Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Estimating and Quoting Systems (e.g., Atlas, EskoArtios) interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Estimating and Quoting Systems (e.g., Atlas, EskoArtios) Interview

Q 1. Explain your experience with Atlas or Esko Artios software.

My experience with both Atlas and Esko Artios is extensive, spanning over seven years. I’ve used them in various capacities, from initial project scoping and estimation to pre-press preparation and job tracking. Atlas, with its strong focus on automation and integration with MIS systems, has been invaluable for streamlining our estimating process in high-volume environments. Esko Artios, on the other hand, excels in its detailed 3D modeling capabilities, particularly useful for complex packaging projects. I’m proficient in both the quoting and nesting features of both systems, allowing me to optimize material usage and minimize waste. For example, I recently used Artios to create a complex die-cut for a client’s custom packaging, significantly reducing material costs through efficient nesting, compared to a manual approach.

In a previous role, I was responsible for training junior estimators on both platforms. This experience honed my understanding of their intricacies and empowered me to troubleshoot complex issues quickly and efficiently. I regularly utilize the reporting features of both systems to identify trends, pinpoint areas for improvement in our processes, and ultimately enhance our profitability.

Q 2. Describe your process for creating accurate estimates in a high-volume environment.

My process for creating accurate estimates in a high-volume environment relies heavily on a standardized workflow and the efficient use of software like Atlas or Esko Artios. It begins with a thorough understanding of the client’s specifications, including the job’s complexity, quantity, materials, and finishing requirements. I then leverage the automated features of the chosen software to break down the project into its individual components (printing, cutting, folding, binding, etc.). This allows for precise costing of each step. The software’s database, which houses historical data on material costs and production times, plays a crucial role in the accuracy of my estimations. For example, I can easily access historical data on the cost of specific paper stocks and the average setup time for different printing presses.

In addition to software assistance, I maintain a comprehensive list of all variable costs, regularly updated to reflect market fluctuations. This prevents unexpected surprises. Finally, I perform a quality check, ensuring all costs and times are realistically accounted for, and add a contingency buffer to account for unforeseen circumstances. This ensures both accuracy and profitability.

Q 3. How do you handle unexpected cost increases during a project?

Unexpected cost increases are an unfortunate reality. My approach involves immediate transparency with the client. I document the unforeseen circumstances (e.g., material price surge, equipment malfunction) and present a clear and concise explanation of the increased costs, along with supporting documentation. I offer several options to the client: accepting the revised estimate, exploring alternative materials or processes to mitigate the increase, or potentially delaying the project until market conditions stabilize.

Open communication is key here. Proactive reporting, using the reporting features within Atlas or Esko, can help identify potential cost increases early on, mitigating some of the impact. For instance, if a specific material’s price significantly increases, I might proactively suggest alternative materials that retain the desired quality without drastically impacting the final cost. Ultimately, the goal is to find a mutually acceptable solution that preserves the client relationship while protecting the company’s profitability.

Q 4. What are the key factors you consider when estimating a print job?

Estimating a print job requires considering several key factors. First, the job specifications: the size, quantity, and type of print (e.g., offset, digital, screen). Second, material costs: paper type, ink, and any special finishes. Third, labor costs: pre-press time, press time, finishing time, and any specialized skills required. Fourth, equipment costs: machine setup, run time, and maintenance. Fifth, overhead: rent, utilities, and administrative costs. Finally, profit margin: a crucial element ensuring the job is financially viable. For example, if I’m estimating a large-format poster print, I’d need to factor in the larger paper rolls, the longer press run, and the potential need for specialized handling equipment.

I often use a spreadsheet or the built-in costing modules within Atlas or Esko Artios to systematically capture and calculate these factors. Each factor is detailed, allowing for quick identification of cost contributors.

Q 5. How do you account for material costs in your estimates?

Material costs are a critical part of any estimate. I use a combination of real-time pricing data from suppliers and historical cost data within the estimation software. I maintain an updated database of material costs, regularly reviewing and adjusting it to account for market fluctuations and supplier discounts. For example, if the price of a specific type of paper increases, I update the database immediately. This ensures that my estimates accurately reflect the current market rates.

Furthermore, I account for waste. Printing processes inevitably generate waste, so I factor in this loss in my material calculations. This is especially important in projects with complex die-cuts or specialized finishing, where waste can be more significant. The nesting features in Esko Artios assist in minimizing this waste and provide a realistic calculation to include in the estimate.

Q 6. How do you ensure your estimates are accurate and profitable?

Ensuring accurate and profitable estimates involves a multi-faceted approach. Accurate estimates stem from meticulous data collection, using up-to-date pricing, labor rates, and machine running costs. I regularly audit my estimates against actual costs to identify areas for improvement and refine my costing models. This continuous improvement process helps increase the accuracy of future estimates.

Profitability is ensured by understanding all direct and indirect costs and building a suitable profit margin into each estimate. This margin should be sufficient to cover unexpected costs and ensure the overall profitability of the business. My experience allows me to accurately assess the inherent risks in a project and build an appropriate contingency into my estimates. Furthermore, analyzing historical data from both Atlas and Esko Artios helps identify patterns in job profitability, enabling me to make informed decisions and adjust my pricing strategies accordingly.

Q 7. Describe your experience with different types of printing processes and their cost implications.

I have extensive experience with various printing processes, including offset lithography, digital printing, screen printing, and large format inkjet printing. Each process has unique cost implications. Offset lithography, while cost-effective for large print runs, has higher setup costs. Digital printing is ideal for shorter runs and offers quicker turnaround times, but the per-unit cost can be higher for smaller quantities. Screen printing is excellent for specialized effects but involves higher setup and labor costs. Large format inkjet printing is suitable for billboards and posters, but the material costs can be substantial, especially for high-resolution prints.

Understanding these nuances is critical for accurate estimating. For instance, I would never recommend offset printing for a small run of personalized business cards; digital printing would be far more cost-effective. The chosen printing process significantly impacts the overall estimate, and my experience allows me to recommend and price the optimal process for each project.

Q 8. How familiar are you with different paper stocks and their cost variations?

Understanding paper stock and its cost variations is fundamental to accurate print estimating. Different papers possess unique properties impacting price – weight (basis weight, measured in gsm – grams per square meter), material (coated, uncoated, recycled), and finish (gloss, matte, etc.). Heavier papers obviously cost more due to increased material. Coated papers, used for high-quality images, are generally pricier than uncoated papers. Recycled content can sometimes lower costs, but not always, as the manufacturing process can differ.

For example, a 100gsm uncoated paper will be significantly cheaper than a 300gsm gloss-coated paper of the same size. I regularly consult paper stock catalogs and supplier pricing guides to obtain the most up-to-date cost information. Software like Esko Artios integrates these pricing directly, streamlining the process.

In practice, I build a paper cost database within my estimating system, regularly updating it based on supplier quotes and market fluctuations. This database is crucial for generating accurate and competitive quotes.

Q 9. How do you incorporate finishing costs (e.g., binding, die-cutting) into your estimates?

Finishing costs are incorporated meticulously into my estimates. I break down finishing into individual components, ensuring accurate cost calculation. This includes:

- Binding: The type of binding (perfect, saddle-stitch, wire-o, case) significantly impacts cost. Perfect binding is more expensive than saddle-stitch due to the complex process involved. I account for the cost per book/unit for each binding type.

- Die-cutting: The complexity of the die-cutting design directly affects the cost. Simple shapes are less expensive than intricate designs that require more setup time and tooling. I usually request die-cutting quotes from specialized vendors based on the design complexity and order quantity.

- Folding: Simple folds cost less than intricate ones involving multiple panels or specialized techniques.

- Other Finishing: This includes lamination (gloss, matte), embossing, UV coating, and other value-added processes. Each adds to the total cost, and I carefully analyze each step.

I often use spreadsheet templates or dedicated estimating software to organize these costs, keeping a running total of finishing expenditures. This ensures transparency and allows for easy adjustments based on client preferences and budgetary concerns.

Q 10. Explain your understanding of variable and fixed costs in print estimation.

Understanding variable and fixed costs is paramount in accurate print estimation. Fixed costs remain constant regardless of the production volume (e.g., rent, salaries, equipment depreciation). Variable costs fluctuate with production volume (e.g., paper, ink, labor directly related to production).

Fixed Costs: These are incorporated into the overall cost structure as a fixed overhead rate per job or per hour. For example, if my monthly fixed costs are $10,000 and I operate for 200 hours, my fixed cost per hour is $50. This overhead is then added to the variable costs to determine the final price.

Variable Costs: These are usually calculated based on the quantity produced. The cost of paper per sheet is a variable cost – the more sheets, the higher the cost. Labor for printing and finishing is also a variable cost, often measured as cost per unit/hour.

Accurate allocation of fixed and variable costs ensures accurate pricing, allowing for profitable pricing and preventing underestimation. I utilize cost accounting principles and regularly review my cost structure to adjust for market changes and efficiency improvements.

Q 11. How do you manage and track your estimates throughout the project lifecycle?

I utilize a robust system for managing and tracking estimates throughout the project lifecycle. This typically involves:

- Dedicated Estimating Software (e.g., Atlas, Esko Artios): These systems provide templates for consistent quote creation, automatically calculate costs based on specified parameters, and store project details for easy tracking.

- Version Control: Each revision of an estimate is saved and clearly documented. This allows for easy comparison and clarifies any changes made during negotiations.

- Centralized Database: All project-related documents, including estimates, specifications, and communications, are stored in a centralized, easily accessible location.

- Regular Review: I regularly review estimates and compare them to actual costs to identify areas for improvement in my estimation accuracy.

A client-facing portal, where clients can access their estimates and approvals, further ensures transparency and seamless communication.

Q 12. How do you handle discrepancies between estimated and actual costs?

Discrepancies between estimated and actual costs are inevitable. A crucial part of my role is analyzing these differences to identify the root cause and prevent future errors. I typically follow these steps:

- Detailed Cost Reconciliation: I perform a thorough comparison of the estimated costs versus the actual incurred costs, itemizing each cost component.

- Identify Variance Drivers: I analyze the significant variances to pinpoint the reason. This could be inaccurate material pricing, unforeseen finishing challenges, unexpected labor costs, or inaccurate estimations of production time.

- Implement Corrective Actions: Once the root causes are identified, corrective actions are implemented to prevent similar discrepancies in future projects. This might involve refining my estimation process, updating cost databases, or improving communication with vendors and production staff.

- Documentation and Reporting: A detailed report is generated documenting the discrepancies, root causes, and corrective actions. This report serves to improve future estimations.

Regular cost analysis and a culture of continuous improvement are essential in reducing cost estimation errors.

Q 13. What methods do you use to improve the efficiency and accuracy of your estimating process?

Improving the efficiency and accuracy of my estimating process is an ongoing effort. My strategies include:

- Leveraging Estimating Software: Utilizing software like Atlas or Esko Artios automates calculations, reducing manual errors and improving speed.

- Regular Cost Database Updates: Maintaining an up-to-date database of material and labor costs is crucial for accuracy. I routinely update this database with current supplier pricing and internal cost analyses.

- Standardized Processes: Employing standardized templates and workflows ensures consistency and minimizes mistakes in the estimating process.

- Continuous Learning: Staying current on industry trends, material prices, and finishing techniques helps in accurate costing.

- Data Analysis: Regularly analyzing past projects to identify trends and potential areas of improvement in estimation accuracy.

- Collaboration: Open communication with production staff and vendors helps in securing accurate cost information for materials and labor.

By continuously refining these methods, I strive for the highest level of accuracy and efficiency in my estimations.

Q 14. How familiar are you with different types of die-cutting and their cost implications?

My familiarity with die-cutting types and their cost implications is extensive. Die-cutting encompasses various techniques, each influencing the cost:

- Standard Die-Cutting: This involves simple shapes and is relatively inexpensive. The cost is primarily determined by the die creation and the press time.

- Rotary Die-Cutting: Used for high-volume jobs, rotary die-cutting is generally more efficient and cost-effective for large quantities. However, the initial investment in rotary dies is higher.

- Kiss-Cutting: This cuts only through the surface, ideal for labels or stickers. Cost is lower compared to full-depth cuts.

- Embossing and Debossing: These processes add texture and depth. The cost increases significantly with intricacy and the material used.

- Custom Shapes and Intricate Designs: Complex shapes require more intricate dies, leading to higher setup and tooling costs.

I consider factors such as design complexity, material, quantity, and required precision when estimating die-cutting costs. I typically obtain quotes from multiple die-cutting vendors to ensure competitive pricing and to accommodate specific needs.

Q 15. How do you incorporate client-specific requirements into your estimates?

Incorporating client-specific requirements into estimates is crucial for accuracy and client satisfaction. It’s not just about plugging numbers into a system; it’s about understanding the nuances of each project. I begin by carefully reviewing the client’s specifications, paying close attention to details like material preferences, desired quality levels, and any unique design elements. For instance, if a client specifies a particular type of sustainable paper stock, I’ll factor in its higher cost and potential impact on production time. I then use the estimating software (like Atlas or Esko Artios) to input these parameters. These systems allow for custom variables and adjustments that reflect these specific requirements. I’ll also add notes and comments within the software to document any non-standard aspects for future reference and team communication. Finally, I always discuss the estimate with the client, clarifying any assumptions or potential variations before finalizing the quote. This collaborative approach prevents misunderstandings and ensures the estimate accurately reflects the client’s vision.

For example, if a client requests a specific embossing technique, I wouldn’t simply use a generic embossing cost; I’d research the precise technique, factoring in any additional setup or tooling needed, and adjusting the estimate accordingly. This ensures a transparent and accurate final price.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of finishing techniques.

My experience encompasses a wide range of finishing techniques, crucial for providing accurate estimates. This includes:

- Die-cutting: I’m proficient in estimating various die-cutting complexities, including intricate shapes and multiple layers, factoring in die creation costs and potential waste.

- Embossing and Debossing: I understand the nuances of different embossing and debossing techniques, considering the type of foil (if applicable), and the complexity of the design, which impacts setup times and potential for material waste.

- Foil Stamping: My experience includes estimating costs for various foil types, colors, and application methods, understanding the impact of intricate designs on production time and material usage.

- Laminating: I can accurately estimate costs for different types of laminates (gloss, matte, soft-touch), considering both material costs and machine setup times.

- Varnishing (UV and Aqueous): I’m familiar with both UV and aqueous varnishes, understanding their differing application processes, drying times, and environmental impact.

My experience isn’t just theoretical; I’ve consistently demonstrated the ability to accurately predict finishing costs, minimizing discrepancies between estimated and actual costs. This is largely due to my thorough understanding of production processes and my familiarity with the material and machine costs.

Q 17. How familiar are you with the different modules within Atlas or Esko Artios?

I’m highly proficient in both Atlas and Esko Artios, understanding their respective strengths and how to leverage their functionalities for accurate and efficient estimating. In Atlas, I’m well-versed in modules like:

- Job Setup: This is where I define all project specifics, from substrate selection to finishing options.

- Costing: This is where I integrate material costs, labor rates, and machine setup times.

- Reporting: I leverage this module to generate detailed reports, invaluable for analysis and client communication.

Similarly, in Esko Artios, I frequently use modules such as:

- ArtiosCAD: I utilize this for accurate die-making estimations, considering the complexity of the design and the material specifications.

- ArtiosEstimate: This module facilitates accurate cost estimations, integrating job specifics with pre-defined pricing structures.

- ArtiosWorkflow: This streamlines the workflow, improving the efficiency of the entire estimating and production process.

My experience with both systems allows me to select the most suitable software for the specific project, optimizing accuracy and efficiency.

Q 18. How do you use reporting features in your estimating software?

Reporting features in estimating software are essential for tracking performance, identifying areas for improvement, and demonstrating value to clients. I regularly use reporting features to generate:

- Detailed cost breakdowns: These reports show material, labor, and overhead costs, providing complete transparency to clients.

- Profitability analysis: I use these reports to assess the profitability of individual jobs and project categories, identifying areas needing adjustments.

- Production efficiency reports: These help identify bottlenecks or inefficiencies in the production process.

- Custom reports for clients: Tailored reports can showcase the value delivered, addressing specific client concerns or requests.

For example, a client might request a detailed breakdown of material costs. I can easily generate such a report, showcasing the exact type and quantity of materials used, with corresponding unit prices.

Q 19. Explain your experience with integrating estimating software with other business systems (e.g., ERP).

Integrating estimating software with other business systems like ERP (Enterprise Resource Planning) is crucial for efficient workflow and data accuracy. I have experience integrating Atlas and Esko Artios with various ERP systems. This integration usually involves:

- Data transfer: Information like material costs, labor rates, and customer details are seamlessly transferred between the systems, minimizing manual data entry.

- Automated workflows: Once an estimate is approved, the data can automatically feed into production scheduling and inventory management systems.

- Real-time updates: Changes made in one system automatically update the other, maintaining data consistency across the enterprise.

In a practical setting, integration ensures that the estimate accurately reflects the current inventory levels and material costs, prevents discrepancies between different departments, and reduces the risk of human error. This streamlines operations and contributes significantly to the overall efficiency of the business.

Q 20. How do you handle rush jobs and their impact on estimation?

Handling rush jobs requires a strategic approach to estimation. While maintaining accuracy is paramount, speed is also a critical factor. My process involves:

- Identifying the impact on resources: Rush jobs often require overtime pay, expedited material procurement, and potentially, prioritized machine scheduling. All of this affects the overall cost.

- Adjusting labor rates: Overtime premiums are factored into the labor cost estimation.

- Expediting fees: Any additional charges for expedited material delivery are included.

- Transparency with the client: I clearly communicate the impact of the rush on the cost, ensuring transparency and agreement on the revised estimate.

I’ve learned that clearly articulating the trade-off between speed and cost is crucial. Often, clients are willing to absorb some additional cost in exchange for a faster turnaround time, but only if they understand the justification. Open communication avoids surprises and maintains a positive client relationship.

Q 21. What are your strategies for negotiating with vendors to secure favorable pricing?

Negotiating favorable pricing with vendors requires a strategic and collaborative approach. My strategy involves:

- Building strong relationships: Maintaining consistent communication and building trust with vendors is vital for securing better pricing over time.

- Leveraging volume discounts: Negotiating volume discounts based on projected usage is crucial.

- Comparing prices: Obtaining quotes from multiple vendors helps in identifying the best pricing.

- Negotiating payment terms: Favorable payment terms can significantly affect the overall cost. For instance, early payment discounts can lead to significant cost savings.

- Analyzing pricing models: I meticulously examine each vendor’s pricing structure to ensure fairness and identify areas for potential negotiation.

For example, by demonstrating a consistent and high volume of orders, I’ve secured significant discounts on materials and even preferential treatment during peak seasons. This proactive approach results in significant cost savings, positively impacting the company’s bottom line and our clients’ final price.

Q 22. Describe your process for validating the accuracy of your estimates.

Validating the accuracy of estimates is crucial for project success and profitability. My process involves a multi-step approach combining automated systems with experienced judgment. Firstly, I leverage estimating software like Esko ArtiosCAD or Atlas to generate initial estimates. These systems automate calculations based on material costs, press time, finishing operations, and other variables, minimizing human error.

Secondly, I perform a thorough manual review. This includes cross-checking the software’s output against historical data for similar projects. For instance, if I’m estimating a large-format print job, I’d compare the material and labor costs to previous jobs with similar specifications. This helps identify any potential anomalies or inconsistencies.

Thirdly, I incorporate a contingency factor to account for unforeseen issues. This buffer, usually a percentage of the total estimate, helps absorb unexpected costs like material shortages or equipment malfunctions. Finally, I conduct a sensitivity analysis, altering key variables (e.g., paper price, press speed) to understand their impact on the overall estimate. This helps identify areas where cost savings might be possible or areas of higher risk.

Q 23. How familiar are you with different pricing models (e.g., cost-plus, value-based)?

I’m proficient in various pricing models, each suited to different situations. Cost-plus pricing is straightforward: I calculate all direct and indirect costs and add a markup percentage for profit. This is transparent but relies on accurate cost tracking. It’s ideal when the project scope is well-defined and risks are low. For example, a simple short-run print job with standard specifications is well-suited for this model.

Value-based pricing focuses on the value delivered to the client. This requires a thorough understanding of client needs and the perceived value of the final product. Instead of basing pricing solely on costs, I consider the project’s strategic importance to the client and position it accordingly. This model works best for complex projects or when competing on factors beyond just price. For instance, a high-end packaging project demanding sophisticated design and printing would benefit from value-based pricing.

Other models, such as time and materials (suitable for projects with evolving scope), and fixed-price (ideal for well-defined, low-risk projects) are also within my expertise. Choosing the right model depends on the project’s specifics and client relationship.

Q 24. How do you manage changes to project scope and their impact on estimates?

Managing scope changes requires a systematic approach to avoid cost overruns. My process begins with a clearly defined scope of work within the initial estimate. Any deviations, however minor, are formally documented as change requests. Each request is evaluated independently, taking into account its impact on costs, time, and resources. I use a Change Order form to detail the change, its justification, the revised estimate, and the client’s approval.

For example, if a client requests a change to the paper stock after the initial estimate, I’d calculate the price difference between the original and new stock, considering any waste implications or potential press adjustments. This revised cost is then presented to the client as a change order. Using a change management system within our estimating software allows for transparent tracking and accurate accounting of all alterations. This protects both the company and the client from unexpected costs and ensures mutual understanding.

Q 25. Describe a time when you had to make a difficult decision regarding an estimate.

Once, I faced a situation where a rush order significantly impacted our capacity. The initial estimate assumed standard turnaround time. Accepting the rush order at the original price would have meant compromising on other scheduled jobs and potentially impacting customer relationships and deadlines. The decision was to either adjust the estimate to reflect the urgency (increased labor costs, overtime) or refuse the order.

After careful consideration of the potential profit margin, existing workload, and the client’s importance, I decided to offer a revised, higher estimate with transparent justification for the additional costs. This resulted in a slightly lower profit margin but maintained our operational integrity and client relationships. Ultimately, it demonstrated honesty and professionalism, strengthening the client relationship long-term despite the short-term financial compromise.

Q 26. How do you ensure your estimates are compliant with industry standards and regulations?

Compliance is paramount. I ensure adherence to industry standards and regulations (e.g., environmental regulations for inks and substrates, labor laws regarding overtime, safety standards for equipment handling) in several ways. Firstly, I use estimating software that incorporates these regulations into its calculations. Secondly, I regularly update my knowledge through industry publications, certifications, and professional development courses. This keeps my estimates legally sound and environmentally responsible.

For example, when estimating jobs involving specific inks or substrates, I carefully check for certifications like FSC (Forest Stewardship Council) or similar environmental certifications to ensure the materials meet required sustainability standards and I include those costs in the calculation. Any potential non-compliance is flagged and addressed before finalizing the estimate. Regular audits of our estimating procedures also guarantee continued adherence to all relevant standards.

Q 27. What are some common mistakes to avoid when estimating print projects?

Common mistakes in print project estimating include:

- Underestimating pre-press time: Failing to account for design revisions, file preparation, color proofing, and plate making can lead to significant delays and cost overruns.

- Ignoring finishing costs: Overlooking costs for binding, cutting, folding, lamination, or other finishing operations. These costs can add up quickly.

- Inaccurate material calculations: Miscalculating the amount of paper, ink, or other materials needed leads to waste and increased expenses.

- Failing to include overhead: Neglecting to account for indirect costs like rent, utilities, and administrative expenses skews the estimate and undermines profitability.

- Not accounting for waste: Print projects always have some waste. Failing to factor in this inherent waste can significantly impact material costs.

Avoiding these mistakes requires meticulous planning, accurate data collection, and careful consideration of all project phases.

Q 28. How do you stay up-to-date on industry best practices in estimating and quoting?

Staying updated is critical in this dynamic industry. I achieve this through several channels. I regularly attend industry conferences and workshops to learn about new technologies, software, and best practices. I subscribe to relevant trade publications and online resources that provide insights into market trends and emerging standards. Also, I actively participate in professional organizations like the PIA (Printing Industries of America) to network with peers and stay abreast of the latest developments.

Furthermore, I actively seek out training opportunities offered by software vendors (like Esko or Atlas) to enhance my proficiency with estimating and quoting tools. This commitment to continuous learning ensures that my estimates reflect the most current industry knowledge and technologies, leading to greater accuracy and profitability.

Key Topics to Learn for Estimating and Quoting Systems (e.g., Atlas, EskoArtios) Interview

- System Navigation and Interface: Mastering the software’s layout, menus, and tools is fundamental. Practice navigating efficiently and locating key features.

- Job Setup and Data Input: Understand how to accurately input job specifications, including dimensions, materials, and printing requirements. Practice with various scenarios.

- Estimating Techniques and Calculations: Become proficient in using the system’s built-in calculators and formulas to generate accurate cost estimates. Understand the underlying principles.

- Material Costing and Management: Learn how to manage material databases, track pricing updates, and account for waste in your estimations. Practice cost analysis.

- Labor Cost Calculation: Understand how the system handles labor costs, including setup, production, and finishing times. Analyze different labor scenarios.

- Report Generation and Analysis: Practice generating different reports (e.g., cost summaries, material breakdowns). Understand how to interpret the data for decision-making.

- Quoting Strategies and Pricing Models: Learn how to effectively use the system to generate competitive and profitable quotes. Explore different pricing models.

- Integration with other systems (if applicable): If the system integrates with other software (e.g., MIS, ERP), understand the data flow and implications for estimating and quoting.

- Troubleshooting and Problem Solving: Practice identifying and resolving common issues encountered during the estimating and quoting process. Develop your problem-solving skills.

- Best Practices and Efficiency: Learn techniques for optimizing workflow and maximizing efficiency within the system.

Next Steps

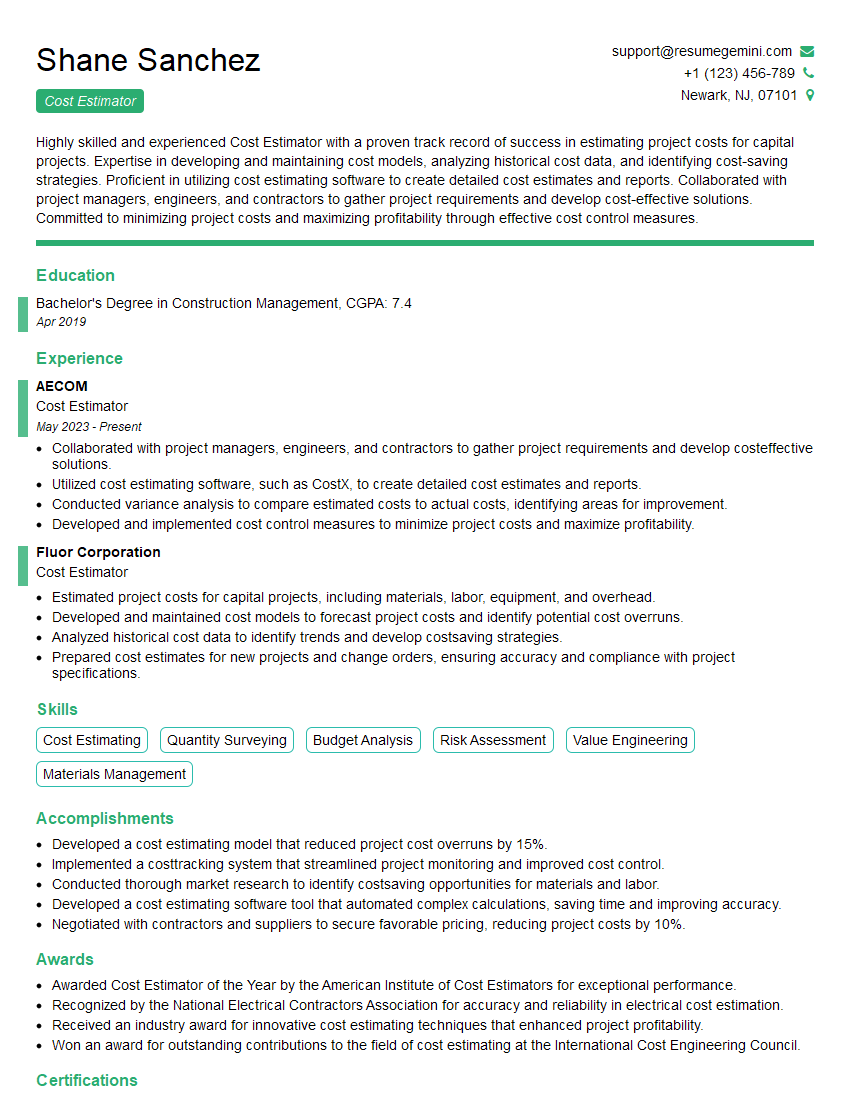

Mastering Estimating and Quoting Systems like Atlas and EskoArtios is crucial for career advancement in the printing and packaging industries. These systems are essential for accurate cost estimations, efficient project management, and ultimately, business profitability. To significantly boost your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific needs. Examples of resumes tailored to showcasing expertise in Estimating and Quoting Systems (e.g., Atlas, EskoArtios) are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO