Unlock your full potential by mastering the most common Emergency ShutOff Procedures interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Emergency ShutOff Procedures Interview

Q 1. Describe the hierarchy of emergency shutdown procedures in your experience.

The hierarchy of emergency shutdown procedures typically follows a layered approach, prioritizing safety and minimizing damage. It often starts with local shutdown controls, readily accessible to operators at the immediate equipment level. These are often supplemented by area-specific shutdowns, controlling a group of interconnected equipment. Finally, we have plant-wide emergency shutdowns, activated in cases of widespread hazard or imminent catastrophic failure. This is akin to a military command structure, with escalating levels of authority and impact. For example, in a chemical processing plant, a local shutdown might stop a single reactor experiencing a pressure surge, an area shutdown might isolate that reactor from the rest of the processing line, and a plant-wide shutdown would halt all operations to prevent a major incident.

- Level 1: Local Shutdowns – Immediate action by the operator.

- Level 2: Area Shutdowns – Control over a section of the plant.

- Level 3: Plant-Wide Shutdowns – Total cessation of operations.

Q 2. Explain the difference between an emergency shutdown and a trip.

While both emergency shutdowns and trips result in the immediate cessation of a process, they differ significantly in their initiation and purpose. An emergency shutdown (ESD) is a deliberate action, initiated by an operator or an automated safety system in response to a hazardous condition, such as a fire, leak, or equipment malfunction. Think of it as a controlled, albeit rapid, halt. A trip, on the other hand, is often an automatic, instantaneous response to a predetermined process parameter exceeding a safe limit, such as high pressure or temperature. It’s a more immediate, pre-programmed reaction, lacking the human intervention element often present in an ESD. For instance, a high-pressure trip on a boiler immediately shuts off the fuel supply, a necessary safeguard but not necessarily a full plant-wide emergency.

Q 3. What are the key safety considerations before initiating an emergency shutdown?

Before initiating an ESD, paramount safety considerations must be addressed. This includes verifying the actual existence and nature of the hazard, ensuring all personnel are aware of the impending shutdown, and assessing the potential consequences of the shutdown itself. Rushing into an ESD without proper assessment can lead to secondary hazards, equipment damage, and even injuries. We must confirm the alarm is legitimate and not a false trigger. A pre-shutdown checklist ensures we do not inadvertently create new issues. For example, in an offshore oil rig, ensuring safe evacuation routes are clear before triggering a shutdown is critical. Also, confirming the absence of personnel in hazardous areas must be validated before initiating the shutdown.

- Hazard Verification: Is the alarm valid?

- Personnel Safety: Are all personnel accounted for and in safe locations?

- Consequence Assessment: What are the potential risks of the shutdown itself?

Q 4. How do you verify the effectiveness of an emergency shutdown system?

Verifying ESD system effectiveness involves a multi-pronged approach, combining regular testing, inspections, and documentation. This includes routine functional testing of the ESD system, often using simulated scenarios to evaluate the speed and effectiveness of the shutdown sequence. We also meticulously inspect all safety-related instrumentation and components for any signs of wear or damage. Detailed records of all tests, inspections, and maintenance activities are meticulously maintained. Imagine regularly checking the pressure release valves on a high-pressure vessel; this is similar to the testing and inspection of critical components in an ESD system. Failure to perform these tests could lead to a failure of the ESD system at the critical moment. Further, we may use sophisticated software to simulate different failure scenarios to ensure the system can react appropriately.

Q 5. What are the common causes of emergency shutdowns in your industry?

Common causes of emergency shutdowns vary greatly depending on the industry. In the chemical processing industry, it might be a runaway reaction, a pressure surge, or a leak of hazardous materials. In power generation, it could be a loss of cooling, an electrical fault, or equipment malfunction. In any scenario, however, common factors include equipment failures, operator error, and external events. For instance, a power surge could trigger multiple system failures in a manufacturing plant, leading to an ESD. Similarly, a natural disaster (like an earthquake) can trigger multiple safety systems, forcing an immediate shutdown.

- Equipment Failure: Pump failure, valve malfunction etc.

- Operator Error: Incorrect procedure, missed alarm etc.

- External Events: Power outages, natural disasters etc.

Q 6. Describe your experience with lockout/tagout procedures related to emergency shutdowns.

Lockout/Tagout (LOTO) procedures are fundamental to ensuring the safety of personnel during any maintenance or repair work on equipment involved in an ESD. Before any work can begin, the system needs to be completely isolated and rendered incapable of accidental operation. This involves physically locking out power supplies, isolating valves, and tagging the equipment to indicate it is under maintenance and must not be operated. Strict adherence to LOTO procedures is vital, ensuring that no one can inadvertently restart the equipment while work is underway. Think of it as a crucial safety net. Failure to follow LOTO could lead to catastrophic injury, should the equipment unexpectedly restart during maintenance or repair.

Q 7. How do you ensure proper communication during an emergency shutdown event?

Effective communication during an ESD is crucial. This usually involves a pre-established communication protocol, utilizing multiple channels for redundancy. This could involve alarms, public address systems, and direct communication with emergency response teams. Clearly defined roles and responsibilities ensure everyone understands their tasks during an emergency. Regular drills and training exercises help to hone these communication skills and ensure everyone is familiar with the procedures. A clear and concise communication system minimizes confusion and maximizes response effectiveness during a plant emergency. Imagine a fire breaking out; clear and concise instructions are essential for a rapid and orderly evacuation. This same principle applies to an ESD scenario.

Q 8. What are the post-emergency shutdown procedures you’re familiar with?

Post-emergency shutdown procedures are crucial for ensuring safety, minimizing damage, and facilitating a swift return to normal operations. These procedures typically involve a series of steps to verify the shutdown was successful, assess the cause of the emergency, initiate repairs or replacements, and thoroughly document the entire event.

- Verification: Confirming all affected systems are indeed shut down, checking for residual energy or hazards, and ensuring the environment is safe to enter.

- Root Cause Analysis: Identifying the root cause of the emergency shutdown, whether it was a malfunction, human error, or an external factor, through thorough investigation and data analysis. For example, reviewing sensor readings, log files, and operator actions.

- Repairs and Replacements: Executing necessary repairs or replacing faulty components. This might involve replacing a failed pressure sensor, repairing a damaged pipe, or recalibrating a control system. Safety protocols must be meticulously followed throughout this phase.

- System Restoration: Carefully restoring the system to its normal operating state, undergoing rigorous testing to verify proper functionality and safety before resuming operations. This often includes a staged restart, closely monitoring critical parameters.

- Documentation and Reporting: A comprehensive report detailing the emergency shutdown, the root cause, repairs undertaken, and lessons learned should be meticulously documented and submitted to relevant authorities.

For example, in a chemical plant, a post-emergency shutdown might involve isolating the affected reactor, verifying zero pressure, analyzing the contents for contamination, and performing a leak test before restarting.

Q 9. Explain the role of emergency shutdown systems in preventing major incidents.

Emergency shutdown systems (ESD) are lifesavers, designed to automatically or manually stop operations when hazardous conditions are detected, preventing potentially catastrophic events. Think of them as the ultimate safety net.

Their role is to mitigate risks by:

- Preventing escalation of hazards: By swiftly halting processes, ESD systems prevent the escalation of minor malfunctions into major incidents. For example, detecting a pressure surge and automatically shutting down a pipeline before a rupture occurs.

- Protecting personnel and equipment: These systems safeguard personnel from exposure to hazardous materials or environments and prevent extensive damage to expensive equipment.

- Minimizing environmental impact: ESD systems can help prevent releases of hazardous substances into the environment by rapidly isolating contaminated areas.

- Providing time for corrective action: By halting operations, ESD systems provide the crucial time needed to assess the situation and take corrective measures without endangering anyone or causing further damage.

Imagine a power plant experiencing a sudden temperature surge. The ESD system immediately shuts down the reactor, preventing a meltdown.

Q 10. How do you identify potential hazards that could trigger an emergency shutdown?

Identifying potential hazards that could trigger an emergency shutdown requires a proactive and multi-faceted approach. It involves a combination of risk assessments, process hazard analyses (PHA), and regular safety inspections.

- Hazard Identification through PHA: We use systematic methods like HAZOP (Hazard and Operability Study) or FMEA (Failure Mode and Effects Analysis) to identify potential hazards in the process. This might include equipment failure, human error, or external events like natural disasters.

- Process Knowledge: A deep understanding of the processes involved is vital. Knowing the limits and tolerances of each system, and the potential consequences of exceeding them, is key to anticipating potential problems.

- Equipment Monitoring and Data Analysis: Utilizing data from sensors, historical records, and equipment maintenance logs enables the identification of recurring issues or trends that could lead to an emergency.

- Regular Inspections: Thorough and frequent inspections of equipment and facilities help identify potential issues before they become hazards. This includes checking safety devices, looking for corrosion, and verifying proper functionality.

- Operator Training and Feedback: Training operators on recognizing and reporting potential hazards is extremely important. Encouraging reporting of near misses provides valuable insights into potential weaknesses in the system.

For example, in a refinery, regular inspections might reveal corrosion in a pipe, which, if left unaddressed, could lead to a leak and trigger an emergency shutdown.

Q 11. Describe your experience with different types of emergency shutdown systems.

My experience encompasses a variety of emergency shutdown systems, each with its own strengths and weaknesses. These systems can be broadly categorized as:

- High-integrity pressure protection systems (HIPPS): These systems are specifically designed to shut down processes when pressure exceeds safe limits. I’ve worked extensively with HIPPS in refineries and chemical plants, ensuring their correct calibration and timely response.

- Fire and gas detection systems: These systems detect the presence of flammable gases or fire and initiate emergency shutdowns to prevent explosions or large-scale fires. My experience includes installing and maintaining these systems, ensuring reliable detection and timely response.

- Temperature monitoring and shutdown systems: These systems monitor temperature and shut down processes if temperatures exceed predetermined limits. I’ve worked with systems controlling critical parameters in power generation and industrial furnaces.

- Level monitoring and shutdown systems: These systems prevent overflows or underflows in tanks and vessels by monitoring liquid levels and shutting down processes when critical limits are reached. My experience involves configuring and maintaining these systems to ensure precise level control.

I’ve also worked with systems that integrate multiple sensors and utilize advanced logic to trigger emergency shutdowns based on complex conditions. Each system required a thorough understanding of the specific process and safety requirements.

Q 12. What are the regulatory requirements for emergency shutdown procedures in your industry?

Regulatory requirements for emergency shutdown procedures vary significantly depending on the industry and geographical location. However, common themes include compliance with:

- Industry-specific standards: Standards such as API (American Petroleum Institute), IEC (International Electrotechnical Commission), or ANSI (American National Standards Institute) provide guidelines for the design, implementation, and testing of ESD systems. Adherence is crucial for compliance and safety.

- Environmental regulations: Regulations like those from the EPA (Environmental Protection Agency) or equivalent bodies govern the prevention of hazardous substance releases into the environment. ESD systems play a vital role in minimizing such incidents.

- Occupational safety and health regulations: OSHA (Occupational Safety and Health Administration) or equivalent agencies mandate the implementation of safety systems to protect workers from hazards. ESD systems are a critical part of ensuring worker safety.

- National and international codes: Numerous national and international codes provide guidelines for safe operation and maintenance of hazardous processes. Understanding these codes is critical to ensuring regulatory compliance.

Failure to comply with these regulations can result in significant penalties, including fines, operational shutdowns, and legal action.

Q 13. How do you document and report emergency shutdown events?

Documenting and reporting emergency shutdown events is a critical step in learning from mistakes and preventing future incidents. It involves a structured approach:

- Immediate Actions: Recording initial observations, actions taken, and the state of the system during the emergency is the first step. This might include sensor readings, timestamps, and operator actions.

- Root Cause Analysis: A detailed investigation to determine the root cause of the shutdown, analyzing data and interviewing personnel involved.

- Corrective Actions: Documenting the repairs and modifications made to prevent recurrence of the event, ensuring appropriate testing and verification.

- Report Generation: Creating a comprehensive report including all the information gathered during the investigation, corrective actions, and recommendations for improvement.

- Submission and Review: Submitting the report to relevant authorities and stakeholders for review and approval. This might involve regulatory bodies, management, and other safety teams.

These reports are essential for continuous improvement and informing future safety protocols. We use a specific reporting template that ensures consistent and comprehensive documentation of each event, allowing for effective trend analysis.

Q 14. How do you conduct regular inspections and maintenance of emergency shutdown systems?

Regular inspections and maintenance are critical for ensuring the reliable operation of emergency shutdown systems. A robust maintenance program includes:

- Preventive Maintenance: Regularly scheduled maintenance activities, such as testing of safety valves, sensors, and actuators. This is crucial for early detection of potential problems.

- Predictive Maintenance: Using data analysis and monitoring techniques to anticipate potential failures and schedule maintenance proactively. This helps prevent unexpected shutdowns and minimizes downtime.

- Functional Testing: Regularly testing the entire ESD system to ensure it functions correctly in simulated emergency conditions. This involves activating the system and verifying its proper response.

- Calibration and Verification: Ensuring that all sensors and instruments are correctly calibrated and their readings are accurate. Regular calibration maintains the integrity of the safety system.

- Documentation: Maintaining comprehensive records of all maintenance activities, including test results, calibration data, and repairs. This documentation is essential for tracking system performance and regulatory compliance.

For instance, we perform monthly functional tests on our fire suppression system, and quarterly calibrations of our pressure sensors. This rigorous approach ensures that our ESD systems are always ready to protect our personnel and facilities.

Q 15. Describe a time you had to troubleshoot an emergency shutdown system malfunction.

During my time at a petrochemical plant, the emergency shutdown system (ESD) for a critical reactor experienced a malfunction. The system failed to initiate a shutdown after detecting a high-pressure alarm. My initial troubleshooting involved verifying the alarm itself – was the pressure truly high, or was there a sensor fault? After confirming the high pressure was genuine, I systematically checked the ESD system. This involved reviewing the logic solver’s output to identify the point of failure. I discovered a faulty solenoid valve, preventing the necessary shutdown sequence. Replacing the valve immediately resolved the issue. This incident underscored the criticality of regular maintenance, redundant systems, and thorough testing, which we subsequently implemented.

The systematic approach I followed involved:

- Verification: Confirming the initial trigger (high pressure) was accurate.

- System Check: Examining the logic solver output and all components in the shutdown sequence.

- Isolation: Pinpointing the faulty component (solenoid valve).

- Repair/Replacement: Fixing or replacing the faulty part.

- Testing: Verifying the system’s functionality after the repair.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you train personnel on emergency shutdown procedures?

Training personnel on emergency shutdown procedures is crucial for safety. My approach utilizes a multi-faceted strategy combining classroom instruction, simulations, and hands-on training. Classroom sessions cover theoretical aspects: understanding the ESD system’s logic, identifying potential hazards, and reviewing the step-by-step shutdown procedures for various scenarios. Simulations, often using process simulators, allow trainees to practice responding to different emergency situations without risk. Finally, hands-on training, involving actual equipment (where safety allows), solidifies their understanding and builds muscle memory. Regular drills and refresher courses are vital for maintaining proficiency.

For example, we use realistic scenarios within the simulations—a sudden power failure, a runaway reaction, or a leak—forcing trainees to make decisions under pressure. This reinforces the importance of following established procedures and thinking critically in stressful conditions. Post-simulation debriefings allow for constructive feedback and continuous improvement.

Q 17. What are the key performance indicators (KPIs) for emergency shutdown system effectiveness?

Key Performance Indicators (KPIs) for emergency shutdown system effectiveness focus on reliability, safety, and efficiency. These include:

- Mean Time Between Failures (MTBF): Measures the average time between system failures, indicating reliability.

- Mean Time To Repair (MTTR): Indicates how quickly the system can be restored after failure.

- Proof Test Success Rate: Percentage of successful proof tests, showing the system’s functionality.

- Number of False Trips: The frequency of unintended shutdowns, highlighting potential issues with the system’s sensitivity.

- Safety Integrity Level (SIL) Achievement: Verification that the system meets the required safety integrity level for the specific application.

Monitoring these KPIs allows for proactive maintenance and continuous improvement, ensuring the ESD system remains reliable and effective in preventing accidents.

Q 18. How do you prioritize emergency shutdown actions during a complex event?

Prioritizing actions during a complex event involving an emergency shutdown requires a structured approach. A decision matrix based on risk assessment is crucial. Factors such as the severity of the hazard, the potential for escalation, and the impact on personnel and equipment are considered. This matrix assigns priority levels to various actions, guiding responders. For instance, containing a hazardous spill might be prioritized over a less immediate concern like minimizing production loss.

Imagine a scenario with a fire and a simultaneous chemical leak. The immediate priority is addressing the fire (life safety) followed by containing the leak before secondary hazards develop. This requires clear communication, coordinated actions, and a pre-defined emergency response plan.

Q 19. Explain your understanding of safety instrumented systems (SIS) and their role in emergency shutdowns.

Safety Instrumented Systems (SIS) are independent systems designed to protect against major hazards. They are critical components of emergency shutdown systems. An SIS uses sensors, logic solvers, and final elements to automatically shut down a process when dangerous conditions are detected. The SIS operates independently of the basic process control system (PCS) to ensure its reliability and prevent cascading failures. Each SIS is designed to a specific Safety Integrity Level (SIL), which quantifies the probability of failure on demand. A higher SIL indicates a lower probability of failure and is required for more hazardous applications.

For example, an SIS might shut down a reactor if pressure exceeds a setpoint, preventing a potential explosion. The independence of the SIS ensures that if the PCS fails, the SIS can still effectively protect the process.

Q 20. Describe your experience with alarm management systems related to emergency shutdowns.

Alarm management systems are integral to effective emergency shutdowns. They provide early warning of hazardous conditions, guiding operators to take appropriate actions, including initiating an ESD. A well-designed alarm management system minimizes alarm fatigue by filtering out nuisance alarms and prioritizing critical alarms. This ensures that operators can focus on the most important alerts without being overwhelmed. Effective alarm systems are crucial for preventing human error during emergencies.

For example, a sophisticated alarm management system might prioritize a high-pressure alarm in a reactor over a minor temperature fluctuation, ensuring that the critical alarm receives immediate attention. This is achieved through alarm rationalization and clear alarm hierarchy within the system.

Q 21. How do you ensure the integrity of emergency shutdown systems during maintenance?

Maintaining the integrity of emergency shutdown systems during maintenance is paramount. My approach involves a multi-layered strategy. First, a thorough risk assessment is conducted before any maintenance activity to identify potential hazards. Then, lockout/tagout procedures are strictly followed to prevent accidental activation or energy release during work. Testing and verification after maintenance are crucial, ensuring that the system functions correctly. This often includes proof testing to simulate an emergency shutdown and confirm the system’s response. Comprehensive documentation is maintained, detailing all maintenance activities, test results, and any modifications made to the system. This ensures traceability and accountability.

For instance, before working on a solenoid valve in the ESD system, we would lock it out to prevent accidental operation. After the repair, we perform a functional test to verify that the valve operates correctly and is properly integrated with the ESD logic.

Q 22. What are the potential consequences of failure to follow emergency shutdown procedures?

Failure to follow emergency shutdown procedures can lead to a cascade of catastrophic consequences. Think of it like a chain reaction – one small mistake can trigger a series of events with devastating outcomes.

- Equipment Damage: Without proper shutdown, equipment can overheat, rupture, or experience catastrophic mechanical failure, leading to extensive and costly repairs or complete replacement.

- Environmental Hazards: Uncontrolled release of hazardous materials – chemicals, gases, or liquids – poses significant risks to the environment, potentially causing pollution and long-term ecological damage. This could lead to hefty fines and legal repercussions.

- Injury or Fatality: Improper shutdowns can result in explosions, fires, or the release of toxic substances, directly endangering personnel on-site and potentially the surrounding community. This is, of course, the most serious consequence.

- Production Downtime: A poorly executed shutdown can cause extended downtime, impacting production schedules, meeting deadlines, and potentially affecting the company’s bottom line.

- Reputational Damage: Accidents stemming from inadequate emergency procedures can severely damage a company’s reputation, impacting public trust and investor confidence.

Each of these consequences can be avoided or mitigated through strict adherence to well-defined and regularly practiced emergency shutdown procedures.

Q 23. Describe your experience with different types of safety relief valves and their role in emergency shutdowns.

My experience encompasses a wide range of safety relief valves, crucial components in any emergency shutdown system. These valves automatically relieve excess pressure or flow to prevent catastrophic failures.

- Spring-loaded Pressure Relief Valves (PRVs): These are the most common type, relying on a spring to maintain a set pressure. When pressure exceeds the setpoint, the valve opens, releasing the excess. I’ve worked extensively with these in chemical processing plants, ensuring their proper sizing and regular testing.

- Pilot-operated Pressure Relief Valves: These use a pilot signal to control the main valve, offering more precise control and often used in applications requiring a more nuanced response to pressure fluctuations. I’ve seen their application in high-pressure steam systems, where precise control is critical.

- Rupture Discs: These are pressure-relief devices that rupture at a predetermined pressure. They are often used as a secondary protection measure or in situations where a faster response is needed. I’ve incorporated these into systems handling flammable materials, where quick pressure relief is vital to preventing explosions.

During emergency shutdowns, these valves play a vital role in preventing equipment damage and protecting personnel by quickly releasing hazardous materials or pressure. Regular inspection, testing, and maintenance are paramount to ensuring their reliable operation in emergency situations.

Q 24. How do you manage the risks associated with manual emergency shutdowns?

Manual emergency shutdowns, while sometimes necessary, inherently carry higher risks due to the human element. To mitigate these risks, a structured approach is crucial.

- Clear Procedures: Detailed, step-by-step instructions must be readily available and easily understandable by all personnel involved. These should include visual aids and flowcharts, minimizing ambiguity.

- Training and Drills: Regular, realistic training simulations and drills are vital to ensure personnel are competent and confident in executing the procedures under pressure. This includes practice with personal protective equipment (PPE).

- Communication: Effective communication channels are necessary to coordinate actions during a shutdown. Dedicated communication systems, perhaps separate from regular operations, prevent confusion and ensure everyone is informed of the situation and their roles.

- Supervision: Supervisory personnel should be present to oversee the shutdown, provide guidance, and address any unforeseen challenges.

- Lockout/Tagout (LOTO) Procedures: Strict adherence to LOTO protocols is essential to ensure equipment is isolated and prevented from restarting inadvertently during the shutdown.

By implementing these risk management strategies, the likelihood of errors during manual shutdowns can be significantly reduced.

Q 25. How do you ensure that emergency shutdown procedures are kept up-to-date and relevant?

Keeping emergency shutdown procedures up-to-date is a continuous process that requires vigilance and proactive measures.

- Regular Reviews: Procedures should be reviewed at least annually, or more frequently if there are changes in equipment, processes, or regulatory requirements. This review should involve personnel from various departments to capture all perspectives.

- Incident Investigations: After any incident or near-miss, a thorough investigation should be conducted to identify weaknesses in the existing procedures and incorporate necessary improvements.

- Technology Updates: Advancements in technology might necessitate updating procedures to incorporate new safety devices or monitoring systems. For example, the integration of advanced process control systems might require modifications to shutdown protocols.

- Regulatory Compliance: Procedures must remain compliant with all applicable industry regulations and safety standards. Any changes in these regulations require immediate updates to procedures.

- Version Control: Maintaining version control of procedures, perhaps using a document management system, helps track changes and ensures everyone is working from the most current version.

Using a combination of these strategies ensures that emergency shutdown procedures are always relevant, effective, and aligned with best practices.

Q 26. What are your strategies for improving the effectiveness of emergency shutdown procedures?

Improving the effectiveness of emergency shutdown procedures is an ongoing effort. My strategies center around enhancing both the procedural aspects and the human factors involved.

- Simplified Procedures: Procedures should be as clear, concise, and straightforward as possible. Complex jargon should be avoided, and visuals should be employed to enhance understanding.

- Improved Training: Regular, realistic training using simulations and scenarios should be implemented to build confidence and competence among personnel. This could include virtual reality simulations to replicate real-world emergencies.

- Enhanced Communication: Investing in robust communication systems and establishing clear communication protocols ensures everyone is informed and coordinated during a shutdown event. This includes clear designation of roles and responsibilities.

- Data Analysis: Analyzing data from past shutdowns, including both successful and unsuccessful ones, can reveal areas for improvement in the procedures or training programs. Identifying common errors is key.

- Human Factors Engineering: Applying principles of human factors engineering to procedure design reduces the likelihood of human error, considers cognitive limitations, and ensures that the procedures are compatible with human capabilities.

By focusing on these improvements, we can create more robust and effective emergency shutdown procedures that significantly reduce the risk of accidents and improve overall safety.

Q 27. Describe a time you had to make a critical decision during an emergency shutdown event.

During a chemical spill incident, we faced a rapidly escalating situation where a reaction vessel was overheating, threatening a potential explosion. The established procedure called for a complete plant shutdown, but the quick-shutdown sequence would have left a significant amount of hazardous material exposed.

After a quick assessment of the situation, I made the critical decision to deviate slightly from the standard procedure. We prioritized isolating the affected vessel using emergency isolation valves, which minimized the exposure, before proceeding with the full plant shutdown. This faster approach ensured faster containment and reduced the risk of a major incident.

Post-incident review validated the decision, highlighting the need for more nuanced responses within our established procedures. This experience emphasized the importance of both following protocols and making quick, informed decisions when facing unpredictable situations.

Q 28. How do you stay updated on the latest best practices for emergency shutdown procedures?

Staying current on best practices is paramount in this field. I utilize a multi-faceted approach to continuous learning.

- Industry Publications and Journals: I regularly read industry publications and journals, specifically those focusing on process safety and emergency response, to stay informed about new technologies, techniques, and regulatory changes.

- Professional Organizations: Active participation in professional organizations like the AIChE (American Institute of Chemical Engineers) provides access to conferences, workshops, and networking opportunities, keeping me abreast of the latest research and best practices.

- Training Courses and Seminars: I regularly attend training courses and seminars offered by reputable organizations on topics such as process safety management, emergency response, and risk assessment. These often include updates on regulatory changes and new technologies.

- Regulatory Updates: I actively monitor changes in relevant regulations and standards to ensure our procedures remain compliant. This includes following OSHA and EPA guidelines where applicable.

- Case Studies and Incident Reports: Analyzing case studies and reports from past incidents helps to learn from others’ experiences and identify areas for improvement in our own procedures. This provides valuable insights into real-world challenges.

Through this ongoing commitment to professional development, I ensure my knowledge and expertise remain current and relevant in the dynamic field of emergency shutdown procedures.

Key Topics to Learn for Emergency ShutOff Procedures Interview

- Understanding Different Shut-Off Types: Learn the variations in emergency shutoff systems (electrical, gas, water, chemical) and their specific procedures.

- Identifying Emergency Situations: Practice recognizing scenarios requiring immediate shutoff actions and differentiating between urgency levels.

- Locating and Accessing Shut-Off Mechanisms: Familiarize yourself with the location and operation of various shutoff valves, switches, and breakers within different settings.

- Safe Shut-Off Procedures: Master the step-by-step process for safely and effectively initiating emergency shutdowns, prioritizing safety protocols.

- Post-Shutdown Procedures: Understand the necessary actions after a shutdown, including reporting, documentation, and potential follow-up steps.

- Troubleshooting Common Issues: Prepare to discuss potential problems encountered during shutdown procedures and how to resolve them effectively and safely.

- Regulatory Compliance: Be aware of relevant safety regulations and industry standards related to emergency shut-off procedures in your field.

- Teamwork and Communication: Discuss the importance of clear communication and coordination with colleagues during emergency situations.

- Practical Application: Be ready to describe real-world scenarios where you’ve applied or would apply emergency shutoff procedures, highlighting your problem-solving skills.

Next Steps

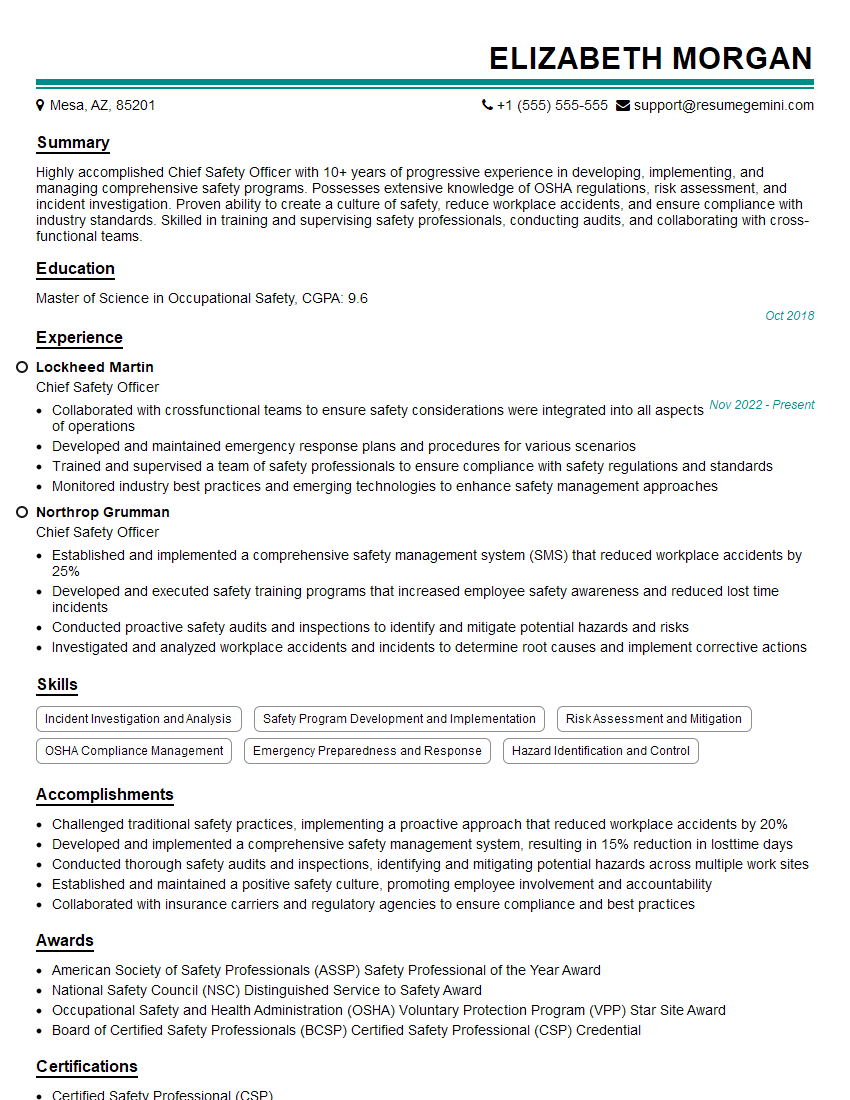

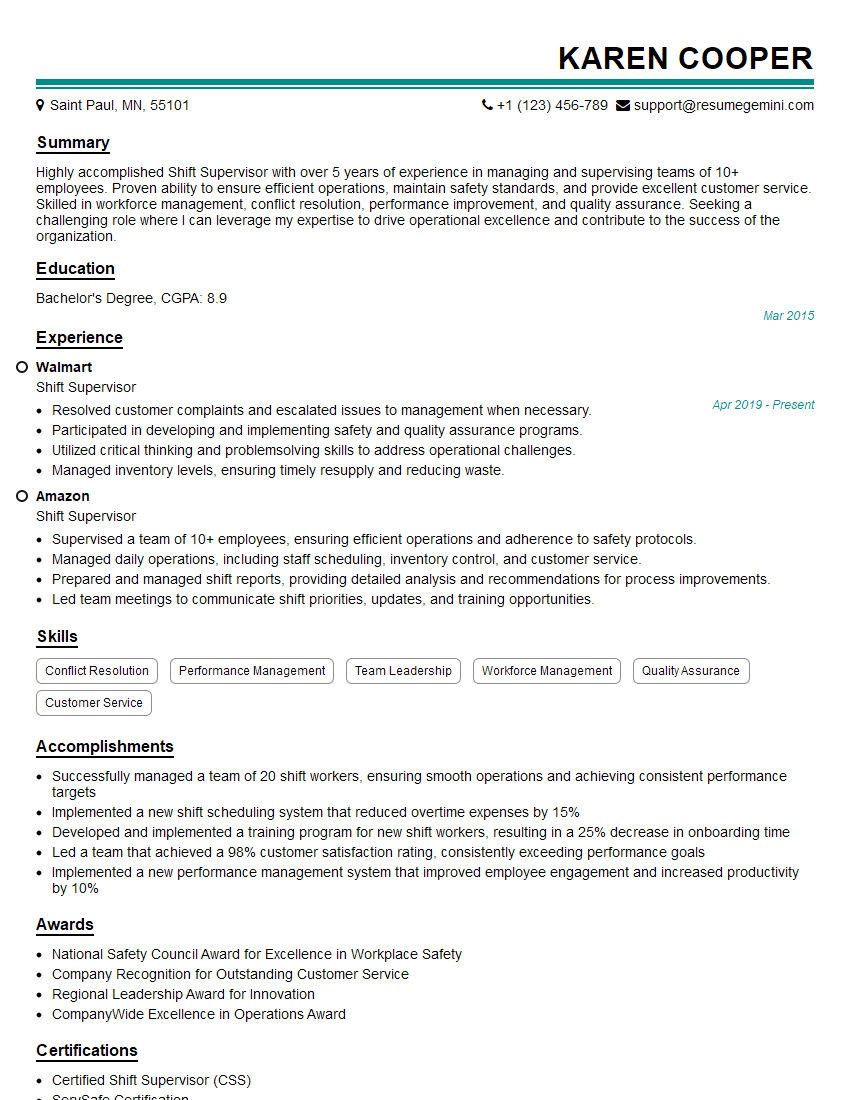

Mastering emergency shut-off procedures demonstrates a crucial skillset, significantly enhancing your value to potential employers and opening doors to advanced roles within your field. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your expertise. ResumeGemini is a trusted resource that can help you build a professional resume tailored to showcase your skills and experience effectively. Examples of resumes tailored to Emergency ShutOff Procedures are available, demonstrating the impact of a well-crafted resume. Invest in your future – build a strong resume and showcase your mastery of emergency procedures.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO