The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Emergency and Safety Procedures interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Emergency and Safety Procedures Interview

Q 1. Describe your experience developing and implementing emergency response plans.

Developing and implementing emergency response plans is a multi-stage process requiring careful consideration of potential hazards and the organization’s unique needs. My approach involves a thorough risk assessment (discussed further in the next question), followed by the creation of detailed plans outlining roles, responsibilities, procedures, and communication protocols. This isn’t a one-size-fits-all approach; I tailor plans to the specific setting, whether it’s a manufacturing facility, a hospital, or an office building. For example, in a manufacturing facility, the plan would heavily emphasize evacuation procedures, equipment shutdown protocols, and handling of hazardous materials, while a hospital would require plans for mass casualty incidents and effective internal communication within a complex system.

Implementation involves regular drills and training to ensure familiarity and preparedness. Post-incident reviews are crucial for continuous improvement, analyzing what worked well and what needs adjustment. In one instance, I worked with a logistics company to implement an emergency plan that addressed severe weather events. This included detailed procedures for securing cargo, protecting personnel, and communication protocols with external stakeholders. The subsequent review identified the need for improved real-time communication tools, leading to enhanced system adoption.

Q 2. How do you conduct a risk assessment?

A risk assessment is a systematic process of identifying hazards and evaluating their potential to cause harm. It’s a proactive approach, not a reactive one. My method involves five key steps:

- Hazard Identification: This involves systematically identifying all potential hazards, from slips, trips, and falls to equipment malfunctions and chemical spills. Walkthroughs, checklists, and input from employees are crucial.

- Risk Analysis: Once identified, each hazard is analyzed by considering the likelihood of it occurring and the severity of the potential consequences.

- Risk Evaluation: The likelihood and severity are weighed to determine the overall level of risk for each hazard. This usually uses a matrix system to categorize risks as high, medium, or low.

- Risk Control: Based on the risk evaluation, control measures are implemented to mitigate or eliminate the identified hazards. This might involve implementing engineering controls (e.g., machine guarding), administrative controls (e.g., safety training), or personal protective equipment (PPE).

- Monitoring and Review: The entire process should be regularly monitored and reviewed to ensure the effectiveness of the control measures and to identify any new or emerging hazards. Regular updates to the risk assessment reflect changes in the workplace.

For instance, during a risk assessment for a construction site, I identified the risk of falls from heights as high. The control measures included implementing fall protection systems, providing proper training, and regular inspections of equipment.

Q 3. Explain your understanding of OSHA regulations (or relevant local regulations).

My understanding of OSHA regulations (Occupational Safety and Health Administration, in the US, or equivalent local regulations) is comprehensive. These regulations are designed to protect employee safety and health in the workplace. Key areas of focus include:

- Hazard Communication: Proper labeling, safety data sheets (SDS), and employee training on hazardous materials.

- Personal Protective Equipment (PPE): Providing and ensuring the use of appropriate PPE, such as hard hats, safety glasses, and respirators.

- Lockout/Tagout: Procedures for safely de-energizing equipment to prevent accidental start-up during maintenance.

- Emergency Action Plans: Development and implementation of plans for various emergencies, including fires, evacuations, and medical emergencies.

- Recordkeeping: Maintaining accurate records of workplace injuries and illnesses.

Compliance is crucial, as violations can lead to significant penalties. I ensure compliance by staying updated on current regulations, conducting regular inspections, and providing training to employees. For example, I recently helped a client implement a new lockout/tagout procedure that not only complied with OSHA standards but also improved the efficiency of their maintenance operations.

Q 4. What methods do you use to train employees on safety procedures?

Effective safety training is crucial. I use a multi-faceted approach combining various methods for optimal knowledge retention. This includes:

- On-the-job training: Mentorship and hands-on training are effective for procedural learning.

- Classroom training: Lectures, presentations, and interactive sessions facilitate understanding of broader safety concepts.

- Online modules: E-learning provides flexibility and allows employees to learn at their own pace.

- Simulations and drills: These create realistic scenarios to practice emergency procedures, building confidence and muscle memory.

- Gamification: Incorporating interactive elements and quizzes can make training more engaging and memorable.

I regularly assess the effectiveness of training programs by conducting post-training evaluations, observing employee behavior, and reviewing incident reports. For example, I developed a gamified online module on fire safety procedures which resulted in a significant increase in employee knowledge retention compared to traditional classroom training.

Q 5. How would you handle a workplace accident?

Handling a workplace accident requires a calm and efficient response. My protocol involves these steps:

- First Aid and Medical Attention: Assess the situation, providing immediate first aid if qualified and calling emergency services if necessary.

- Secure the Scene: Prevent further injuries by isolating the area and ensuring the safety of others. This may include shutting down equipment or evacuating the area.

- Incident Reporting: Follow established procedures for reporting the accident, documenting details such as date, time, location, witnesses, and injuries. This is crucial for investigation and prevention.

- Investigation: Conduct a thorough investigation to determine the root cause of the accident, identifying contributing factors and areas for improvement.

- Corrective Actions: Implement corrective measures to prevent similar accidents from happening again. This might involve modifying equipment, changing procedures, or providing additional training.

Following these steps ensures that immediate needs are met while maintaining a focus on preventing future incidents. For instance, in a recent incident involving a minor chemical spill, I followed this protocol, leading to a swift response that minimized impact and prevented further issues. The subsequent investigation revealed a deficiency in the storage procedures, which was promptly rectified.

Q 6. Describe your experience with incident reporting and investigation.

Incident reporting and investigation are critical components of a robust safety management system. My experience involves using a structured approach, ensuring thorough documentation and analysis. I use standardized forms to record incident details, including the date, time, location, individuals involved, witnesses, injuries, and a detailed description of the events. This ensures accuracy and consistency.

The investigation process follows a systematic approach to identify the root cause. This often includes reviewing safety procedures, conducting interviews with individuals involved, examining equipment, and reviewing relevant documentation. The goal is not to assign blame, but to identify contributing factors and preventative measures. I use techniques like ‘5 Whys’ to drill down to the underlying causes. Following each investigation, a comprehensive report is prepared and shared with relevant stakeholders, outlining the findings, corrective actions, and preventative measures. For example, a near-miss incident involving a forklift and a pedestrian led to a review of traffic flow on the factory floor, ultimately resulting in the implementation of designated pedestrian walkways and improved signage.

Q 7. What are your strategies for improving safety culture within an organization?

Improving safety culture is a continuous process requiring a multi-pronged approach. It’s not just about rules; it’s about fostering a shared commitment to safety at all levels of the organization. My strategies include:

- Leadership Commitment: Safety must be a top priority, demonstrated through visible leadership support and active involvement.

- Open Communication: Create an environment where employees feel comfortable reporting hazards and concerns without fear of retribution.

- Employee Involvement: Encourage participation in safety committees, hazard identification, and the development of safety procedures.

- Recognition and Incentives: Recognize and reward employees for safe work practices and contributions to safety initiatives.

- Regular Training and Education: Ongoing training keeps safety awareness current and relevant.

- Performance Measurement: Track key safety metrics (e.g., incident rates, near-misses) to identify areas for improvement.

I believe that a strong safety culture is built on trust, respect, and shared responsibility. In one organization, I implemented a peer-to-peer safety observation program, where employees actively looked out for each other’s safety. This initiative not only improved safety performance but also strengthened teamwork and collaboration.

Q 8. How do you prioritize risks in a dynamic environment?

Prioritizing risks in a dynamic environment requires a structured approach. We use a combination of methods, including a qualitative risk assessment, considering factors like likelihood and impact. Think of it like a decision matrix: you plot each potential hazard (e.g., fire, equipment malfunction, hazardous spill) based on how likely it is to occur and the severity of its consequences. High likelihood and high impact risks naturally move to the top of the priority list. For example, a chemical spill in a confined space would likely rank higher than a minor equipment failure. In a dynamic environment, continuous monitoring and reassessment are crucial. Real-time data and situational awareness allow for agile adjustments to the priority list as the situation unfolds. This might involve using a dynamic risk matrix updated regularly based on new information.

This isn’t just about checklists; it’s about a process of critical thinking, informed by experience and training. I’ve worked on sites with multiple concurrent risks—a large-scale construction project with significant machinery and hazardous materials, for instance. We use color-coded systems and regular briefings to keep everyone informed of the current top priorities.

Q 9. What are the key components of a comprehensive emergency preparedness plan?

A comprehensive emergency preparedness plan needs several key components to be effective. First, a thorough hazard analysis identifies all potential threats—fires, floods, earthquakes, active shooter situations, etc. This is followed by developing prevention measures to minimize the likelihood of these hazards occurring. Next, emergency response procedures must be clearly defined, with step-by-step instructions for each type of emergency. These procedures need to incorporate communication protocols, ensuring clear and consistent messaging during an emergency. Regular training and drills are vital to ensure personnel are familiar with these procedures. Finally, a strong post-incident analysis allows us to learn from past incidents and improve the plan’s effectiveness.

Consider a hospital—its emergency preparedness plan would differ significantly from that of a manufacturing plant, adapting to unique vulnerabilities and potential hazards. The goal is to always be prepared for the worst-case scenario while also having adaptable protocols for a range of situations. This requires constant review and updates to stay current and relevant.

Q 10. Explain your understanding of different types of emergency response systems.

Emergency response systems vary widely depending on the scale and type of emergency. Internal systems might involve dedicated emergency response teams within an organization, utilizing internal communication channels and pre-established procedures. Think of a fire alarm system coupled with a company’s internal emergency notification system. External systems involve collaboration with external agencies like fire departments, police, and emergency medical services (EMS). These systems frequently rely on established protocols and standardized communication channels to ensure efficient coordination. For instance, a 911 call activates a cascade of responses from different agencies, guided by dispatch systems.

Then there are technology-driven systems, like mass notification systems using SMS, email, and app-based alerts. These allow for rapid dissemination of information to a large audience during an emergency. A crucial element in any system is the chain of command which clarifies roles, responsibilities, and reporting structures to ensure a coordinated and effective response. A well-defined chain of command prevents confusion and ensures that all efforts are focused and efficient.

Q 11. How do you ensure compliance with safety regulations and standards?

Ensuring compliance with safety regulations and standards is a multifaceted process. It begins with a thorough understanding of all applicable regulations and standards, which vary by industry, location, and specific hazards. This involves staying updated on changes and amendments. Then we implement robust safety management systems (SMS) to ensure compliance. These SMS often include regular safety audits, inspections, and risk assessments to identify potential non-compliance. Documentation is crucial, meticulously recording all inspections, training, and incident reports. Employee training is paramount—everyone from management to frontline staff needs proper training on relevant safety procedures and regulations.

Consider OSHA (Occupational Safety and Health Administration) guidelines in the US, or equivalent regulations in other countries. Regular safety training and the implementation of appropriate safety equipment are key elements. We use checklists, training records, and incident reports to maintain a clear audit trail, demonstrating our commitment to compliance and providing evidence for regulatory audits.

Q 12. How do you communicate effectively during an emergency?

Effective communication during an emergency is critical. It hinges on clear, concise, and accurate messaging. Before an incident, having pre-established communication channels, contact lists, and designated spokespeople is essential. During an emergency, information needs to be relayed efficiently across multiple channels, using multiple forms like verbal instructions, visual cues, and written alerts, such as mass SMS messages or digital signage. Using plain language, avoiding jargon and technical terms, is important. The information should be tailored to the audience’s needs, with relevant actions clearly defined.

I’ve experienced situations where clear, calm communication was crucial in preventing panic and ensuring a coordinated response. In one instance, using a clear, pre-planned communication strategy helped guide hundreds of people to safety during an evacuation. A consistent message, relayed through various channels, prevents misinformation and chaos. Post-incident, communication continues with debriefing sessions and follow-up communication to address concerns and provide support.

Q 13. Describe your experience with evacuation procedures.

My experience with evacuation procedures is extensive. I’ve been involved in planning and executing evacuations in various settings, from office buildings to large industrial facilities. The key is having a well-defined plan, regularly practiced through drills and exercises. This includes clearly marked escape routes, designated assembly points, and pre-assigned roles and responsibilities. Emergency lighting and clear signage play a huge part. During an actual evacuation, maintaining order and assisting those who may need help are critical functions. Regular training ensures that everyone knows their roles, understands the routes, and understands the procedures.

I recall one instance where our carefully practiced evacuation plan proved invaluable during a sudden fire. The calm and efficient execution minimized disruption and ensured the safety of everyone present. This highlights the significance of regular training and the effectiveness of well-thought-out procedures. We’ve even used simulations and virtual reality training to enhance the realism of our exercises and preparedness.

Q 14. How would you manage a crisis situation?

Managing a crisis situation requires a calm, decisive, and structured approach. The first step is to assess the situation, determining the nature and extent of the emergency. This involves gathering information from various sources and identifying immediate threats. Next, activate the emergency response plan, assigning roles and responsibilities to personnel, and initiating communication protocols. Containing and controlling the situation is paramount, taking immediate steps to mitigate the threat and minimize further damage. This might involve emergency medical treatment, fire suppression, or evacuation. Then we focus on communication and information management, ensuring that accurate and timely information is disseminated to all stakeholders. Finally, we execute a post-incident analysis, reviewing the response to identify strengths and weaknesses, allowing for continuous improvement of the preparedness plan.

Think of a major power outage affecting a large hospital. The crisis management would involve ensuring backup power, managing patient care, and coordinating with external agencies. Successful crisis management requires clear thinking, strong leadership, and effective teamwork. Regular drills and simulations are key to effective response and preparedness.

Q 15. What are your methods for evaluating the effectiveness of safety programs?

Evaluating the effectiveness of safety programs isn’t a one-size-fits-all approach; it requires a multifaceted strategy. We need to look beyond simply the absence of accidents, and delve into leading indicators that predict future performance.

Lagging Indicators: These are measures of past performance, such as the number of accidents, injuries, or near misses. While important for understanding historical trends, they don’t proactively identify areas needing improvement. For example, a high number of lost-time injuries indicates a problem, but doesn’t tell us *why*.

Leading Indicators: These are proactive measures that predict future performance. They’re crucial for identifying potential hazards before they result in incidents. Examples include the frequency of safety training, the number of safety inspections conducted, employee participation in safety committees, and the number of safety observations reported.

Data Analysis: We meticulously track both lagging and leading indicators. Statistical analysis, such as trend analysis and root cause analysis, helps us identify patterns and pinpoint areas requiring attention. For instance, if we see a spike in near misses related to a specific piece of equipment, we investigate the equipment’s maintenance records and training procedures.

Employee Feedback: Regularly soliciting feedback from employees, through surveys, safety meetings, or informal conversations, is critical. Employees are often the first to identify potential hazards. An anonymous reporting system is essential to encourage open communication.

Audits and Inspections: Regular safety audits and inspections provide a systematic evaluation of the program’s implementation and effectiveness. We use checklists and standardized procedures to ensure consistency and thoroughness.

By combining these methods, we gain a comprehensive understanding of the safety program’s effectiveness and can make data-driven improvements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to make a quick decision in a high-pressure situation.

During a chemical spill at a manufacturing plant, I had to make a rapid decision. A large container of corrosive liquid had ruptured, posing a significant risk to personnel and the environment. The initial response team was overwhelmed.

My immediate priority was to ensure the safety of everyone present. I quickly assessed the situation, prioritizing the evacuation of personnel from the immediate danger zone. Simultaneously, I deployed the emergency response team to contain the spill using appropriate absorbent materials and neutralizing agents, following established emergency protocols.

The pressure was immense. There was a risk of further escalation, environmental damage, and potential injuries. However, by focusing on clear, prioritized steps – evacuation first, containment second – we managed to avert a major catastrophe. No one was injured and environmental impact was minimized. This experience underscored the importance of clear communication, rapid assessment, and decisive action during emergencies.

Q 17. How familiar are you with fire safety regulations and equipment?

I’m highly familiar with fire safety regulations and equipment. My understanding encompasses various aspects, from NFPA standards and local fire codes to the practical application of fire prevention and suppression techniques.

Regulations: I’m well-versed in the relevant codes governing fire prevention, detection, and suppression systems in different building types and industrial settings. This includes understanding requirements for fire alarms, sprinkler systems, emergency exits, and fire extinguishers.

Equipment: I possess hands-on experience with various types of fire extinguishers (Class A, B, C, K), understanding their appropriate use and limitations. I’m also familiar with the operation and maintenance of fire detection systems, sprinkler systems, and other fire safety equipment.

Practical Application: I’ve conducted numerous fire safety training sessions, educating employees on evacuation procedures, fire extinguisher operation, and the importance of fire prevention. This includes practical demonstrations and simulated emergency scenarios.

My knowledge extends to fire investigation, conducting post-incident analyses to identify contributing factors and implement preventative measures. Keeping up with evolving regulations and best practices is crucial in this field, which I ensure through continuous professional development.

Q 18. What experience do you have with personal protective equipment (PPE)?

My experience with personal protective equipment (PPE) is extensive. It’s not just about knowing what PPE exists; it’s about understanding its proper selection, use, maintenance, and limitations for various hazards.

Selection: I’m experienced in selecting appropriate PPE based on hazard assessments, considering factors like the type of hazard (chemical, physical, biological), the severity of the risk, and the specific work task. For example, working with chemicals requires different PPE than working at heights.

Use and Maintenance: I’ve trained employees on the proper donning, doffing, and inspection of PPE, emphasizing the importance of regular maintenance and replacement to ensure its effectiveness. This includes understanding the limitations of PPE and knowing when it’s no longer suitable for use.

Compliance: I ensure compliance with all relevant regulations and standards regarding the provision, use, and maintenance of PPE. This includes record-keeping and inspections to verify that PPE is being used correctly.

Ultimately, my focus is on ensuring that employees understand the importance of PPE as a critical element of a comprehensive safety program and empowering them to use it effectively to protect themselves.

Q 19. Describe your experience with conducting safety inspections.

Conducting safety inspections is a cornerstone of proactive safety management. My approach is systematic and thorough, ensuring comprehensive coverage of all potential hazards.

Planning: Before an inspection, I develop a checklist tailored to the specific area and potential hazards. This includes reviewing previous inspection reports and considering any recent changes or activities.

Inspection: I conduct a physical inspection, systematically checking for compliance with safety regulations, identifying potential hazards, and observing employee work practices. I document all findings thoroughly using photos and detailed descriptions.

Reporting: Following the inspection, I prepare a comprehensive report that details all findings, including observations of both good and bad practices. This report includes recommendations for corrective actions and preventative measures.

Follow-up: I ensure that corrective actions are implemented and verified. I conduct follow-up inspections to assess the effectiveness of the implemented measures.

I utilize a combination of planned inspections and random spot checks to maximize the effectiveness of the process. This keeps employees alert to safety concerns and encourages a proactive safety culture.

Q 20. How do you handle employee concerns about safety?

Employee concerns about safety are paramount. My approach is built on open communication, active listening, and a commitment to addressing concerns promptly and effectively.

Open Communication Channels: I establish multiple channels for employees to raise safety concerns, including regular safety meetings, suggestion boxes, anonymous reporting systems, and open-door policies.

Active Listening: When an employee expresses a concern, I actively listen, ensuring I understand their perspective and the nature of the concern. I avoid dismissing concerns, even if they seem minor.

Investigation: I thoroughly investigate all reported concerns, identifying the root cause and assessing the level of risk. This may involve conducting further inspections, interviewing employees, or consulting with experts.

Corrective Action: Based on the investigation, I implement appropriate corrective actions, ensuring that these are communicated to the employee who raised the concern and any other relevant personnel.

Follow-up: I follow up with the employee to ensure their concerns have been addressed and to determine if further action is required. This demonstrates a commitment to employee safety and builds trust.

Creating a culture of safety where employees feel comfortable voicing their concerns without fear of reprisal is essential for a safe and productive workplace.

Q 21. How do you stay current on the latest safety regulations and best practices?

Staying current on the latest safety regulations and best practices is crucial for maintaining a high standard of safety. I use a multi-pronged approach to achieve this.

Professional Organizations: I’m an active member of professional organizations such as the National Safety Council (NSC), allowing me access to the latest research, publications, and networking opportunities with other safety professionals.

Conferences and Workshops: Attending industry conferences and workshops enables me to learn about emerging trends, new technologies, and best practices from leading experts.

Regulatory Updates: I regularly monitor changes in relevant legislation, such as OSHA regulations and industry-specific standards. I subscribe to newsletters and alerts to stay informed about updates.

Industry Publications: I read industry publications and journals to remain abreast of new research and best practices in various areas of safety.

Online Resources: I utilize online resources, such as government websites and reputable industry associations, to access information and guidance on safety-related topics.

Continuous learning is fundamental in the ever-evolving field of safety. By combining these methods, I ensure that my knowledge and skills remain up-to-date, enabling me to effectively manage safety programs and create a safe workplace.

Q 22. How do you measure the success of your safety initiatives?

Measuring the success of safety initiatives requires a multi-faceted approach, moving beyond simply tracking incident rates. We need to consider leading indicators – proactive measures that predict future performance – alongside lagging indicators – reactive measures showing past performance.

- Leading Indicators: These include the number of safety training hours completed, the frequency of safety inspections, the number of hazard reports submitted, and employee participation in safety committees. A high number of reported near-misses, while seemingly negative, actually indicates a strong safety culture where employees feel comfortable reporting potential hazards before they escalate into incidents.

- Lagging Indicators: These are more traditional metrics such as the number of accidents, lost-time injuries, and the total cost of injuries. A decrease in these numbers demonstrably shows a successful safety program.

- Qualitative Measures: Beyond numbers, we also need to assess employee perceptions of safety through surveys and feedback sessions. Do employees feel safe? Are they confident in reporting hazards? Are they actively involved in safety initiatives? This provides crucial context to the quantitative data.

For example, in a previous role, we saw a 20% reduction in lost-time injuries after implementing a new hazard identification program. Simultaneously, employee satisfaction surveys showed a significant increase in their confidence in the safety measures in place. This holistic approach gave us a comprehensive picture of our success.

Q 23. What is your experience with emergency response training and drills?

My experience with emergency response training and drills is extensive. I’ve developed and delivered training programs for various organizations, covering topics from fire safety and evacuation procedures to chemical spills and active shooter response. The key to effective training is a blend of theoretical knowledge and practical application.

- Scenario-Based Training: I design training scenarios that mimic real-life emergencies, forcing participants to apply their knowledge under pressure. This includes tabletop exercises for strategic planning and full-scale drills for hands-on practice.

- Regular Drills and Audits: Regular drills, coupled with post-drill debriefings, are crucial for identifying weaknesses and improving response effectiveness. Auditing emergency procedures ensures that plans are up-to-date, relevant, and effective.

- Technology Integration: I leverage technology, such as online training modules and simulation software, to enhance engagement and provide accessible learning opportunities. For instance, we used virtual reality to simulate a building evacuation, providing a realistic experience without the logistical constraints of a real-world drill.

In one instance, we conducted a surprise fire drill that revealed several deficiencies in our evacuation procedures. This led to improved signage, updated escape routes, and enhanced communication protocols. The feedback from the drill, coupled with the resulting improvements, demonstrably improved response time and employee safety.

Q 24. Describe your experience with hazard identification and control.

Hazard identification and control is a cornerstone of any effective safety program. It’s a continuous process of proactively identifying potential hazards, assessing their risks, and implementing controls to mitigate those risks.

- Hazard Identification Methods: I utilize a variety of methods, including workplace inspections, job safety analyses (JSAs), checklists, and employee feedback. JSAs, for instance, involve breaking down a task into its individual steps to pinpoint potential hazards at each stage.

- Risk Assessment: Once hazards are identified, I conduct a thorough risk assessment, considering the likelihood and severity of potential incidents. This helps prioritize the implementation of control measures.

- Hierarchy of Controls: My approach follows the hierarchy of controls, prioritizing elimination, substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE). For example, replacing a hazardous chemical with a less hazardous alternative is preferable to simply providing workers with protective gloves.

In a past role, we identified a significant risk of slips and falls in a warehouse due to poor floor maintenance. By implementing improved cleaning protocols, installing anti-slip surfaces, and providing appropriate footwear, we significantly reduced the number of incidents.

Q 25. How do you deal with conflicting priorities during an emergency?

Conflicting priorities during an emergency are inevitable. Effective decision-making requires a structured approach that prioritizes the most critical tasks while ensuring overall safety.

- Prioritization Matrix: I use a prioritization matrix to rank tasks based on their urgency and importance. This helps focus resources on the most critical aspects of the emergency response. For example, evacuating personnel is typically higher priority than securing equipment.

- Clear Communication: Open and consistent communication among the emergency response team is paramount. Establishing clear roles and responsibilities prevents confusion and ensures coordinated efforts.

- Scalable Response: The response should be scalable, adapting to the evolving situation. Initial priorities may shift as the emergency unfolds, requiring adjustments to the response plan. Regular reassessments and updates are crucial.

For instance, during a chemical spill, we prioritized securing the area and preventing further contamination before initiating the cleanup process. This decision, while potentially delaying the complete cleanup, ensured the safety of personnel first.

Q 26. What are your strategies for preventing workplace accidents?

Preventing workplace accidents is a proactive endeavor requiring a layered approach. It’s about creating a safety-conscious culture where employees feel empowered to identify and report hazards.

- Proactive Hazard Identification: Regular safety inspections, audits, and employee feedback sessions are crucial for identifying potential hazards before they lead to accidents. The more eyes on the ground, the more hazards are likely to be identified.

- Comprehensive Training: Providing thorough training on safe work practices, equipment operation, and emergency procedures is essential. This training must be regularly updated and reinforced.

- Enforcement of Safety Rules: A robust system for enforcing safety rules and regulations is necessary. This should include consequences for non-compliance to reinforce safe behaviours.

- Ergonomic Considerations: Designing workspaces and tasks to minimize physical strain on employees is vital. This includes providing ergonomic equipment and adjusting workstations to fit individual needs.

- Promoting a Safety Culture: This involves fostering a culture where safety is prioritized, and employees feel empowered to report hazards without fear of reprisal. Leadership commitment to safety is essential in setting the tone.

In one organization, we implemented a comprehensive safety program that included ergonomic assessments of workstations, enhanced training programs, and a robust reporting system. This resulted in a significant reduction in workplace accidents and increased employee morale.

Q 27. How would you assess the effectiveness of safety training programs?

Assessing the effectiveness of safety training programs requires a multi-pronged approach that goes beyond simply measuring attendance. We need to determine if the training has actually improved employee knowledge, skills, and behaviours.

- Pre- and Post-Training Assessments: Conducting pre- and post-training assessments helps measure the improvement in knowledge and understanding. These could be written exams, practical demonstrations, or simulations.

- Observation of Behaviour: Observing employees’ behaviours on the job after the training to see if they are applying what they learned is crucial. This might involve direct observation by supervisors or using video recordings.

- Incident Data: Tracking the number and types of incidents after the training provides another indicator of its effectiveness. A reduction in incidents related to the topics covered in training shows positive impact.

- Employee Feedback: Gathering feedback from employees about the training itself, including its content, delivery, and effectiveness, provides valuable insights for improvement.

For example, in one training program, we noticed that post-training assessments showed a significant increase in knowledge, but observation of workplace behaviors revealed that employees weren’t consistently applying the new skills. This led us to revise the training to include more practical exercises and on-the-job coaching.

Q 28. Describe your experience with developing and implementing safety policies.

Developing and implementing safety policies requires a collaborative, systematic approach, ensuring that policies are legally compliant, practical, and readily understood by all employees.

- Needs Assessment: First, I conduct a thorough needs assessment, identifying specific hazards and risks within the workplace. This involves reviewing existing regulations, conducting risk assessments, and consulting with employees.

- Policy Development: I then draft clear, concise, and comprehensive safety policies addressing the identified hazards and risks. These policies should align with legal requirements and industry best practices.

- Communication and Training: Effective communication is critical. Policies should be distributed to all employees through various channels (e.g., email, intranet, meetings). Training sessions should be held to explain the policies and ensure understanding.

- Enforcement and Monitoring: A mechanism for enforcing the policies and monitoring compliance needs to be established. This could include regular safety inspections, incident investigations, and a system for reporting and addressing safety concerns.

- Regular Review and Update: Safety policies should be reviewed and updated regularly to reflect changes in legislation, technology, and workplace practices.

In a previous role, we developed a new safety policy for handling hazardous materials, which included detailed procedures for storage, handling, and disposal. This policy, accompanied by comprehensive training, significantly reduced the risk of accidents involving hazardous materials.

Key Topics to Learn for Emergency and Safety Procedures Interview

- Emergency Response Planning: Understanding the principles of creating and implementing comprehensive emergency response plans, including risk assessment, hazard identification, and mitigation strategies.

- Emergency Procedures & Protocols: Practical application of established procedures during various emergencies (fire, medical, security incidents). This includes understanding roles, responsibilities, and communication protocols.

- Safety Regulations & Compliance: Knowledge of relevant safety regulations, industry best practices, and legal compliance requirements. Be prepared to discuss how these regulations impact daily operations and emergency preparedness.

- Incident Reporting & Investigation: Understanding the process of reporting incidents, conducting thorough investigations, and documenting findings to prevent future occurrences. This includes analyzing root causes and implementing corrective actions.

- Risk Assessment & Mitigation: Demonstrating the ability to identify potential hazards, assess risks, and develop effective mitigation strategies to minimize the likelihood and impact of incidents.

- Emergency Communication Systems: Familiarity with various communication systems used during emergencies (e.g., alarms, public address systems, two-way radios). Discuss effective communication strategies and their importance in managing crises.

- Evacuation Procedures & Drills: Practical knowledge of evacuation procedures, including planning, execution, and post-evacuation accounting. Discuss the importance of regular drills and training exercises.

- First Aid & CPR: While not always required, demonstrating knowledge of basic first aid and CPR can be a significant advantage, especially in roles with direct responsibility for employee safety.

- Teamwork & Leadership in Emergency Situations: Highlight your ability to work effectively under pressure as part of a team, and showcase leadership skills in coordinating responses and delegating tasks during emergencies.

Next Steps

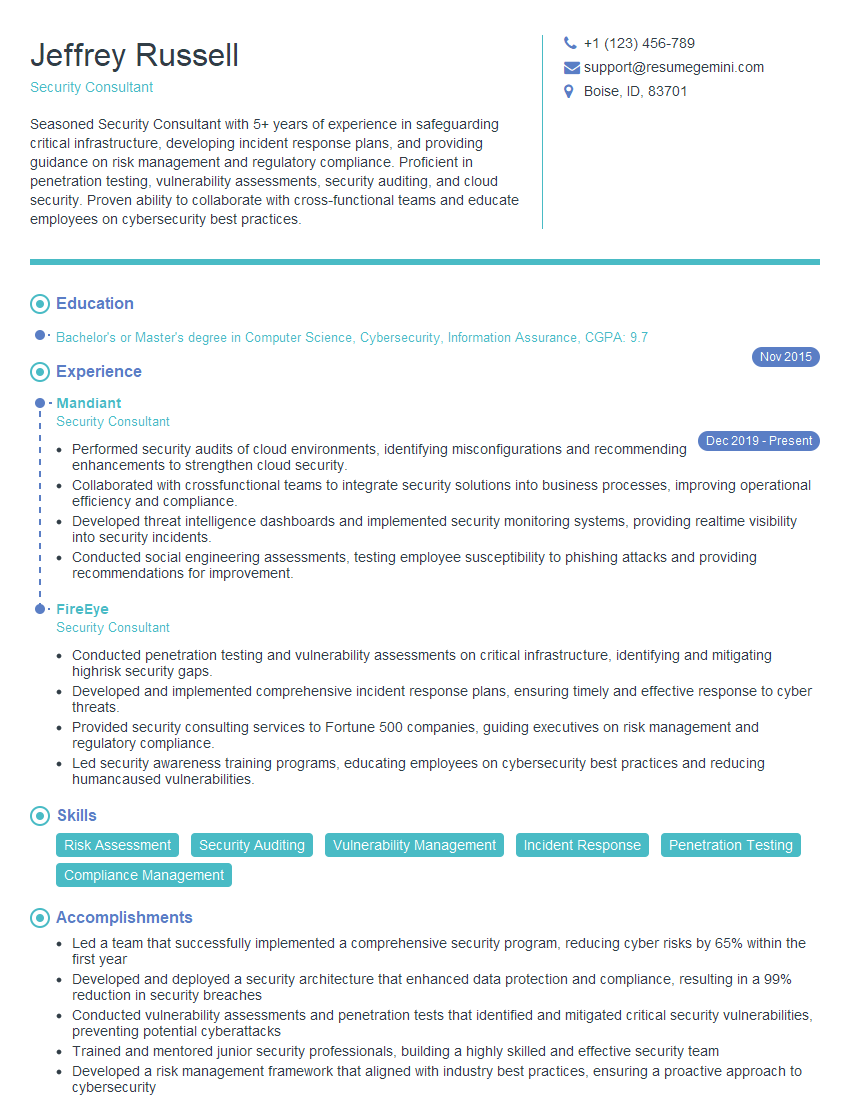

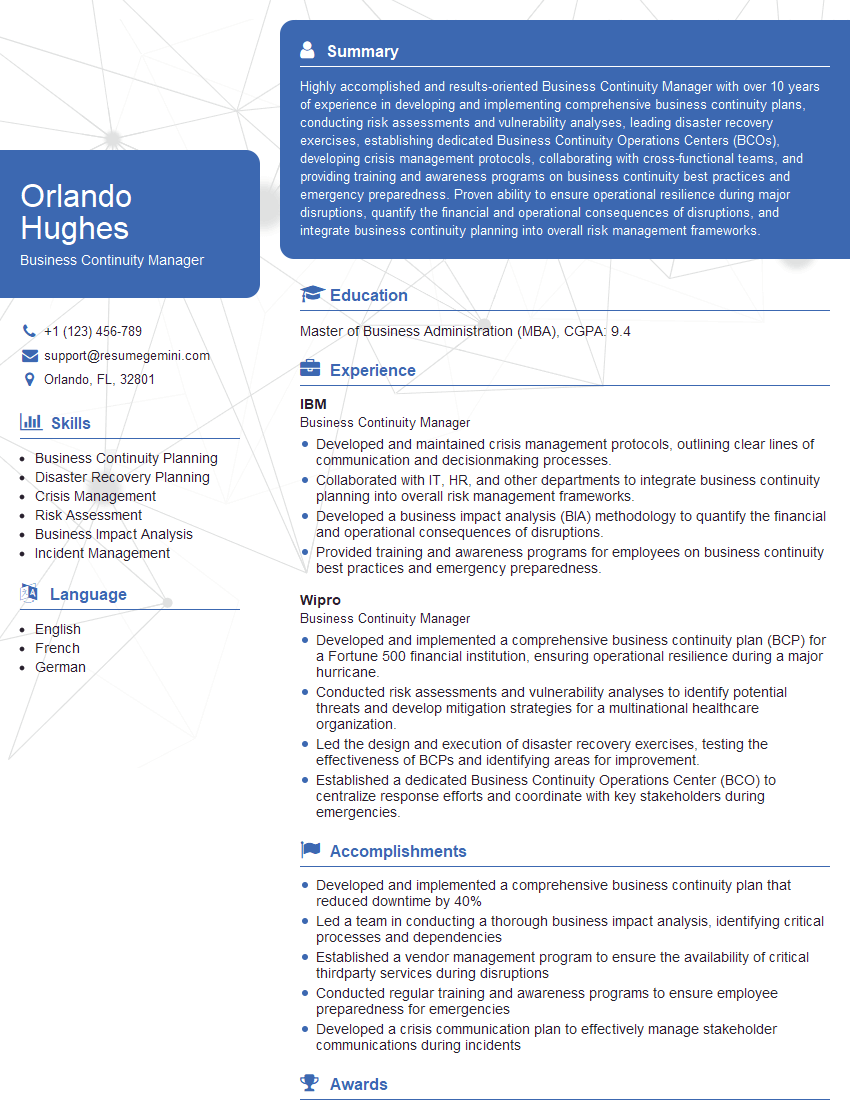

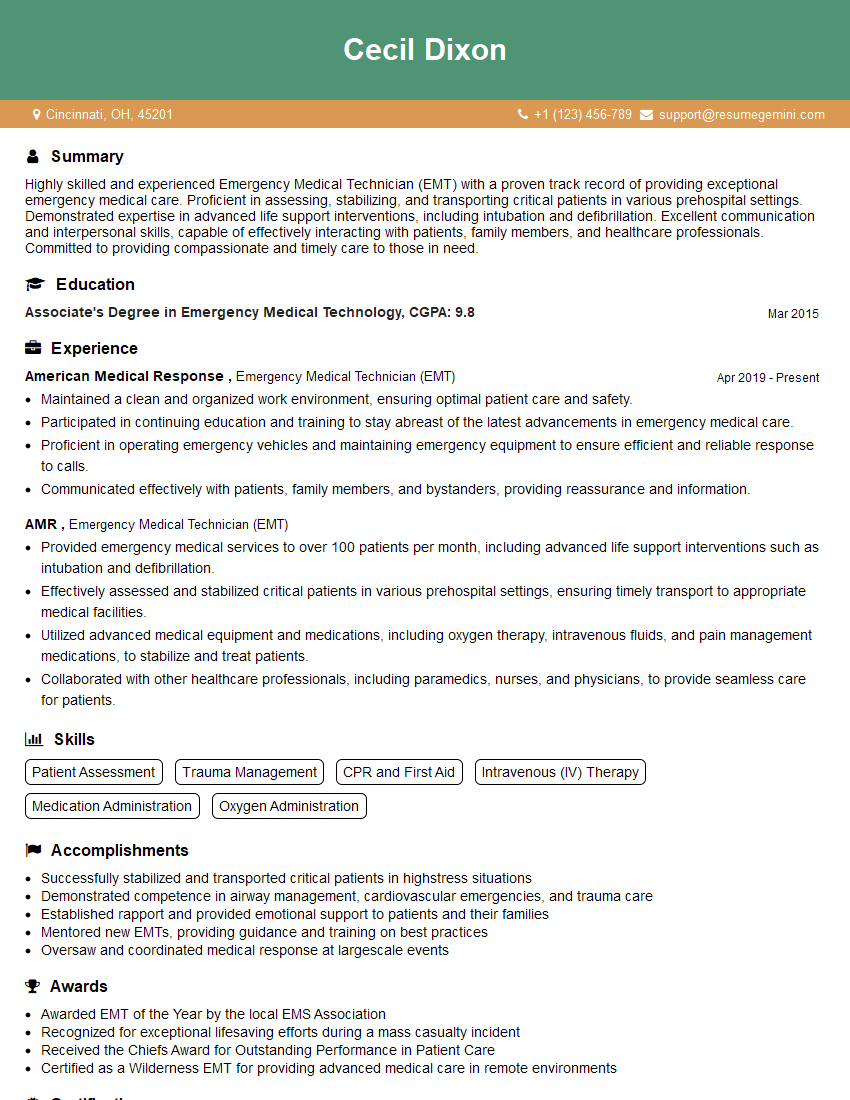

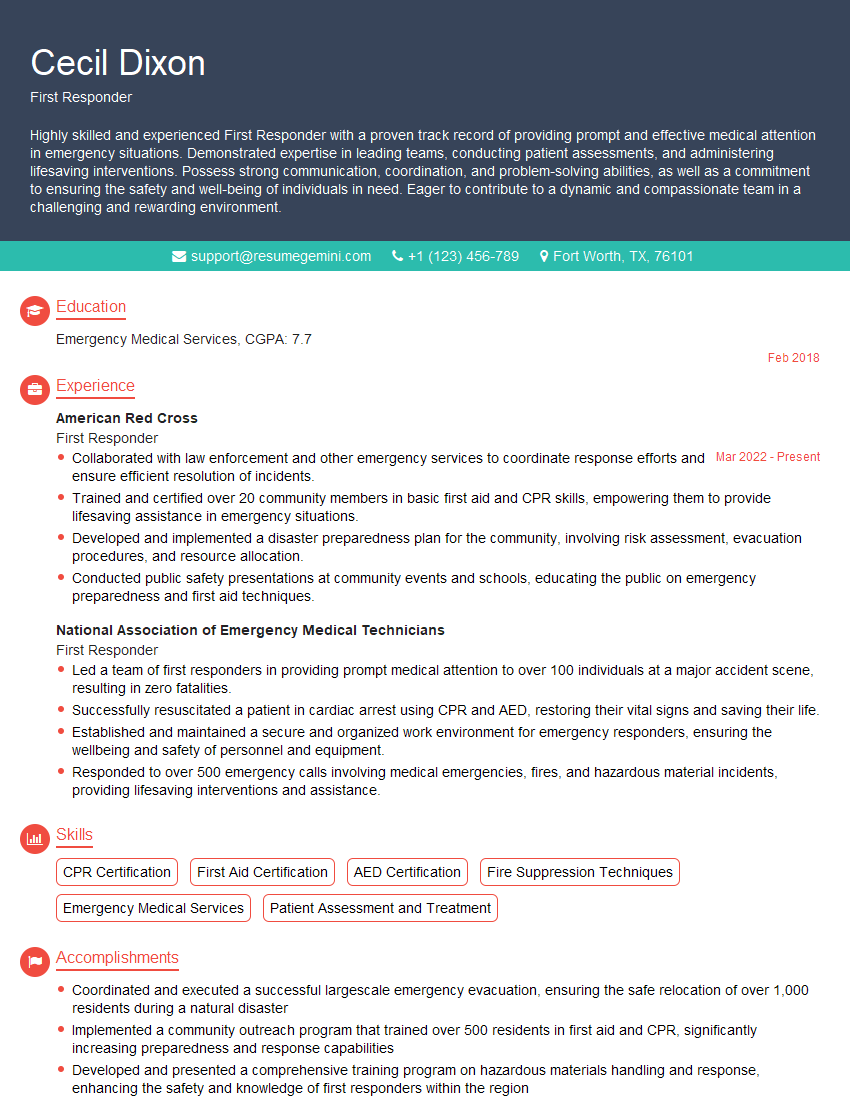

Mastering Emergency and Safety Procedures demonstrates a commitment to workplace safety and can significantly enhance your career prospects in many fields. A strong understanding of these procedures makes you a valuable asset to any organization. To further strengthen your job application, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to Emergency and Safety Procedures are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO