The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Ensuring product quality and compliance with specifications interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Ensuring product quality and compliance with specifications Interview

Q 1. Explain your experience with ISO 9001 or other quality management systems.

My experience with ISO 9001 is extensive. I’ve been involved in implementing, maintaining, and auditing this quality management system across multiple organizations in the manufacturing and technology sectors. ISO 9001 provides a framework for consistently meeting customer and regulatory requirements. This involves establishing and maintaining documented processes, controlling documents and records, managing resources, and continuously improving the quality management system. In one particular project, I led the implementation of ISO 9001 in a small manufacturing company. This involved training staff, developing and documenting processes, conducting internal audits, and ultimately achieving certification. The result was a significant reduction in defects, improved customer satisfaction, and increased efficiency. Beyond ISO 9001, I’m also familiar with other quality management systems like AS9100 (for aerospace) and IATF 16949 (for automotive), understanding their unique requirements and adapting quality processes accordingly.

Q 2. Describe your process for developing a quality control plan.

Developing a quality control plan is a systematic process that begins with clearly defining the product or service and its specifications. It involves understanding the customer requirements, identifying potential failure points, and determining the most effective methods for preventing and detecting defects. My process typically follows these steps:

- Define product specifications: This includes documenting all functional and non-functional requirements.

- Identify critical quality characteristics (CQCs): These are the parameters that most significantly impact product performance and customer satisfaction.

- Determine inspection and testing methods: Selecting appropriate methods for verifying that CQCs meet specifications. This might involve visual inspections, dimensional measurements, functional testing, or destructive testing.

- Establish acceptance criteria: Defining clear pass/fail criteria for each inspection and test.

- Develop a control chart: This is used to monitor process performance and detect potential deviations from specification.

- Create a corrective action plan: This outlines the steps to take if defects are found.

- Document the plan: All aspects of the plan should be clearly documented for easy reference and auditing.

For instance, in a project involving the development of a software application, the quality control plan would include unit testing, integration testing, system testing, and user acceptance testing. Each stage would have clearly defined acceptance criteria and a documented process for addressing any defects found.

Q 3. How do you identify and prioritize quality risks?

Identifying and prioritizing quality risks involves a systematic approach. I often use Failure Mode and Effects Analysis (FMEA) to systematically identify potential failure modes, their severity, probability of occurrence, and the detectability of the failure. This allows for a quantitative assessment of risk. For each potential failure mode, I then determine the risk priority number (RPN) using a formula that considers these factors. Higher RPN values indicate higher-priority risks. For instance, a high-severity failure with a high probability of occurrence and low detectability would have a very high RPN, requiring immediate attention. Prioritization is done based on the RPN values, focusing resources on addressing the highest-risk items first. This risk-based approach ensures that resources are allocated effectively to mitigate the most critical threats to product quality.

Q 4. What are your preferred methods for conducting root cause analysis?

Root cause analysis is crucial for preventing future defects. I utilize several methods depending on the context. The 5 Whys technique is a simple and effective way to drill down to the root cause by repeatedly asking “Why?” until the fundamental problem is uncovered. Another method I often use is the Fishbone diagram (Ishikawa diagram), which helps to visually organize potential causes categorized by different factors like materials, methods, manpower, machinery, measurements, and environment. For more complex situations, I employ Fault Tree Analysis (FTA), a deductive reasoning approach that diagrams potential failure events and their contributing factors. Selecting the appropriate method depends on the complexity of the problem and the available data. In one instance, using the 5 Whys, we uncovered that seemingly minor variations in the raw materials were the root cause of consistent defects in a manufacturing process. Addressing this directly solved the problem, saving significant time and resources.

Q 5. Explain your experience with statistical process control (SPC).

Statistical Process Control (SPC) is an essential tool for monitoring and improving process stability. I have extensive experience using control charts, such as X-bar and R charts, to track key process parameters over time. These charts help to identify trends, variations, and assignable causes of variation in the process. By analyzing data from control charts, I can detect shifts in the process mean or increases in variability, allowing for timely intervention and correction before defects occur. For example, in a manufacturing setting, we utilized X-bar and R charts to monitor the diameter of a critical component. The charts revealed an upward trend in the average diameter, which, upon investigation, was traced to a worn-out machine tool. Replacing the tool brought the process back under control, avoiding significant scrap and rework. Beyond basic control charts, I’m proficient in using more advanced SPC techniques, like capability analysis, to assess the process’s potential to meet specifications.

Q 6. Describe your experience with different testing methodologies (e.g., unit, integration, system).

My experience encompasses a wide range of testing methodologies. Unit testing verifies individual components or modules of software or a system; integration testing focuses on the interaction between different components; and system testing assesses the functionality of the complete system as a whole. I am also familiar with other types like acceptance testing (user acceptance testing) and performance testing (load and stress testing). The choice of testing method depends on the product and its complexity. For example, in a software development project, we would start with unit testing, ensuring each module works as expected. This is followed by integration testing, verifying that modules work together seamlessly. Finally, system testing assesses the overall functionality and performance of the complete system. Throughout this process, detailed test plans, test cases, and defect tracking are meticulously managed to ensure comprehensive testing and efficient issue resolution.

Q 7. How do you measure the effectiveness of your quality control processes?

Measuring the effectiveness of quality control processes involves several key metrics. Defect rates are fundamental, tracking the number of defects found per unit of product or service. This provides a clear indication of process performance and allows for trending over time. Customer satisfaction surveys can provide valuable feedback on product quality and help identify areas for improvement. Process capability indices (Cp and Cpk) quantify how well a process meets specifications, indicating whether the process is capable of producing products within acceptable limits. Cycle times, the time taken to complete a process, can be tracked to evaluate efficiency and identify bottlenecks. Finally, the cost of quality (COQ), encompassing prevention, appraisal, internal failure, and external failure costs, provides a comprehensive picture of the financial impact of quality control efforts. Regularly reviewing these metrics allows for data-driven improvements to our quality management system, and helps us to continuously refine our processes.

Q 8. How do you handle conflicts between quality, cost, and schedule?

The classic ‘iron triangle’ of quality, cost, and schedule often presents conflicts. Balancing these three requires a thoughtful, prioritized approach. It’s not about finding a perfect balance – that’s rarely possible – but rather about making informed trade-offs.

My strategy begins with clearly defining priorities. For example, in a medical device project, quality would unequivocally be the top priority, even if it means higher costs and a slightly longer schedule. In a less critical project, we might prioritize speed to market (schedule) with a carefully managed compromise on cost. Prioritization establishes a framework for decision-making.

Next, I employ techniques like:

- Value engineering: This involves scrutinizing every aspect of the product to identify areas where costs can be reduced without compromising quality or functionality. This could involve using alternative, cost-effective materials or simplifying the design.

- Risk management: Identifying and mitigating potential risks that could impact quality, cost, or schedule is crucial. A thorough risk assessment helps proactively address potential issues before they become major problems, leading to better resource allocation.

- Agile methodologies: Iterative development allows for flexibility and adaptation. Changes in priorities or unforeseen challenges can be addressed more easily in smaller, manageable iterations, minimizing the impact on overall delivery.

Finally, open and transparent communication with stakeholders is essential to ensure everyone understands the trade-offs and is on board with the chosen approach. Regular progress reports and clear communication of any deviations from the plan maintain alignment and prevent misunderstandings.

Q 9. Describe your experience with quality improvement methodologies (e.g., Lean, Six Sigma).

I’ve extensively utilized Lean and Six Sigma methodologies throughout my career. Lean focuses on eliminating waste and maximizing efficiency, while Six Sigma aims to reduce defects and improve process capability. They’re not mutually exclusive; often, they’re complementary.

Lean: In a previous project involving software development, we implemented Kanban to visualize workflow, limiting work in progress and identifying bottlenecks. This significantly improved our delivery time and reduced waste associated with unnecessary tasks or features. We also conducted 5S audits to maintain a clean and organized workspace, improving efficiency and reducing errors.

Six Sigma: I’ve used DMAIC (Define, Measure, Analyze, Improve, Control) to address a recurring manufacturing defect. We defined the problem, measured the defect rate, analyzed the root causes using tools like Pareto charts and fishbone diagrams, implemented corrective actions (improved training and equipment calibration), and then established controls to prevent recurrence. This resulted in a dramatic reduction in defect rates and improved customer satisfaction.

My experience extends to other quality improvement methodologies like Kaizen (continuous improvement) and Total Quality Management (TQM), which emphasize continuous process improvement through employee involvement and customer focus.

Q 10. How do you ensure compliance with relevant regulations and standards?

Ensuring compliance is paramount. My approach involves a multi-faceted strategy focusing on proactive measures and robust documentation.

First, I thoroughly understand all applicable regulations and standards relevant to the product. This includes researching industry-specific requirements, governmental regulations (e.g., FDA, ISO), and customer-specific demands.

Next, we build compliance into the product development lifecycle from the beginning. This means selecting appropriate materials, designing for compliance, and incorporating rigorous testing procedures. We use Design Failure Mode and Effects Analysis (DFMEA) to identify potential failure modes and mitigate risks early on.

Furthermore, meticulous record-keeping is essential. We maintain comprehensive documentation of all compliance-related activities, including testing results, certifications, and audits. This ensures traceability and allows for easy verification during audits or inspections.

Finally, regular training programs keep our team updated on evolving regulations and best practices. Proactive compliance prevents costly recalls and legal issues and enhances our reputation for quality and reliability.

Q 11. Explain your experience with defect tracking and reporting systems.

I’ve used various defect tracking and reporting systems, including Jira, Bugzilla, and custom-built solutions. The key is not the specific tool but the effectiveness of the system in capturing, tracking, and resolving defects efficiently.

A well-designed system facilitates:

- Clear defect descriptions: Each defect report includes detailed information about the problem, steps to reproduce it, and the expected behavior.

- Prioritization and assignment: Defects are prioritized based on severity and impact, then assigned to the appropriate team members for resolution.

- Tracking and monitoring: The system allows us to track the status of each defect from reporting to resolution, providing visibility into the overall quality of the product.

- Reporting and analysis: The system generates reports on defect trends, which can be used to identify areas for process improvement.

For instance, in a past project, using Jira allowed us to efficiently manage over 1000 defects, providing dashboards that illustrated defect density by module, highlighting areas needing immediate attention. This data-driven approach resulted in faster problem resolution and proactive improvement of the development process.

Q 12. How do you communicate quality issues to stakeholders?

Communicating quality issues effectively is critical. My approach is to ensure transparency, clarity, and timely communication across all stakeholders.

I use various methods depending on the audience and the severity of the issue. For minor issues, a brief email update might suffice. However, for critical issues, a formal report with detailed analysis and recommended actions is essential.

Key aspects of my communication strategy include:

- Clear and concise language: Avoid technical jargon unless absolutely necessary and always define any specialized terms.

- Data-driven insights: Support claims with factual data and evidence, such as defect rates, test results, and customer feedback.

- Proactive communication: Inform stakeholders early and often, preventing surprises and allowing for collaborative problem-solving.

- Appropriate communication channels: Use the most suitable channel – email, phone call, meeting, or formal report – based on the situation.

- Actionable recommendations: Don’t just highlight problems; propose concrete solutions and corrective actions.

For example, when addressing a major quality issue with senior management, I would present a comprehensive report with charts and graphs illustrating the problem’s impact, the root causes identified, and a proposed mitigation plan with associated costs and timelines.

Q 13. Describe your experience with audits and inspections.

I have extensive experience participating in and leading audits and inspections. These are crucial for ensuring compliance and identifying areas for improvement.

Audits are usually more comprehensive, examining the entire quality management system. I’ve participated in ISO 9001 and FDA audits, where I’ve been responsible for preparing documentation, guiding auditors through our processes, and addressing their findings.

Inspections are typically focused on specific aspects of the product or process. I’ve led inspection teams to verify conformance to specifications, reviewing manufacturing processes, inspecting finished goods, and ensuring compliance with regulatory requirements.

My role in these processes involves:

- Preparation: Ensuring all necessary documentation is available and organized.

- Conducting the audit/inspection: Following a structured approach, documenting findings, and taking photos or videos as needed.

- Following up on findings: Developing and implementing corrective and preventive actions (CAPA) to address identified deficiencies.

- Reporting: Preparing clear and concise reports summarizing the audit/inspection findings and recommendations.

Through these experiences, I’ve developed strong skills in identifying weaknesses, implementing improvements, and demonstrating compliance to external stakeholders.

Q 14. How do you manage and resolve customer complaints related to product quality?

Managing customer complaints regarding product quality is a critical aspect of maintaining customer satisfaction and brand reputation. My approach is rooted in empathy, efficiency, and a commitment to resolution.

My process typically involves:

- Acknowledgement and empathy: Promptly acknowledging the complaint and expressing understanding of the customer’s frustration. A timely response is vital.

- Information gathering: Thoroughly gathering information about the complaint, including detailed descriptions of the problem, the product’s serial number (if applicable), and any supporting documentation.

- Investigation and root cause analysis: Investigating the complaint to determine the root cause of the problem. This might involve examining the product, reviewing manufacturing records, and consulting with engineering or production teams.

- Resolution and communication: Developing a solution, which might involve repair, replacement, or refund, and promptly communicating the resolution to the customer. Maintaining open communication throughout the process.

- Preventative actions: Implementing corrective actions to prevent similar complaints from occurring in the future. This often involves process improvements or design modifications.

I’ve managed numerous customer complaints, often turning negative experiences into opportunities to demonstrate our commitment to quality and build stronger customer relationships. I believe that effective complaint management enhances customer loyalty and provides valuable feedback for continuous improvement.

Q 15. Explain your experience with quality metrics and key performance indicators (KPIs).

Quality metrics and KPIs are crucial for monitoring and improving product quality. They provide quantifiable data to track progress and identify areas for improvement. My experience involves utilizing a range of metrics, tailored to the specific project and its goals.

- Defect Density: This measures the number of defects per unit of code (e.g., lines of code or function points). A lower defect density indicates higher quality. For example, in a recent project, we tracked defect density weekly, aiming for under 0.5 defects per 1000 lines of code. We used this metric to identify specific modules requiring more rigorous testing.

- Test Coverage: This metric shows the percentage of code covered by automated tests. High test coverage reduces the risk of undiscovered defects. In a previous role, we targeted 80% code coverage for critical modules and 60% for less critical ones, using tools like SonarQube to monitor progress.

- Mean Time To Failure (MTTF): This measures the average time a system operates before failing. A higher MTTF is desirable. We used this extensively in embedded systems projects to gauge the reliability of hardware and software components.

- Customer Satisfaction (CSAT): While not directly a development metric, CSAT scores reflect the ultimate impact of our quality efforts. We actively solicited feedback and used this to guide improvements in future releases.

By regularly tracking and analyzing these KPIs, we can identify trends, pinpoint bottlenecks, and implement corrective actions to enhance the overall quality and reliability of our products.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and reliability of test data?

Ensuring accurate and reliable test data is paramount for generating meaningful test results. My approach involves a multi-pronged strategy:

- Data Generation Techniques: I use a combination of techniques including generating synthetic data that mimics real-world scenarios, using anonymized production data (with appropriate privacy considerations), and leveraging test data management tools to create and maintain test datasets.

- Data Validation: Rigorous validation is crucial. I employ data validation rules to check for data completeness, accuracy, consistency, and conformity to pre-defined data schemas. We utilize both manual checks and automated data validation scripts for efficiency and accuracy.

- Data Cleansing: Cleaning the data is vital, removing duplicates, handling inconsistencies, and correcting errors before using it in testing. We employ various techniques like data profiling and scrubbing to improve the quality of the data used in testing.

- Version Control: Tracking changes and maintaining different versions of test data is essential for reproducibility and managing various test environments. We use version control systems (like Git) to manage and track test data versions.

- Data Masking and Anonymization: When using real-world data, ensuring data privacy is critical. Employing techniques such as data masking and anonymization is essential for complying with regulations and protecting sensitive information.

By meticulously managing and validating our test data, we ensure that our test results accurately reflect the system’s behavior in a reliable and trustworthy manner. For example, in one project, we used a test data management tool that allowed us to easily create different subsets of data, facilitating parallel testing and reducing dependencies.

Q 17. Describe your experience with different types of quality testing (e.g., destructive, non-destructive).

My experience encompasses various testing types, each with its specific purpose and methodologies:

- Unit Testing: This involves testing individual components or modules of the software in isolation. I use unit testing frameworks like JUnit or pytest extensively to ensure each component functions correctly before integration.

- Integration Testing: This verifies the interaction between different modules or components. We use integration tests to ensure seamless communication and data flow between various parts of the system.

- System Testing: This validates the entire system as a whole, ensuring all components work together as expected. This often includes performance, security, and usability testing.

- User Acceptance Testing (UAT): This involves testing the system with end-users to ensure it meets their requirements and expectations. We use feedback from UAT to refine the product before release.

- Destructive Testing: This involves deliberately stressing a product beyond its operational limits to determine its breaking point. In hardware development, we used destructive testing to determine the tolerance of components to extreme temperatures and forces.

- Non-Destructive Testing: This involves evaluating a product’s properties without causing damage. We use this extensively in software, employing techniques like static analysis to identify potential vulnerabilities without executing the code.

The choice of testing methods depends on the product, its complexity, and the risk involved. A well-balanced testing strategy incorporates a combination of these techniques to ensure comprehensive quality assurance.

Q 18. How do you ensure traceability throughout the product lifecycle?

Traceability throughout the product lifecycle is vital for effective quality management. This involves establishing a clear link between requirements, design, development, testing, and deployment. My approach focuses on several key aspects:

- Requirements Traceability Matrix (RTM): I utilize an RTM to link requirements to design specifications, test cases, and code modules. This allows us to easily track the implementation and testing status of each requirement.

- Version Control Systems (VCS): Using a VCS like Git allows us to track changes in code, documentation, and test cases, making it easier to understand the evolution of the product and identify the source of any issues.

- Defect Tracking System: We use a defect tracking system (like Jira) to record and manage defects discovered during testing. Each defect is linked to the relevant requirements, test cases, and code changes, providing a complete audit trail.

- Documentation: Detailed documentation is crucial. This includes requirements documents, design specifications, test plans, test reports, and release notes. Consistent and well-organized documentation simplifies the process of tracing issues and changes throughout the product’s lifecycle.

By implementing these practices, we ensure that every change and issue is properly documented and traceable, allowing for efficient debugging, impact analysis, and continuous improvement.

Q 19. Explain your experience with risk assessment and mitigation strategies.

Risk assessment and mitigation are essential for proactive quality management. My experience includes:

- Risk Identification: We begin by identifying potential risks throughout the product lifecycle, considering factors like technical challenges, dependencies on external systems, regulatory requirements, and potential user errors.

- Risk Analysis: Each identified risk is analyzed based on its likelihood and potential impact. We use a risk matrix to prioritize risks based on their severity.

- Risk Mitigation Strategies: For each high-priority risk, we develop mitigation strategies. These might include developing contingency plans, implementing additional testing, enhancing security measures, or improving documentation.

- Risk Monitoring and Review: Throughout the project, we regularly monitor the identified risks and review the effectiveness of the mitigation strategies. This enables us to adapt our approach as needed.

For instance, in a recent project, we identified a high risk associated with integrating a third-party API. To mitigate this, we implemented comprehensive integration testing, established a clear communication channel with the API provider, and developed a fallback mechanism in case of API failure.

Q 20. How do you balance the need for thorough testing with project deadlines?

Balancing thorough testing with project deadlines requires a strategic approach that prioritizes testing efforts effectively. I use a risk-based approach:

- Prioritization: We prioritize testing efforts based on risk. Critical features and components receive more extensive testing, while less critical areas may receive less rigorous testing.

- Test Automation: Automating repetitive test cases significantly speeds up the testing process, allowing for more comprehensive coverage within the available time frame. We use tools like Selenium or Appium for UI testing and JUnit for unit testing.

- Test Case Optimization: We design efficient and effective test cases to maximize test coverage while minimizing testing time. We focus on covering critical functionality and user flows, avoiding redundant or unnecessary tests.

- Parallel Testing: Running tests concurrently using techniques like parallel execution can significantly reduce the overall testing time.

- Early Testing: Starting testing early in the development lifecycle, ideally during the design phase, helps identify and fix defects earlier when they are less costly to address.

Sometimes, compromises are necessary. In these situations, I work with the project team to clearly communicate the risks associated with reduced testing scope and define acceptance criteria that balance risk and deadlines.

Q 21. Describe your experience with automation testing tools and frameworks.

I have extensive experience with various automation testing tools and frameworks. My expertise includes:

- Selenium: I use Selenium for automating web application testing. I’m proficient in writing Selenium scripts using various programming languages like Java and Python.

- Appium: I leverage Appium for automating mobile application testing across both Android and iOS platforms. My experience includes creating robust and maintainable Appium test suites.

- JUnit/pytest: I use JUnit (Java) and pytest (Python) for unit testing, writing effective unit tests that provide high code coverage and early defect detection.

- TestNG: I’m familiar with TestNG, a testing framework for Java, offering features like parallel test execution and data-driven testing.

- CI/CD Integration: I have experience integrating automated tests into CI/CD pipelines using tools like Jenkins or GitLab CI. This ensures automated tests are run regularly as part of the development process.

- Reporting and Analysis: I am proficient in using test automation tools to generate reports that provide comprehensive insights into test results, identify trends, and highlight areas requiring further investigation.

The choice of tools and frameworks depends on the specific project requirements and the technologies used. I always strive to select the most appropriate tools to optimize efficiency and effectiveness.

Q 22. How do you handle situations where quality issues are discovered late in the product development cycle?

Discovering quality issues late in the development cycle is challenging, but a systematic approach is crucial. My first step would be to conduct a thorough root cause analysis to understand precisely why the issue wasn’t caught earlier. This involves interviewing the relevant teams, examining the testing procedures, and analyzing the documentation. Once the root cause is identified, we prioritize mitigation. This might involve a hotfix, a complete redesign of the affected component (depending on the severity and time remaining until release), or, in extreme cases, delaying the release to address the problem fully. Communication is paramount – transparency with stakeholders about the issue, its impact, and the remediation plan is essential to maintain trust and manage expectations. Finally, we implement corrective actions to prevent similar issues from recurring in future projects. This could involve enhancing testing protocols, adding new checks to the development workflow, or providing additional training for the team. For example, if the issue stemmed from inadequate testing, we might implement more rigorous automated tests or introduce code reviews. This ensures learning from mistakes and continuous improvement.

Q 23. How do you ensure that quality standards are consistently maintained across different teams?

Maintaining consistent quality across different teams requires a multi-pronged strategy. Firstly, a centralized quality management system (QMS) is indispensable. This system would define standardized procedures, templates, and metrics for all teams to follow. Regular cross-team training sessions and knowledge sharing workshops help ensure everyone understands and adheres to the same quality standards. Clear communication channels, including regular meetings and project management tools, foster collaboration and early identification of potential problems. We also use shared repositories for documentation, code snippets, and best practices. This fosters consistency and allows teams to learn from each other’s experiences. Finally, regular audits and performance reviews ensure accountability and identify areas needing improvement. For instance, we might use a standardized checklist for code reviews across all teams to guarantee a common level of scrutiny.

Q 24. What are your strategies for preventing quality problems from occurring in the first place?

Preventing quality problems proactively is far more efficient than fixing them later. My strategies focus on a robust process starting with well-defined requirements. Clear, unambiguous requirements are the foundation for quality. This involves close collaboration with stakeholders to ensure we understand the needs and expectations thoroughly. We then employ design reviews and code reviews to identify potential issues early in the development cycle. Automated testing plays a critical role – unit tests, integration tests, and system tests help catch bugs before they reach the end-user. We also adopt practices like continuous integration and continuous delivery (CI/CD), which enables frequent testing and early feedback. This allows for swift identification and resolution of problems. Furthermore, investing in employee training and upskilling ensures the team possesses the necessary skills and knowledge to build high-quality products. For instance, we might conduct training on secure coding practices to prevent vulnerabilities. Finally, a strong emphasis on documentation aids maintainability and reduces the risk of future errors.

Q 25. Describe your experience with implementing and maintaining a quality management system.

In my previous role, I was instrumental in implementing and maintaining an ISO 9001-compliant QMS. This involved establishing clear roles and responsibilities within the team, developing comprehensive documentation, and implementing a robust document control system. We used a project management tool to track progress, manage risks, and document all activities related to quality. Key aspects included defining clear metrics for measuring quality (such as defect density, customer satisfaction scores, and adherence to deadlines), conducting regular internal audits to ensure compliance with the QMS, and establishing a process for handling non-conformances. We used a combination of visual management tools (like Kanban boards) and automated reporting to make the QMS easily accessible and transparent for everyone in the organization. The success of our implementation was measured by a significant reduction in defects, an improvement in customer satisfaction, and a more efficient and streamlined development process.

Q 26. How do you stay up-to-date with the latest quality assurance best practices and technologies?

Staying current with best practices and technologies is vital. I actively participate in industry conferences and workshops to learn about emerging trends and techniques. I subscribe to leading quality assurance publications and online resources. I also actively engage in online communities and forums, exchanging knowledge and ideas with other professionals in the field. Moreover, I regularly review and update our internal QMS to incorporate new standards and best practices. This continuous learning ensures that we’re always using the most effective tools and techniques to build high-quality products. For example, I’ve recently been researching the implementation of AI-powered testing tools to improve the efficiency and accuracy of our testing processes.

Q 27. Explain your understanding of different quality costs (prevention, appraisal, internal failure, external failure).

Understanding quality costs is crucial for effective quality management. Prevention costs are incurred to prevent defects from occurring in the first place – this includes activities such as training, process improvement initiatives, and quality planning. Appraisal costs are associated with evaluating the quality of products and services, such as inspection, testing, and audits. Internal failure costs are the costs of defects discovered before the product reaches the customer, including rework, scrap, and downtime. External failure costs are the costs associated with defects discovered after the product reaches the customer, such as warranty repairs, product recalls, and loss of reputation. By analyzing these costs, we can identify areas for improvement and optimize our quality management efforts. For instance, if we observe high internal failure costs, it suggests a need to strengthen our testing procedures or improve employee training. A high external failure cost might indicate the need for more robust customer service and improved product design.

Q 28. Describe a time you had to make a difficult decision regarding product quality.

In a previous project, we discovered a critical bug just before the release date. Fixing this bug would require significant overtime from the team and potentially delay the launch. The decision was whether to release with the bug (risking customer dissatisfaction and potential reputational damage) or delay the launch. After careful consideration of the risk factors, the severity of the bug, and the potential impact on customers, we decided to delay the release. This decision, while difficult, prioritized customer satisfaction and product quality. We communicated transparently with stakeholders, explaining the situation and the rationale behind our decision. Although this resulted in a short delay, it prevented a major crisis and ultimately strengthened customer trust. The subsequent thorough investigation into the root cause of the defect led to improvements in our development and testing processes, preventing similar issues in future projects.

Key Topics to Learn for Ensuring Product Quality and Compliance with Specifications Interview

- Quality Management Systems (QMS): Understanding ISO 9001 or other relevant standards, and how they are implemented to ensure consistent product quality. Practical application: Describe your experience with implementing or improving a QMS in a previous role.

- Testing and Inspection Methods: Familiarize yourself with various testing methodologies (e.g., unit testing, integration testing, system testing, user acceptance testing) and inspection techniques used to verify product specifications. Practical application: Explain how you’ve designed and executed a robust testing plan to identify and resolve defects.

- Specification Analysis and Interpretation: Demonstrate your ability to thoroughly understand and interpret product specifications, including tolerances, performance requirements, and regulatory compliance needs. Practical application: Describe a situation where you had to clarify ambiguous specifications and ensure a clear understanding across teams.

- Defect Prevention and Root Cause Analysis: Understand techniques for identifying and preventing defects throughout the product lifecycle, including tools like 5 Whys and Fishbone diagrams. Practical application: Detail a time you successfully identified the root cause of a recurring product defect and implemented a corrective action.

- Compliance and Regulatory Requirements: Demonstrate knowledge of relevant industry regulations and standards (e.g., FDA, RoHS, etc.) and how they impact product development and quality assurance. Practical application: Describe your experience ensuring compliance with specific industry regulations.

- Data Analysis and Reporting: Show your proficiency in collecting, analyzing, and presenting quality data to stakeholders. Practical application: Explain how you’ve used data to track product quality metrics, identify trends, and inform improvement initiatives.

- Continuous Improvement Methodologies: Familiarity with Lean, Six Sigma, or other continuous improvement methodologies to enhance product quality and efficiency. Practical application: Describe your experience with implementing a continuous improvement project to improve product quality or reduce defects.

Next Steps

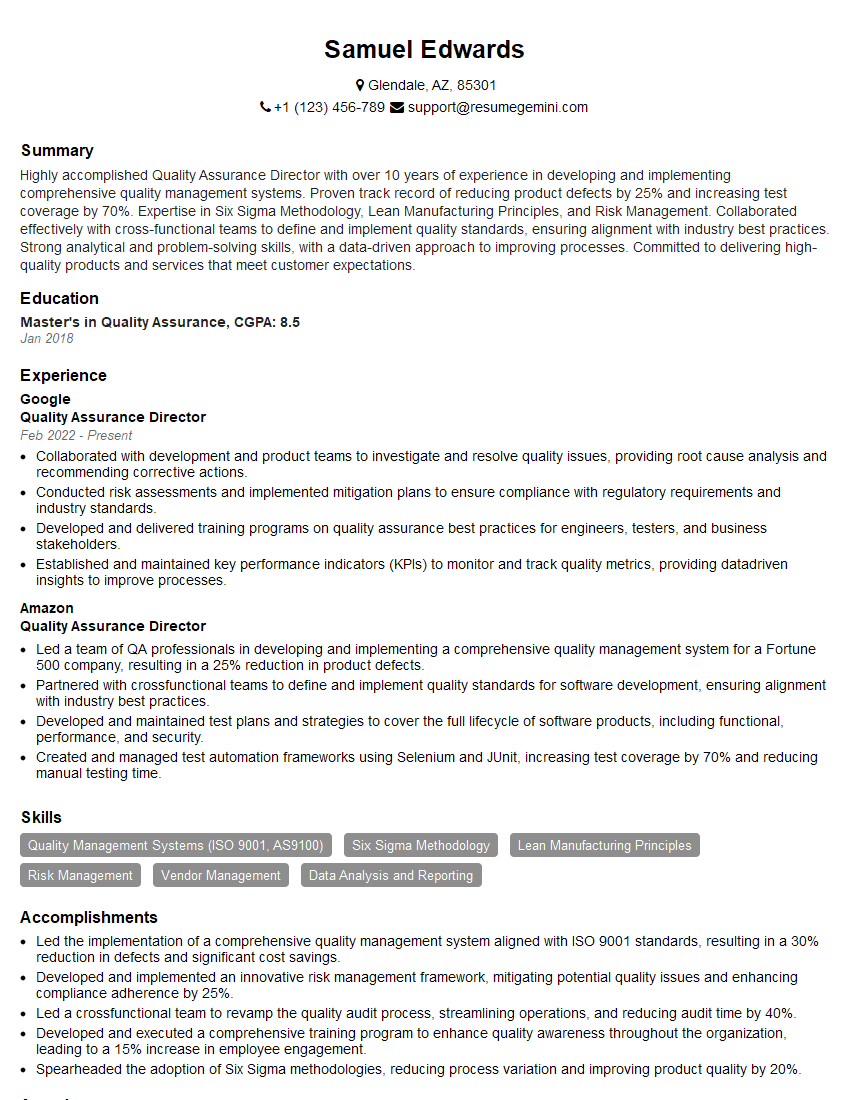

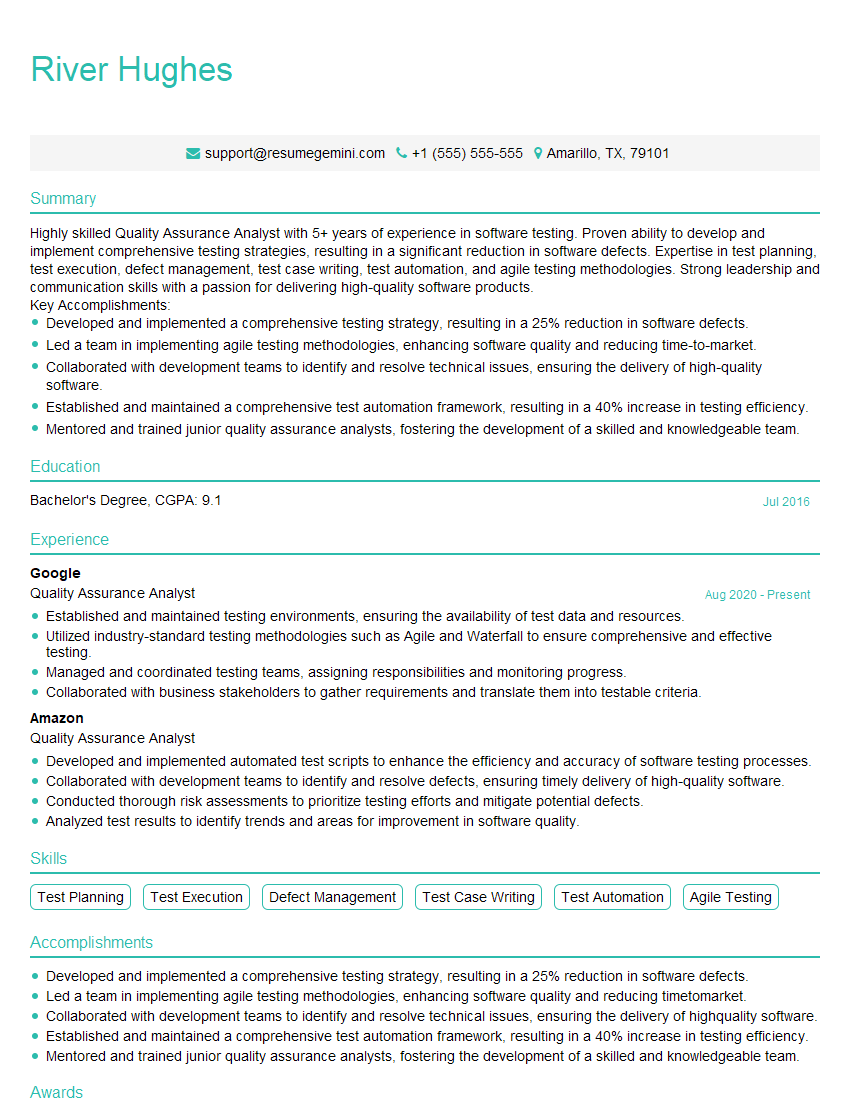

Mastering the art of ensuring product quality and compliance is crucial for career advancement in any technical field. It demonstrates your commitment to excellence and your ability to deliver high-quality products that meet customer expectations and regulatory requirements. To significantly boost your job prospects, invest time in crafting an ATS-friendly resume that highlights your key skills and accomplishments. ResumeGemini is a trusted resource to help you build a professional and effective resume tailored to your experience. Examples of resumes specifically designed for candidates focusing on ensuring product quality and compliance with specifications are available to guide you. Take advantage of these resources and confidently present your skills to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO