overheating. Without a properly selected and installed overcurrent protection device, the outcome could be significantly more serious.

Q 10. What are the rules regarding working on energized electrical equipment?

Working on energized electrical equipment is extremely dangerous and should only be done by qualified individuals who have undergone extensive safety training and possess the necessary experience and equipment. The NEC doesn’t explicitly say ‘never work on energized equipment’ but implicitly emphasizes the necessity of de-energization through various safety-oriented articles. The guiding principle is to always prioritize safety by using appropriate safety measures, including:

- Lockout/Tagout Procedures: This crucial process ensures that the equipment is de-energized and cannot be re-energized inadvertently while work is being performed. It involves physically locking out the power source and tagging the equipment to indicate that it’s out of service.

- Arc Flash Hazard Analysis: This analysis is essential when working near energized equipment. It evaluates potential arc flash hazards and determines the appropriate personal protective equipment (PPE) required to mitigate risk.

- Personal Protective Equipment (PPE): Proper PPE is critical and should always be worn when working near energized equipment, including insulated tools, gloves, eye protection, and arc flash suits.

- Proper Training and Qualifications: Only qualified individuals with documented training in electrical safety procedures should work on electrical equipment.

Working on energized equipment without taking appropriate safety precautions can result in serious injury, electrocution, or death. It is never worth the risk.

Q 11. How do you interpret electrical drawings and schematics?

Interpreting electrical drawings and schematics requires understanding the symbols and conventions used to represent electrical components and wiring. It is a vital skill for electricians and electrical engineers. Here’s a breakdown of the process:

- Symbol Recognition: Familiarize yourself with common electrical symbols. For instance, a circle with a cross inside usually represents a ground connection, while a zig-zag line often depicts a resistor. Numerous resources like the NEC and online references offer comprehensive guides to standard symbols.

- Wiring Diagrams: These diagrams show the physical layout of wiring and components. Trace the path of wires from their source to their destination, noting the components they connect to.

- Schematic Diagrams: These diagrams use standardized symbols to illustrate the functional relationships between components. They focus less on the physical layout and more on the circuit’s functionality.

- One-Line Diagrams: These diagrams simplify complex systems, showing only the main power lines and major components. They are useful for system overview and troubleshooting.

- Reading and Understanding the Legends: Always refer to the legend or key on the drawing to understand the meaning of specific symbols or abbreviations.

Interpreting electrical drawings is like reading a map. With practice and understanding of the symbols, you can navigate the system and understand its functionality. For example, tracing a wire from a switch to a light fixture on a wiring diagram helps you understand how the switch controls the light.

Q 12. What are the requirements for lighting fixtures in various locations?

Lighting fixture requirements vary significantly depending on the location and intended use. The NEC provides detailed requirements for different areas to ensure safety and appropriate illumination. Key factors include:

- Damp or Wet Locations: Fixtures in bathrooms, kitchens, or outdoor areas must be specifically designed for these conditions (e.g., wet location rated). This typically involves specific sealing and construction to prevent shock hazards.

- Hazardous Locations: Areas with flammable or combustible materials (e.g., garages, workshops) require fixtures that are designed to prevent ignition. They often need special certifications for use in Class I, II, or III hazardous locations (depending on the type of hazard).

- Accessible Ceilings: Fixtures in readily accessible ceilings must be securely installed to prevent accidental falls and potential injury. This includes using appropriate mounting hardware and ensuring that the fixture is not a tripping hazard.

- Exit Lights: These fixtures have specific requirements for placement, visibility, and power source (battery backup is often mandatory) to ensure safe egress during emergencies.

- Illumination Levels: The NEC doesn’t specify precise illumination levels for all areas, but building codes often dictate minimum light levels based on room usage. For example, task lighting in kitchens or workshops needs significantly higher illumination than hallways.

Failing to use appropriately rated fixtures in wet locations can result in shock or electrical fires. Understanding these differences and applying the correct fixtures are vital for safety and compliance.

Q 13. Explain the requirements for grounding electrode conductors.

Grounding electrode conductors connect the grounding electrode system to the electrical system’s grounding point. This connection provides a path for fault currents to flow to the earth, preventing dangerous voltage buildup and protecting people and equipment. Key requirements include:

- Material: Copper or other approved conductive materials are typically used. The size of the conductor is specified based on the amperage rating of the service.

- Size: The size of the grounding electrode conductor must be sufficient to carry fault currents without overheating or damage.

- Connection Methods: The conductor must be securely connected to both the grounding electrode (e.g., ground rod) and the electrical system’s grounding busbar using appropriate clamps and connectors. Corrosion must be prevented.

- Protection: The grounding electrode conductor should be protected from physical damage, corrosion, and other environmental factors. This often involves placing it in a protective conduit.

Imagine a fault in an appliance. Without a properly installed grounding electrode conductor, the appliance casing may become energized, posing a serious shock hazard. A properly functioning grounding electrode conductor provides a safe path for fault currents, minimizing the risk of injury or damage.

Q 14. What are the common causes of electrical fires?

Electrical fires are a serious hazard and can result in significant property damage and loss of life. Common causes include:

- Overloaded Circuits: When too many appliances or devices are plugged into a single circuit, the current exceeds the circuit’s capacity, causing overheating and potentially igniting nearby materials.

- Faulty Wiring: Damaged or improperly installed wiring can lead to shorts and arcing, which can generate enough heat to ignite surrounding materials. This is especially dangerous with old or deteriorated wiring.

- Overheated Appliances: Appliances with faulty heating elements or worn-out cords can overheat and ignite surrounding materials.

- Loose Connections: Loose connections in electrical systems create resistance and can generate significant heat, potentially causing a fire. This is common at outlets, switches and other connection points.

- Improper Use of Extension Cords: Overloading extension cords or using them incorrectly can cause overheating and fire.

Regular electrical inspections, proper maintenance of appliances, and adherence to electrical codes are crucial for preventing electrical fires. These simple yet effective measures can greatly reduce the risk of this devastating hazard.

Q 15. How do you identify and correct electrical hazards?

Identifying and correcting electrical hazards requires a systematic approach combining visual inspection, testing, and adherence to relevant electrical codes (like the NEC in the US). Think of it like a detective solving a case – you need to gather evidence and interpret it correctly.

Visual Inspection: Look for frayed wires, damaged insulation, loose connections, overloaded circuits, improperly grounded equipment, and signs of overheating (scorching, discoloration).

Testing: Use appropriate testing equipment like multimeters to check voltage, current, and resistance. Ground continuity testing is crucial to ensure proper grounding and protection against electric shock. Specialized testing may be required for arc flash hazard assessment.

Corrective Actions: Once hazards are identified, the necessary repairs must be made according to code. This might involve replacing damaged wiring, tightening connections, installing GFCIs (Ground Fault Circuit Interrupters) in wet areas, upgrading outdated panels, or replacing faulty equipment. Always de-energize circuits before working on them, and employ lockout/tagout procedures.

Example: Imagine discovering a receptacle with exposed wiring. This is a clear hazard. The corrective action would be to safely de-energize the circuit, replace the damaged receptacle, and verify the repair using a multimeter to confirm the circuit’s integrity and proper grounding.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the regulations for arc flash hazards?

Arc flash hazards are a significant concern in electrical systems. They occur when a short circuit or fault creates a high-energy arc, resulting in intense heat, light, and pressure. Regulations aim to minimize the risk of injury or death from these events.

Risk Assessment: A crucial first step is performing an arc flash risk assessment, determining the potential arc flash energy for various points in the system. This is often done using software which takes into account system characteristics and fault currents.

Personal Protective Equipment (PPE): Based on the risk assessment, appropriate PPE must be worn, including arc flash suits, face shields, and insulated gloves. The level of PPE required is directly proportional to the calculated arc flash boundary.

Engineering Controls: Modifying the electrical system to reduce the incident energy is paramount. This can include using current-limiting devices, improved grounding, and implementing proper maintenance procedures.

Training and Procedures: Workers must receive comprehensive training on arc flash hazards, safety procedures, and the use of appropriate PPE. Safe work practices, including lockout/tagout, must always be followed.

Compliance with Standards: Adherence to relevant standards, such as NFPA 70E (Standard for Electrical Safety in the Workplace), is mandatory. These standards provide guidelines for risk assessment, PPE selection, and safe work practices.

Example: Working on a 480V switchgear requires a thorough arc flash risk assessment. The assessment might dictate the use of Category 4 arc flash suits and other high-level PPE. The work must be performed following a strict lockout/tagout procedure to ensure the system is completely de-energized before any work commences.

Q 17. Explain the difference between a fuse and a circuit breaker.

Both fuses and circuit breakers are overcurrent protection devices, preventing damage to equipment and reducing fire risks. However, they operate differently.

Fuse: A fuse is a one-time use device. When a fault occurs resulting in excessive current, the fuse’s internal element melts, opening the circuit and interrupting the current flow. It must be replaced after it blows.

Circuit Breaker: A circuit breaker is a reusable device. It uses a bimetallic strip or electromagnetic mechanism to detect overcurrent. Upon exceeding the rated current, the breaker trips, opening the circuit. It can then be reset, restoring power after the fault is corrected.

Key Differences Summarized:

Replaceability: Fuses are replaced; circuit breakers are reset.

Speed: Fuses generally have faster response times than circuit breakers, especially for extremely high fault currents.

Cost: Fuses are typically less expensive initially than circuit breakers, but the replacement cost over time could be higher.

Example: In a residential setting, fuses were commonly used in older homes. Modern construction largely uses circuit breakers because of their reusability and easier maintenance. In industrial settings, both are frequently used based on specific protection needs and cost-benefit analysis.

Q 18. What is the role of a lockout/tagout procedure?

Lockout/Tagout (LOTO) is a safety procedure designed to prevent the accidental energization or startup of equipment during maintenance or repair. It’s a crucial step in preventing serious injuries or fatalities.

The process involves:

Lockout: Disconnecting the energy source and applying a lock to the disconnect device to prevent re-energization.

Tagout: Attaching a tag to the lockout device, clearly indicating who has locked out the equipment and the reason for the lockout.

The procedure is critical because it creates a physical barrier preventing unintentional activation. Each worker involved in the process should have their own lock and tag to ensure that everyone is aware and involved.

Example: Before working on a motor, the electrician will first de-energize the circuit by turning off the breaker. Then, they’ll apply their personal lockout device to the breaker handle, preventing anyone else from turning the power back on. A tag will be attached, clearly identifying the person, task, and date.

Q 19. Describe the different types of conduit and their applications.

Conduit is used to protect electrical wiring from physical damage and environmental factors. Several types exist, each suited to different applications.

Rigid Metal Conduit (RMC): Strong and durable, often used in industrial settings where impact and corrosion resistance are essential. Think of it as a steel pipe protecting the wires.

Intermediate Metal Conduit (IMC): Lighter than RMC, yet still offering good protection. Commonly used in commercial and industrial settings.

Electrical Metallic Tubing (EMT): Also known as thin-walled conduit, it’s lightweight and easy to bend. Suitable for less demanding applications, frequently used in residential and commercial settings.

Flexible Metal Conduit (FMC): Offers flexibility for connecting to moving equipment or in tight spaces. Not as robust as rigid conduit.

Plastic Conduit (PVC): Less expensive than metal conduit, ideal for applications where corrosion is a major concern, like outdoor installations. However, its strength is less than metal conduit.

Example: RMC would be used in a chemical plant to protect wiring from corrosive chemicals. EMT is commonly found in residential wiring applications because of its ease of installation and lower cost.

Q 20. What are the requirements for electrical panels and their installation?

Electrical panels, also known as distribution boards, house circuit breakers or fuses that protect circuits from overcurrent. Their installation is critical for safety and code compliance.

Location: Panels must be installed in easily accessible, dry locations, protected from damage and unauthorized access. They should not be installed in areas prone to flooding or excessive heat.

Clearance: Adequate clearance must be provided around the panel for maintenance and inspection. This often depends on the voltage of the system.

Grounding: The panel must be properly grounded to protect against electric shock. The grounding conductor must be securely connected to the panel and the grounding system of the building.

Overcurrent Protection: Each circuit within the panel must have its own overcurrent protection device (fuse or circuit breaker) sized appropriately for the circuit’s load. This protects the wiring from overheating and potential fires.

Wiring Methods: Wiring within the panel must be neatly organized and secured to prevent short circuits or damage. Wiring methods must comply with the appropriate electrical code.

Compliance with Codes: Installation must comply with all applicable electrical codes (like the NEC) regarding spacing, grounding, labeling, and other safety requirements.

Example: A main electrical panel in a house is typically located in a dry basement or utility closet, with ample clearance for access. Each circuit breaker is sized to protect the wires connected to it, based on the ampacity of those wires and the load they serve. The panel itself will be properly grounded, typically through a connection to the building’s grounding system.

Q 21. How do you determine the ampacity of a conductor?

Ampacity is the maximum current a conductor can carry continuously under the specified conditions without exceeding its temperature rating. Determining a conductor’s ampacity is essential to prevent overheating, fire hazards, and equipment damage.

Factors influencing ampacity:

Conductor Material: Copper has a higher ampacity than aluminum for the same size.

Conductor Size (AWG): Larger diameter conductors (smaller AWG number) have higher ampacity.

Ambient Temperature: Higher ambient temperatures reduce ampacity.

Installation Method: Ampacity is affected by whether the conductor is installed in free air, conduit, raceway, or buried underground. Conduit reduces heat dissipation, thus lower ampacity.

Number of Conductors in a Raceway: More conductors in a raceway means less heat dissipation, lower ampacity.

Ampacity values are found in:

Electrical Codes: The NEC and other national or regional electrical codes provide tables listing ampacity values for various conductors and installation methods.

Manufacturer’s Data: Always consult the manufacturer’s specifications for the precise ampacity ratings of the conductors being used.

Example: A 12 AWG copper conductor in free air might have an ampacity of 20 amps, but its ampacity would be reduced if installed in conduit with other conductors.

Q 22. What are the requirements for installing electrical outlets and switches?

Installing electrical outlets and switches requires adherence to the National Electrical Code (NEC), specifically Article 210. The key considerations are location, spacing, and protection. Outlets must be readily accessible, typically no more than 6 feet apart along a wall and within 12 feet of any doorway. Bathrooms, kitchens, and garages have stricter requirements, often demanding GFCI (Ground Fault Circuit Interrupter) protection for safety. Switches should also be readily accessible and appropriately rated for the load they control. For example, a 15-amp circuit should not power switches controlling heavy-duty appliances. The type of switch (e.g., single-pole, double-pole, three-way, four-way) is determined by the circuit configuration and the number of control points. Properly sized wiring is crucial, matching the current-carrying capacity of the circuit breaker. For instance, a 15-amp circuit generally requires 14 AWG wiring, while a 20-amp circuit needs 12 AWG. Always ensure proper grounding connections to prevent shock hazards.

- Location: Outlets must be conveniently located, considering furniture placement and anticipated use.

- Spacing: NEC dictates maximum spacing between outlets.

- GFCI Protection: Essential in wet locations.

- Wiring Size: Must match circuit breaker rating for safe operation.

Q 23. Explain the requirements for motor control circuits.

Motor control circuits, as defined in NEC Article 430, have specific requirements to ensure safe and reliable operation. These include overload protection, short-circuit protection, and disconnects. Overload protection prevents motor damage from excessive current draw due to factors like overloading or jams. This is typically achieved using thermal overload relays or circuit breakers. Short-circuit protection, usually provided by fuses or circuit breakers, safeguards the circuit and motor from damaging short circuits. Disconnects allow the motor to be isolated from the power source for maintenance or emergencies, and are often provided by a manually operated disconnect switch or circuit breaker. The size and type of these protective devices must match the motor’s rated characteristics, including horsepower and full-load current. Additionally, proper wiring, grounding, and enclosure are essential to prevent electrical shock and other hazards. Motor starters, such as magnetic starters or solid-state starters, may also be required to manage motor starting current and provide additional protection.

Consider a scenario involving a 5 HP motor. You’d need to consult the motor’s nameplate for the full-load current (FLA) and then select a motor starter and protective devices (circuit breaker or fuses) with ratings that exceed the FLA, following the NEC guidelines for motor protection.

Q 24. Describe your experience with electrical code compliance inspections.

Throughout my career, I’ve conducted numerous electrical code compliance inspections for both residential and commercial projects. My experience encompasses various stages of construction, from initial rough-in inspections to final inspections before occupancy. This involves verifying that all wiring, devices, and equipment meet the requirements of the NEC and any applicable local codes. I meticulously examine the grounding system, ensuring continuity and proper bonding. I check for proper wiring methods, using appropriate conduit and cable types for various applications. I pay close attention to details like proper labeling, ensuring that the panelboard is correctly labeled. I also evaluate the safety of equipment installations, confirming proper clearances, protection against hazards, and appropriate grounding. Non-compliance issues are documented with detailed reports that clearly highlight the necessary corrections, ensuring that safety and code compliance are maintained.

In one instance, I discovered an improperly grounded subpanel in a commercial building during a final inspection. This posed a serious safety risk. My report clearly outlined the problem, and I required corrective action before issuing the certificate of occupancy, ensuring the building’s electrical system met all safety standards.

Q 25. How do you stay current with changes in electrical codes?

Staying current with evolving electrical codes is paramount for maintaining competence and ensuring safety. I actively participate in professional development programs offered by organizations such as the IEEE and NFPA. I subscribe to industry publications that provide updates and interpretations of the NEC. I frequently review the latest NEC handbook and attend seminars and workshops presented by code experts and regulatory agencies. This ongoing professional development ensures that my knowledge remains up-to-date, allowing me to apply the most current and effective safety standards in my work.

Q 26. What is your understanding of Article 250 (Grounding) in the NEC?

Article 250 of the NEC, Grounding, is foundational for electrical safety. It establishes requirements for grounding and bonding systems to protect people and equipment from electric shock and other hazards. The article details methods for grounding electrical systems, including grounding electrodes (e.g., ground rods), grounding conductors (typically bare copper wires), and bonding (connecting metallic parts together to create a low-impedance path for fault currents). The goal is to ensure a safe path for fault currents to flow to the earth, preventing dangerous voltage buildup on metallic enclosures or equipment. Different grounding systems are prescribed depending on the type of installation (e.g., service grounding, equipment grounding, grounding of metallic conduits).

A critical aspect is ensuring proper grounding electrode resistance, typically below 25 ohms, to provide an effective path to earth. Failure to adhere to Article 250 can lead to serious consequences, including electric shock, fire hazards, and equipment damage.

Q 27. Explain the importance of proper cable sizing and selection.

Proper cable sizing and selection are crucial for safe and efficient operation of electrical systems. Undersized cables can overheat, causing fire hazards, while oversized cables are wasteful and unnecessary. The correct cable size is determined by the ampacity (current-carrying capacity) required by the load, considering factors like the length of the run, ambient temperature, and installation method (e.g., in conduit, in free air). The NEC provides tables to determine the appropriate ampacity for various cable types and installation conditions. The selected cable must have an ampacity rating at least equal to, or greater than, the load’s current draw. This prevents overheating and ensures the cable can handle the current without causing damage. For instance, using a 14 AWG cable on a 20-amp circuit is unsafe because the cable’s ampacity is insufficient to handle the load.

Choosing the correct cable type is equally important. Different cable types (e.g., THHN, THWN, UF) are designed for various applications and environmental conditions. Selecting the wrong cable type can compromise safety and longevity.

Q 28. Describe a situation where you had to troubleshoot an electrical problem and how you resolved it.

I once encountered an intermittent power outage affecting a portion of a commercial building. The initial diagnosis pointed to a faulty circuit breaker. However, after replacing the breaker, the issue persisted. Using a multimeter, I systematically checked the voltage at various points in the circuit, gradually isolating the problem. I discovered a loose connection in a junction box located in a hard-to-reach area within the ceiling. The loose connection caused intermittent arcing and the subsequent power outages. I carefully tightened the connection, ensuring a secure and reliable contact, and the problem was resolved. This highlights the importance of thorough investigation and methodical troubleshooting when dealing with electrical issues. It’s never enough to focus on the most obvious source of failure. A careful and systematic approach always leads to a more efficient solution.

Key Topics to Learn for Electrical Codes Interview

- National Electrical Code (NEC) Overview: Understanding the structure, purpose, and application of the NEC is fundamental. Focus on the articles most relevant to your experience.

- Wiring Methods and Materials: Become proficient in identifying appropriate wiring methods (e.g., conduit, cable) for different applications and understanding the properties of various insulating materials. Practice calculating voltage drop and sizing conductors.

- Overcurrent Protection: Master the principles of circuit breakers and fuses, including their selection, sizing, and coordination to ensure safety and prevent equipment damage. Be prepared to discuss arc flash hazards and mitigation.

- Grounding and Bonding: Thoroughly understand the purpose and methods of grounding and bonding to ensure electrical safety and equipment protection. Be ready to discuss different grounding electrode systems.

- Motor Controls and Power Distribution: Familiarize yourself with the principles of motor control circuits, including starters, contactors, and overload relays. Understand the principles of power distribution systems and their components.

- Lighting and Branch Circuits: Be prepared to discuss different lighting systems and their design considerations. Understand the requirements for branch circuits, including load calculations and overcurrent protection.

- Problem-Solving Approach: Practice applying your knowledge to solve practical problems related to code compliance, troubleshooting, and safety. This includes interpreting code sections and applying them to real-world scenarios.

- Safety Regulations and Practices: Demonstrate a strong understanding of electrical safety regulations and best practices, including lockout/tagout procedures and personal protective equipment (PPE).

Next Steps

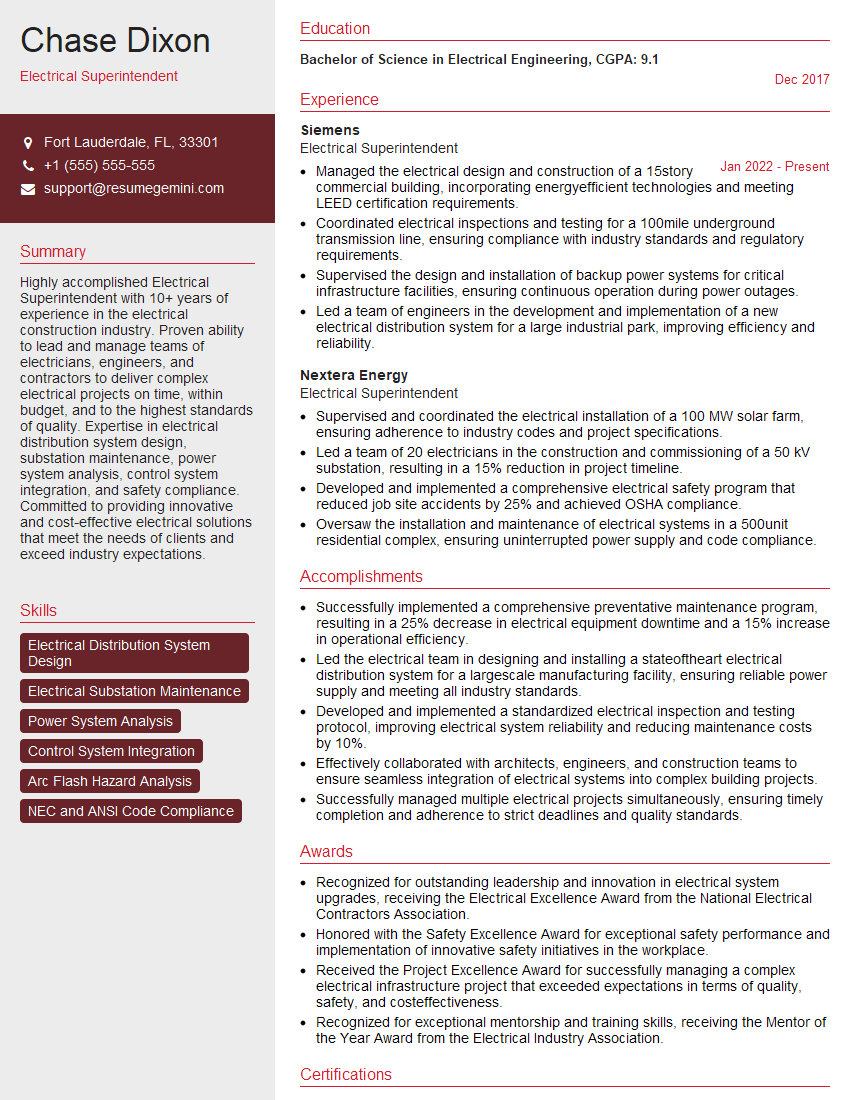

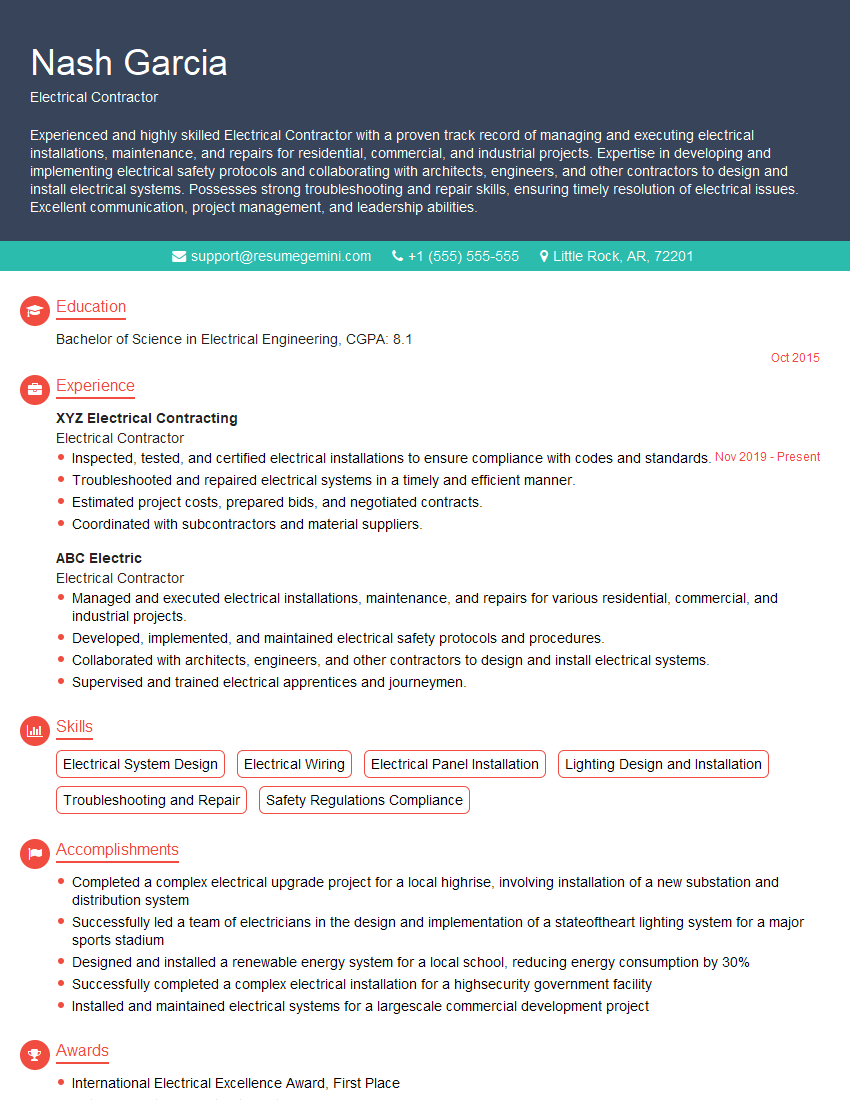

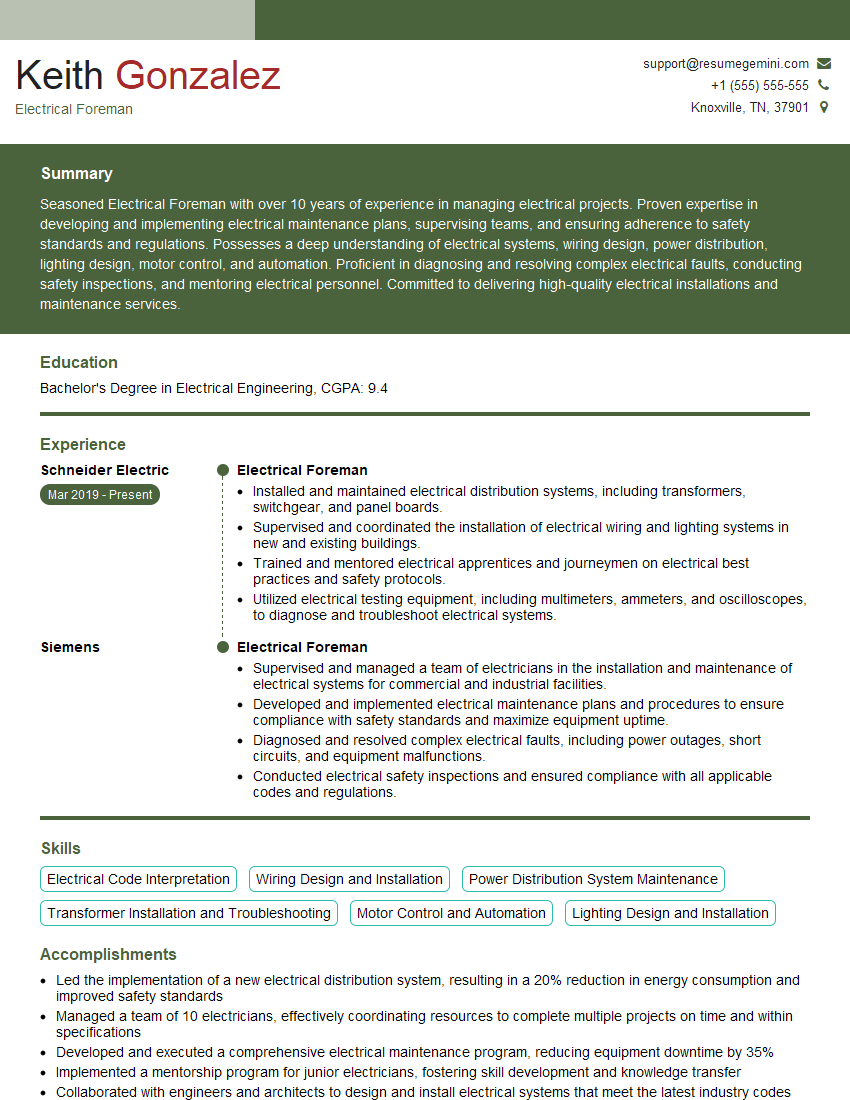

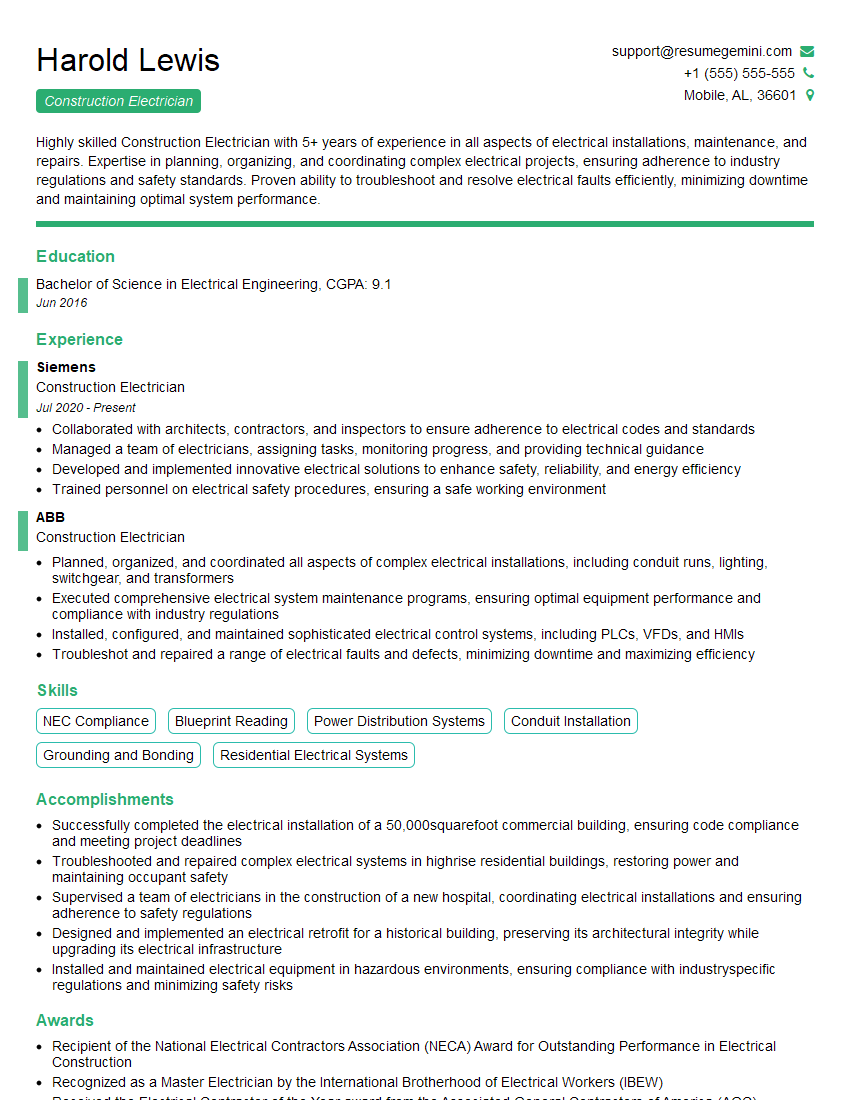

Mastering Electrical Codes is crucial for career advancement in the electrical field, opening doors to more challenging and rewarding opportunities. A well-crafted resume is your first impression on potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. We strongly encourage you to leverage ResumeGemini to build a professional and impactful resume that highlights your skills and experience in Electrical Codes. ResumeGemini provides examples of resumes tailored to this specific field to guide you in crafting the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO