Unlock your full potential by mastering the most common Equipment Sanitation and Maintenance interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Equipment Sanitation and Maintenance Interview

Q 1. Describe your experience with various sanitation methods (CIP, COP, manual cleaning).

My experience encompasses all three major sanitation methods: CIP (Clean-In-Place), COP (Clean-Out-of-Place), and manual cleaning. I’ve worked extensively with CIP systems in large-scale pharmaceutical and food processing facilities, where automated systems are crucial for efficiency and consistency. This involves programming and monitoring automated cycles, ensuring proper chemical delivery and temperature control. COP, on the other hand, is more hands-on, requiring disassembly and thorough cleaning of equipment, often smaller or more intricate pieces. I’ve led teams in implementing robust COP procedures, focusing on standardized methods to prevent cross-contamination and ensure complete cleaning. Manual cleaning remains important for certain tasks, particularly in areas where automated systems are impractical. My experience includes training personnel in proper manual cleaning techniques, emphasizing the critical role of meticulous scrubbing, rinsing, and sanitizing in preventing microbial growth.

For example, in one pharmaceutical facility, we successfully transitioned from primarily COP to a hybrid CIP/COP system for improved efficiency and reduced labor costs while maintaining stringent sanitation standards. This involved careful selection of equipment suitable for both methods and rigorous validation to ensure efficacy.

Q 2. What are the key differences between CIP and COP cleaning systems?

The key difference between CIP and COP lies in the location of cleaning. CIP involves cleaning equipment in place without disassembly, using automated systems to circulate cleaning solutions through the equipment. This is highly efficient for large-scale production, reducing downtime and labor costs. COP, conversely, requires dismantling the equipment for cleaning. Each component is cleaned manually or using smaller automated systems. COP is better suited for complex or delicate equipment that can’t withstand the pressure of a CIP system, or when thorough visual inspection of all components is essential. CIP offers superior efficiency for large, straightforward systems, but COP provides a more thorough cleaning for intricate equipment where complete visual inspection is necessary. Think of it like this: CIP is like washing a car in your driveway using a pressure washer, quick and efficient, while COP is like taking the car apart to detail each component individually, offering a deeper clean.

Q 3. Explain your understanding of GMP (Good Manufacturing Practices) as it relates to sanitation.

GMP (Good Manufacturing Practices) are a set of guidelines that ensure the quality and safety of manufactured products. Regarding sanitation, GMP emphasizes the prevention of contamination at every stage of production. This means establishing and meticulously following documented procedures for sanitation, including equipment cleaning, sanitization, and validation. GMP compliance requires detailed records of cleaning processes, chemical usage, personnel training, and environmental monitoring. Failure to adhere to GMP sanitation guidelines can result in product recalls, regulatory penalties, and damage to brand reputation. Think of it like a recipe for safety: every step is crucial, and deviation can spoil the final product.

For instance, GMP guidelines mandate regular microbial testing of cleaned surfaces to ensure effective sanitation. This involves taking samples, culturing them, and documenting the results to demonstrate that the cleaning process consistently meets predetermined standards.

Q 4. How do you ensure proper chemical handling and safety during sanitation procedures?

Safe chemical handling is paramount in sanitation. This begins with proper training for all personnel involved in handling cleaning and sanitizing agents. Training covers understanding safety data sheets (SDS), proper personal protective equipment (PPE) usage (gloves, eye protection, respirators), safe storage practices (labeled containers, appropriate ventilation), and spill response procedures. We use color-coded systems for chemical identification and storage, reducing the risk of accidental mixing. All chemicals are stored in designated areas with appropriate ventilation, away from food products or incompatible materials. Furthermore, meticulous record-keeping of chemical usage, including lot numbers and expiration dates, is crucial for traceability and accountability. In case of a spill, we have clearly defined protocols for containment, cleanup, and reporting to ensure the safety of personnel and the environment.

Q 5. What are the common types of sanitizers used, and when would you choose one over another?

Common sanitizers include chlorine-based compounds (sodium hypochlorite), iodophors, quaternary ammonium compounds (quats), and peracetic acid. The choice depends on several factors, including the type of equipment, the nature of the soiling, the required contact time, and potential compatibility issues. For example, chlorine-based solutions are effective against a broad spectrum of microorganisms but can be corrosive to certain materials. Iodophors are less corrosive but may require longer contact times. Quats are generally less corrosive and effective against many bacteria and fungi. Peracetic acid is a powerful sanitizer suitable for equipment sensitive to chlorine, but it has a shorter shelf life. Careful consideration of these factors is essential in selecting the most effective and safe sanitizer for a given situation. If there is a concern about potential corrosion, a test on a small sample area of the equipment may be required before widespread application of the sanitizer.

Q 6. Describe your experience with validation and documentation of sanitation procedures.

Validation and documentation are critical aspects of ensuring consistent sanitation efficacy and GMP compliance. Validation involves a systematic process to demonstrate that the sanitation procedures consistently achieve the desired level of cleanliness and microbial reduction. This involves establishing standardized operating procedures (SOPs), performing regular monitoring of cleaning parameters (temperature, chemical concentration, contact time), and conducting microbial testing to verify the effectiveness of the sanitation process. Comprehensive documentation is essential, including SOPs, validation reports, microbial test results, chemical usage logs, and equipment maintenance records. This documentation serves as evidence of compliance with regulations and internal quality standards. In a recent project, we successfully validated a new CIP system by performing multiple cleaning cycles under different conditions, collecting samples, and analyzing them to ensure consistent sterility. The resulting report detailed the validated parameters and demonstrated the effectiveness of our approach.

Q 7. How do you identify and troubleshoot sanitation equipment malfunctions?

Troubleshooting sanitation equipment malfunctions requires a systematic approach. First, identify the specific malfunction—is it a pump failure, a temperature sensor issue, a chemical delivery problem, or something else? Then, systematically investigate potential causes. This may involve checking for power supply issues, inspecting pumps and valves for blockages or damage, verifying sensor calibration, reviewing cleaning cycle parameters, and checking for chemical leaks or malfunctions. Involving a qualified technician for complex problems may be necessary. Preventive maintenance, including regular inspections and calibration of equipment, is crucial in minimizing malfunctions and extends the operational lifespan of the system. Detailed logs of equipment maintenance, repairs, and any malfunctions are essential for tracking and improving sanitation efficiency and reliability. For instance, in one instance, we identified a recurring pump malfunction by analyzing maintenance logs and ultimately discovered a recurring issue with a specific part that was replaced with an upgraded model.

Q 8. Explain your understanding of HACCP principles in relation to sanitation.

HACCP, or Hazard Analysis and Critical Control Points, is a systematic preventive approach to food safety. In sanitation, its principles are crucial for preventing contamination. Think of it as a proactive strategy, not just a reactive one. Instead of simply cleaning up after a mess, HACCP helps us identify potential contamination points before they become problems.

- Hazard Analysis: We identify potential biological, chemical, and physical hazards in the sanitation process. For example, a hazard could be bacterial growth due to inadequate cleaning of equipment or chemical residue left behind from sanitizing agents.

- Critical Control Points (CCPs): We pinpoint steps in the sanitation process where these hazards can be controlled. A CCP might be the rinsing temperature after washing or the contact time of the sanitizing solution.

- Critical Limits: We establish measurable parameters for each CCP. For example, a critical limit might be a minimum rinse temperature of 180°F (82°C) to ensure bacterial inactivation or a minimum contact time of 30 seconds for the sanitizing agent.

- Monitoring: We regularly monitor CCPs to ensure they remain within critical limits. This often involves checking temperatures, times, and visually inspecting surfaces.

- Corrective Actions: If a CCP deviates from its critical limits, we have pre-determined corrective actions to take. This could range from re-cleaning a surface to notifying management and potentially halting production.

- Records: We keep detailed records of all monitoring and corrective actions taken. This documentation is crucial for traceability and demonstrates our commitment to food safety.

- Verification: We regularly verify that the HACCP plan is effective. This often involves microbiological testing and audits.

For instance, in a dairy processing plant, a CCP might be the sanitation of the milk pasteurization equipment. Failure to properly sanitize this equipment could lead to bacterial contamination, so we’d establish critical limits for cleaning temperature, chemical concentration, and contact time, and monitor these diligently.

Q 9. What is your experience with microbiological testing and its role in sanitation verification?

Microbiological testing is an essential part of verifying the effectiveness of our sanitation procedures. It provides objective evidence that our cleaning and sanitizing efforts are reducing microbial loads to safe levels. This is like getting a report card for our sanitation practices – it tells us how well we’re doing.

My experience includes performing and interpreting various tests, such as ATP bioluminescence testing (measuring the presence of adenosine triphosphate, an indicator of organic residue), swab tests for microbial counts (identifying the number of bacteria present), and environmental monitoring to look for indicator organisms (like coliforms which may signal fecal contamination).

For example, in a previous role, we used ATP testing after each sanitation cycle. If the ATP reading was too high, it indicated that cleaning was inadequate and the process needed to be repeated. This provided immediate feedback and ensured that equipment was properly sanitized before restarting operations. Regular swab testing and environmental monitoring helps us identify and address trends in contamination and ensure consistent sanitation across our operation. We utilize the results to adjust cleaning and sanitation procedures, and to demonstrate compliance to regulatory agencies.

Q 10. How do you maintain accurate sanitation logs and records?

Maintaining accurate sanitation logs and records is critical for traceability, compliance, and continuous improvement. Think of these records as a comprehensive history of our sanitation activities.

We use a combination of electronic and paper-based systems to ensure accuracy and accessibility. Electronic systems often use software designed specifically for sanitation management that can automate data collection and reporting, and reduce human error. However, having a backup hard copy ensures redundancy in case of technological issues.

Each log includes: the date and time of the sanitation, the equipment sanitized, the cleaning and sanitizing agents used, the concentrations of the agents, contact times, temperatures (if applicable), the names of personnel involved, the results of any microbiological testing conducted, and any corrective actions taken. We make sure our documentation is clear, concise, and easy to understand. Signatures and approval processes are in place to ensure verification and accountability.

Regular audits of sanitation logs are conducted to ensure accuracy and compliance. Any discrepancies are immediately investigated and corrected. This systematic approach helps identify areas for improvement and contributes to consistent sanitation practices.

Q 11. How do you manage and dispose of sanitation waste properly?

Proper management and disposal of sanitation waste is essential for environmental protection and worker safety. This involves following all relevant environmental regulations and employing safe handling procedures.

Our waste management program segregates waste according to its composition: chemical waste, organic waste, and regular trash. Chemical waste, such as used sanitizing solutions, is collected in designated containers, labeled appropriately, and disposed of through licensed waste disposal companies. Organic waste, like food scraps or soiled cleaning cloths, is often disposed of through approved composting or waste-to-energy facilities, following any necessary pre-treatment like washing to reduce pathogens.

All personnel involved in handling sanitation waste receive comprehensive training on safe handling procedures, including the use of personal protective equipment (PPE) such as gloves and aprons, and understanding the hazards associated with the various waste streams. We maintain detailed records of waste disposal, including the type of waste, quantity, and disposal method used. Regular reviews of waste management procedures are performed to identify potential improvements and maintain compliance.

Q 12. Describe your experience with different types of cleaning equipment (e.g., high-pressure washers, scrubbers).

My experience encompasses a wide range of cleaning equipment. I’m proficient in the safe and effective operation of high-pressure washers, floor scrubbers, and other sanitation equipment commonly used in food processing and industrial settings.

High-pressure washers are powerful tools for removing stubborn dirt and debris, but require careful handling to prevent damage to surfaces or injury to personnel. I understand how to select the appropriate nozzle and pressure settings for various surfaces and materials. I am also well-versed in the safety precautions necessary when operating this equipment, including proper PPE and safe handling practices.

Floor scrubbers are essential for maintaining clean floors, and I’m familiar with both automatic and manual scrubbers. I know how to select appropriate detergents and maintain optimal water levels to ensure both efficiency and effectiveness. I understand the proper maintenance and repair processes for floor scrubbers and other equipment, reducing downtime and increasing their operational lifespan.

Beyond these, I have experience with various other equipment such as automated cleaning systems, ultrasonic cleaning devices, and specialized cleaning tools depending on the environment and the materials that need cleaning. Regardless of the equipment used, I prioritize safety and efficiency in every sanitation task.

Q 13. How do you prioritize tasks in a fast-paced sanitation environment?

In a fast-paced sanitation environment, prioritization is key. I utilize a combination of techniques to ensure efficiency and meet deadlines.

First, I assess the urgency and criticality of each task. Tasks associated with CCPs (critical control points) in our HACCP plan always take precedence. For example, cleaning equipment used in direct food contact must be completed before other tasks. Second, I break down large tasks into smaller, more manageable components. This makes it easier to track progress and allocate resources more efficiently. Third, I create a prioritized task list, typically using a system where I identify and clearly demarcate urgent, important and less important tasks.

Communication is crucial. I work closely with the production team to understand their schedules and any urgent cleaning needs. Flexibility is also essential; I need to be able to adapt to unexpected changes or delays. Finally, regular review and refinement of our sanitation schedule helps identify bottlenecks or areas where improvements can be made.

Q 14. How do you train others on proper sanitation techniques?

Training others on proper sanitation techniques is a critical aspect of maintaining a safe and efficient work environment. My training approach is comprehensive and hands-on, combining theoretical knowledge with practical application.

Training starts with a review of relevant regulations and company policies. Then, I cover the theory of sanitation: why it’s important, the types of microorganisms we are aiming to control, and the principles of effective cleaning and sanitizing. We discuss the different types of cleaning agents, their proper use and dilution, and safety precautions. I explain the importance of proper personal hygiene, the use of PPE, and safe handling procedures for cleaning chemicals and waste. Then we move to practical exercises, where trainees participate in the actual cleaning and sanitizing procedures, guided by my supervision and feedback. This includes using various cleaning equipment and ensuring they follow all safety guidelines. We also perform simulated microbiological testing to emphasize the importance of proper sanitation.

Finally, we have regular refresher training and ongoing assessments to ensure that our sanitation standards are consistently met. This combination of theory, practical application, and ongoing support ensures our workforce is fully trained to maintain hygiene standards.

Q 15. What is your experience with allergen control and cross-contamination prevention?

Allergen control and cross-contamination prevention are paramount in maintaining food safety and preventing allergic reactions. My experience encompasses a multi-faceted approach, starting with a thorough understanding of the allergens present in our processing environment. This involves identifying potential sources like nuts, dairy, soy, etc., and mapping their potential pathways through the facility.

We utilize color-coded systems for equipment and utensils, dedicated allergen-free processing zones, and strict cleaning protocols to prevent cross-contamination. These protocols include the use of validated cleaning and sanitizing agents, appropriate cleaning equipment like high-pressure washers and specialized brushes, and rigorous rinsing procedures to eliminate any trace residues. Regular allergen testing, both environmental swabs and finished product analysis, ensures the effectiveness of our controls. For example, in one facility, we implemented a separate line for gluten-free products, with dedicated equipment and personnel, significantly reducing the risk of cross-contamination. We also conduct regular training for staff on proper allergen handling procedures, including gowning, equipment change-overs, and sanitation practices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to troubleshoot a sanitation-related issue. What was the problem, and how did you solve it?

During a large-scale production run, we experienced an unusually high bacterial count in our final product testing. This indicated a failure in our sanitation process. Initially, we suspected a problem with our chemical sanitizer concentration, but testing confirmed the solution was correctly prepared. Further investigation revealed the issue stemmed from inadequate rinsing of the equipment after sanitation. Residue of the sanitizer was left behind, interfering with subsequent product testing.

To solve this, we implemented several changes. Firstly, we increased the rinse time and water pressure during the cleaning cycle. Secondly, we introduced a visual inspection checklist for each piece of equipment after rinsing to ensure complete removal of sanitizer residue. Finally, we conducted additional training for our sanitation team emphasizing the importance of thorough rinsing and the correct use of our equipment. We immediately retested the equipment’s sanitation effectiveness and saw a significant reduction in the bacterial counts within acceptable limits.

Q 17. How do you stay current with the latest sanitation regulations and best practices?

Staying current with sanitation regulations and best practices is crucial. I actively participate in industry conferences and workshops, attending sessions focused on new technologies, emerging pathogens, and updated regulatory requirements like those from the FDA or USDA. I also subscribe to relevant industry publications and journals, and maintain membership in professional organizations like the Institute of Food Technologists (IFT). Online resources and government websites provide the most recent updates and guidance.

Furthermore, I actively network with other professionals in the field, participating in online forums and attending local industry gatherings to share knowledge and learn about new approaches to sanitation and best practices. This continuous learning approach ensures that our facility’s sanitation practices always reflect current standards and advancements in the field.

Q 18. How do you ensure the effectiveness of the sanitation process?

Ensuring the effectiveness of the sanitation process relies on a multi-pronged approach. Firstly, we use validated cleaning and sanitizing agents based on scientific data to confirm their efficacy against the specific microorganisms prevalent in our environment. We regularly test the concentration of our solutions to maintain optimal performance.

Secondly, we employ standardized operating procedures (SOPs) for each cleaning and sanitizing step. These procedures detail the specific chemicals to be used, contact times, water temperatures, and methods of application. Thirdly, we use ATP bioluminescence testing, a rapid method for detecting residual organic matter, to verify that cleaning is thorough before the sanitation step. Lastly, we implement regular environmental monitoring programs, involving microbial testing of surfaces to confirm the effectiveness of our sanitation protocols. Deviations from our standards trigger an immediate investigation to identify and correct any process failures.

Q 19. What are some common sanitation challenges and how would you address them?

Common sanitation challenges include biofilm formation (the sticky film of microorganisms that can be resistant to cleaning), hard-to-reach areas within equipment, and proper training of sanitation personnel.

We address biofilm through the use of appropriate detergents and enzymatic cleaners, along with thorough mechanical cleaning to physically remove the biofilm. To overcome access challenges, we use specialized tools like long-handled brushes, automated cleaning systems, and high-pressure sprayers for areas that are difficult to clean manually. Regarding personnel training, we provide regular refresher courses covering safe chemical handling, proper cleaning techniques, SOP adherence, and the importance of hygiene. We also utilize visual aids, hands-on training, and performance-based assessments to ensure that our team has the necessary skills and knowledge to effectively execute our sanitation procedures.

Q 20. How do you balance speed and thoroughness in the sanitation process?

Balancing speed and thoroughness requires careful planning and optimization. We utilize efficient cleaning methods like CIP (Clean-in-Place) systems for large equipment, reducing downtime. However, we don’t sacrifice thoroughness for speed. We strictly adhere to the recommended contact times for sanitizers and meticulously follow our SOPs. We also incorporate standardized visual inspections at each stage to detect any issues promptly.

For example, the implementation of a timed cleaning cycle with automated monitoring ensures that the appropriate sanitation time is maintained without manual intervention, ensuring both speed and consistency. Regularly reviewing our processes and looking for areas for improvement is key to achieving the right balance between efficiency and the absolute highest level of sanitation.

Q 21. Describe your experience with preventative maintenance of sanitation equipment.

Preventative maintenance is crucial for keeping our sanitation equipment in top condition and ensuring its longevity. We establish a preventative maintenance schedule that includes regular inspections, lubrication of moving parts, cleaning of filters and nozzles, and replacement of worn components according to the manufacturer’s recommendations. We document all maintenance activities, including any repairs made, to track equipment performance and identify potential issues early on.

For example, regularly checking and calibrating the temperature and pressure gauges on our high-pressure washers is crucial to ensuring that the cleaning process operates at the correct parameters, preventing equipment damage and maintaining cleaning effectiveness. This proactive approach minimizes unexpected breakdowns, extends the life of our equipment, and ultimately contributes to a more efficient and reliable sanitation process.

Q 22. What are the key performance indicators (KPIs) you use to measure sanitation effectiveness?

Measuring sanitation effectiveness relies on a suite of Key Performance Indicators (KPIs). These KPIs aren’t just about cleanliness; they reflect the reduction of microbial load and the overall hygiene status of equipment. We use a multi-pronged approach, focusing on both qualitative and quantitative measures.

- Microbial Counts: This is arguably the most crucial KPI. We use ATP bioluminescence testing to quickly assess surface cleanliness. A lower ATP reading indicates fewer microorganisms. We also conduct regular microbiological testing – swabbing surfaces and analyzing samples in a lab to determine the presence and count of specific bacteria, fungi, or yeasts. Acceptable limits vary depending on the equipment and regulatory requirements, but consistently low counts are paramount.

- Visual Inspections: A trained eye can detect residues or signs of inadequate cleaning. Regular visual checks form a fundamental part of our process, complemented by documented checklists. Think of it like a quality control check during a manufacturing process, ensuring no visible contaminants are left behind.

- Sanitation Log Compliance: Meticulous record-keeping is crucial. Our sanitation logs track cleaning schedules, chemical usage, personnel involved, and the results of all tests. Consistent, accurate record-keeping allows us to pinpoint trends, identify problem areas, and demonstrate compliance to auditors.

- Equipment Downtime: While sanitation is essential, excessive downtime due to prolonged cleaning processes is inefficient. We track sanitation time to optimize procedures and minimize production disruption. A reduction in downtime, coupled with consistently low microbial counts, is a sign of a well-functioning sanitation program.

For example, in a previous role, we implemented a new cleaning protocol for a high-speed filling line. By optimizing chemical application and implementing a more effective rinsing procedure, we reduced ATP readings by 40% and cut sanitation downtime by 15%, demonstrating a substantial improvement in sanitation effectiveness.

Q 23. How familiar are you with different types of sanitation chemicals and their applications?

My familiarity with sanitation chemicals is extensive, encompassing their chemical properties, applications, and safety protocols. We use a range of chemicals, each selected for its efficacy against specific microorganisms and its compatibility with the equipment being cleaned. Improper chemical selection can lead to damage, residue, or ineffective sanitation.

- Acid Cleaners: Effective against mineral deposits and scale buildup on stainless steel surfaces.

- Alkaline Cleaners: Excellent at removing organic soils, fats, and proteins. Often used for heavy-duty cleaning.

- Chlorine-based Sanitizers: Broad-spectrum disinfectants, highly effective against bacteria and viruses. However, they need careful handling and dilution to avoid corrosion.

- Quaternary Ammonium Compounds (Quats): Another broad-spectrum disinfectant, generally less corrosive than chlorine-based options, but their efficacy can vary depending on the specific microorganism and concentration.

- Peroxyacetic Acid (PAA): A powerful disinfectant ideal for use in food processing environments because it breaks down into environmentally friendly substances.

The choice of chemical depends heavily on the type of equipment and the nature of the soil. For example, we use acid cleaners to descale brewing equipment, while alkaline cleaners are essential for removing milk residue from dairy processing lines. We always follow the manufacturer’s instructions for dilution and application, meticulously recording all chemical usage for traceability purposes. Safety data sheets (SDS) are readily available and regularly reviewed to ensure safe handling and disposal of chemicals.

Q 24. What is your approach to managing a sanitation team?

Managing a sanitation team requires strong leadership, effective communication, and a commitment to training. My approach is rooted in empowerment, ensuring each team member feels valued and understands their role in maintaining high hygiene standards. I favor a collaborative approach rather than a strictly hierarchical one.

- Clear Expectations and Training: Thorough training on proper cleaning techniques, chemical handling, and safety procedures is paramount. This isn’t just initial training; it’s continuous, with refresher courses and updates on best practices. We use videos, hands-on demonstrations and regular quizzes to ensure knowledge retention.

- Effective Communication: Open communication channels are vital. Regular team meetings address concerns, celebrate successes, and discuss improvements. This fosters a sense of ownership and shared responsibility.

- Performance Monitoring and Feedback: We track individual performance based on KPIs like ATP readings, adherence to procedures and completion of tasks. Regular feedback, both positive and constructive, helps team members grow and improve their performance. We use a performance tracking system that helps us identify any recurring problems or training needs.

- Motivation and Recognition: A positive work environment fosters productivity. I believe in recognizing good work, rewarding initiative, and fostering a sense of team pride. We regularly celebrate milestones reached and successes achieved.

In one instance, I implemented a peer-to-peer mentorship program within the sanitation team, pairing experienced members with newer ones. This improved training effectiveness and boosted team morale, resulting in a noticeable improvement in sanitation performance across the board.

Q 25. How do you assess the risk of cross-contamination during cleaning and sanitation?

Assessing cross-contamination risk is crucial in maintaining hygiene and preventing product spoilage or contamination. My approach involves a multi-layered strategy focusing on proactive risk mitigation.

- Facility Layout: The physical layout of the facility significantly impacts cross-contamination risk. Raw materials and finished products should be clearly separated. High-risk areas should be physically isolated to minimize the potential spread of contaminants.

- Cleaning and Sanitation Procedures: Detailed Standard Operating Procedures (SOPs) are essential. These SOPs should specify cleaning and sanitizing steps, chemical usage, and drying methods. The SOPs should address the specific risk areas and equipment involved.

- Equipment Design: Equipment should be designed to minimize crevices and hard-to-clean areas. Smooth surfaces are easier to sanitize, reducing the likelihood of harboring contaminants.

- Personal Protective Equipment (PPE): Team members should wear appropriate PPE, such as gloves, aprons, and hairnets, to minimize the risk of personal contamination.

- Monitoring and Verification: Regular microbial testing helps identify potential cross-contamination hotspots. Environmental monitoring techniques, such as air sampling, can identify airborne contamination.

For example, in a beverage production facility, we identified a cross-contamination risk associated with the flow of materials. By redesigning the workflow and introducing improved sanitation procedures between different processing stages, we effectively mitigated the risk.

Q 26. Explain your understanding of cleaning validation.

Cleaning validation is the documented process of proving that a cleaning procedure effectively removes residues from equipment, preventing cross-contamination. It’s not just about visual inspection; it’s about demonstrating, with evidence, that the process consistently meets predefined acceptance criteria.

- Defining Acceptance Criteria: First, we establish clear acceptance criteria. This typically involves setting limits on the amount of residue that can remain after cleaning. These limits are determined based on regulatory guidelines, product characteristics, and toxicity concerns. For example, for a high-sensitivity product, the acceptance criteria might be much stricter.

- Sampling and Analysis: After cleaning, samples are collected from various points on the equipment. These samples are analyzed using appropriate methods, such as HPLC (High-Performance Liquid Chromatography) or other sensitive detection techniques to quantify remaining residues.

- Validation Protocol: A detailed protocol documents all aspects of the validation process, including the cleaning procedure, sampling locations, analytical methods, and acceptance criteria. This protocol must be precisely followed to ensure the integrity of the validation study.

- Reporting and Documentation: A comprehensive report summarizes the results of the validation study. This report provides evidence that the cleaning procedure consistently meets the established acceptance criteria. The report includes the data from the analysis and any deviations from the protocol.

In essence, cleaning validation provides documented evidence that a cleaning process is robust and reliable, protecting product quality and safety. It’s a critical component of Good Manufacturing Practices (GMP).

Q 27. How do you deal with unexpected sanitation issues?

Unexpected sanitation issues are inevitable. My approach emphasizes swift response, root cause analysis, and preventative measures to avoid recurrence.

- Immediate Action: The first step is to contain the issue. This might involve isolating the affected equipment, halting production, and contacting relevant personnel. Safety is paramount.

- Root Cause Analysis: A thorough investigation determines the cause of the problem. This involves reviewing sanitation logs, interviewing personnel, and examining the equipment itself. We often employ 5 Whys analysis or Fishbone diagrams to thoroughly explore the underlying causes.

- Corrective Actions: Based on the root cause analysis, appropriate corrective actions are implemented. This might include retraining personnel, modifying cleaning procedures, replacing equipment, or adjusting chemical usage.

- Preventative Measures: The most important step is implementing preventative measures to avoid similar incidents. This could involve enhanced training, improved SOPs, or more frequent inspections.

- Documentation: All aspects of the issue, the investigation, corrective actions, and preventative measures are thoroughly documented and included in the sanitation logs.

For instance, we once experienced an unexpectedly high microbial count on a specific piece of equipment. Our investigation revealed a faulty cleaning solution dispensing system. We repaired the system and updated our maintenance protocols, preventing future occurrences.

Q 28. How do you ensure compliance with regulatory standards (e.g., FDA, USDA)?

Ensuring compliance with regulatory standards, such as those from the FDA (Food and Drug Administration) and USDA (United States Department of Agriculture), is a cornerstone of our sanitation program. Compliance isn’t a one-time task but an ongoing commitment.

- Comprehensive Understanding of Regulations: We maintain a deep understanding of all relevant regulations, keeping abreast of any changes or updates. We use regularly updated regulatory handbooks and attend industry conferences to maintain compliance.

- Standard Operating Procedures (SOPs): All sanitation procedures are meticulously documented in SOPs that align with regulatory requirements. These SOPs are regularly reviewed and updated.

- Record Keeping: Detailed and accurate record-keeping is crucial for demonstrating compliance to auditors. Our records include sanitation logs, chemical usage logs, equipment maintenance logs, training records, and results of all testing.

- Employee Training: All personnel receive thorough training on relevant regulations and how to adhere to them. This training is documented and updated regularly.

- Regular Audits and Inspections: We conduct regular internal audits to identify any areas needing improvement and proactively address compliance issues. This helps identify potential compliance issues before an external audit.

Regular mock audits help us prepare for external audits and simulate real-world scenarios. This proactive approach ensures we’re always prepared to demonstrate our commitment to compliance and uphold the highest standards of hygiene and food safety.

Key Topics to Learn for Equipment Sanitation and Maintenance Interview

- Sanitation Procedures: Understanding and applying various cleaning and sanitizing methods for different equipment types (e.g., CIP systems, manual cleaning, specific chemical usage).

- Preventive Maintenance: Implementing regular inspection, lubrication, and minor repair procedures to extend equipment lifespan and prevent breakdowns. Practical application: Describing your experience with preventative maintenance schedules and record-keeping.

- Troubleshooting & Repair: Identifying common equipment malfunctions, diagnosing issues, and performing basic repairs or escalating to appropriate personnel. Problem-solving example: Explaining how you’d approach a malfunctioning conveyor belt.

- Safety Regulations & Compliance: Knowledge of relevant health and safety regulations (e.g., OSHA, GMP) pertaining to sanitation and equipment maintenance. Practical application: Demonstrating understanding of proper PPE usage and hazard identification.

- Documentation & Record Keeping: Maintaining accurate and detailed records of cleaning, maintenance, and repair activities. Practical application: Describing your experience with different record-keeping systems (e.g., digital logs, paper-based systems).

- Cleaning Agents & Chemicals: Safe handling, storage, and application of various cleaning agents and disinfectants, understanding their effectiveness and potential hazards.

- Equipment Specifics: Demonstrating in-depth knowledge of the specific types of equipment used in your target industry (e.g., processing equipment, packaging machinery). This may involve discussing specific brands or models.

Next Steps

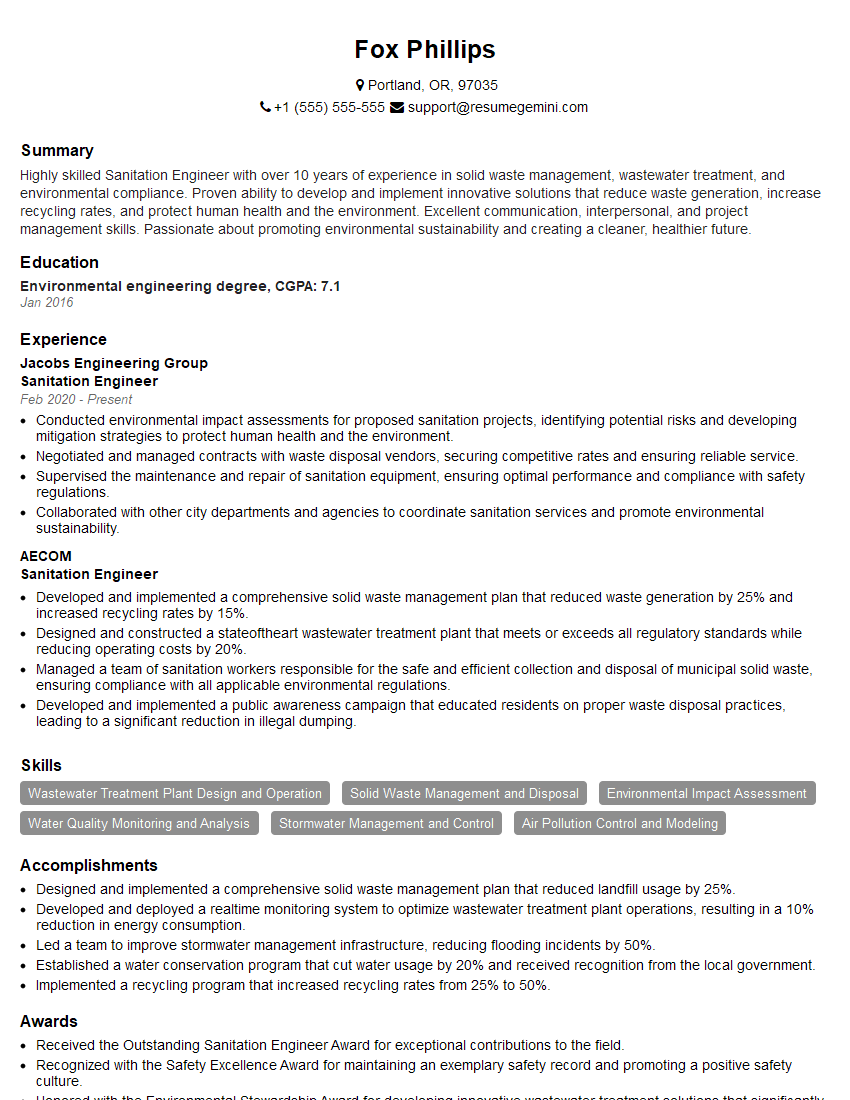

Mastering Equipment Sanitation and Maintenance opens doors to rewarding careers with excellent growth potential. Proficiency in this field demonstrates valuable skills in technical problem-solving, safety adherence, and meticulous attention to detail – all highly sought after by employers. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes specifically designed for Equipment Sanitation and Maintenance professionals are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.