Unlock your full potential by mastering the most common Experience in Supply Chain Management interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Experience in Supply Chain Management Interview

Q 1. Explain the bullwhip effect and how to mitigate it.

The bullwhip effect is a phenomenon in supply chains where demand variability is amplified as you move upstream in the supply chain. Imagine a whip – a small flick at the end (consumer demand) creates a large swing at the handle (supplier orders). This leads to excess inventory at some points and shortages at others, ultimately increasing costs and inefficiencies.

Mitigation Strategies:

- Improved Information Sharing: Implementing systems like point-of-sale (POS) data sharing across the supply chain allows all parties to have a clearer picture of actual consumer demand, reducing forecasting errors. For instance, a retailer sharing daily sales data with its distributor and manufacturer helps everyone adjust production and inventory levels more accurately.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): This collaborative approach involves sharing forecasts and sales data between supply chain partners. By working together, companies can create more accurate forecasts and reduce demand variability.

- Vendor Managed Inventory (VMI): In this model, a supplier manages the inventory levels at a customer’s location. The supplier is responsible for ordering and replenishing inventory based on actual demand, preventing overstocking or stockouts.

- Reducing Lead Times: Shorter lead times reduce the time it takes for goods to move through the supply chain, making it easier to respond quickly to changes in demand. This might involve optimizing transportation or finding suppliers closer geographically.

- Demand Stabilization: Offering consistent pricing and promotions can help reduce the fluctuations in consumer demand, thereby decreasing the bullwhip effect.

For example, during a period of unexpectedly high demand, a company using effective mitigation strategies would be able to quickly adjust its production and distribution without experiencing excessive inventory buildup or significant stockouts.

Q 2. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO, EOQ).

I have extensive experience with various inventory management techniques. The choice of technique depends heavily on the nature of the inventory (perishable vs. durable) and the business context.

- FIFO (First-In, First-Out): This method assumes that the oldest inventory is used or sold first. It’s ideal for perishable goods or items with short shelf lives. Using FIFO helps minimize waste from spoilage and ensures that customers receive the freshest products. Imagine a bakery – they’d naturally sell the oldest bread first.

- LIFO (Last-In, First-Out): Here, the newest inventory is used or sold first. This method is often used for non-perishable goods, and is particularly relevant for accounting purposes as it can lower taxable income during periods of inflation (though less so under IFRS).

- EOQ (Economic Order Quantity): This is a mathematical model that helps determine the optimal order quantity to minimize the total inventory costs, balancing ordering costs and holding costs. The formula considers factors such as demand, ordering cost, and holding cost. For example, a company manufacturing screws would use EOQ to calculate the optimal number of screws to order each time to minimize warehousing and ordering expense.

- Just-in-Time (JIT): This approach focuses on receiving materials only when needed for production. This minimizes inventory holding costs, but requires precise forecasting and strong relationships with suppliers. It is crucial for effective JIT inventory management to have a reliable supply chain.

In my previous role, we successfully transitioned from a LIFO system to a FIFO system for our perishable goods, resulting in a significant reduction in waste and an improvement in product quality. For non-perishable goods, we utilized EOQ to optimize our order quantities, reducing inventory holding costs by 15%.

Q 3. What are the key performance indicators (KPIs) you track in supply chain management?

The KPIs I track in supply chain management are multifaceted and tailored to the specific business objectives. However, some key metrics consistently provide valuable insights:

- Inventory Turnover Ratio: Measures how efficiently inventory is managed. A higher ratio indicates better inventory management.

- On-Time Delivery Rate: Percentage of orders delivered on time. Critically important for customer satisfaction.

- Lead Time: The time it takes to fulfill an order, from order placement to delivery. Shorter lead times mean greater responsiveness.

- Order Fill Rate: The percentage of orders fulfilled completely and accurately. High fill rate indicates efficient order processing and inventory management.

- Perfect Order Rate: A comprehensive metric encompassing on-time delivery, complete orders, accurate orders, and undamaged goods. This is a powerful measure of overall supply chain performance.

- Transportation Costs as a Percentage of Revenue: Tracks efficiency of transportation and logistics.

- Customer Satisfaction (CSAT): Directly reflects the impact of the supply chain on the end customer.

- Total Landed Cost: The total cost of acquiring a product, including all expenses from origin to destination.

I regularly analyze these KPIs to identify areas for improvement and make data-driven decisions to optimize the supply chain. For instance, a consistently low on-time delivery rate might indicate issues with transportation or production scheduling that need immediate attention.

Q 4. How do you handle supply chain disruptions?

Handling supply chain disruptions requires a proactive and multi-faceted approach. My strategy involves:

- Risk Assessment and Mitigation Planning: Regularly identifying potential disruptions (natural disasters, political instability, supplier issues, pandemics etc.) and developing contingency plans. This involves diversifying sourcing and maintaining safety stock for critical items.

- Real-Time Monitoring and Early Warning Systems: Implementing systems that provide real-time visibility into the supply chain, allowing for early detection of potential problems and rapid response.

- Agile Supply Chain Design: Building a flexible supply chain capable of adapting quickly to changes. This includes having multiple suppliers and flexible manufacturing processes.

- Collaboration and Communication: Maintaining strong relationships with suppliers and other stakeholders to facilitate quick information sharing and collaborative problem-solving during disruptions.

- Scenario Planning: Developing plans for different scenarios, including worst-case scenarios, to ensure that the business can continue to operate even under extreme circumstances.

- Post-Disruption Analysis: Conducting thorough reviews of events to understand the root causes and implement improvements to prevent future disruptions.

During a recent supplier shortage, our proactive risk assessment and mitigation plan enabled us to quickly identify alternative suppliers and maintain production with minimal disruption to customers. We leveraged our strong relationships with suppliers to secure alternative sourcing, and regular communication minimized anxiety across the supply chain.

Q 5. Explain your understanding of Lean manufacturing principles and their application in supply chain.

Lean manufacturing principles focus on eliminating waste and maximizing efficiency throughout the entire production process. These principles translate seamlessly into supply chain optimization.

- Value Stream Mapping: Identifying and analyzing all the steps involved in bringing a product to the customer, and eliminating non-value-added activities. This helps pinpoint bottlenecks and inefficiencies.

- Waste Reduction (Muda): Targeting and eliminating seven types of waste: Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, and Defects. This improves efficiency and reduces costs.

- Kaizen (Continuous Improvement): Implementing a culture of continuous improvement through small, incremental changes. This ensures ongoing optimization and adaptation.

- 5S Methodology: Organizing the workplace to improve efficiency and reduce waste (Sort, Set in Order, Shine, Standardize, Sustain).

- Pull System (Just-in-Time): Producing goods only when needed, minimizing inventory and waste.

In a previous role, we implemented Lean principles to optimize our warehouse operations, resulting in a 20% reduction in lead times and a 15% decrease in warehouse space requirements. We achieved this through value stream mapping to identify bottlenecks, implementing 5S for better organization, and adopting a pull system for inventory management.

Q 6. Describe your experience with different forecasting methods.

I have experience with a range of forecasting methods, selecting the most appropriate method depends on data availability, forecast horizon, and the level of accuracy required.

- Qualitative Forecasting: Relies on expert judgment and intuition. Useful when historical data is limited or unreliable (e.g., market research, Delphi method).

- Quantitative Forecasting: Uses statistical techniques to predict future demand based on historical data. Examples include:

- Moving Average: Simple average of demand over a specific period. Useful for stable demand patterns.

- Exponential Smoothing: Assigns weights to past data, giving more weight to recent data. Effective for situations with trend and seasonality.

- ARIMA (Autoregressive Integrated Moving Average): A sophisticated statistical model that considers trends, seasonality, and other factors. Provides more accurate forecasts for complex demand patterns.

In practice, I often use a combination of qualitative and quantitative methods. For example, I might use quantitative methods to establish a baseline forecast, then adjust it based on qualitative insights from sales teams and market research. The choice of method is driven by data availability and the inherent uncertainty in the predicted period.

Q 7. How do you optimize transportation costs and routes?

Optimizing transportation costs and routes involves a strategic approach leveraging various techniques and technologies.

- Route Optimization Software: Utilizing software to determine the most efficient routes considering factors like distance, traffic, delivery time windows, and fuel costs. This can significantly reduce transportation time and fuel consumption.

- Carrier Management: Negotiating favorable rates and service levels with multiple carriers to ensure cost-effectiveness and reliability. This includes consolidating shipments to leverage economies of scale.

- Load Consolidation: Combining multiple shipments into larger loads to reduce the number of shipments and transportation costs. This requires careful planning and coordination.

- Mode Selection: Choosing the optimal transportation mode (truck, rail, air, sea) based on factors like cost, speed, and reliability. Each mode has its own strengths and weaknesses.

- Freight Auditing: Regularly auditing freight bills to ensure accuracy and identify potential cost savings. This can often uncover discrepancies or overcharges.

- Real-time Tracking and Monitoring: Using GPS tracking to monitor shipments in real-time, allowing for proactive problem-solving and improved delivery efficiency.

In my experience, implementing route optimization software reduced our transportation costs by 12% and improved on-time delivery rates by 8%. This was achieved by dynamically adjusting routes based on real-time traffic conditions and leveraging load consolidation strategies.

Q 8. What software or tools are you proficient in for supply chain management?

My proficiency in supply chain management software spans a range of tools, each tailored to specific needs. I’m highly skilled in enterprise resource planning (ERP) systems like SAP and Oracle, utilizing their modules for inventory management, procurement, and production planning. I’m also adept at Transportation Management Systems (TMS) such as Blue Yonder and Manhattan Associates, leveraging them for route optimization and carrier management. For data analysis and visualization, I’m proficient in tools like Tableau and Power BI, which allow me to glean actionable insights from supply chain data. Finally, I’m experienced with specialized software for warehouse management (WMS), demand forecasting, and supplier relationship management (SRM), adapting my toolset based on the project’s specific requirements.

For example, in a previous role, I used SAP’s MM module to streamline procurement processes, resulting in a 15% reduction in procurement lead times. My proficiency with Tableau allowed me to create interactive dashboards visualizing key performance indicators (KPIs) like on-time delivery and inventory turnover, enabling data-driven decision-making.

Q 9. Explain your experience with supplier relationship management (SRM).

Supplier Relationship Management (SRM) is crucial for building strong, collaborative partnerships with suppliers. My experience encompasses the entire SRM lifecycle, from supplier selection and onboarding to performance monitoring and continuous improvement. This involves developing robust selection criteria based on factors like financial stability, quality certifications, and production capacity. I’ve implemented collaborative portals to facilitate communication, information sharing, and issue resolution. Performance monitoring involves regular review of KPIs like on-time delivery, quality metrics, and pricing. I actively work to identify areas for improvement through strategies like collaborative problem-solving and continuous improvement initiatives.

In one project, I implemented a new supplier onboarding process that reduced onboarding time by 40%, leading to faster time-to-market for new products. This involved creating standardized documentation, automating key processes, and implementing a centralized knowledge base for suppliers.

Q 10. How do you ensure supply chain visibility and traceability?

Ensuring supply chain visibility and traceability requires a multi-faceted approach. This starts with implementing robust tracking and tracing systems throughout the entire supply chain, from raw materials to finished goods. This often involves RFID tagging, barcodes, and GPS tracking technologies. Real-time data integration across different systems is crucial, enabling a single source of truth for inventory levels, location, and movement. Data analytics play a key role, allowing us to identify bottlenecks, predict potential disruptions, and optimize processes. Finally, collaboration with suppliers and logistics partners is paramount, fostering information sharing and proactive communication.

For instance, I implemented a blockchain-based system to track the origin and movement of raw materials in a food supply chain. This enhanced transparency and boosted consumer confidence, while simultaneously enabling faster recall management in case of contamination.

Q 11. Describe a time you had to make a critical decision under pressure in a supply chain context.

During a major port strike, a critical component for our flagship product faced a significant delay. Under immense pressure to meet customer deadlines, I had to quickly assess the situation, evaluating alternative suppliers and transportation modes. This involved coordinating with multiple teams, including procurement, logistics, and manufacturing. We opted for air freight for a portion of the shipment, a more expensive solution, but essential to minimize production downtime. Simultaneously, we leveraged our existing inventory strategically and expedited production on less affected product lines to balance customer demand. Through proactive communication with customers, we managed to mitigate the impact of the delay, minimizing disruptions and maintaining customer loyalty. This crisis highlighted the value of having flexible contingency plans and strong cross-functional collaboration.

Q 12. How do you manage risk in a global supply chain?

Managing risk in a global supply chain is a continuous process requiring a proactive and comprehensive approach. It begins with risk identification, assessing potential disruptions such as geopolitical instability, natural disasters, pandemics, and supplier financial issues. Risk mitigation strategies are then developed based on the likelihood and impact of each identified risk. These strategies might include diversification of suppliers, establishing safety stock levels, implementing robust contingency plans, and investing in supply chain insurance. Regular monitoring of key indicators and continuous improvement are vital for adapting to changing circumstances and preventing future disruptions.

For example, during the COVID-19 pandemic, we implemented a scenario planning approach, modeling various pandemic scenarios to anticipate potential impacts. This enabled us to preemptively diversify our supplier base, build up safety stock of critical components, and develop alternate transportation routes. This proactive risk management enabled us to navigate the crisis with minimal disruptions.

Q 13. What is your experience with warehouse management systems (WMS)?

My experience with Warehouse Management Systems (WMS) includes implementation, optimization, and ongoing management. I’ve worked with various WMS platforms, customizing them to meet specific warehouse layouts and operational processes. This includes configuring settings for inventory tracking, putaway strategies, order fulfillment processes, and labor management. I’m also experienced in integrating WMS with other systems such as ERP and TMS, ensuring seamless data flow throughout the supply chain. Moreover, I’ve led projects focused on optimizing warehouse operations through improved layout design, enhanced picking strategies, and the implementation of automation technologies, resulting in significant improvements in efficiency and cost savings.

In a previous project, I implemented a new WMS which streamlined the picking process, reducing order fulfillment time by 20%. This was achieved by optimizing warehouse layout, implementing a more efficient picking strategy, and deploying mobile handheld devices for real-time inventory updates and order fulfillment.

Q 14. Explain the concept of total cost of ownership (TCO) in supply chain.

Total Cost of Ownership (TCO) in supply chain management goes beyond the initial purchase price of goods or services. It encompasses all costs associated with acquiring, using, and disposing of an item throughout its entire lifecycle. This includes direct costs such as purchasing, transportation, and warehousing, as well as indirect costs such as inventory holding, quality control, and potential warranty claims. Understanding TCO is crucial for making informed sourcing decisions, optimizing inventory levels, and identifying areas for cost reduction. By considering the total cost, rather than simply focusing on the initial purchase price, businesses can achieve significant cost savings and improve their overall supply chain efficiency.

For example, while a supplier might offer a lower initial price for a component, a thorough TCO analysis might reveal higher transportation costs, lower quality leading to increased warranty claims, or a longer lead time affecting production schedules. By factoring in all these costs, a more informed decision can be made selecting the most cost-effective supplier in the long run.

Q 15. How do you handle capacity planning within a supply chain?

Capacity planning in supply chain management is the process of determining the resources needed to meet anticipated demand. It’s like planning a large party – you need to figure out how many chairs, tables, and food you’ll need based on the number of guests. In supply chain terms, this means assessing the capacity of your manufacturing facilities, warehouses, transportation networks, and workforce to handle projected sales volumes and order fulfillment.

My approach involves a multi-step process:

- Demand Forecasting: Accurately predicting future demand is crucial. I leverage techniques like time series analysis, regression models, and machine learning algorithms to create robust forecasts.

- Capacity Assessment: This involves evaluating current capacity across all supply chain nodes. This includes analyzing production line speeds, warehouse storage space, and transportation fleet size.

- Gap Analysis: Comparing forecasted demand with available capacity identifies any potential shortfalls. This allows for proactive planning and mitigation of potential issues.

- Capacity Optimization: Based on the gap analysis, strategies are developed to address any capacity constraints. This could involve investing in new equipment, expanding warehouse space, optimizing production processes, or outsourcing to third-party logistics providers.

- Contingency Planning: It’s crucial to plan for unexpected events, such as supplier disruptions or sudden spikes in demand. This involves developing backup plans and having flexible capacity options available.

For example, in a previous role, we used a simulation model to optimize production capacity for a new product launch. The model helped us identify bottlenecks in the manufacturing process and allowed us to adjust production schedules and resource allocation to meet anticipated demand, avoiding costly stockouts or excess inventory.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with demand planning and forecasting.

Demand planning and forecasting are critical for effective supply chain management. It’s like predicting the weather – you can’t control it, but accurate predictions help you prepare. I have extensive experience in developing and implementing demand plans, using both qualitative and quantitative methods.

My experience includes:

- Qualitative Forecasting: Utilizing expert opinions, market research, and sales force inputs to understand market trends and potential disruptions.

- Quantitative Forecasting: Employing statistical methods, such as moving averages, exponential smoothing, and ARIMA models, to analyze historical sales data and predict future demand. I’ve also worked with more advanced techniques, such as machine learning algorithms, to incorporate external factors like economic indicators and competitor actions.

- Collaboration: Effectively collaborating with sales, marketing, and product development teams to gather relevant information and ensure alignment between forecast and business objectives.

- Forecast Monitoring and Adjustment: Continuously monitoring forecast accuracy and adjusting models as needed based on actual sales data and market changes. This iterative approach ensures that the forecast remains relevant and reliable.

In one project, we implemented a collaborative forecasting system that significantly improved forecast accuracy by leveraging the combined knowledge of sales representatives, marketing analysts, and data scientists. This reduced inventory holding costs and improved customer service levels by minimizing stockouts.

Q 17. How do you measure the effectiveness of your supply chain strategies?

Measuring the effectiveness of supply chain strategies requires a balanced scorecard approach, considering both financial and operational metrics. Think of it as evaluating a sports team – you need to look at both wins (financial performance) and individual player statistics (operational efficiency).

Key metrics I use include:

- On-Time Delivery Rate: Percentage of orders delivered on or before the promised delivery date.

- Inventory Turnover Rate: How many times inventory is sold and replenished during a specific period.

- Order Fulfillment Cycle Time: The time it takes to process and fulfill an order.

- Cost of Goods Sold (COGS): The direct cost of producing goods sold.

- Customer Satisfaction (CSAT): Measures customer satisfaction with delivery speed, accuracy, and overall experience.

- Supply Chain Resilience: The ability of the supply chain to withstand disruptions and maintain operations.

- Return on Assets (ROA): Measures the profitability of assets invested in the supply chain.

By tracking these metrics over time, I can identify areas for improvement and assess the impact of implemented strategies. For instance, implementing a new warehouse management system might lead to a reduction in order fulfillment cycle time and an increase in inventory turnover, demonstrating the system’s effectiveness.

Q 18. Explain your understanding of different warehousing strategies.

Warehousing strategies are crucial for efficient inventory management. The best strategy depends on factors such as product type, demand variability, and storage space availability. Think of it like organizing a closet – different clothing items need different storage solutions.

Different warehousing strategies include:

- Dedicated Warehousing: Using a single warehouse to store all inventory for a specific product line or customer. This is suitable for high-volume, predictable demand.

- Public Warehousing: Renting space in a shared warehouse facility. This is cost-effective for businesses with fluctuating demand or limited storage space.

- Cross-Docking: Directly transferring goods from receiving to shipping docks without storing them. This is ideal for fast-moving goods and minimizes storage costs.

- Value-Added Warehousing: Performing additional services like packaging, labeling, or kitting within the warehouse. This can improve efficiency and customer satisfaction.

- 3PL Warehousing: Outsourcing warehousing operations to a third-party logistics provider. This can reduce costs and free up internal resources.

In a previous role, I helped a client transition from a dedicated warehousing system to a 3PL solution. This reduced their warehousing costs significantly while improving their overall supply chain agility and scalability.

Q 19. What is your experience with different transportation modes (e.g., air, sea, rail)?

Selecting the optimal transportation mode depends on factors like cost, speed, reliability, and product characteristics. It’s like choosing the right vehicle for a trip – a car for short distances, a plane for long ones. My experience encompasses various transportation modes:

- Air Freight: Fastest but most expensive mode, suitable for high-value, time-sensitive goods.

- Ocean Freight: Cost-effective for large volumes, but slower and less flexible than air freight.

- Rail Freight: Cost-effective for bulky goods over long distances.

- Truck Freight: Flexible and reliable for shorter distances, suitable for smaller shipments.

I’ve worked on projects optimizing transportation networks by leveraging different modes strategically. For example, using air freight for critical components and ocean freight for bulk materials to balance speed and cost-effectiveness. In another instance, I implemented a route optimization software that significantly reduced transportation costs by optimizing delivery routes and consolidating shipments.

Q 20. How do you ensure compliance with relevant regulations in your supply chain?

Compliance is paramount in supply chain management. It’s like following traffic laws – it ensures safety and avoids penalties. My approach to ensuring compliance involves:

- Identifying Relevant Regulations: Thoroughly understanding and staying updated on all applicable regulations, including customs regulations, import/export laws, environmental regulations, and labor laws.

- Implementing Compliance Programs: Developing and implementing comprehensive compliance programs that encompass all aspects of the supply chain, from sourcing raw materials to delivering finished goods.

- Risk Assessment: Regularly assessing supply chain risks related to compliance, and implementing mitigation strategies to address potential issues.

- Documentation and Record Keeping: Maintaining accurate and detailed records of all relevant transactions and activities to facilitate audits and demonstrate compliance.

- Training and Education: Providing regular training to employees on relevant regulations and compliance procedures.

- Auditing and Monitoring: Conducting regular internal audits and external compliance checks to ensure adherence to regulations.

In one project, we developed a comprehensive system for tracking and managing compliance with international trade regulations, avoiding potential delays and penalties. This involved integrating various data sources and implementing automated checks to identify potential compliance issues early on.

Q 21. Describe your experience with implementing or improving supply chain processes.

I have extensive experience in implementing and improving supply chain processes, focusing on efficiency, cost reduction, and customer satisfaction. My approach is data-driven and iterative, always aiming for continuous improvement. Think of it like building a house – you need a solid foundation (data analysis), a well-thought-out plan (process design), and ongoing maintenance (monitoring and adjustments).

Examples of improvements I’ve implemented include:

- Lean Manufacturing: Implementing Lean principles to eliminate waste and improve efficiency in manufacturing processes, leading to significant cost reductions and increased throughput.

- Supply Chain Visibility: Implementing real-time tracking and monitoring systems to enhance supply chain visibility, enabling proactive responses to disruptions and improved decision-making.

- Inventory Optimization: Utilizing advanced inventory management techniques, including ABC analysis and safety stock optimization, to reduce inventory holding costs while maintaining sufficient stock levels.

- Process Automation: Automating manual tasks and processes to reduce operational costs, improve accuracy, and free up resources for higher-value activities.

- Supplier Relationship Management (SRM): Developing strong relationships with key suppliers to improve collaboration, communication, and supply chain resilience.

In one instance, we redesigned a client’s order fulfillment process, implementing automated order routing and warehouse management systems. This resulted in a 20% reduction in order fulfillment cycle time and a 15% decrease in order errors.

Q 22. How do you use data analytics to improve supply chain efficiency?

Data analytics is the backbone of modern supply chain efficiency. It allows us to move beyond gut feelings and reactive decision-making to a proactive, data-driven approach. I utilize various analytical techniques to gain valuable insights from supply chain data, improving forecasting accuracy, optimizing inventory levels, and streamlining logistics.

- Predictive Analytics for Demand Forecasting: I leverage time series analysis, machine learning algorithms (like ARIMA or LSTM), and even incorporate external factors like weather patterns or economic indicators to create more accurate demand forecasts. This minimizes stockouts and overstocking, directly impacting profitability. For example, in my previous role, we implemented a machine learning model that reduced our forecast error by 15%, leading to a significant decrease in warehousing costs.

- Inventory Optimization: Analyzing historical data, sales trends, and lead times helps determine optimal inventory levels for each product. Techniques like ABC analysis (classifying inventory based on value and consumption) and safety stock calculations are essential. This reduces storage costs, minimizes obsolescence, and ensures timely fulfillment of orders.

- Logistics Optimization: Analyzing transportation data (route optimization, carrier performance, delivery times) helps identify bottlenecks and inefficiencies. Tools like route planning software and network analysis can significantly improve delivery speeds and reduce transportation costs. In one project, we optimized delivery routes using a Geographic Information System (GIS) which resulted in a 10% reduction in fuel consumption.

- Supplier Performance Monitoring: Analyzing supplier delivery performance, quality metrics, and lead times allows for proactive identification of potential risks and improved supplier selection and management. This ensures a more reliable and responsive supply chain.

Q 23. Explain your experience with different procurement strategies.

My experience spans a variety of procurement strategies, each tailored to the specific needs of the business and the nature of the goods or services being procured. I’m proficient in both traditional and modern approaches.

- Cost-Based Pricing: This involves negotiating prices based on the supplier’s cost structure. It’s effective for high-volume, standardized goods where transparency is possible. However, it requires a deep understanding of the supplier’s operations.

- Market-Based Pricing: This approach utilizes market data and competitor pricing to determine a fair price. It’s suitable for commoditized products with readily available market information.

- Negotiated Pricing: This involves direct negotiations with suppliers to reach mutually agreeable terms. It’s flexible but requires strong negotiation skills and a good understanding of the supplier landscape.

- Strategic Sourcing: This takes a holistic view, considering total cost of ownership (TCO), supplier relationship management, risk mitigation, and innovation. It aims to build long-term relationships with key suppliers to achieve mutual benefit. This strategy was particularly successful in a previous role where we consolidated suppliers, reducing lead times and improving product quality.

- E-Procurement: Utilizing online platforms for sourcing, bidding, and purchase order management. This streamlines the process, improves transparency, and can lead to significant cost savings.

Q 24. How do you manage relationships with third-party logistics providers (3PLs)?

Managing relationships with 3PLs requires a strategic approach focusing on clear communication, performance monitoring, and collaborative problem-solving. I believe in building strong partnerships based on trust and mutual benefit.

- Service Level Agreements (SLAs): Establishing clear SLAs outlining performance expectations (e.g., delivery times, damage rates, order accuracy) is crucial. These agreements provide a framework for measuring performance and holding the 3PL accountable.

- Regular Communication and Reporting: Maintaining open communication channels through regular meetings, performance reports, and data sharing is essential. This ensures that both parties are aligned and any issues are addressed promptly.

- Performance Monitoring: Continuous monitoring of key performance indicators (KPIs) defined in the SLAs is critical. This allows for early identification of performance gaps and timely corrective actions.

- Collaboration and Problem-Solving: A proactive approach to problem-solving is necessary. When issues arise, collaborative efforts are prioritized to find mutually acceptable solutions. In one instance, we worked closely with our 3PL to implement a new warehouse management system, significantly improving order fulfillment efficiency.

- Relationship Management: Building strong relationships with key personnel within the 3PL is vital. This fosters trust and mutual understanding, making collaboration easier and more effective.

Q 25. Describe your experience with supply chain sustainability initiatives.

Sustainability is no longer a niche concern; it’s integral to successful supply chain management. I’ve been involved in various initiatives focused on reducing the environmental and social impact of our operations.

- Carbon Footprint Reduction: Implementing initiatives to reduce greenhouse gas emissions throughout the supply chain. This includes optimizing transportation routes, using more fuel-efficient vehicles, and exploring sustainable packaging options. In a past project, we partnered with a supplier to transition to recycled packaging, reducing our carbon footprint by 20%.

- Sustainable Sourcing: Prioritizing suppliers who demonstrate commitment to ethical labor practices and environmental responsibility. This involves conducting due diligence, implementing supplier codes of conduct, and engaging in collaborative sustainability projects.

- Waste Reduction: Minimizing waste throughout the supply chain, from manufacturing to packaging and transportation. This includes implementing lean manufacturing principles, optimizing packaging design, and exploring waste recycling programs. We implemented a program to reduce packaging waste by 15% through improved design and material selection.

- Ethical Sourcing: Ensuring that products are sourced ethically and do not contribute to human rights abuses or environmental degradation. This often involves third-party audits and certifications.

Q 26. How would you handle a situation where a key supplier fails to deliver on time?

A key supplier failing to deliver on time is a serious disruption. My response would be multi-faceted and prioritize minimizing the impact on our customers.

- Immediate Communication: Contact the supplier immediately to understand the reason for the delay and potential solutions. Determine the extent of the delay and its impact on our production schedule.

- Risk Assessment: Evaluate the potential impact of the delay on our customers and downstream operations. Quantify the financial consequences of the delay.

- Contingency Planning: Implement a contingency plan, which might include expediting shipments from alternative suppliers, re-prioritizing orders, or utilizing emergency stock (if available). This requires having alternative suppliers identified and pre-qualified.

- Communication with Customers: Communicate with affected customers, providing transparent updates on the situation and revised delivery timelines. Proactive communication mitigates potential damage to our reputation.

- Root Cause Analysis: Once the situation is under control, conduct a root cause analysis to identify the reasons for the failure and implement corrective actions to prevent similar situations in the future. This may involve renegotiating contracts or finding a more reliable supplier.

Q 27. How do you balance cost optimization with service level expectations in supply chain?

Balancing cost optimization and service level expectations is a crucial aspect of supply chain management. It’s not a zero-sum game; both are essential for long-term success. The key is finding the optimal balance point that maximizes profitability while maintaining customer satisfaction.

- Total Cost of Ownership (TCO): Consider the entire cost of the supply chain, not just the initial purchase price. Factors like transportation, warehousing, inventory holding, and potential stockouts need to be considered. A lower initial price might lead to higher overall costs.

- Service Level Agreements (SLAs): Develop clear SLAs with suppliers that outline acceptable performance levels. These SLAs should be based on customer expectations and business needs. Penalties for non-compliance can incentivize suppliers to meet their commitments.

- Demand Forecasting and Inventory Management: Accurate demand forecasting and effective inventory management techniques reduce the risk of stockouts and overstocking. This minimizes both lost sales and excess inventory costs.

- Supply Chain Network Optimization: Optimizing the entire supply chain network, including sourcing locations, transportation routes, and warehousing, can reduce transportation and logistics costs without negatively impacting service levels.

- Technology Implementation: Using supply chain management software and analytics tools improves visibility, allows for data-driven decision making, and helps to optimize costs and service levels simultaneously.

Q 28. What are your thoughts on the future of supply chain technology?

The future of supply chain technology is incredibly exciting, driven by advancements in several key areas.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML will continue to revolutionize forecasting, optimization, and automation across the supply chain. We’ll see more sophisticated predictive models, automated decision-making, and improved inventory management.

- Blockchain Technology: Blockchain offers the potential to enhance transparency and traceability throughout the supply chain, improving accountability and reducing counterfeiting. This is particularly relevant for industries with complex supply chains.

- Internet of Things (IoT): The proliferation of IoT sensors provides real-time visibility into inventory levels, transportation conditions, and equipment performance. This allows for proactive management and reduces disruptions.

- Robotics and Automation: Automation in warehouses and distribution centers will continue to increase efficiency and reduce labor costs. This includes the use of autonomous vehicles, robots, and automated guided vehicles (AGVs).

- Cloud Computing and Data Analytics: The cloud offers scalability, cost-effectiveness, and improved data accessibility. Advanced analytics platforms will enable better decision-making based on real-time data.

However, the adoption of these technologies requires careful consideration of data security, integration challenges, and the need for skilled workforce development.

Key Topics to Learn for Your Supply Chain Management Interview

- Demand Planning & Forecasting: Understanding forecasting methods (e.g., moving average, exponential smoothing), their applications, and limitations. Consider how inaccuracies impact the supply chain.

- Inventory Management: Explore different inventory control techniques (e.g., EOQ, JIT), their practical implications, and how to optimize inventory levels to balance cost and service levels. Discuss scenarios where you’ve had to manage stockouts or excess inventory.

- Procurement & Sourcing: Review strategies for supplier selection, negotiation, and relationship management. Be prepared to discuss your experience with sourcing strategies like global sourcing vs. regional sourcing.

- Logistics & Transportation: Understand various modes of transportation, their cost-effectiveness, and the impact on delivery times. Discuss experiences optimizing logistics networks or resolving transportation challenges.

- Supply Chain Risk Management: Explore different types of supply chain risks (e.g., natural disasters, geopolitical instability, supplier disruptions) and strategies for mitigation. Prepare examples showcasing your proactive risk assessment and management skills.

- Supply Chain Technology & Analytics: Familiarize yourself with common supply chain software (e.g., ERP systems) and data analytics techniques used for optimization and decision-making. Discuss how data has informed your decisions in the past.

- Lean Principles & Continuous Improvement: Understand lean methodologies like Kaizen and Six Sigma, and how they can be applied to improve efficiency and reduce waste within the supply chain. Be prepared to discuss examples where you’ve implemented process improvements.

Next Steps: Unlock Your Supply Chain Career

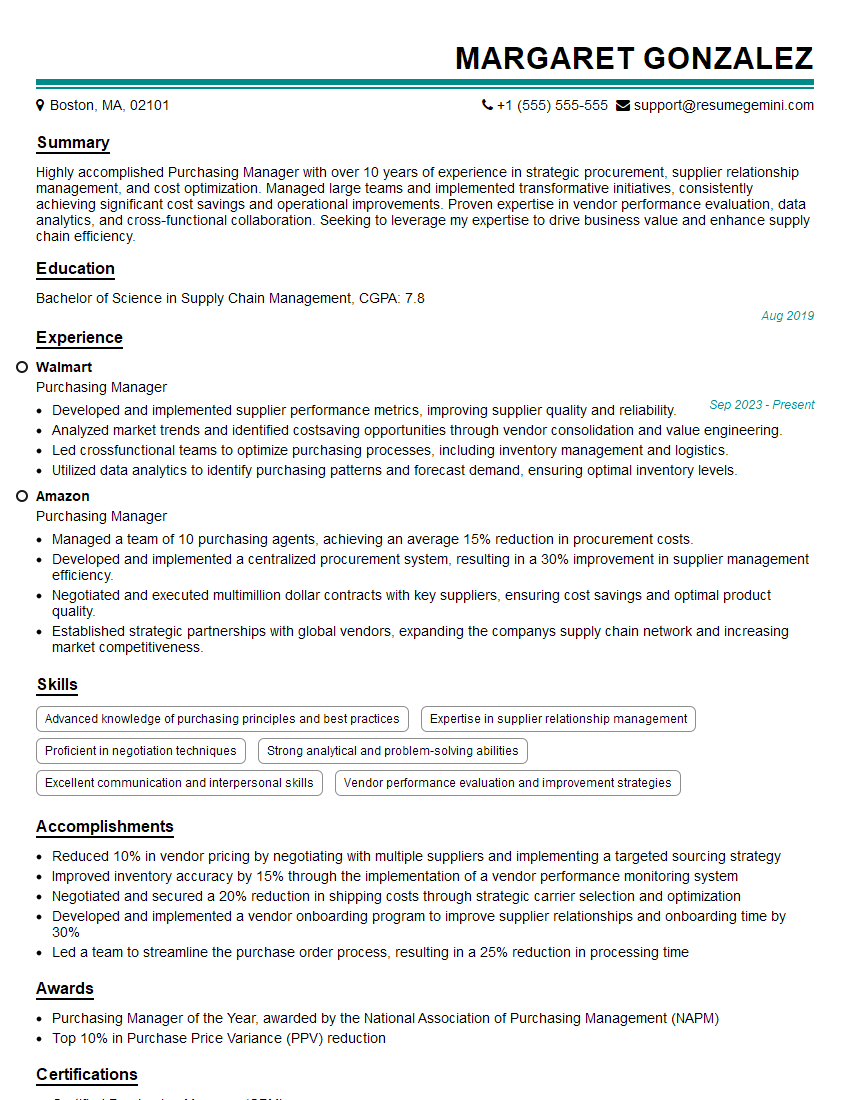

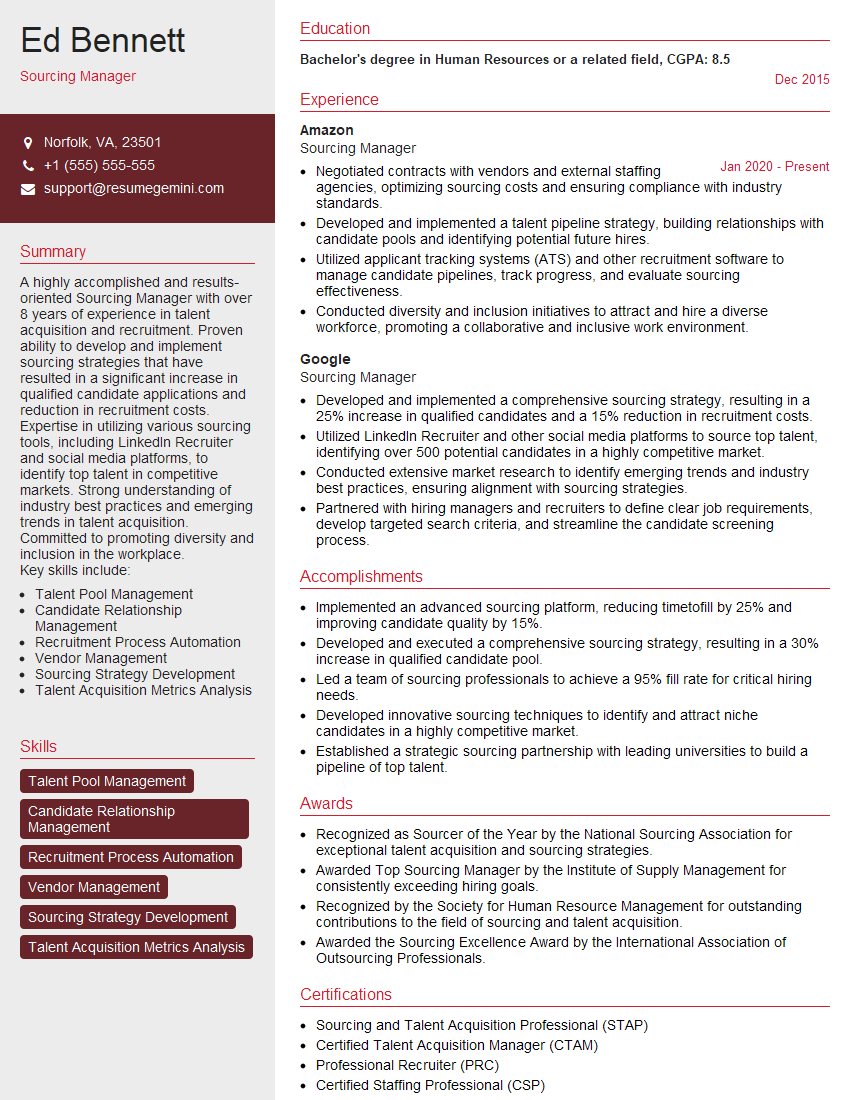

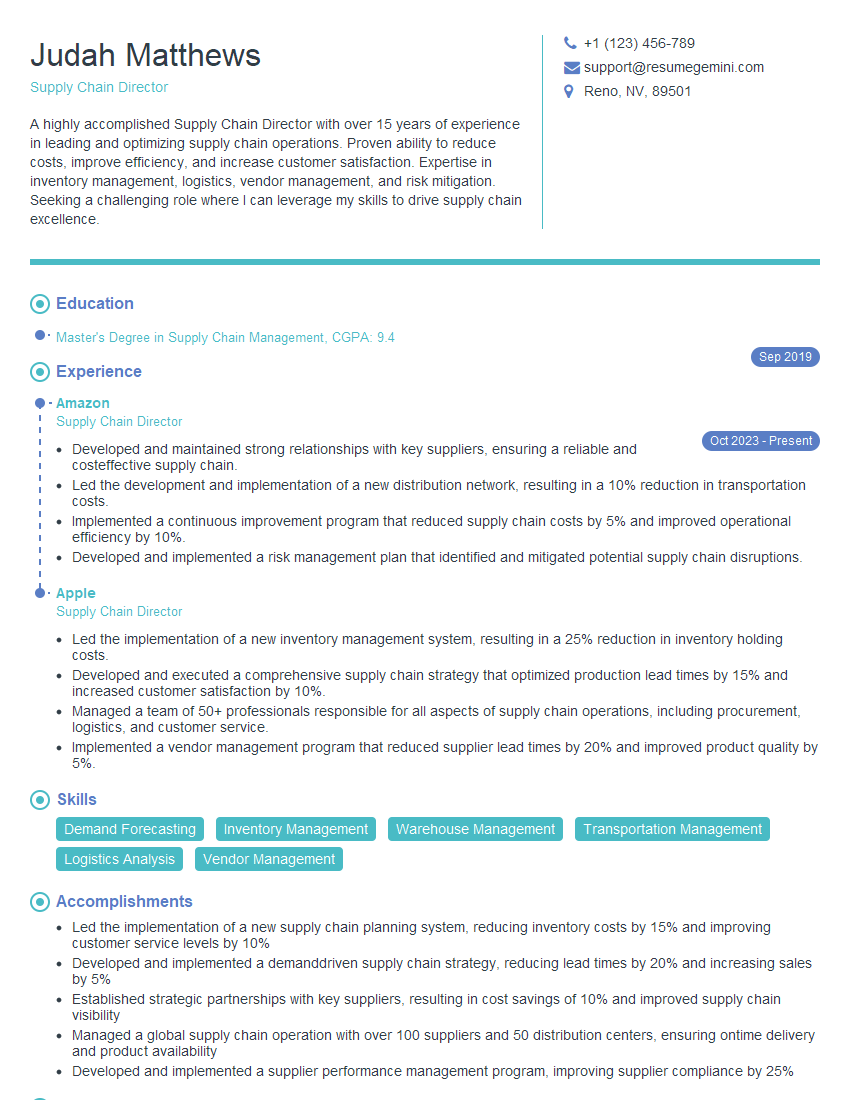

Mastering these key areas of supply chain management is crucial for career advancement. A strong understanding of these concepts, coupled with practical experience, will significantly enhance your interview performance and job prospects. Creating an ATS-friendly resume is vital to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to supply chain management are available on ResumeGemini to help guide you. Take control of your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO