Are you ready to stand out in your next interview? Understanding and preparing for Electroplating Knowledge interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Electroplating Knowledge Interview

Q 1. Explain the difference between electroplating and electroless plating.

Electroplating and electroless plating are both methods used to deposit a thin layer of metal onto a substrate, but they differ significantly in their mechanisms. Electroplating uses an electric current to drive the deposition process, while electroless plating is an autocatalytic process that doesn’t require an external power source.

In electroplating, the substrate acts as the cathode in an electrolytic cell. A direct current is passed through the cell, causing metal ions from the electrolyte solution (the plating bath) to be reduced and deposited onto the substrate. Think of it like painting with charged particles; the electricity forces the metal ions to stick to the surface. A sacrificial anode is used to replenish metal ions in the solution.

Electroless plating, on the other hand, relies on a chemical reducing agent in the solution to reduce the metal ions and deposit them onto the substrate. This process doesn’t require an external current, but it does need careful control of the chemical environment to ensure even deposition. Imagine it as a self-catalyzing reaction where the already deposited metal acts as a catalyst to encourage further deposition.

A simple analogy: electroplating is like painting with a charged paintbrush, while electroless plating is like a self-spreading paint that chemically bonds to the surface.

Q 2. Describe the Faraday’s laws of electrolysis and their relevance to electroplating.

Faraday’s laws of electrolysis are fundamental to electroplating. They govern the quantitative relationship between the amount of electricity passed through an electrolytic cell and the mass of metal deposited.

Faraday’s First Law: The mass of a substance deposited or liberated at an electrode is directly proportional to the quantity of electricity passed through the electrolyte. This means that the more electricity you use, the more metal you plate. Mathematically, it’s expressed as: m = (Q * A) / (n * F), where m is the mass of the substance, Q is the quantity of electricity (in Coulombs), A is the atomic weight of the substance, n is the number of electrons involved in the reduction reaction, and F is Faraday’s constant (approximately 96485 C/mol).

Faraday’s Second Law: When the same quantity of electricity is passed through different electrolytes, the masses of the substances liberated or deposited are proportional to their equivalent weights. This means different metals will deposit at different rates even with the same current. For example, plating silver will require a different current density than plating copper for the same deposition rate.

In electroplating, these laws are crucial for controlling the thickness and quality of the deposited layer. By precisely controlling the current and time, we can achieve the desired coating thickness, ensuring consistent and predictable results in industrial applications.

Q 3. What factors influence the quality of an electroplated coating?

The quality of an electroplated coating is influenced by a multitude of factors, including:

- Current Density: Too high a current density can lead to rough, porous, or burned deposits; too low a density can result in slow, uneven deposition. It’s like painting too thickly or too thinly – neither is ideal.

- Temperature: Temperature affects the rate of reaction and solubility of ions, influencing the coating quality. Higher temperatures generally improve plating rate but can also lead to defects if not managed properly.

- pH: The pH of the plating bath significantly impacts the metal ion concentration and the deposition rate. An incorrect pH can lead to poor adhesion, pitting, or other defects.

- Agitation: Proper agitation ensures uniform distribution of ions in the plating bath, leading to a more consistent and uniform coating. Think of stirring the paint before applying it to avoid clumps.

- Purity of the plating bath: Impurities can affect the quality of the deposit and lead to various defects. Regular filtering and maintenance of the bath are crucial.

- Substrate preparation: A clean, well-prepared substrate surface is essential for good adhesion. This involves cleaning, degreasing, and often etching the substrate to provide a suitable surface for plating.

- Type of plating solution: Different plating baths have different characteristics and are suited for specific applications. The choice of bath is crucial for achieving the desired properties in the final coating.

Controlling these parameters is essential for achieving high-quality, consistent electroplated coatings in industrial processes.

Q 4. How do you control the thickness of an electroplated layer?

The thickness of an electroplated layer is primarily controlled by adjusting the plating time and the current density. Faraday’s laws provide the basis for this control.

By precisely measuring the current and the duration of the process, you can accurately calculate the amount of metal deposited. Higher current densities (amperes per unit area) result in faster deposition and thus thicker coatings. However, excessively high current densities can lead to poor quality coatings (as discussed earlier). The formula mentioned in the answer to question 2 is key to calculating this. In practice, we often use empirical data and standardized plating procedures to determine optimal current and time for a given thickness.

Another method involves using coulometers, which measure the total charge passed during the electroplating process. Knowing the charge passed allows a precise calculation of the deposited mass and hence thickness. Modern plating setups often utilize automated control systems to maintain consistent current and track the total charge, ensuring precise control of coating thickness.

Q 5. What are the common types of plating baths used in industry?

The choice of plating bath depends heavily on the desired metal and properties of the coating. Common types include:

- Cyanide baths: Commonly used for plating precious metals like gold, silver, and cadmium. They are effective but require careful handling due to their toxicity.

- Acid baths: Used for plating various metals such as copper, nickel, chromium, and zinc. They offer better throwing power than cyanide baths.

- Alkaline baths: Typically used for plating zinc, cadmium, and some other metals. They are less toxic than cyanide baths.

- Sulfate baths: Frequently used for nickel plating and offer good control over the plating process and coating quality.

- Chloride baths: Used for gold and other metals, often offering a faster plating rate than cyanide baths.

Each type of bath has its own advantages and disadvantages in terms of plating efficiency, coating properties, and safety considerations. Selecting the appropriate bath requires considering the application, desired coating properties, environmental regulations, and cost factors.

Q 6. Explain the concept of throwing power in electroplating.

Throwing power in electroplating refers to the ability of a plating bath to produce a uniform coating thickness on complex shapes with recesses and protrusions. A plating bath with good throwing power will deposit metal evenly across all surfaces, even those that are not directly exposed to the anode. This is crucial for applications where uniformly coated parts are required.

High throwing power is desirable as it minimizes the variation in coating thickness across a component. Poor throwing power, in contrast, leads to uneven coating, with thicker deposits on areas close to the anode and thinner deposits in recesses. This can compromise the protective or functional properties of the coating.

Several factors influence throwing power, including the electrolyte composition, current density, geometry of the plating setup, and the presence of additives in the plating bath. Additives such as brighteners and levelers are often added to improve throwing power and coating quality.

Imagine plating a complex part with many crevices. A plating bath with good throwing power would ensure that even the deepest recesses receive a uniform coating thickness, while one with poor throwing power might leave some areas uncoated or with a much thinner coating.

Q 7. Describe the different types of plating defects and their causes.

Several types of plating defects can occur during electroplating, each with specific causes:

- Pitting: Small holes or depressions in the coating. Caused by impurities in the bath, improper substrate preparation, or localized variations in current density.

- Burning: Rough, uneven deposits caused by excessively high current density, leading to hydrogen gas evolution and poor metal deposition.

- Nodules: Small bumps or protrusions on the coating surface. Typically caused by impurities or variations in the plating bath’s composition.

- Treeing: Irregular, dendritic growths of the plated metal. Caused by high current density or contamination.

- Roughness: An uneven surface texture resulting from high current density, contamination, or improper agitation.

- Poor adhesion: The coating peels or flakes off the substrate. Caused by poor substrate preparation, improper cleaning, or a mismatch in the thermal expansion coefficients between the coating and substrate.

- Blistering: Bubbles or blisters forming within the coating, often indicating trapped gases or internal stresses.

Identifying and addressing these defects requires careful analysis of the process parameters and systematic troubleshooting. Microscopic examination of the coating often helps in determining the root cause of the defect.

Q 8. How do you measure the thickness of an electroplated coating?

Measuring the thickness of an electroplated coating is crucial for quality control. Several methods exist, each with its own advantages and limitations. The most common techniques include:

- Destructive methods: These methods involve removing a section of the coating to measure its thickness directly. For example, cross-sectional microscopy involves embedding the plated sample in resin, sectioning it, polishing it, and then examining it under a microscope to measure the coating’s thickness. Another method is coulometric stripping, where the coating is dissolved electrochemically, and the current is measured to calculate the thickness. This is highly accurate but destructive.

- Non-destructive methods: These methods allow for measurement without damaging the plated part. Magnetic methods utilize the principle of magnetic induction to measure the thickness of non-magnetic coatings on a magnetic substrate. Electromagnetic methods (Eddy current testing) are used for conductive coatings on conductive substrates. The technique involves measuring the change in impedance of an electromagnetic coil placed near the plated surface. X-ray fluorescence (XRF) is a powerful technique for measuring coating thickness, even on complex geometries. It works by irradiating the surface and analyzing the emitted X-rays, allowing for non-destructive determination of both layer thickness and composition. Ultrasonic testing can also measure coating thickness and identify defects within the coating or substrate.

The choice of method depends on factors like coating material, substrate material, required accuracy, and the available budget and equipment.

Q 9. What are the safety precautions necessary when working with electroplating processes?

Electroplating involves working with potentially hazardous chemicals, requiring strict adherence to safety protocols. Key precautions include:

- Proper ventilation: Electroplating baths often release toxic fumes; a well-ventilated workspace or a fume hood is essential.

- Personal protective equipment (PPE): This includes gloves (nitrile or neoprene), safety glasses or a face shield, and an apron to protect against splashes of corrosive chemicals.

- Handling of chemicals: Always follow the manufacturer’s safety data sheets (SDS) for proper handling and storage of chemicals. Avoid skin contact and inhalation. Use designated containers and proper disposal techniques for waste chemicals.

- Emergency procedures: A readily accessible emergency shower and eyewash station are crucial, along with a clearly defined emergency response plan.

- Training and awareness: All personnel must receive thorough training on safe handling procedures, emergency response, and waste disposal protocols.

- Regular monitoring: Regular monitoring of air quality and bath composition is critical for maintaining a safe and effective operation. This includes checking for the presence of harmful gases or airborne particles.

Failure to comply with these safety measures can result in serious health hazards and environmental problems.

Q 10. Explain the importance of pre-treatment processes in electroplating.

Pre-treatment processes are paramount in electroplating, ensuring a high-quality, adherent coating. They prepare the substrate’s surface for optimal plating by:

- Cleaning: Removes oils, grease, dirt, and other contaminants from the substrate’s surface, ensuring good adhesion of the plating. Common cleaning methods include solvent cleaning, alkaline cleaning, and emulsion cleaning.

- Degreasing: Effectively removes oily residues that might hinder the plating process. Solvents or alkaline cleaners can be employed depending on the nature of the oil.

- Descaling/Pickling: Removes oxides, scale, and other surface imperfections from the substrate. Acidic solutions are commonly used for metal substrates.

- Surface activation: Improves the surface’s wettability and reactivity to enhance the adhesion of the plating. Processes like etching and electropolishing can achieve this.

- Rinsing: Thorough rinsing between each pre-treatment step is essential to prevent cross-contamination. Multiple rinse tanks with flowing water are commonly used.

Without proper pre-treatment, the plated coating might peel off, resulting in product failure. For example, a poorly cleaned surface will lead to poor adhesion, and a surface with residual oxides will result in an uneven coating.

Q 11. What are the environmental concerns associated with electroplating?

Electroplating, while a crucial industrial process, poses significant environmental concerns:

- Heavy metal contamination: Electroplating solutions often contain heavy metals like chromium, nickel, cadmium, and copper. Improper disposal of these solutions can contaminate water bodies and soil, posing serious risks to human health and the ecosystem. This is particularly crucial for hexavalent chromium, a known carcinogen.

- Cyanide and other toxic compounds: Some plating baths utilize cyanide for complexing metal ions, posing a significant environmental hazard due to its high toxicity. Other compounds like chromic acid are equally harmful.

- Wastewater treatment: Electroplating generates wastewater that requires special treatment to remove heavy metals and other pollutants before it can be safely discharged into the environment. Untreated wastewater can lead to severe environmental pollution.

- Air emissions: Electroplating processes may release gaseous pollutants, particularly during certain stages like pickling. Proper ventilation and air filtration are critical to minimize air emissions.

Stringent environmental regulations and the implementation of cleaner technologies are crucial for mitigating these environmental impacts. Recycling plating solutions and implementing closed-loop systems can significantly reduce waste generation.

Q 12. How do you troubleshoot common problems encountered during electroplating?

Troubleshooting electroplating problems requires a systematic approach. Common problems and solutions include:

- Poor adhesion: This might be caused by inadequate cleaning, surface contamination, or improper pre-treatment. Solutions include more thorough cleaning, appropriate pre-treatment steps, or a different plating process.

- Rough or pitted deposits: This can result from high current density, impurities in the bath, or inadequate agitation. Solutions include reducing current density, filtering the bath, improving agitation, and adjusting bath parameters.

- Burning: This occurs due to excessively high current density, leading to a burnt, dark appearance. Lowering current density will resolve the issue.

- Thin deposits: This may indicate low current density, low metal concentration in the bath, or excessive agitation. Adjusting the current density, adding more metal salts, or reducing agitation can fix this.

- Blistering or peeling: This is often caused by trapped hydrogen within the coating. Solutions might include changing the plating solution, pre-treatment steps, or adopting a different plating process.

- Dark or dull deposits: Impurities in the bath or improper rinsing may lead to a lack of luster. Filtering the solution, ensuring thorough rinsing, and adding brightening agents may help.

Careful observation, systematic analysis, and understanding of electroplating chemistry are essential for effective troubleshooting.

Q 13. Describe the different types of anodes used in electroplating.

The choice of anode in electroplating is crucial, as it determines the composition and quality of the deposit. Different types of anodes are used, including:

- Insoluble anodes: These anodes, such as lead, lead alloys (lead-antimony, lead-tin), platinum, and graphite, do not dissolve during the plating process. They primarily serve as current conductors and maintain the bath composition. Lead anodes are commonly used in chromic acid baths, while platinum anodes are preferred for highly corrosive solutions. Insoluble anodes are vital for maintaining bath chemistry and requiring separate replenishment of metal ions.

- Soluble anodes: These anodes, made of the same metal being plated, dissolve during the process, replenishing the metal ions in the bath. For example, a nickel anode is used in nickel plating. This simplifies the plating process and automatically maintains the concentration of the metal ions in the solution. This approach requires careful control of the anode dissolution rate to avoid imbalances in the bath composition.

The choice between soluble and insoluble anodes depends on factors like the specific metal being plated, the desired bath chemistry, and cost considerations.

Q 14. What is the role of additives in electroplating baths?

Additives play a vital role in electroplating baths, modifying the properties of the deposited coating. They influence several aspects:

- Brighteners: Enhance the brightness and luster of the plated coating, making the finish more appealing. They typically modify the crystal growth process on the substrate surface.

- Levelers: Improve the smoothness and uniformity of the deposit, filling in imperfections on the substrate surface. They often work by preferentially adsorbing on high-energy sites and slowing down deposition in those areas.

- Stress relievers: Reduce the internal stress within the plated coating, preventing cracking and improving its durability. They reduce the build-up of tensile stress.

- Carriers: Enhance the dissolution and distribution of metal ions in the plating bath. They ensure uniform plating across the workpiece.

- Wetting agents: Improve the wettability of the substrate surface, promoting better coating adhesion. They lower surface tension.

- Buffers: Maintain the pH of the plating bath, ensuring consistent plating conditions. They help to prevent significant changes in pH.

The type and concentration of additives are carefully selected to achieve the desired properties of the final plated coating. The selection is usually determined by the substrate, desired coating properties, and other process parameters.

Q 15. How do you maintain the quality of an electroplating bath?

Maintaining the quality of an electroplating bath is crucial for consistent and high-quality plating. It involves a multi-pronged approach focused on several key aspects: filtration to remove impurities, regular analysis of the bath’s composition (metal ion concentration, pH, additives), and periodic replenishment of depleted chemicals. Think of it like maintaining a finely tuned engine; regular checks and adjustments are vital for optimal performance.

- Filtration: Particles in the bath can cause pitting or other defects on the plated surface. Regular filtration using methods like cartridge filters or gravity filters removes these particles, ensuring a smoother finish. The frequency depends on the plating process and the cleanliness of the parts being plated.

- Analysis: Regular chemical analysis using techniques like titration or atomic absorption spectroscopy (AAS) helps maintain the correct concentration of metal ions, pH, and additives. Variations can lead to poor plating quality, such as uneven deposition, dull finish, or weak adhesion.

- Replenishment: As the plating process progresses, metal ions are consumed, and additives are depleted. Regular replenishment with fresh chemicals ensures the bath remains effective and consistent. This helps to maintain a stable plating process and avoid inconsistent plating thickness or quality.

- Temperature control: Maintaining a consistent temperature is crucial, as temperature affects the plating rate, efficiency, and the quality of the deposit. Deviation from the ideal temperature can lead to variations in the plating thickness and surface finish.

- Anode control: Using soluble anodes in the plating bath replenishes the metal ions during the process. Ensuring the anodes have proper surface area and composition and are free of impurities also maintains the bath’s quality.

For example, in a nickel plating bath, regularly checking and adjusting the nickel sulfate concentration, boric acid concentration, and pH is essential for obtaining a bright, uniform, and highly adherent nickel layer. Ignoring these aspects can quickly lead to a significant drop in plating quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of stripping an electroplated coating.

Stripping an electroplated coating involves removing the plated metal from the substrate. The method depends largely on the type of plating and the substrate material. Common techniques include chemical stripping and electrochemical stripping. It’s like carefully removing a layer of paint to reveal the original surface underneath.

- Chemical Stripping: This involves immersing the plated part in a chemical solution that dissolves the plating without significantly affecting the base metal. The choice of stripping solution depends heavily on the type of plating. For example, chromic acid is commonly used to strip nickel plating but is highly corrosive and requires careful handling. More environmentally friendly options, like proprietary formulations, are increasingly used.

- Electrochemical Stripping: This technique uses an electrolytic cell to reverse the plating process. The plated part becomes the anode, and the plated metal dissolves into the solution. Careful control of current density and solution composition is necessary to avoid damaging the base metal. This method offers more precise control over the stripping process compared to chemical stripping and can help to strip different layers selectively in complex plated parts.

For instance, stripping a gold layer from a PCB (printed circuit board) would often require a reverse plating process. It’s critical to choose a stripping solution that won’t damage the underlying copper traces on the PCB.

Q 17. What are the different types of plating solutions used for different metals?

Different metals require different plating solutions, tailored to their unique electrochemical properties. The solutions are typically composed of metal salts, conducting salts, and additives that influence the plating characteristics.

- Nickel Plating: Often uses nickel sulfate or nickel chloride as the primary metal salt, with boric acid as a buffer to maintain pH and improve plating quality. Brighteners and levelers are commonly added to improve the surface finish and smoothness.

- Chrome Plating: Uses chromic acid as the primary ingredient, often with sulfuric acid as a catalyst. This process typically produces a hard and wear-resistant chromium layer.

- Copper Plating: Commonly uses copper sulfate as the primary metal salt, with sulfuric acid as a conductive salt. Additives might include brighteners for a lustrous finish or levelers for uniform thickness. Often used as an undercoat for other plating processes.

- Gold Plating: Can be done from various solutions containing gold salts, such as gold cyanide (though less common now due to environmental concerns) or gold sulfite. The choice depends on the application and desired properties of the gold layer.

- Silver Plating: Typically uses silver cyanide (again, environmental considerations are important) or other silver salts in a cyanide or non-cyanide-based bath. Silver plating finds use in jewelry and electronics due to its conductivity and reflectivity.

The choice of plating solution is paramount for successful electroplating. Using an unsuitable solution can lead to poor adhesion, lack of uniformity, or other defects, leading to product failure.

Q 18. Describe the process of rack plating vs. barrel plating.

Rack plating and barrel plating are two distinct methods for electroplating parts, each with its own advantages and disadvantages. The choice depends on the size, shape, and quantity of parts to be plated.

- Rack Plating: This method involves individually hanging parts on racks made of a non-conductive material, usually plastic, which are then immersed in the plating bath. It’s best suited for larger, irregularly shaped parts that need careful placement to ensure even plating. It gives excellent control over the plating process and allows for complex parts to be plated consistently. However, it’s labor-intensive and less efficient for large-scale production.

- Barrel Plating: This method uses a rotating barrel filled with small parts, which are tumbled in the plating solution. The parts are electrically connected to the cathode by the barrel itself. It’s highly efficient and cost-effective for small, similar-shaped parts. However, it may cause parts to scratch or become damaged during tumbling, and it is not suitable for delicate parts or those with sharp edges. The plating quality might be slightly less consistent compared to rack plating due to the tumbling action.

For example, plating intricate automotive components would typically require rack plating to ensure a consistent and high-quality finish. In contrast, plating small fasteners in high volume is much more efficiently handled by barrel plating.

Q 19. How do you ensure the adhesion of an electroplated coating?

Good adhesion of the electroplated coating to the substrate is crucial for the longevity and performance of the plated part. Several factors influence adhesion:

- Surface Preparation: This is arguably the most critical step. The substrate surface must be thoroughly cleaned and prepared to ensure good contact between the plating and the base material. This often involves degreasing, cleaning, and activating the surface through processes like pickling or etching to increase surface roughness for better mechanical interlocking. Think of it as creating a strong foundation for the plating to adhere to.

- Pre-plating Treatments: Using pre-plating treatments such as strike plating (a thin initial layer of the plating metal applied with high current density) can greatly enhance adhesion by providing a smoother and more uniform surface for the subsequent thicker plating layer to adhere to.

- Plating Parameters: Careful control of the plating parameters, such as current density, temperature, and solution composition, is also important. The use of appropriate additives and current waveforms helps to improve adhesion. Too high a current density can lead to burning and poor adhesion.

- Substrate Material: The substrate’s nature plays a significant role. Different materials have different affinities to various plating metals. For example, some metals are naturally more compatible with specific plating materials, resulting in better adhesion.

For example, before chrome plating, the base metal must be thoroughly cleaned, often employing a series of chemical treatments to etch the surface, increasing its roughness and therefore improving the mechanical bonding to the chrome layer.

Q 20. What are the different types of current used in electroplating (DC, pulsed DC, AC)?

Different types of current can be used in electroplating, each affecting the plating process and the resulting deposit’s properties.

- Direct Current (DC): This is the most common type, providing a constant flow of electrons from the anode to the cathode. It’s simple to implement and results in relatively uniform plating. However, it can sometimes lead to less efficient plating processes and undesirable dendritic growth.

- Pulsed Direct Current (Pulsed DC): This involves applying short bursts of DC current followed by short off-times. The pulse parameters (on-time, off-time, duty cycle) can be adjusted to optimize the plating process. Pulsed DC can lead to improved grain refinement and reduced stress in the plating compared to conventional DC.

- Alternating Current (AC): This involves current flowing back and forth periodically. While less common in plating due to its tendency to cause etching and poor plating quality unless very carefully controlled, it is sometimes used in specific applications, for example for cleaning processes and selective etching.

The choice of current type influences the efficiency, uniformity, and stress within the coating. For example, pulsed DC is often used in decorative plating to achieve a bright and smooth finish by better controlling crystal growth in the plated layer.

Q 21. Explain the concept of current density and its importance in electroplating.

Current density is defined as the amount of current flowing per unit area of the cathode surface (amperes per square decimeter, A/dm²). It’s a critical parameter in electroplating that significantly impacts the plating process and the quality of the deposit. Think of it as the intensity of the plating process at a given point on the part’s surface.

- Influence on Plating Rate: Higher current density generally leads to a faster plating rate. However, exceeding a certain threshold can lead to rough, non-uniform deposits, burning, and poor adhesion.

- Impact on Deposit Properties: Current density affects the crystal structure and grain size of the deposit. Different current densities can lead to different plating properties, such as hardness, ductility, and internal stress.

- Ensuring Uniformity: Achieving uniform current density distribution across the entire part’s surface is crucial for producing a consistent and uniform plating thickness. Irregularities in shape and the arrangement of parts in the bath can create variations in current density, leading to uneven plating.

Optimizing current density for a given part and plating solution is often achieved through experimentation and careful consideration of factors like part geometry and solution conductivity. A well-designed electroplating setup aims to minimize the current density variations across the part to ensure a uniform and high-quality plating layer.

Q 22. How do you control the plating solution’s temperature and pH?

Controlling the temperature and pH of an electroplating solution is crucial for achieving consistent and high-quality plating. These parameters directly influence the rate of deposition, the crystalline structure of the deposit, and the overall quality of the finish. Temperature is typically controlled using heating elements and thermostats, often integrated into the plating tank itself. Imagine a thermostat in your home – it works similarly, maintaining a set temperature by switching the heating element on and off. For electroplating, this ensures the solution remains within the optimal temperature range specified for the particular plating process. The pH, or acidity/alkalinity, of the solution is equally vital and is monitored and adjusted using pH meters and chemical additives. For instance, if the pH becomes too high, acidic chemicals like sulfuric acid might be added to lower it, and vice versa. Precise control of both temperature and pH is usually achieved through automated systems that monitor and adjust these parameters continuously, minimizing variations and ensuring consistent plating quality. This automation is particularly important for large-scale production runs.

Consider an example involving nickel plating: If the temperature is too low, the nickel deposition rate will be slow, resulting in a dull and uneven finish. Conversely, if it’s too high, the plating might be pitted or burnt. Similarly, deviations in pH can cause the formation of undesirable precipitates or affect the adhesion of the plating.

Q 23. What are the different methods used for waste treatment in electroplating?

Waste treatment in electroplating is vital for environmental protection and regulatory compliance. Several methods are employed, often in combination, to reduce the environmental impact. These generally include chemical precipitation, ion exchange, electrodialysis, and evaporation. Chemical precipitation involves adding chemicals to the wastewater to precipitate out heavy metal ions, forming a solid sludge that can be collected and disposed of safely. For example, adding hydroxide to a solution containing hexavalent chromium (Cr6+) converts it to trivalent chromium (Cr3+), which is less toxic and easier to precipitate. Ion exchange uses resin beads to selectively absorb metal ions from the wastewater, effectively removing them. Electrodialysis uses an electric field to separate ions from the water, concentrating the contaminants into a smaller volume for easier disposal. Finally, evaporation concentrates the wastewater, making it easier to manage the remaining contaminants. The choice of method depends on factors such as the type and concentration of contaminants, the volume of wastewater, and the cost-effectiveness of each technique. Many electroplaters also employ filtration steps to remove particulate matter before the treatment process begins.

Q 24. Describe your experience with different types of electroplating equipment.

My experience encompasses a wide range of electroplating equipment, including both manual and automated systems. I’ve worked with various tank configurations, from small laboratory-scale setups to large-scale production lines. This includes different types of rectifiers (DC power supplies crucial for the plating process), filtration systems (essential for maintaining solution purity), heating and cooling systems (for temperature control), and automated plating machines that handle multiple parts simultaneously. I’m familiar with both barrel plating systems, ideal for smaller parts, and rack plating systems used for larger or more complex components. I have significant experience troubleshooting and maintaining these systems, ensuring efficient and reliable operation. For instance, I’ve worked with programmable logic controllers (PLCs) to manage automated systems, ensuring the precise control of parameters like current density, voltage, and plating time.

One specific example involves my work with a fully automated rack plating line for automotive parts. This system included sophisticated robotics for part handling, precise temperature and pH control, and an automated rinsing system to minimize water usage. My role involved not only routine maintenance but also optimizing the plating process to improve efficiency and reduce defects.

Q 25. How do you ensure the compliance of your electroplating process with environmental regulations?

Ensuring compliance with environmental regulations is paramount in electroplating. This involves meticulous record-keeping, regular monitoring of wastewater discharge, and adherence to all relevant local, regional, and national regulations. We perform regular water quality analysis to ensure our effluent meets the discharge limits set by the environmental agencies. This includes measuring the concentration of heavy metals, chemicals, and other pollutants. We also maintain detailed records of all chemical usage, wastewater generation, and treatment processes. This documentation is vital for audits and demonstrates our commitment to environmental responsibility. Furthermore, we regularly update our processes to incorporate the latest advancements in waste treatment technology and best practices to minimize our environmental footprint. We also work closely with environmental consultants to ensure we stay abreast of changing regulations and best practices. This proactive approach helps us remain compliant and maintain our environmental stewardship.

Q 26. What are the latest advancements in electroplating technology?

The electroplating industry is constantly evolving, with several exciting advancements shaping the future. One key area is the development of more environmentally friendly processes. This includes the exploration of alternative plating chemistries that use less toxic chemicals, such as those based on water-based solutions instead of traditional chromic acid. Another area of significant progress is in automation and process control, including the use of advanced sensors and AI to optimize plating parameters in real-time. This leads to increased efficiency, reduced waste, and improved plating consistency. Additive manufacturing, often referred to as 3D printing, is also transforming the industry, offering the possibility of directly plating onto complex three-dimensional structures, opening up new avenues for functional and aesthetic applications. Furthermore, pulsed current techniques are becoming increasingly common, offering better control over the plating process and improving deposit quality. These advancements are not just about efficiency, but about creating sustainable and high-quality plating solutions for diverse applications.

Q 27. Describe a time you had to troubleshoot a plating issue. What was your approach?

During a large-scale production run of gold plating for electronic connectors, we experienced a significant increase in the number of rejected parts due to poor adhesion. My approach involved a systematic troubleshooting process. First, I reviewed the entire process, from pre-treatment steps (cleaning, etching, activation) to the plating itself, analyzing each stage for potential problems. I then conducted detailed analyses of the plating solution, including its pH, concentration of gold ions, and the presence of any contaminants. This revealed a significant drop in the concentration of a key additive responsible for ensuring proper adhesion. Once the cause was identified, I immediately corrected the solution chemistry by adding the missing additive. Furthermore, we implemented stricter quality control checks at each stage of the process to prevent similar issues in the future. This included more frequent testing of the plating solution and more rigorous inspection of the parts before and after plating. The combination of analytical investigation and process improvements enabled us to quickly resolve the issue and restore the quality of our product.

Q 28. Explain your understanding of electroplating quality control procedures and documentation.

Electroplating quality control involves a multifaceted approach, encompassing process monitoring, regular testing, and detailed documentation. This includes strict adherence to established plating parameters (current density, time, temperature, pH), regular analysis of the plating solution, and thorough inspection of the plated parts. We use various techniques for assessing the quality, including visual inspection for defects like pitting, burning, or discoloration; thickness measurements using techniques like X-ray fluorescence (XRF) to ensure adherence to specifications; and adhesion testing to guarantee the plating’s durability. All data is meticulously recorded, along with any deviations or corrective actions taken. This information is essential not only for maintaining consistent quality but also for continuous improvement and troubleshooting. Our documentation includes detailed process parameters, test results, inspection reports, and any necessary corrective actions. This meticulous documentation is crucial for meeting quality standards, complying with regulations, and ensuring traceability of our processes and product quality.

Key Topics to Learn for Electroplating Knowledge Interview

- Fundamentals of Electrochemistry: Understand oxidation-reduction reactions, Faraday’s laws, and the electrochemical series. Consider how these principles directly impact the electroplating process.

- Electroplating Processes: Become familiar with different plating techniques (e.g., DC plating, pulse plating, barrel plating) and their applications. Analyze the advantages and disadvantages of each method.

- Electrolyte Solutions: Master the composition and function of various electrolyte solutions. Understand factors influencing conductivity, throwing power, and plating efficiency.

- Surface Preparation: Explore the critical role of pre-treatment processes (cleaning, degreasing, etching) in ensuring successful adhesion and quality of the plated layer. Be prepared to discuss different techniques and their suitability for various substrates.

- Plating Thickness and Control: Discuss methods for monitoring and controlling plating thickness. Understand the importance of achieving uniform thickness and the impact of parameters like current density and time.

- Troubleshooting and Quality Control: Develop your problem-solving skills related to common electroplating issues (e.g., pitting, burning, poor adhesion). Understand quality control methods used to ensure consistent product quality.

- Safety and Environmental Considerations: Be aware of the safety precautions and environmental regulations associated with electroplating chemicals and processes. Discuss responsible waste management practices.

- Material Selection and Applications: Gain a strong understanding of the various metals and alloys commonly used in electroplating and their specific applications in different industries (e.g., automotive, electronics, jewelry).

Next Steps

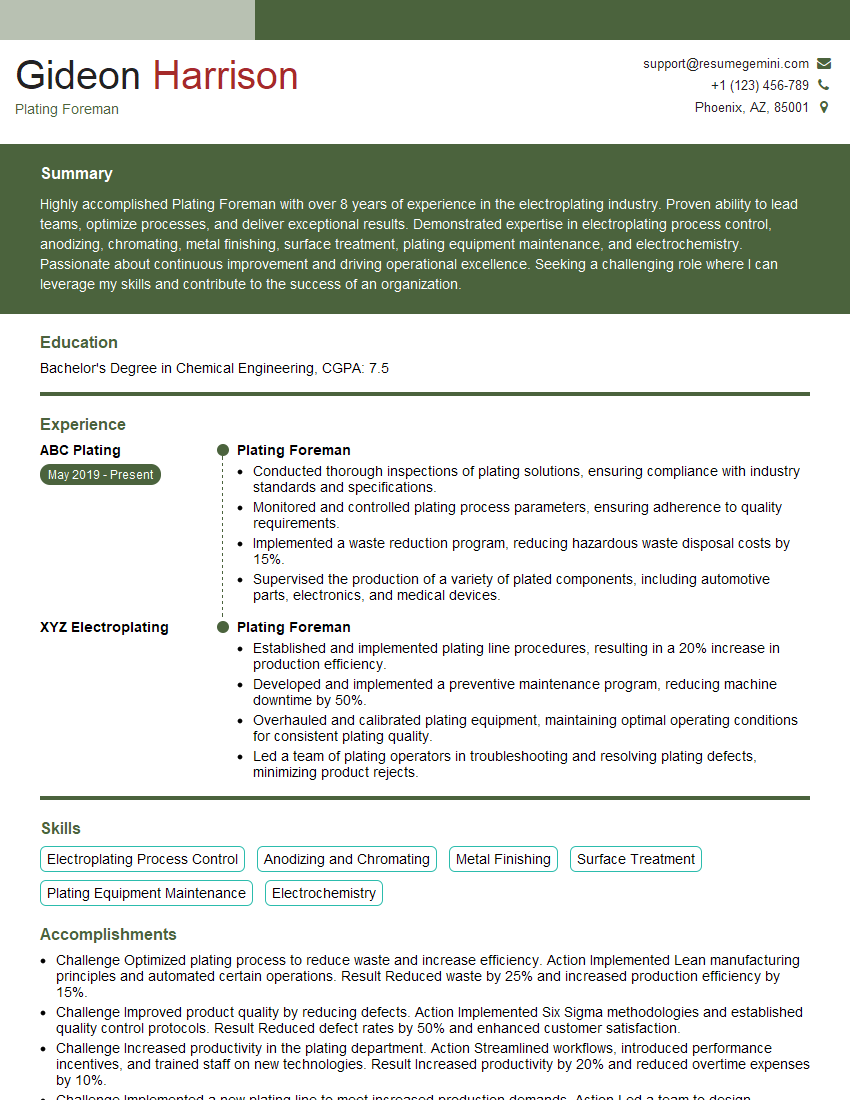

Mastering electroplating knowledge opens doors to exciting career opportunities in diverse industries. A strong understanding of these principles demonstrates technical proficiency and problem-solving capabilities, highly valued by employers. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that stands out. We provide examples of resumes tailored to electroplating knowledge to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO