Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Equipment Inspection and Compliance interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Equipment Inspection and Compliance Interview

Q 1. Describe your experience conducting equipment inspections.

My experience in conducting equipment inspections spans over 10 years, encompassing a wide range of industries, including manufacturing, construction, and healthcare. I’ve inspected everything from basic hand tools to complex machinery, utilizing various inspection methods and technologies. I’m proficient in both planned preventative maintenance (PPM) inspections and reactive inspections following incidents or near misses. For example, in a manufacturing plant, I conducted regular inspections of automated assembly lines, identifying and documenting issues like worn bearings, loose fasteners, and hydraulic leaks, preventing potential breakdowns and safety hazards. In a construction setting, I’ve inspected scaffolding, cranes, and other heavy equipment to ensure compliance with safety regulations and prevent accidents. My approach always emphasizes thoroughness, attention to detail, and a focus on proactive risk mitigation.

Q 2. What are the key elements of a comprehensive equipment inspection checklist?

A comprehensive equipment inspection checklist should include several key elements: First, identification information: the equipment’s name, ID number, location, and last inspection date. Next, a section on visual inspection covering aspects like physical damage (dents, cracks, corrosion), leaks, and proper functioning of safety devices (guards, interlocks). Then, functional testing should be documented. This includes verifying operational parameters (pressure, temperature, voltage) and checking for proper functionality. A section for calibration verification is vital for instruments and measuring devices. Finally, the checklist must allow for documenting non-conformances, including a detailed description of the defect, its severity, and recommended corrective actions. A space for inspector’s signature and date of inspection is also crucial.

- Example: For a forklift, the checklist would include visual inspection of tires, brakes, forks, lights, and the mast; functional testing of the hydraulic system and steering; and calibration verification for the load capacity indicator.

Q 3. How do you identify and document equipment defects or non-conformances?

Identifying and documenting defects or non-conformances requires a systematic approach. I use a standardized reporting format, typically a digital system or a well-structured paper form, that includes a clear description of the defect, its location on the equipment (using diagrams or photos if needed), and a severity rating (e.g., minor, major, critical). I always take detailed photographs or videos as supporting evidence. For example, a crack in a weld on a pressure vessel would be described precisely, noting its length, depth, and location. The severity would be rated as critical due to potential for catastrophic failure, and immediate corrective action would be recommended. This detailed documentation allows for tracking of the defect, verification of corrective actions, and facilitates root cause analysis to prevent similar issues in the future.

Q 4. Explain your understanding of relevant safety regulations and standards (e.g., OSHA, ISO).

My understanding of relevant safety regulations and standards is extensive. I’m familiar with OSHA (Occupational Safety and Health Administration) guidelines, particularly those concerning lockout/tagout procedures, personal protective equipment (PPE) requirements, and machine guarding. I’m also well-versed in ISO (International Organization for Standardization) standards, such as ISO 45001 (occupational health and safety management systems) and ISO 9001 (quality management systems), which provide frameworks for effective safety and quality control programs. These standards guide my inspection procedures, ensuring that all equipment is operated and maintained in a safe and compliant manner. For example, I ensure all lockout/tagout procedures are followed before any maintenance work on equipment, and verify the presence and proper use of PPE by personnel working near or with the equipment. Non-compliance with any of these standards is always documented and reported immediately.

Q 5. How do you prioritize equipment inspection tasks based on risk assessment?

Prioritizing inspection tasks is crucial for efficiency and safety. I use a risk-based approach, categorizing equipment according to the potential consequences of failure. Equipment with high potential for causing severe injury or significant financial loss (e.g., cranes, pressure vessels) will be inspected more frequently than equipment with lower risk (e.g., hand tools). This risk assessment considers factors like the criticality of the equipment’s function, its age and condition, the potential for failure, and the consequences of failure. A risk matrix can be employed to visually represent this prioritization. Equipment with high risk and high likelihood of failure gets the highest priority and more frequent inspections.

Q 6. What methods do you use to ensure the accuracy and reliability of inspection results?

Ensuring accuracy and reliability of inspection results is paramount. This involves using calibrated inspection equipment, following standardized procedures, and conducting regular audits of the inspection process itself. Calibration certificates for all measuring instruments are maintained and reviewed. Two-person checks or independent verification can be incorporated for high-risk equipment to confirm findings. Documented evidence, including photographs, videos, and detailed reports, supports the accuracy of the results. Regular training and competency assessment for inspectors also enhance the reliability of the inspection process. Blind audits or spot checks on previously inspected equipment can be used to evaluate inspector consistency and identify any potential biases or oversights.

Q 7. Describe your experience using inspection equipment and tools.

I’m experienced in using a variety of inspection equipment and tools. This includes, but isn’t limited to, ultrasonic thickness gauges for detecting corrosion, infrared cameras for detecting overheating components, vibration analyzers for identifying mechanical imbalances, and borescopes for inspecting hard-to-reach areas. I also regularly utilize digital calipers, micrometers, and other precision measuring tools. Proficiency in using these tools, coupled with a solid understanding of their limitations, is essential for accurate and reliable inspections. For example, using an infrared camera to detect a loose connection in an electrical panel can prevent a fire hazard; or using ultrasonic thickness gauging to identify thinning in a pipe can prevent a potentially catastrophic rupture. I’m always updating my knowledge and skills to keep up with new technologies and advancements in inspection equipment.

Q 8. How do you manage and track inspection data and records?

Managing and tracking inspection data and records is crucial for maintaining compliance and improving equipment reliability. We employ a robust, multi-faceted system typically involving a combination of digital and physical methods.

- Digital Database: We utilize a dedicated software solution (e.g., CMMS – Computerized Maintenance Management System) to store all inspection data. This allows for centralized access, easy searching, and automated reporting. Data includes inspection dates, equipment details, findings, corrective actions, and associated documentation (photos, videos). The system often incorporates features for automated reminders for scheduled inspections.

- Physical Records: While digital records are preferred, we maintain physical copies of crucial inspection reports and certificates in secure, climate-controlled storage. This acts as a backup in case of system failures and complies with regulations requiring physical documentation in some industries.

- Barcode/QR Code System: To improve efficiency and reduce errors, we often employ barcode or QR code scanning linked to equipment identifiers in our database. This ensures quick data entry and accurate record-keeping.

- Version Control: Any changes made to inspection reports or documents are carefully tracked to ensure accuracy and maintain a complete audit trail. Older versions are retained as needed.

For example, in a recent project involving a fleet of heavy machinery, our CMMS system allowed us to track the inspection history of each vehicle, identify recurring issues, and schedule preventive maintenance, ultimately reducing downtime and maintenance costs.

Q 9. How do you communicate inspection findings to relevant stakeholders?

Effective communication of inspection findings is critical for preventing accidents and ensuring compliance. Our strategy focuses on clarity, timeliness, and appropriate audience targeting.

- Formal Reports: Detailed reports are generated after each inspection, clearly outlining findings, including any deficiencies or non-compliances. These are distributed to relevant stakeholders according to predefined roles and responsibilities, usually using an established notification system within our database.

- Visual Aids: Where appropriate, we incorporate photographs, videos, or diagrams to illustrate the inspection findings. This improves comprehension and strengthens the impact of the report.

- Verbal Briefings: For urgent or critical findings, we conduct immediate verbal briefings with those responsible for corrective actions, ensuring a rapid response.

- Meeting Summaries: Following meetings to discuss inspection findings and corrective actions, detailed summaries are distributed to all relevant parties.

- Escalation Procedures: A clear escalation path is established in case of significant non-compliances. This involves informing senior management and relevant regulatory bodies, if necessary.

For instance, in a case of a critical safety defect detected during a routine inspection of a food processing plant, we issued an immediate verbal warning to the plant manager, followed by a formal written report outlining the corrective actions needed. This rapid response prevented potential accidents and ensured compliance.

Q 10. Explain your experience with corrective and preventive action (CAPA) processes.

Corrective and Preventive Action (CAPA) processes are essential for addressing inspection findings and preventing future occurrences. We follow a structured approach, typically involving these steps:

- Identify the Problem: Clearly define the root cause of the non-compliance or defect.

- Implement Corrective Action: Take immediate steps to rectify the identified problem.

- Implement Preventive Action: Develop and implement measures to prevent the problem from recurring. This often involves process improvements, training, or equipment upgrades.

- Verify Effectiveness: Confirm that the corrective and preventive actions are effective in resolving the issue and preventing recurrence. This often includes follow-up inspections and audits.

- Document Everything: Meticulous documentation of each step in the CAPA process is crucial for traceability and demonstrating compliance. This includes the initial finding, the corrective actions taken, and the verification of their effectiveness.

For example, if an inspection reveals improper labeling on some equipment, the CAPA would involve: (1) correcting the labels on all affected equipment (corrective action), (2) implementing new labeling procedures and training for personnel to avoid future occurrences (preventive action), and (3) verifying all labels are corrected and the new procedures are followed (verification).

Q 11. How do you handle disagreements or conflicting information during inspections?

Disagreements or conflicting information during inspections are addressed through a systematic and objective process.

- Review the Evidence: Carefully examine all available evidence, including inspection reports, test data, and witness statements. If necessary, conduct additional testing or investigations.

- Consult with Experts: If a technical disagreement arises, seek input from experienced personnel or external experts in the relevant field.

- Document the Discrepancy: Clearly document the disagreement and any attempts to resolve it. The documentation should include the date, time, individuals involved, and the resolution reached.

- Mediation or Arbitration: In cases where a resolution cannot be reached, consider mediation or arbitration from a neutral third party.

- Escalation: If the disagreement has significant implications, escalate it to senior management for review and decision-making.

For example, if there’s a discrepancy between two inspectors’ findings on a weld’s quality, we might utilize non-destructive testing methods (like ultrasonic testing) to verify the weld’s integrity and resolve the conflict objectively.

Q 12. Describe your experience with different types of inspection techniques (e.g., visual, non-destructive testing).

My experience encompasses a wide range of inspection techniques, tailored to the specific equipment and regulatory requirements.

- Visual Inspection: This fundamental technique involves a thorough visual examination of the equipment for any visible defects, damage, or wear. It forms the basis of many inspections and is often combined with other methods.

- Non-Destructive Testing (NDT): I am proficient in several NDT methods including ultrasonic testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT), and radiographic testing (RT). UT is used to detect internal flaws in materials, MT detects surface cracks in ferromagnetic materials, PT reveals surface-breaking flaws in various materials, and RT uses X-rays or gamma rays to detect internal defects.

- Dimensional Inspection: Using tools like calipers, micrometers, and laser scanners, we ensure that equipment dimensions meet specifications, preventing misalignment and other operational problems.

- Functional Testing: This verifies that equipment performs as intended, often involving operational testing and performance monitoring.

For example, in a pipeline inspection, we’d use UT to detect internal corrosion or cracks, while visual inspection would check for external damage or leaks. In a pressure vessel inspection, we’d use both RT and visual inspection to assess its structural integrity.

Q 13. How do you ensure compliance with industry-specific regulations and standards?

Ensuring compliance with industry-specific regulations and standards is a cornerstone of our work. Our approach involves proactive monitoring and a detailed understanding of applicable codes and guidelines.

- Regular Audits: We conduct regular internal audits to identify and correct any potential compliance gaps. These audits are based on relevant standards and regulations.

- Standard Operating Procedures (SOPs): We develop and maintain detailed SOPs for all inspection procedures, ensuring consistency and adherence to best practices.

- Training Programs: We provide ongoing training for our inspection personnel to keep them updated on the latest regulations, standards, and inspection techniques.

- Documentation and Record-Keeping: We meticulously document all inspection activities, ensuring traceability and accountability. Records are readily available for audits by regulatory bodies.

- Proactive Monitoring: We actively track updates and changes in regulations and standards, ensuring our practices remain current.

For example, in the pharmaceutical industry, we would meticulously adhere to cGMP (current Good Manufacturing Practice) guidelines for equipment cleaning, validation, and documentation, ensuring the safety and efficacy of produced medications.

Q 14. How do you stay updated on changes in regulations and best practices?

Staying updated on changes in regulations and best practices is paramount. We employ a multi-pronged approach to maintain our expertise.

- Subscription to Regulatory Updates: We subscribe to relevant newsletters, journals, and online resources that provide updates on changes in regulations and standards.

- Industry Conferences and Workshops: We attend industry conferences and workshops to learn about the latest advancements and best practices. This often involves networking with other professionals in the field.

- Professional Development: We encourage our team members to pursue professional development opportunities, including certifications and training courses, to enhance their knowledge and skills.

- Collaboration with Regulatory Bodies: We maintain open communication with relevant regulatory bodies to stay informed of any changes or clarifications.

- Internal Knowledge Sharing: We foster a culture of internal knowledge sharing, encouraging our team to discuss new regulations and best practices.

For example, membership in professional organizations like ASME (American Society of Mechanical Engineers) provides access to updated codes and standards, training opportunities, and networking events.

Q 15. Describe a time you had to deal with a critical equipment failure. What was your role?

During my time at a large manufacturing plant, a critical failure occurred in our primary pressurization system. This system was crucial for maintaining the integrity of our high-pressure chemical reaction vessels. The failure resulted in a complete shutdown of the production line, posing significant financial and safety risks. My role as the Lead Equipment Inspector was to immediately assess the situation, ensure the safety of personnel, and initiate a comprehensive investigation into the root cause of the failure.

My initial actions involved isolating the affected system, implementing emergency shutdown procedures, and verifying that all personnel were safely evacuated from the immediate area. I then collaborated with engineering and maintenance teams to analyze the situation. This included examining the failed components, reviewing maintenance logs, and assessing operational data. The root cause was eventually identified as a faulty pressure relief valve that had not been replaced during the scheduled preventive maintenance. This incident highlighted the critical importance of strict adherence to maintenance schedules and thorough documentation. The investigation led to improved training protocols for maintenance personnel and a revised inspection checklist, minimizing the risk of similar future incidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle situations where equipment is found to be operating outside of safety limits?

When equipment operates outside of safety limits, my immediate priority is to ensure the safety of personnel and prevent further damage. This involves immediately shutting down the equipment, if safe to do so, and isolating it to prevent any potential hazards. A detailed assessment then follows, documenting the specific deviation from safety limits, the time of occurrence, and any observed anomalies.

This data is then used to inform a thorough investigation into the root cause, much like in the example of the pressurization system failure. Depending on the severity of the deviation, this might involve reviewing operational logs, conducting visual inspections, and even engaging external specialists for further analysis. Once the root cause is identified and corrected, a thorough verification process is performed to ensure the equipment operates safely within its specified limits before resuming operation. Following these steps ensures that both immediate safety concerns are addressed and that a longer-term solution is implemented to prevent future occurrences.

Q 17. What is your experience with root cause analysis in equipment failures?

Root cause analysis (RCA) is a critical aspect of equipment inspection and compliance. My experience with RCA involves using various methodologies, including the ‘5 Whys’ technique, fault tree analysis, and fishbone diagrams. I’ve successfully employed these methods to investigate numerous equipment failures, ranging from minor malfunctions to major incidents.

For instance, in analyzing a recurring problem with a conveyor belt system, I used the ‘5 Whys’ technique. The initial problem was belt slippage. By repeatedly asking ‘why,’ I uncovered the underlying issues: 1) Why was the belt slipping? Because it was worn. 2) Why was it worn? Because of excessive loading. 3) Why was there excessive loading? Because of an inaccurate production scheduling system. 4) Why was the scheduling inaccurate? Due to outdated software. 5) Why was the software outdated? Lack of budget for upgrades. This analysis highlighted the need for software upgrades and improved scheduling processes, preventing future belt slippage. This systematic approach ensures a comprehensive understanding of the underlying causes, preventing merely addressing symptoms.

Q 18. Explain your understanding of preventive maintenance programs.

Preventive maintenance programs are crucial for ensuring equipment reliability, safety, and compliance. These programs involve a schedule of regular inspections, servicing, and repairs designed to prevent equipment failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs in the long run, and extends the lifespan of equipment. A well-designed program includes:

- Regular inspections: Visual checks, performance testing, and lubrication schedules.

- Predictive maintenance: Utilizing technologies like vibration analysis or oil analysis to predict potential failures.

- Corrective maintenance: Addressing any issues identified during inspections.

- Detailed documentation: Maintaining thorough records of all maintenance activities.

For example, in a pharmaceutical facility, a preventive maintenance program might involve regular calibration of critical instruments, such as autoclaves, to ensure consistent product quality and regulatory compliance. The failure to properly calibrate equipment can result in a substantial financial penalty.

Q 19. How do you contribute to a culture of safety and compliance within a team?

Contributing to a culture of safety and compliance involves leading by example, promoting open communication, and empowering the team to actively participate in safety processes. This involves:

- Leading by example: Consistently adhering to safety protocols and reporting any potential hazards.

- Open communication: Fostering an environment where team members feel comfortable raising concerns without fear of retribution.

- Training and education: Providing regular training on safety procedures and equipment operation.

- Regular safety meetings: Discussing safety incidents, improvements, and best practices.

- Incentivizing safe practices: Rewarding safe behaviors and recognizing contributions to safety improvements.

I’ve successfully implemented these strategies by organizing regular safety meetings, initiating a suggestion box for safety improvements, and implementing a ‘buddy system’ where experienced employees mentor newer ones on safe work practices. This collective approach fostered a stronger sense of responsibility and ownership, resulting in a significantly reduced number of workplace incidents.

Q 20. What software or systems are you familiar with for managing equipment inspections?

I am proficient in several software systems for managing equipment inspections. My experience includes using Computerized Maintenance Management Systems (CMMS) such as Fiix, UpKeep, and SAP PM. These systems allow for efficient scheduling of inspections, tracking of maintenance activities, and generation of reports for compliance purposes. I also have experience with specialized software for specific types of equipment, such as those used for managing calibration records of measuring instruments, and utilizing data analytics for preventative maintenance planning.

The use of CMMS software greatly improves efficiency by automating many tasks, providing real-time data on equipment status, and improving the overall organization of maintenance records, simplifying compliance auditing.

Q 21. Describe your experience with auditing processes related to equipment compliance.

My experience with auditing processes related to equipment compliance is extensive. I’ve participated in numerous internal and external audits, ensuring compliance with relevant regulations and standards (e.g., ISO 9001, OSHA, FDA). This includes reviewing maintenance records, inspection reports, and calibration certificates to verify adherence to established procedures and regulatory requirements.

During audits, I typically employ a systematic approach, verifying the completeness and accuracy of documentation, examining the effectiveness of maintenance programs, and identifying any gaps or deficiencies. I then work collaboratively with the relevant teams to develop corrective action plans to address any identified non-compliances. Thorough documentation and follow-up are essential to ensure that corrective actions are implemented effectively and prevent future occurrences. My objective during an audit is not just to find issues but to use the process as an opportunity for continuous improvement and to ensure a safer and more efficient operation.

Q 22. How do you verify the calibration and accuracy of inspection equipment?

Verifying the calibration and accuracy of inspection equipment is paramount to ensuring reliable and compliant inspection results. This involves a multi-step process, beginning with understanding the equipment’s specifications and the relevant standards it must meet.

Firstly, we establish a calibration schedule based on the equipment’s manufacturer recommendations and the frequency of its use. This might range from daily checks for simple measuring tools to annual calibrations for more sophisticated instruments. Secondly, the calibration process itself involves comparing the equipment’s readings to those of a known, traceable standard. This standard is typically certified by a nationally recognized metrology laboratory. We meticulously document all calibration activities, including the date, the standard used, the readings obtained, and any adjustments made. For example, a digital caliper might be calibrated against a gauge block set, while a pressure gauge might be checked against a deadweight tester. Any discrepancies outside the acceptable tolerance limits necessitate repair or replacement of the equipment. Thirdly, we maintain comprehensive records of all calibrations, ensuring traceability and accountability. This documentation is crucial for audits and demonstrates our commitment to maintaining the integrity of our inspection data. Failure to perform proper calibration could result in inaccurate measurements, leading to unsafe conditions or non-compliant equipment.

Q 23. How familiar are you with different types of inspection reports and documentation?

My familiarity with various inspection reports and documentation is extensive. I’ve worked with a wide range of formats, from simple checklists and data sheets to sophisticated software-generated reports. Understanding the nuances of each type is vital for effective communication and regulatory compliance.

- Checklists: These provide a simple yet structured method for recording basic inspections, ensuring all key aspects are covered. They’re useful for quick inspections of readily accessible equipment.

- Data Sheets: Often used for more detailed inspections, these sheets allow for recording numerical data, observations, and any deviations from specifications. They’re ideal for documenting measurements and defects.

- Inspection Reports: These compile the findings of an inspection, presenting them in a clear and concise manner, often including recommendations for corrective actions. They’re formal documents used for management review and regulatory submission.

- Software-Generated Reports: Modern inspection management software generates detailed and customized reports, often with the ability to create trend analysis and dashboards. These offer superior data management and analytical capabilities.

- Non-Conformity Reports: These document instances where equipment or processes deviate from established standards. These reports are crucial for initiating corrective and preventive actions.

My experience ensures I can adapt to different reporting requirements and accurately interpret and utilize the data within these reports for informed decision-making. For instance, I’ve utilized software-generated reports to identify patterns in equipment failures and develop proactive maintenance strategies.

Q 24. How do you maintain confidentiality of inspection findings?

Maintaining confidentiality of inspection findings is critical, reflecting both ethical responsibilities and regulatory compliance. I adhere strictly to company policies and relevant industry standards regarding data protection. This includes securing physical documents, limiting access to digital records through password protection and access controls, and only disclosing information to authorized personnel on a need-to-know basis.

For example, sensitive information about specific equipment defects or safety issues is handled with discretion, shared only with those responsible for addressing the issues, such as maintenance personnel or management. I never discuss inspection findings with unauthorized individuals or external parties. Furthermore, I understand the importance of data anonymization when reporting aggregated data or trends to protect the confidentiality of individual clients or organizations. My commitment to confidentiality is unwavering, reflecting my professional ethics and respect for the trust placed in me.

Q 25. Describe your experience with developing and implementing inspection procedures.

I have extensive experience in developing and implementing inspection procedures, spanning diverse industries and equipment types. My approach is methodical and always begins with a thorough risk assessment, identifying potential hazards and critical equipment. Based on this assessment, I tailor the procedures to ensure adequate coverage of all relevant aspects. The process includes defining inspection frequencies, setting acceptance criteria, documenting the steps involved, and clearly specifying the required personnel qualifications.

For instance, in a previous role, I developed a comprehensive inspection procedure for high-pressure vessels, incorporating specific checks for corrosion, fatigue, and proper safety relief valve functioning. The procedure was designed to meet industry standards and regulatory requirements, ensuring consistent inspections across multiple sites. The implementation involved training personnel, establishing a system for tracking inspection records, and providing regular updates to keep the procedures current with evolving regulations and best practices. Successful implementation of this resulted in a significant reduction in equipment-related incidents.

Q 26. How do you prioritize competing demands and deadlines during inspections?

Prioritizing competing demands and deadlines during inspections requires a structured approach. I utilize project management techniques, like creating a prioritized task list based on risk and urgency. Critical inspections, those affecting safety or regulatory compliance, always take precedence. I then break down larger inspections into smaller, manageable tasks, scheduling them efficiently to optimize my time. Communication with stakeholders is also crucial, ensuring that expectations are aligned and any potential conflicts are addressed proactively. When faced with conflicting deadlines, I transparently communicate potential delays and work collaboratively to find mutually agreeable solutions, prioritizing tasks based on their overall impact and risk.

For instance, if faced with a critical safety inspection and a less urgent routine inspection, I’ll prioritize the safety inspection, informing the relevant parties about a potential shift in the routine inspection schedule. This ensures that safety is not compromised while minimizing any disruption to the overall inspection program.

Q 27. What are your strengths and weaknesses regarding Equipment Inspection and Compliance?

My strengths lie in my meticulous attention to detail, my ability to adapt to diverse situations, and my proficiency in interpreting technical documentation and standards. I am highly organized, effectively managing multiple concurrent tasks and maintaining accurate records. I am also a strong communicator, capable of explaining complex technical information to diverse audiences in a clear and concise manner. My experience with various software and technologies further enhances my efficiency and analytical capabilities.

A potential area for improvement is further developing my expertise in specific, highly specialized equipment. While I have a broad understanding of many types of equipment, I am continually seeking opportunities to expand my knowledge in niche areas through additional training and experience. This commitment to continuous learning ensures that I remain at the forefront of best practices within the field.

Q 28. Where do you see yourself in five years in the field of Equipment Inspection and Compliance?

In five years, I envision myself as a recognized expert in Equipment Inspection and Compliance, potentially leading a team or specializing in a particular industry sector. I aspire to leverage my experience and skills to contribute to the development of innovative inspection methods and technologies. This could involve developing and implementing new inspection procedures, leading training programs, or contributing to the advancement of industry best practices. My goal is to continue learning and contributing to a safer and more compliant industrial environment. I see a strong future in implementing advanced technologies for predictive maintenance and remote inspection, and I aim to be at the forefront of this transition.

Key Topics to Learn for Equipment Inspection and Compliance Interview

- Regulatory Compliance: Understanding relevant safety regulations (OSHA, ASME, etc.) and their practical application in equipment inspection.

- Inspection Techniques: Mastering visual inspection, non-destructive testing (NDT) methods, and the use of specialized equipment for thorough assessments.

- Documentation and Reporting: Proficiency in accurately documenting inspection findings, creating comprehensive reports, and using relevant software for data management.

- Preventive Maintenance: Knowledge of preventative maintenance schedules, their importance in compliance, and how inspections inform maintenance strategies.

- Risk Assessment and Mitigation: Identifying potential hazards associated with equipment malfunction, implementing appropriate safety measures, and documenting risk mitigation plans.

- Corrective Actions: Developing and implementing effective corrective actions based on inspection findings to ensure equipment safety and regulatory compliance.

- Data Analysis and Interpretation: Analyzing inspection data to identify trends, predict potential failures, and optimize inspection processes.

- Communication and Collaboration: Effectively communicating inspection findings to various stakeholders (management, technicians, clients) and collaborating on solutions.

- Specific Equipment Knowledge: Depending on the role, familiarize yourself with the specific types of equipment you’ll be inspecting (e.g., pressure vessels, cranes, electrical systems).

Next Steps

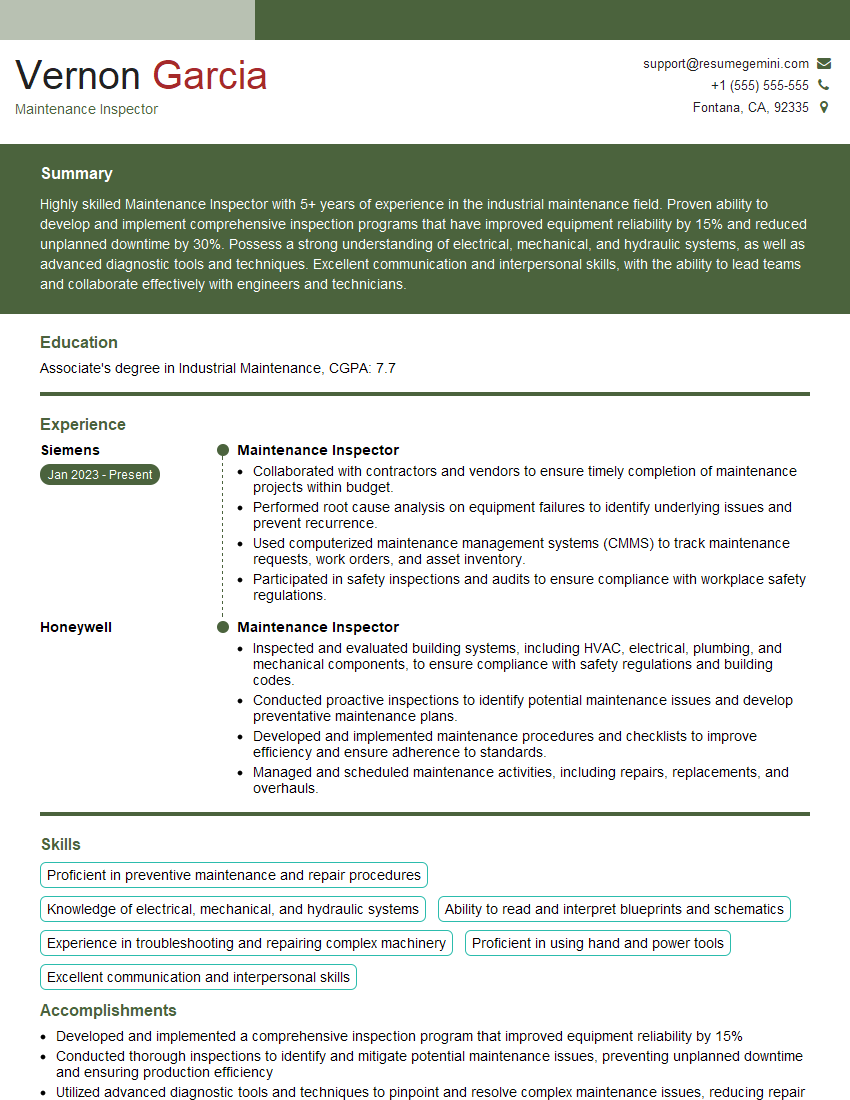

Mastering Equipment Inspection and Compliance opens doors to rewarding and impactful careers, offering opportunities for growth and specialization within safety-critical industries. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and effective resume. We provide examples of resumes tailored to Equipment Inspection and Compliance to give you a head start. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO