Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fabrication Equipment Maintenance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fabrication Equipment Maintenance Interview

Q 1. Describe your experience with preventative maintenance on CNC machines.

Preventative maintenance (PM) on CNC machines is crucial for maximizing uptime and preventing costly repairs. My approach involves a structured program based on the manufacturer’s recommendations and the machine’s operational history. This includes regular lubrication of moving parts, checking for wear and tear on critical components like spindles and tool holders, and inspecting the coolant system for contamination.

- Regular Lubrication: I meticulously follow the lubrication chart, using the specified lubricants and ensuring proper application to minimize friction and extend the life of bearings and other moving components. For example, I’d use a high-pressure grease gun for ball screws and a low-viscosity oil for linear guides.

- Coolant System Maintenance: Regularly checking and changing coolant, inspecting for leaks, and cleaning the coolant tank are essential to prevent corrosion and bacterial growth. A dirty coolant system can lead to premature tool wear and reduced machining accuracy.

- Tool Management: Implementing a proper tool management system, including regular inspection and sharpening or replacement, prevents collisions and increases machining efficiency. A well-maintained tool library saves time and reduces machine downtime.

- Electrical Checks: I conduct regular checks of electrical connections and wiring harnesses, looking for loose connections, frayed wires, or signs of overheating. These checks are critical for safety and to prevent electrical malfunctions.

By implementing a comprehensive PM schedule, I’ve successfully reduced downtime on CNC machines by an average of 20% in my previous roles, leading to increased productivity and cost savings.

Q 2. How do you troubleshoot a malfunctioning laser cutting machine?

Troubleshooting a malfunctioning laser cutting machine requires a systematic approach. Safety is paramount – always ensure the machine is powered off and locked out before beginning any troubleshooting.

- Safety First: Power down the machine, lock out/tag out the power source, and verify that the laser is deactivated.

- Identify the Problem: What exactly is malfunctioning? Is the laser not firing? Are there inaccuracies in the cuts? Are there error codes displayed?

- Check the Obvious: Begin by checking the most common causes: Ensure the material is properly loaded and positioned, the laser lens is clean and undamaged, the gas supply (if applicable) is functioning correctly, and that the machine’s cooling system is operating within the normal parameters.

- Error Codes and Diagnostics: Consult the machine’s manual for any displayed error codes. These codes provide valuable clues to the problem’s origin.

- Check Electrical Connections: Inspect power supply connections, control cables, and any internal wiring for loose connections or damage.

- System Checks: Check the laser tube, power supply, and control system for any indications of malfunction. A malfunctioning cooling system can be a significant issue requiring immediate attention.

- Software Check: If the machine is controlled by software, examine the settings and parameters to ensure they are correct for the material being cut and the desired cut quality.

- Professional Assistance: If the problem persists after following these steps, contact a qualified service technician for professional assistance.

For example, a common problem is a dirty laser lens, which causes poor cut quality. Cleaning the lens with a suitable lens cleaning kit will often resolve this issue. However, more complex issues may require specialized tools and expertise.

Q 3. Explain the process of diagnosing and repairing a faulty welding machine.

Diagnosing and repairing a faulty welding machine involves a methodical approach that combines electrical, mechanical, and welding knowledge. Safety precautions are crucial throughout the entire process.

- Safety Precautions: Always disconnect the power supply and lock out/tag out before commencing any work on the welding machine. Ensure that the welding area is free from flammable materials and is well-ventilated.

- Visual Inspection: Begin by carefully inspecting the machine for any obvious signs of damage, loose connections, leaks, or burnt components. Check the cables, clamps, and electrodes for wear and tear.

- Testing the Power Supply: Verify the power supply is functioning correctly by checking the voltage and amperage using a multimeter. A faulty power supply is a common cause of welding machine malfunction.

- Check the Control Circuitry: Inspect the control circuitry for any loose connections, burnt resistors, or damaged components. A multimeter can be used to check for continuity and voltage in the circuitry.

- Welding Process Assessment: Evaluate the welding process itself. Poor welds might indicate issues with arc length, welding current, or gas flow (for gas metal arc welding or gas tungsten arc welding).

- Hydraulic/Pneumatic Systems: If the welding machine utilizes hydraulic or pneumatic systems, check for leaks and ensure they are operating correctly.

- Component Replacement: If necessary, replace faulty components after carefully identifying the problem. Always ensure that any replacement components are compatible with the machine.

- Professional Help: If the problem is complex or beyond your expertise, it is best to seek professional assistance from a qualified welding machine technician.

For instance, a consistent lack of arc may indicate a problem with the electrode, the welding cable, or the welding machine’s power supply. A systematic approach, combined with a solid understanding of welding principles, enables quick and efficient troubleshooting.

Q 4. What are the common causes of press brake malfunctions and how do you address them?

Press brake malfunctions often stem from issues with hydraulics, mechanical components, or the control system. Addressing these issues requires both technical skill and a methodical approach.

- Hydraulic System Problems: Leaks in hydraulic lines, faulty hydraulic pumps, or problems with the hydraulic cylinders can all affect the press brake’s operation. These typically manifest as inconsistent bending force or complete failure to operate.

- Mechanical Issues: Worn-out ram bearings, damaged slideways, or problems with the crankshaft mechanism can reduce the accuracy and precision of the bending process or cause complete machine failure. Regular lubrication and inspection can help prevent these problems.

- Control System Malfunctions: Problems with the press brake’s control system, such as faulty sensors, damaged wiring, or software glitches, can result in inaccurate bending, erratic movements, or complete operational failure. Inspecting the wiring and checking sensor readings are vital.

- Safety Mechanisms: Malfunctions in safety mechanisms, like light curtains or pressure sensors, can cause the machine to shut down unexpectedly or to operate unsafely. Testing these safety mechanisms is crucial for both safety and compliance.

Addressing these issues often involves replacing faulty components, adjusting hydraulic pressure, or recalibrating sensors and the control system. In some instances, advanced diagnostic tools may be required to pinpoint the exact source of the problem. For example, a persistent leak in a hydraulic line requires identifying the leak location, replacing the damaged section of the line, and bleeding the hydraulic system to remove air bubbles.

Q 5. What safety precautions do you take when maintaining fabrication equipment?

Safety is my paramount concern when maintaining fabrication equipment. My approach is based on adherence to established safety protocols and the use of appropriate personal protective equipment (PPE).

- Lockout/Tagout Procedures: Before performing any maintenance, I always disconnect the power source and implement lockout/tagout procedures to prevent accidental start-ups. This is non-negotiable.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, including safety glasses, hearing protection, gloves, and steel-toe boots, depending on the specific task. The type of PPE varies depending on the task.

- Understanding Hazards: I thoroughly assess the potential hazards associated with each piece of equipment before beginning any maintenance. This includes identifying potential pinch points, moving parts, and energized components.

- Safe Working Practices: I adhere to all relevant safety regulations and best practices when performing maintenance tasks. This includes following proper lifting techniques to avoid injuries and using appropriate tools for the job.

- Regular Equipment Inspections: I perform regular inspections of the equipment to identify and address potential safety hazards before they escalate into accidents.

- Emergency Procedures: I am familiar with the emergency procedures for the workplace and know how to respond to various emergencies, including accidents and equipment malfunctions.

Safety isn’t just a set of rules; it’s a mindset. I’ve personally witnessed the devastating consequences of neglecting safety precautions, and I’m committed to preventing such incidents through vigilance and proactive measures.

Q 6. How do you interpret and utilize maintenance manuals and schematics?

Maintenance manuals and schematics are essential tools for efficient and effective equipment maintenance. I utilize them to understand the equipment’s functionality, identify potential problems, and perform repairs.

- Manual Interpretation: I thoroughly read and understand the maintenance manuals, focusing on the preventative maintenance schedules, troubleshooting guides, and parts lists. This gives me a comprehensive understanding of the equipment’s operational principles and maintenance requirements.

- Schematic Interpretation: I’m proficient in reading and interpreting electrical, hydraulic, and pneumatic schematics. These diagrams allow me to trace circuits, identify components, and understand the flow of power, fluids, or air within the system. This helps in pinpointing the location of faults.

- Troubleshooting Guides: I leverage the troubleshooting guides provided in the manuals to diagnose and resolve equipment malfunctions. These guides offer systematic steps to identify the root cause of the problem and suggest solutions.

- Parts Lists and Diagrams: I use parts lists and exploded diagrams to identify parts, order replacement components, and understand the assembly process during repairs.

- Cross-referencing Information: I often cross-reference information from different sections of the manuals and schematics to gain a complete understanding of the system’s behavior. For example, I’ll often refer to the electrical schematic while performing a troubleshooting exercise.

My experience has shown that a thorough understanding of the manuals and schematics significantly reduces downtime and improves the efficiency of maintenance activities. It’s like having a detailed roadmap for the equipment, guiding me through the repair process.

Q 7. Describe your experience with hydraulic and pneumatic systems in fabrication equipment.

Hydraulic and pneumatic systems are common in fabrication equipment, powering everything from press brakes and shears to robotic arms. My experience encompasses diagnosing, maintaining, and repairing these systems.

- Hydraulic Systems: I understand hydraulic principles, including pressure, flow, and fluid power. I can identify and resolve problems such as leaks, low pressure, contamination, and component failures. This includes diagnosing issues with hydraulic pumps, valves, cylinders, and accumulators.

- Pneumatic Systems: I’m adept at working with pneumatic systems, understanding the role of compressed air in powering actuators, clamps, and other components. I can troubleshoot problems such as air leaks, low pressure, and component failures. I also understand the use of pressure regulators, air filters, and lubricators.

- System Diagnostics: I utilize pressure gauges, flow meters, and other diagnostic tools to assess the health of hydraulic and pneumatic systems. This allows me to detect subtle issues before they escalate into major problems. For instance, a pressure gauge can help pinpoint a leak in a hydraulic system.

- Component Repair and Replacement: I can perform repairs, including replacing seals, hoses, valves, and other components in both hydraulic and pneumatic systems.

- Safety Practices: I always prioritize safety when working with hydraulic and pneumatic systems. This includes proper pressure relief procedures, the use of appropriate PPE, and understanding the potential hazards associated with high-pressure systems.

In a practical example, I once diagnosed a malfunctioning press brake by tracing a hydraulic leak to a faulty seal in a hydraulic cylinder. Replacing the seal restored the machine’s functionality, preventing significant downtime and production losses.

Q 8. Explain your experience with robotic welding cell maintenance.

My experience with robotic welding cell maintenance spans over eight years, encompassing preventative maintenance, troubleshooting, and emergency repairs. I’ve worked with various robotic brands, including FANUC and ABB, and am proficient in diagnosing and resolving issues related to robot kinematics, welding parameters, and peripheral equipment. For instance, I once diagnosed a recurring arc-fault in a robotic welding cell by systematically checking the wire feeder, the power supply, and ultimately, identifying a loose connection within the robot’s welding torch. This involved meticulously tracing the wiring and ensuring proper grounding, highlighting the importance of methodical troubleshooting.

My responsibilities extended to maintaining the entire cell, including vision systems, part positioners, and safety interlocks. I’m familiar with programming and re-programming robot paths, adjusting welding parameters to optimize weld quality, and performing regular maintenance tasks such as lubrication, cleaning, and sensor calibration to ensure optimal performance and prevent costly downtime.

Q 9. How do you prioritize maintenance tasks in a busy manufacturing environment?

Prioritizing maintenance tasks in a busy manufacturing environment requires a systematic approach. I utilize a combination of methods, including:

- CMMS (Computerized Maintenance Management System): This software allows me to schedule preventative maintenance based on equipment criticality, manufacturer recommendations, and historical data. This helps prioritize tasks based on their potential impact on production.

- Risk-Based Prioritization: I assess the risk associated with equipment failure. Equipment critical to the production line receives higher priority, while less critical equipment can be scheduled for maintenance during less busy periods. For example, a faulty robotic arm on the primary assembly line would be prioritized over a minor issue with a secondary support system.

- Run-to-Failure Analysis: For some non-critical components, I’ll monitor their performance and allow them to run until failure if the risk of failure is low. This helps optimize maintenance scheduling by avoiding unnecessary downtime.

Finally, regular communication with the production team is crucial to understand their priorities and adjust maintenance schedules accordingly. This ensures that maintenance activities minimize disruption to production workflows.

Q 10. What software or systems do you use for managing maintenance activities?

Throughout my career, I’ve used various software systems for managing maintenance activities. These include enterprise-level CMMS solutions like SAP PM and IBM Maximo, as well as more specialized software for specific equipment, such as robotic arm control software and PLC programming interfaces.

These systems allow me to track work orders, manage spare parts inventory, schedule maintenance tasks, analyze equipment performance, and generate reports on maintenance costs and efficiency. I’m also proficient in using Microsoft Excel for data analysis and report generation, which is crucial for identifying trends and improving maintenance strategies.

Q 11. How do you handle emergency repairs on critical fabrication equipment?

Handling emergency repairs on critical fabrication equipment requires a quick, decisive, and methodical approach. My first priority is always safety. I ensure the equipment is properly locked out and tagged out before commencing any repairs, following strict safety protocols.

My approach involves:

- Quick Assessment: I quickly assess the situation to determine the nature of the problem and its potential impact on production. This often involves gathering information from the operators.

- Troubleshooting: I systematically troubleshoot the problem using my experience and diagnostic tools, aiming for a quick fix. If the problem is complex, I collaborate with other technicians or specialists.

- Temporary Fix: If a complete repair is not immediately feasible, I’ll implement a temporary solution to restore partial functionality and minimize downtime until a permanent fix can be implemented. This might involve using a backup component or adjusting operating parameters.

- Documentation: Thorough documentation of the emergency repair, including the cause of the failure, the implemented solution, and any necessary follow-up actions, is crucial for preventative maintenance and future troubleshooting.

I’ve learned to prioritize speed and efficiency during emergencies, but never at the expense of safety.

Q 12. Describe your experience with different types of welding processes and their maintenance.

My experience encompasses various welding processes, including MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), and spot welding. Each process has its unique maintenance requirements:

- MIG Welding: Maintenance includes regular checks of the wire feeder, contact tips, gas flow, and shielding gas purity. Regular cleaning and replacement of consumables are crucial for optimal weld quality and arc stability. I’ve dealt with issues like wire jams, inconsistent wire feed, and gas leaks.

- TIG Welding: TIG welding maintenance focuses on tungsten electrode integrity, gas flow, and torch cleanliness. Tungsten contamination can significantly affect weld quality, and proper cleaning is vital. I’ve handled issues like tungsten inclusions in welds and inconsistent arc initiation.

- Spot Welding: Spot welding machines require regular electrode maintenance, including cleaning, dressing, and replacement. Proper electrode alignment is crucial for consistent welds. I’ve experienced issues like inconsistent weld strength, electrode wear, and power supply fluctuations.

In each case, I perform regular preventative maintenance, and conduct thorough inspections to detect early signs of wear or malfunction. This proactive approach minimizes downtime and ensures consistent weld quality.

Q 13. What is your experience with PLC programming and troubleshooting?

I have extensive experience with PLC (Programmable Logic Controller) programming and troubleshooting. I am proficient in various PLC platforms, including Allen-Bradley and Siemens. My skills encompass ladder logic programming, troubleshooting faulty logic, and implementing modifications to existing programs.

For example, I recently resolved a production bottleneck by modifying the PLC program to optimize the sequencing of robotic movements within a welding cell. This involved analyzing the existing program, identifying the bottlenecks, and making targeted adjustments to improve efficiency.

I’m familiar with using programming software, diagnostic tools, and troubleshooting techniques to identify and resolve issues in PLC-controlled equipment. This includes using hand-held programming devices, simulation software, and diagnostic software to identify and rectify problems efficiently.

Q 14. How do you ensure compliance with safety regulations during equipment maintenance?

Ensuring compliance with safety regulations during equipment maintenance is paramount. My approach is based on a strong understanding of OSHA regulations and other relevant safety standards. I always follow a strict lockout/tagout (LOTO) procedure to isolate equipment from power sources before performing any maintenance activities. This is critical to prevent accidental energization and injuries.

I also wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection, and ensure that the work area is properly cleaned and organized to prevent accidents. Regular safety training and awareness sessions are essential to maintaining a safe work environment. I actively participate in these sessions and ensure my team does the same. Any deviation from standard safety procedures is immediately reported and rectified.

Furthermore, I actively participate in safety audits and inspections to identify potential hazards and implement corrective actions. My goal is to maintain a zero-accident workplace through continuous vigilance and adherence to best safety practices.

Q 15. Describe your experience with various types of machine tools (e.g., lathes, mills).

My experience with machine tools spans over 15 years, encompassing a wide range of equipment including CNC lathes, vertical and horizontal milling machines, grinders, and drilling machines. I’ve worked extensively with both conventional and computer numerical control (CNC) machines. With conventional machines, my expertise lies in setup, operation, and maintenance, including tool changes, speed and feed adjustments, and troubleshooting mechanical issues. For CNC machines, I’m proficient in programming (using G-code and CAM software), setting up work holding fixtures, performing diagnostics using machine parameters and error codes, and conducting preventative maintenance. For example, I once troubleshooted a recurring chatter issue on a CNC lathe by meticulously analyzing the cutting parameters, tool geometry, and machine vibrations, ultimately identifying and resolving the problem through a combination of improved toolpath programming and spindle bearing adjustment.

I’m also familiar with various types of tooling and understand the importance of proper tool selection for different materials and operations. This includes understanding tool life, wear patterns, and the importance of regular inspection and replacement to maintain machining accuracy and prevent damage to the machine or workpiece.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address root causes of recurring equipment failures?

Identifying the root cause of recurring equipment failures requires a systematic approach. I typically follow a five-step process: First, I thoroughly document the failure, including the symptoms, date and time, and any relevant operational data. Second, I collect data from multiple sources – maintenance logs, operator reports, and sensor data (if available). Third, I analyze this data to identify trends and patterns. This often involves using statistical process control (SPC) charts to track failure rates. Fourth, I use various diagnostic tools, such as vibration analyzers, thermal imaging cameras, and electrical multimeters, to pinpoint the specific component or system causing the failure. Finally, I implement corrective actions that address the root cause, not just the symptoms. This may involve repairing or replacing faulty components, improving lubrication procedures, or modifying operating parameters.

For instance, we once experienced repeated failures in a hydraulic press. By analyzing the maintenance logs and performing a thorough examination of the system, we found that a faulty pressure relief valve was repeatedly leading to pressure spikes and subsequent component failures. By replacing the valve and improving our hydraulic fluid monitoring procedures, we were able to eliminate the recurring problem.

Q 17. What is your experience with lubrication and bearing maintenance?

Lubrication and bearing maintenance are critical for the longevity and performance of fabrication equipment. My experience includes selecting appropriate lubricants based on bearing type, operating conditions (temperature, speed, load), and environmental factors. I’m proficient in performing various lubrication techniques, such as grease gun lubrication, oil bath lubrication, and oil mist lubrication. I also understand the importance of regular bearing inspection for signs of wear, contamination, or damage. This involves checking for excessive play, noise, or temperature rise. I know how to effectively clean and repack bearings when necessary, ensuring proper lubrication and preventing premature failure.

For example, I developed a scheduled lubrication program for a large CNC milling machine that significantly reduced bearing failures and extended the machine’s lifespan. The program included detailed lubrication points, types of lubricants, and recommended intervals, all documented in a central maintenance database.

Q 18. How do you manage spare parts inventory for fabrication equipment?

Managing spare parts inventory effectively requires balancing the need for readily available parts with the cost of storage and obsolescence. I use a combination of techniques, including: maintaining a detailed inventory database, using minimum-maximum stock levels to determine reorder points, and implementing a just-in-time (JIT) inventory system where appropriate. I also leverage predictive maintenance techniques to anticipate potential failures and proactively order necessary parts. This reduces downtime and prevents unexpected production disruptions. Regular inventory audits help to ensure accuracy and identify potential discrepancies.

Furthermore, I work closely with suppliers to ensure timely delivery and negotiate favorable pricing and terms. For critical components, I maintain a safety stock to mitigate the risk of delays. My experience has shown that a well-managed inventory system not only reduces downtime but also optimizes inventory costs and ensures that the right parts are available when needed.

Q 19. Describe your experience with electrical troubleshooting in industrial machinery.

I possess extensive experience in electrical troubleshooting in industrial machinery. This includes diagnosing problems in motors, drives, control systems (PLCs, HMIs), and other electrical components. My skills involve using various testing instruments such as multimeters, oscilloscopes, and insulation testers to identify faults. I understand electrical schematics and wiring diagrams and can trace circuits to locate shorts, opens, or other issues. I’m proficient in identifying and rectifying safety hazards associated with electrical maintenance, following all relevant safety protocols.

For instance, I recently troubleshooted a problem in a robotic welding cell where the robot arm would intermittently stop moving. By systematically checking the power supply, motor controllers, and communication signals, I pinpointed a faulty encoder in the robot joint that was causing intermittent data errors. Replacing the encoder resolved the issue.

Q 20. Explain your understanding of vibration analysis in machinery diagnostics.

Vibration analysis is a powerful tool for diagnosing mechanical problems in machinery. It involves measuring the vibrations produced by equipment and analyzing the frequency and amplitude of these vibrations to identify potential issues such as unbalance, misalignment, looseness, or bearing defects. I have experience using handheld vibration analyzers and more sophisticated data acquisition systems to collect and interpret vibration data. I understand different vibration analysis techniques, such as frequency spectrum analysis and time-waveform analysis. I’m also able to interpret the results and use this information to pinpoint the source of the problem and recommend appropriate corrective actions.

For example, using vibration analysis, we were able to detect an impending bearing failure in a high-speed centrifugal pump weeks before it catastrophically failed. This allowed us to schedule a preventative maintenance intervention, preventing costly downtime and potential damage to the system.

Q 21. How do you document and track maintenance activities?

Accurate documentation and tracking of maintenance activities are vital for effective equipment management. I use a computerized maintenance management system (CMMS) to record all maintenance activities, including preventative maintenance schedules, corrective maintenance repairs, and spare parts inventory. This system allows for efficient scheduling of maintenance tasks, tracking of work orders, and monitoring of equipment performance. Data is easily accessible for analysis and reporting purposes, facilitating performance improvement initiatives. I use a combination of digital and paper-based documentation, ensuring that all relevant information is readily available.

The CMMS includes detailed descriptions of the work performed, parts used, labor hours, and any associated costs. This detailed record-keeping is crucial for managing warranty claims, conducting root cause analysis, and identifying areas for improvement in our maintenance processes. All documentation adheres to industry best practices and regulatory requirements for safety and compliance.

Q 22. What is your experience with lean manufacturing principles and their application to maintenance?

Lean manufacturing principles, at their core, focus on eliminating waste and maximizing efficiency. In maintenance, this translates to minimizing downtime, optimizing resource allocation, and proactively preventing equipment failures. My experience involves implementing several key lean tools within maintenance operations. For instance, I’ve successfully utilized 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our maintenance areas, improving accessibility to tools and parts. This drastically reduced the time spent searching for items, leading to faster repairs. Furthermore, I’ve implemented Total Productive Maintenance (TPM), which involves engaging operators in preventative maintenance activities. This collaborative approach not only improves equipment reliability but also fosters a culture of ownership and responsibility among the workforce. I’ve also used Value Stream Mapping to identify and eliminate bottlenecks in our maintenance processes, leading to a significant reduction in repair times and improved overall efficiency.

For example, in a previous role, we identified a significant delay in obtaining replacement parts. By streamlining the procurement process through improved communication and vendor relationships, we reduced the average parts procurement time by 40%, directly impacting machine uptime.

Q 23. How familiar are you with different types of sensors and their applications in fabrication equipment?

My familiarity with sensors used in fabrication equipment is extensive. I’m proficient in applying various sensor types to monitor different aspects of the equipment’s performance and health. This includes:

- Temperature Sensors (Thermocouples, RTDs): Crucial for monitoring overheating in motors, bearings, and cutting tools. Early detection of elevated temperatures prevents catastrophic failures.

- Vibration Sensors (Accelerometers): These detect imbalances, misalignments, and bearing wear. Changes in vibration patterns are strong indicators of impending equipment malfunction.

- Pressure Sensors: Used to monitor hydraulic and pneumatic systems, ensuring proper operation and preventing leaks or pressure surges.

- Proximity Sensors: Detect the presence or absence of objects, crucial for safety interlocks and process control in automated systems. For example, ensuring proper workpiece placement.

- Optical Sensors: Used for dimensional measurements, surface inspection, and quality control in real-time, providing immediate feedback and preventing defects.

Understanding the specific applications and limitations of each sensor type is key to designing a robust monitoring system. In practice, I often integrate data from multiple sensors to get a holistic view of the equipment’s condition, enabling more informed maintenance decisions.

Q 24. Describe your experience with predictive maintenance techniques.

Predictive maintenance is a cornerstone of modern fabrication equipment management. My experience includes implementing and managing predictive maintenance programs using various techniques. These include:

- Vibration Analysis: Analyzing vibration data from sensors to identify developing faults in rotating machinery, such as bearings or motors.

- Oil Analysis: Regularly analyzing oil samples to detect wear particles, contaminants, and changes in oil viscosity, indicating potential problems within the lubrication system.

- Infrared Thermography: Using infrared cameras to identify temperature anomalies, revealing potential overheating or insulation issues.

- Data Analytics and Machine Learning: Leveraging sensor data and historical maintenance records to build predictive models that anticipate potential failures. This allows for proactive maintenance scheduling before a breakdown occurs.

For example, in one project, we used vibration analysis to identify a failing bearing in a high-speed milling machine weeks before it actually failed. This prevented costly downtime and avoided a potentially hazardous situation. The implementation of predictive maintenance reduced our unplanned downtime by 35% within the first year.

Q 25. What is your experience with different types of cutting tools and their maintenance?

My experience with cutting tools encompasses a wide range, including high-speed steel (HSS), carbide, and ceramic tools, as well as various tool geometries (e.g., end mills, drills, taps). Proper maintenance of cutting tools is critical for ensuring accuracy, surface finish, and extending tool life. This involves:

- Regular Inspection: Checking for signs of wear, chipping, or breakage before each use.

- Sharpness Assessment: Utilizing appropriate methods, such as microscopic inspection or specialized sharpness measurement tools, to gauge the remaining tool life.

- Proper Storage: Storing tools in controlled environments to prevent corrosion and damage.

- Regrinding/Resharpening: Employing appropriate techniques and equipment to resharpen tools, extending their usable life.

- Tool Management System: Implementing a system for tracking tool usage, sharpening history, and replacement schedules to optimize tool life and minimize waste.

Ignoring proper cutting tool maintenance can lead to poor surface finishes, increased production time, higher scrap rates, and ultimately, more expensive tool replacement in the long run. I find regularly scheduled tool inspections and meticulous record-keeping are key to successful tool maintenance.

Q 26. How do you ensure the accuracy and precision of fabrication equipment?

Ensuring the accuracy and precision of fabrication equipment requires a multi-faceted approach. It starts with:

- Regular Calibration: Utilizing certified standards and procedures to calibrate all measuring devices and control systems. This includes regularly checking and adjusting lasers, encoders, and other precision measuring equipment.

- Preventative Maintenance: Adhering to a strict PM schedule ensures that all components are functioning optimally and prevents wear and tear from compromising accuracy. This also involves regular cleaning and lubrication.

- Environmental Control: Maintaining a stable and controlled environment is crucial. Temperature fluctuations and vibrations can directly impact accuracy, so controlled environments are a priority.

- Operator Training: Well-trained operators are essential. Proper handling, setup, and operation of equipment minimizes errors and prevents damage that can lead to inaccuracy.

- Quality Control Procedures: Implementing robust quality control procedures with regular checks of output using precision measuring tools confirms that the equipment consistently meets the required tolerances.

For example, regular calibration of our CNC milling machine ensures consistent tolerances within 0.001 inches, which is critical for meeting customer specifications. Failing to maintain this accuracy could lead to scrap and significant production delays.

Q 27. What is your approach to training others on proper equipment maintenance procedures?

My approach to training others on proper equipment maintenance procedures is based on a combination of theoretical instruction and hands-on experience. I believe in a blended learning approach that includes:

- Classroom Instruction: Providing clear and concise instruction on equipment operation, maintenance procedures, safety protocols, and troubleshooting techniques. This includes the use of visual aids, manuals, and training videos.

- Hands-on Training: Providing guided, practical experience on the equipment itself, allowing trainees to perform maintenance tasks under supervision. This provides valuable practical skills and reinforces theoretical knowledge.

- Mentorship and Shadowing: Pairing trainees with experienced technicians for a period of shadowing and mentorship to learn best practices and observe real-world application of procedures.

- Documentation and Checklists: Providing comprehensive, step-by-step checklists and documentation for all maintenance procedures to ensure consistency and accuracy.

- Performance Evaluation and Feedback: Regularly evaluating trainee progress, providing constructive feedback, and offering opportunities for skill development and improvement.

I always tailor my training to the specific needs and experience levels of the trainees. Clear communication, patience, and a focus on safety are essential components of my training methodology. A well-trained maintenance team is crucial for minimizing downtime and maximizing the lifespan of our valuable equipment.

Key Topics to Learn for Fabrication Equipment Maintenance Interview

- Preventive Maintenance Procedures: Understanding and implementing scheduled maintenance tasks to minimize downtime and extend equipment lifespan. This includes lubrication schedules, component inspections, and cleaning protocols.

- Troubleshooting and Diagnostics: Identifying and resolving malfunctions in fabrication equipment through systematic analysis. This involves understanding fault codes, using diagnostic tools, and applying logical problem-solving techniques. Practical application includes experience with hydraulic systems, pneumatic systems, and electrical circuits common in fabrication machinery.

- Safety Regulations and Procedures: Demonstrating knowledge of relevant safety standards (OSHA, etc.) and safe working practices for operating and maintaining fabrication equipment. This includes lockout/tagout procedures and proper handling of hazardous materials.

- Hydraulic and Pneumatic Systems: Deep understanding of the principles of hydraulic and pneumatic systems, including component function, troubleshooting common issues, and performing repairs. Practical experience working on these systems is crucial.

- Electrical Systems: Familiarity with electrical schematics, troubleshooting electrical faults, and performing repairs on electrical components within fabrication equipment. This also includes understanding motor controls and safety devices.

- Welding Equipment Maintenance: Specific knowledge of maintaining various welding processes (MIG, TIG, etc.), including gas supply systems, wire feeders, and torch maintenance. Understanding the importance of proper gas shielding and safety precautions.

- CNC Machine Maintenance: Experience maintaining Computer Numerical Control (CNC) machines, including understanding programming basics, diagnostic procedures, and tool changes. This requires a good understanding of mechanical and electrical systems within CNC equipment.

- Record Keeping and Documentation: Maintaining accurate and detailed records of maintenance activities, repairs, and parts used. This is vital for tracking equipment performance and ensuring compliance.

- Root Cause Analysis: Applying techniques to identify the underlying cause of equipment failures to prevent recurrence. This involves using data analysis and problem-solving skills to effectively address recurring issues.

Next Steps

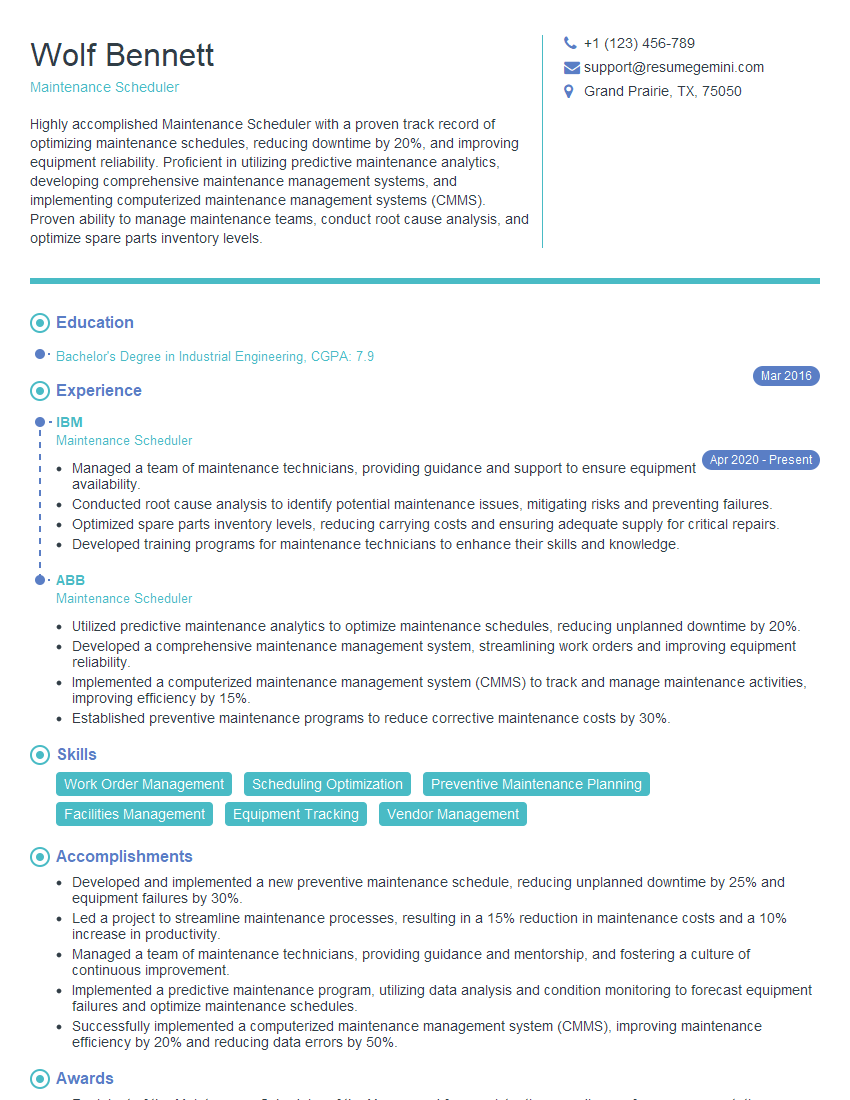

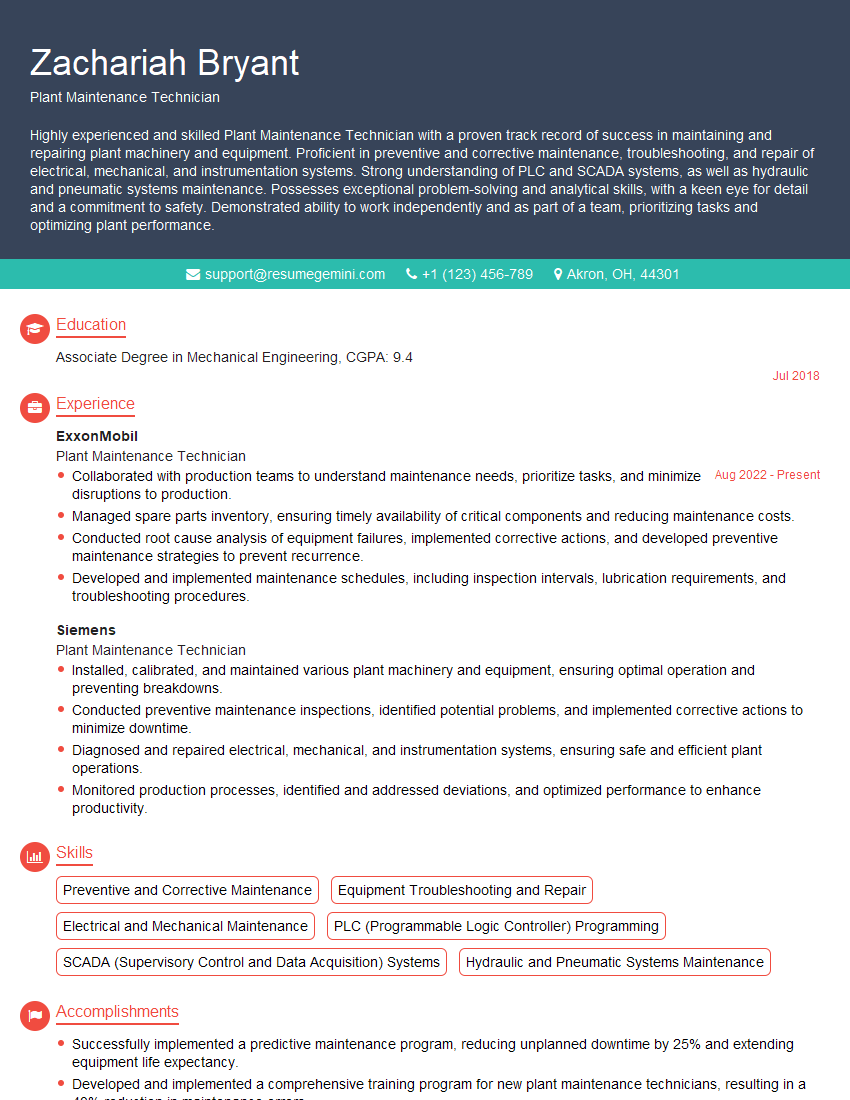

Mastering Fabrication Equipment Maintenance is key to a rewarding and successful career, offering opportunities for advancement and specialization. A strong resume is crucial for landing your dream job. Creating an ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting noticed by recruiters. Use ResumeGemini to build a professional and impactful resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Fabrication Equipment Maintenance to help guide you in crafting the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO