Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Experience with using disinfectants and sanitizers interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Experience with using disinfectants and sanitizers Interview

Q 1. What are the key differences between disinfectants and sanitizers?

Disinfectants and sanitizers are both used to reduce the number of germs on surfaces, but they differ significantly in their effectiveness. Think of it like this: sanitizing is like tidying a room, while disinfecting is like giving it a deep clean.

Sanitizers reduce the number of microorganisms to a safe level, as defined by public health standards. They typically lower the microbial population by at least 99.9%. They’re great for everyday use in food preparation areas, for example.

Disinfectants, on the other hand, kill or inactivate a wider range of microorganisms, including bacteria, viruses, and fungi. They aim for a much higher level of microbial reduction, often exceeding 99.999%. Disinfectants are usually reserved for situations requiring a higher level of cleanliness, such as hospitals or laboratories.

- Key Difference 1: Level of Microbial Reduction: Sanitizers reduce, disinfectants kill or inactivate.

- Key Difference 2: Scope of Microorganisms Targeted: Sanitizers focus on common bacteria; disinfectants target a broader spectrum.

- Key Difference 3: Application: Sanitizers are suitable for frequent use; disinfectants are used when higher germ reduction is essential.

Q 2. Explain the process of properly diluting a disinfectant.

Diluting disinfectants correctly is crucial for safety and effectiveness. An incorrect dilution can render the disinfectant useless or even dangerous. Always follow the manufacturer’s instructions precisely; these instructions are usually found on the product label.

The process typically involves mixing a specific amount of the concentrated disinfectant with a specific amount of water. For instance, a 1:10 dilution means mixing one part disinfectant with nine parts water. Let’s say you need 1000ml of diluted disinfectant, you’d add 100ml of concentrated solution to 900ml of water.

Steps to Proper Dilution:

- Measure carefully: Use accurate measuring tools like graduated cylinders or measuring cups to ensure precise measurements.

- Add the disinfectant to the water: Always add the concentrated disinfectant to the water, not the other way around. This prevents splashing and ensures thorough mixing.

- Mix thoroughly: Stir the solution gently but thoroughly to ensure even distribution of the disinfectant.

- Label and date the container: Clearly label the container with the name of the disinfectant, dilution ratio, and date of preparation. This helps prevent confusion and ensures safe use.

- Follow storage guidelines: Store the diluted disinfectant in a cool, dry place, away from direct sunlight, and out of the reach of children and pets. Check the product label for specific storage instructions.

Example: If the label instructs for a 1:32 dilution of a 1-liter bottle, you would add 30 ml of disinfectant to 970 ml of water.

Q 3. What safety precautions should be taken when handling disinfectants?

Handling disinfectants requires vigilance to avoid potential hazards. Always treat them with respect.

- Wear appropriate Personal Protective Equipment (PPE): This includes gloves (preferably nitrile), eye protection (goggles or face shield), and a long-sleeved apron or gown, depending on the situation and disinfectant.

- Work in a well-ventilated area: Disinfectants often release fumes that can be irritating or harmful if inhaled. Use adequate ventilation or respiratory protection (mask) if necessary.

- Avoid skin contact: Disinfectants can irritate or damage skin. Wash your hands thoroughly with soap and water after handling disinfectants, even if you wore gloves.

- Avoid ingestion: Never eat, drink, or smoke while handling disinfectants. Keep them away from food and drink.

- Follow manufacturer’s instructions: Each disinfectant will have specific safety precautions on the label. Adhere to these diligently.

- Proper Disposal: Dispose of used disinfectant solutions and containers according to local regulations. Never pour disinfectants down the drain unless specifically permitted.

- Emergency Preparedness: Know the location of emergency eyewash stations and safety showers and understand how to use them in case of accidental exposure.

Q 4. What are the common types of disinfectants and their applications?

Many types of disinfectants are available, each with its specific applications:

- Chlorine Bleach (Sodium Hypochlorite): A broad-spectrum disinfectant effective against many bacteria and viruses. Commonly used for general surface disinfection, but it can corrode some materials and should be used with caution.

- Quaternary Ammonium Compounds (Quats): Effective against a range of bacteria and some viruses. Frequently used in hospitals, schools, and food processing facilities. Often found in ready-to-use formulations.

- Alcohols (Ethanol, Isopropanol): Rapid-acting disinfectants effective against many bacteria and viruses. Commonly used for hand sanitizers and disinfecting small surfaces. They evaporate quickly and are generally non-corrosive.

- Hydrogen Peroxide: A broad-spectrum disinfectant effective against various bacteria, viruses, and fungi. It’s a good choice for sensitive surfaces due to its relative safety and decomposition into water and oxygen.

- Phenolics: Effective against a wide range of microorganisms, including some bacteria, viruses, and fungi. Often used in healthcare settings and on hard surfaces. Some are corrosive.

The choice of disinfectant depends on the specific microorganisms to be controlled, the surface to be disinfected, and other factors such as safety and cost.

Q 5. How do you determine the appropriate contact time for a disinfectant?

The appropriate contact time for a disinfectant is crucial for its effectiveness. This is the amount of time the disinfectant must remain wet on a surface to kill or inactivate the targeted microorganisms. Contact time is specified by the disinfectant manufacturer and is typically listed on the product label. It varies depending on the disinfectant type and the target microorganisms.

Factors affecting contact time:

- Type of disinfectant: Some disinfectants act faster than others.

- Type of microorganism: Some microorganisms are more resistant to disinfectants than others.

- Organic matter: The presence of organic matter (e.g., blood, body fluids) can interfere with the disinfectant’s action and require longer contact time.

- Temperature: Temperature can affect the efficacy of some disinfectants.

- Surface type: Porous surfaces may require longer contact time.

Always consult the product label for the recommended contact time. A shorter contact time than indicated may result in inadequate disinfection. Ensure the surface remains wet for the entire recommended duration.

Q 6. Describe the proper technique for disinfecting a surface.

Proper disinfection technique ensures effective germ reduction. Think of it as painting a surface—you want even coverage.

- Cleaning: First, clean the surface thoroughly to remove visible soil and organic matter. This step is essential as debris can interfere with the disinfectant’s effectiveness.

- Application: Apply the diluted disinfectant evenly to all surfaces. Use enough disinfectant to keep the surface wet for the entire recommended contact time. For larger areas, work in sections.

- Contact Time: Allow the disinfectant to remain wet on the surface for the manufacturer’s recommended contact time. Do not allow the surface to dry before the contact time is up.

- Drying: Air-drying is usually sufficient. Avoid wiping or rinsing unless specifically instructed by the manufacturer.

- Disposal: Dispose of used cloths or materials appropriately.

For example, when disinfecting a countertop, spray the disinfectant evenly, ensuring the whole surface stays wet for the required time (e.g., 10 minutes).

Q 7. How do you ensure the effectiveness of a disinfectant?

Ensuring disinfectant effectiveness involves a multi-faceted approach:

- Proper Dilution and Application: Always follow the manufacturer’s instructions for dilution and application to maintain the disinfectant’s potency.

- Regular Monitoring: Regularly check the disinfectant’s expiry date and ensure proper storage. Disinfectants degrade over time.

- Testing (if applicable): Some facilities perform regular testing (using methods like ATP bioluminescence) to confirm the effectiveness of their disinfection protocols. This ensures that disinfection practices are working as intended and addresses any potential failures.

- Surface Cleanliness: Remember, cleaning (removal of dirt and organic matter) is crucial before disinfection. Without this step, disinfection will be less effective.

- Contact Time: Maintain the required contact time as specified on the product label.

- Personnel Training: Ensuring personnel are trained in the proper handling, dilution, and application of disinfectants is essential.

By following these guidelines, you can significantly increase the likelihood of successful disinfection and maintain a safer, cleaner environment.

Q 8. What are the signs that a disinfectant has lost its potency?

Disinfectants, unlike fine wine, don’t improve with age! Several signs indicate a loss of potency. The most obvious is if the solution is visibly cloudy, discolored, or has developed an unusual odor, deviating from its original appearance. This often suggests chemical degradation. Furthermore, checking the expiration date is crucial; many disinfectants have a shelf life, after which their effectiveness is compromised. Finally, and perhaps most importantly, if the disinfectant is failing to consistently eliminate microorganisms – if you’re noticing persistent contamination despite proper application – it’s a strong sign it’s time to replace it. Think of it like this: if your usual cleaning solution isn’t cutting it anymore, it’s time for a new bottle.

- Visible changes: Cloudiness, discoloration, unusual odor.

- Expired: Check the label for the expiration date.

- Ineffective cleaning: Persistent contamination despite proper use.

Q 9. What are the different methods for disinfecting equipment?

Disinfecting equipment relies on several effective methods, each with its strengths and weaknesses. High-level disinfection, targeting a broad range of microbes, can be achieved through chemical disinfection, using EPA-registered disinfectants. We follow strict protocols, ensuring the correct contact time and concentration. For example, we might immerse instruments in a specific disinfectant solution for a precise duration as indicated on the product label. Alternatively, we might use a chemical wipe-down method, ideal for larger equipment. Physical methods are also important; heat sterilization, such as autoclaving, is the gold standard for eliminating all microorganisms, including spores, and is especially valuable for heat-resistant medical equipment. Another effective physical method is using ultraviolet (UV) light, which can damage the DNA of microorganisms. The choice of method depends heavily on the type of equipment, the level of disinfection needed, and the presence of heat-sensitive components.

- Chemical disinfection: Immersion or wiping with EPA-registered disinfectants.

- Heat sterilization (autoclaving): High-temperature steam sterilization.

- Ultraviolet (UV) light: Damages microbial DNA.

Q 10. How do you handle spills of disinfectants?

Spills of disinfectants require immediate and careful attention, prioritizing safety. The first step is to prevent further spread by containing the spill with absorbent materials like spill pads or paper towels. Never use bare hands; always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator if necessary, as many disinfectants are harmful if inhaled or absorbed through the skin. Once contained, carefully clean the area following the manufacturer’s instructions for the specific disinfectant. This might involve diluting the spill with water (if permitted by the manufacturer) followed by thorough cleaning and disinfection of the affected surface. Any contaminated materials should be disposed of according to local regulations and hazardous waste guidelines. It’s always best to err on the side of caution and report larger spills to relevant authorities.

- Contain the spill: Use absorbent materials.

- Wear PPE: Gloves, eye protection, respirator if needed.

- Clean the area: Follow manufacturer’s instructions.

- Dispose of waste: According to regulations.

Q 11. What are the regulatory guidelines for using disinfectants in your industry?

Regulatory guidelines for disinfectant use vary depending on the industry and location, but they generally focus on safety and efficacy. In many countries, the Environmental Protection Agency (EPA) or equivalent agencies register disinfectants, ensuring they meet specific efficacy standards and are labeled correctly. These regulations often dictate proper application methods, contact times, concentration levels, and safety precautions. Failure to comply with these regulations can lead to penalties, and more importantly, could expose individuals to health risks. We routinely review and update our procedures to ensure strict compliance with current regulations and best practices in our facility, ensuring that all personnel are adequately trained and aware of the regulations.

Q 12. What is the difference between sterilization and disinfection?

While both sterilization and disinfection aim to reduce microbial load, they differ significantly in their scope. Sterilization is the complete elimination or destruction of all forms of microbial life, including bacteria, viruses, fungi, and spores. Think of it as a complete wipeout. Disinfection, on the other hand, reduces the number of viable microorganisms on a surface to a safe level. It doesn’t eliminate all microbes, just enough to reduce the risk of infection. Therefore, sterilization is a more stringent process than disinfection. Autoclaving is a sterilization method, while using a disinfectant wipe is a disinfection method.

Q 13. How do you select the appropriate disinfectant for a specific application?

Selecting the appropriate disinfectant depends on several critical factors. First, identify the target microorganisms. Different disinfectants are effective against different types of microbes (bacteria, viruses, fungi, spores). Second, consider the surface being treated. Some disinfectants can damage certain materials. Third, assess the level of disinfection required—is disinfection sufficient, or is sterilization needed? Fourth, evaluate the safety profile of the disinfectant, ensuring it’s compatible with the environment and poses minimal risk to humans and the surroundings. Finally, practicality matters; consider the ease of use, cost, and availability of the disinfectant. It’s crucial to consult the product label and follow manufacturer’s instructions meticulously.

Q 14. What are the common safety hazards associated with disinfectants?

Disinfectants, while essential for hygiene, pose several safety hazards. Many are corrosive and can cause skin irritation, burns, or eye damage upon direct contact. Inhalation of fumes can lead to respiratory problems, and ingestion can have severe consequences. Some disinfectants are also flammable or can react unpredictably with other chemicals. Therefore, proper personal protective equipment (PPE), such as gloves, goggles, and respirators, is paramount during handling. Always store disinfectants safely, away from children and incompatible substances. Adequate ventilation is also crucial during use to minimize exposure to fumes. Regular training on safe handling practices and emergency procedures is a must for anyone working with disinfectants.

- Skin/eye irritation: Corrosiveness can cause burns.

- Respiratory problems: Inhalation of fumes.

- Ingestion hazards: Severe health consequences if swallowed.

- Flammability: Some disinfectants are highly flammable.

- Chemical reactions: Potential for unpredictable reactions with other chemicals.

Q 15. What is your experience with different types of sanitizing solutions?

My experience encompasses a wide range of sanitizing solutions, from common household disinfectants like bleach solutions (always diluted according to manufacturer instructions for safety) and alcohol-based products (isopropyl alcohol 70% is a common example), to quaternary ammonium compounds (quats) frequently used in industrial settings and specialized disinfectants for healthcare environments like those containing hydrogen peroxide or glutaraldehyde. I’m familiar with their respective strengths and weaknesses, including their efficacy against various microorganisms (bacteria, viruses, fungi), material compatibility (some disinfectants can damage certain surfaces), and safety considerations (proper ventilation, PPE usage). For example, while bleach is effective and cost-effective, it’s corrosive and can damage some materials. Alcohol is quick-acting but less effective against certain spores. Quats offer broader spectrum activity but require longer contact times.

- Bleach Solutions: Effective, cost-effective, but corrosive.

- Alcohol-based products: Fast-acting, but less effective against certain microorganisms.

- Quaternary Ammonium Compounds (Quats): Broad-spectrum activity, but require longer contact times.

- Hydrogen Peroxide: Effective against a wide range of pathogens, leaves no residue.

- Glutaraldehyde: Powerful sterilant, used for critical medical equipment, but requires careful handling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a situation where you had to troubleshoot a sanitation issue.

In a previous role at a food processing plant, we experienced a higher-than-acceptable bacterial count in a specific area of the production line. We initially suspected inadequate sanitation, but our standard procedure, which involved a two-step process of cleaning followed by disinfection with a quat-based solution, seemed to be followed correctly. To troubleshoot, I implemented a systematic approach:

- Re-evaluation of the procedure: We carefully examined the cleaning and disinfection steps, paying close attention to contact times and solution concentrations.

- Environmental testing: We increased the frequency of environmental swabbing to identify potential contamination sources. This revealed a leak in a pipe that was releasing contaminated water into the area, causing re-contamination after the sanitation procedure.

- Corrective actions: The leak was repaired, and the affected area was thoroughly cleaned and disinfected. We also updated our sanitation procedures to include a check for potential water leaks as a preventative measure.

- Monitoring and validation: Post-repair, we continued environmental monitoring to verify the effectiveness of the corrective actions. The bacterial count returned to acceptable levels.

This highlighted the importance of a thorough investigation beyond just assuming the sanitation process was at fault.

Q 17. How do you verify the efficacy of a sanitation procedure?

Verifying sanitation efficacy involves a combination of methods. Simply observing a clean surface isn’t sufficient; we need objective measures. This typically involves:

- Visual inspection: This is the first step, ensuring all visible soil and debris have been removed.

- ATP bioluminescence testing: This rapid method measures the adenosine triphosphate (ATP) levels, which indicate the presence of organic matter. Lower ATP readings suggest more effective cleaning.

- Microbial testing (environmental swabbing): Samples are collected from surfaces and cultured to determine the presence and levels of specific microorganisms. This provides direct evidence of sanitation effectiveness and compliance with regulatory standards.

- Indicator organism testing: Testing for specific bacteria that are easy to detect and indicate the presence of other potentially harmful microorganisms.

The choice of method depends on the context. For example, ATP testing is quick and useful for routine monitoring, while microbial testing is more comprehensive but takes longer to produce results. Maintaining detailed records of these tests is crucial for demonstrating compliance and identifying trends.

Q 18. What are the key factors to consider when developing a sanitation plan?

Developing a comprehensive sanitation plan requires careful consideration of several key factors:

- Type of facility and its purpose: A food processing plant requires much stricter standards than a general office space.

- Identification of critical control points (CCPs): These are areas where contamination is most likely to occur and require enhanced sanitation.

- Selection of appropriate disinfectants: Choosing disinfectants effective against target microorganisms and compatible with the surfaces being treated.

- Cleaning procedures: Defining the steps for removing soil and debris before disinfection, including the type of cleaning agents to be used.

- Disinfection procedures: Specifying contact times, concentrations of disinfectants, and application methods.

- Personal protective equipment (PPE): Mandating appropriate PPE (gloves, eye protection, etc.) to protect personnel from exposure to cleaning and disinfecting agents.

- Training and supervision: Providing comprehensive training to staff on proper sanitation techniques.

- Monitoring and validation: Implementing a system for regular monitoring and testing to ensure effectiveness.

- Record-keeping: Documenting all aspects of the sanitation process to aid in compliance and auditing.

A well-structured plan ensures consistency and helps to mitigate risks related to contamination.

Q 19. What is your experience with using personal protective equipment (PPE) during disinfection?

My experience with PPE during disinfection is extensive. I understand the importance of selecting appropriate PPE based on the specific disinfectants and the nature of the task. This includes:

- Gloves: Nitrile gloves are commonly used due to their chemical resistance. The choice depends on the disinfectant used – some chemicals can degrade certain glove materials.

- Eye protection: Safety glasses or goggles are essential to prevent splashing of disinfectants into the eyes.

- Aprons or coveralls: These protect skin and clothing from contact with disinfectants.

- Respiratory protection: In cases involving strong or aerosolizing disinfectants, respirators might be needed to prevent inhalation.

Proper donning and doffing (putting on and taking off) procedures are critical to prevent contamination and protect the user. We always follow a strict protocol, and regular training and refresher courses ensure everyone is competent in using PPE safely and effectively.

Q 20. How do you ensure that all surfaces have been adequately disinfected?

Ensuring adequate disinfection requires a methodical approach. Simply spraying a disinfectant isn’t enough. I utilize the following strategies:

- Thorough pre-cleaning: Removing visible soil and debris is crucial for effective disinfection. Disinfectants work best when they come into direct contact with the microorganisms.

- Appropriate application methods: Different methods (spraying, wiping, immersion) are better suited for different surfaces and situations. The goal is to ensure complete coverage.

- Correct contact time: Allowing the disinfectant to remain in contact with the surface for the recommended time (usually specified by the manufacturer) is critical for its efficacy.

- Systematic approach: Following a pre-determined cleaning and disinfection plan ensures thorough coverage of all surfaces. This might involve a color-coded system or checklists.

- Validation methods: Post-disinfection testing (as discussed earlier) is the only way to definitively verify adequate disinfection.

Think of it like painting a wall: you need to prepare the surface (pre-cleaning), use the right paint (disinfectant), apply it correctly, and allow sufficient drying time (contact time) to ensure the best results. Validation then confirms that the paint job (disinfection) was effective.

Q 21. Describe your experience with cleaning and disinfecting sensitive equipment.

Cleaning and disinfecting sensitive equipment requires a delicate balance between achieving sanitation and avoiding damage. I have experience handling a variety of sensitive equipment, including:

- Medical devices: These often require specialized disinfectants and procedures to prevent damage to delicate components. Manufacturers’ instructions are always followed strictly.

- Laboratory equipment: Similar to medical devices, specific procedures are required to maintain calibration and functionality.

- Electronic equipment: Many electronics are vulnerable to damage from moisture or certain chemicals. I always utilize disinfectants and procedures suitable for electronic components, often using alcohol wipes for quick disinfection.

The key is to select appropriate cleaning and disinfecting agents, use correct methods, and carefully follow manufacturer’s instructions for cleaning and disinfection to prevent damage. Thorough rinsing and drying are often crucial to avoid residue that could compromise the equipment’s function.

Q 22. What is your experience with training others in proper disinfection techniques?

Training others in proper disinfection techniques requires a multi-faceted approach. I begin by emphasizing the importance of understanding the difference between cleaning, sanitizing, and disinfecting. Cleaning removes visible dirt and debris, sanitizing reduces the number of microorganisms, and disinfecting kills or inactivates most microorganisms. I then provide hands-on training, demonstrating the correct application of disinfectants, including appropriate contact time, surface preparation, and personal protective equipment (PPE) use. This often involves role-playing scenarios to reinforce the learning. For example, I’ll guide trainees through the proper disinfection of a patient room in a healthcare setting, highlighting the critical control points like doorknobs, light switches, and bedrails. Finally, I create and distribute a detailed checklist to ensure consistent and accurate disinfection procedures are followed, and I regularly conduct follow-up evaluations and retraining as needed to maintain proficiency and address any emerging questions or concerns.

Q 23. How do you maintain accurate records of disinfection procedures?

Maintaining accurate records of disinfection procedures is crucial for accountability and regulatory compliance. We use a combination of methods. First, we utilize a digital logbook integrated into our facility’s management system. This electronic system tracks the date, time, area disinfected, specific disinfectant used, contact time, the personnel who performed the disinfection, and any unusual observations or incidents. Secondly, each team member receives specific training on filling out the relevant sections of the log accurately and honestly. Third, we conduct regular internal audits to verify the accuracy and completeness of the logbook data. Finally, this data is reviewed during our routine infection control meetings to identify trends, address potential issues, and continuously improve our disinfection processes.

Q 24. What are the environmental considerations related to using disinfectants?

Environmental considerations are paramount when using disinfectants. We must always consider the potential impact on the environment, human health, and the longevity of treated surfaces. For example, some disinfectants may be harmful to aquatic life if improperly disposed of. We use environmentally friendly disinfectants whenever possible, selecting products with lower toxicity and biodegradable ingredients. Proper ventilation is crucial to minimize exposure to disinfectant fumes, especially in enclosed spaces. Furthermore, we meticulously follow the manufacturer’s instructions for use, paying close attention to the recommended dilution ratios and application methods to avoid unnecessary environmental contamination. We also implement strict waste management protocols for used disinfectants and their packaging, ensuring proper disposal in accordance with local regulations.

Q 25. Explain the importance of hand hygiene in preventing the spread of infections.

Hand hygiene is the cornerstone of infection prevention. Hands act as vectors for countless pathogens, transferring microorganisms from contaminated surfaces to our mouths, noses, eyes, and even to other people or surfaces. Thorough handwashing with soap and water or the use of an alcohol-based hand rub for at least 20 seconds significantly reduces the microbial load on hands. Think of it like this: your hands are constantly interacting with the environment, picking up unseen germs. Proper hand hygiene is the first line of defense against the spread of infections, protecting both yourself and those around you. In healthcare settings, meticulous hand hygiene before and after patient contact is non-negotiable, preventing the transmission of hospital-acquired infections (HAIs).

Q 26. What are the common microorganisms that disinfectants target?

Disinfectants target a broad spectrum of microorganisms, including bacteria (like Staphylococcus aureus and Escherichia coli), viruses (including influenza and norovirus), fungi (such as Candida albicans), and some spores (though not all). The specific microorganisms targeted vary depending on the disinfectant used. For example, a quaternary ammonium compound (quat) might effectively eliminate many bacteria and some viruses, while a bleach solution might be more effective against a broader range of microorganisms, including spores. Choosing the right disinfectant requires understanding the specific pathogens present in a given environment and selecting a product with proven efficacy against those organisms. Regular testing and evaluation of our disinfection procedures help us ensure the effectiveness of our approach.

Q 27. How do you manage the disposal of used disinfectants and cleaning supplies?

Safe and proper disposal of used disinfectants and cleaning supplies is critical for environmental protection and worker safety. We follow a strict protocol based on local and national regulations. Used disinfectants are never poured down drains; instead, they are carefully collected in designated containers. These containers are clearly labeled and stored safely until disposal by a licensed waste management company. Cleaning supplies such as wipes and mops are also disposed of according to guidelines, separating contaminated materials from non-contaminated ones to avoid cross-contamination. Furthermore, all personnel involved in the disposal process receive specific training to ensure compliance and minimize risks. Maintaining detailed records of all disposal activities is crucial for auditing and regulatory compliance. This includes tracking the type and quantity of waste generated, the date of disposal, and the name of the disposal company involved.

Q 28. Describe your experience with different types of cleaning equipment.

My experience encompasses a wide variety of cleaning equipment, from basic tools like mops and buckets to more advanced technologies such as electrostatic sprayers and automated floor scrubbers. I’m proficient in using and maintaining equipment like autoclaves for sterilization, ultrasonic cleaners for delicate instruments, and various types of vacuum cleaners for different applications. I understand the importance of selecting the appropriate equipment for each task, considering factors like surface type, the level of contamination, and the desired outcome. For instance, electrostatic sprayers are ideal for quickly and efficiently disinfecting large areas, ensuring even coverage, while ultrasonic cleaners offer precise cleaning and sterilization for sensitive medical instruments. Regular maintenance and calibration of this equipment are crucial for maintaining its effectiveness and preventing damage.

Key Topics to Learn for Experience with using disinfectants and sanitizers Interview

- Understanding Disinfectant Types: Learn the differences between disinfectants (killing microorganisms) and antiseptics (reducing microorganisms on living tissue). Explore various types like quaternary ammonium compounds, alcohols, chlorine bleach, and hydrogen peroxide, understanding their strengths and limitations.

- Safe Handling and Application: Master safe handling procedures, including personal protective equipment (PPE) use (gloves, masks, eye protection), proper dilution techniques, and understanding safety data sheets (SDS) for each product. Discuss practical scenarios of applying disinfectants and sanitizers in different settings.

- Efficacy and Effectiveness: Understand the factors influencing disinfectant effectiveness, such as contact time, temperature, concentration, and the presence of organic matter. Be prepared to discuss how to ensure proper disinfection and sanitation procedures are followed to achieve optimal results.

- Environmental Considerations: Discuss the environmental impact of disinfectants and sanitizers. Know about sustainable practices and environmentally friendly alternatives. This shows awareness of broader implications.

- Regulations and Compliance: Familiarize yourself with relevant regulations and guidelines pertaining to the use and storage of disinfectants and sanitizers in your industry. Demonstrate awareness of best practices and legal requirements.

- Troubleshooting and Problem-Solving: Be ready to discuss instances where disinfection or sanitation procedures may have failed and how you addressed the issue. Highlight your problem-solving skills and ability to adapt to unexpected challenges.

Next Steps

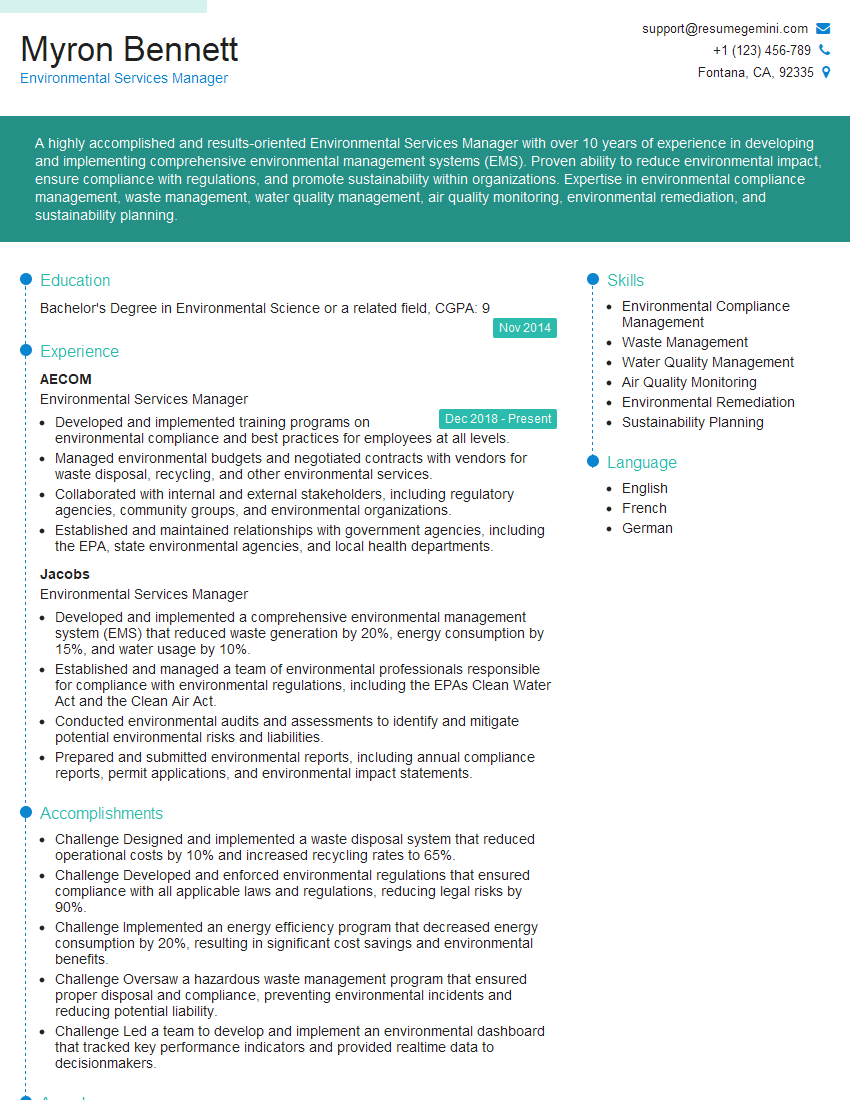

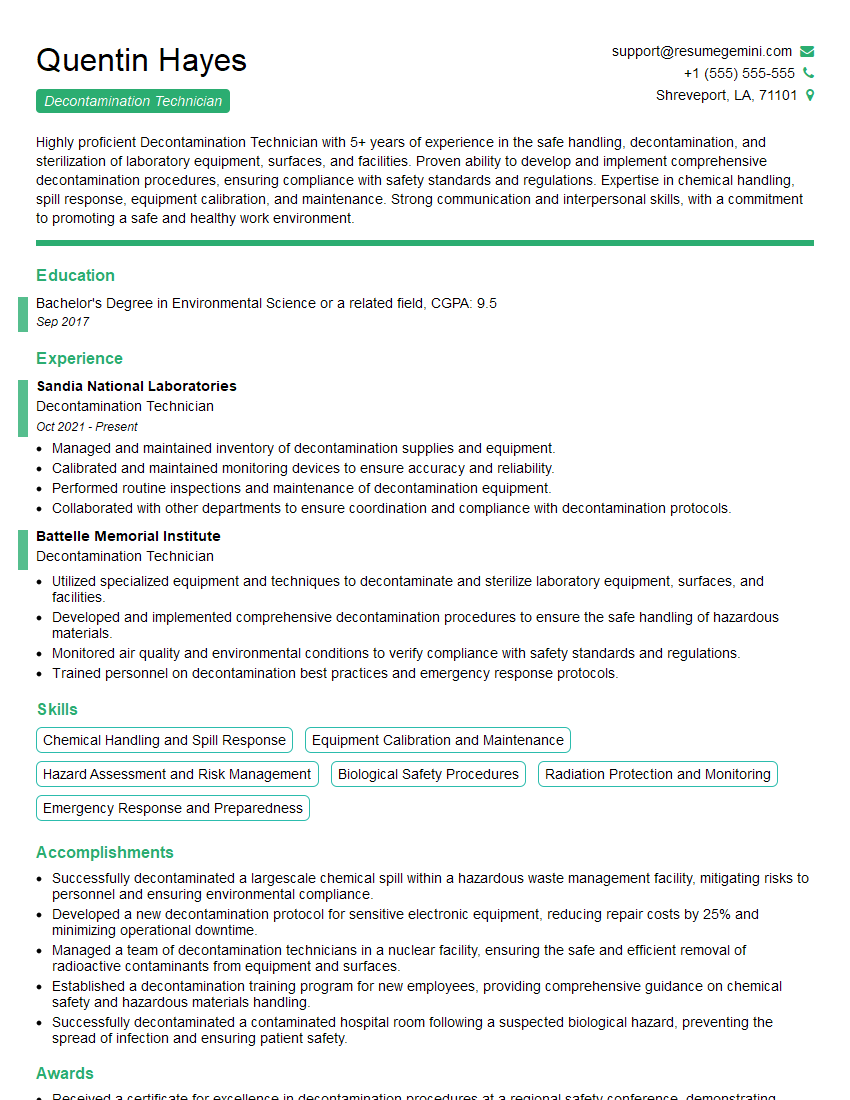

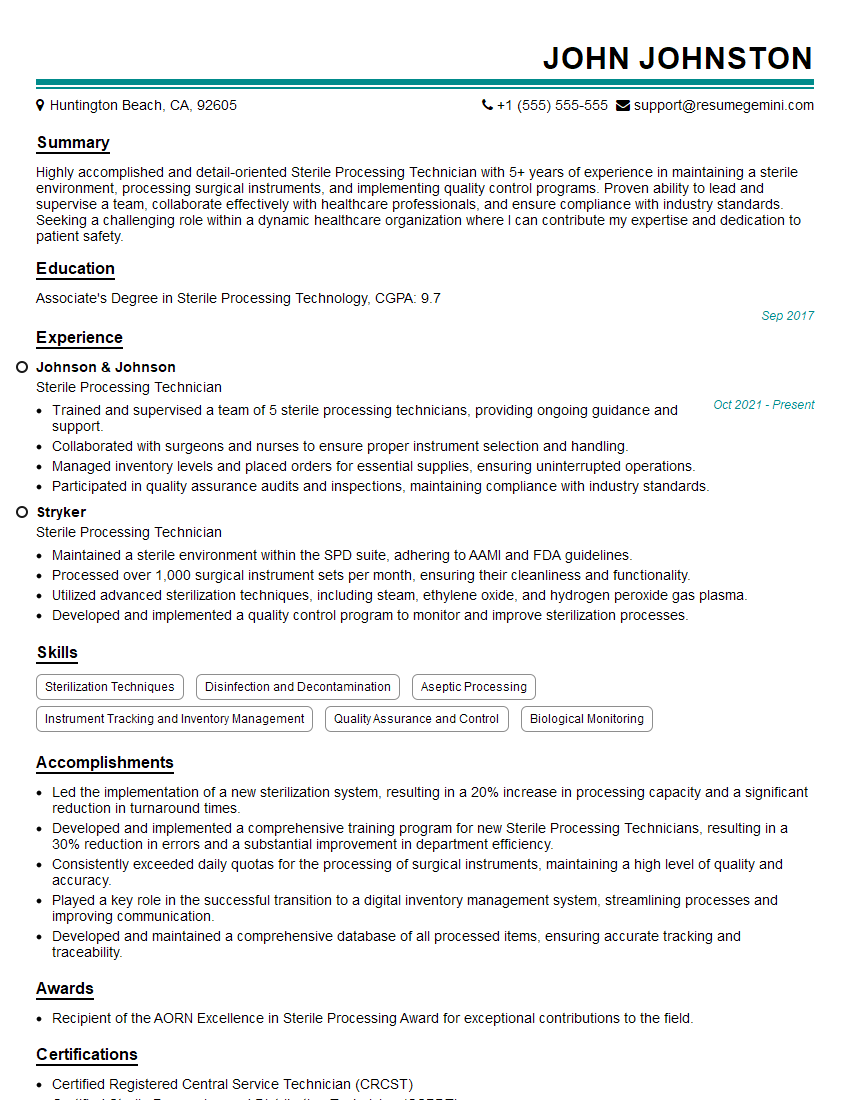

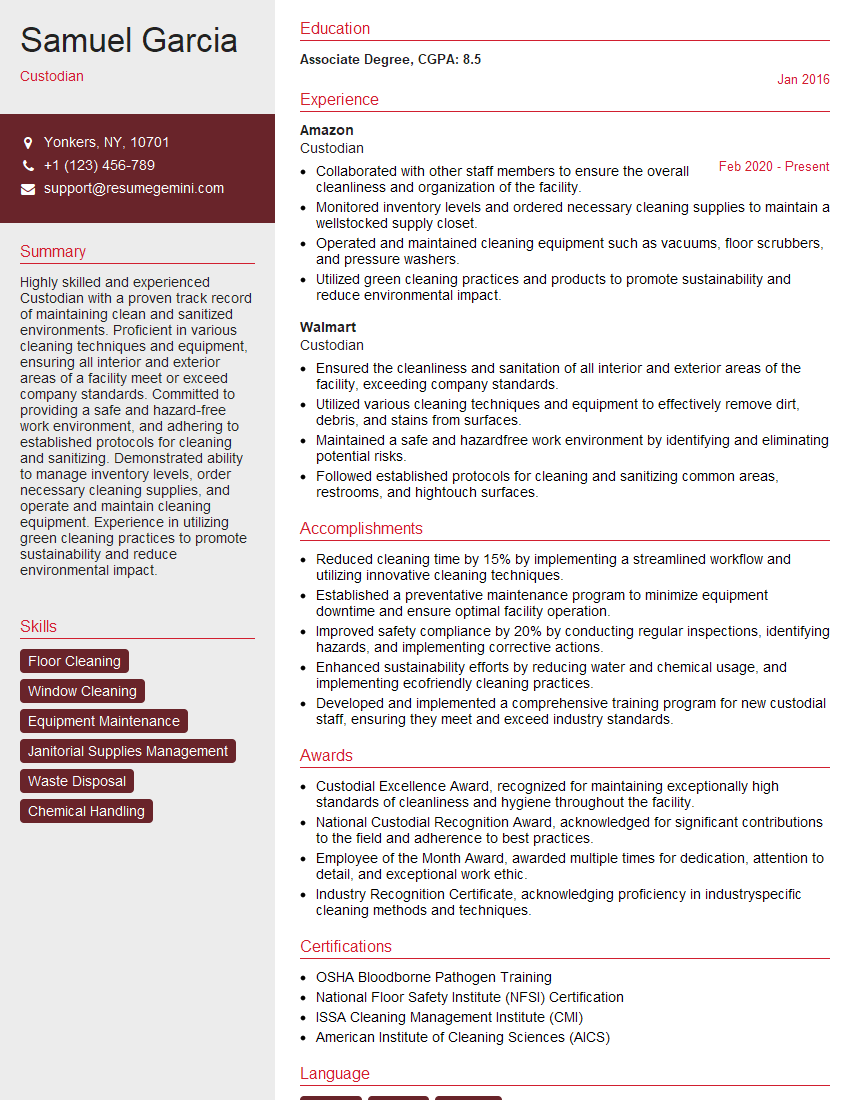

Mastering the use of disinfectants and sanitizers is crucial for numerous roles emphasizing hygiene and safety. A strong understanding of these concepts demonstrates responsibility and professionalism, significantly boosting your career prospects. To maximize your job search success, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. We provide examples of resumes tailored to highlight experience with disinfectants and sanitizers to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO