Preparation is the key to success in any interview. In this post, we’ll explore crucial Fiber Optic Cable Routing and Management interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Fiber Optic Cable Routing and Management Interview

Q 1. Explain the different types of fiber optic cables and their applications.

Fiber optic cables come in various types, each suited for different applications. The core difference lies in the number of fibers, their type (single-mode or multi-mode), and the cable’s overall construction.

- Single-mode fiber: Uses a very thin core, allowing for long-distance transmission with minimal signal degradation. Think of it like a laser pointer – the light travels in a straight line. Ideal for long-haul telecommunications, submarine cables, and high-bandwidth applications like 10 Gigabit Ethernet and beyond.

- Multi-mode fiber: Employs a thicker core, allowing multiple light paths. Imagine a flashlight – light disperses. Suitable for shorter distances, such as within a building or campus network, and applications like Gigabit Ethernet. Comes in various types, such as OM1, OM2, OM3, and OM4, with OM4 offering the highest bandwidth capabilities.

- Loose tube cable: Fibers are housed within a loose tube filled with a water-resistant gel, offering excellent protection against moisture. Common in outside plant applications.

- Tight-buffered cable: Each fiber is individually coated with a tight buffer, providing compact construction ideal for indoor applications.

- Ribbon cable: Multiple fibers are bundled together in a ribbon-like structure, facilitating mass deployment and easier termination.

The choice of fiber type depends heavily on the application’s bandwidth requirements, distance, and budget. For instance, a data center might use multi-mode OM4 for high-speed connections between servers within a limited area, while a long-haul telecommunications network would rely on single-mode fiber for its superior distance capabilities.

Q 2. Describe the process of fiber optic cable routing in an outside plant environment.

Fiber optic cable routing in an outside plant (OSP) environment is a meticulous process involving careful planning and execution. It’s crucial to minimize bends, maintain proper slack, and protect the cables from environmental hazards.

- Planning & Design: This stage involves route surveying, considering factors like terrain, underground utilities, and potential environmental threats (e.g., flooding, rodent activity). Detailed maps and drawings are essential.

- Excavation & Trenching: Once the route is determined, trenches are dug with sufficient depth and width to accommodate the cable and provide protection from damage. Accurate excavation is crucial to avoid damaging existing utilities.

- Cable Placement: The fiber optic cable is carefully placed in the trench, often with warning tape above it for safety. Adequate slack is provided at intervals to allow for thermal expansion and contraction, preventing strain on the cable. Often, conduit is used to further protect the cables.

- Grounding & Bonding: Proper grounding and bonding are essential to protect the cables from lightning strikes and electrical surges. This involves connecting the metallic components of the cable infrastructure to earth ground.

- Splicing & Termination: Splices connect fiber optic cables, and terminations connect them to equipment. This process needs precision and specialized tools. Fusion splicing is typically preferred for its low loss.

- Testing & Documentation: The entire network is rigorously tested using Optical Time Domain Reflectometers (OTDRs) to ensure continuity and identify potential faults. Detailed documentation of the entire routing process, including cable locations, splice points, and test results, is crucial for future maintenance and repairs.

Ignoring any step can lead to signal attenuation, service interruptions, and even safety hazards. A well-planned and executed OSP routing ensures optimal network performance and longevity.

Q 3. What safety precautions are essential when working with fiber optic cables?

Working with fiber optic cables requires strict adherence to safety protocols to prevent injury and damage. The primary hazards involve eye damage from laser light and potential cuts from sharp fibers.

- Eye Protection: Always wear appropriate laser safety eyewear designed for the specific wavelength of the fiber optic system. This is paramount, even during seemingly harmless tasks.

- Gloves: Wear cut-resistant gloves to prevent cuts and abrasions from sharp fibers. Broken or damaged fibers can be extremely hazardous.

- Proper Tools: Use the appropriate tools for cutting, stripping, and cleaning fibers. Improper tools can easily damage the fiber or cause injury.

- Grounding & Bonding: Ensure proper grounding and bonding procedures are followed to prevent static electricity buildup and damage to equipment.

- Caution Signs: Place clear warning signs to alert others about ongoing fiber optic work and potential hazards.

- Training & Certification: Workers should receive thorough training and potentially certification in fiber optic cable handling and installation practices.

Ignoring safety precautions can lead to serious injury, significant equipment damage, and expensive repair costs. Always prioritize safety when working with fiber optics.

Q 4. How do you test for fiber optic cable continuity and identify faults?

Testing fiber optic cable continuity and identifying faults relies heavily on specialized equipment. The most common tool is an Optical Time Domain Reflectometer (OTDR).

An OTDR sends light pulses down the fiber and measures the time it takes for the light to return, indicating the distance to events along the fiber such as splices, connectors, and faults. The OTDR displays a trace showing the signal loss and reflections. This trace helps pinpoint the exact location and type of fault (e.g., attenuation, break, connector loss).

Other testing methods include:

- Visual Inspection: Checking for physical damage, broken fibers, or poorly terminated connectors. A simple magnifying glass can help here.

- Optical Power Meter (OPM): Measures the optical power level at different points along the fiber, indicating signal loss or attenuation.

- Light Source: Used in conjunction with an OPM to verify connectivity. A light source sends a signal, and the OPM measures it at the receiving end.

Systematic testing using these tools is essential in identifying and resolving issues, ensuring a reliable network. For example, a sudden drop in power on an OTDR trace might indicate a macro-bend in the cable, or a high reflection might pinpoint a poorly cleaned connector.

Q 5. Explain the different types of fiber optic connectors and their advantages/disadvantages.

Several types of fiber optic connectors exist, each with its strengths and weaknesses. The most common are:

- SC (Subscriber Connector): A simple, reliable connector with a push-pull mechanism. Relatively inexpensive but susceptible to misalignment.

- FC (Ferrule Connector): Uses a threaded coupling for precise alignment, offering excellent repeatability and low loss. More expensive than SC and takes longer to terminate.

- LC (Lucent Connector): A small, compact connector becoming increasingly popular due to its space-saving design and ease of use.

- ST (Straight Tip): A bayonet-style connector, easy to connect and disconnect but prone to damage if improperly handled.

- MT-RJ (Mechanically Transferable RJ): A duplex connector commonly used in high-density applications; two fibers within a single connector.

The selection of connectors depends on factors like application requirements (high-density or single-fiber), budget, and the need for high precision. LC connectors are favored for their smaller size and cost-effectiveness in high-density applications like data centers, while SC connectors offer a good balance of reliability and cost for less demanding deployments.

Q 6. Describe the process of fusion splicing fiber optic cables.

Fusion splicing joins two fiber optic cables together by melting their ends using an electric arc. This creates a permanent, low-loss connection. Here’s the process:

- Fiber Preparation: The cable jacket and buffer coatings are carefully removed, exposing the fiber’s cladding. The fiber ends are then cleaved using a precision cleaver to create a perfectly perpendicular surface. An imperfect cleave will introduce signal loss.

- Fiber Alignment: The cleaved fiber ends are precisely aligned using a microscope integrated into the fusion splicer. Accuracy is critical for minimizing splice loss.

- Fusion Splicing: An electric arc is applied to the aligned fiber ends, melting them together and forming a permanent, fused connection.

- Splice Verification: An OTDR or optical power meter is used to verify the quality of the splice by measuring the optical loss. Acceptable loss is usually below 0.2dB.

- Protection: The splice is protected using a heat-shrink tube or splice tray to shield it from environmental factors.

Fusion splicing is favored over mechanical splicing due to its superior performance and lower optical loss. However, it requires specialized equipment and training. Incorrect splicing can cause significant signal degradation and network outages.

Q 7. What are the common causes of fiber optic cable damage and how can they be prevented?

Fiber optic cables can suffer damage from various causes, many preventable with proper planning and maintenance.

- Physical Damage: Accidental cuts, crushing, or bending can damage the fiber and cause signal loss. Excavation work near buried cables is a major culprit. Proper cable marking, trenching depth, and conduit protection significantly reduce this risk.

- Environmental Factors: Moisture, extreme temperatures, and rodent activity can compromise the integrity of the cable. Appropriate cable selection (e.g., waterproof jackets) and rodent-resistant conduit can mitigate these problems.

- Improper Handling & Installation: Incorrect termination, excessive bending radius, or poor splicing techniques can lead to signal degradation or complete failure. Proper training and adherence to industry best practices are essential.

- Macro-bending: Excessive bending of the cable over a large radius, often due to cable slack problems, can disrupt light propagation and lead to significant loss. Planning for slack during installation is essential.

- Micro-bending: This occurs at a microscopic level due to tiny compressions in the cable. This could be because of excessive pressure on the cable during installation. This reduces light transmission.

Regular cable inspections, proper installation techniques, and proactive maintenance can minimize damage and ensure network longevity. It’s much cheaper to prevent damage than to repair it.

Q 8. Explain the importance of proper cable management in a data center.

Proper cable management in a data center is paramount for several reasons. Think of it like organizing a meticulously stocked library – without it, finding the right book (or in our case, fiber optic cable) becomes a nightmare. Poor cable management leads to increased downtime, higher operational costs, and safety hazards. Specifically, it impacts:

- Reduced Downtime: Organized cables are easier to trace and troubleshoot, minimizing downtime during repairs or upgrades. Imagine trying to fix a tangled mess of wires – it’s far more time-consuming and frustrating.

- Improved Airflow: Tangled cables obstruct airflow, which can lead to overheating of equipment and even equipment failure. This is crucial in data centers, where heat dissipation is vital for performance and longevity.

- Enhanced Safety: Properly routed cables prevent tripping hazards and reduce the risk of accidental damage to equipment. A neatly managed cabling system is a safer working environment.

- Easier Upgrades and Expansion: With a well-organized system, adding new cables or expanding the network is significantly simpler and faster, saving time and money.

- Increased Network Efficiency: Well-managed cables minimize signal attenuation and interference, contributing to a more efficient and reliable network.

In short, effective cable management is an investment in operational efficiency, safety, and the overall longevity of your data center infrastructure.

Q 9. What are the different methods of fiber optic cable termination?

Fiber optic cable termination involves preparing the fiber optic cable end for connection to other equipment. It’s a precise process that requires specialized tools and expertise to avoid signal degradation or damage. The most common methods include:

- Mechanical Splicing: This method uses specialized connectors that align and clamp the fiber ends together. It’s faster and less expensive than fusion splicing but may result in slightly higher signal loss.

- Fusion Splicing: This technique uses an electric arc to melt and fuse the fiber ends together, creating a permanent and highly reliable connection. It offers minimal signal loss, but requires specialized equipment and expertise.

- Connectors: Various types of connectors exist, including SC, FC, LC, and ST connectors. These connectors terminate the fiber optic cable with a standardized interface that plugs into various equipment. Proper cleaning and precision are crucial for reliable connectivity.

The choice of termination method depends on factors such as budget, required signal quality, and the specific application. In high-bandwidth applications, fusion splicing is often preferred for its superior performance. For simpler deployments, mechanical splicing or connectors might suffice.

Q 10. How do you identify and troubleshoot common fiber optic network problems?

Troubleshooting fiber optic network problems often involves a systematic approach. Here’s a general strategy:

- Visual Inspection: Start by visually inspecting cables for any physical damage, such as bends, cracks, or loose connectors. This often reveals the source of the problem quickly.

- Light Source and Power Meter: Use a light source and power meter to check for light signal continuity. This simple test can quickly pinpoint breaks or significant attenuation in the fiber.

- OTDR Testing (Optical Time Domain Reflectometry): An OTDR provides detailed information about the fiber optic link, identifying the location and severity of faults like breaks, splices, and connectors with high signal loss.

- Connector Inspection: Carefully inspect the connectors for cleanliness and proper alignment. Even a speck of dust can significantly impair the signal.

- Check Equipment: Verify that all the network equipment (switches, transceivers, etc.) is functioning correctly. A faulty transceiver, for instance, can mimic a fiber optic problem.

- Test at different layers: Check the physical layer (cables, connectors), the data link layer (signal strength, errors), and the network layer (connectivity between devices).

Remember to always follow safety procedures when working with fiber optic cables. Always use appropriate safety glasses to protect your eyes from potential laser damage.

Q 11. Explain the concept of Optical Time Domain Reflectometry (OTDR) and its uses.

Optical Time Domain Reflectometry (OTDR) is a powerful tool used to test and troubleshoot fiber optic cables. Imagine it as a radar for fiber optics. It sends a light pulse down the fiber and measures the time it takes for the light to return after reflection from various points along the cable. This allows for the precise identification of:

- Fiber breaks: The OTDR will show a sudden drop in signal strength at the point of the break.

- Splices and connectors: These appear as small dips in the signal trace, providing information about the connection quality.

- Bends and macrobends: Excessive bending of the fiber can be detected by signal loss.

- Fiber attenuation: The gradual signal loss over the cable length is measured, indicating the fiber quality and length.

OTDRs are essential for proactive maintenance and fault finding in fiber optic networks. They provide detailed information about the fiber link’s condition, allowing for targeted repairs and efficient network management. The data generated provides a visual representation of the fiber’s characteristics, akin to a map of the fiber’s condition.

Q 12. Describe different types of fiber optic cable routing techniques (e.g., aerial, underground).

Fiber optic cable routing techniques vary based on the environment and the application. Common methods include:

- Aerial Routing: Cables are strung along existing infrastructure like power lines or telephone poles. This method is cost-effective for long distances but is susceptible to weather damage and vandalism.

- Underground Routing: Cables are buried in trenches, providing protection from environmental factors. This is more expensive initially but offers better protection and longevity.

- Indoor/Data Center Routing: Inside buildings or data centers, cables are routed using cable trays, conduits, and other management systems. This requires careful planning to ensure proper airflow and easy access for maintenance.

- Undersea Routing: For long-distance communication across oceans, specialized cables are laid on the seabed. This necessitates robust cable construction and specialized installation techniques.

The choice of routing method is determined by factors such as cost, distance, environmental conditions, security requirements, and maintenance accessibility. Careful planning and design are crucial to ensure the longevity and reliability of the fiber optic infrastructure.

Q 13. What is the difference between single-mode and multi-mode fiber optic cables?

The core difference between single-mode and multi-mode fiber optic cables lies in the size of the core and the way light propagates through it:

- Single-Mode Fiber: This type of fiber has a very small core diameter (around 9 micrometers), allowing only a single ray of light to propagate. This minimizes modal dispersion (spreading of light signals) and allows for much longer transmission distances with higher bandwidths, making them ideal for long-haul telecommunications and high-speed data transmission.

- Multi-Mode Fiber: This type has a larger core diameter (around 50 or 62.5 micrometers), allowing multiple light rays to propagate along different paths. This leads to modal dispersion, limiting transmission distances and bandwidth compared to single-mode fiber. However, multi-mode fiber is generally less expensive and easier to work with, making it suitable for shorter distances and applications such as local area networks (LANs).

Think of it like driving on a single-lane road versus a multi-lane highway. Single-mode fiber is like the single-lane road: fewer ‘cars’ (light signals) but they travel faster and further without colliding. Multi-mode fiber is the highway, with more ‘cars’ but potential for congestion (dispersion).

Q 14. What are the benefits of using fiber optic cables over copper cables?

Fiber optic cables offer several significant advantages over copper cables, particularly for high-bandwidth applications:

- Higher Bandwidth: Fiber optics can transmit significantly more data than copper cables due to their higher capacity and lower signal attenuation.

- Longer Distances: Fiber optic signals can travel much farther without significant signal degradation, making them suitable for long-haul applications.

- Immunity to Electromagnetic Interference (EMI): Unlike copper cables, fiber optics are not susceptible to EMI, making them ideal for environments with high electromagnetic noise.

- Increased Security: Tapping into a fiber optic cable is much more difficult than tapping into a copper cable, improving security and reducing the risk of eavesdropping.

- Lower Signal Attenuation: Fiber optics experience significantly less signal loss over distance compared to copper.

- Thinner and Lighter: Fiber optic cables are often thinner and lighter than equivalent copper cables, making them easier to install and manage.

In summary, fiber optic cables offer superior performance, reliability, and security compared to copper for many applications, especially where high bandwidth and long distances are involved. The higher initial cost is often offset by the long-term benefits of reduced maintenance and improved network performance.

Q 15. How do you calculate fiber optic cable bending radius?

Calculating the minimum bending radius for a fiber optic cable is crucial to prevent signal loss and damage. The minimum bending radius is specified by the manufacturer and is dependent on the cable type and its construction, particularly the fiber diameter and the type of jacket. Think of it like bending a garden hose – bend it too sharply, and you kink it, restricting water flow. Similarly, excessive bending of a fiber optic cable can break the glass fiber core, leading to signal attenuation or complete signal failure.

Manufacturers usually provide this information in their datasheets. You’ll typically find it expressed in millimeters or inches. For example, a datasheet might state a minimum bending radius of 10 times the cable’s outer diameter. So, if the cable’s outer diameter is 2mm, the minimum bending radius would be 20mm (2mm x 10). Always consult the manufacturer’s specifications; violating this can void warranties and damage the cable.

In the field, using appropriate tools such as cable reels and properly designed cable trays helps ensure that bending radii are maintained. Incorrect bending can cause micro-bends that gradually degrade the signal over time, a much more insidious problem than an immediate break.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper grounding and bonding in fiber optic installations.

Proper grounding and bonding in fiber optic installations are critical, despite the fact that fiber itself is not electrically conductive. The importance lies in protecting the associated equipment. Lightning strikes, electrical surges, or ground faults can induce voltages into the metallic components of the system – connectors, enclosures, and cable armor – causing damage to sensitive electronic devices like optical transceivers.

Grounding involves connecting the metallic parts of the installation to earth ground, providing a low-impedance path for stray currents. Bonding connects various metallic parts of the system together, ensuring they are at the same electrical potential. This prevents voltage differentials that could lead to arcing or damage.

Imagine a building struck by lightning. If the fiber optic cabling system is not properly grounded, the surge could travel along the metallic components, frying expensive equipment at the other end. Proper grounding acts as a lightning rod, safely diverting the surge into the earth.

Good grounding practices include using appropriately sized grounding conductors, using grounding lugs and clamps that meet industry standards, and ensuring good physical contact at all connections. Regular inspections to check for corrosion are also vital.

Q 17. Describe your experience with different types of fiber optic cable installation tools.

My experience encompasses a wide array of fiber optic cable installation tools. These range from basic hand tools to sophisticated automated systems. I’ve worked extensively with:

- Fiber optic cleavers: These precision tools are used to create perfectly flat ends on fiber optic cables for optimal connection. Different cleavers offer various levels of precision and automated features.

- Fusion splicers: These devices fuse two fiber optic strands together using an electric arc, creating a strong and lossless connection. They often incorporate cameras for precise alignment and splicing parameters.

- Mechanical splicers: As an alternative to fusion splicers, these tools use mechanical clamping to connect fibers. They are typically faster than fusion but can have higher insertion loss.

- Optical time-domain reflectometers (OTDRs): While a testing tool, it’s indispensable during installation. I use it to locate faults, measure fiber length, and verify proper splicing.

- Cable pulling equipment: This includes hand-pulled systems for shorter runs and more powerful winches for longer distances. Safety is paramount, so the right equipment and techniques for the cable length and environment are critical.

- Fiber optic identification tools: These tools, including visual fault locators (VFLs) and fiber identifiers, are used to trace and identify the specific fibers within a cable.

The choice of tools depends heavily on the project requirements – the type of fiber, the environment, and the budget. Proper tool selection and maintenance significantly impact the installation’s quality and efficiency. I prioritize using tools certified to the relevant industry standards (e.g., TIA, IEC).

Q 18. How do you document fiber optic cable routes and configurations?

Thorough documentation of fiber optic cable routes and configurations is paramount for efficient maintenance, troubleshooting, and future expansion. I use a combination of methods to ensure complete and accurate records:

- As-built drawings: Detailed drawings showing the exact cable routes, splice locations, equipment placements, and fiber identification numbers are created and updated during installation. These drawings are often created using CAD software.

- Fiber optic management systems (FOMS): These software applications provide centralized databases to store and manage information about the entire fiber optic infrastructure, including cable details, connection points, and test results. They help in easily tracking changes over time.

- Physical labeling: Each cable and splice location is clearly marked with labels that contain relevant information like cable ID, fiber type, and termination points. Using consistent and easily readable labels is key to efficient maintenance.

- Splice closure documentation: Detailed records within splice closures show the fiber pairings, test results, and the date of installation. These records ensure the long-term integrity of the splices.

Maintaining up-to-date documentation is crucial. Any changes to the network, such as adding new cables or performing maintenance, should be promptly documented. Using a version control system to manage these drawings and records is advisable.

Q 19. What are the key performance indicators (KPIs) for fiber optic networks?

Key Performance Indicators (KPIs) for fiber optic networks are crucial for monitoring performance and ensuring optimal network functionality. They help identify potential issues before they impact service. Some key KPIs include:

- Optical signal loss (dB): This measures the attenuation of the optical signal as it travels through the fiber. Higher loss indicates potential problems like bending, poor splices, or connector issues.

- Bit error rate (BER): This indicates the frequency of errors in data transmission. A high BER signifies problems that need immediate attention.

- Return loss (dB): This measures the amount of optical signal reflected back towards the source. High return loss can indicate poor connections or reflections.

- Availability (uptime): This measures the percentage of time the network is operational. High availability is essential for reliable service.

- Mean time between failures (MTBF): This indicates the average time between failures in the network. A high MTBF suggests a robust and reliable network.

- Mean time to repair (MTTR): This measures the average time it takes to repair a network failure. A low MTTR is desirable for quick service restoration.

Regular monitoring of these KPIs and analysis of trends help in proactive maintenance and prevent service disruptions. Setting acceptable thresholds for each KPI is vital for effective management.

Q 20. Explain your experience with fiber optic cable testing equipment (e.g., power meters, OTDRs).

I have extensive experience using fiber optic testing equipment, including power meters and OTDRs. Power meters measure the optical power level at various points in the network, helping identify signal loss. OTDRs, on the other hand, provide a more comprehensive view of the fiber link. They send pulses of light down the fiber and analyze the reflections to identify faults, measure fiber length, and assess splice quality.

Power meters are relatively simple to use; you simply connect the meter to the fiber and read the optical power level. OTDRs, however, require more expertise. Interpreting the OTDR trace requires understanding concepts like Fresnel reflections, Rayleigh scattering, and fiber attenuation. The trace shows the locations and severity of events like breaks, bends, and poor splices. Accurate interpretation is key to effective troubleshooting.

I regularly use both to verify the proper installation and performance of fiber optic networks. For example, after a fiber splice, I would use a power meter to measure the loss introduced by the splice, and then use an OTDR to confirm that no other faults exist within the link.

Q 21. How do you handle situations where fiber optic cables are damaged or compromised?

Handling damaged or compromised fiber optic cables requires a systematic approach that prioritizes safety and minimizes downtime. The first step is to assess the damage. Is it a simple break, a bend exceeding the minimum bending radius, or something more extensive?

For minor damage, such as a slight bend, I would carefully straighten the cable, ensuring I don’t exceed the minimum bending radius. I’d then test the link with an OTDR and power meter to check for signal degradation. If necessary, I’ll replace the affected section. For more severe damage, like a broken fiber, I might need to splice or replace a section of cable. This usually involves cleaving the damaged ends, preparing the fibers for splicing (using either fusion or mechanical splicing), and testing the splice to ensure it meets specifications.

In case of major damage or widespread disruption, involving the network owner or provider is vital. This is usually followed by a detailed investigation to determine the cause of the damage and implement preventative measures to minimize future occurrences. Accurate record-keeping helps pinpoint potential causes and guide the repair strategy. Safety is paramount, always following proper safety protocols and using appropriate personal protective equipment (PPE).

Q 22. What is your experience with fiber optic cable splicing techniques (e.g., fusion, mechanical)?

Fiber optic splicing is crucial for connecting fiber optic cables. I’m proficient in both fusion and mechanical splicing techniques. Fusion splicing uses heat and pressure to melt and fuse the fiber ends together, creating a strong, low-loss connection. This method provides the highest quality and lowest loss but requires specialized equipment and training. Think of it like welding two metal rods together – a precise and permanent bond. Mechanical splicing, on the other hand, uses precision alignment and a sleeve or connector to physically join the fibers. This method is faster and requires less specialized equipment, making it suitable for field deployments or situations where fusion splicing isn’t feasible. It’s like using a strong adhesive to join two pieces – quicker but potentially less durable and with a slightly higher loss.

My experience includes extensive use of fusion splicers from various manufacturers, ensuring low splice loss consistently. I also have experience working with various mechanical splice kits, understanding their limitations and strengths in diverse environments. I always meticulously clean the fibers before splicing, using appropriate cleaning solutions and tools, to ensure optimal performance and longevity of the connection.

Q 23. Describe your understanding of different fiber optic network topologies (e.g., star, ring).

Fiber optic network topologies determine how network devices are interconnected. Two common topologies are star and ring networks. In a star topology, all devices connect to a central hub or switch. This design simplifies network management and fault isolation; if one device fails, the rest remain operational. It’s like the spokes of a wheel connecting to the hub. A ring topology, however, connects devices in a closed loop. Data travels in one direction around the ring. While offering redundancy – if one connection fails, data can still flow in the opposite direction – it can be more complex to manage and troubleshoot. Imagine a circular track with devices located along the track.

Beyond these, we also have bus, mesh, and tree topologies, each with its own advantages and disadvantages. The choice of topology depends on factors like network size, scalability needs, and required levels of redundancy and fault tolerance. In my experience, I have designed and implemented networks using both star and ring topologies, selecting the most appropriate based on the client’s specific needs and constraints.

Q 24. How do you ensure compliance with industry standards and regulations for fiber optic installations?

Compliance with industry standards and regulations is paramount in fiber optic installations. This ensures safety, reliability, and interoperability. I am familiar with standards such as TIA-568, IEC 60794, and relevant local regulations. These standards cover aspects such as cable specifications, installation methods, testing procedures, and safety protocols. For instance, TIA-568 dictates cabling standards for structured cabling systems, defining cable types, connector types, and testing methodologies. IEC 60794 specifies requirements for optical fibers and cables.

My approach involves meticulously documenting every step of the installation, from cable routing and splicing to testing and documentation. This ensures traceability and facilitates easy troubleshooting and future maintenance. We always adhere to safety protocols when working with fiber optics, including the use of safety glasses and appropriate grounding techniques to prevent damage and injuries. I regularly stay updated on the latest industry standards and regulations through professional development courses and industry publications.

Q 25. Explain your understanding of color coding and labeling practices for fiber optic cables.

Consistent color coding and labeling is essential for easy identification and efficient troubleshooting of fiber optic cables. Color codes typically identify the fiber type (single-mode or multi-mode), wavelength, and directionality (transmit or receive). For example, common color codes might use yellow for single-mode and orange for multi-mode fibers. A consistent labeling system, often incorporating cable identifiers, location information, and fiber numbers, is also crucial.

I use standardized labeling systems and always ensure that labels are clearly visible, durable, and accurately reflect the cable’s characteristics and routing. This practice drastically reduces troubleshooting time and minimizes errors during maintenance or expansion of the network. Think of it as a detailed map of the fiber optic network – clear labels help you navigate the system effectively. Using standardized labels minimizes confusion and promotes efficiency among multiple technicians who may be working on the network.

Q 26. How do you manage and mitigate risk during fiber optic cable installation and maintenance?

Risk management is a critical aspect of fiber optic cable installations and maintenance. Potential risks include fiber breakage, damage to connectors, and environmental factors. My approach involves a thorough risk assessment at the beginning of any project, identifying potential hazards and implementing mitigation strategies. This includes careful planning of cable routes, avoiding sharp bends or excessive tension. We use appropriate cable protection methods such as conduits and microducting to safeguard the cables from physical damage.

Proper training and use of specialized tools also minimize the risk of human error. Regular inspections and testing are critical to identify potential problems early on. In case of an emergency, we have well-defined emergency procedures in place, ensuring prompt and effective response to minimize potential damage and disruption. For example, we might use specific cable types for harsh environments (like outdoor installations) to mitigate risks posed by weather conditions.

Q 27. What is your experience with fiber optic cable management systems?

I have significant experience with various fiber optic cable management systems. These systems are crucial for organizing, protecting, and maintaining fiber optic cables. They range from simple cable trays and racks to sophisticated patch panels and cable management cabinets. The choice of system depends on factors such as the size and complexity of the network, the environment, and budget constraints.

My experience encompasses the design, installation, and maintenance of several fiber optic cable management systems. I’m familiar with various types of cable trays, including ladder trays, trough trays, and J-hooks. I’ve worked with different patch panels and splice closures, ensuring proper grounding and protection from environmental factors. I also have experience using cable management software to track and document cable routes, improving efficiency and reducing the risk of errors.

Q 28. Describe a challenging fiber optic cable installation project you’ve worked on and how you overcame the challenges.

One challenging project involved installing a fiber optic network in a historic building with limited access and complex infrastructure. The building’s old wiring and construction posed significant challenges, restricting cable routing options and making access to certain areas difficult. Additionally, the need to preserve the building’s historical integrity further constrained the project.

To overcome these challenges, we utilized a detailed 3D modeling software to plan the cable routes, meticulously avoiding disruption to the building’s structure. We employed specialized small-diameter microducting to navigate narrow spaces and existing conduit systems. We also coordinated closely with the building’s preservation team to ensure minimal impact on the historical aspects of the structure. Through careful planning, innovative solutions, and strong collaboration, we successfully completed the project on time and within budget, delivering a reliable and high-performing fiber optic network.

Key Topics to Learn for Fiber Optic Cable Routing and Management Interview

- Fiber Optic Cable Types and Properties: Understanding different fiber types (single-mode, multi-mode), their characteristics, and applications in various network environments.

- Routing Principles and Best Practices: Learn about proper cable pathways, bend radius limitations, slack management, and techniques for minimizing signal loss and ensuring network integrity. Consider practical scenarios like routing in tight spaces or around obstacles.

- Splicing and Termination Techniques: Familiarize yourself with different splicing methods (fusion splicing, mechanical splicing) and termination techniques for connectors (e.g., SC, LC, ST). Understand the importance of proper cleaning and testing procedures.

- Optical Power Budget and Loss Calculations: Master the principles of optical power budgeting, understanding how to calculate signal loss across different fiber lengths and components. This is crucial for designing and troubleshooting fiber optic networks.

- Testing and Troubleshooting: Develop proficiency in using OTDRs (Optical Time-Domain Reflectometers) and other testing equipment to identify faults, measure signal attenuation, and locate cable breaks or damage. Practice troubleshooting common fiber optic problems.

- Network Infrastructure and Design: Understand the role of fiber optics within larger network architectures. Be prepared to discuss different network topologies and how fiber optic cable routing contributes to overall network performance.

- Safety Regulations and Procedures: Demonstrate awareness of safety standards and procedures related to handling fiber optic cables, working with lasers, and maintaining a safe work environment.

- Documentation and Management: Understand the importance of accurate cable labeling, documentation of cable routes, and maintaining comprehensive records for network management.

Next Steps

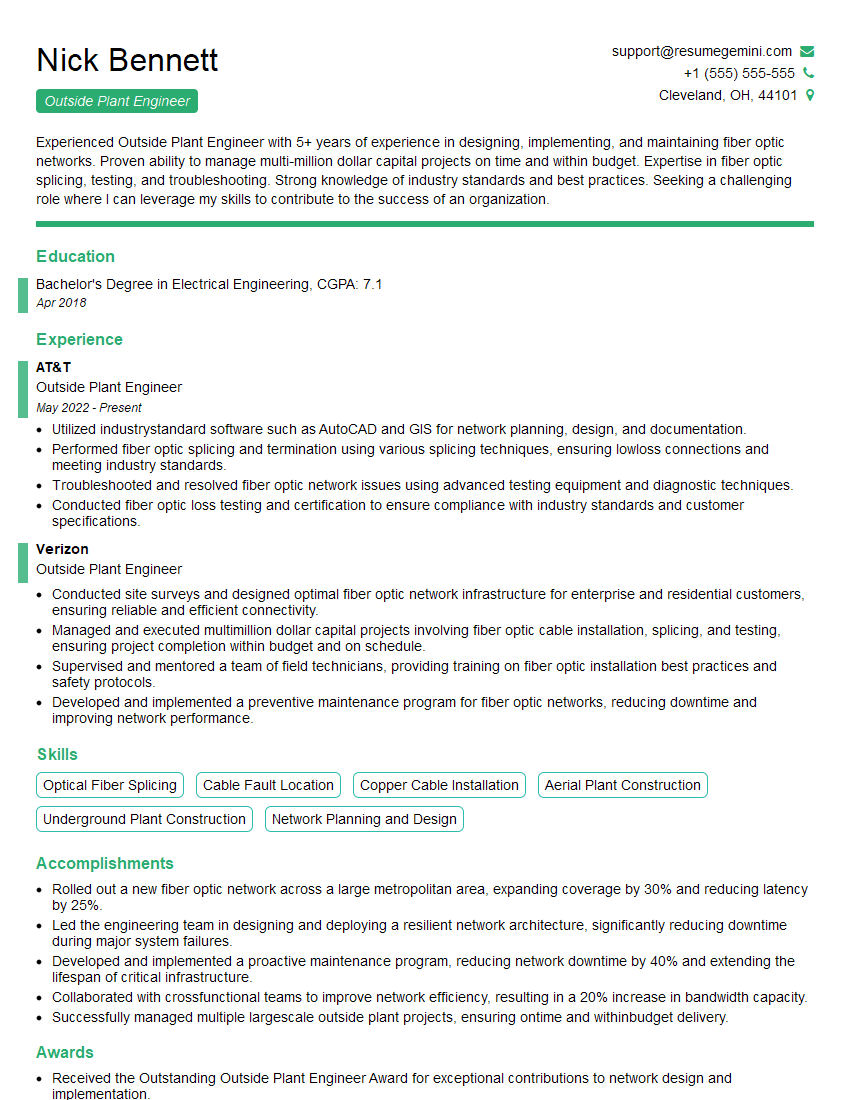

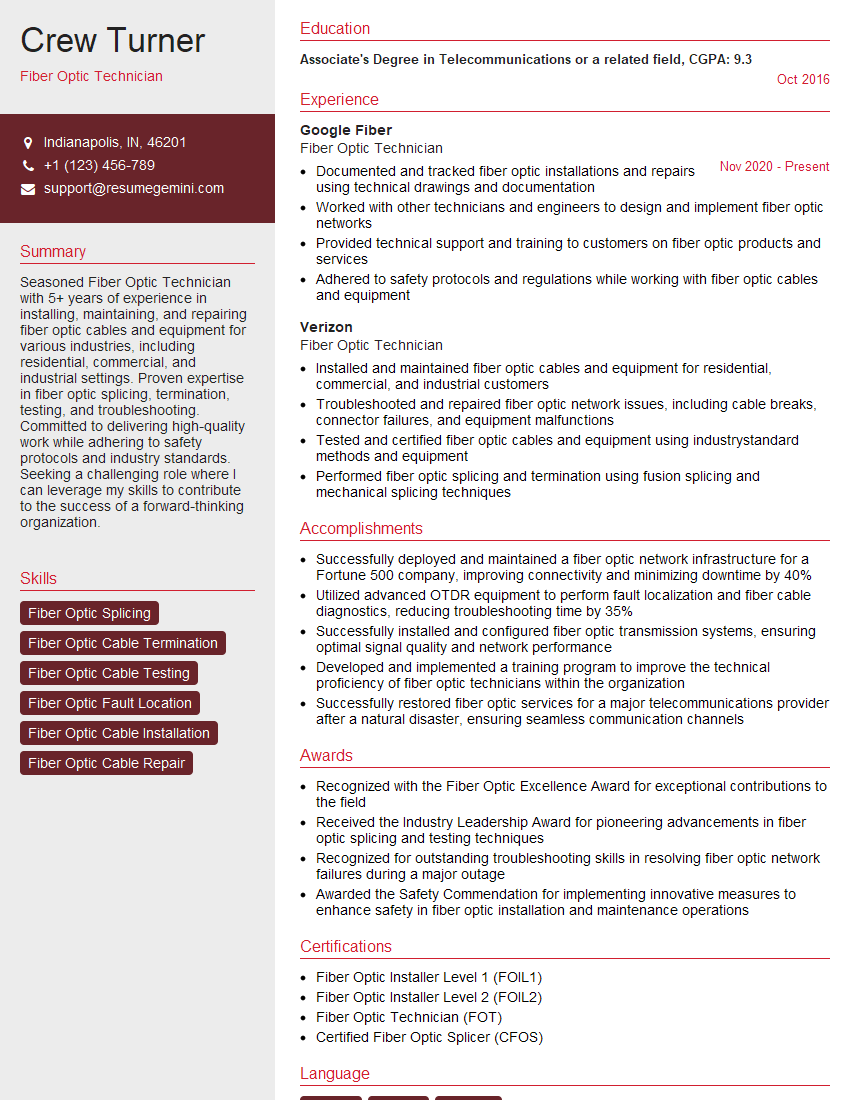

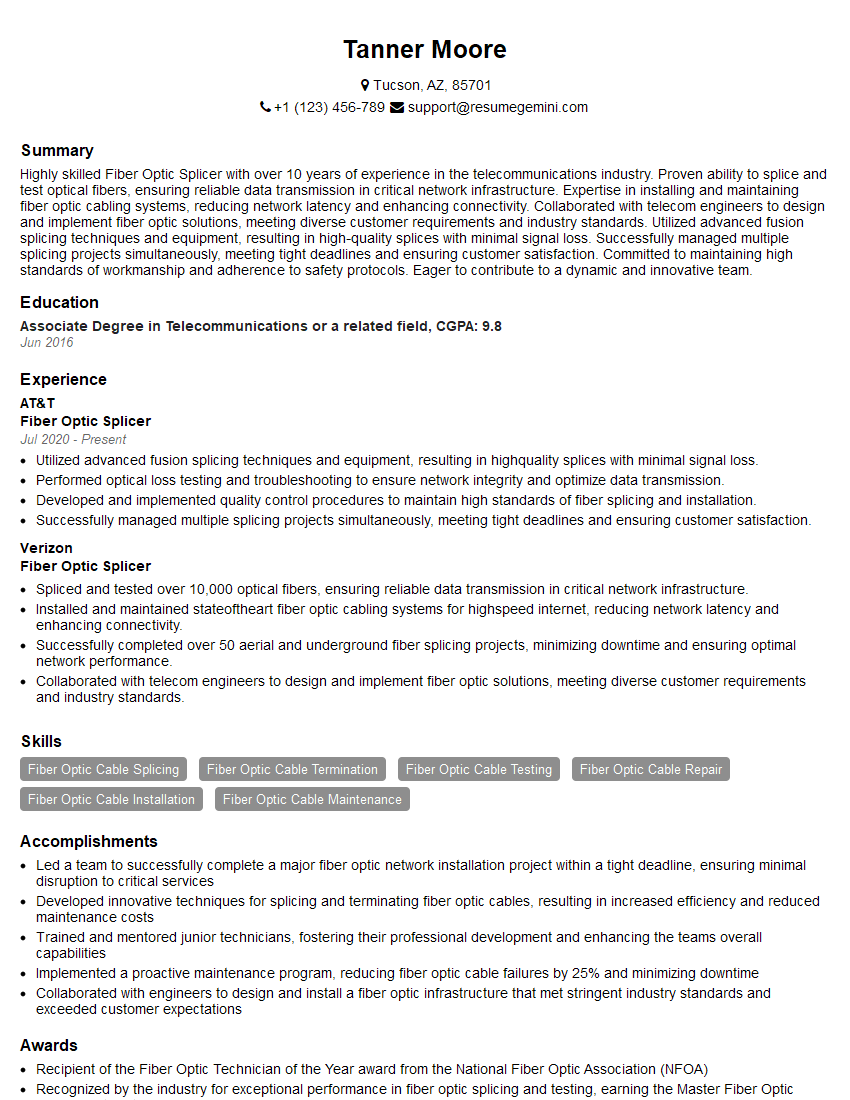

Mastering Fiber Optic Cable Routing and Management opens doors to exciting career opportunities in telecommunications, data centers, and other technology-driven industries. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. ResumeGemini can help you create a compelling resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to Fiber Optic Cable Routing and Management roles to help you present your qualifications in the best possible light. Take the next step towards your dream career – build your resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO