Unlock your full potential by mastering the most common Fiber Spinning and Maintenance interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Fiber Spinning and Maintenance Interview

Q 1. Explain the different types of fiber spinning processes.

Fiber spinning involves transforming fibers into yarn. Several processes exist, each suited to different fiber types and desired yarn properties. Key methods include:

- Ring Spinning: This is a classic method, relatively simple and versatile. It uses a rotating ring and traveler to twist fibers together, producing a strong, even yarn. Think of it like carefully wrapping thread around a spool. This process excels in producing high-quality yarns from various fibers, but it’s relatively slow.

- Rotor Spinning: A high-speed process creating open-structured, bulky yarns. Imagine a miniature tornado whipping fibers together into a yarn. This method is efficient and cost-effective, perfect for producing yarns for sweaters or less demanding applications.

- Air-Jet Spinning: Uses compressed air to twist and compact fibers, resulting in fine and strong yarns. Picture miniature air jets delicately twisting and compacting the fibers. This technique produces high-quality yarns, but requires precise air pressure control.

- Friction Spinning: Relies on friction between rotating elements to twist and solidify the fibers. Imagine rubbing fibers together vigorously to create a cohesive strand. It’s suitable for producing textured yarns.

- Open-End Spinning (OE Spinning): A high-speed process that creates yarns directly from the fiber without using a ring and traveler. This method is very productive but may result in slightly less consistent yarns compared to ring spinning. It’s ideal for mass production.

The choice of spinning process depends heavily on the fiber type (cotton, wool, synthetic), desired yarn characteristics (strength, evenness, texture), and production volume requirements.

Q 2. Describe the role of twist in yarn formation.

Twist is absolutely crucial in yarn formation. It’s the force that binds individual fibers together, transforming a loose collection into a cohesive, strong strand. Without twist, the fibers would simply fall apart.

The twist level is measured in turns per inch (tpi) or turns per centimeter (tpc). Higher twist generally means stronger, more compact yarn, but it can also make the yarn less flexible. Think of a tightly twisted rope – it’s strong but stiff. A loosely twisted rope is more flexible but weaker.

The twist is introduced during the spinning process, either by rotating elements (like in ring spinning) or by using air jets (air-jet spinning). The amount of twist is carefully controlled to achieve the desired yarn properties. Insufficient twist results in weak, easily broken yarn, while excessive twist leads to a stiff, inflexible yarn and can cause breakage during processing.

Q 3. What are the common causes of yarn defects in fiber spinning?

Yarn defects can significantly impact quality and are often caused by a variety of factors. Common causes include:

- Fiber imperfections: Short fibers, neps (small entangled fiber clusters), and variations in fiber length or fineness lead to uneven yarn and weak points.

- Machine malfunctions: Incorrect machine settings (e.g., twist, speed), faulty rollers, or broken components can result in thick or thin places, slubs (thick areas), and yarn breaks.

- Environmental factors: High humidity can affect fiber properties, leading to uneven yarn. Static electricity can cause problems with fiber alignment and yarn breakage.

- Improper cleaning: Contamination from foreign materials (e.g., dust, leaves) in the fiber supply leads to visible flaws in the yarn.

- Insufficient lubrication: Insufficient or improper lubrication of the spinning machine causes increased friction, leading to heat buildup and eventual yarn breakage.

Identifying the root cause of a defect requires careful observation, understanding the spinning process, and potentially using magnifying tools or testing equipment.

Q 4. How do you troubleshoot a broken spinning machine?

Troubleshooting a broken spinning machine requires a systematic approach. First, ensure safety by turning off the power and locking out the machine. Then:

- Identify the problem: Pinpoint the exact location and nature of the breakdown. Is the machine completely stopped, or is there a specific component malfunctioning? Listen for unusual noises, inspect for broken parts, and observe the yarn for irregularities.

- Check for obvious issues: Look for things like broken belts, loose connections, or damaged rollers. Simple repairs can often resolve the issue quickly.

- Consult maintenance logs and manuals: Check the machine’s history for similar problems and follow the manufacturer’s instructions for troubleshooting.

- Systematic elimination: If the problem isn’t immediately apparent, systematically check each component, isolating the faulty part. Sometimes it’s a simple electrical issue; other times, a more complex mechanical failure.

- Replace or repair: Once the faulty component is identified, it needs to be replaced or repaired. If you lack the expertise, call a qualified technician.

- Testing: After repair, thoroughly test the machine to ensure the issue is resolved and the machine operates within specifications.

Detailed records of each issue and its resolution are essential for preventative maintenance.

Q 5. Explain the importance of fiber quality in the spinning process.

Fiber quality plays a pivotal role in the spinning process and the final yarn quality. The properties of the fibers directly influence the yarn’s strength, evenness, appearance, and overall performance.

High-quality fibers, with consistent length, fineness, and strength, lead to yarns with superior properties. Imagine trying to build a strong rope with uneven, weak threads; the result would be a fragile and unreliable rope. Similarly, using inferior fibers in spinning results in weaker, uneven, and less aesthetically pleasing yarns.

Factors like fiber maturity, cleanliness, and the presence of impurities affect yarn quality. Contaminated or damaged fibers lead to yarn defects and reduced production efficiency. Therefore, careful selection and pre-processing of fibers are crucial to ensure optimal yarn quality and efficient spinning.

Q 6. Describe the maintenance schedule for a typical spinning machine.

A typical spinning machine requires a regular maintenance schedule to prevent breakdowns and ensure optimal performance. The schedule usually involves:

- Daily checks: Visual inspection of the machine for any loose parts, unusual noises, or signs of wear and tear. Checking oil levels and lubrication points.

- Weekly maintenance: More thorough cleaning of the machine, including removing lint and dust build-up. Checking and adjusting tension settings on various components.

- Monthly maintenance: More in-depth checks, potentially including lubrication of specific moving parts, and inspection of critical components like rollers and bearings.

- Quarterly maintenance: A comprehensive inspection and cleaning of the entire machine. This may involve replacing worn parts.

- Annual maintenance: A complete overhaul of the machine, including a thorough cleaning, lubrication, and replacement of worn-out parts. A professional technician might be required for this.

The exact maintenance schedule depends on the specific machine model, the intensity of use, and the type of fiber being processed. A detailed log of all maintenance activities is crucial for tracking the machine’s health and predicting potential issues.

Q 7. How do you identify and address fiber contamination issues?

Fiber contamination is a significant concern in spinning, as it leads to defects in the final yarn. Identifying and addressing these issues requires a multi-pronged approach:

- Visual inspection: Regularly inspect the raw fiber bales and the fiber feed system for any foreign materials like leaves, twigs, seeds, or plastic.

- Fiber testing: Use appropriate laboratory techniques to assess the cleanliness and identify specific contaminants.

- Improved cleaning methods: Implement effective cleaning procedures at each stage of fiber processing. This might involve using air cleaners, mechanical cleaning equipment, or chemical treatments.

- Source control: Identify the source of contamination in the supply chain and work with suppliers to improve fiber quality and minimize impurities.

- Monitoring: Continuously monitor the fiber feed and the spun yarn for any signs of contamination. This can involve using sensors or automated quality control systems.

- Employee training: Train personnel to identify contaminants and follow proper cleaning and handling procedures.

Addressing fiber contamination requires a comprehensive strategy that combines preventative measures, early detection, and effective remediation techniques. The goal is to minimize the impact on yarn quality and production efficiency.

Q 8. What are the safety procedures to follow when working with spinning machinery?

Safety is paramount in a fiber spinning environment. Before even approaching the machinery, ensure you’ve received comprehensive safety training and understand the specific hazards of your workplace. This includes knowing the location and use of emergency stop buttons, fire extinguishers, and first-aid kits. Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and sturdy, closed-toe shoes. Loose clothing and jewelry should be avoided.

Never attempt to clean, adjust, or repair machinery while it’s running. Always follow the lockout/tagout procedure before performing any maintenance. This ensures the machine is completely de-energized and cannot accidentally start. Regularly inspect the machinery for any signs of wear and tear or damage, reporting any issues immediately to your supervisor. Understanding the specific safety protocols for each machine, including its operation manual, is crucial. Think of it like this: Treat every machine as if it’s capable of causing serious harm – because it is. Proactive safety measures protect you and your colleagues.

Q 9. Explain the concept of ring spinning and its advantages/disadvantages.

Ring spinning is a widely used yarn manufacturing process where fibers are twisted together into a yarn using a rotating spindle and a traveler that moves around a ring. Imagine a tiny bobbin spinning at high speed – that’s the spindle. The traveler, a small metal ring, guides the fiber onto the bobbin, twisting it as it goes. This creates a strong, even yarn.

- Advantages: Ring spinning produces high-quality yarns with excellent strength, uniformity, and evenness. It’s highly versatile and can process a wide range of fibers. The yarn produced is generally smooth and has good abrasion resistance.

- Disadvantages: Ring spinning is relatively slow and has a high energy consumption compared to other spinning methods. It’s also more labor-intensive and requires more maintenance.

For example, ring-spun cotton yarn is commonly used in high-quality apparel due to its softness and strength. However, for mass production of cheaper yarns, other methods like rotor spinning might be preferred.

Q 10. What are the key performance indicators (KPIs) for a fiber spinning process?

Key Performance Indicators (KPIs) in fiber spinning are crucial for monitoring efficiency and quality. These metrics provide insights into the health of the spinning process and allow for timely adjustments. Some essential KPIs include:

- Production Rate (kg/hr or m/min): Measures the amount of yarn produced per unit of time.

- Yarn Count (Ne or Tex): Indicates the fineness of the yarn.

- Yarn Strength (cN/tex): Measures the yarn’s tensile strength, crucial for its durability.

- Yarn Evenness (CV%, U%): Measures the uniformity of the yarn’s thickness. Lower values indicate better evenness.

- Yarn Hairiness: Measures the amount of protruding fibers, impacting the yarn’s quality and appearance.

- Machine Efficiency (%): The percentage of time the machine is actively producing yarn, excluding downtime.

- Waste Percentage (%): The proportion of raw materials lost during the spinning process.

Tracking these KPIs allows for process optimization, identification of bottlenecks, and proactive maintenance to improve overall quality and productivity.

Q 11. How do you maintain optimal spindle speed and tension in spinning?

Maintaining optimal spindle speed and tension is vital for consistent yarn quality and machine efficiency. Spindle speed affects the twist intensity, influencing the yarn’s strength and evenness. Tension controls the fiber delivery and prevents yarn breakage. These are interlinked; improper balance leads to quality issues.

Optimal settings are determined by the fiber type, yarn count, and desired yarn properties. Modern spinning machines have sophisticated control systems that automatically adjust spindle speed and tension based on pre-set parameters or real-time feedback from sensors. Regular monitoring of these parameters, combined with routine machine inspections, helps identify deviations early on. For instance, if yarn breakage increases, it might indicate excessive tension. Conversely, low spindle speed can lead to weak, uneven yarn. Adjustments are often made through the machine’s control panel or by adjusting mechanical components, always ensuring safety protocols are followed.

Q 12. Explain the principles of rotor spinning.

Rotor spinning is a high-speed spinning method that produces open-end yarns. Unlike ring spinning, it doesn’t use a traveler. Instead, fibers are opened and cleaned, then fed into a rotor – a rapidly rotating cylinder with air channels. This rotor creates a vortex that opens and aligns the fibers. As the fibers are drawn through the rotor, they are twisted and compacted into yarn. The yarn is then wound onto a bobbin.

The principle lies in the centrifugal forces created by the high-speed rotor that force the fibers together, creating the yarn. It’s like a miniature tornado compacting fibers into a yarn. Rotor spinning is known for its high production speed, lower energy consumption, and ability to produce relatively low-cost yarns. However, the resulting yarn generally has lower strength and uniformity compared to ring-spun yarns.

Q 13. Describe different types of spinning machine maintenance (preventive, predictive, corrective).

Spinning machine maintenance is crucial for maximizing productivity, maintaining yarn quality, and ensuring worker safety. Three primary types of maintenance are:

- Preventive Maintenance: This involves scheduled inspections and servicing to prevent breakdowns and prolong machine lifespan. Think of it as a regular health checkup for your machine. This includes cleaning, lubricating, and replacing worn parts according to a predetermined schedule. This type of maintenance is proactive and cost-effective in the long run.

- Predictive Maintenance: This uses sensors and data analysis to predict potential problems before they occur. It’s like having a warning system for your machine. By monitoring vibration levels, temperature, and other parameters, you can anticipate issues and schedule maintenance accordingly. This minimizes downtime and prevents unexpected failures.

- Corrective Maintenance: This involves repairing or replacing parts after a failure has occurred. It’s the reactive approach, often resulting in unplanned downtime and higher costs. While necessary, minimizing corrective maintenance through proactive preventive and predictive strategies is crucial for efficient operations.

A well-planned maintenance program combining all three types is vital for efficient spinning operations.

Q 14. How do you perform a lubrication check on spinning machinery?

Lubrication is vital for reducing friction and wear in spinning machinery. A regular lubrication check involves visually inspecting lubrication points for signs of oil leaks, low oil levels, or excessive grease buildup. The frequency of checks depends on the machine type and manufacturer’s recommendations. Always refer to the machine’s manual for specifics.

The steps usually include:

- Safety First: Ensure the machine is turned off and locked out before starting any lubrication check.

- Visual Inspection: Check oil levels in reservoirs, inspect oil lines for leaks, and examine moving parts for signs of insufficient lubrication (dryness, squeaking, or unusual wear).

- Grease Application: Apply fresh grease to designated grease points using a grease gun, ensuring proper amounts are applied. Too much grease can attract contaminants.

- Oil Level Checks: Check and replenish oil levels in oil reservoirs as per the machine’s specifications.

- Documentation: Record the date, time, and details of the lubrication check.

Proper lubrication significantly extends the lifespan of the equipment and ensures its efficient operation. Ignoring lubrication can lead to premature wear, component failure, and costly repairs.

Q 15. What are the different types of sensors used in modern fiber spinning machines?

Modern fiber spinning machines rely on a sophisticated network of sensors to monitor various parameters crucial for yarn quality and machine health. These sensors can be broadly categorized as follows:

- Fiber Properties Sensors: These measure characteristics of the input fiber, such as length, fineness (diameter), and maturity. Examples include optical sensors using laser diffraction for fiber diameter measurement and capacitance sensors for fiber length determination.

- Process Parameter Sensors: These monitor the spinning process itself. This includes sensors for measuring:

- Tension: Load cells measure tension at various points along the spinning line, ensuring even fiber draw and preventing breaks.

- Speed: Tachometers monitor the speed of rollers and other spinning components to ensure consistent processing.

- Temperature: Thermocouples and other temperature sensors monitor the temperature of components to prevent overheating and maintain optimal operating conditions.

- Humidity: Humidity sensors, especially important in environments where static electricity can be a problem, help maintain consistent fiber behavior.

- Yarn Count/Linear Density: Sensors measure the mass per unit length of the yarn.

- Yarn Strength: Sensors measure the tensile strength of the yarn.

- Hairiness/Unwinding Tension: Sensors evaluate surface characteristics of the yarn.

The type and number of sensors used depend on the specific machine, the type of fiber being spun, and the desired level of process control.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret data from these sensors to prevent failures?

Interpreting sensor data is crucial for predictive maintenance and preventing failures. We use a combination of techniques:

- Real-time Monitoring: Constantly monitoring sensor data allows for immediate detection of deviations from normal operating parameters. For instance, a sudden increase in motor current could indicate impending motor failure, while a drop in yarn tension might signal a fiber break.

- Statistical Process Control (SPC): Using control charts to track sensor data over time helps identify trends and potential problems before they lead to failures. This allows for timely interventions, such as adjusting machine settings or replacing worn components.

- Data Analytics and Machine Learning: Sophisticated algorithms can analyze historical sensor data to identify patterns and predict potential failures. For example, a machine learning model trained on vibration data can predict bearing failure with significant lead time, allowing for proactive replacement and avoiding unplanned downtime.

- Alert Systems: These systems are programmed to trigger alerts when sensor data exceeds predefined thresholds. This ensures immediate attention to critical issues, preventing escalating problems.

For example, if the yarn count sensor shows consistent deviation from the setpoint, we can investigate the drafting system, roller alignment, or fiber feed rate to identify the root cause. A sudden increase in vibration on a specific spindle can point to a worn bearing, prompting its replacement before a catastrophic failure occurs.

Q 17. Explain the concept of yarn count and its measurement.

Yarn count, or linear density, refers to the mass of yarn per unit length. It’s a critical indicator of yarn quality and is used in various textile applications to specify the yarn’s thickness and strength. The lower the yarn count, the thicker the yarn.

Yarn count can be expressed in several systems, the most common being:

- English system (e.g., counts): This system expresses the count as the number of hanks (840 yards) of yarn that weigh one pound. For example, a yarn count of 40s means that one pound of yarn will make 40 hanks of 840 yards each.

- Metric system (e.g., tex, denier): This system expresses the count as the mass (in grams) of 1,000 meters of yarn. Tex is directly proportional to yarn thickness (higher tex = thicker yarn); denier is similar but uses 9000 meters instead of 1000.

Yarn count is measured using various instruments, including:

- Direct weighing methods: A known length of yarn is weighed to calculate its mass per unit length.

- Uster Tester: Advanced instruments like the Uster Tester provide highly precise measurements of yarn count and other yarn properties.

Accurate yarn count measurement is crucial for consistent product quality, as it directly impacts fabric properties like drape, strength, and appearance. Inconsistent yarn count leads to non-uniform fabrics.

Q 18. What are the common problems related to drafting in fiber spinning?

Drafting, the process of attenuating the fiber mass, is a critical step in fiber spinning and is susceptible to several problems:

- Uneven drafting: This results in variations in yarn thickness and strength, caused by factors like uneven fiber distribution, incorrect roller spacing, or roller surface imperfections. It manifests as thick and thin places in the yarn (slubbing).

- Fiber breakage: Excessive drafting or poorly maintained rollers can cause fibers to break, resulting in thin places or complete yarn breaks. This can stem from high drafting forces, static electricity issues, or insufficient lubrication.

- Roller slippage: If the rollers don’t grip the fiber effectively, it can lead to uneven drafting and inconsistent yarn quality. This can be due to worn rollers, improper roller pressure, or insufficient friction.

- Fiber parallelization problems: Poor fiber alignment during drafting results in weak and uneven yarn. It might arise from problems in the carding process or incorrect drafting geometry.

- Roller misalignment: If the rollers are not properly aligned, it can lead to uneven fiber distribution and hence inconsistent drafting. This can create a weaker and less uniform yarn.

Addressing these problems requires regular maintenance, including roller cleaning, replacement of worn components, optimization of drafting parameters (draft ratio, roller speed), and checking for correct alignment. Regular quality checks, like visual inspection of the yarn and use of an Uster Tester, are essential.

Q 19. How do you ensure consistent yarn quality throughout the spinning process?

Ensuring consistent yarn quality involves careful control and monitoring throughout the spinning process, encompassing:

- Consistent raw material: Using fibers with uniform properties (length, fineness, strength) is fundamental. Regular quality checks of incoming fibers are essential.

- Precise machine settings: Optimal settings for drafting, twisting, and winding parameters are crucial. These settings are determined through experimentation and process optimization techniques.

- Regular maintenance: Preventative maintenance is essential to minimize mechanical issues that affect yarn consistency. This includes cleaning, lubrication, and timely replacement of worn parts.

- Environmental control: Maintaining stable temperature and humidity levels minimizes fiber variations due to environmental factors, particularly relevant in processes involving natural fibers.

- Real-time monitoring and control: Employing sensors and automated control systems allows for immediate adjustments to maintain consistent yarn properties. Any deviation from setpoints should be investigated and corrected.

- Quality control checks: Regular testing of yarn properties (count, strength, evenness) is critical for detecting variations and identifying corrective actions. This can range from simple visual inspection to sophisticated automated testing.

Imagine trying to build a Lego castle with mismatched bricks—you’ll get an uneven and weak structure. Similarly, variations in fiber and process parameters result in inconsistent yarn quality. Implementing robust quality control methods throughout the process helps produce a consistent and high-quality end product.

Q 20. Describe your experience with PLC programming related to fiber spinning machinery.

I have extensive experience in PLC (Programmable Logic Controller) programming for fiber spinning machinery. My expertise includes developing and modifying PLC programs to control various aspects of the spinning process, such as:

- Speed and tension control: Programming PLCs to precisely control the speed of rollers and maintain consistent yarn tension throughout the process.

- Automated doffing and piecing: Developing programs to automate the process of removing full bobbins and piecing together broken yarns.

- Data acquisition and monitoring: Programming PLCs to collect and store data from various sensors, allowing for real-time monitoring and analysis of the spinning process.

- Alarm and safety systems: Designing and implementing PLC-based systems to detect and respond to various machine faults and emergency situations.

I’m proficient in various PLC programming languages, including Ladder Logic and Structured Text. I can work with different PLC brands and integrate them with various sensor and actuator systems. One project involved optimizing a PLC program to minimize yarn breaks by implementing a sophisticated tension control algorithm, resulting in a significant reduction in production downtime and improved yarn quality. I used SFC (Sequential Function Chart) to design the logic for the automated piecing system. This chart made the complex operation easy to understand and maintain.

Q 21. How do you handle emergency situations on the fiber spinning line?

Handling emergency situations on a fiber spinning line requires a quick, decisive, and systematic approach. My procedure involves:

- Safety first: Immediately stop the machine and ensure the safety of personnel. This is the paramount concern.

- Assess the situation: Identify the nature of the emergency – fiber break, machine malfunction, power failure, etc. Utilize the alarm systems and sensor data to understand the scope of the problem.

- Isolate the problem: If possible, isolate the affected section of the line to minimize disruption to the rest of the process.

- Implement immediate corrective actions: This may involve restarting the machine after addressing a minor issue (like a fiber break), or replacing a broken component. Use established troubleshooting procedures.

- Call for assistance if needed: If the problem is beyond my expertise or requires specialized tools, I’ll seek assistance from maintenance personnel or engineers.

- Document the incident: Thoroughly document the emergency, including the cause, corrective actions taken, and downtime experienced. This assists in preventative maintenance and future problem-solving.

- Analyze root cause: Once the emergency is resolved, a thorough analysis is conducted to identify the root cause of the issue. This analysis will help prevent similar incidents in the future.

For example, during a major power outage, we immediately shut down the machine to prevent damage to equipment. We then followed our emergency shutdown procedure, which included a safe and controlled power-down sequence and a systematic restart procedure once power was restored. The entire sequence was carefully documented, including the duration of downtime and any adjustments needed post-restart.

Q 22. Explain your experience with different types of fiber (cotton, polyester, etc.)

My experience encompasses a wide range of natural and synthetic fibers. With cotton, I’ve worked extensively on optimizing spinning parameters to achieve desired yarn properties like strength and evenness, understanding the crucial role of fiber length and maturity. Different cotton varieties present unique challenges – longer staple lengths generally result in higher-quality yarns but might require adjustments to machine settings. With polyester, the focus shifts to managing fiber crimp and electrostatic charge, which significantly impact yarn quality. I’ve worked with various polyester types, from standard staple fibers to more specialized ones like hollow or conjugate fibers, each requiring specific processing techniques. For example, optimizing the drafting system is critical for hollow fibers to prevent fiber collapse during spinning. My experience also includes working with other fibers like viscose, nylon, and blends, demanding a nuanced understanding of each fiber’s unique characteristics and processing requirements.

In one project, we faced challenges with inconsistent yarn quality from a particular cotton batch. Through careful analysis, we identified variations in fiber length distribution as the root cause. We adjusted the carding and combing processes, optimizing the drafting system to accommodate the uneven fiber lengths, ultimately resolving the quality issues. This highlighted the importance of tailored processing for each fiber batch.

Q 23. Describe your experience with different types of spinning machines.

My experience spans various spinning systems, including ring spinning, rotor spinning, air-jet spinning, and friction spinning. Ring spinning, the traditional method, allows for high-quality yarns but is relatively slower and energy-intensive. I’ve extensively worked on optimizing ring spinning machines, focusing on parameters such as twist, drafting, and traveler settings to achieve the desired yarn count and strength. Rotor spinning, on the other hand, is a high-speed process ideal for producing shorter staple yarns. My experience here includes troubleshooting issues with rotor damage and optimizing the rotor cleaning and maintenance schedule to maximize productivity. Air-jet and friction spinning offer unique advantages for specialized yarns, and I’ve gained practical experience in maintaining and optimizing these machines as well, focusing on nozzle adjustments and air pressure regulation.

A particular challenge involved improving the efficiency of our ring spinning machines. By implementing a predictive maintenance program based on vibration analysis of the spindles, we significantly reduced downtime and improved overall machine productivity. This is a testament to the importance of utilizing advanced technologies for optimizing traditional spinning methods.

Q 24. How do you ensure the efficient use of energy in fiber spinning?

Energy efficiency is paramount in fiber spinning. My approach focuses on several key areas. Firstly, optimizing machine settings to reduce energy consumption without compromising yarn quality is crucial. For example, fine-tuning the drafting system to minimize fiber breakage leads to less energy wasted in re-processing broken fibers. Secondly, implementing energy-efficient technologies like high-efficiency motors and variable speed drives for spinning machines can significantly lower energy usage. Regular maintenance and lubrication of machines are crucial, as friction increases energy consumption. I’ve also been involved in projects focused on optimizing the air conditioning and humidity control systems in the spinning mill, as maintaining optimal environmental conditions reduces energy waste. Finally, careful monitoring of energy consumption data allows for identifying areas for further improvement and facilitates proactive measures.

In one project, we switched from traditional motors to high-efficiency motors in our ring spinning machines. This, along with optimized drafting settings, resulted in a noticeable reduction in energy consumption by approximately 15%, while maintaining yarn quality standards. This demonstrated the tangible benefits of targeted energy efficiency measures.

Q 25. What is your experience with root cause analysis in a fiber spinning environment?

Root cause analysis is a crucial skill in troubleshooting fiber spinning problems. I utilize several methods, including the ‘5 Whys’ technique to drill down to the fundamental cause of an issue, and the Fishbone diagram (Ishikawa diagram) to identify potential contributing factors. Data analysis plays a vital role; I utilize process data (e.g., yarn count, strength, breakage rate) to identify trends and anomalies. Statistical Process Control (SPC) charts are instrumental in monitoring key parameters and detecting deviations from expected performance. Furthermore, I involve operators and maintenance personnel in the root cause analysis process, leveraging their firsthand experience and knowledge. This collaborative approach promotes better understanding and ownership of solutions.

For example, we once experienced high yarn breakage rates. Using SPC charts, we identified a pattern linked to specific shifts. Through discussions with operators, we discovered that a slight misalignment in the drafting rollers, missed during regular checks, was the culprit. Implementing a more thorough daily checklist and enhanced operator training prevented this issue from recurring.

Q 26. Explain your experience with implementing process improvements in fiber spinning.

Implementing process improvements involves a systematic approach. It starts with identifying areas of improvement through data analysis and operator feedback. Then, I develop and implement solutions, sometimes involving new technologies or process modifications. For example, I’ve implemented automation in various stages of the spinning process, leading to increased efficiency and reduced labor costs. I’ve also focused on improving quality control measures, for instance, by introducing online monitoring systems that provide real-time feedback on yarn parameters. This allows for quick identification and resolution of quality issues, minimizing waste and improving overall quality. Continuous improvement methodologies like Lean manufacturing and Six Sigma have been integral in streamlining processes and reducing waste throughout the production line.

One successful project involved implementing a new yarn cleaning system, which reduced the number of defects significantly. The implementation involved careful planning, operator training, and ongoing monitoring to ensure its effectiveness and identify any unexpected consequences. This exemplifies a successful process improvement initiative yielding tangible results.

Q 27. How do you prioritize maintenance tasks in a busy fiber spinning environment?

Prioritizing maintenance tasks in a busy environment requires a structured approach. I utilize a combination of methods including Criticality analysis (ranking tasks by their impact on production), Preventive Maintenance schedules (routine inspections and lubrication), and Predictive Maintenance (using vibration analysis, thermal imaging, etc., to anticipate potential failures). A Computerized Maintenance Management System (CMMS) helps track work orders, manage spare parts inventory, and schedule tasks effectively. I also prioritize tasks based on urgency (immediate need for repair) and the potential for downtime. Regular communication and collaboration with the maintenance team and production floor are crucial for effective task prioritization and resource allocation.

For instance, we employ a color-coded system for maintenance tasks, with red for critical tasks requiring immediate attention, yellow for urgent tasks, and green for routine maintenance. This ensures that the most critical tasks are always addressed first.

Q 28. Describe your experience with different types of fiber spinning lubricants.

My experience covers various fiber spinning lubricants, including mineral oils, synthetic oils, and greases. The choice of lubricant depends on several factors, including the type of fiber, spinning machine, and environmental conditions. Mineral oils are cost-effective but can be less effective in extreme conditions. Synthetic oils provide better performance in terms of lubrication and resistance to oxidation and degradation. Greases are generally used in areas requiring more robust lubrication. I carefully consider the lubricant’s viscosity, which needs to be adjusted based on operating temperatures and the machine’s specific requirements. Selecting an environmentally friendly and biodegradable lubricant is also a priority whenever possible. Regular analysis of used lubricants helps monitor their effectiveness and detect potential issues like contamination.

In one instance, we switched to a synthetic lubricant in our ring spinning machines, which resulted in improved spindle life and reduced friction. This led to a reduction in energy consumption and fewer machine breakdowns, demonstrating the significant benefits of selecting the right lubricant.

Key Topics to Learn for Your Fiber Spinning and Maintenance Interview

- Fiber Properties and Selection: Understanding fiber types (natural and synthetic), their characteristics (strength, elasticity, fineness), and suitability for different applications. Consider the impact of fiber selection on the final product quality and processing efficiency.

- Spinning Processes: Familiarize yourself with various spinning methods (ring spinning, rotor spinning, air-jet spinning, etc.), their principles, and advantages/disadvantages. Be prepared to discuss the parameters affecting yarn quality in each process.

- Yarn Quality Control: Master the techniques and instruments used for yarn quality assessment (tensile strength, evenness, hairiness). Understand how to interpret test results and identify potential problems in the spinning process.

- Maintenance Procedures: Learn about preventative and corrective maintenance strategies for spinning machinery. This includes lubrication schedules, cleaning procedures, troubleshooting common machine malfunctions, and understanding safety protocols.

- Troubleshooting and Problem-Solving: Develop your ability to diagnose and resolve issues related to yarn defects, machine breakdowns, and production inefficiencies. Practice using systematic approaches to fault finding.

- Production Optimization: Understand the factors impacting production efficiency (speed, yield, quality). Be ready to discuss strategies for improving overall productivity and reducing waste.

- Health and Safety: Demonstrate knowledge of relevant safety regulations and procedures within a fiber spinning and maintenance environment. This is crucial for a safe and efficient workplace.

- Automation and Control Systems: Familiarity with automated systems used in modern fiber spinning plants and their maintenance is highly beneficial. Understanding PLC programming or similar systems will be a plus.

Next Steps

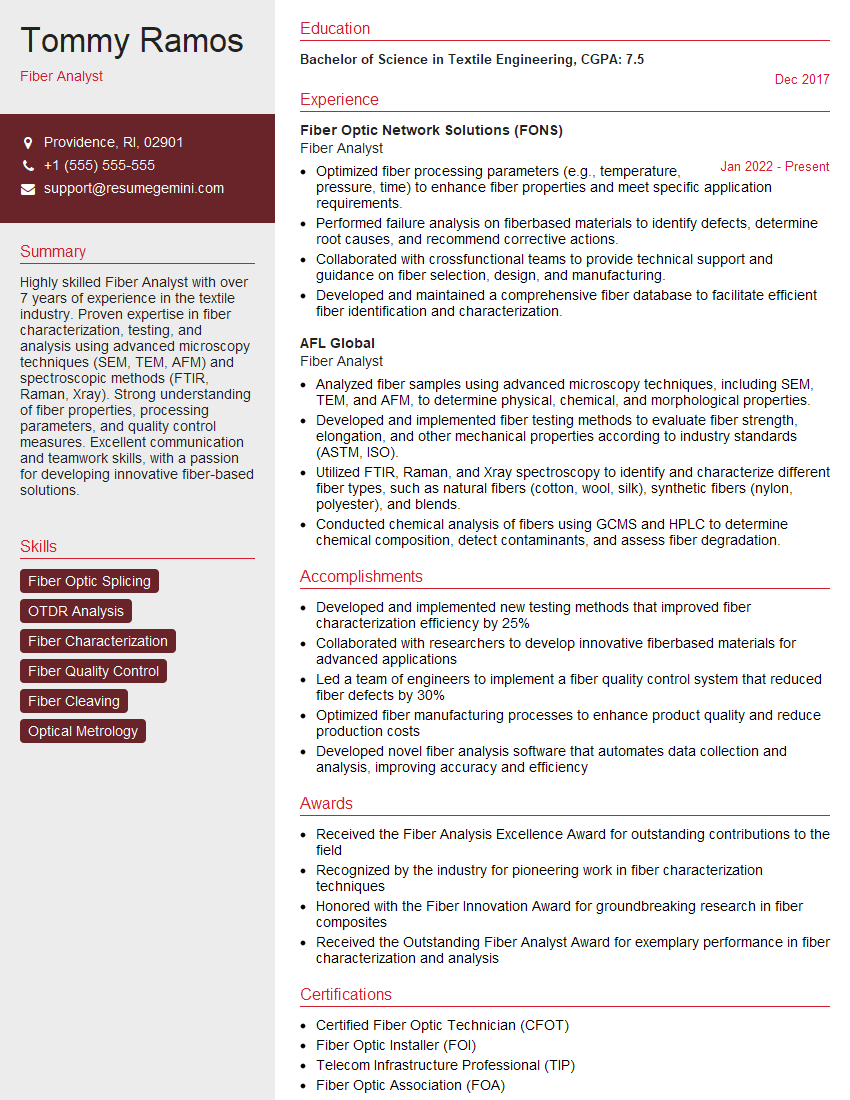

Mastering Fiber Spinning and Maintenance opens doors to rewarding careers with excellent growth potential. As you advance your knowledge, a strong resume is key to showcasing your skills and experience to potential employers. An ATS-friendly resume significantly increases your chances of getting your application noticed. We highly recommend using ResumeGemini to create a professional and impactful resume that highlights your expertise in Fiber Spinning and Maintenance. ResumeGemini offers examples of resumes tailored to this specific field to help you get started. Invest in your future – craft a resume that reflects your skills and ambition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO