Preparation is the key to success in any interview. In this post, we’ll explore crucial Familiarity with Quality Control Procedures interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Familiarity with Quality Control Procedures Interview

Q 1. Explain the difference between Quality Control (QC) and Quality Assurance (QA).

While both Quality Control (QC) and Quality Assurance (QA) aim to improve product quality, they differ significantly in their approach. Think of QA as the prevention strategy and QC as the detection strategy.

Quality Assurance (QA) is a proactive process focused on preventing defects. It involves establishing procedures, processes, and standards to ensure that the final product meets the required quality levels. This includes things like design reviews, risk assessments, training, and process improvement. It’s about building quality into the system from the beginning.

Quality Control (QC), on the other hand, is a reactive process that focuses on identifying defects after the product or service has been created. QC involves inspecting, testing, and verifying the product against pre-defined standards to ensure it meets those requirements. Think of QC as a quality gatekeeper; it ensures that defects are caught before reaching the customer.

Analogy: Imagine baking a cake. QA would involve ensuring you have the correct recipe, the right ingredients, and a clean workspace. QC would be inspecting the baked cake for proper texture, taste, and appearance.

Q 2. Describe your experience with ISO 9001 standards.

I have extensive experience working within the framework of ISO 9001 standards. In my previous role at [Previous Company Name], we implemented and maintained an ISO 9001:2015 certified Quality Management System (QMS). My responsibilities included:

- Developing and reviewing documented procedures and work instructions to ensure compliance with the standard.

- Conducting internal audits to assess the effectiveness of the QMS and identify areas for improvement.

- Participating in management review meetings to report on the performance of the QMS and recommend corrective actions.

- Managing non-conformances and implementing corrective and preventive actions (CAPA).

- Training employees on ISO 9001 requirements and best practices.

This involved a deep understanding of the standard’s requirements, particularly in areas like risk-based thinking, continuous improvement, and customer focus. We achieved certification and consistently maintained our compliance through meticulous documentation and ongoing monitoring of key processes.

Q 3. What are the different types of quality control charts you’re familiar with?

I’m familiar with a variety of control charts used in statistical process control (SPC). The choice of chart depends on the type of data being collected. Some of the most common ones include:

- Control charts for variables: These charts are used for continuous data (data that can take on any value within a range), such as weight, length, or temperature.

- X-bar and R chart: Monitors the average and range of subgroups of data.

- X-bar and s chart: Monitors the average and standard deviation of subgroups of data.

- Control charts for attributes: These charts are used for discrete data (data that can only take on specific values), such as the number of defects or the number of non-conforming units.

- p-chart: Monitors the proportion of non-conforming units in a sample.

- np-chart: Monitors the number of non-conforming units in a sample.

- c-chart: Monitors the number of defects per unit.

- u-chart: Monitors the number of defects per unit of opportunity.

The selection of the appropriate chart is crucial for accurate process monitoring and effective decision-making.

Q 4. How do you handle non-conforming materials or products?

Handling non-conforming materials or products requires a structured approach to prevent further issues and ensure customer satisfaction. My process generally involves the following steps:

- Identification and Isolation: Immediately identify and isolate the non-conforming materials or products to prevent their use or further processing.

- Documentation: Thoroughly document the nature of the non-conformance, including the quantity, location, and any potential causes.

- Investigation: Conduct a thorough investigation to determine the root cause of the non-conformance using tools like fishbone diagrams or 5 Whys analysis.

- Disposition: Determine the appropriate disposition for the non-conforming materials or products. This might involve repair, rework, scrap, or concession (allowing the material to proceed after approval).

- Corrective and Preventive Actions (CAPA): Implement corrective actions to address the immediate non-conformance and preventive actions to prevent similar occurrences in the future.

- Verification: Verify the effectiveness of the corrective and preventive actions.

The specific approach might differ depending on the severity and nature of the non-conformance, but the focus always remains on maintaining quality and preventing recurrence.

Q 5. Explain your approach to root cause analysis in a quality control setting.

My approach to root cause analysis in a quality control setting is systematic and data-driven. I typically utilize a combination of techniques, selecting the most appropriate based on the situation. Common methods include:

- 5 Whys Analysis: A simple yet powerful technique involving repeatedly asking ‘why’ to drill down to the root cause of a problem. While simple, it’s surprisingly effective for many issues.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps brainstorm potential causes categorized by category (e.g., manpower, methods, materials, machinery, environment). This provides a more comprehensive view of potential causes.

- Pareto Analysis: Identifies the ‘vital few’ causes contributing to the majority of the effects (e.g., 80% of problems stem from 20% of the causes). This helps focus efforts on the most impactful areas.

- Fault Tree Analysis (FTA): A more complex method useful for analyzing complex systems and identifying potential failure points that may lead to non-conformances.

Regardless of the method, the process always includes data collection, analysis, and verification of the identified root cause before implementing corrective actions.

Q 6. What are some common quality control metrics you use?

The choice of quality control metrics depends on the specific goals and context. However, some common metrics I frequently use include:

- Defect Rate: The number of defects per unit or per 1000 units produced.

- Yield: The percentage of conforming units produced.

- First Pass Yield (FPY): The percentage of units that pass inspection on the first attempt.

- Customer Complaints: The number of customer complaints related to quality issues.

- Process Capability Indices (Cp, Cpk): Measures the ability of a process to meet specifications.

- Mean Time Between Failures (MTBF): For products, the average time between failures.

These metrics provide a quantitative measure of process performance and help identify areas needing improvement. I frequently create dashboards and reports to visually communicate these metrics.

Q 7. Describe your experience with statistical process control (SPC).

My experience with Statistical Process Control (SPC) is extensive. I’ve utilized SPC techniques to monitor and control various manufacturing and service processes throughout my career. This has involved:

- Developing and implementing control charts: Selecting the appropriate control chart (as discussed earlier) based on the type of data and process characteristics.

- Data analysis and interpretation: Analyzing control chart data to identify trends, patterns, and out-of-control points, indicating process instability or the presence of assignable causes.

- Process capability analysis: Determining the capability of a process to meet its specifications, using indices such as Cp and Cpk.

- Process improvement: Using SPC data to identify and implement corrective actions to improve process stability and reduce variability.

For example, in a previous role, we used SPC to reduce the defect rate in a specific assembly process by over 60%. This involved identifying and eliminating the root cause of variation using control charts and subsequent process adjustments.

Q 8. How do you develop and implement quality control plans?

Developing and implementing a quality control plan involves a systematic approach, starting with a thorough understanding of the product and its specifications. This includes defining acceptance criteria, identifying potential failure points, and outlining the necessary inspection and testing procedures.

First, I’d define the scope – what aspects of the product or process require quality control? This might include raw materials, in-process stages, and the finished product itself. Then, I’d identify critical quality characteristics (CQCs), the features that are most crucial to customer satisfaction and product functionality. For example, for a precision-engineered part, CQCs might include dimensions, surface finish, and material properties.

Next, I create the plan itself. This involves specifying the methods for inspection (visual, dimensional, functional testing, etc.), the frequency of inspections (e.g., every 100 units, at the end of each production run), and the acceptance criteria. I’d also detail the corrective actions to be taken if non-conformances are found. This could include rework, rejection, or process adjustment. The plan should clearly outline responsibilities, record-keeping procedures, and the resources required (personnel, equipment, and materials).

Finally, implementation requires training staff, ensuring the availability of necessary resources, and monitoring the effectiveness of the plan. Regular review and updates are essential to maintain its relevance and effectiveness.

Q 9. Explain your experience with different inspection methods (visual, dimensional, etc.).

I have extensive experience with various inspection methods, both destructive and non-destructive. Visual inspection is the most basic, allowing for the detection of surface defects, scratches, or discoloration. This is often the first step in any inspection process. Dimensional inspection, using tools like calipers, micrometers, or coordinate measuring machines (CMMs), verifies that the product meets the specified dimensions and tolerances. This is crucial for precision parts where minute variations can significantly affect functionality.

Functional testing assesses the performance of the product. This could involve testing electronic components, mechanical assemblies, or software functionality. Other methods include material testing (e.g., tensile strength, hardness), chemical analysis, and non-destructive techniques like ultrasonic testing or X-ray inspection, used to detect internal flaws without damaging the product.

For example, in my previous role manufacturing medical devices, visual inspection was used to check for any foreign material or damage, dimensional inspection using CMMs ensured precise dimensions were met, and rigorous functional testing validated the devices’ performance before release. The selection of the appropriate inspection method depends entirely on the product’s nature and the critical quality characteristics being assessed.

Q 10. How do you handle customer complaints related to product quality?

Handling customer complaints regarding product quality requires a systematic and empathetic approach. My first step is to acknowledge the complaint, thank the customer for bringing it to our attention, and assure them we’ll investigate thoroughly. This initial response is crucial for maintaining a positive customer relationship.

Next, I gather all relevant information – details of the defect, product batch number, date of purchase, and any supporting evidence (photos, videos). This information helps in identifying the root cause of the problem. I then carefully analyze the complaint to determine whether the issue is related to manufacturing defects, material deficiencies, or perhaps misuse on the customer’s part.

Once the root cause is identified, appropriate corrective actions are implemented. This may involve returning the defective product, offering a replacement, or issuing a refund. Simultaneously, we investigate the underlying problem in our manufacturing process to prevent similar issues from recurring. This might necessitate process adjustments, equipment recalibration, or operator retraining. Throughout the process, I maintain open communication with the customer, keeping them updated on the progress of the investigation and resolution. Finally, a comprehensive report is generated to document the complaint, investigation, and corrective actions taken.

Q 11. Describe a time you identified a significant quality issue. How did you resolve it?

In a previous project involving the manufacture of circuit boards, we experienced a significant increase in the failure rate of a specific component. Initial investigation pointed to a potential problem with the solder paste used in the assembly process. The problem manifested as intermittent connections, leading to unreliable board performance.

My first step was to gather data – failure rates, batch numbers, and relevant production logs. This helped isolate the problem to a specific batch of solder paste. We then conducted a thorough analysis of the solder paste, which revealed inconsistencies in its viscosity. Further investigation revealed a problem with the supplier’s manufacturing process. The solution involved working closely with the supplier to resolve the quality issue at their facility and replacing the affected batch of solder paste. In the meantime, we initiated a 100% inspection of the boards assembled with the suspect paste, replacing the faulty ones. This involved considerable extra effort but prevented defective products from reaching our customers.

This experience highlighted the importance of proactive supplier management and robust quality control measures throughout the supply chain. We implemented more stringent quality checks on incoming materials and increased the frequency of process monitoring to prevent similar issues in the future. The incident also led to the development of a more detailed failure analysis procedure and better communication protocols with the supplier.

Q 12. What are your preferred quality control tools and techniques?

My preferred quality control tools and techniques are diverse and chosen based on the specific application. Statistical Process Control (SPC) charts (like control charts and run charts) are invaluable for monitoring process variation and identifying potential problems before they become major issues. These charts visually display data over time, allowing for easy identification of trends and outliers.

Root cause analysis techniques, such as the 5 Whys or Fishbone diagrams, are crucial for identifying the underlying causes of quality problems. Pareto charts help prioritize issues by showing the relative frequency of different defects, allowing for targeted improvement efforts. Checklists are simple yet effective for ensuring consistent execution of inspection procedures. And finally, data analysis tools and software are increasingly essential for analyzing large datasets and identifying subtle patterns or trends that might otherwise be missed.

For example, in a manufacturing setting, I might use SPC charts to monitor the dimensions of a critical part, a Pareto chart to identify the most common defects in a product, and a Fishbone diagram to analyze the root causes of a recurring failure. The choice of tools depends on the context and aims to provide a holistic view of quality performance.

Q 13. How do you ensure traceability throughout the manufacturing process?

Ensuring traceability throughout the manufacturing process is essential for identifying and addressing quality issues efficiently and effectively. This involves creating a clear and detailed audit trail for each product, from raw material acquisition to final delivery. This is usually accomplished through a combination of documentation and unique identification systems.

Each component or material is typically assigned a unique identification number, which is tracked throughout the process. This might involve barcodes, RFID tags, or serial numbers. Production records are meticulously kept, documenting the processing steps, the personnel involved, the equipment used, and the test results at each stage. This detailed record allows for complete retracing of a product’s journey through the manufacturing process.

In the event of a quality issue, this traceability enables prompt identification of the defective product’s origin, allowing for timely corrective actions and minimizing potential impact. For example, if a faulty batch of raw materials is identified, the traceability system would enable the quick identification of all products manufactured using this batch, enabling targeted recall or remediation actions.

Q 14. What is your experience with calibration and verification procedures?

Calibration and verification procedures are fundamental to maintaining the accuracy and reliability of measurement equipment. Calibration involves comparing a measuring instrument to a known standard to verify its accuracy and adjust it if necessary. Verification, on the other hand, confirms that the instrument is performing within its specified tolerances without necessarily making adjustments. Both are crucial for ensuring the validity of quality control data.

My experience includes developing and implementing calibration schedules for various measurement instruments, including CMMs, micrometers, scales, and testing equipment. I’m familiar with different calibration standards and procedures, including ISO 17025 requirements. I ensure that all calibration records are meticulously maintained and that instruments are calibrated at the appropriate intervals, based on manufacturer recommendations and usage patterns.

Failure to properly calibrate equipment can lead to inaccurate measurements, incorrect conclusions, and ultimately, the release of non-conforming products. A well-defined calibration and verification program helps to mitigate this risk and ensure the integrity of quality control data. For example, in a laboratory setting, routinely calibrating weighing balances is crucial for obtaining accurate measurements of samples, while in a manufacturing environment, calibrating measuring equipment is crucial for precise production of parts.

Q 15. Describe your experience with audit preparation and execution.

Audit preparation involves meticulously planning and organizing all aspects of the audit process to ensure its effectiveness. This includes defining the audit scope, identifying relevant standards and regulations, developing an audit checklist, and scheduling the audit activities. Execution involves systematically following the pre-defined plan, collecting evidence through observation, interviews, and document review, and documenting all findings.

For example, in preparing for a quality audit of a manufacturing process, I would first identify the specific processes to be audited, gather relevant documentation such as standard operating procedures (SOPs), quality records, and training materials. I would then create a detailed audit checklist that aligns with the relevant quality standards (e.g., ISO 9001) and the specific goals of the audit. During the execution phase, I would meticulously follow this checklist, performing observations on the shop floor, interviewing relevant personnel, and reviewing production and inspection records. Any non-conformances would be meticulously documented with clear descriptions, evidence, and severity levels. After the audit, a comprehensive report would be prepared outlining the findings, recommendations for corrective actions, and a follow-up plan.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your understanding of process capability analysis?

Process capability analysis (PCA) is a statistical method used to determine if a process can consistently produce output within predetermined specifications. It assesses the inherent variability of a process compared to the customer’s requirements. The primary goal is to understand whether the process is capable of meeting the quality standards, and if not, identify areas for improvement.

Common metrics used in PCA include Cp (process capability index) and Cpk (process capability index that accounts for process centering). Cp measures the potential capability of a process, while Cpk considers both the potential and the actual performance, factoring in the process mean’s deviation from the target. A Cpk value greater than 1.33 generally indicates a capable process.

For instance, consider a bottling plant filling soda bottles. The target fill volume is 1 liter, with acceptable tolerances of ± 20 ml. Using PCA, we collect data on the fill volume from a representative sample. Statistical analysis is then employed to determine the process mean and standard deviation. The Cp and Cpk values can be calculated and interpreted, showing if the process is capable of consistently delivering fill volumes within the acceptable range. If the Cpk is less than 1.33, it indicates that improvements in the filling process are needed, perhaps through machine calibration or operator training.

Q 17. How do you maintain accurate and up-to-date quality control records?

Maintaining accurate and up-to-date quality control records is crucial for ensuring traceability, facilitating audits, and supporting continuous improvement. This is achieved through a combination of digital and physical record-keeping systems.

I typically use a combination of a digital database and a well-organized physical filing system. The digital database offers easy searchability and data analysis capabilities, allowing for efficient retrieval and reporting of quality data. The physical filing system allows for quick access to hard copies of important documents. A robust record management system with version control is implemented to ensure data integrity. Regular data backups are essential. A detailed audit trail is always maintained to track all changes and access to the records. For example, each inspection report includes unique identification numbers, date and time stamps, inspector’s signature, and all test results and observations. This ensures complete transparency and accountability.

Q 18. How do you communicate quality control findings to stakeholders?

Communicating quality control findings effectively to stakeholders is critical for driving improvements and preventing future problems. My approach involves tailoring the communication style and content to the audience.

For executive stakeholders, I summarize key findings and recommendations in concise reports and presentations, highlighting the impact on business goals. For operational teams, I provide detailed reports with specific action plans and timelines. I always use clear, unambiguous language, avoiding technical jargon where possible. Visual aids, such as charts and graphs, are incorporated to make the data easily understandable. Feedback mechanisms are established to gather input and foster collaboration. Regular meetings, both formal and informal, provide opportunities for interaction and ongoing communication. Using dashboards and regular reporting, I can show trends and progress toward improvement goals.

Q 19. Describe your experience working with quality management systems (QMS).

I have extensive experience working with various quality management systems (QMS), including ISO 9001, and have led teams in implementing and maintaining these systems. This includes developing and implementing quality policies, procedures, and work instructions; conducting internal audits; managing non-conformances and corrective actions; and ensuring compliance with relevant regulations.

In a previous role, I led a team in implementing ISO 9001:2015 in a manufacturing facility. This involved conducting a gap analysis to identify areas needing improvement, creating a comprehensive QMS documentation system, training employees on the new procedures, conducting internal audits, and ultimately achieving certification. My responsibilities included overseeing the entire process, managing resources, and ensuring that the system effectively integrated into the organization’s daily operations. This resulted in significant improvements in product quality, reduced waste, and enhanced customer satisfaction.

Q 20. What is your approach to continuous improvement in quality control?

My approach to continuous improvement in quality control relies on the Plan-Do-Check-Act (PDCA) cycle and data-driven decision making.

The PDCA cycle is a continuous loop: Plan involves identifying areas for improvement through data analysis and stakeholder input. Do is implementing changes and monitoring the results. Check is analyzing the collected data to assess the effectiveness of the implemented changes. Act is standardizing successful changes and addressing any issues that arose during the implementation. This iterative approach allows for consistent refinement of processes and enhancement of quality control measures. I also utilize tools such as root cause analysis (RCA) and 5 Whys to deeply investigate problems and implement lasting solutions. Regular performance reviews and team discussions further foster a culture of continuous improvement.

Q 21. How do you balance quality control with production efficiency?

Balancing quality control with production efficiency is a crucial aspect of successful manufacturing. It’s not a trade-off, but rather a synergistic relationship.

Effective quality control proactively prevents defects, reducing waste and rework, thereby enhancing overall efficiency. Implementing robust quality control measures early in the production process prevents costly downstream issues. This includes rigorous incoming material inspection, process monitoring, and final product testing. Investing in automation and advanced quality control technologies can significantly improve both quality and efficiency. By implementing lean manufacturing principles, waste is minimized, and efficiency is maximized without sacrificing quality. Regularly reviewing and optimizing processes identify areas where quality improvements enhance efficiency. For example, implementing statistical process control (SPC) allows for early detection of deviations from expected performance, preventing larger scale quality issues down the line.

Q 22. What is your experience with different sampling methods?

Sampling methods are crucial for efficient quality control, allowing us to assess the quality of a batch or population without inspecting every single item. The choice of method depends on factors like the size of the population, the cost of inspection, and the acceptable risk level. I’m experienced with several common techniques:

Random Sampling: Each item has an equal chance of being selected. This is ideal for homogenous populations and ensures unbiased results. For example, randomly selecting 100 widgets from a production run of 10,000.

Stratified Sampling: The population is divided into subgroups (strata), and a random sample is taken from each stratum. This is useful when the population is heterogeneous, ensuring representation from all subgroups. Imagine sampling from different production lines, each potentially having slight variations.

Systematic Sampling: Items are selected at regular intervals. This is efficient but can be problematic if there’s a pattern in the production process that coincides with the sampling interval. For example, selecting every 10th item off the assembly line.

Cluster Sampling: The population is divided into clusters, and a random sample of clusters is selected for inspection. All items within the selected clusters are then examined. This is cost-effective for geographically dispersed populations. Consider inspecting all products from randomly selected batches.

My experience includes applying the appropriate sampling method based on the specific context and risk assessment, ensuring representative data and minimizing bias.

Q 23. Describe your familiarity with corrective and preventive action (CAPA) processes.

Corrective and Preventive Action (CAPA) is a systematic process for identifying, investigating, and resolving quality issues to prevent recurrence. I have extensive experience implementing and managing CAPA processes, focusing on a structured approach:

Identifying the problem: Clearly defining the quality issue, its impact, and affected areas.

Investigating the root cause: Using tools like 5 Whys, fishbone diagrams, and data analysis to identify the underlying reasons for the issue. For instance, analyzing production logs to determine if a machine malfunction was responsible for defects.

Implementing corrective actions: Taking immediate steps to resolve the current issue, such as repairing faulty equipment or retraining staff.

Implementing preventive actions: Implementing changes to the process to prevent the issue from recurring. This might involve process improvements, equipment upgrades, or revised training programs. Examples include improving machine maintenance schedules or adjusting manufacturing parameters.

Verifying effectiveness: Monitoring the effectiveness of both corrective and preventive actions to ensure the issue is resolved and won’t reoccur.

I’ve successfully used CAPA to reduce defect rates, improve product quality, and enhance overall process efficiency in various settings.

Q 24. How do you stay updated on current quality control best practices?

Staying current in quality control requires continuous learning and engagement with the industry. My approach involves several key strategies:

Professional Organizations: Active membership in organizations like the American Society for Quality (ASQ) provides access to resources, publications, and networking opportunities.

Conferences and Webinars: Attending industry conferences and participating in webinars allows me to learn about the latest trends, techniques, and best practices from leading experts.

Industry Publications and Journals: I regularly read industry journals and publications to stay informed on advancements and research in quality control.

Online Courses and Certifications: I actively pursue online courses and certifications to deepen my knowledge and skills in specific areas of quality control.

This multi-faceted approach ensures I remain at the forefront of quality control advancements and best practices.

Q 25. How would you handle a situation where a critical quality issue is detected?

Detecting a critical quality issue requires immediate and decisive action. My approach would follow these steps:

Isolate and Contain: Immediately isolate the affected product or process to prevent further distribution or production of defective items.

Notify Relevant Stakeholders: Inform management, relevant teams, and potentially customers depending on the severity and scope of the issue.

Investigate Root Cause: Initiate a thorough investigation to determine the root cause of the issue, employing appropriate tools and methodologies, like those outlined in the CAPA process.

Implement Corrective Actions: Implement immediate corrective actions to address the immediate problem and minimize further impact. This might involve halting production, recalling products, or implementing temporary fixes.

Implement Preventive Actions: Develop and implement long-term preventive actions to ensure the issue does not recur, as detailed in the CAPA process.

Document Everything: Maintain detailed records of the entire process, including findings, actions taken, and their effectiveness.

Effective communication and swift action are paramount in mitigating the impact of critical quality issues.

Q 26. How do you ensure that quality control procedures are consistently followed?

Consistency in following quality control procedures is crucial for maintaining product quality and regulatory compliance. I ensure consistent adherence through several methods:

Clear and Concise Documentation: Develop clear, concise, and easily understood Standard Operating Procedures (SOPs) and work instructions.

Training and Competency Assessment: Provide comprehensive training to all personnel involved in quality control procedures, followed by competency assessments to verify understanding and skill.

Regular Audits and Inspections: Conduct regular internal audits and inspections to verify compliance with SOPs and identify any deviations or areas for improvement. This includes both process and product audits.

Performance Monitoring and Metrics: Track key performance indicators (KPIs) related to quality control, such as defect rates, non-conformances, and customer complaints, to monitor effectiveness and identify trends.

Feedback Mechanisms: Implement feedback mechanisms to encourage employees to report any issues or inconsistencies they encounter, ensuring proactive problem-solving.

A combination of these strategies fosters a culture of quality and ensures consistent adherence to established procedures.

Q 27. What is your experience with implementing and maintaining a quality management system?

I have extensive experience in implementing and maintaining Quality Management Systems (QMS), most notably working with ISO 9001. My experience includes:

Gap Analysis: Conducting gap analyses to assess the current state of the organization’s quality processes against the requirements of the chosen QMS standard (e.g., ISO 9001).

System Design and Implementation: Designing, developing, and implementing QMS documentation, including policies, procedures, work instructions, and forms.

Training and Awareness: Providing comprehensive training to all relevant personnel on the QMS and its procedures.

Internal Audits: Performing regular internal audits to ensure compliance with the QMS and identify areas for improvement.

Management Review: Participating in management reviews to assess the effectiveness of the QMS and make necessary improvements.

Continuous Improvement: Utilizing tools and techniques like PDCA (Plan-Do-Check-Act) to continually improve the effectiveness of the QMS.

My experience ensures a robust and efficient QMS, leading to improved product quality, customer satisfaction, and regulatory compliance.

Q 28. What are your strengths and weaknesses regarding quality control procedures?

My strengths lie in my analytical abilities, attention to detail, and proactive approach to problem-solving. I excel at identifying root causes, implementing effective corrective and preventive actions, and ensuring consistent adherence to quality control procedures. I am also adept at communicating complex information clearly and concisely to both technical and non-technical audiences.

One area for potential improvement is my delegation skills. While I am highly effective independently, I am working on improving my ability to delegate tasks effectively to team members, empowering them to take ownership and responsibility for their contributions to quality control efforts. This is an area I actively work on through mentoring and shadowing team members.

Key Topics to Learn for Familiarity with Quality Control Procedures Interview

- Understanding Quality Management Systems (QMS): Learn the principles and frameworks behind ISO 9001 or other relevant standards. Understand how a QMS is implemented and maintained.

- Quality Control Methods and Tools: Become familiar with various statistical process control (SPC) techniques like control charts, process capability analysis (Cpk), and root cause analysis (RCA) methods like the 5 Whys or Fishbone diagrams. Understand their practical applications in identifying and resolving quality issues.

- Inspection and Testing Procedures: Explore different inspection methods, both destructive and non-destructive, and understand how to develop and implement effective testing protocols. Consider the importance of accurate documentation and record-keeping.

- Corrective and Preventive Actions (CAPA): Master the process of identifying, investigating, and implementing corrective actions to prevent recurrence of quality issues. Understand the importance of effective problem-solving methodologies.

- Auditing and Compliance: Familiarize yourself with internal and external audit processes, and understand the importance of adhering to industry regulations and standards.

- Continuous Improvement Methodologies: Gain insight into Lean manufacturing principles, Six Sigma methodologies, or other continuous improvement initiatives used to enhance quality control processes.

- Data Analysis and Interpretation: Develop your ability to collect, analyze, and interpret quality data to identify trends, patterns, and areas for improvement. Practice presenting your findings clearly and concisely.

Next Steps

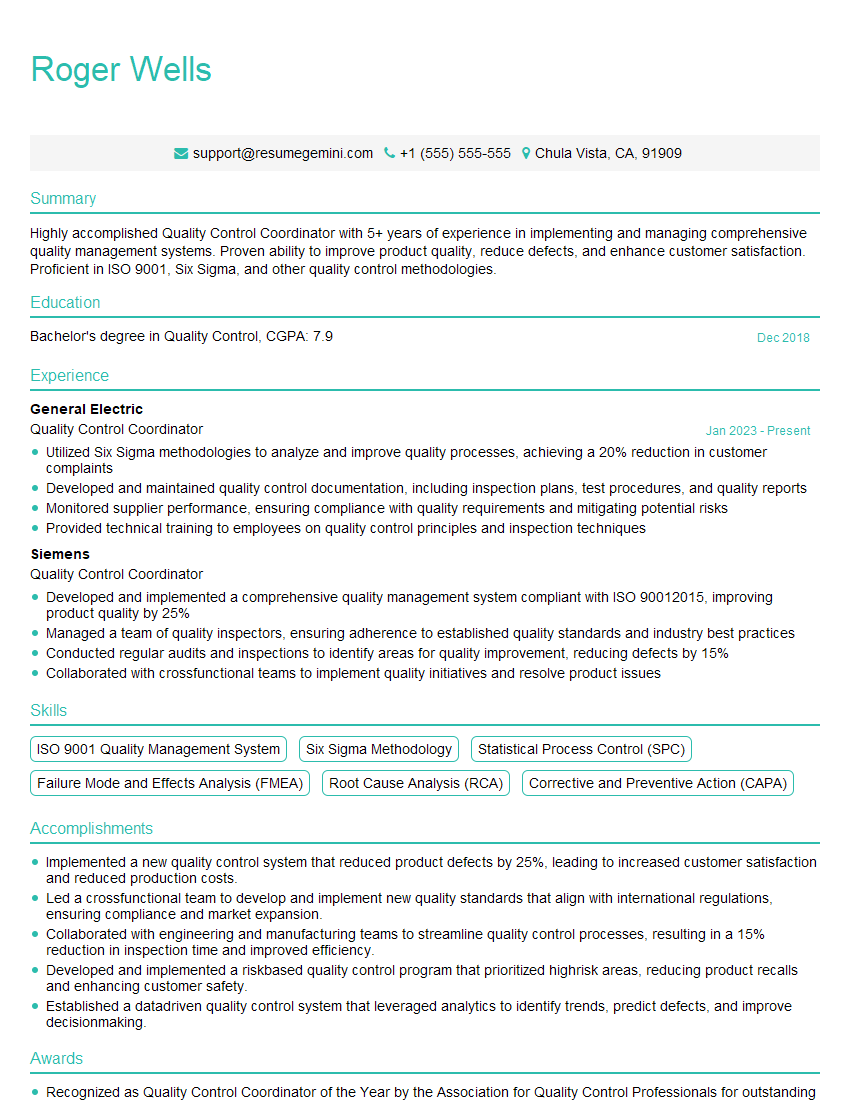

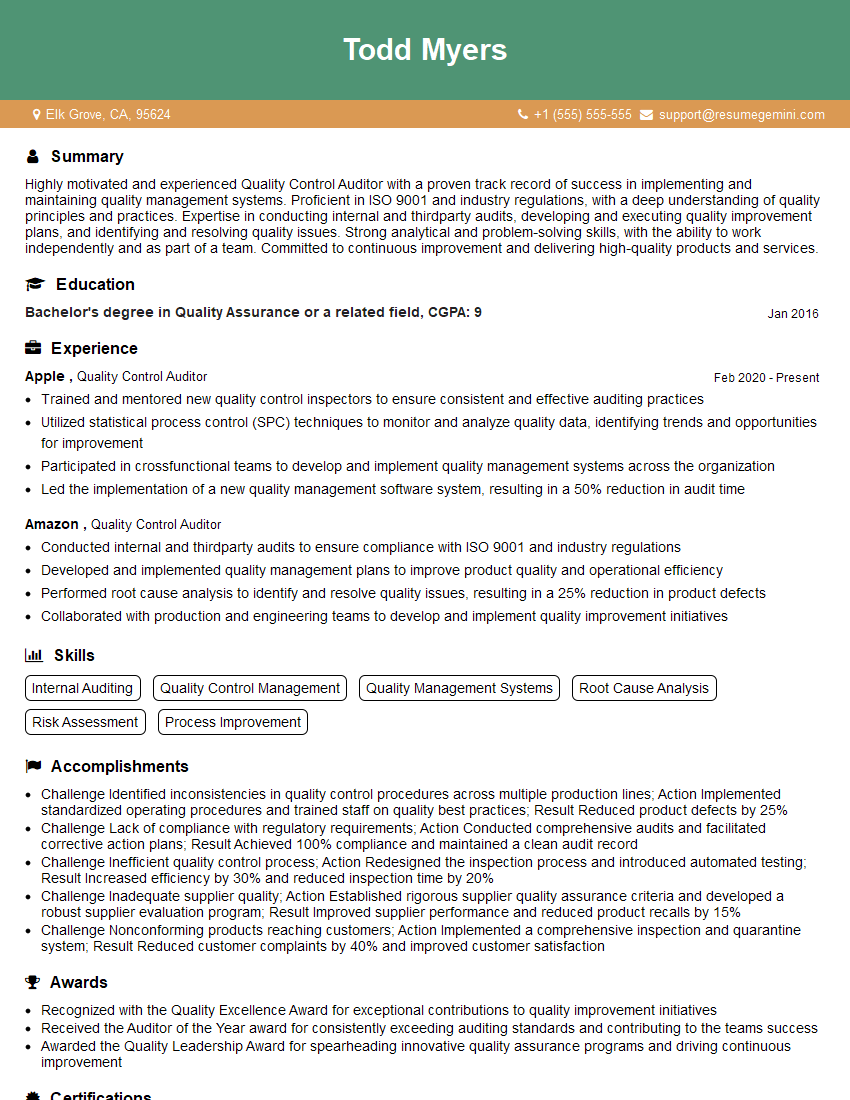

Mastering Quality Control Procedures is crucial for career advancement in many industries. A strong understanding of these concepts demonstrates your commitment to excellence and problem-solving, opening doors to more challenging and rewarding roles. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. We provide examples of resumes tailored to Familiarity with Quality Control Procedures to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO