The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience with electrical systems interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience with electrical systems Interview

Q 1. Explain Ohm’s Law and its applications.

Ohm’s Law is a fundamental principle in electrical engineering that describes the relationship between voltage (V), current (I), and resistance (R) in a circuit. It states that the voltage across a conductor is directly proportional to the current flowing through it, provided the temperature remains constant. The mathematical representation is: V = I * R

Applications: Ohm’s Law is incredibly versatile. We use it to calculate any one of the three variables (V, I, or R) if we know the other two. For example, we might use it to determine the current draw of a device given its voltage rating and resistance. In circuit design, it’s crucial for sizing components like resistors to ensure the correct current flows through a circuit. It’s also fundamental in analyzing power consumption (P = V * I = I² * R = V²/R), a critical aspect of designing efficient and safe systems.

Example: Imagine you have a 12V battery connected to a lightbulb with a resistance of 6 ohms. Using Ohm’s Law, you can calculate the current: I = V/R = 12V / 6Ω = 2A. This means 2 amperes of current will flow through the lightbulb.

Q 2. Describe different types of electrical circuits (series, parallel, etc.).

Electrical circuits can be categorized into several types, with series and parallel circuits being the most basic.

- Series Circuit: In a series circuit, components are connected end-to-end, forming a single path for current flow. The current is the same through each component. The total resistance is the sum of individual resistances (

Rtotal = R1 + R2 + R3 ...). If one component fails, the entire circuit breaks. - Parallel Circuit: In a parallel circuit, components are connected across each other, providing multiple paths for current flow. The voltage is the same across each component. The total resistance is less than the smallest individual resistance (

1/Rtotal = 1/R1 + 1/R2 + 1/R3 ...). If one component fails, the others continue to operate. - Combination Circuits: Many real-world circuits are a combination of series and parallel arrangements, requiring more complex analysis to determine total resistance and current flow through each branch.

Example: A simple Christmas light string is often a series circuit. If one bulb burns out, the entire string goes dark. Household wiring, on the other hand, is typically a parallel circuit, so if one appliance malfunctions, the others continue to function.

Q 3. What are the safety precautions when working with high-voltage systems?

Working with high-voltage systems demands stringent safety precautions. A single mistake can be fatal. Here are some key safety measures:

- Lockout/Tagout Procedures: Before working on any high-voltage equipment, always follow established lockout/tagout procedures to prevent accidental energization.

- Personal Protective Equipment (PPE): Use appropriate PPE, including insulated gloves, safety glasses, and arc-flash protective clothing, depending on the voltage level.

- Proper Training and Certification: Only qualified and trained personnel should work on high-voltage systems. Relevant certifications are essential.

- Grounding and Bonding: Ensure proper grounding and bonding to prevent electrical shocks and equipment damage.

- Voltage Testing: Always verify that the circuit is de-energized before starting work using appropriate voltage testing equipment.

- Emergency Response Plan: Be aware of the emergency response plan and procedures in case of accidents.

Never compromise on safety. High-voltage work is inherently dangerous. A cautious and methodical approach is crucial to minimizing risks.

Q 4. Explain the difference between AC and DC current.

AC (Alternating Current) and DC (Direct Current) are two fundamental types of electrical current, differing primarily in the direction of electron flow.

- DC: Electrons flow in one consistent direction. Batteries are the most common source of DC power. The voltage and current remain relatively constant over time.

- AC: Electrons periodically change direction, oscillating back and forth. This oscillation is typically sinusoidal. The voltage and current vary over time. AC power is the standard for electrical grids worldwide.

Key Differences Summarized:

| Feature | DC | AC |

|---|---|---|

| Electron Flow | One direction | Periodically reverses |

| Voltage/Current | Constant | Variable |

| Source | Batteries, solar cells | Power plants, generators |

| Transmission | Less efficient over long distances | More efficient over long distances |

The choice between AC and DC depends on the application. DC is often preferred for electronic devices, while AC is more efficient for long-distance power transmission.

Q 5. How do you troubleshoot a faulty electrical circuit?

Troubleshooting a faulty electrical circuit involves a systematic approach:

- Safety First: Always disconnect the power before starting any troubleshooting. Use a multimeter to verify the circuit is de-energized.

- Visual Inspection: Carefully examine the circuit for any obvious problems, such as loose connections, damaged wires, or burnt components.

- Use a Multimeter: Use a multimeter to measure voltage, current, and resistance at various points in the circuit to identify the fault location. Compare the readings to the expected values based on the circuit design.

- Check Individual Components: If a specific component is suspected, test it individually to determine if it’s faulty. This might involve replacing components one at a time if unsure.

- Trace the Circuit: If the problem is not easily identifiable, systematically trace the circuit, checking connections and components along the way.

- Consult Schematics: Use the circuit’s schematic diagram to aid in troubleshooting. The schematic provides a visual representation of the circuit’s components and connections.

- Consult Documentation: Refer to any relevant documentation, such as manuals or specifications, for troubleshooting guidance.

Troubleshooting is often a process of elimination. Through systematic testing and careful observation, the fault can usually be identified and rectified.

Q 6. Describe your experience with electrical schematics and blueprints.

I have extensive experience interpreting and working with electrical schematics and blueprints. My experience includes using schematics to understand the functionality of complex circuits, identify component values, and troubleshoot problems. I’m proficient in reading various schematic symbols and notations, including those for common components like resistors, capacitors, inductors, transistors, and integrated circuits. I’ve also used blueprints to understand the physical layout of electrical systems in buildings and industrial settings, ensuring proper placement of equipment and wiring.

For example, in a recent project, I used schematics to design a control system for a robotic arm. The schematics helped to visualize the interaction of various sensors, microcontrollers, and actuators, allowing me to select the correct components and ensure seamless integration. Additionally, I’ve used blueprints to plan and execute the wiring of a large industrial power distribution system. This included calculating wire sizes and cable routing based on the requirements of the equipment and safety regulations.

Q 7. What is grounding and why is it important?

Grounding, also known as earthing, is the connection of an electrical system to the earth. It provides a low-resistance path for fault currents to flow back to the source, preventing hazardous voltage buildup and protecting people and equipment.

Importance:

- Safety: Grounding provides a path for fault currents to flow to the earth, preventing dangerous voltages from appearing on exposed conductive surfaces, thus protecting individuals from electric shock.

- Equipment Protection: Grounding helps protect equipment from damage caused by voltage surges and lightning strikes. The ground acts as a sink for excess current, preventing damage to sensitive electronics.

- Noise Reduction: Grounding helps to reduce electrical noise in circuits, improving signal quality and preventing interference.

Example: The metal casing of an appliance is often grounded to prevent electric shock. If a fault occurs inside the appliance, the current will flow through the grounding wire to the earth, instead of through the user.

Q 8. Explain the concept of impedance and its significance.

Impedance is the opposition to the flow of alternating current (AC) in a circuit. Unlike resistance, which only considers the opposition to direct current (DC), impedance considers both resistance and reactance. Reactance arises from the energy storage elements in the circuit, namely inductors and capacitors.

Think of it like this: resistance is like friction in a pipe slowing down water flow. Impedance is like friction plus the pressure build-up from bends and constrictions in the pipe, further hindering the flow. The unit of impedance is the ohm (Ω), just like resistance.

Significance: Understanding impedance is crucial for designing efficient AC circuits. It helps in calculating current flow, voltage drops, and power transfer. Mismatched impedance can lead to signal reflections, power loss, and damage to equipment. For example, in audio systems, impedance matching between amplifier and speakers is essential for optimal sound quality and preventing damage to the amplifier.

For instance, a circuit with a 10Ω resistor and a 5Ω inductive reactance will have an impedance greater than 10Ω, depending on the phase relationship between the resistance and reactance. The calculation of impedance requires considering both magnitude and phase.

Q 9. What are the different types of transformers and their applications?

Transformers are passive electrical devices that transfer electrical energy between two or more circuits through electromagnetic induction. They are primarily used to change the voltage level of an AC power supply. There are various types, each suited for specific applications:

- Step-up Transformer: Increases voltage. Used in power transmission to minimize power loss over long distances.

- Step-down Transformer: Decreases voltage. Used in household appliances to reduce the high voltage from the power grid to a safe level for operation.

- Isolation Transformer: Provides electrical isolation between circuits, preventing ground faults and enhancing safety. Commonly used in medical equipment.

- Autotransformer: Uses a single winding with a tap to change the voltage. Simpler and more compact than two-winding transformers, but lacks the isolation benefit.

- Instrument Transformer: Used for measurement and protection purposes. Current transformers (CTs) measure high currents, while potential transformers (PTs) measure high voltages safely.

The choice of transformer depends heavily on the application. For instance, power distribution networks rely on large step-up and step-down transformers, while a small electronic device might use a miniaturized step-down transformer.

Q 10. Describe your experience with PLC programming.

I have extensive experience in PLC programming using various platforms like Siemens TIA Portal, Rockwell Automation Studio 5000, and Allen-Bradley RSLogix 5000. I’ve worked on projects involving process automation, robotics control, and industrial machinery.

My experience encompasses designing ladder logic programs, configuring input/output modules, implementing communication protocols (e.g., Ethernet/IP, Profibus), and integrating PLCs with SCADA systems. I’m proficient in using timers, counters, comparators, and other functional blocks to create robust and efficient control systems. I’ve also worked extensively with PID controllers for precise process regulation. One notable project involved designing a PLC program for an automated assembly line, significantly improving production efficiency.

I’m comfortable troubleshooting PLC programs, identifying and resolving hardware and software issues. I always ensure my code is well-documented and easily maintainable, a key factor in efficient project lifecycle management. Furthermore, I actively seek opportunities to expand my knowledge with new PLC technologies and programming practices.

Q 11. How do you select the appropriate size of wire for a given application?

Selecting the appropriate wire size depends on several factors: the current carrying capacity, the voltage drop, the ambient temperature, and the installation method. A larger wire gauge (smaller number) indicates a thicker wire with higher current carrying capacity. We use tables and online calculators that take into account these factors.

The process typically involves these steps:

- Determine the required current: This is based on the load’s power consumption and voltage. For example, a 1200W heater operating at 120V requires 10A (Power/Voltage).

- Consider voltage drop: Excessive voltage drop can lead to poor performance or equipment malfunction. Consult tables or calculators to find the appropriate wire size to maintain acceptable voltage drop (typically less than 3%).

- Account for ambient temperature and installation method: Higher temperatures or conduit installation necessitate derating the wire’s current carrying capacity. Consult the relevant NEC (National Electrical Code) or other applicable standards for derating factors.

- Select the appropriate wire size: Based on the calculated current, voltage drop, temperature and installation method, select the wire size from a table or calculator that satisfies all requirements. Always choose a wire size that’s larger than the minimum calculated size to allow for future load increases.

For example, if a calculation shows a minimum of 8 AWG wire is needed, selecting a 6 AWG wire provides a safety margin for increased future loads.

Q 12. Explain the principles of motor control.

Motor control involves regulating the speed, torque, and direction of an electric motor to meet the demands of the application. This is achieved through various methods, often involving electronic controllers.

Key principles include:

- Speed Control: This can be achieved through methods like varying the voltage or frequency supplied to the motor (for AC motors) or altering the armature current (for DC motors). Pulse Width Modulation (PWM) is a common technique for controlling the voltage and frequency.

- Torque Control: Maintaining desired torque (rotational force) is essential for many applications. This can be managed by adjusting the motor’s current. High torque is required for applications such as lifting heavy loads.

- Direction Control: Reversing the polarity of the motor’s supply voltage reverses its rotation. This is commonly achieved using contactors or solid-state relays.

- Protection: Essential features of motor control include overcurrent protection, thermal protection, and short-circuit protection to prevent motor damage.

The complexity of motor control systems varies widely, from simple on/off control to sophisticated closed-loop systems employing feedback sensors to maintain precise control.

Q 13. What are the different types of electrical motors and their characteristics?

Several types of electrical motors exist, each with unique characteristics:

- DC Motors: These are relatively simple and easy to control. Types include brushed DC motors (simpler but require maintenance), brushless DC motors (longer lifespan, more efficient), and stepper motors (precise rotational control). Applications range from small appliances to robotics.

- AC Motors: More common in industrial settings due to their robustness and efficiency. Types include induction motors (simple and rugged, widely used in industrial applications), synchronous motors (precise speed control, used in applications requiring constant speed), and servo motors (precise control, used in robotics and automation).

- Universal Motors: Can operate on both AC and DC power, but often less efficient than specialized AC or DC motors. Used in portable power tools.

- Stepper Motors: Provide precise, step-by-step rotational movement, commonly used in printers, 3D printers, and CNC machines.

The selection of an appropriate motor depends on the specific application requirements such as required speed, torque, efficiency, cost, and maintenance requirements.

Q 14. Describe your experience with SCADA systems.

My experience with SCADA (Supervisory Control and Data Acquisition) systems includes designing, implementing, and maintaining SCADA systems for various industrial processes. I’ve worked with several SCADA platforms, including Wonderware InTouch, Siemens WinCC, and Rockwell FactoryTalk.

My responsibilities have included:

- System Design: Defining the scope of the SCADA system, selecting hardware and software components, and developing the system architecture.

- Database Design: Designing and implementing databases to store historical and real-time data.

- HMI Development: Creating user-friendly graphical interfaces for operators to monitor and control processes.

- Data Acquisition: Configuring communication protocols (e.g., Modbus, Profibus) to acquire data from various field devices such as PLCs, sensors, and actuators.

- Alarm Management: Configuring alarm systems to alert operators of abnormal conditions.

- Reporting and Analytics: Generating reports and analyzing data to improve process efficiency and optimize operations.

I’ve worked on projects involving water treatment, power generation, and manufacturing processes, successfully implementing SCADA systems that enhance operational efficiency and safety. A notable example includes implementing a SCADA system for a water treatment plant, resulting in improved water quality monitoring and reduced operational costs.

Q 15. What are your experiences with electrical power distribution systems?

My experience with electrical power distribution systems spans over ten years, encompassing design, implementation, and maintenance of various systems, from low-voltage residential installations to high-voltage industrial setups. I’ve worked on projects involving substation design, transmission line analysis, and the integration of renewable energy sources into existing grids. For instance, on a recent project, I was responsible for optimizing the distribution network of a large manufacturing plant, leading to a 15% reduction in energy losses through strategic placement of transformers and improved cable routing. I am proficient in using software like ETAP and EasyPower for system modeling and analysis.

- Substation Design: Designing and overseeing the construction of substations, including protection and control systems.

- Transmission Line Analysis: Performing load flow studies, short circuit calculations, and stability analysis to ensure reliable power delivery.

- Renewable Energy Integration: Integrating solar and wind power generation into existing distribution networks, addressing technical challenges associated with intermittent energy sources.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of power factor and its correction.

Power factor represents the efficiency of electrical power utilization. Ideally, it should be 1 (or 100%), meaning the current and voltage are perfectly in phase. However, inductive loads (like motors) cause the current to lag behind the voltage, resulting in a power factor less than 1. This means we’re paying for more power than we’re actually using.

Power factor correction involves adding capacitive elements (capacitors) to the system to counteract the inductive reactance. These capacitors bring the current and voltage closer to being in phase, improving the power factor. This leads to reduced energy losses, lower electricity bills, and improved system efficiency.

Example: Imagine a factory with numerous induction motors. A low power factor (e.g., 0.7) means the factory is drawing more current than necessary to perform the same work. By installing capacitor banks, the power factor can be improved to, say, 0.95, significantly reducing the current draw and improving efficiency. The size of the capacitor bank is carefully calculated based on the load characteristics and desired power factor improvement.

Q 17. How do you perform a load calculation?

A load calculation determines the total electrical demand of a building or system. It’s crucial for proper system design and ensuring adequate power supply. The process involves identifying all the loads (lighting, appliances, HVAC, motors, etc.), determining their individual power requirements, and adding them together to find the total load. Different methods exist, depending on the complexity of the system. For simple systems, a straightforward summation might suffice. More complex systems might require considering diversity factors (not all loads operate simultaneously), demand factors (peak demand is usually less than the sum of individual loads), and other factors like future expansion needs.

Steps:

- Identify all loads: List every electrical appliance, fixture, and equipment.

- Determine individual loads: Note the voltage and current or power rating (watts, kilowatts) of each load.

- Apply diversity and demand factors: If applicable, apply appropriate factors to account for simultaneous operation and peak demand.

- Calculate total load: Sum the individual loads (after applying factors, if any).

- Add safety margin: Include a safety margin (usually 20-25%) to account for future expansion and unforeseen loads.

Example: For a residential building, I might use readily available data for appliances and lighting, while for industrial settings, I would use manufacturer data sheets and possibly conduct field measurements.

Q 18. What is your experience with electrical safety standards (e.g., NEC)?

My experience with electrical safety standards, primarily the National Electrical Code (NEC), is extensive. I am thoroughly familiar with its requirements for wiring methods, overcurrent protection, grounding, and other safety aspects. I’ve consistently designed and implemented systems in strict accordance with the NEC, ensuring compliance through proper documentation and inspections. I’m also familiar with other relevant standards, like OSHA regulations for workplace safety. I ensure all my designs and work practices prioritize safety, mitigating risks through proper grounding, appropriate circuit breakers, and regular system inspections.

Example: In a recent project involving a commercial kitchen, I meticulously followed NEC Article 517 (Commercial Cooking Equipment) to ensure the electrical system could handle the high loads and specific requirements of commercial cooking appliances. This included appropriate wiring, overcurrent protection, and specialized grounding procedures.

Q 19. Describe your experience with relay protection schemes.

I have significant experience with relay protection schemes, including design, testing, and troubleshooting. I’m proficient in various types of relays, such as overcurrent, differential, distance, and ground fault relays. My experience involves working with both numerical and electromechanical relays. I understand the importance of proper coordination between relays to ensure selective fault clearing, minimizing the impact of faults on the system. I’ve used relay testing equipment and software to commission and maintain protection systems.

Example: On a power transmission line project, I designed a protection scheme using distance relays to provide fast and selective fault clearing, minimizing the impact of faults on the system and preventing cascading failures. The scheme involved careful coordination of various relay settings to ensure the correct relay tripped for each type of fault.

Q 20. What is your experience with fault current calculations?

Fault current calculations are crucial for ensuring the proper sizing of protective devices and ensuring system safety. I’m proficient in performing these calculations using various methods, including software tools like ETAP and manual calculations based on impedance and Ohm’s Law. I consider various factors influencing fault current, such as source impedance, cable impedance, and transformer characteristics. Accurate fault current calculations are essential for selecting appropriate circuit breakers, fuses, and other protective devices that can safely interrupt fault currents without damage.

Example: When designing a new industrial facility, I performed a comprehensive short-circuit study to determine the available fault current at various points in the electrical system. This information was critical in selecting the appropriate circuit breakers and other protective devices capable of safely interrupting these high fault currents.

Q 21. Explain your understanding of harmonic distortion in power systems.

Harmonic distortion in power systems refers to the presence of non-linear loads that generate harmonic currents. These currents are multiples of the fundamental frequency (50Hz or 60Hz) and can cause several problems, including increased heating in equipment, malfunction of sensitive electronics, and reduced power system efficiency. Non-linear loads like rectifiers, variable-speed drives, and switching power supplies are common culprits. Understanding harmonic distortion is crucial for designing systems that can mitigate its effects. Techniques include using harmonic filters, selecting equipment with low harmonic generation, and careful system grounding.

Example: A factory using large numbers of variable-frequency drives (VFDs) might experience significant harmonic distortion. This could lead to premature failure of capacitors in the power system. To address this, harmonic filters could be strategically placed to mitigate the harmonic currents and protect sensitive equipment.

Q 22. How do you ensure electrical safety in a workplace?

Ensuring electrical safety in the workplace is paramount and involves a multi-faceted approach. It’s not just about following regulations; it’s about fostering a safety-conscious culture.

- Regular Inspections: Thorough and routine inspections of all electrical equipment, wiring, and safety devices are crucial. This includes checking for frayed wires, damaged insulation, overloaded circuits, and proper grounding. Think of it like a doctor’s checkup for your electrical system – preventative maintenance is key.

- Lockout/Tagout Procedures: Before any electrical work, a strict lockout/tagout (LOTO) procedure must be followed to de-energize equipment and prevent accidental re-energization. This prevents potentially fatal electrical shocks. It’s like turning off the gas before working on a gas appliance – a critical safety measure.

- Personal Protective Equipment (PPE): Employees working with electricity must always use appropriate PPE, including insulated gloves, safety glasses, and arc flash suits depending on the voltage. This is their personal shield against potential hazards. Think of it as a knight’s armor for electrical work.

- Training and Awareness: Comprehensive training programs are essential to educate employees on electrical hazards, safe work practices, and emergency procedures. Regular refresher courses keep safety top of mind.

- Grounding and Bonding: Proper grounding and bonding techniques are vital to prevent electrical shocks and equipment damage. Grounding provides a safe path for fault currents to flow to earth, preventing dangerous build-up.

- Compliance with Regulations: Strict adherence to all relevant electrical codes and regulations is non-negotiable. This ensures the workplace is meeting minimum safety standards.

By implementing and enforcing these measures, we significantly reduce the risk of electrical accidents and create a safer working environment.

Q 23. Describe your experience with renewable energy systems.

My experience with renewable energy systems spans several projects, focusing primarily on photovoltaic (PV) solar and wind energy integration. I’ve been involved in the design, installation, and commissioning of several grid-tied solar systems for residential and commercial applications. This involved selecting appropriate inverters, designing optimal array layouts to maximize energy yield, and ensuring compliance with grid interconnection standards.

With wind energy, my experience is more focused on the grid integration aspects. I’ve worked on projects assessing the impact of variable wind power generation on the stability of the electrical grid. This includes studying power quality issues and developing solutions for efficient energy storage and management using battery systems to smooth out the intermittent nature of wind power. One project specifically involved optimizing a hybrid system combining solar and wind power with battery storage to achieve higher reliability and reduce reliance on the grid.

Q 24. What are your experiences with different types of sensors and transducers?

I have extensive experience with a wide range of sensors and transducers. This includes:

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors for various temperature monitoring applications, from industrial process control to building automation systems.

- Pressure Sensors: Strain gauge-based pressure transducers, piezoelectric sensors, and capacitive pressure sensors for applications in fluid dynamics, hydraulic systems, and HVAC.

- Flow Sensors: Various types, including ultrasonic flow meters, vortex shedding flow meters, and magnetic flow meters for applications in industrial pipelines, water distribution networks, and environmental monitoring.

- Light Sensors: Photodiodes, photoresistors, and phototransistors for applications in lighting control systems, robotics, and automated manufacturing.

- Position Sensors: Potentiometers, LVDTs (Linear Variable Differential Transformers), and encoders for accurate measurement of position and movement in industrial machinery and robotics.

My experience extends to integrating these sensors into various control systems, often involving signal conditioning circuits to amplify, filter, and convert sensor signals into usable data for control algorithms and data logging.

Q 25. Explain your understanding of circuit breakers and their functionality.

Circuit breakers are safety devices designed to protect electrical circuits from overcurrent conditions. They automatically interrupt the flow of current when a fault occurs, such as a short circuit or overload, preventing damage to equipment and reducing the risk of fire or injury.

They work by detecting excessive current flow. When the current exceeds a predetermined threshold, a mechanism within the circuit breaker trips, breaking the electrical connection. There are several types, including:

- Thermal Circuit Breakers: These use a bimetallic strip that bends and breaks the circuit when it heats up due to excessive current.

- Magnetic Circuit Breakers: These use an electromagnet that creates enough force to trip the breaker when the current exceeds a certain level.

- Thermomagnetic Circuit Breakers: These combine both thermal and magnetic tripping mechanisms for broader protection.

The functionality is essential for safety and reliability. Consider a household circuit overloaded with too many appliances. A circuit breaker prevents the wires from overheating and potentially causing a fire. They’re the unsung heroes of electrical safety.

Q 26. Describe your experience with electrical testing equipment.

My experience encompasses a wide range of electrical testing equipment, from basic multimeters to sophisticated diagnostic tools. I’m proficient in using:

- Multimeters: For measuring voltage, current, resistance, and continuity – essential for basic troubleshooting.

- Clamp Meters: For measuring current without breaking the circuit, useful in high-current applications.

- Insulation Testers (Meggers): For measuring the insulation resistance of cables and equipment, crucial for identifying insulation breakdown.

- Ground Resistance Testers: To measure the effectiveness of grounding systems, preventing potential shock hazards.

- Oscilloscope: For analyzing waveforms and identifying electrical faults in complex circuits; this tool is crucial for diagnosing dynamic issues.

- Power Quality Analyzers: To monitor and analyze power quality parameters, identifying issues such as harmonics and voltage sags.

Proficiency with these tools ensures accurate testing, efficient troubleshooting, and safe operation of electrical systems.

Q 27. What are your problem-solving approaches when dealing with electrical issues?

My problem-solving approach to electrical issues is systematic and thorough. I typically follow these steps:

- Safety First: Always prioritize safety. De-energize the circuit if possible and use appropriate PPE.

- Gather Information: Thoroughly investigate the problem. What are the symptoms? When did it start? What changes were made recently?

- Visual Inspection: Carefully examine the system for obvious problems like loose connections, damaged insulation, or overheating components.

- Testing and Measurement: Use appropriate testing equipment to measure voltages, currents, and resistances to pinpoint the fault.

- Fault Isolation: Systematically isolate the faulty component or circuit section using tracing techniques and testing procedures.

- Repair or Replacement: Once the fault is identified, repair or replace the faulty component, adhering to safety standards and best practices.

- Verification: After the repair, test the system thoroughly to ensure the problem is resolved and the system is operating safely.

- Documentation: Record all findings, repairs, and tests for future reference.

This approach ensures a comprehensive and effective solution while minimizing downtime and risk.

Q 28. Describe a challenging electrical project you worked on and how you overcame it.

One challenging project involved troubleshooting a complex industrial control system experiencing intermittent shutdowns. The system controlled a large manufacturing process, and these shutdowns caused significant production losses.

Initial investigations revealed no obvious faults. Using an oscilloscope, we detected anomalous voltage spikes coinciding with the shutdowns. These spikes were too short and erratic to be identified with standard multimeters. After careful investigation and signal tracing, we pinpointed the source to a faulty capacitor in the power supply unit. This capacitor was responsible for smoothing out voltage fluctuations. The spikes were caused by the capacitor failing intermittently.

Replacing the capacitor resolved the issue, and the system operated smoothly afterward. The challenge lay in isolating the intermittent fault given the complex nature of the system and the subtle nature of the failure. The project emphasized the importance of utilizing advanced diagnostic equipment and a systematic, investigative approach to problem-solving.

Key Topics to Learn for Electrical Systems Interviews

- Fundamentals of Circuit Analysis: Understanding Ohm’s Law, Kirchhoff’s Laws, and basic circuit theorems is crucial for analyzing and troubleshooting electrical systems. Consider practicing different circuit configurations and solving related problems.

- AC/DC Systems: Differentiate between AC and DC power, their applications, and the components used in each system (transformers, rectifiers, inverters). Be ready to discuss their advantages and disadvantages in various contexts.

- Electrical Power Distribution: Familiarize yourself with the principles of power generation, transmission, and distribution. Understanding different voltage levels, protection devices (circuit breakers, fuses), and safety regulations is essential.

- Electrical Machines: Gain a solid understanding of various electrical machines like motors (DC, AC induction, synchronous) and generators. Know their operating principles, characteristics, and applications.

- Control Systems: Explore basic control system concepts, including feedback loops, PID controllers, and their application in controlling electrical systems. Understanding programmable logic controllers (PLCs) is a significant advantage.

- Troubleshooting and Diagnostics: Practice identifying and resolving common problems in electrical systems. Discuss methodologies for fault finding, using appropriate tools and techniques.

- Safety Regulations and Codes: Demonstrate awareness of relevant electrical safety regulations and codes (e.g., NEC in the US). This highlights your commitment to safe work practices.

- Practical Application: Be prepared to discuss real-world projects or experiences where you applied your knowledge of electrical systems. Focus on your problem-solving skills and contributions to the project’s success.

Next Steps

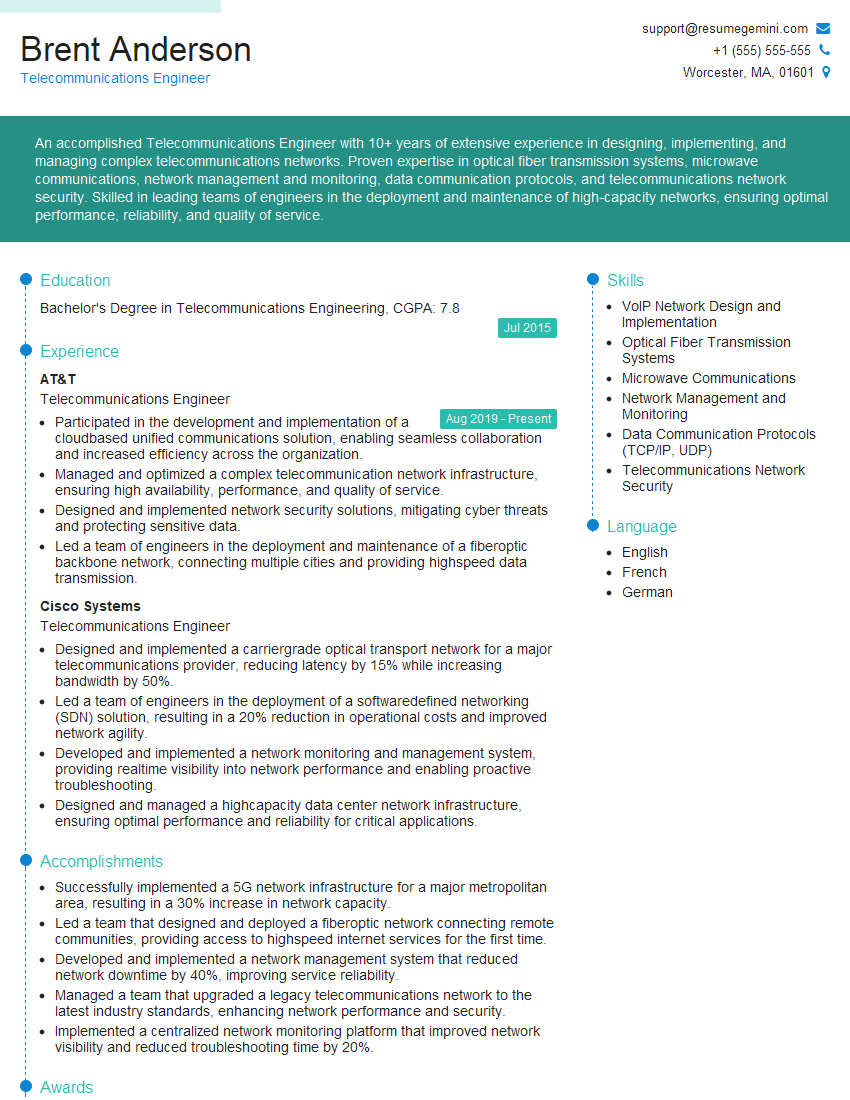

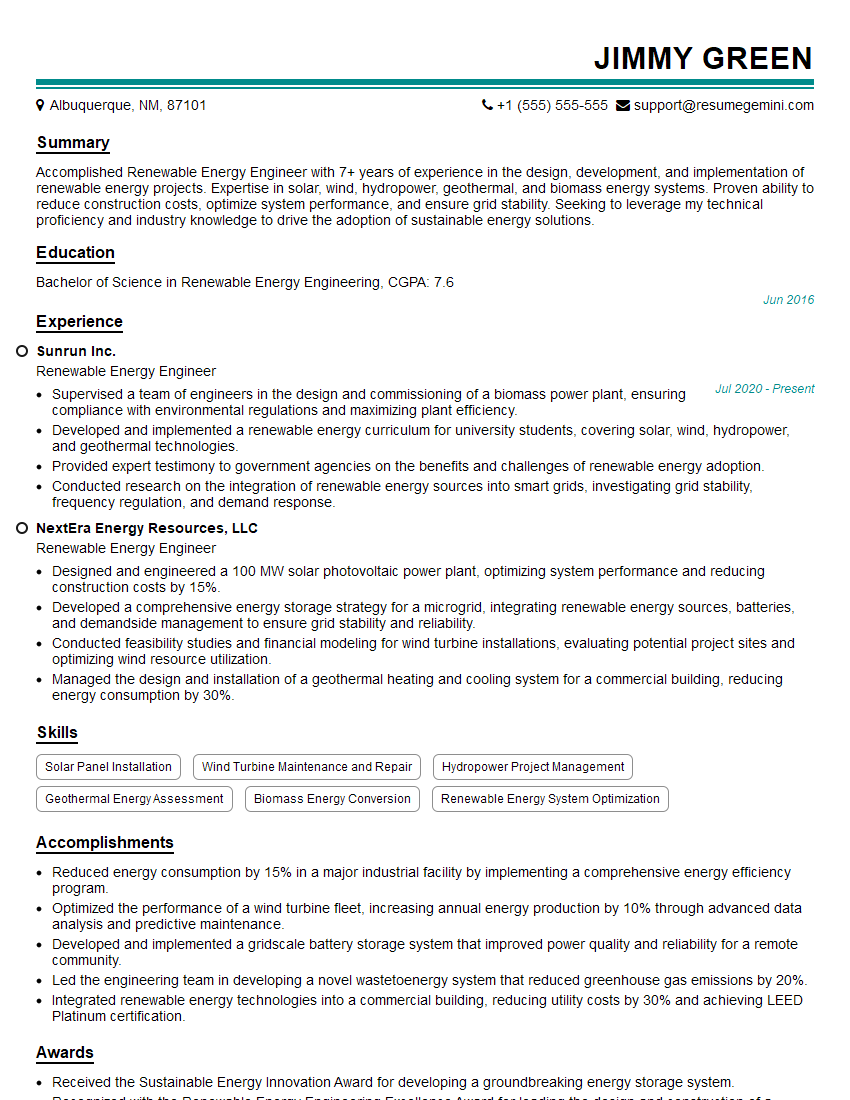

Mastering electrical systems knowledge is vital for career advancement in various engineering and technical fields, opening doors to exciting opportunities and higher earning potential. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini can significantly enhance your resume-building experience, helping you create a professional document that showcases your skills and experience effectively. Examples of resumes tailored to electrical systems experience are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO